Microalgal Carotenoids: A Review of Production, Current Markets, Regulations, and Future Direction

Abstract

:1. Unlocking the Potential of Microalgae

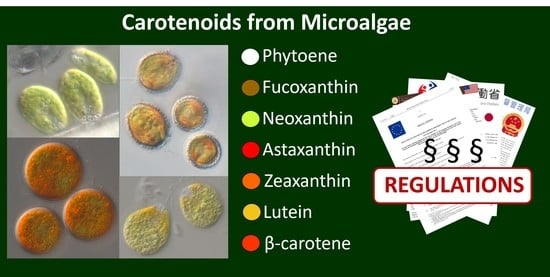

2. Carotenoid Classification and History

3. Carotenoid Synthesis inside Microalgal Cells

4. Carotenogenesis

5. Commercial Applications

6. Natural versus Synthetic Carotenoid

7. Mass Production of Microalgae

8. Biomass Harvesting and Carotenoids Extraction

9. Legislations and Regulatory Aspects

9.1. Europe

9.1.1. European Regulations: Food/Feed and Nutraceuticals

9.1.2. European Regulations: Cosmetics

9.2. United States of America

9.2.1. US Regulations: Food/feed and Nutraceuticals

9.2.2. US Regulations: Cosmetics

9.3. Asia

9.3.1. Regulations in the People’s Republic of China: Food/feed and Nutraceuticals

9.3.2. Regulations in the People’s Republic of China: Cosmetics

9.3.3. Regulations in Japan: Food/feed and Nutraceuticals

9.3.4. Regulations in Japan: Cosmetics

9.4. The Nagoya Protocol

10. Opportunities and Challenges

10.1. Strengths and Opportunities

10.2. Weaknesses and Threats

11. Major Players, Current Trends and Future Research

12. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Andersen, R.A. The microalgal cell. In Handbook of Microalgal Culture; Richmond, A., Hu, Q., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 1–20. [Google Scholar]

- Zimmer, C. On the origin of life on Earth. Science 2009, 323, 198–199. [Google Scholar] [CrossRef] [PubMed]

- Leya, T.; Rahn, A.; Lütz, C.; Remias, D. Response of arctic snow and permafrost algae to high light and nitrogen stress by changes in pigment composition and applied aspects for biotechnology. FEMS Microbiol. Ecol. 2009, 67, 432–443. [Google Scholar] [CrossRef] [PubMed]

- Seckbach, J. The first eukaryotic cells—Acid hot-spring algae. J. Biol. Phys. 1995, 20, 335–345. [Google Scholar] [CrossRef]

- Falkowski, P.G.; Barber, R.T.; Smetacek, V. Biogeochemical controls and feedbacks on ocean primary production. Science 1998, 281, 200–207. [Google Scholar] [CrossRef] [PubMed]

- Borowitzka, M.A. High-value products from microalgae—Their development and commercialisation. J. Appl. Phycol. 2013, 25, 743–756. [Google Scholar] [CrossRef]

- Guiry, M.D. How many species of algae are there? J. Phycol. 2012, 48, 1057–1063. [Google Scholar] [CrossRef]

- Day, J.G.; Slocombe, S.P.; Stanley, M.S. Overcoming biological constraints to enable the exploitation of microalgae for biofuels. Bioresour. Technol. 2012, 109, 245–251. [Google Scholar] [CrossRef]

- Yabuzaki, J. Carotenoids Database: Structures, chemical fingerprints and distribution among organisms. Database 2017, 2017. [Google Scholar] [CrossRef]

- Meléndez-Martínez, A.J.; Britton, G.; Vicario, I.M.; Heredia, F.J. Relationship between the colour and the chemical structure of carotenoid pigments. Food Chem. 2007, 101, 1145–1150. [Google Scholar] [CrossRef]

- Moore, B.Y.T. The association of vitamin A activity with carotene in the carrot root. Biochem. J. 1929, 23, 803–811. [Google Scholar]

- Jin, E.; Juergen, P.W.; Kum, L.H.; Min, H.S.; Man, C. Xanthophylls in microalgae: From biosynthesis to biotechnological mass production and application. J. Microbiol. Biotechnol. 2003, 13, 165–174. [Google Scholar]

- Ambati, R.R.; Moi, P.S.; Ravi, S.; Aswathanarayana, R.G. Astaxanthin: Sources, extraction, stability, biological activities and its commercial applications—A review. Mar. Drugs 2014, 12, 128–152. [Google Scholar] [CrossRef] [PubMed]

- Takaichi, S. Carotenoids in algae: Distributions, biosyntheses and functions. Mar. Drugs 2011, 9, 1101–1118. [Google Scholar] [CrossRef] [PubMed]

- Rabbani, S.; Beyer, P.; von Lintig, J.; Hugueney, P.; Kleinig, H. Induced β-carotene synthesis driven by triacylglycerol deposition in the unicellular alga Dunaliella bardawil. Plant Physiol. 1998, 116, 1239–1248. [Google Scholar] [CrossRef] [PubMed]

- Demmig-Adams, B.; Adams, W.W. Antioxidants in photosynthesis and human nutrition. Science 2002, 298, 2149–2153. [Google Scholar] [CrossRef] [PubMed]

- Butler, T.; McDougall, G.; Campbell, R.; Stanley, M.; Day, J. Media screening for obtaining Haematococcus pluvialis red motile macrozooids rich in astaxanthin and fatty acids. Biology 2018, 7, 2. [Google Scholar] [CrossRef] [PubMed]

- FEEDAP. Safety and efficacy of Panaferd-AX (red carotenoid-rich bacterium Paracoccus carotinifaciens) as feed additive for salmon and trout. EFSA J. 2003, 5, 546. [Google Scholar]

- Andrewes, A.G.; Starr, M.P. (3R,3′R)-astaxanthin from the yeast Phaffia rhodozyma. Phytochemistry 1976, 15, 1009–1011. [Google Scholar] [CrossRef]

- Jeong, J.S.; Kim, I.H. Effect of astaxanthin produced by Phaffia rhodozyma on growth performance, meat quality, and fecal noxious gas emission in broilers. Poult. Sci. 2014, 93, 3138–3144. [Google Scholar] [CrossRef]

- Hu, J.; Lu, W.; Lv, M.; Wang, Y.; Ding, R.; Wang, L. Extraction and purification of astaxanthin from shrimp shells and the effects of different treatments on its content. Rev. Bras. Farmacogn. 2019, 29, 24–29. [Google Scholar] [CrossRef]

- Lin, J.H.; Lee, D.J.; Chang, J.S. Lutein production from biomass: Marigold flowers versus microalgae. Bioresour. Technol. 2015, 184, 421–428. [Google Scholar] [CrossRef] [PubMed]

- Breitmaier, E. Terpenes: Importance, General Structure, and Biosynthesis. In Terpenes: Flavors, Fragrances, Pharmaca, Pheromones; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2006; pp. 1–9. [Google Scholar]

- Capa, W.; Paniagua-Michel, J.; Olmos-Soto, J. The biosynthesis and accumulation of β-carotene in Dunaliella salina proceed via the glyceraldehyde 3-phosphate/pyruvate pathway. Nat. Prod. Res. 2009, 23, 1021–1028. [Google Scholar] [CrossRef] [PubMed]

- Han, D.; Li, Y.; Hu, Q. Astaxanthin in microalgae: Pathways, functions and biotechnological implications. Algae 2013, 28, 131–147. [Google Scholar] [CrossRef]

- Jahns, P.; Latowski, D.; Strzalka, K. Mechanism and regulation of the violaxanthin cycle: The role of antenna proteins and membrane lipids. Biochim. Biophys. Acta Bioenerg. 2009, 1787, 3–14. [Google Scholar] [CrossRef] [PubMed]

- Ambati, R.R.; Gogisetty, D.; Aswathanarayana, R.G.; Ravi, S.; Bikkina, P.N.; Bo, L.; Yuepeng, S. Industrial potential of carotenoid pigments from microalgae: Current trends and future prospects. Crit. Rev. Food Sci. Nutr. 2019, 59, 1880–1902. [Google Scholar] [CrossRef]

- Deinove. Available online: https://www.deinove.com/en/news/all-press-releases/strategic-partnership-between-deinove-and-solvay-marketing-phytoene-north-america-and-asia (accessed on 18 July 2019).

- Markets and Markets. Carotenoid Market: By Type (Astaxanthin, Beta-Carotene, Canthaxanthin, Lutein, Lycopene, and Zeaxanthin), Source (Synthetic and Natural), Application (Supplements, Food, Feed, and Cosmetics), and by Region—Global Trends and Forecast to 2021. 2015, pp. 1–172. Available online: https://www.marketsandmarkets.com/Market-Reports/carotenoid-market-158421566.html (accessed on 30 June 2019).

- Englmaierová, M.; Skřivan, M.; Bubancová, I. A comparison of lutein, spray-dried Chlorella, and synthetic carotenoids effects on yolk colour, oxidative stability, and reproductive performance of laying hens. Czech J. Anim. Sci. 2013, 58, 412–419. [Google Scholar] [CrossRef]

- Surai, P.F.; Speake, B.K.; Sparks, N.H.C. Carotenoids in avian nutrition and embryonic development. 1. Absorption, availability and levels in plasma and egg yolk. J. Poult. Sci. 2001, 38, 1–27. [Google Scholar] [CrossRef]

- Lorenz, R.T.; Cysewski, G.R. Commercial potential for Haematococcus microalgae as a natural source of astaxanthin. Trends Biotechnol. 2000, 18, 160–167. [Google Scholar] [CrossRef]

- Ottinger, M.; Clauss, K.; Kuenzer, C. Aquaculture: Relevance, distribution, impacts and spatial assessments—A review. Ocean Coast. Manag. 2016, 119, 244–266. [Google Scholar] [CrossRef]

- Scottish Government. Available online: https://www2.gov.scot/Topics/marine/Fish-Shellfish (accessed on 23 September 2019).

- Fennema, O.R. Food Chemistry, 3rd ed.; Marcel Dekker, Inc.: New York, NY, USA, 1996; p. 1069. [Google Scholar]

- Stahl, W.; Sies, H. β-carotene and other carotenoids in protection from sunlight. Am. J. Clin. Nutr. 2012, 96, 1179–1184. [Google Scholar] [CrossRef]

- Eclae Cosmetics. Available online: http://eclae.com/en/eclae/9-discover-eclae#dunaliellasalina (accessed on 16 October 2019).

- Cho, K.S.; Shin, M.; Kim, S.; Lee, S.B. Recent advances in studies on the therapeutic potential of dietary carotenoids in neurodegenerative diseases. Oxidative Med. Cell. Longev. 2018, 2018, 4120458. [Google Scholar] [CrossRef]

- Griffiths, K.; Aggarwal, B.; Singh, R.; Buttar, H.; Wilson, D.; De Meester, F. Food antioxidants and their anti-inflammatory properties: A potential role in cardiovascular diseases and cancer prevention. Diseases 2016, 4, 28. [Google Scholar] [CrossRef]

- Sathasivam, R.; Ki, J.S. A review of the biological activities of microalgal carotenoids and their potential use in healthcare and cosmetic industries. Mar. Drugs 2018, 16, 26. [Google Scholar] [CrossRef] [PubMed]

- Sluijs, I.; Cadier, E.; Beulens, J.W.J.; van der A., D.L.; Spijkerman, A.M.W.; van der Schouw, Y.T. Dietary intake of carotenoids and risk of type 2 diabetes. Nutr. Metab. Cardiovasc. Dis. 2015, 25, 376–381. [Google Scholar] [CrossRef] [PubMed]

- Eggersdorfer, M.; Wyss, A. Carotenoids in human nutrition and health. Arch. Biochem. Biophys. 2018, 652, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Gammone, M.A.; D’Orazio, N. Anti-obesity activity of the marine carotenoid fucoxanthin. Mar. Drugs 2015, 13, 2196–2214. [Google Scholar] [CrossRef] [PubMed]

- Fernández, M.J.F.; Rincon-Frutos, E.V.C.; Rincon-Frutos, L. Food components with the potential to be used in the therapeutic approach of mental diseases. Curr. Pharm. Biotechnol. 2019, 20, 100–113. [Google Scholar] [CrossRef]

- Koller, M.; Muhr, A.; Braunegg, G. Microalgae as versatile cellular factories for valued products. Algal Res. 2014, 6, 52–63. [Google Scholar] [CrossRef]

- Li, J.; Zhu, D.; Niu, J.; Shen, S.; Wang, G. An economic assessment of astaxanthin production by large scale cultivation of Haematococcus pluvialis. Biotechnol. Adv. 2011, 29, 568–574. [Google Scholar] [CrossRef]

- Bogacz-Radomska, L.; Harasym, J. β-Carotene-properties and production methods. Food Qual. Saf. 2018, 2, 69–74. [Google Scholar] [CrossRef] [Green Version]

- Capelli, B.; Bagchi, D.; Cysewski, G.R. Synthetic astaxanthin is significantly inferior to algal-based astaxanthin as an antioxidant and may not be suitable as a human nutraceutical supplement. Nutrafoods 2013, 12, 145–152. [Google Scholar] [CrossRef]

- NAXA. Available online: https://astaxanthin.org/verification/naxa-verified-products/ (accessed on 12 August 2019).

- EU 2017/962 EQ. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32017R0962 (accessed on 26 September 2019).

- Aitken, D.; Antizar-Ladislao, B. Achieving a green solution: Limitations and focus points for sustainable algal fuels. Energies 2012, 5, 1613–1647. [Google Scholar] [CrossRef] [Green Version]

- Henley, W.J.; Litaker, R.W.; Novoveská, L.; Duke, C.S.; Quemada, H.D.; Sayre, R.T. Initial risk assessment of genetically modified (GM) microalgae for commodity-scale biofuel cultivation. Algal Res. 2013, 2, 66–77. [Google Scholar] [CrossRef]

- Fasaei, F.; Bitter, J.H.; Slegers, P.M.; van Boxtel, A.J.B. Techno-economic evaluation of microalgae harvesting and dewatering systems. Algal Res. 2018, 31, 347–362. [Google Scholar] [CrossRef]

- Ufraction8. Available online: http://ufraction8.com/ (accessed on 22 July 2019).

- Scholz, M.J.; Weiss, T.L.; Jinkerson, R.E.; Jing, J.; Roth, R.; Goodenough, U.; Posewitz, M.C.; Gerken, H.G. Ultrastructure and composition of the Nannochloropsis gaditana cell wall. Eukaryot. Cell 2014, 13, 1450–1464. [Google Scholar] [CrossRef] [Green Version]

- Saini, R.K.; Keum, Y.S. Carotenoid extraction methods: A review of recent developments. Food Chem. 2018, 240, 90–103. [Google Scholar] [CrossRef]

- Gallego, R.; Bueno, M.; Herrero, M. Sub-and supercritical fluid extraction of bioactive compounds from plants, food-by-products, seaweeds and microalgae—An update. TrAC Trends Anal. Chem. 2019, 116, 198–213. [Google Scholar] [CrossRef]

- Gallego, R.; Martínez, M.; Cifuentes, A.; Ibáñez, E.; Herrero, M. Development of a green downstream process for the valorization of Porphyridium cruentum biomass. Molecules 2019, 24, 1564. [Google Scholar] [CrossRef] [Green Version]

- Torregrosa-Crespo, J.; Montero, Z.; Fuentes, J.L.; García-Galbis, M.R.; Garbayo, I.; Vílchez, C.; Martínez-Espinosa, R.M. Exploring the valuable carotenoids for the large-scale production by marine microorganisms. Mar. Drugs 2018, 16, 203. [Google Scholar] [CrossRef] [Green Version]

- PCPC. International Nomenclature Cosmetic Ingredient. Available online: https://www.personalcarecouncil.org/resources/inci/ (accessed on 15 October 2019).

- PCPC. The International Regulatory Database. Available online: https://www.personalcarecouncil.org/resources/international-regulatory-database/ (accessed on 15 October 2019).

- BCC. Research Global Carotenoid Market. Available online: https://www.globenewswire.com/news-release/2018/05/21/1509412/0/en/Global-Carotenoids-Market-to-Reach-2-0-Billion-by-2022.html (accessed on 23 September 2019).

- European Committe for Standardization (CEN). Available online: https://www.cen.eu/Pages/resultsearch.aspx?k=algae (accessed on 5 September 2019).

- Enzing, C.; Ploeg, M.; Barbosa, M.; Lolke, S. EU JRC Scientific and Policy Reports: Microalgae-Based Products for the Food and Feed Sector: An Outlook for Europe; Publications Office of the European Union: Brussels, Belgium, 2014. [Google Scholar]

- Araujo, R. Report on the Community of Practice Workshop: Algae production in Europe: Status, Challenges and Future Developments; The European Commission’s Knowledge Centre for Bioeconomy: Brussels, Belgium, 2019. [Google Scholar]

- European Algae Biomass Association (EABA). Available online: https://eaba-association.org/en (accessed on 17 October 2019).

- EC No 178/2002 Food Safety. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02002R0178-20180701 (accessed on 29 July 2019).

- EC No 852/2004 Food Hygiene. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32004R0852 (accessed on 17 October 2019).

- EU 2015/2283 Novel Foods. Available online: https://eur-lex.europa.eu/eli/reg/2015/2283/oj (accessed on 29 July 2019).

- European Food Safety Authority (EFSA). Available online: http://www.efsa.europa.eu/en/topics/topic/novel-food (accessed on 17 October 2019).

- EC Q&A New Novel Food Regulations. Available online: https://ec.europa.eu/food/sites/food/files/safety/docs/fs_novel-food_leg_q-n-a-new-regulation-nf_en.pdf (accessed on 18 October 2019).

- EC No 1924/2006 Nutrition and Health Claims Made on Foods. Available online: https://eur-lex.europa.eu/eli/reg/2006/1924/2012-11-29 (accessed on 29 July 2019).

- EFSA Press Release. Available online: https://www.efsa.europa.eu/en/press/news/110728 (accessed on 29 July 2019).

- EC No 767/2009 Feed. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32009R0767 (accessed on 17 October 2019).

- EC No 183/2005 Feed Hygiene. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32005R0183 (accessed on 17 October 2019).

- EC No 1223/2009 Cosmetic Regulation. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02009R1223-20180801 (accessed on 31 July 2019).

- Cosmetic Regulation in the European Union. Available online: https://cosmeticsinfo.org/Regulation-in-eu (accessed on 17 October 2019).

- ISO 22716:2007. Available online: https://www.iso.org/standard/36437.html (accessed on 31 July 2019).

- CNPN. Available online: https://ec.europa.eu/growth/sectors/cosmetics/cpnp_en (accessed on 31 July 2019).

- COSING. Available online: https://ec.europa.eu/growth/tools-databases/cosing/index.cfm?fuseaction=search.simple (accessed on 31 July 2019).

- Farm Bill. Available online: https://docs.house.gov/billsthisweek/20181210/CRPT-115hrpt1072.pdf (accessed on 5 September 2019).

- ABO. Available online: https://algaebiomass.org/blog/10509/algae-gets-a-boost-in-agriculture-carbon-capture-and-infrastructure-policy/ (accessed on 5 September 2019).

- Algae University. Available online: https://www.algaeu.com/maps.html (accessed on 2 August 2019).

- FD&C Act. Available online: https://www.fda.gov/regulatory-information/laws-enforced-fda/federal-food-drug-and-cosmetic-act-fdc-act (accessed on 1 August 2019).

- GRAS. Available online: https://www.accessdata.fda.gov/scripts/fdcc/index.cfm?set=GRASNotices&sort=GRN_No&order=DESC&startrow=1&type=basic&search= (accessed on 31 July 2019).

- SAFUS. Available online: https://www.accessdata.fda.gov/scripts/fdcc/index.cfm?set=FoodSubstances&sort=Sortterm&order=ASC&startrow=1&type=basic&search= (accessed on 31 July 2019).

- Association of American Feed Control Officials (AAFCO). Available online: https://www.aafco.org/Regulatory/Committees/Ingredient-Definitions (accessed on 17 October 2019).

- FPLA. Available online: https://www.ftc.gov/enforcement/rules/rulemaking-regulatory-reform-proceedings/fair-packaging-labeling-act (accessed on 6 September 2019).

- Suphanchaimat, R.; Pudpong, N.; Tangcharoensathien, V. Extreme exploitation in Southeast Asia waters: Challenges in progressing towards universal health coverage for migrant workers. PLoS Med. 2017, 14, e1002441. [Google Scholar] [CrossRef] [Green Version]

- FEPC. Available online: https://www.fepc.or.jp/english/energy_electricity/supply_situation/index.html (accessed on 10 September 2019).

- Yamaguchi, K. Recent advances in microalgal bioscience in Japan, with special reference to utilization of biomass and metabolites: A review. J. Appl. Phycol. 1997, 8, 487–502. [Google Scholar] [CrossRef]

- Herrador, M. The Microalgae/Biomass Industry in Japan—An Assessment of Cooperation and Business Potential with European Companies. Available online: https://www.eu-japan.eu/sites/default/files/publications/docs/microalgaebiomassiindustryinjapan-herrador-min16-1.pdf (accessed on 1 October 2019).

- HFG. Food Safety Law in China. Available online: https://www.hfgip.com/sites/default/files/law/food_safety_-_16.02.2016.pdf (accessed on 11 September 2019).

- Food Safety in China. Available online: https://www.sjgrand.cn/china-issues-new-food-safety-guidelines/ (accessed on 11 September 2019).

- CIRS. Health Food in China. Available online: http://www.cirs-reach.com/news-and-articles/How-Many-Health-Food-are-Registered-in-China.html (accessed on 12 September 2019).

- Law of the People’s Republic of China on Traditional Chinese Medicine. Available online: http://en.pkulaw.cn/display.aspx?cgid=287286&lib=law (accessed on 16 October 2019).

- CIRS. Inventory of Existing Chemical Ingredient in China. Available online: http://www.cirs-reach.com/news-and-articles/new-inventory-of-existing-cosmetic-ingredients-in-china-launched-(iecic-2015,-final-version).html (accessed on 12 September 2019).

- STSC. Available online: http://www.sesec.eu/app/uploads/2016/02/Cosmetics-Safety-and-Technical-Standards-2015-Version-Foreword-and-summary.pdf (accessed on 12 September 2019).

- Food Safety in Japan. Available online: https://www.mhlw.go.jp/english/topics/foodsafety/index.html (accessed on 6 September 2019).

- Shen, R. Health Food Regulatory System in Japan. Available online: https://food.chemlinked.com/foodpedia/health-food-regulatory-system-japan (accessed on 30 September 2019).

- MHLW. Health Foods in Japan. Available online: https://www.mhlw.go.jp/stf/seisakunitsuite/bunya/kenkou_iryou/shokuhin/hokenkinou/index_00010.html (accessed on 30 September 2019).

- JPMA. Pharmaceudical Administration and Regulations in Japan. Available online: http://www.jpma.or.jp/english/parj/ (accessed on 1 October 2019).

- ACMA. Cosmetic Regulation in Japan. Available online: https://www.acma.us/cosmeticregulationinjapan.html (accessed on 30 September 2019).

- UN. Nagoya Protocol. Available online: https://treaties.un.org/Pages/ViewDetails.aspx?src=TREATY&mtdsg_no=XXVII-8-b&chapter=27&clang=_en (accessed on 30 September 2019).

- CBD. The Access and Benefit-Sharing Clearing-House. Available online: https://absch.cbd.int/ (accessed on 30 September 2019).

- Lorenz, M.; Cambell, C.; Friedl, T.; Day, J.G. A European perspective on algal resources: Biodiversity, biotechnology and beyond. Eur. J. Phycol. 2011, 46, 95–96. [Google Scholar]

- Culture Collection of Algae and Protozoa. Available online: https://www.ccap.ac.uk/abs.htm (accessed on 30 September 2019).

- Nagoya Protocol on Access and Benefit Sharing. Available online: https://www.gov.uk/guidance/abs (accessed on 30 September 2019).

- McCluskey, K.; Barker, K.B.; Barton, H.A.; Boundy-Mills, K.; Brown, D.R.; Coddington, J.A.; Cook, K.; Desmeth, P.; Geiser, D.; Glaeser, J.A.; et al. The U.S. culture collection network responding to the requirements of the Nagoya protocol on access and benefit sharing. mBio 2017, 8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kroll, H.; Friedrich, J.; Menzel, M.; Schreier, P. Carbon and hydrogen stable isotope ratios of carotenoids and β-carotene-based dietary supplements. J. Agric. Food Chem. 2008, 56, 4198–4204. [Google Scholar] [CrossRef]

- Kiesenhofer, D.P.; Fluch, S. The promises of microalgae-still a long way to go. FEMS Microbiol. Lett. 2018, 365, 2017–2019. [Google Scholar] [CrossRef]

- BASF. Available online: https://nutrition.basf.com/en/Animal-nutrition/Carotenoids.html (accessed on 26 July 2019).

- DSM. Available online: https://www.dsm.com/markets/human-nutrition/en/products/carotenoids.html (accessed on 26 July 2019).

- Kemin. Available online: https://www.kemin.com/na/en-us/products/organic-kem-glo (accessed on 26 July 2019).

- Vitatene. Available online: https://www.nutraingredients.com/Suppliers/Vitatene (accessed on 26 July 2019).

- Algatech. Available online: https://www.prnewswire.com/news-releases/algatech-partners-with-sphera-on-microalgae-682262301.html (accessed on 9 August 2019).

- AlgaeHealth. Available online: https://www.algaehealthsciences.com/about (accessed on 9 August 2019).

- Solix. Available online: https://www.nutraingredients-usa.com/Article/2018/05/17/Astaxanthin-firms-BGG-Solix-join-forces-on-new-Colorado-based-company (accessed on 9 August 2019).

- Algaennovation. Available online: http://www.thinkgeoenergy.com/algae-production-to-be-set-up-at-hellisheidi-geothermal-plant-in-iceland/ (accessed on 12 August 2019).

- Zoccali, M.; Giuffrida, D.; Salafia, F.; Socaciu, C.; Skjånes, K.; Dugo, P.; Mondello, L. First apocarotenoids profiling of four microalgae strains. Antioxidants 2019, 8, 209. [Google Scholar] [CrossRef] [Green Version]

- Colorspore. Available online: https://www.carodel.eu/ (accessed on 23 July 2019).

| Role of Carotenoids within Microalgal Cell | Benefits of Carotenoids to Human Health | ||

|---|---|---|---|

|  |

|  |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Novoveská, L.; Ross, M.E.; Stanley, M.S.; Pradelles, R.; Wasiolek, V.; Sassi, J.-F. Microalgal Carotenoids: A Review of Production, Current Markets, Regulations, and Future Direction. Mar. Drugs 2019, 17, 640. https://doi.org/10.3390/md17110640

Novoveská L, Ross ME, Stanley MS, Pradelles R, Wasiolek V, Sassi J-F. Microalgal Carotenoids: A Review of Production, Current Markets, Regulations, and Future Direction. Marine Drugs. 2019; 17(11):640. https://doi.org/10.3390/md17110640

Chicago/Turabian StyleNovoveská, Lucie, Michael E. Ross, Michele S. Stanley, Rémi Pradelles, Virginie Wasiolek, and Jean-François Sassi. 2019. "Microalgal Carotenoids: A Review of Production, Current Markets, Regulations, and Future Direction" Marine Drugs 17, no. 11: 640. https://doi.org/10.3390/md17110640