Effect of Limited Hydrolysis on Traditional Soy Protein Concentrate

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

3.1. Protein extractability

| Sample** | Extractability

mg/g | Total protein (%)

(N x 6.25) |

| defatted soy flour | 388.30±0.75a | 51.66a |

| TC | 247.01±1.26b | 66.02b |

| FC | 524.76±3.80c | 68.08c |

| AMC | 304.30±0.46d | 67.04d |

| TMC30 | 507.40±0.75e | 70.02e |

| TMC60 | 615.90±2.09f | 70.36e |

| TMC90 | 660.50±1.85g | 70.76 e, f |

| PMC | 466.40±0.59h | 71.30f |

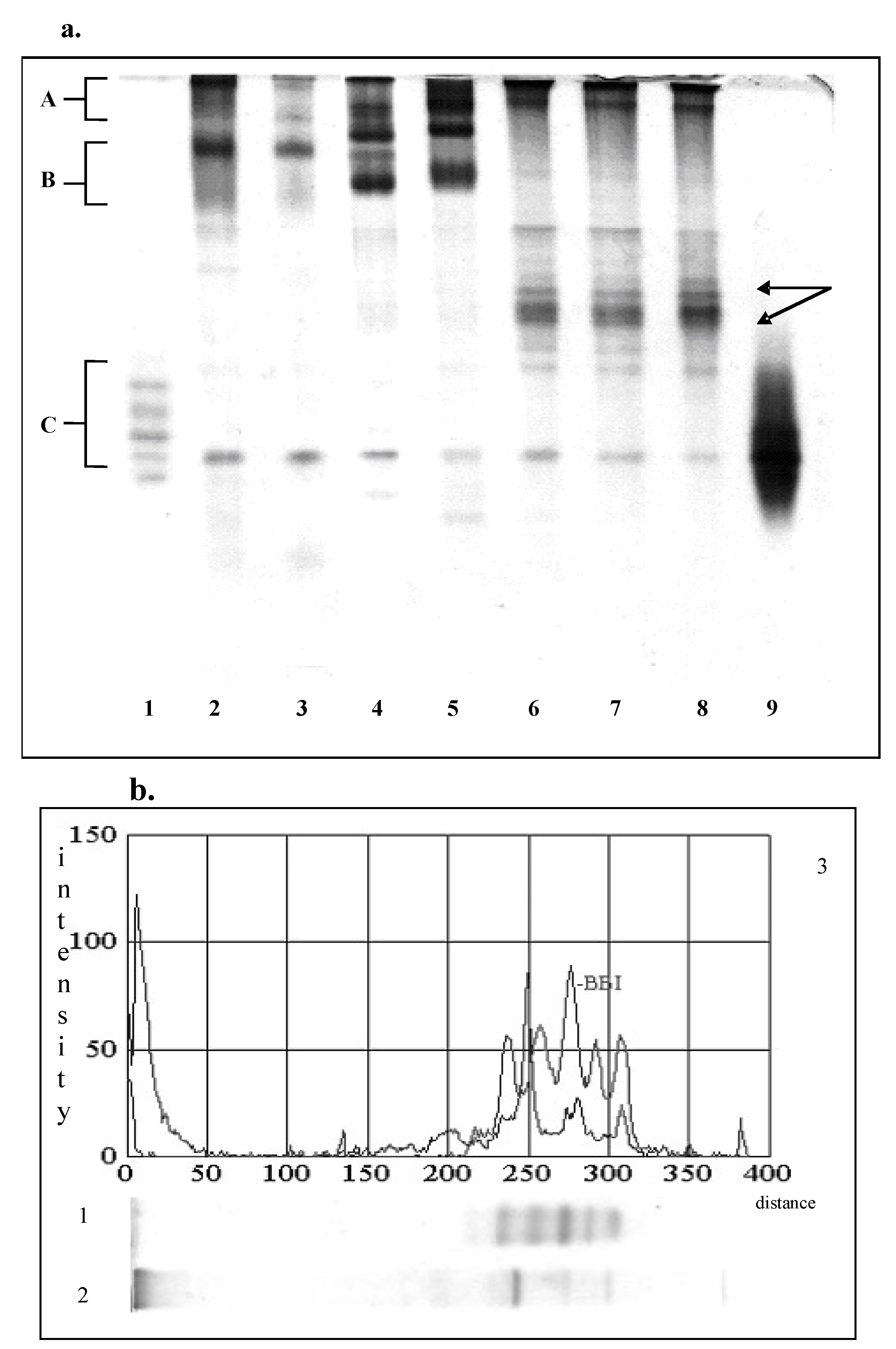

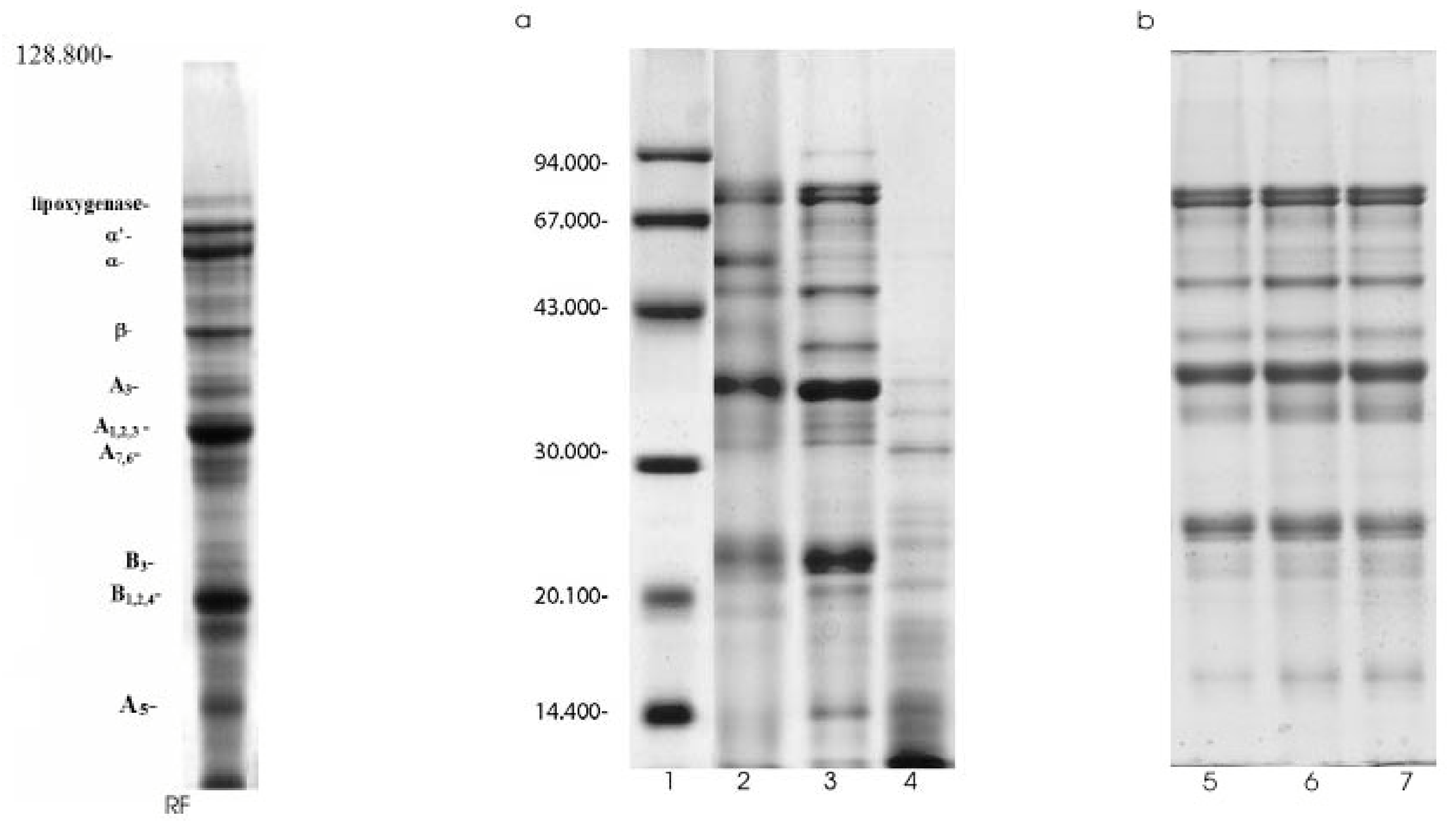

3.2 Extractable protein composition

| Protein | Sample | ||||

|---|---|---|---|---|---|

| subunit | Raw soy flour | TC | TMC30 | TMC60 | TMC90 |

| β-conglucinin | Concentration (%) | ||||

| α`- | 5.04 | 6.48 | 8.33 | 10.86 | 8.59 |

| α- | 6.07 | 5.74 | 9.96 | 10.00 | 10.89 |

| β- | 6.79 | 5.52 | 8.59 | 7.16 | 7.66 |

| ∑ | 17.9 | 17.74 | 26.88 | 28.02 | 27.14 |

| Glycinin | |||||

| A3- | 3.93 | 1.95 | 5.33 | 6.56 | 6.74 |

| A1,2,4- | 16.05 | 12.94 | 19.13 | 22.23 | 20.28 |

| A5- | 7.39 | 4.17 | 2.45 | 2.66 | 4.79 |

| A7,6- | 2.45 | 3.51 | 6.70 | 7.83 | 7.42 |

| B1,2,3,4- | 18.87 | 18.96 | 15.75 | 15.30 | 10.70 |

| ∑ | 48.69 | 41.53 | 49.36 | 54.58 | 49.93 |

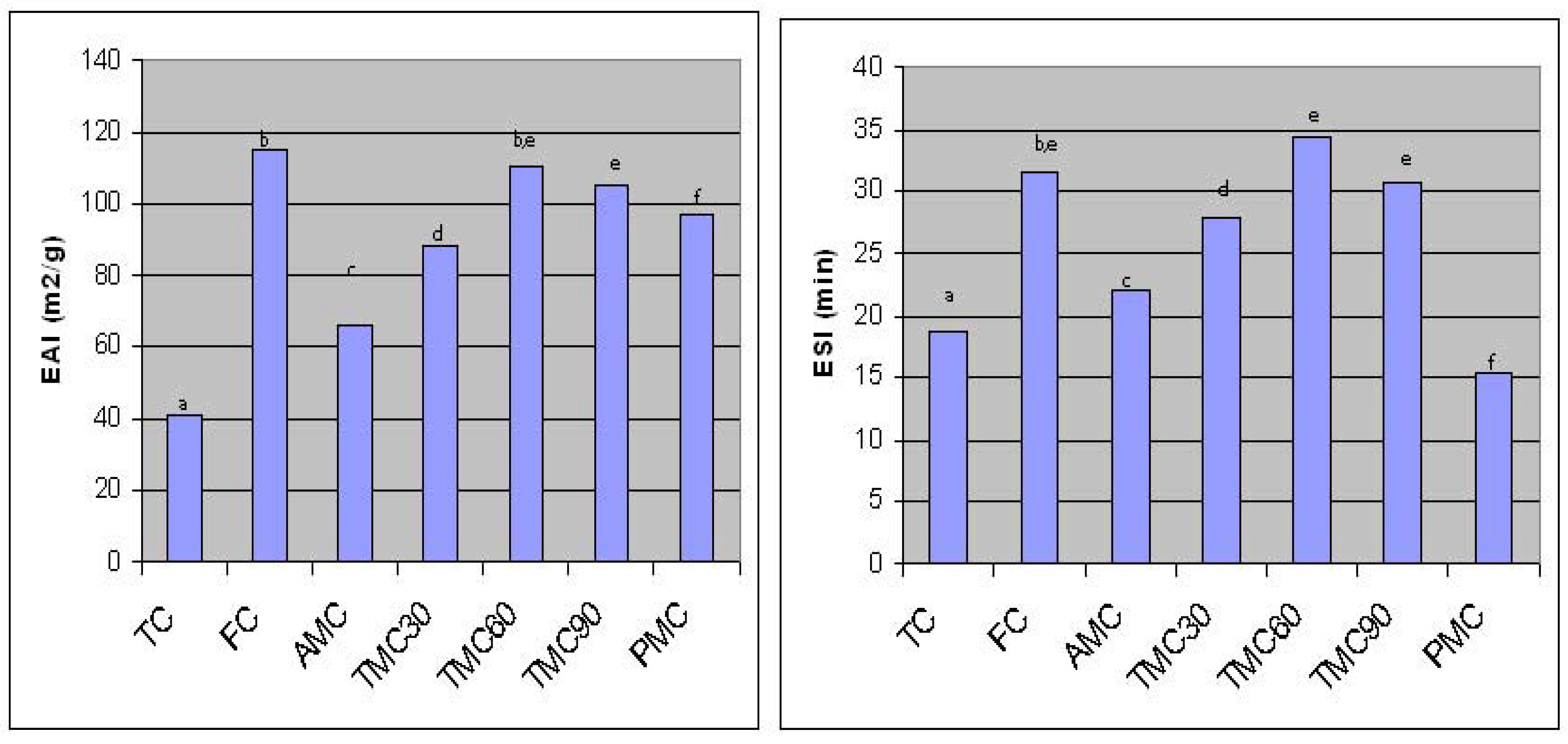

3.3 Emulsifying properties

3.4 Trypsin-inhibitor activity and phytic acid content

| Sample | Residual Ti-activity | Phytic acid** % | |

| TUI/g** | % | ||

| Row flour | 178.50 ±0.71 a | 100 | 4.10 ±0.07 a |

| TC | 31.57 ±0.80 b | 17.34 | 4.95 ±0.03b |

| FC | 135.62 ±0.08 c | 76.01 | 4.81±0.05 b |

| AMC | 29.61± 1.86b,d | 15.51 | 3.89±0.13a,c,d |

| TMC30 | 29.50 ±0.79d | 17.31 | 4.03 ±0.03 a |

| TMC60 | 26.78 ±0.76b,e | 15.15 | 3.65 ±0.05 e,c |

| TMC90 | 27.50 ±1.80 e,d | 15.56 | 3.47±0.05c,d,e |

| PMC | 27.47±0.60e,d | 15.66 | 3.60±0.03e,c |

4. Conclusion

References

- Sorgentini, A. D.; Wagner, J. R.; Anon, M. C. Effect of thermal treatment soy protein isolate on the characteristics and structure- function relationship of soluble and insoluble fractions. J. Agric. Food Chem. 1995, 43, 2471–2479. [Google Scholar] [CrossRef]

- Beery, K. E. Preparation of soy protein concentrate products and their application in food systems. In Proceedings of the World Congress of Vegetable Proteins Utilization in Human Food and Animal Food Stuffs; Applewhite, TH, AOCS, Champaign, USA, 1989; pp. 62–67. [Google Scholar]

- Kinsella, J. E.; German, B.; Damodoran, s. Physicochemical and functional properties of oilseed proteins with emphasis on soy proteins. In New Protein Foods; Altschul, A.M., Wilke, H.L., Eds.; Academic Press: New York, 1985; Vol. 5, pp. 107–179. [Google Scholar]

- Kinsella, J. E. Functional properties of soy proteins. J. Am. Oil Chem. Soc. 1979, 56, 242–258. [Google Scholar] [CrossRef]

- Rhee, K. C. Functionality of soy proteins. In Protein Functionality in Food Systems; Hettiarachchy, N. S., Ziegler, G. R., Eds.; Dekker, New York, 1994; pp. 311–324. [Google Scholar]

- Chobert, J. M; Sitohy, M.Z.; Whitaker, D. J.R. Specific limited hudrolysis and phosphorylation of food proteins for improvement of functional and nutritional properties. J.Am. Oil Chem. Soc 1987, 36, 1704–1711. [Google Scholar] [CrossRef]

- Petrucelli, S.; Anon, M. C. The relationship between the method of obtention and the structural and functional properties of soy protein isolates 1. Structural and hydration properties. J. Agric. Food Chem 1994a, 42, 2161–2169. [Google Scholar] [CrossRef]

- Petrucelli, S.; Anon, M. C. The relationship between the method of obtention and the strustural and functional properties of soy protein isolates 2. Surface properties. J. Agric. Food Chem 1994b, 42, 2170–2176. [Google Scholar] [CrossRef]

- Wagner, J. R.; Anon, M. C. Influence of denaturation degree, hydrophobicity and sulphydryl content on solubility and water absorbing capacity of soy protein isolates. J. Agric. Food Chem. 1990, 50, 765–770. [Google Scholar]

- Arrese, E.L.; Sorgentini, D. A.; Wagner, .J.R.; Annon, M.C. Electrophoretic, solubility, and functional properties of commercial soy protein isolates. J. Agric .Food Chem 1991, 39, 1029–1032. [Google Scholar] [CrossRef]

- Wagner, J. R.; Sorgentini, D. A; Anon, M. C. Relation between solubility and surface hydrophobicity as an indicator of modifications during preparation processes of commercial and laboratory-prepared soy protein isolates. J. Agric. Food Chem. 2000, 48, 3159–3165. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.Y.; Park, P.S.W.; Rhee, K.C. Functional properties of proteolytic enzyme modified soy protein isolate. J. Agric. Food Chem. 1990, 33, 651–656. [Google Scholar] [CrossRef]

- Kamata, Y.; Otsuka, S.; Sato, M.; Shibasaki, K. Limited proteolysis of soybean beta-conglycinin. Agric. Biol. Chem. 1982, 46, 2829–2834. [Google Scholar] [CrossRef]

- Shutov, A.D.; Pineda, V. I.; Senyuk, V.; Reva, V. A; Vaintraub, I. A. Action of trypsin on glycinin. Eur.J.Biochem. 1991, 199, 539–543. [Google Scholar] [CrossRef] [PubMed]

- Were, L.; Hettiarachchy, N. S.; Kalapathy, U. In vitro accessibility of untreated, toasted and extruded soybean meals for proteases and carbohydrases. J. Food Sci. 1997, 62, 821–823. [Google Scholar] [CrossRef]

- Calderon de la Barca, A. M.; Ruiz-Salazar, R. A.; Jara-Marini, M. E. Enzymatic hydrolysis and synthesis of soy protein to improve its amino acid composition and functional properties. J. Food Sci. 2000, 65, 246–253. [Google Scholar] [CrossRef]

- Molina Ortiz, S.E.; Wagner, J.R. Hydrolysates of native and modified soy protein isolates: structural characteristics, solubility and foaming properties. Food Res. Int. 2002, 35, 511–518. [Google Scholar] [CrossRef]

- Hrackova, M.; Rusnakova, M.; Zemanovic, J. Enzymatic hydrolysis of defatted soy four by three different proteases and their effect on the functional properties of resulting protein hydrolysates. Czech Journal of Food Science 2002, 20, 7–14. [Google Scholar]

- Achouri, A.; Zhang, W.; Xu, S. Enzymatic hydrolysis of soy protein isolate and effect of succinylation on the functional properties of resulting hydrolysates. Food Res. Int. 1998, 31, 617–623. [Google Scholar] [CrossRef]

- Achouri, A.; Zhang, W. Effect of succinylation on the physicochemical properties of soy protein hydrolysate. Food Res. Int. 2001, 56, 507–514. [Google Scholar] [CrossRef]

- Fischer, M.; Gruppen, H.; Piersma, S. R.; Kofod, L. V.; Schols, H. A.; Voragen, A. G. J. Aggregation of peptides during hydrolysis as a cause of reduced enzymatic extractability of soybean meal proteins. J. Agric. Food Chem. 2002, 50, 4512–4519. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Association of Official Analytical Chemists, Official methods of analysis, 12 edn. 1975; Washington, DC. [Google Scholar]

- Thanh, V. H.; Shibasaki, K. Major proteins of soybean seeds. A straightforward fractionation and their characterization. J. Agric. Food Chem. 1976, 24, 1117–1121. [Google Scholar] [CrossRef] [PubMed]

- Lowry, O.H.; Rosebrough, N.J.; Farr, A.L.; Randall, R. J. Protein measurement with the Folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [PubMed]

- Davis, J. Disc Electrophoresis- II Method and application to human serum proteins. Annals N. Y. Ac. Sci. 1964, 121, 404–427. [Google Scholar] [CrossRef]

- Fling, S. P.; Gregerson, D. S. Peptide and protein molecular weight determination by electrophoresis using a high-molarity Tris- buffer system without urea. Anal. Biochem. 1986, 155, 83–88. [Google Scholar] [CrossRef]

- Wu, W. U.; Hettiararchy, N. S.; Qui, M. Hydrophobicity, solubility, and emulsifying of soy protein prepared by papain modification and ultrafiltration. J.Am. Oil Chem. Soc. 1998, 75, 845–850. [Google Scholar] [CrossRef]

- Liu, M.; Markakis, P. An improved colorimetric method for determination antitryptic activity in soybean products. Cereal Chem. 1989, 66, 415–421. [Google Scholar]

- Thomson, D.B.; Erdman, J. W. Phytic acid determination in soybeans. J.Food Sci. 1982, 47, 513–519. [Google Scholar] [CrossRef]

- Velickovic, D.; Vucelic-Radovic, B.; Blagojevic, S.; Barac, M.; Stanojevic, S.; Ljubicic, M. A modification of a method for phytic acid determination. J. Serb. Chem. Soc 1999, 64, 303–310. [Google Scholar]

- Barac, M.; Stanojevic, s. The effect of microwave roasting on soybean protein composition and components with trypsin inhibitor activity. Acta Alimentaria 2005, 34, 23–31. [Google Scholar] [CrossRef]

- Marcone, M.F.; Kakuda, Y.; Yada, R.Y. Imunochemical examination of the surface physico-chemical properties of various dicotyledonous and monocotyledonous globulin seed storage proteins. Food Chem 1998, 63, 85–95. [Google Scholar] [CrossRef]

- Moreira, M. A.; Hermodson, M. A.; Larkins, B. A.; Nielsen, N.C. Comparison of the primary structure of the acidic polypeptides of glycinin. Arch. Biochem. Biophys. 1981, 210, 633–642. [Google Scholar] [CrossRef]

- Fukazawa, C.; Momma, T.; Hirano, H.; Harada, K.; Udaka, K. Glycinin A3B4 mRNA: cloning and sequencing of double stranded cDNA complementary to a soybean storage protein. J. Biol. Chem. 1985, 260, 6234–6239. [Google Scholar] [PubMed]

- Molina Ortiz, S.E.; Anon, M.C. Analysis of products, mechanisms of reaction, and some functional properties of soy protein hydrolysates. J. Am.Oil Chem. Soc 2000, 77, 1293–1302. [Google Scholar] [CrossRef]

- Kato, A.; Nakai, S. Hydrophobicity Determined by Fluorescence probe Method and Its Correlation with Surface Properties of Proteins. Biochim.Biophys.Acta 1980, 624, 13–20. [Google Scholar] [CrossRef]

- Nakai, S. Structure-Functional Relationship of Food Proteins with Emphasis on the Importance of the Protein Hydrophobicity. J.Agric.Food Chem. 1983, 31, 676–683. [Google Scholar] [CrossRef]

- Pesic, M.; Vucelic-Radovic, B.; Barac, M.; Stanojevic, S. The Influence of Genotypic Variation in Protein Composition on Emulsifying Properties of Soy Proteins. J.Am.Oil.Chem. 2005, 82(9), 667–672. [Google Scholar] [CrossRef]

- Sessa, D. J.; Wolf, W.J. Bowman-Birk inhibitors in soybean seed coats. Ind. Crops Prod 2001, 14, 73–83. [Google Scholar] [CrossRef]

- Thomson, L. Reduction of phytic acid concentration in protein isolates by acylation techniques. J. Am. Oil. Chem. Soc 1987, 64, 1712. [Google Scholar] [CrossRef]

- Wang, C.; Wixon, R. Phytochemicals in soybean – Their potential helth benefits. Inform 1999, 10, 315–320. [Google Scholar]

© 2006 by MDPI (http://www.mdpi.org). Reproduction is permitted for noncommercial purposes.

Share and Cite

Barac, M.B.; Jovanovic, S.T.; Stanojevic, S.P.; Pesic, M.B. Effect of Limited Hydrolysis on Traditional Soy Protein Concentrate. Sensors 2006, 6, 1087-1101. https://doi.org/10.3390/s6091087

Barac MB, Jovanovic ST, Stanojevic SP, Pesic MB. Effect of Limited Hydrolysis on Traditional Soy Protein Concentrate. Sensors. 2006; 6(9):1087-1101. https://doi.org/10.3390/s6091087

Chicago/Turabian StyleBarac, Miroljub B., Snezana T. Jovanovic, Sladjana P. Stanojevic, and Mirjana B. Pesic. 2006. "Effect of Limited Hydrolysis on Traditional Soy Protein Concentrate" Sensors 6, no. 9: 1087-1101. https://doi.org/10.3390/s6091087