Multilevel Safety Climate and Safety Performance in the Construction Industry: Development and Validation of a Top-Down Mechanism

Abstract

:1. Introduction

2. Literature Review

2.1. Safety Climate in Construction

2.2. Safety Performance

2.3. Relationship between Safety Climate and Safety Performance

3. Research Methods

3.1. Questionnaire Design

3.2. Participants and Procedure

3.3. Data Analysis

3.3.1. Exploratory Factor Analysis

3.3.2. Structural Equation Modelling

4. Results

4.1. The Samples

4.2. Exploratory Factor Analysis

4.3. Measurement Model Assessment

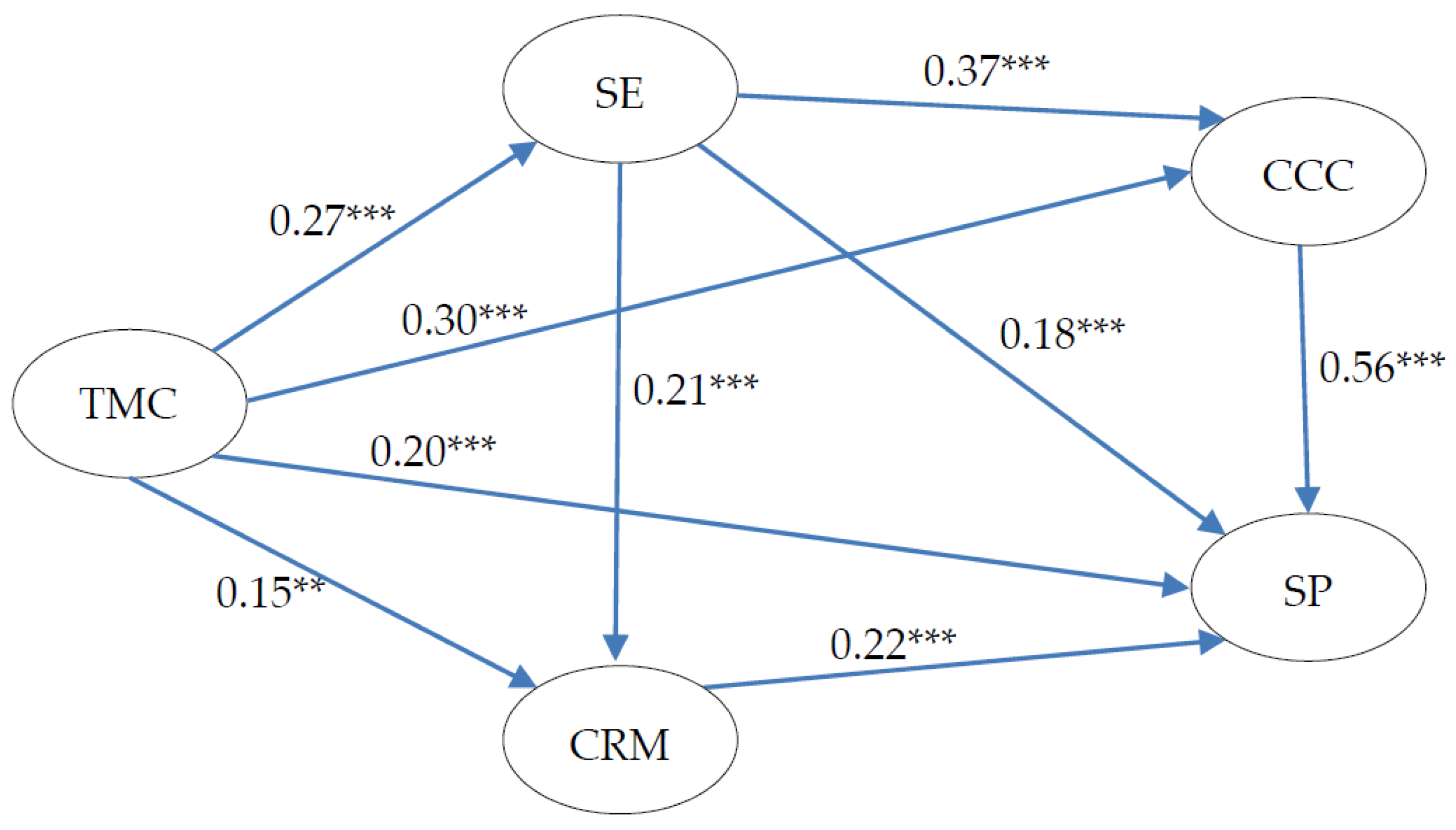

4.4. Structural Model Assessment

5. Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mohamed, S. Safety Climate in Construction Site Environments. J. Constr. Eng. Manag. 2002, 128, 375–384. [Google Scholar] [CrossRef]

- Swuste, P.; Frijters, A.; Guldenmund, F. Is it possible to influence safety in the building sector? A literature review extending from 1980 until the present. Saf. Sci. 2012, 50, 1333–1343. [Google Scholar] [CrossRef]

- Sunindijo, R.Y.; Zou, P.X.W. Political Skill for Developing Construction Safety Climate. J. Constr. Eng. Manag. 2012, 138, 605–612. [Google Scholar] [CrossRef]

- Huang, X.; Hinze, J. Owner’s role in construction safety. J. Constr. Eng. Manag. 2006, 132, 164–173. [Google Scholar] [CrossRef]

- Neal, A.; Griffin, M.A.; Hart, P.M. The impact of organizational climate on safety climate and individual behavior. Saf. Sci. 2000, 34, 99–109. [Google Scholar] [CrossRef]

- Clarke, S. The relationship between safety climate and safety performance: A meta-analytic review. J. Occup. Health Psychol. 2006, 11, 315. [Google Scholar] [CrossRef] [PubMed]

- Hon, C.K.H.; Chan, A.P.C.; Yam, M.C.H. Relationships between safety climate and safety performance of building repair, maintenance, minor alteration, and addition (RMAA) works. Saf. Sci. 2014, 65, 10–19. [Google Scholar] [CrossRef]

- Barbaranelli, C.; Petitta, L.; Probst, T.M. Does safety climate predict safety performance in Italy and the USA? Cross-cultural validation of a theoretical model of safety climate. Accid. Anal. Prev. 2015, 77, 35–44. [Google Scholar] [CrossRef] [PubMed]

- Desai, V.M.; Roberts, K.H.; Ciavarelli, A.P. The relationship between safety climate and recent accidents: Behavioral learning and cognitive attributions. Hum. Factors 2006, 48, 639–650. [Google Scholar] [CrossRef] [PubMed]

- Pinto, A. QRAM a Qualitative Occupational Safety Risk Assessment Model for the construction industry that incorporate uncertainties by the use of fuzzy sets. Saf. Sci. 2014, 63, 57–76. [Google Scholar] [CrossRef]

- Sparer, E.H.; Murphy, L.A.; Taylor, K.M.; Dennerlein, J.T. Correlation between safety climate and contractor safety assessment programs in construction. Am. J. Ind. Med. 2013, 56, 1463–1472. [Google Scholar] [CrossRef] [PubMed]

- Meliá, J.L.; Mearns, K.; Silva, S.A.; Lima, M.L. Safety climate responses and the perceived risk of accidents in the construction industry. Saf. Sci. 2008, 46, 949–958. [Google Scholar] [CrossRef]

- Brondino, M.; Silva, S.A.; Pasini, M. Multilevel approach to organizational and group safety climate and safety performance: Co-workers as the missing link. Saf. Sci. 2012, 50, 1847–1856. [Google Scholar] [CrossRef]

- Fang, D.; Chen, Y.; Wong, L. Safety climate in construction industry: A case study in Hong Kong. J. Constr. Eng. Manag. 2006, 132, 573–584. [Google Scholar] [CrossRef]

- Dedobbeleer, N.; Béland, F. A safety climate measure for construction sites. J. Saf. Res. 1991, 22, 97–103. [Google Scholar] [CrossRef]

- Hon, C.K.H.; Chan, A.P.C.; Yam, M.C.H. Determining Safety Climate Factors in the Repair, Maintenance, Minor Alteration, and Addition Sector of Hong Kong. J. Constr. Eng. Manag. 2013, 139, 519–528. [Google Scholar] [CrossRef]

- Lingard, H.C.; Cooke, T.; Blismas, N. Properties of group safety climate in construction: The development and evaluation of a typology. Constr. Manag. Econ. 2010, 28, 1099–1112. [Google Scholar] [CrossRef]

- Zohar, D. A Group-Level Model of Safety Climate: Testing the Effect of Group Climate on Microaccidents in Manufacturing Jobs. J. Appl. Psychol. 2000, 85, 587–596. [Google Scholar] [CrossRef] [PubMed]

- Zohar, D.; Luria, G. A multilevel model of safety climate: Cross-level relationships between organization and group-level climates. J. Appl. Psychol. 2005, 90, 616–628. [Google Scholar] [CrossRef] [PubMed]

- Lingard, H.C.; Cooke, T.; Blismas, N. Group-level safety climate in the Australian construction industry: Within-group homogeneity and between-group differences in road construction and maintenance. Constr. Manag. Econ. 2009, 27, 419–432. [Google Scholar] [CrossRef]

- Lingard, H.; Cooke, T.; Blismas, N. Coworkers’ response to occupational health and safety: An overlooked dimension of group-level safety climate in the construction industry? Eng. Constr. Archit. Manag. 2011, 18, 159–175. [Google Scholar] [CrossRef]

- Christian, M.S.; Bradley, J.C.; Wallace, J.C.; Burke, M.J. Workplace safety: A meta-analysis of the roles of person and situation factors. J. Appl. Psychol. 2009, 94, 1103–1127. [Google Scholar] [CrossRef] [PubMed]

- Grabowski, M.; Ayyalasomayajula, P.; Merrick, J. Denise Mccafferty Accident precursors and safety nets: Leading indicators of tanker operations safety. Marit. Policy Manag. 2007, 34, 405–425. [Google Scholar] [CrossRef]

- Johnson, S.E. The predictive validity of safety climate. J. Saf. Res. 2007, 38, 511–521. [Google Scholar] [CrossRef] [PubMed]

- Neal, A.; Griffin, M.A. A study of the lagged relationships among safety climate, safety motivation, safety behavior, and accidents at the individual and group levels. J. Appl. Psychol. 2006, 91, 946. [Google Scholar] [CrossRef] [PubMed]

- Griffin, M.A.; Neal, A. Perceptions of safety at work: A framework for linking safety climate to safety performance, knowledge, and motivation. J. Occup. Health Psychol. 2000, 5, 347–358. [Google Scholar] [CrossRef] [PubMed]

- Neal, A.; Griffin, M.A. Safety Climate and Safety at Work; American Psychological Association: Washington, DC, USA, 2004. [Google Scholar]

- Siu, O.-L.; Phillips, D.R.; Leung, T.-W. Safety climate and safety performance among construction workers in Hong Kong. Accid. Anal. Prev. 2004, 36, 359–366. [Google Scholar] [CrossRef]

- Huang, Y.H.; Ho, M.; Smith, G.S.; Chen, P.Y. Safety climate and self-reported injury: Assessing the mediating role of employee safety control. Accid. Anal. Prev. 2006, 38, 425–433. [Google Scholar] [CrossRef] [PubMed]

- Guo, B.H.W.; Yiu, T.W.; González, V.A. Predicting safety behavior in the construction industry: Development and test of an integrative model. Saf. Sci. 2016, 84, 1–11. [Google Scholar] [CrossRef]

- Morrow, S.L.; McGonagle, A.K.; Dove-Steinkamp, M.L.; Walker, C.T.; Marmet, M.; Barnes-Farrell, J.L. Relationships between psychological safety climate facets and safety behavior in the rail industry: A dominance analysis. Accid. Anal. Prev. 2010, 42, 1460–1467. [Google Scholar] [CrossRef] [PubMed]

- Thompson, B. Exploratory and Confirmatory factor Analysis: Understanding Concepts and Applications; American Psychological Association: Washington, DC, USA, 2004. [Google Scholar]

- Choudhry, R.; Fang, D.; Lingard, H. Measuring Safety Climate of a Construction Company. J. Constr. Eng. Manag. 2009, 135, 890–899. [Google Scholar] [CrossRef]

- Pallant, J. A Step by Step Guide to Data Analysis Using SPSS for Windows Version 15; Open University Press: Milton Keynes, UK, 2007. [Google Scholar]

- Lingard, H.; Sublet, A. The impact of job and organizational demands on marital or relationship satisfaction and conflict among Australian civil engineers. Constr. Manag. Econ. 2002, 20, 507–521. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Shen, Y. An Investigation of Safety Climate on Hong Kong Construction Sites. Ph.D. Thesis, University of Hong Kong, Hong Kong, China, January 2013. [Google Scholar]

- Shrout, P.E.; Bolger, N. Mediation in experimental and nonexperimental studies: New procedures and recommendations. Psychol. Methods 2002, 7, 422–445. [Google Scholar] [CrossRef] [PubMed]

- Kaiser, H.F. An index of factorial simplicity. Psychometrika 1974, 39, 31–36. [Google Scholar] [CrossRef]

- Litwin, M.S. How to Measure Survey Reliability and Validity; Sage Publications: New York, NY, USA, 1995; Volume 7. [Google Scholar]

- Zhou, Q.; Fang, D.; Mohamed, S. Safety climate improvement: Case study in a Chinese construction company. J. Constr. Eng. Manag. 2010, 137, 86–95. [Google Scholar] [CrossRef]

- Choudhry, R.M.; Fang, D.; Mohamed, S. The nature of safety culture: A survey of the state-of-the-art. Saf. Sci. 2007, 45, 993–1012. [Google Scholar] [CrossRef]

- Lingard, H.; Cooke, T.; Blismas, N. Do Perceptions of Supervisors’ Safety Responses Mediate the Relationship between Perceptions of the Organizational Safety Climate and Incident Rates in the Construction Supply Chain? J. Constr. Eng. Manag. 2012, 138, 234–241. [Google Scholar] [CrossRef]

- Zohar, D. Safety climate in industrial organizations: Theoretical and applied implications. J. Appl. Psychol. 1980, 65, 96–102. [Google Scholar] [CrossRef] [PubMed]

- Aksorn, T.; Hadikusumo, B.H.W. Critical success factors influencing safety program performance in Thai construction projects. Saf. Sci. 2008, 46, 709–727. [Google Scholar] [CrossRef]

- Tucker, S.; Chmiel, N.; Turner, N.; Hershcovis, M.S.; Stride, C.B. Perceived organizational support for safety and employee safety voice: The mediating role of coworker support for safety. J. Occup. Health Psychol. 2008, 13, 319–330. [Google Scholar] [CrossRef] [PubMed]

- Chiaburu, D.S.; Harrison, D.A. Do peers make the place? Conceptual synthesis and meta-analysis of coworker effects on perceptions, attitudes, OCBs, and performance. J. Appl. Psychol. 2008, 93, 1082. [Google Scholar] [CrossRef] [PubMed]

- Conchie, S.M.; Moon, S.; Duncan, M. Supervisors’ engagement in safety leadership: Factors that help and hinder. Saf. Sci. 2013, 51, 109–117. [Google Scholar] [CrossRef]

| Construct | Code | Factor Loading | Cronbach’s Alpha | Variance Explained (%) |

|---|---|---|---|---|

| Top Management Commitment (TMC) | OSC2 | 0.886 | 0.961 | 23.19 |

| OSC1 | 0.873 | |||

| OSC6 | 0.872 | |||

| OSC15 | 0.866 | |||

| OSC12 | 0.853 | |||

| OSC7 | 0.852 | |||

| OSC16 | 0.850 | |||

| OSC3 | 0.846 | |||

| OSC8 | 0.809 | |||

| OSC5 | 0.807 | |||

| Coworkers’ Caring and Communication (CCC) | CSC10 | 0.795 | 0.887 | 16.09 |

| CSC11 | 0.780 | |||

| CSC6 | 0.749 | |||

| CSC7 | 0.745 | |||

| CSC9 | 0.745 | |||

| CSC4 | 0.728 | |||

| CSC5 | 0.726 | |||

| CSC3 | 0.662 | |||

| Coworkers’ Role Models (CRM) | CSC8 | 0.834 | 0.897 | 10.84 |

| CSC2 | 0.830 | |||

| CSC12 | 0.814 | |||

| CSC1 | 0.699 | |||

| Supervisors’ Expectation (SE) | SSC9 | 0.874 | 0.890 | 6.81 |

| SSC10 | 0.869 | |||

| SSC6 | 0.799 | |||

| SSC8 | 0.786 | |||

| SSC7 | 0.701 |

| Construct | Code | Factor Loading | Variance Explained (%) |

|---|---|---|---|

| Safety Performance (SP) | SPart.1 | 0.777 | 56.04 |

| SComp.3 | 0.777 | ||

| SComp.2 | 0.759 | ||

| SComp.1 | 0.758 | ||

| SPart.3 | 0.743 | ||

| SPart.2 | 0.673 |

| Construct | Code | Loading | AVE (Average Variance Extracted) | Composite Reliability |

|---|---|---|---|---|

| TMC (OSC) | OSC2 | 0.743 | 0.704 | 0.934 |

| OSC3 | 0.873 | |||

| OSC5 | 0.863 | |||

| OSC8 | 0.868 | |||

| OSC12 | 0.845 | |||

| OSC16 | 0.836 | |||

| SE (SSC) | SSC6 | 0.651 | 0.635 | 0.895 |

| SSC7 | 0.699 | |||

| SSC8 | 0.805 | |||

| SSC9 | 0.877 | |||

| SSC10 | 0.919 | |||

| CCC (CSC-Factor 1) | CSC4 | 0.696 | 0.504 | 0.859 |

| CSC5 | 0.709 | |||

| CSC6 | 0.708 | |||

| CSC9 | 0.679 | |||

| CSC10 | 0.736 | |||

| CSC11 | 0.729 | |||

| CRM (CSC-Factor 2) | CSC2 | 0.793 | 0.525 | 0.766 |

| CSC8 | 0.602 | |||

| CSC12 | 0.765 | |||

| SP | SComp. 1 | 0.677 | 0.492 | 0.794 |

| SComp. 2 | 0.727 | |||

| SComp. 3 | 0.766 | |||

| SPart. 1 | 0.627 |

| Model | χ2 | χ2/DF | GFI | AGFI | RMSEA | TLI | CFI |

|---|---|---|---|---|---|---|---|

| Measurement | 989.918 | 4.091 | 0.879 | 0.849 | 0.073 | 0.898 | 0.911 |

| Structural | 1116.697 | 4.595 | 0.864 | 0.833 | 0.079 | 0.882 | 0.896 |

| Effect Paths | Total Effect | Indirect Effect | Direct Effect | Type |

|---|---|---|---|---|

| Effect of OSC on CSC | ||||

| TMC→SE→CCC | 0.341 ***, (0.249, 0.440) | 0.083 ***, (0.047, 0.128) | 0.258 ***, (0.176, 0.354) | Partial Mediation |

| TMC→SE→CRM | 0.155 ***, (0.079, 0.229) | 0.042 ***, (0.014, 0.079) | 0.113 *, (0.031, 0.192) | Partial Mediation |

| Effect of OSC on SP | ||||

| TMC→SE→SP | 0.416 ***, (0.328, 0.522) | 0.091 ***, (0.055, 0.136) | 0.325 ***, (0.244, 0.417) | Partial Mediation |

| TMC→CCC→SP | 0.427 ***, (0.339, 0.529) | 0.243 ***, (0.173, 0.337) | 0.184 ***, (0.118, 0.257) | Partial Mediation |

| TMC→CRM→SP | 0.409 ***, (0.319, 0.512) | 0.081 ***, (0.042, 0.128) | 0.328 ***, (0.249, 0.431) | Partial Mediation |

| Effect of SSC on SP | ||||

| SE→CCC→SP | 0.438 ***, (0.336, 0.561) | 0.268 ***, (0.188, 0.364) | 0.170 ***, (0.089, 0.259) | Partial Mediation |

| SE→CRM→SP | 0.419 ***, (0.317, 0.532) | 0.096 ***, (0.050, 0.155) | 0.323 ***, (0.234, 0.421) | Partial Mediation |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, R.; Chan, A.P.C.; Utama, W.P.; Zahoor, H. Multilevel Safety Climate and Safety Performance in the Construction Industry: Development and Validation of a Top-Down Mechanism. Int. J. Environ. Res. Public Health 2016, 13, 1100. https://doi.org/10.3390/ijerph13111100

Gao R, Chan APC, Utama WP, Zahoor H. Multilevel Safety Climate and Safety Performance in the Construction Industry: Development and Validation of a Top-Down Mechanism. International Journal of Environmental Research and Public Health. 2016; 13(11):1100. https://doi.org/10.3390/ijerph13111100

Chicago/Turabian StyleGao, Ran, Albert P.C. Chan, Wahyudi P. Utama, and Hafiz Zahoor. 2016. "Multilevel Safety Climate and Safety Performance in the Construction Industry: Development and Validation of a Top-Down Mechanism" International Journal of Environmental Research and Public Health 13, no. 11: 1100. https://doi.org/10.3390/ijerph13111100

APA StyleGao, R., Chan, A. P. C., Utama, W. P., & Zahoor, H. (2016). Multilevel Safety Climate and Safety Performance in the Construction Industry: Development and Validation of a Top-Down Mechanism. International Journal of Environmental Research and Public Health, 13(11), 1100. https://doi.org/10.3390/ijerph13111100