VOC Removal Performance of a Joint Process Coupling Biofiltration and Membrane-Filtration Treating Food Industry Waste Gas

Abstract

:1. Introduction

2. Materials and Methods

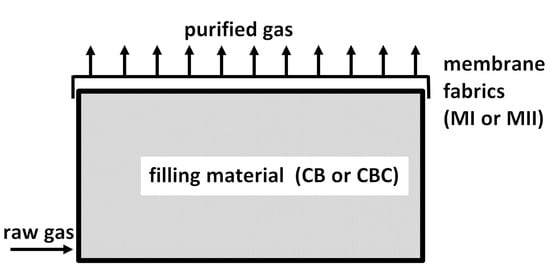

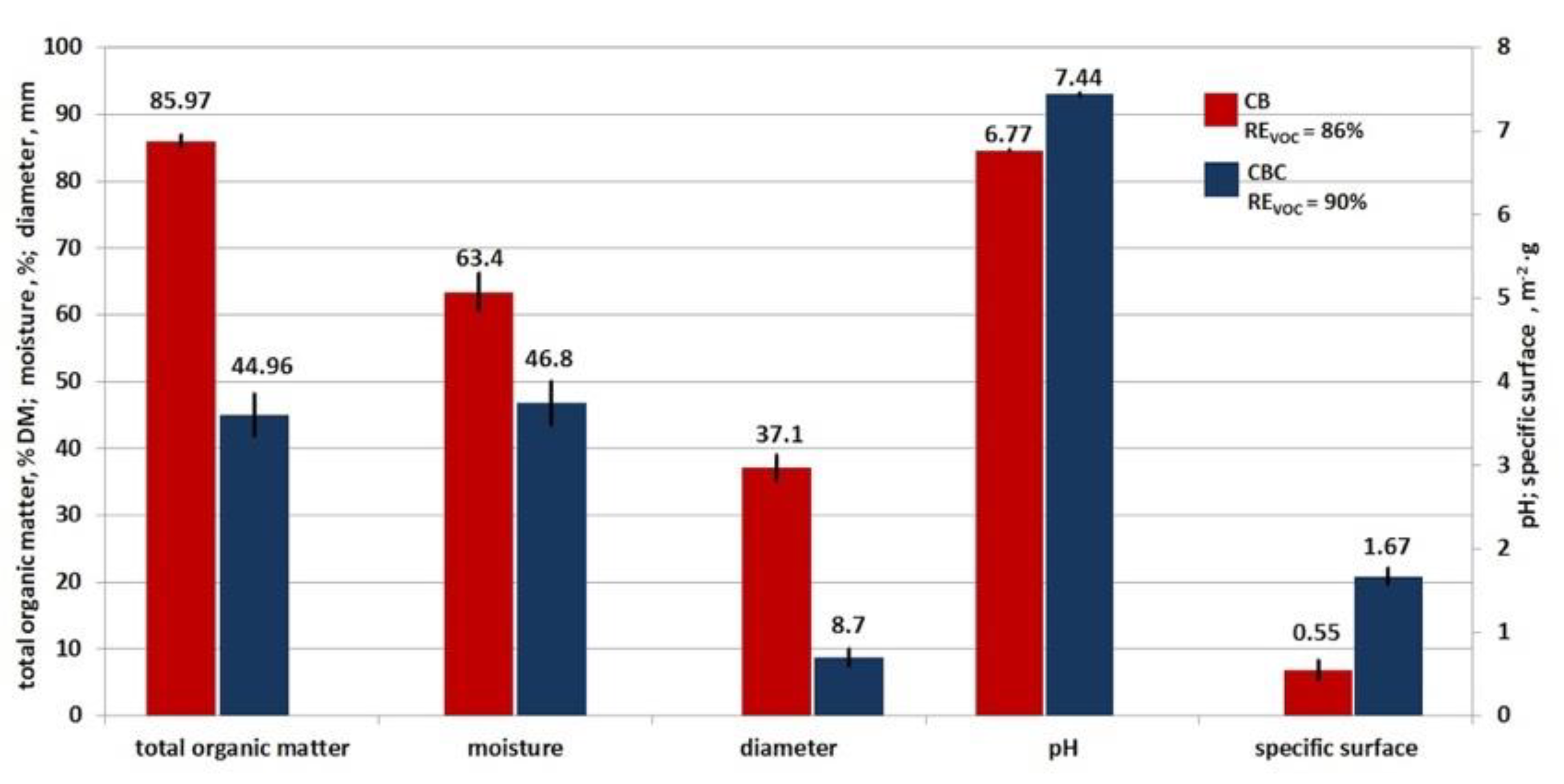

2.1. Semi-Technical Scale Biofilter

2.2. Experimental Design

2.2.1. Experimental Design

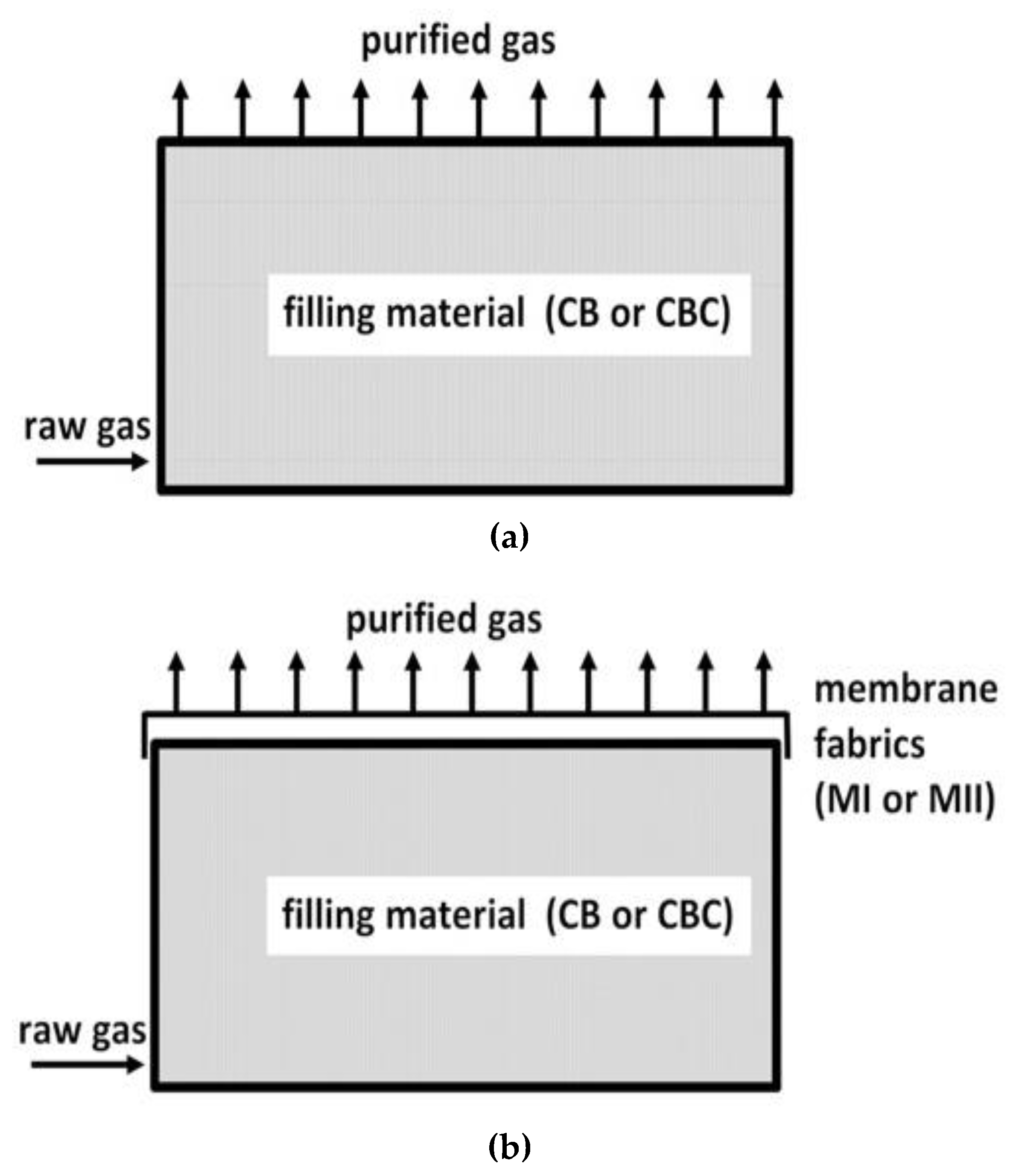

2.2.2. Measurement Points and Number of Measurement Series, Samples, and Measurements

2.3. Analytical Methods

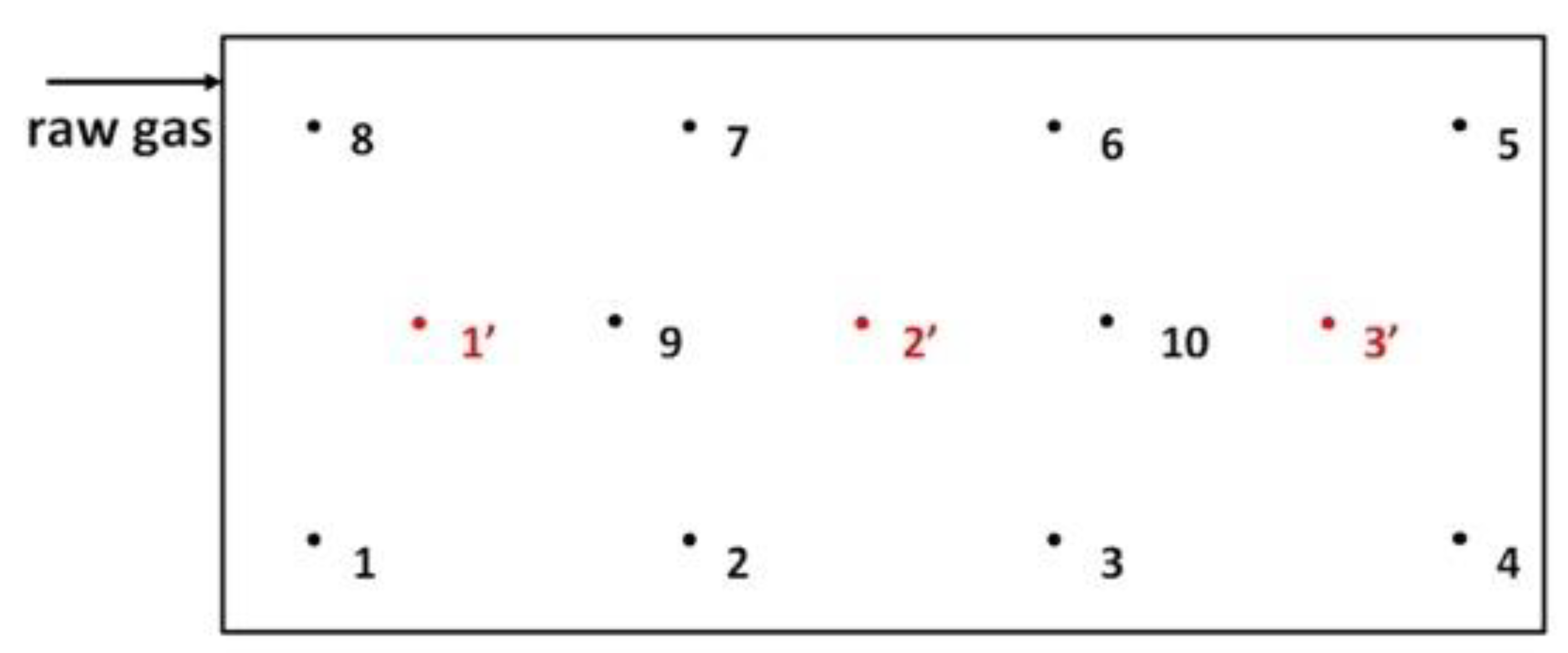

2.4. Filling Material (Filter Bed)

2.5. Membrane Fabrics–Second Stage of Purification

3. Results and Discussion

3.1. Raw Gases Characteristics

3.2. Biofiltration Process Parameters

3.3. Effectiveness of VOC Removal–Influence of the Filterbed (Single-Stage Biofiltration)

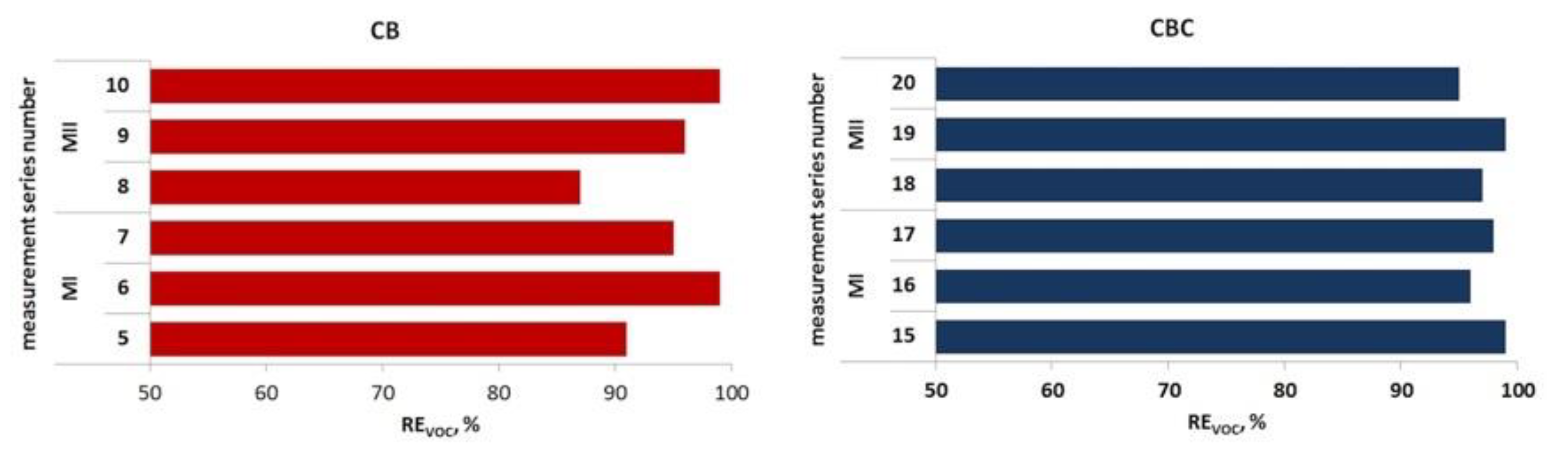

3.4. Effectiveness of VOC Removal–Influence of Membranes (Two-Stage/Integrated Biofiltration)

4. Conclusions

- The application of membrane fabrics as the second stage of purification improved the effectiveness of biofiltration in all the analyzed cases from 7% to 9%.

- In the case of combining both types of membranes (MI and MII) with CBC filling, the effectiveness of VOC removal was more stable than in the case of integrated biofiltration with the application of CB filling.

- The most effective solution for the VOC removal from process gases proved to be an integrated filter with a filter bed in the form of stumpwood chips with bark and compost (CBC), supplemented with the more permeable membrane (MI). The biofiltration effectiveness was maintained between 96% to 99%, reaching an average value of 98%.

- The analyzed pilot integrated biofilter is an innovative solution in which the membrane constituting the cover of the biofilter bed is not only the second stage of purification by itself, but also contributes to the improvement of the first stage processes. Use of the membrane covering the biofilter allows better control of the processes, among others facilitating the maintenance of correct (not too high) humidity content in the biofilter layer. This is extremely important for the process effectiveness–the conducted research showed that the moisture level has a significant effect on the biofiltration efficiency. The effectiveness of VOC removal was higher at lower moisture values and remained within the optimal range.

- The effectiveness of VOC removal varied depending on the applied filling materials. In the case of single-stage biofiltration, the mix of stumpwood chips, bark, and compost proved more beneficial.

- The selection of the filling material in both cases of single-stage and integrated biofiltration should be governed by the parameters important for the biofiltration process–with particular consideration of the specific surface, which plays a substantial role in the sorption process.

- The selection of the membrane fabric, constituting the second stage of purification, should be determined by its permeability (allowing purification of the specified stream of process gases) and the flow resistance values, to eliminate the risk of gas leaks without purification.

- The research was conducted on the semi-technical scale, so it constitutes an important source of credible results.

- Further research on the membranes studied in this paper should be carried out to establish their effect on the flow resistance values and on the filling material changes, resulting from covering with membrane fabrics.

- Further research is carried out in the optimal variant (CBC + MI) identified in the article on the integrated biofilter in full technical scale.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| BAT | Best Available Techniques |

| CB | mix of stumpwood chips and bark |

| CBC | mix of stumpwood chips, bark and compost |

| ePTFE | Expanded polytetrafluoroethylene |

| PID | photoionization gas detector |

| SD | standard deviation |

| VOCs | volatile organic compounds |

References

- Revah, S.; Morgan-Sagastume, J.M. Methods of Odor and VOC Control. In Biotechnology for Odor and Air Pollution Control; Shareefdeen, Z., Singh, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 29–60. [Google Scholar]

- Brancher, M.; Grif, K.D.; Franco, D.; Melo, H.D. A review of odour impact criteria in selected countries around the world. Chemosphere 2017, 168, 1531–1570. [Google Scholar] [CrossRef] [PubMed]

- Hamal, S.M.; Razzak, S.A.; Hossain, M.M. Catalytic oxidation of volatile organic compounds (VOCs)—A review. Atmos. Environ. 2016, 140, 117–134. [Google Scholar]

- Gospodarek, M.; Rybarczyk, P. Comparative Evaluation of Selected Biological Methods for the Removal of Hydrophilic and Hydrophobic Odorous VOCs from Air. Processes 2019, 7, 187. [Google Scholar] [CrossRef]

- Filipy, J.; Rumburg, B.; Mount, G.; Westberg, H.; Lamb, B. Identification and quantification of volatile organic compounds from a dairy. Atmos. Environ. 2006, 40, 1480–1494. [Google Scholar] [CrossRef]

- Alanis, P.; Ashkan, S.; Krauter, C.; Campbell, S.; Hasson, A.S. Emissions of volatile fatty acids from feed at dairy facilities. Atmos. Environ. 2010, 44, 5084–5092. [Google Scholar] [CrossRef]

- Gao, Z.; Hu, G.; Wang, H.; Zhu, B. Characterization and assessment of volatile organic compounds (VOCs) emissions from the typical food manufactures in Jiangsu province, China. Atmos. Pollut. Res. 2019, 10, 571–579. [Google Scholar] [CrossRef]

- Cheng, S.; Wang, G.; Lang, J.; Wen, W.; Wang, X.; Yao, S. Characterization of volatile organic compounds from different cooking emissions. Atmos. Environ. 2016, 145, 299–307. [Google Scholar] [CrossRef]

- Gysel, N.; Welch, W.A.; Chen, C.; Dixit, P.; Iii, D.R.C.; Karavalakis, G. Particulate matter emissions and gaseous air toxic pollutants from commercial meat cooking operations. J. Environ. Sci. 2018, 65, 162–170. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, H.; Nie, L.; Jing, L.I.; Yufei, W.; Gang, W.; Junhui, W. Characterization and assessment of volatile organic compounds (VOCs) emissions from typical industries. Chin. Sci. Bull. 2013, 58, 724–730. [Google Scholar] [CrossRef] [Green Version]

- Rybarczyk, P.; Szulczyński, B.; Gębicki, J.; Hupka, J. Treatment of malodorous air in biotrickling filters: A review. Biochem. Eng. J. 2019, 141, 146–162. [Google Scholar] [CrossRef]

- Ramírez-Sáenz, D.; Zarate-Segura, P.B.; Guerrero-Barajas, C.; García-Pena, E.I. H2S and volatile fatty acids elimination by biofiltration: Clean-up process for biogas potential use. J. Hazard. Mater. 2009, 163, 1272–1281. [Google Scholar] [CrossRef] [PubMed]

- Kwarciak-Kozłowska, A.; Bańka, B. Neutralization of odors generated during composting of biodegradable fraction of municipal and industrial waste by biofiltration. Inz. Ochr. Sr. 2014, 17, 631–645. (In Polish) [Google Scholar]

- Mudliar, S.; Giri, B.; Padoley, K.; Satpute, D.; Dixit, R.; Bhatt, P. Bioreactors for treatment of VOCs and odours—A review. J. Environ. Manag. 2010, 91, 1039–1054. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, B.; Creamer, A.E.; Cao, C.; Li, Y. Adsorption of VOCs onto engineered carbon materials: A review. J. Hazard. Mater. 2017, 338, 102–123. [Google Scholar] [CrossRef]

- Xi, J.; Saingam, P.; Gu, F.; Hu, H. Effect of continuous ozone injection on performance and biomass accumulation of biofilters treating gaseous toluene. Appl. Microbiol. Biotechnol. 2014, 98, 9437–9446. [Google Scholar] [CrossRef] [PubMed]

- European Comission. Commission Implementing Decision (EU) 2018/1147 of 10 August 2018 establishing best available techniques (BAT) conclusions for waste treatment, under Directive 2010/75/EU of the European Parliament and of the Council (notified under document C(2018) 5070). Off. J. Eur. Union 2018, OJL 208, 38–90. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?toc=OJ:L:2018:208:TOC&uri=uriserv:OJ.L_.2018.208.01.0038.01.ENG (accessed on 26 May 2019).

- Soret, R.; Fanlo, J.-L.; Malhautier, L.; Geiger, P.; Bayle, S. Investigation of Removal Capacities of Biofilters for Airborne Viable Micro-Organisms. Int. J. Environ. Res. Public Health 2018, 15, 551. [Google Scholar] [CrossRef] [PubMed]

- Commission Implementing Decision (EU). 2017/302 of 15 February 2017 establishing best available techniques (BAT) conclusions, under Directive 2010/75/EU of the European Parliament and of the Council, for the intensive rearing of poultry or pigs (notified under document C(2017) 688) (Text with EEA relevance. Off. J. Eur. Union 2017, OJL 43, 231–279. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32017D0302 (accessed on 26 May 2019).

- European Comission. Integrated Pollution Prevention and Control Reference Document on Best Available Techniques in the Food, Drink and Milk Industries. 2006. Available online: https://eippcb.jrc.ec.europa.eu/reference/BREF/fdm_bref_0806.pdf (accessed on 26 May 2019).

- Khan, F.I.; Ghoshal, A.K. Removal of Volatile Organic Compounds from polluted air. J. Loss Prev. Process Ind. 2000, 13, 527–545. [Google Scholar] [CrossRef]

- Barbusinski, K.; Kalemba, K.; Kasperczyk, D.; Urbaniec, K.; Kozik, V. Biological methods for odor—A review. J. Clean. Prod. 2017, 152, 223–241. [Google Scholar] [CrossRef]

- Malakar, S.; Das Saha, P.; Baskaran, D.; Rajamanickam, R. Comparative study of biofiltration process for treatment of VOCs emission from petroleum refinery wastewater—A review. Environ. Technol. Innov. 2017, 8, 441–461. [Google Scholar] [CrossRef]

- Kennes, C.; Veiga, M.C. Technologies for the abatement of odours and volatile organic and inorganic compounds. Chem. Eng. Trans. 2010, 23, 1–6. [Google Scholar]

- Wierzbińska, M.; Modzelewski, W.E. The use of biofilters for deodorizing noxious gases. Ecol. Eng. 2015, 41, 125–132. [Google Scholar]

- Lebrero, R.; Rodríguez, E.; Martin, M.; García-Encina, P.A.; Muñoz, R. H2S and VOCs abatement robustness in biofilters and air diffusion bioreactors: A comparative study. Water Res. 2010, 44, 3905–3914. [Google Scholar] [CrossRef]

- Wu, H.; Yan, H.; Quan, Y.; Zhao, H.; Jiang, N.; Yin, C. Recent progress and perspectives in biotrickling filters for VOCs and odorous gases treatment. J. Environ. Manag. 2018, 222, 409–419. [Google Scholar] [CrossRef]

- Dumont, E.; Hamon, L.; Lagadec, S.; Landrain, P.; Landrain, B.; Andrès, Y. NH3 biofiltration of piggery air. J. Environ. Manag. 2014, 140, 26–32. [Google Scholar] [CrossRef]

- Iranpour, R.; Cox, H.H.J.; Deshusses, M.A.; Schroeder, E.D. Literature review of air pollution control biofilters and biotrickling filters for odor and volatile organic compound removal. Environ. Prog. 2005, 24, 254–267. [Google Scholar] [CrossRef]

- Sheridan, B.A.; Curran, T.P.; Dodd, V.A. Assessment of the influence of media particle size on the biofiltration of odorous exhaust ventilation air from a piggery facility. Bioresour. Technol. 2002, 84, 129–143. [Google Scholar] [CrossRef] [Green Version]

- PN-Z-15008-02:1993—Polish Version. Municipal Solid Waste—Testing of Fuel Properties—Determination of Total Moisture; The Polish Committee for Standardization: Warsaw, Poland, 1993. [Google Scholar]

- PN-Z-15011-3:2001—Polish Version. Compost from Municipal Waste—Determination: pH, Organic Matter Content, Organic Carbon, Nitrogen, Phosphorus and Potassium; The Polish Committee for Standardization: Warsaw, Poland, 2001. [Google Scholar]

- PN-EN 15002:2015-07—English Version. Characterization of Waste—Preparation of Samples for Analysis from a Laboratory Sample; The Polish Committee for Standardization: Warsaw, Poland, 2015. [Google Scholar]

- ISO 10390:2005-Soil Quality—Determination of pH; ISO: Geneva, Switzerland, 2005.

- PN-Z-15011-2:1998—Polish Version. Compost from Municipal Solid Waste—Determination of the Content of Particles Exceeding Certain Sizes as well as Glass and Ceramics; The Polish Committee for Standardization: Warsaw, Poland, 1998. [Google Scholar]

- (VDI) TA of GE. VDI-Standard: VDI 3477. Biological Waste Gas Treatment in Biofilters; Verlag des Vereins Deutscher Ingenieure: Düsseldorf, Germany, 2016. [Google Scholar]

- Bajpai, P. Biological Odour Treatment; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Tiwari, A.; Alam, T.; Kumar, A.; Shukla, A.K. Control of Odour, Volatile Organic Compounds (VOCs) & Toxic Gases through Biofiltration—An Overview. Int. J. Tech. Innov. Mod. Eng. Sci. 2019, 5, 1–6. [Google Scholar]

- McNevin, D.; Barford, J. Biofiltration as an odour abatement strategy. Biochem. Eng. J. 2000, 5, 231–242. [Google Scholar] [CrossRef]

- Dorado, A.D.; Lafuente, F.J.; Gabriel, D.; Gamisans, X. A comparative study based on physical characteristics of suitable packing materials in biofiltration. Environ. Technol. 2010, 31, 193–204. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leson, G.; Winer, A.M.; Leson, G. Biofiltration: An Innovative Air Pollution Control Technology for VOC Emissions Biofiltration. J. Air Waste Manag. Assoc. 1991, 41, 1045–1054. [Google Scholar] [CrossRef]

| Filterbed | Membrane Type | Numbers of Measurement Series | Identification of Experiment Phase |

|---|---|---|---|

| mix of stumpwood chips and bark (CB) | - | 1–4 | CB |

| MI | 5–7 | CB + MI | |

| MII | 8–10 | CB + MII | |

| mix of stumpwood chips, bark and compost (CBC) | - | 11–14 | CBC |

| MI | 15–17 | CBC + MI | |

| MII | 18–20 | CBC + MII |

| Operational Parameters | CB * | CBC * | CB + MI * | CBC + MI * | CB + MII * | CBC + MII * | Recommended Values | |

|---|---|---|---|---|---|---|---|---|

| Surface load m3·m−2·h−1 | average value ± SD | 96.5 ± 6.1 | 81.3 ± 21.7 | 97.1 ± 4.2 | 99.4 ± 1.0 | 97.8 ± 1.0 | 100.7 ± 1.1 | 45 ÷ 150 [36,37] |

| range | 87.4 ÷ 100.5 | 62.4 ÷ 100.5 | 92.4 ÷ 100.3 | 98.7 ÷ 100.5 | 97.0 ÷ 99.0 | 99.5 ÷ 101.5 | ||

| Volumetric load m3 m−3·h−1 | average value ± SD | 84.0 ± 5.3 | 70.7 ± 18.9 | 84.5 ± 3.6 | 86.5 ± 0.8 | 85.1 ± 0.9 | 87.6 ± 0.9 | 5 ÷ 500 [38] |

| range | 76.0 ÷ 87.4 | 54.2 ÷ 87.4 | 80.4 ÷ 87.2 | 85.9 ÷ 87.4 | 84.3 ÷ 86.1 | 86.5 ÷ 88.3 | ||

| Duration of gas contact with the filling layer (s) | average value ± SD | 43 ± 3 | 54 ± 14 | 43 ± 2 | 42 ± 1 | 42 ± 1 | 42 ± 1 | 30 ÷ 60 [1,38] |

| range | 41 ÷ 47 | 41 ÷ 66 | 41 ÷ 45 | 41 ÷ 42 | 41 ÷ 43 | 41 ÷ 43 | ||

| Filter bed thickness (m) | range | 1.1 ÷ 1.2 | 1.1 ÷ 1.2 | 1.1 ÷ 1.2 | 1.1 ÷ 1.2 | 1.1 ÷ 1.2 | 1.1 ÷ 1.2 | 1 ÷ 1.5 [1,38,39] |

| Hydraulic Parameters of the Studied Pilot Biofilter | CB * | CBC * | CB + MI * | CBC + MI * | CB + MII * | CBC + MII * | |

|---|---|---|---|---|---|---|---|

| flow rate m3·h−1 | average value ± SD | 382 ± 24 | 322 ± 86 | 385 ± 16 | 394 ± 4 | 387 ± 4 | 399 ± 4 |

| pressure drops in biofilter (Pa) | average value ± SD | 379 ± 13 | 596 ± 84 | 536 ± 129 | 683 ± 54 | 469 ± 12 | 617 ± 48 |

| pressure drops on the membrane (Pa) | average value ± SD | - | - | 64 ± 25 | 59 ± 2 | 28 ± 25 | 63 ± 6 |

| Experiment Phase | Number of Measurement Series | VOC in Raw Gases (ppb) | VOC in Purified Gases (ppb) | ||

|---|---|---|---|---|---|

| Average Value ± SD | Range | Average Value ± SD | Range | ||

| CB | 1 | 1130 ± 207 | 940 ÷ 1350 | 180 ± 9 | 170 ÷ 200 |

| 2 | 1250 ± 190 | 1060 ÷ 1440 | 118 ± 9 | 110 ÷ 130 | |

| 3 | 950 ± 90 | 860 ÷ 1040 | 122 ± 8 | 110 ÷ 130 | |

| 4 | 1220 ± 310 | 910 ÷ 1530 | 220 ± 11 | 210 ÷ 230 | |

| Mean | 1138 ± 135 | 950 ÷ 1250 | 160 ± 49 | 118 ÷ 220 | |

| CBC | 11 | 2500± 390 | 2110 ÷ 2890 | 66 ± 8 | 50 ÷ 80 |

| 12 | 1970 ± 190 | 1780 ÷ 2160 | 87 ± 7 | 80 ÷ 100 | |

| 13 | 1500 ± 230 | 1270 ÷ 1730 | 269 ± 7 | 260 ÷ 280 | |

| 14 | 980 ± 200 | 780 ÷ 1180 | 146 ± 10 | 130 ÷ 160 | |

| Mean | 1738 ± 650 | 980 ÷ 2500 | 142 ± 91 | 66 ÷ 269 | |

| Filter Bed | CB * | CBC * | Recommended Values | |

|---|---|---|---|---|

| Moisture (%) | min | 60,6 | 42.7 | 30–60 [14,37,38] |

| max | 66,3 | 50.5 | ||

| mean ± SD | 63.4 ± 2.9 | 46.8 ± 3.4 | ||

| pH | min | 6.75 | 7.27 | 6–9 [13,37,40] |

| max | 6.79 | 7.7 | ||

| mean ± SD | 6.77 ± 0.02 | 7.44 ± 0.03 | ||

| Total organic matter (% d.m.) | min | 84.97 | 40.61 | >40 [25,41] |

| max | 87.53 | 47.79 | ||

| mean ± SD | 85.97 ± 1.10 | 44.96 ± 3.30 | ||

| Specific surface m2·g−1 | min | 0.37 | 1.53 | 1–100 ** [39,40] |

| max | 0.67 | 1.8 | ||

| mean ± SD | 0.55 ± 0.13 | 1.67 ± 0.11 | ||

| Hydraulic diameter (mm) | min | 34.8 | 6.7 | >4 [25,41] |

| max | 39.6 | 9.9 | ||

| mean ± SD | 37.1 ± 2.0 | 8.7 ± 1.4 | ||

| Experiment Phase | Number of Measurement Series | VOC in Raw Gases (ppb) | VOC in Purified Gases (ppb) | ||

|---|---|---|---|---|---|

| Average Value ± SD | Range | Average Value ± SD | Range | ||

| CB + MI | 5 | 1400 ± 270 | 1130 ÷ 1670 | 125 ± 8 | 110 ÷ 140 |

| 6 | 1170 ± 448 | 670 ÷ 1535 | 12 ± 4 | 10 ÷ 20 | |

| 7 | 480 ± 130 | 350 ÷ 610 | 24 ± 5 | 20 ÷ 30 | |

| mean ± SD | 1017 ± 479 | 480 ÷ 1400 | 54 ± 62 | 12 ÷ 125 | |

| CB + MII | 8 | 9400 ± 1770 | 7630 ÷ 11170 | 1220 ± 11 | 1210 ÷ 1240 |

| 9 | 7700 ± 1200 | 6500 ÷ 8900 | 283 ± 9 | 270 ÷ 300 | |

| 10 | 4700 ± 600 | 4100 ÷ 5300 | 23 ± 5 | 20 ÷ 30 | |

| mean ± SD | 7267 ± 2380 | 4700 ÷ 9400 | 509 ± 630 | 23 ÷ 1220 | |

| CBC + MI | 15 | 990 ± 170 | 820 ÷ 1160 | 10 ± 0 | - |

| 16 | 3300 ± 1180 | 2120 ÷ 4480 | 147 ± 8 | 140 ÷ 160 | |

| 17 | 7680 ± 1690 | 5990 ÷ 9370 | 127 ± 8 | 110 ÷ 140 | |

| mean ± SD | 3990 ± 3398 | 990 ÷ 7680 | 95 ± 74 | 10 ÷ 147 | |

| CBC + MII | 18 | 1660 ± 170 | 1490 ÷ 1830 | 50 ± 5 | 40 ÷ 60 |

| 19 | 1680 ± 160 | 1520 ÷ 1840 | 20 ± 7 | 10 ÷ 30 | |

| 20 | 1580 ± 710 | 860 ÷ 2280 | 80 ± 7 | 70 ÷ 90 | |

| mean ± SD | 1640 ± 53 | 1580 ÷ 1680 | 50 ± 30 | 20 ÷ 80 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lelicińska-Serafin, K.; Rolewicz-Kalińska, A.; Manczarski, P. VOC Removal Performance of a Joint Process Coupling Biofiltration and Membrane-Filtration Treating Food Industry Waste Gas. Int. J. Environ. Res. Public Health 2019, 16, 3009. https://doi.org/10.3390/ijerph16173009

Lelicińska-Serafin K, Rolewicz-Kalińska A, Manczarski P. VOC Removal Performance of a Joint Process Coupling Biofiltration and Membrane-Filtration Treating Food Industry Waste Gas. International Journal of Environmental Research and Public Health. 2019; 16(17):3009. https://doi.org/10.3390/ijerph16173009

Chicago/Turabian StyleLelicińska-Serafin, Krystyna, Anna Rolewicz-Kalińska, and Piotr Manczarski. 2019. "VOC Removal Performance of a Joint Process Coupling Biofiltration and Membrane-Filtration Treating Food Industry Waste Gas" International Journal of Environmental Research and Public Health 16, no. 17: 3009. https://doi.org/10.3390/ijerph16173009