3.2. Full Scale Application

Modified soil flushing with the intermittent air sparging process was applied to soils that were polluted by diesel and gasoline in a full-scale operation for nine months. The variations in the TPH concentrations in the ground water that was discharged from the soil during the full-scale operation relative to the soil pore volume are shown in

Figure 8. The highest TPH concentrations were 43.5, 36.7, 64.3 and 39.2 mg/L at a pore volume of 0.7, which were 3.9, 2.1, 4.0 and 3.5 times greater for MW-1, MW-2, MW-3 and MW-4, respectively, relative to a pore volume of 0. The average discharged TPH concentration from the observation wells was 17.7 mg/L at a pore volume of 1.7, which was greater than the initial concentration at a pore volume of 0. However, the TPH substances were still detected in wells at a pore volume of 2.9. The variations in the TPH concentrations increased in the following order at pore volumes of 0.7 and 1.7 during the full-scale operation: MW-3, MW-1, MW-2 and MW-4. The variation of TPH concentration was the highest at MW-3.

After seven months of operation, the TPH concentration decreased from 654, 1170, 1575 to 441, 662 and 829 mg/kg (standard deviation, SD: 43, 83, 78) at depths 6–7, 7–8 and 8–9 m, at pore volumes of 1.7, respectively (as shown in

Table 3). In particular, 47.4% of the TPH was eliminated at a depth of 8 to 9 m at a pore volume of 1.7 during the full-scale operation. This layer had a low removal efficiency during conventional soil flushing, which indicated that the removal efficiency at depths of less than 7 m was effectively enhanced by using modified soil flushing with air scouring. The average TPH concentrations that were eliminated by using this process for all layers and areas were 18.2%, 43.2% and 58.6% at pore volumes of 0.7, 1.7 and 2.9, respectively.

Figure 8.

Variations in the TPH concentrations in the observation wells.

Figure 8.

Variations in the TPH concentrations in the observation wells.

Table 3.

TPH concentrations of soils relative to the pore volume for full-scale operation at a petroleum-polluted military site.

Table 3.

TPH concentrations of soils relative to the pore volume for full-scale operation at a petroleum-polluted military site.

| Depth (m) | Pore Volume 0 | Pore Volume 0.7 | Pore Volume 1.7 | Pore Volume 2.9 |

|---|

| TPH (mg/kg) | *SD | TPH (mg/kg) | SD | TPH (mg/kg) | SD | TPH (mg/kg) | SD |

|---|

| 6–7 m | 654 | 90 | 684 | 68 | 441 | 44 | 309 | 90 |

| 7–8 m | 1170 | 98 | 892 | 91 | 662 | 83 | 498 | 97 |

| 8−9 m | 1575 | 93 | 1203 | 58 | 829 | 78 | 601 | 93 |

The removal efficiencies of TPH were 52.8%, 57.4%, and 61.8% at depths 6–7, 7–8 and 8–9 m, respectively, at a pore volume of 2.9. In this experiment, the TPH concentrations decreased as the pore volume increased. Bass

et al. reported that the duration of remediation was not correlated with the performance of the remediation process using the air sparging system because of the masking effects of other factors. However, the extent of remediation was proportional to the remediation time. The operation time of successful systems was between a few months to 4 years [

24]. The removal efficiency increased with the depth of the soil layer after applying this process. Previously, the TPH removal rates were comparatively low for the soil layers at less than 7 m, with values of 55.8%, 39.6%, and 38.1% for depths of 6–7, 7–8 and 8–9 m, respectively when conventional soil flushing was used at this site. These values potentially resulted from differences in the surfactant permeability. Air sparging was used at around 8 m on this site, and the pollutant was moved to a higher layer during operation. The TPH concentration decreased with increasing pore volume, with the exception of the temporal increase in soil depth between 6 and 7 m at a pore volume of 1.7. At this site, the mean removal efficiency of TPH was approximately 58.6% at a pore volume of 2.9.

In the full-scale operation of this system, the BTEX concentration at the site decreased with increasing pore volume (

Table 4). However, the reduction in BTEX was nearly complete before the pore volume reached 1.7. The amount of BTEX removed averaged 82% over the 12 months of operation. The BTEX concentrations were 92, 100, 97 and 97 mg/kg at depths of 6–7, 7–8 and 8–9 m, respectively, at a pore volume of 0.7. Volatilization was the dominant process during air sparging trials in a sand aquifer contaminated by dissolved petroleum hydrocarbons (mostly BTEX) [

25]. The movement of ground water and the removal of VOC substances are potentially enhanced by the repeated stopping and starting operations at intervals of 24 h during the air sparging process. Rothmel

et al. reported that mobilization of TCE-NAPLs was maximized when the foam generated from Steol CS-330 was injected in a pulsed operation (350 mL of foam, followed by 200 mL of artificial groundwater, followed by 300 mL of foam, followed by 250 mL of artificial groundwater were injected through a sand column for this condition) [

26].

Table 4.

BTEX concentrations of soils relative to the pore volume for full-scale operation at a petroleum-polluted military site.

Table 4.

BTEX concentrations of soils relative to the pore volume for full-scale operation at a petroleum-polluted military site.

| Depth (m) | Pore Volume 0 | Pore Volume 0.7 | Pore Volume 1.7 | Pore Volume 2.9 |

|---|

| BTEX (mg/kg) | *SD | BTEX (mg/kg) | SD | BTEX (mg/kg) | SD | BTEX (mg/kg) | SD |

|---|

| 6–7 m | 73 | 6 | 92 | 8 | 15 | 6 | 14 | 8 |

| 7–8 m | 119 | 10 | 100 | 6 | 35 | 9 | 30 | 7 |

| 8–9 m | 166 | 7 | 97 | 8 | 30 | 9 | 21 | 6 |

The BTEX concentration were 15, 35, and 30 mg/kg (SD: 6, 9, 9) at depths of 6–7, 7–8 and 8–9 m, respectively, at a pore volume of 1.7 for the full-scale serial operation of the modified soil flushing and air sparging process. These results indicated that the interformational differences in the removal efficiencies were less than the differences that were observed in the previous operation. Moreover, the interformational differences in the BTEX concentrations were lower than the differences of TPH. The removal efficiencies of BTEX were greater than of the efficiencies of TPH at the end of the operation. The mean concentrations of BTEX decreased from 73, 119, 166 (SD: 6, 10, 7) at a pore volume of 0 to 14, 30 and 21 mg/kg (SD: 8, 7, 6) at a pore volume of 2.9, at depths of 6–7, 7–8 and 8–9 m, respectively. Therefore, this process should be operated until the pore volume reaches 1.7 for the removal of BTEX substances.

Tween 80 is generally considered a poor mobilizer. However, our results indicated surfactant flushing in the non-pressure dose with combined of air-sparging improved NAPL mobilization; Especailly, removal efficiency at the layer under 7 m was improved and an overall mass was reduced with the full scale operation of this process. True NAPH phase mobility was observed with 4% Tween 80 using magnetic resonance imaging (MRI) and it was concluded that surfactant flushing causes NAPL mobilization and creates additional NAPL source zones [

27]. The existence of surfactant in the soil flushing operation in combination with air sparging probably enhances the migration ability of contaminant-laden fluids and the upward extraction of volatile organic compounds (VOCs) in the weathered layer. Air injected during the operation of the process might promote the mobilization of contaminants. However, injection of surfactant into the subsurface has been regarded as possible risky because surfactant residuals lead to further broadening of the contaminated zone. Foam generated by air injection might enhance volatilization [

28].

After 2.9 pore volumes of full-scale operation with surfactant-aided soil flushing combined with air-sparging, about 5109 kg and 752 kg (removal efficiency 58.6% and 82.0%) of TPH and BTEX, respectively, were removed (

Table 5). These results indicated that NAPL solubilisation was enhanced with the application of this process. At this site, TPH masses of 1744 kg and 2527 kg were removed at 7–8 m and 8–9 m; these masses were initially 3036 kg and 4087 kg, respectively. Most importantly, an area below 7 m was effectively treated with this process. BTEX masses of 231 kg and 376 kg, which were initially 309 kg and 430 kg, were removed at 7–8 m and 8–9 m, respectively. In particular, the high removal efficiency of BTEX at the depth of 8–9 m indicated that the removal efficiency of volatile contaminants were promoted with this process. Therefore, the results of this study highlight the combined effect of a process using surfactant-enhanced solubilization and air-enhanced NAPL mass mobilization, which may improve the removal efficiency of contaminants from heterogeneous media in the full-scale operations of a system.

Table 5.

TPH and BTEX mass removed during full scale operation at a petroleum polluted military site.

Table 5.

TPH and BTEX mass removed during full scale operation at a petroleum polluted military site.

| Depth | Before Operation | After Operation |

|---|

| Average TPH Mass(kg) | Average BTEX Mass(kg) | Average TPH Mass(kg) | Average BTEX Mass(kg) |

|---|

| 6–7 m | 1589 | 178 | 751 | 34 |

| 7–8 m | 3036 | 309 | 1292 | 78 |

| 8–9 m | 4087 | 430 | 1560 | 54 |

| Total | 8712 | 917 | 3603 (*58.6%) | 165 (*82.0%) |

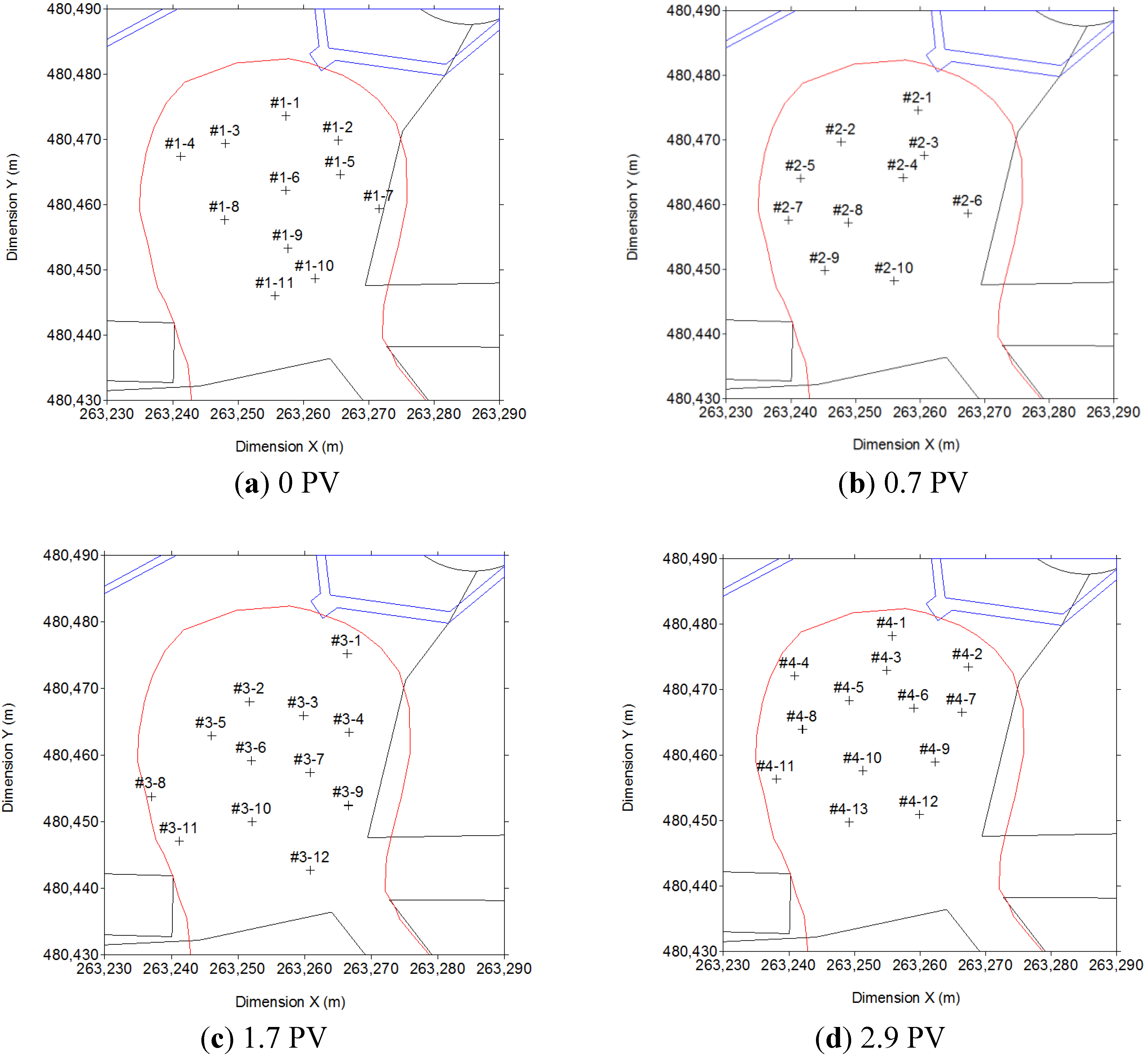

The distribution of TPH in the polluted area is presented in

Table 6. The TPH concentrations in the areas greater than 500 mg/kg noticeably decreased at this site. The initial target area of more than 500 mg/kg was 2530 m

3, which was reduced to 1190 m

3 after remediation using this modified process. The removal efficiencies at 6–7, 7–8, and 8–9 m were 67.4%, 51.6% and 42.4%, respectively. In particular, areas over 2000 mg/kg, which is the standard limit for soil environments in Korea [

29], were not detected. Compared to previous operations that used conventional soil flushing, the removal rate of TPH for the area over 500 mg/kg was enhanced by 14.3%, 20.6%, and 17.1% at depths of 6–7, 7–8 and 8–9 m, respectively. The enhanced effects can be explained by the foam generated by the combined injection of the surfactant and air [

30,

31]. The foam appeared in all of the layers (including below the permeable stratum) and was distributed evenly through all of the soil layers.

Similar to the area polluted by TPH, the distribution of BTEX decreased. Overall, 94% of the BTEX (over 80 mg/kg) was removed. The removal efficiencies at this area at 6–7, 7–8 and 8–9 m were 99.8%, 95.5%, and 89.5%, respectively. The rates of BTEX removal over 80 mg/kg were 40.0%, 53.1%, and 48.4% higher than those of the conventional soil flushing treatment for the layers at depths of 6–7, 7–8, and 8–9 m, respectively. These findings provide useful guidance for optimizing full-scale operations to remediate petroleum-polluted sites with heterogeneous soil layers.

Table 6.

The area polluted by TPH and BTEX (Unit: m2).

Table 6.

The area polluted by TPH and BTEX (Unit: m2).

| Depth | TPH (>500 mg/kg) | BTEX (>80 mg/kg) |

|---|

| Pore Volume 0 | Pore Volume 2.9 | Pore Volume 0 | Pore Volume 2.9 |

|---|

| 6–7 m | 739 | 241 | 160 | 1 |

| 7–8 m | 902 | 437 | 510 | 24 |

| 8–9 m | 889 | 512 | 420 | 52 |

| Total | 2530 | 1190 | 1090 | 77 |