Study on Passive Heating Involving Firewalls with an Additional Sunlight Room in Rural Residential Buildings

Abstract

:1. Introduction

1.1. Motivation

1.2. Literature Studies

1.3. Scientific Originalities

1.4. Aim of the Study

- By comparing the heating conditions of traditional residential buildings with or without the new passive system, the heat load reduction when adopting the new system in winter was estimated.

- In the absence of solar radiation, the heating effects of the ordinary heating system and the new passive system were analyzed. The purpose was to calculate the heating rate, the time required, and the decrease in the annual heat load of the building.

- Considering the presence or absence of solar radiation, the new system was compared to the ordinary heating of residential buildings to simulate and calculate the change in indoor temperature, heating efficiency, heating time, and the value of the annual building heat load.

- Through software simulation computation, the appropriate use time of the whole year after adopting the new system was estimated.

- According to the standard minimum value of indoor thermal comfort temperature, under basic heating, the total time to meet the minimum value of the comfort standard throughout the year was calculated. Compared to the use of the new system with or without solar radiation, the total time to meet the lowest value of the comfort standard throughout the year was estimated.

2. Methodology

2.1. Basic Research

2.1.1. Overview of the Current Situation

2.1.2. Research Method

2.1.3. Research Content

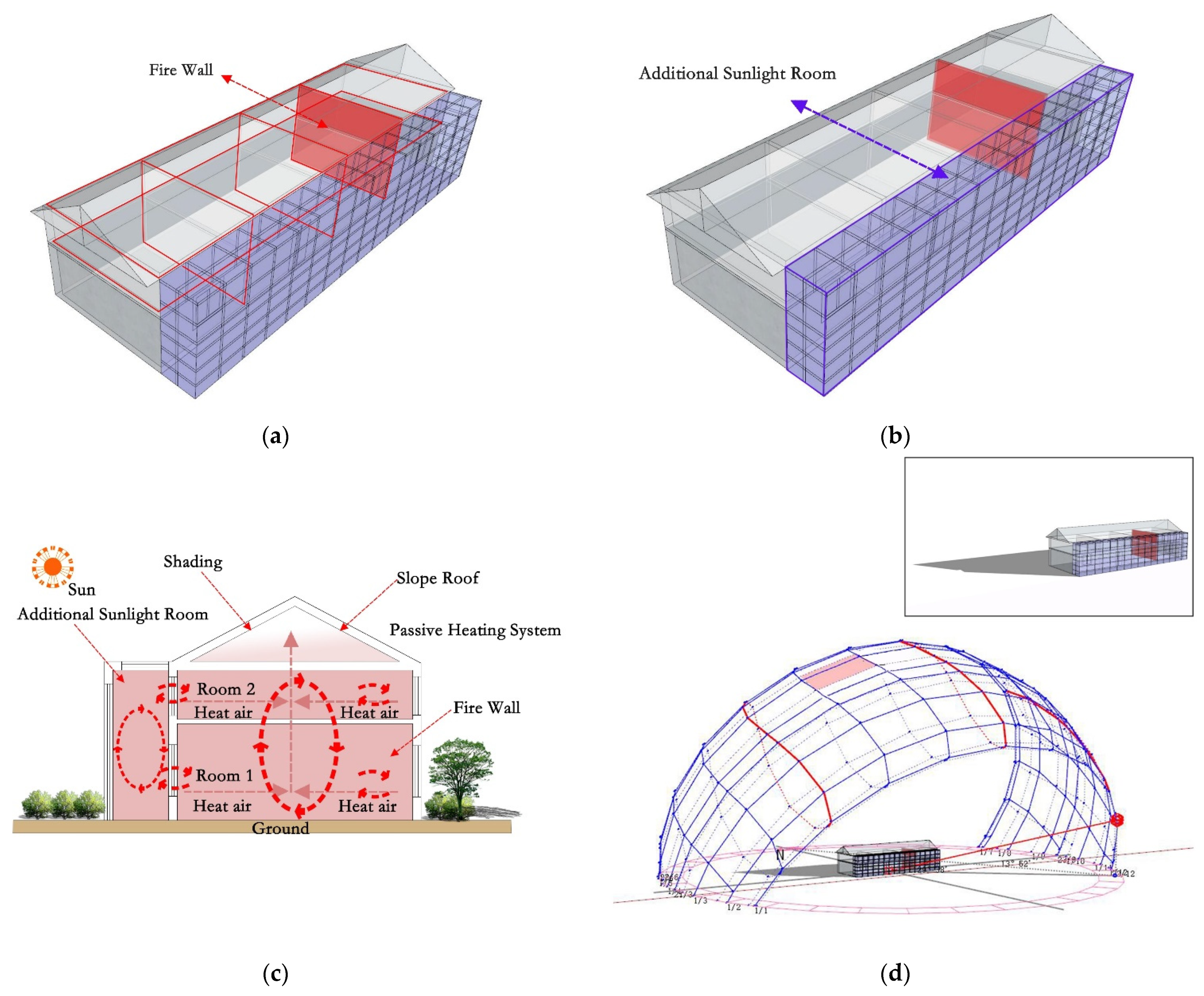

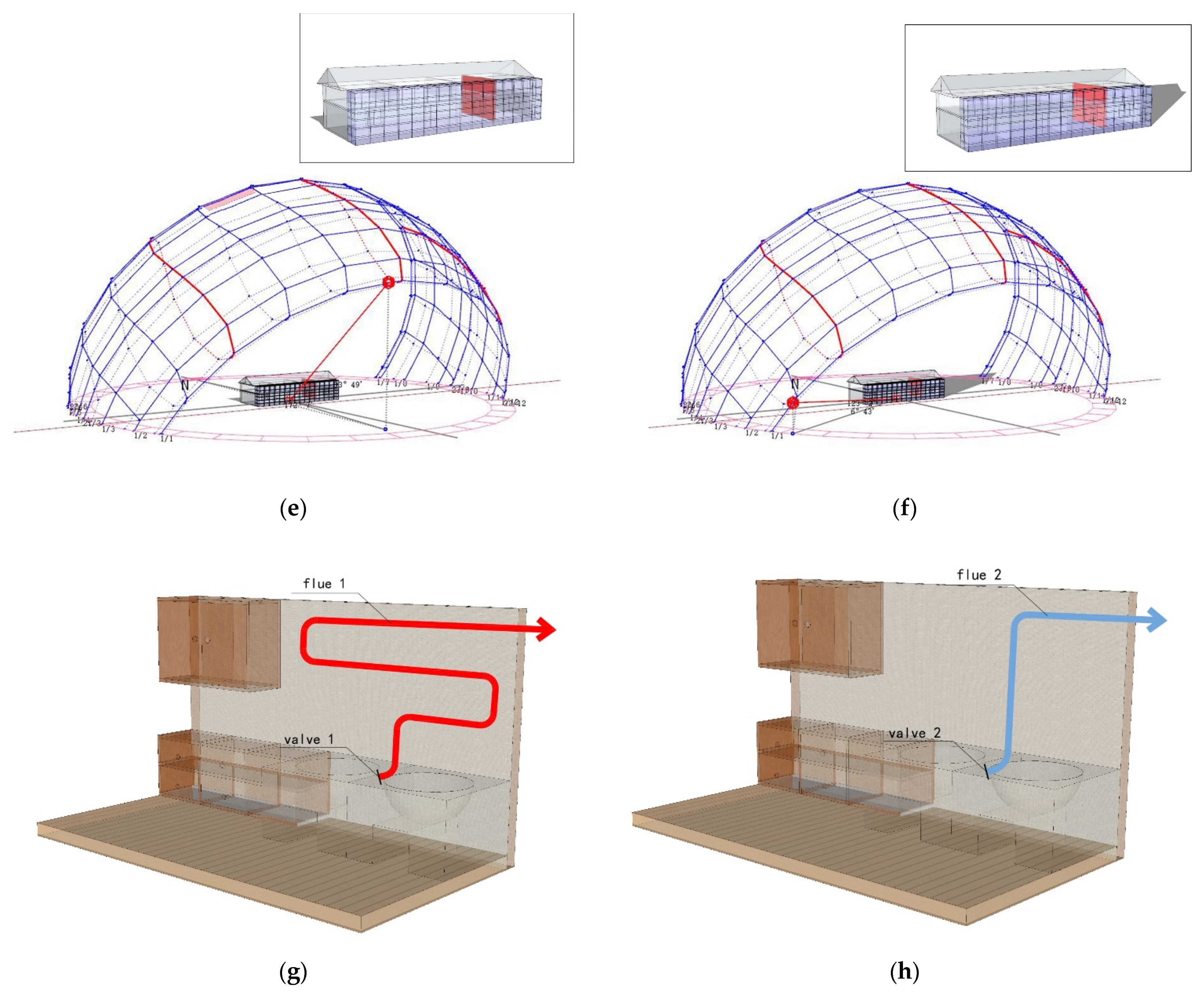

2.2. Cooking Heating and Additional Sunlight Room

2.2.1. Design of Cooking Heating and Additional Sunlight Room

2.2.2. Working Principle of Cooking-Based Heating and an Additional Sunlight Room

2.2.3. Ordinary Heating

2.2.4. Heating between the Firewall and the Additional Sunlight Room

2.3. Simulation Steps

2.3.1. Establishing Grids

2.3.2. Interface Conditions

2.3.3. Boundary Conditions

3. Results and Discussion

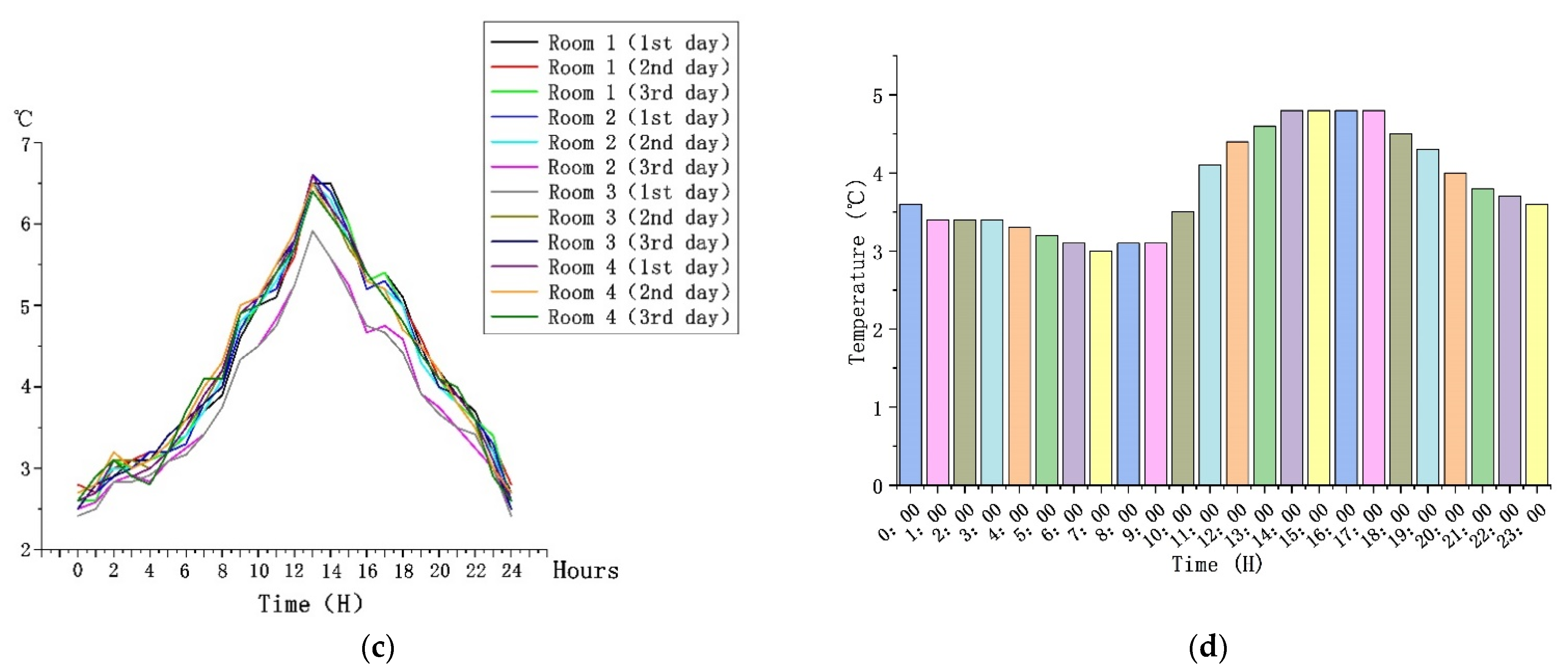

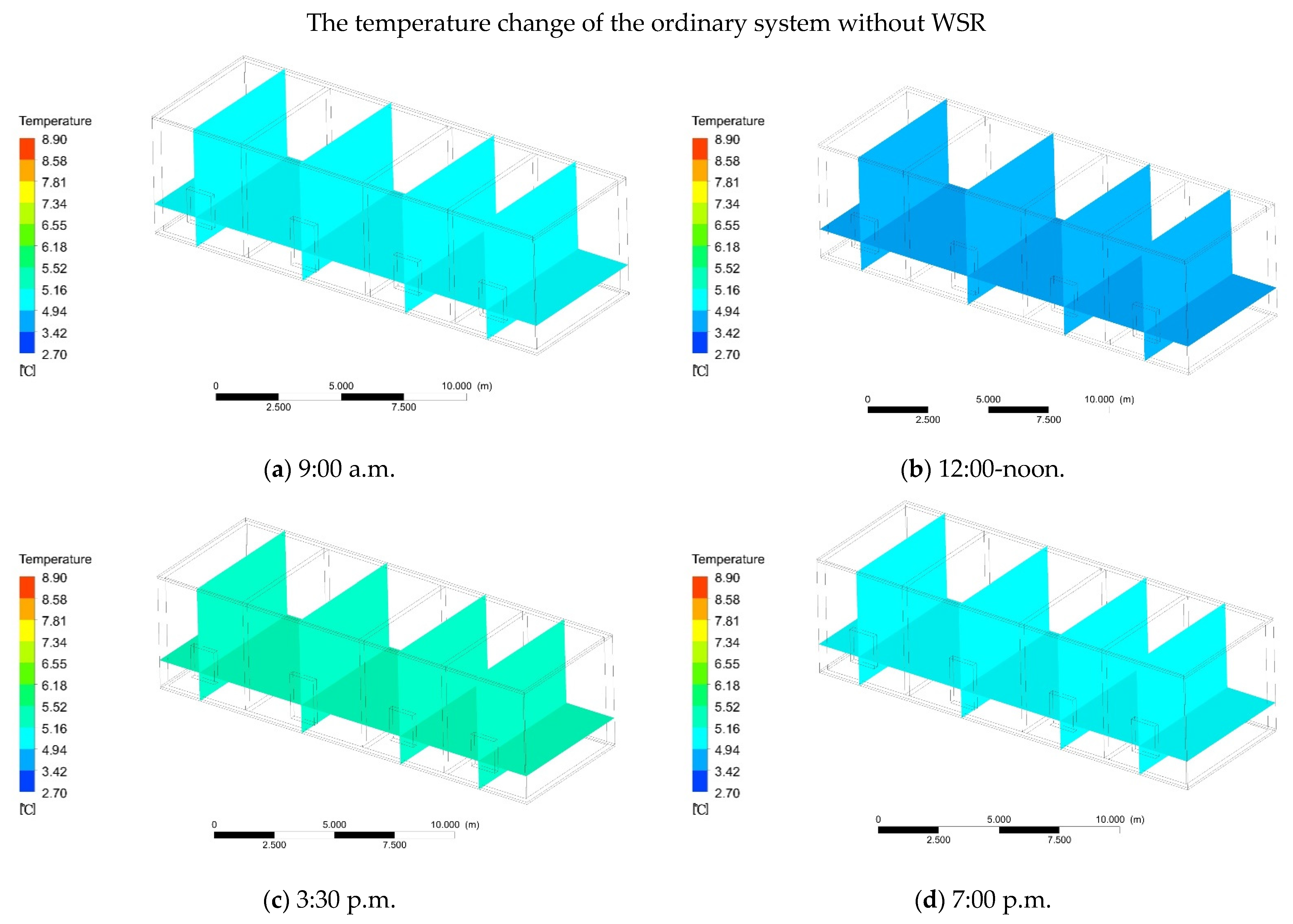

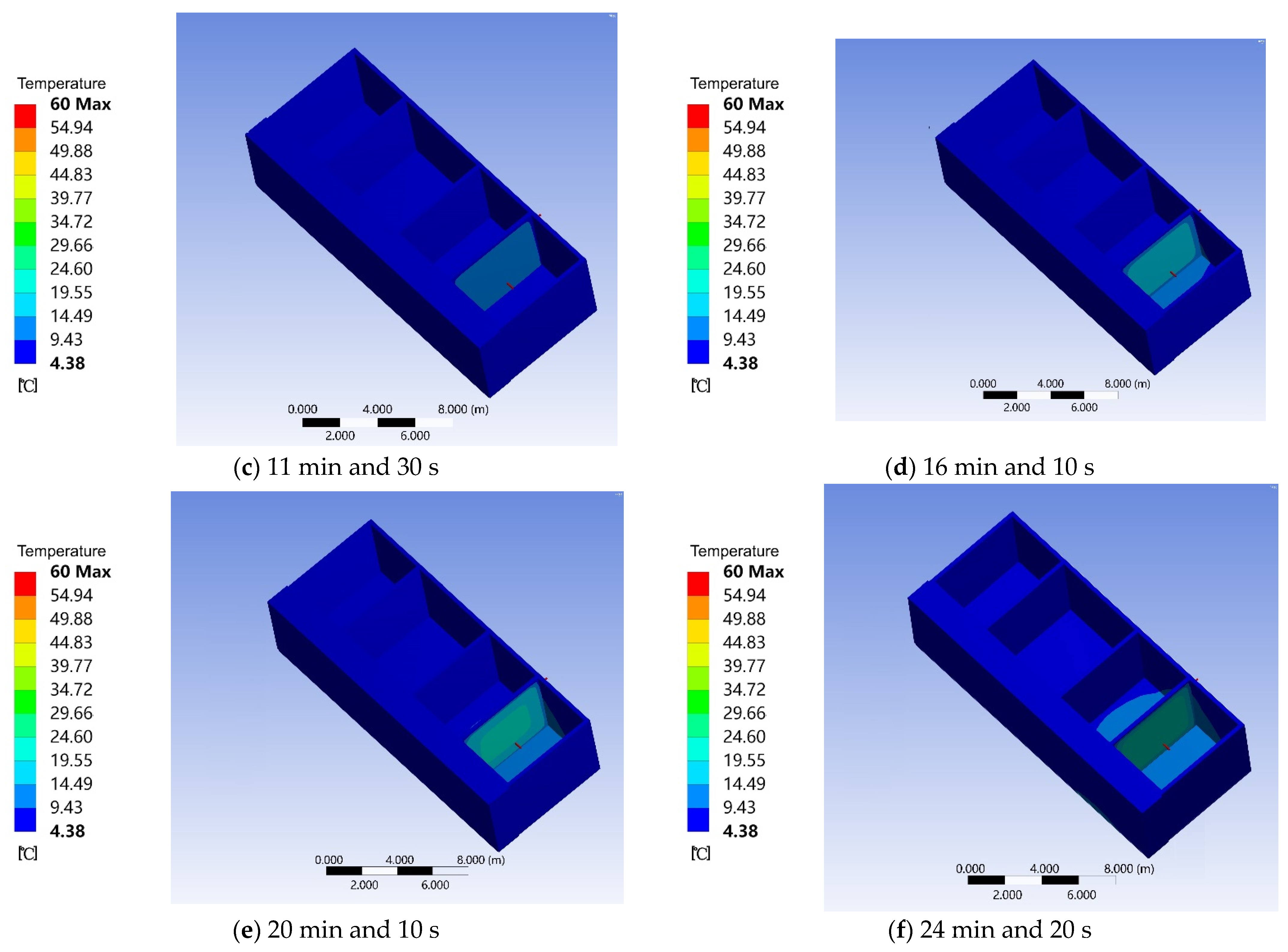

3.1. Comparison of Ordinary Heating with or without WSR

3.1.1. Ordinary Heating with WSR

3.1.2. Ordinary Heating without WSR

3.1.3. Comprehensive Analysis

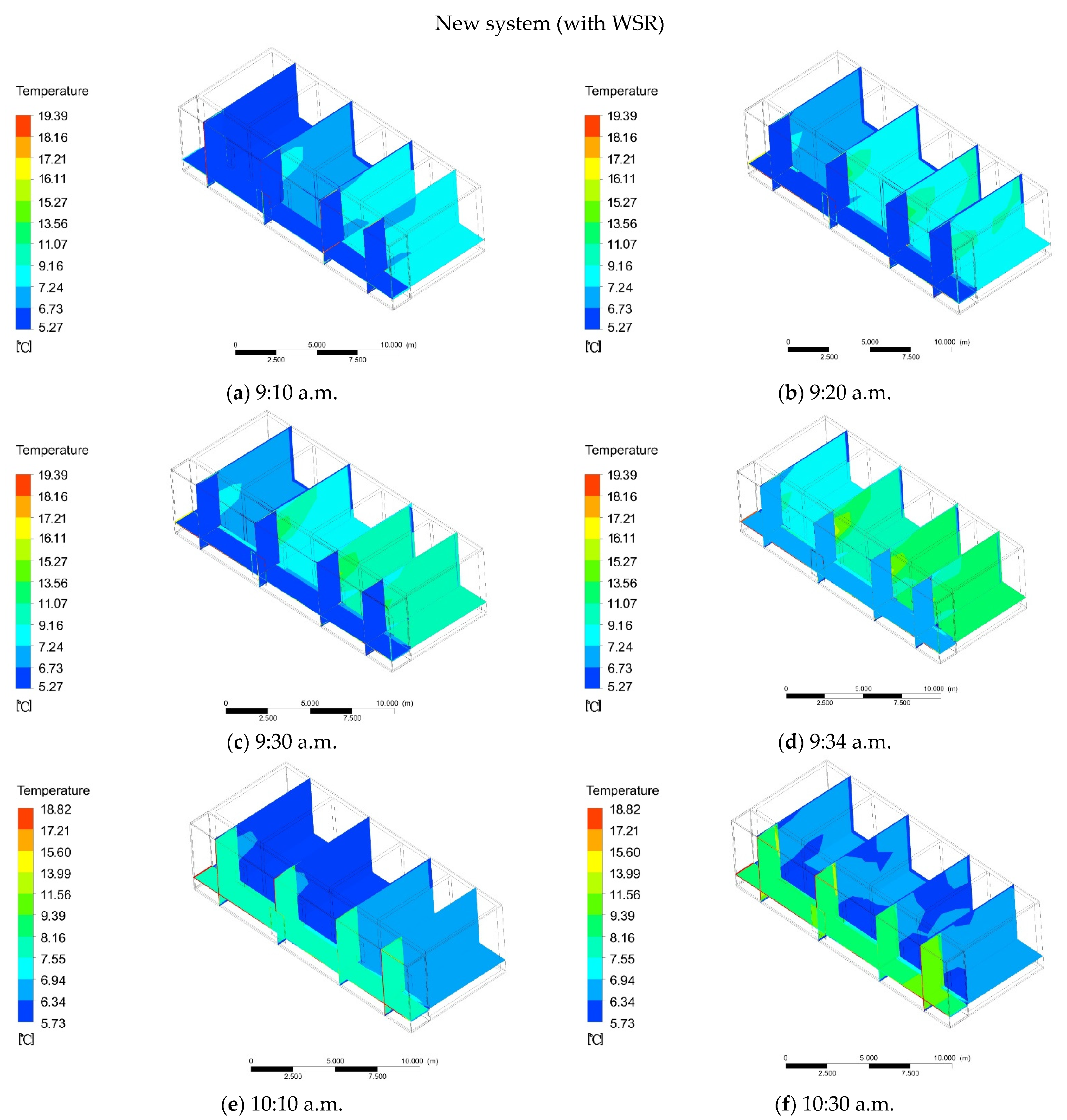

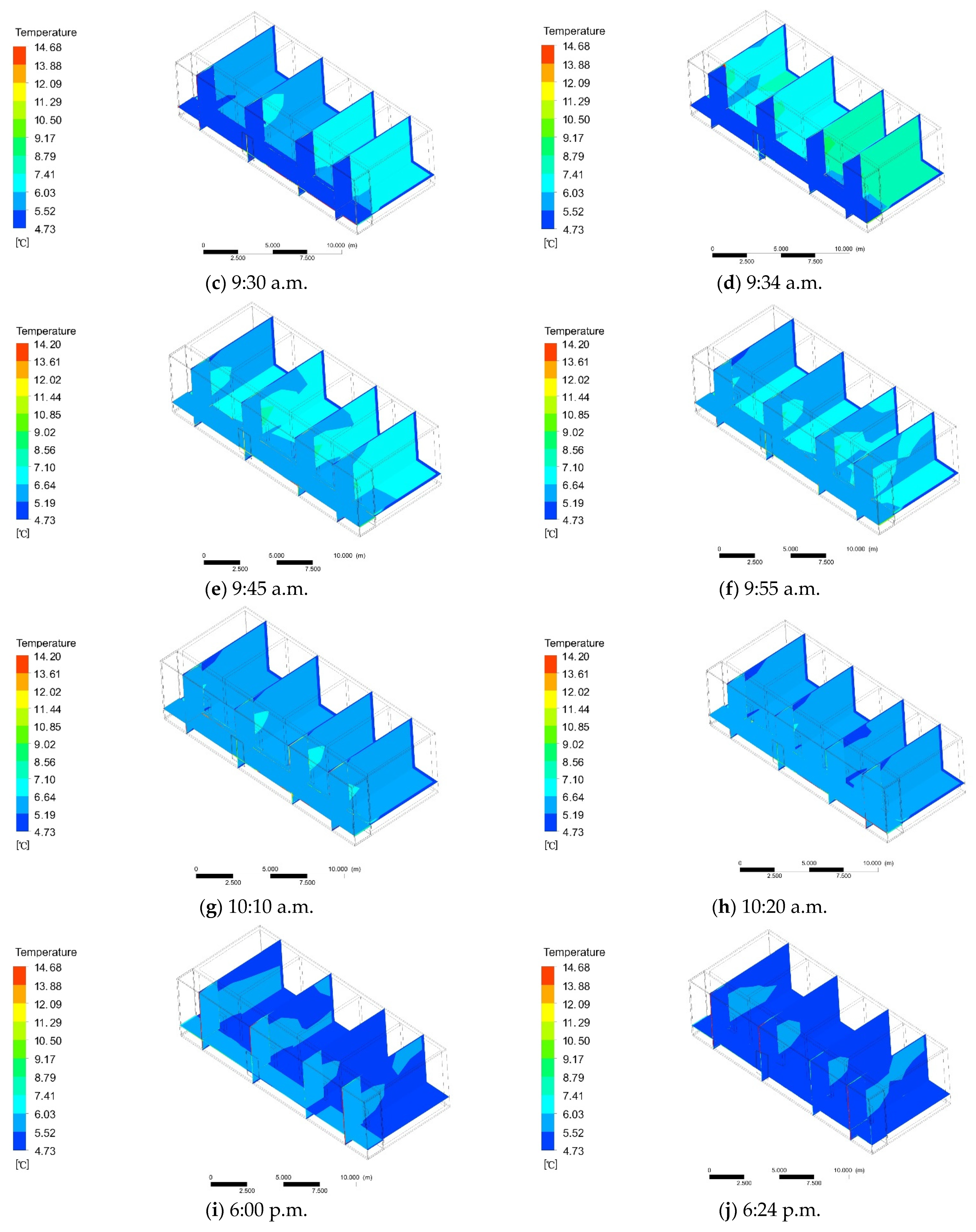

3.2. Comparison of the New System with or without WSR

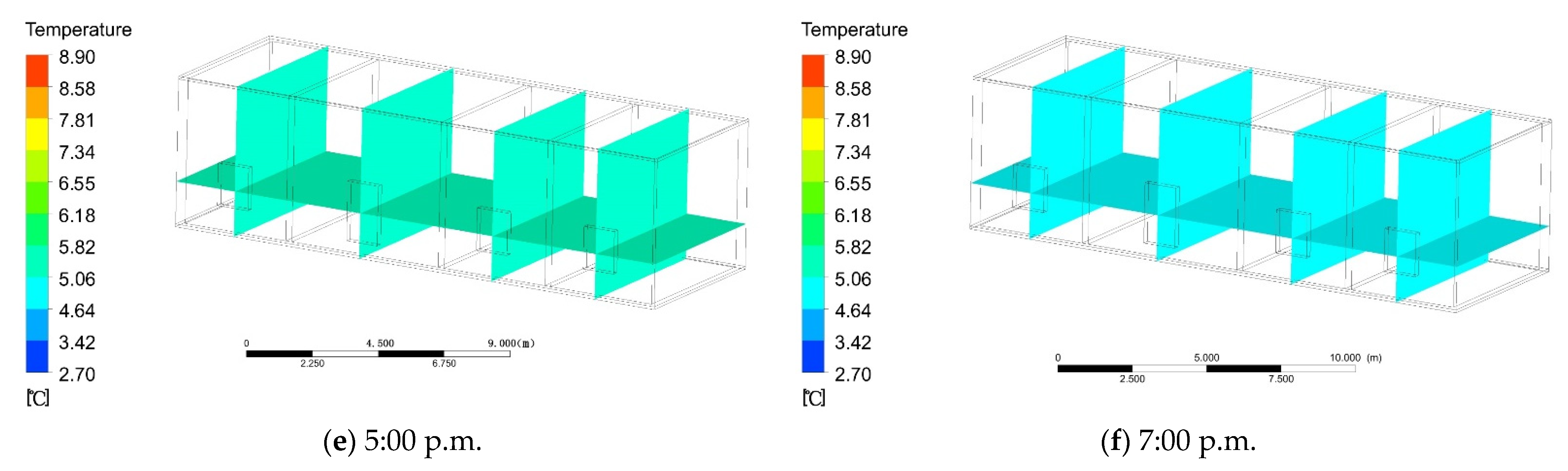

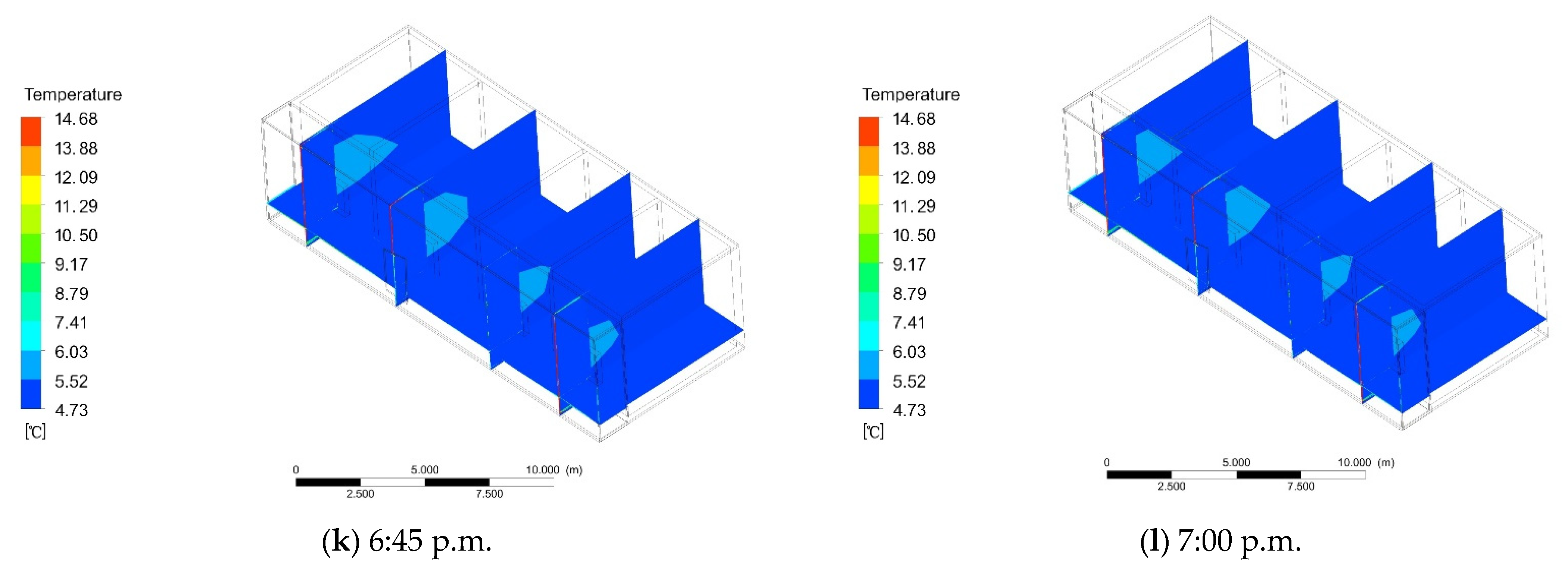

3.2.1. New System with WSR

3.2.2. New System without WSR

3.2.3. Comprehensive Analysis

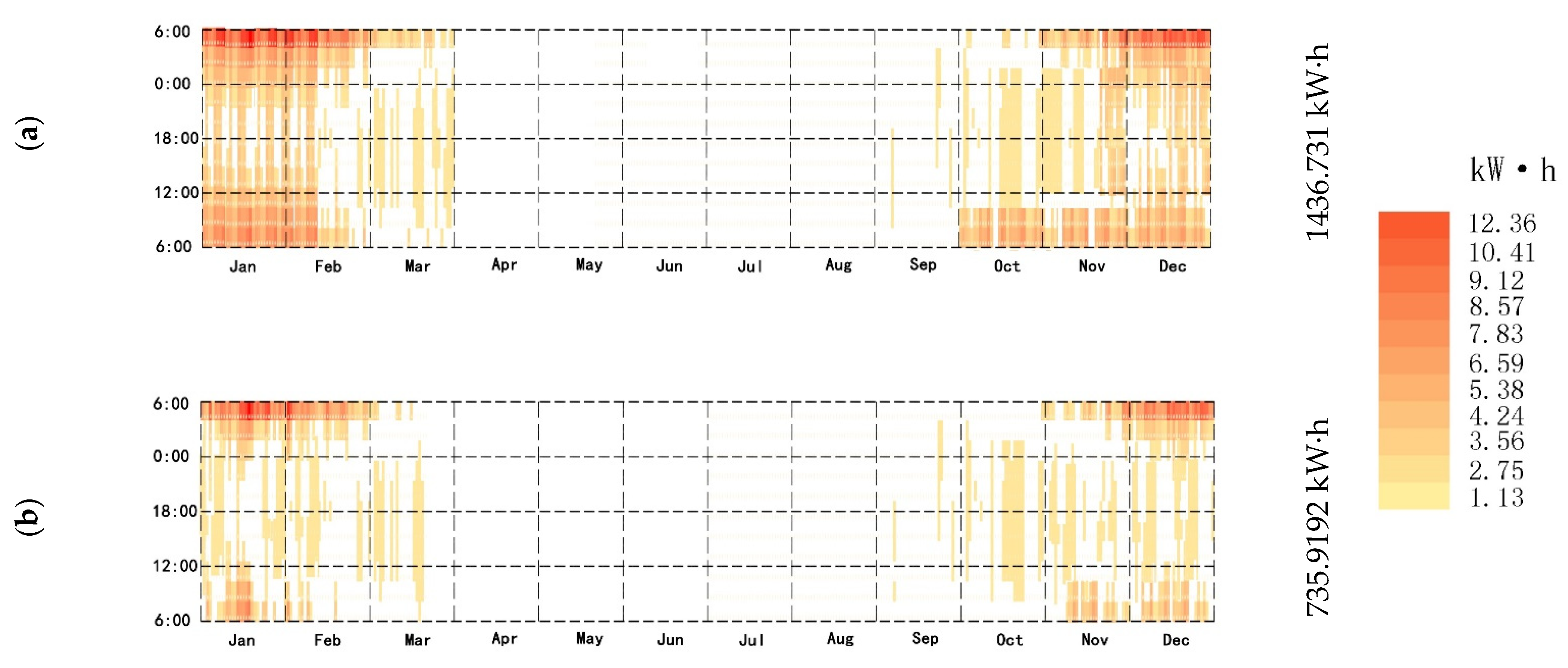

3.3. Heat Load Reduced by the Firewall–Sunlight System

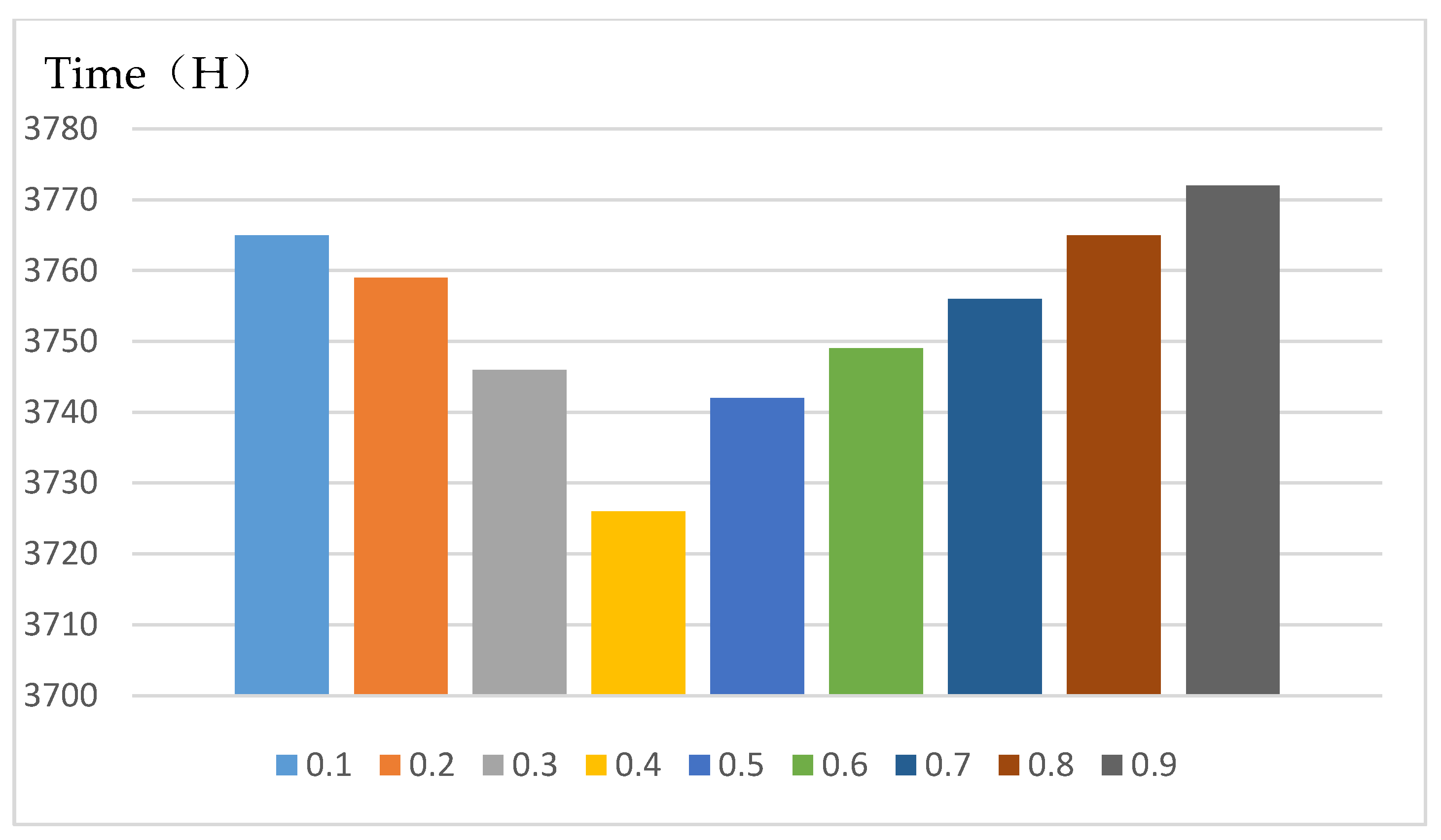

3.4. Suitable Year-Round Time for the Use of the Firewall–Sunlight System

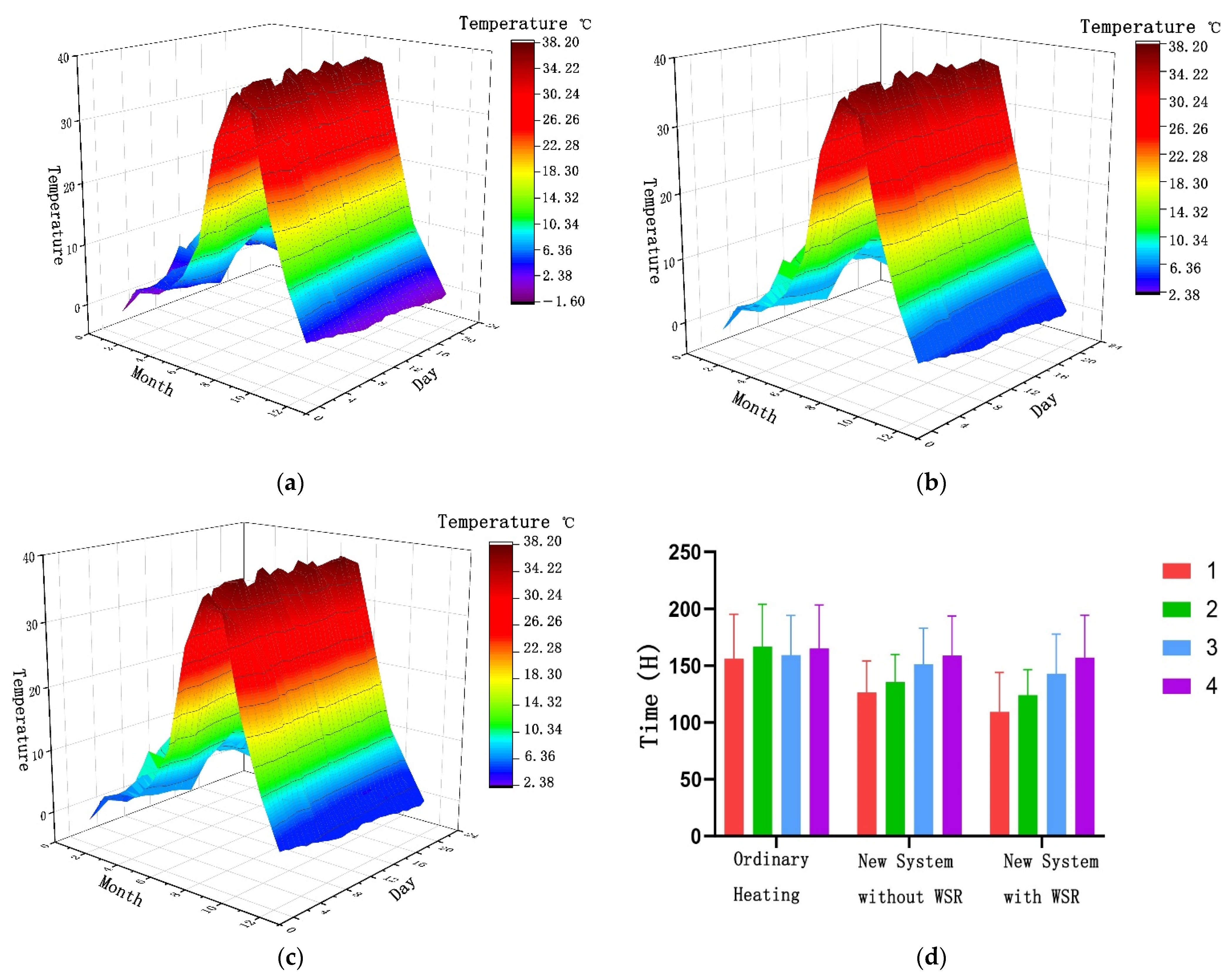

3.5. Adopting the Standard Time of Thermal Comfort of the Firewall–Sunlight System

3.6. Optimization of the New System Heating

3.6.1. Window-to-Wall Ratio

3.6.2. Wall Materials

4. Conclusions and Future Prospects

4.1. Conclusions

- Its working principle is not only to use the heat generated by cooking to heat the wall to raise the indoor temperature, but also to increase the heating effect by adding the characteristics of heat transfer between the sun room and the wall through solar radiation heating. The software simulation proved that the new system is effective for increasing the indoor temperature, and the temperature was increased by 4.16 °C.

- In the presence of solar radiation, the equilibrium temperature in the basic heating room was 6.5 °C, and the heating efficiency was 0.23 °C/h. After adopting the new system, the room temperature after equilibrium was 9.16 °C, and the heating efficiency was 4.09 °C/h.

- In the absence of WSR, the equilibrium temperature in the basic heating room was 5.5 °C, and the heating efficiency was 0.06 °C/h. After adopting the new system, the temperature in the room after equilibrium was 5.43 °C, and the heating efficiency was 2.87 °C/h. Therefore, when there was no WSR, the heating effect of the new system was obvious compared to the basic heating system.

- When the firewall and additional sunlight system were used, the thermal load of the building decreased by 1436.731 kW h during the whole year (with WSR). The thermal load of the building decreased by 735.919 kW· h throughout the year (without WSR). Taking 18 °C as the standard value of the building’s winter thermal comfort, the annual time below 18 °C was 3733 h (the wall has solar radiation) and 4006 h (the wall has no solar radiation).

4.2. Future Prospects

- According to actual investigations, the wall materials of the residential buildings in southern Shaanxi mainly involve clay porous brick masonry. Therefore, in the simulation analysis, the wall material of the model was set as clay porous brick masonry. As the maintenance structure of the building, walls are important for the insulation of the building. In future studies, the selection of wall materials can be an important research direction. Concrete, bamboo charcoal, or new types of materials can be used to find wall materials suitable for local conditions.

- The research aim of this paper was to put forward a firewall system with an additional sunlight room, focusing on the analysis of the impact of this system on improving the indoor temperature. It was verified that this system is effective for indoor heating in residential buildings. The ratio of walls to other elements is also an important factor affecting the heating of the system. In future research, this viewpoint can be used as the main research direction. First, the main elements affecting the indoor temperature can be determined based on the local geographical environment and climatic conditions to further determine the proportion of walls and major elements, so as to optimize the system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Luo, Y.; Zeng, W.; Wang, Y.; Li, D.; Hu, X.; Hua, Z. A hybrid approach for examining the drivers of energy consumption in Shanghai. Renew. Sustain. Energy Rev. 2021, 151, 111571. [Google Scholar] [CrossRef]

- IEA. IEA Online Data Services. Available online: https://www.iea.org/subscribe-to-data-services/world-energy-balances-and-statistics (accessed on 4 August 2021).

- China Association of Building Energy Efficiency. 2018 China building energy research report. Available online: https://www.cabee.org/site/term/107.html (accessed on 4 August 2021).

- Mi, Z.; Zheng, J.; Meng, J.; Shan, Y.; Zheng, H.; Ou, J.; Guan, D.; Wei, Y.-M. China’s Energy Consumption in the New Normal. Earths Future 2018, 6, 1007–1016. [Google Scholar] [CrossRef]

- China Association of Building Energy Efficiency. 2016 China Building Energy Research Report. Available online: https://www.efchina.org/Attachments/Report/report-20170710-1/report-20170710-1 (accessed on 4 August 2021).

- Liu, C.; Xu, W.; Li, A.; Sun, D.; Huo, H. Energy balance evaluation and optimization of photovoltaic systems for zero energy residential buildings in different climate zones of China. J. Clean. Prod. 2019, 235, 1202–1215. [Google Scholar] [CrossRef]

- Neupane, D.; Kafle, S.; Kaji, R.K.; Dae, H.K.; Pradhan, P. Solar and wind energy potential assessment at provincial level in Nepal: Geospatial and economic analysis. Renew. Energy 2022, 181, 278–291. [Google Scholar] [CrossRef]

- Yuan, Y.; Xu, T.; Jiang, Z.; Feng, B. Prospects of power generation from the deep fractured geothermal reservoir using a novel vertical well system in the Yangbajing geothermal field, China. Energy Rep. 2021, 7, 4733–4746. [Google Scholar] [CrossRef]

- Rauf, H.; Muhammad, S.G.; Arshad, N. Complementing hydroelectric power with floating solar PV for daytime peak electricity demand. Renew. Energy 2020, 162, 1227–1242. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; He, B.-J.; Xu, W.; Jin, G.; Zhang, X. Application and suitability analysis of the key technologies in nearly zero energy buildings in China. Renew. Sustain. Energy Rev. 2019, 101, 329–345. [Google Scholar] [CrossRef]

- Siwei, L.; Yu Joe, H. Energy conservation standard for space heating in Chinese urban residential buildings. Energy 1993, 18, 871–892. [Google Scholar] [CrossRef]

- Fallmann, J.; Emeis, S. How to bring urban and global climate studies together with urban planning and architecture? Dev. Built Environ. 2020, 4, 100023. [Google Scholar] [CrossRef]

- Barros, P.; Linda, N.F.; Garcia, L.M.T.; Anne, D.S.; Thomopoulos, N.; Thiago, H.S.; Morais, P.; Mindell, J.S. Social consequences and mental health outcomes of living in high-rise residential buildings and the influence of planning, urban design and architectural decisions: A systematic review. Cities 2019, 93, 263–272. [Google Scholar] [CrossRef]

- Fu, J.; Zhou, J.; Deng, Y. Heritage values of ancient vernacular residences in traditional villages in Western Hunan, China: Spatial patterns and influencing factors. Build. Environ. 2021, 188, 107473. [Google Scholar] [CrossRef]

- Surasit, T.; Tuan, A.D.; Pana, S.; Mona, Y. Energy reduction of split-type air conditioners using a pre-cooling system for the condenser. Energy Rep. 2021, 7, 1–6. [Google Scholar]

- Juan, X.; Ziliang, L.; Weijun, G.; Mengsheng, Y.; Menglong, S. The comparative study on the climate adaptability based on indoor physical environment of traditional dwelling in Qinba mountainous areas, China. Energy Build. 2019, 197, 140–155. [Google Scholar] [CrossRef]

- Zhou, D.; Li, Z.; Wang, S.; Tian, Y.; Zhang, Y.; Jiang, G. How does the newly urban residential built-up density differ across Chinese cities under rapid urban expansion? Evidence from residential FAR and statistical data from 2007 to 2016. Land Use Policy 2021, 104, 105365. [Google Scholar] [CrossRef]

- Chi, F.; Borys, I.; Jin, L.; Zhu, Z.; Bart, D. The strategies and effectiveness of climate adaptation for the thousand pillars dwelling based on passive elements and passive spaces. Energy Build. 2019, 183, 17–44. [Google Scholar] [CrossRef]

- National Bureau of Statistics. Report on Residential Floor Area Per Capita. Available online: http://www.stats.gov.cn/tjsj/sjjd/202007/t20200727_1778643.html (accessed on 4 August 2021).

- Ding, J.; Ma, S. Comparative analysis of habitation behavioral patterns in spatial configuration of traditional houses in Anhui, Jiangsu, and Zhejiang provinces of China. Front. Archit. Res. 2020, 9, 54–66. [Google Scholar] [CrossRef]

- He, B.-j.; Yang, L.; Ye, M.; Mou, B.; Zhou, Y. Overview of rural building energy efficiency in China. Energy Policy 2014, 69, 385–396. [Google Scholar] [CrossRef]

- Ignjatović, D.; Jovanović Popović, M.; Kavran, J. Application of sunspaces in fostering energy efficiency and economical viability of residential buildings in Serbia. Energy Build. 2015, 98, 3–9. [Google Scholar] [CrossRef] [Green Version]

- Ismail, K.A.R.; Salinas, C.T.; Henriquez, J.R. Comparison between PCM filled glass windows and absorbing gas filled windows. Energy Build. 2008, 40, 710–719. [Google Scholar] [CrossRef]

- Chi, F.a.; Zhang, J.; Li, G.; Zhu, Z.; Bart, D. An investigation of the impact of Building Azimuth on energy consumption in sizhai traditional dwellings. Energy 2019, 180, 594–614. [Google Scholar] [CrossRef]

- Acheampong, A.O.; Boateng, E.; Amponsah, M.; Dzator, J. Revisiting the economic growth–energy consumption nexus: Does globalization matter? Energy Econ. 2021, 102, 105472. [Google Scholar] [CrossRef]

- Wang, S.; Sun, S.; Zhao, E.; Wang, S. Urban and rural differences with regional assessment of household energy consumption in China. Energy 2021, 232, 121091. [Google Scholar] [CrossRef]

- Yawale, S.K.; Hanaoka, T.; Kapshe, M. Development of energy balance table for rural and urban households and evaluation of energy consumption in Indian states. Renew. Sustain. Energy Rev. 2021, 136, 110392. [Google Scholar]

- Zi, C.; Qian, M.; Baozhong, G. The consumption patterns and determining factors of rural household energy: A case study of Henan Province in China. Renew. Sustain. Energy Rev. 2021, 146, 111142. [Google Scholar] [CrossRef]

- Dlimi, M.; Iken, O.; Agounoun, R.; Kadiri, I.; Sbai, K. Dynamic assessment of the thermal performance of hemp wool insulated external building walls according to the Moroccan climatic zoning. J. Energy Storage 2019, 26, 101007. [Google Scholar] [CrossRef]

- Fumo, N.; Mago, P.; Luck, R. Methodology to estimate building energy consumption using EnergyPlus Benchmark Models. Energy Build. 2010, 42, 2331–2337. [Google Scholar] [CrossRef]

- Al-Shahri, O.A.; Ismail, F.B.; Hannan, M.A.; Lipu, M.S.H.; Al-Shetwi, A.Q.; Begum, R.A.; Al-Muhsen, N.F.O.; Soujeri, E. Solar photovoltaic energy optimization methods, challenges and issues: A comprehensive Review. J. Clean. Prod. 2021, 284, 125465. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, W. Integrating passive cooling and solar techniques into the existing building in South China. In Proceedings of the 4th International Conference on Technology of Architecture and Structure (ICTAS 2011), Beijing, China, 2012; pp. 3717–3720. [Google Scholar]

- Ahmed, W.A.; Hammad, F.K.; Rosa, A.C.; Vazquez, E.; Haddad, A. Enhancing the passive design of buildings: A mixed integer non-linear programming approach for the selection of building materials and construction building systems. Energy Rep. 2021, 458, 2352–4847. [Google Scholar]

- Ji, H.; Kim, Y.; Jeon, J.; Yun, B.; Kang, Y.; Kim, S. Analysis of biochar-mortar composite as a humidity control material to improve the building energy and hygrothermal performance. Sci. Total Environ. 2021, 775, 145552. [Google Scholar]

- Ma, L.; Zhang, X.; Li, D.; Arıcı, M.; Yıldız, Ç.; Li, Q.; Zhang, S.; Jiang, W. Influence of sunspace on energy consumption of rural residential buildings. Sol. Energy 2020, 211, 336–344. [Google Scholar] [CrossRef]

- Harkouss, F.; Fardoun, F.; Biwole, P.H. Passive design optimization of low energy buildings in different climates. Energy 2018, 165, 591–613. [Google Scholar] [CrossRef]

- Hilliaho, K.; Makitalo, E.; Lahdensivu, J. Energy saving potential of glazed space: Sensitivity analysis. Energy Build. 2015, 99, 87–97. [Google Scholar] [CrossRef]

- Kim, T.; Ahn, S.; Leigh, S.-B. Energy consumption analysis of a residential building with phase change materials under various cooling and heating conditions. Indoor Built Environ. 2014, 23, 730–741. [Google Scholar] [CrossRef]

- Wang, W.; Li, C.; Li, Y.-Z.; Yuan, M. A novel on-top inverse sunspace conception and the passive heating effects on a typical northern China rural house. Indoor Built Environ. 2019, 28, 1406–1421. [Google Scholar] [CrossRef]

- Girard, A.; Muneer, T.; Caceres, G. A validated design simulation tool for passive solar space heating: Results from a monitored house in West Lothian, Scotland. Indoor Built Environ. 2014, 23, 353–372. [Google Scholar] [CrossRef]

- Simões, N.; Manaia, M.; Simões, I. Energy performance of solar and Trombe walls in Mediterranean climates. Energy 2021, 234, 121197. [Google Scholar] [CrossRef]

- Duan, S.; Li, H.; Zhao, Z.; Wang, L. Investigation on heating performance of an integrated phase change material Trombe wall based on state space method. J. Energy Storage 2021, 38, 102460. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Ma, L.; Arıcı, M.; Li, D.; Yıldız, Ç.; Zhu, Y. Effect of sunspace and PCM louver combination on the energy saving of rural residences: Case study in a severe cold region of China. Sustain. Energy Technol. Assess. 2021, 45, 101126. [Google Scholar]

- Barrencua, J.G.; Maritorena, M.O.; Minguillon, R.H.; Arriaran, I.G. Energy savings using sunspaces to preheat ventilation intake air: Experimental and simulation study. J. Build. Eng. 2021, 40, 102343. [Google Scholar] [CrossRef]

- Mihalakakou, G.; Ferrante, A. Energy conservation and potential of a sunspace: Sensitivity analysis. Energy Convers. Manag. 2000, 41, 1247–1264. [Google Scholar] [CrossRef]

- Mottard, J.M.; Fissore, A. Thermal simulation of an attached sunspace and its experimental validation. Sol. Energy 2007, 81, 305–315. [Google Scholar] [CrossRef]

- Li, G.; Bi, X.; Feng, G.; Chi, L.; Zheng, X.; Liu, X. Phase change material Chinese Kang: Design and experimental performance study. Renew. Energy 2020, 150, 821–830. [Google Scholar] [CrossRef]

- Men, R. Origin of Everything; China Economy Press: Beijing, China, 2004. [Google Scholar]

- Cao, G.; Jokisalo, J.; Feng, H.; Duanmu, L.; Vuolle, M.; Kurnitski, J. Simulation of the heating performance of the Kang system in one Chinese detached house using biomass. Energy Build. 2011, 43, 189–199. [Google Scholar] [CrossRef]

- Zhuang, Z.; Li, Y.; Chen, B. Simulation and analysis of the thermal process in a house with an elevated Chinese kang heating system. HV&AC 2009, 12, 96–98. [Google Scholar]

- Ayres de Mello, L.; Moura, L.M.; Mendes, N. A model for assessment of heat and moisture transfer through hollow porous buildings elements. Case Stud. Therm. Eng. 2019, 14, 100446. [Google Scholar] [CrossRef]

- Wang, J.; Lou, H.; Yang, F.; Cheng, F. Development and performance evaluation of a clean-burning stove. J. Clean. Prod. 2016, 134, 447–455. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Y.; Rui, J.; Yoshino, H.; Zhang, J.; Chen, X.; Liu, J. Effects of thermal environment on elderly in urban and rural houses during heating season in a severe cold region of China. Energy Build. 2019, 198, 61–74. [Google Scholar] [CrossRef]

- Niu, H.-F.; Wei, L.-J.; Yu, J.-P.; Lian, Z.; Zhao, J.; Wu, Z.-Z.; Liu, J.-T. Is adjuvant chemotherapy necessary for patients with microinvasive breast cancer after surgery? Cancer Biol. Med. 2016, 13, 142. [Google Scholar] [CrossRef] [Green Version]

- Yu, K.; Tan, Y.; Zhang, T.; Zhang, J.; Wang, X. The traditional Chinese kang and its improvement: A review. Energy Build. 2020, 218, 110051. [Google Scholar] [CrossRef]

- Bian, M. Numerical simulation research on heat transfer characteristics of a Chinese kang. Case Stud. Therm. Eng. 2021, 25, 100922. [Google Scholar] [CrossRef]

- Wang, P.; Yang, M.; Yang, X.; Shan, M. Thermal performance of a traditional Chinese heated wall with the in-series flow pass: Experiment and modeling. Energy Build. 2014, 84, 46–54. [Google Scholar] [CrossRef]

- Chen, B.; Zhuang, Z.; Chen, X.; Jia, X. Field survey on indoor thermal environment of rural residences with coupled Chinese kang and passive solar collecting wall heating in Northeast China. Sol. Energy 2007, 81, 781–790. [Google Scholar] [CrossRef]

- Zhuang, Z.; Li, Y.; Chen, B. Thermal storage performance analysis on Chinese kangs. Energy Build. 2009, 41, 452–459. [Google Scholar] [CrossRef]

- Zhao, D.; Ji, J.; Yu, H.; Wei, W.; Zheng, H. Numerical and experimental study of a combined solar Chinese kang and solar air heating system based on Qinghai demonstration building. Energy Build. 2017, 143, 61–70. [Google Scholar] [CrossRef]

- Wei, H.; Jiang, Q.Y.; Ji, J.; Wei, W. A study on thermal performance, thermal comfort in sleeping environment and solar energy contribution of solar Chinese Kang. Energy Build. 2013, 58, 66–75. [Google Scholar]

- Yang, S.; Bart, D.; Chen, S. Study on the Passive Heating System of a Heated Cooking Wall in Dwellings: A Case Study of Traditional Dwellings in Southern Shaanxi, China. Int. J. Environ. Res. Public Health 2021, 18, 3745. [Google Scholar] [CrossRef]

- Staveckis, A.; Borodinecs, A. Impact of impinging jet ventilation on thermal comfort and indoor air quality in office buildings. Energy Build. 2021, 235, 110738. [Google Scholar] [CrossRef]

- Obrecht, T.P.; Premrov, M.; Vesna, Ž.L. Influence of the orientation on the optimal glazing size for passive houses in different European climates (for non-cardinal directions). Sol. Energy 2019, 189, 15–25. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, R.; Li, G.; Peng, C. An investigation of optimal window-to-wall ratio based on changes in building orientations for traditional dwellings. Sol. Energy 2020, 195, 64–81. [Google Scholar]

- Farzampour, A. Temperature and humidity effects on behavior of grouts. Adv. Concr. Constr. 2017, 5, 659. [Google Scholar]

- Farzampour, A. Compressive Behavior of Concrete under Environmental Effects; IntechOpen: London, UK, 2019. [Google Scholar]

- Mansouri, I.; Shahheidari, F.S.; Hashemi, S.M.A.; Farzampour, A. Investigation of steel fiber effects on concrete abrasion resistance. Adv. Concr. Constr. 2020, 9, 367–374. [Google Scholar]

- Navid, C.; Farzampour, A.; Paslar, N. Nano Silica and Metakaolin Effects on the Behavior of Concrete Containing Rubber Crumbs. CivilEng 2020, 1, 264–274. [Google Scholar] [CrossRef]

- Dong, F. Feasibility and key points of construction technology of pasting decorative brick in external insulation system of external wall (pasting polystyrene board). China Build. Mater. Technol. 2019, 1, 29–30. [Google Scholar]

- Jin, Z. Durability research of external thermal insulation Material for exterior wall of foamed cement board. Sichuan Cem. 2019, 1, 1. [Google Scholar]

| Dwellings | Data Statistics |

|---|---|

| Research location | Hongcun, Houliu town, Shiquan county, Ankang city, and Shaanxi province |

| Climatic conditions | Hot summer and cold winter |

| Time and behavior | 09:00–9:00 a.m. at home, 9:00–11:00 a.m. not at home, 11:00 a.m.–3:00 p.m. at home, 3:00–6:00 p.m. at home, 6:00 p.m.–12:00 a.m. at home |

| Number of occupants | 1–2 |

| Room information | Number: 4; sizes: Meeting room 6 m × 6 m, kitchen 4.2 m × 6 m, and bedroom 4.2 m × 6 m; height: 4.8 m |

| Roof | 5 mm tile + 4 mm waterproof coiled material + 20 mm cement mortar + 4 mm lime cement mortar |

| Wall | 4 mm lime cement mortar + 240 mm clay porous brick masonry + 3 mm cement mortar + 4 mm lime cement mortar |

| Window | Thickness: 6 mm; length: 1200 mm; width: 1300 mm; glass and heat transfer coefficient: 4.7 W/(m2·K); number: 3 |

| Earthen stove | Length: 1800 mm; width: 900 mm; height: 800 mm |

| Door | 45 mm wood; size: 900 mm × 2100 mm; number: 4 |

| Floor | 120 mm lime cement mortar |

| Stoves | Length: 1800 mm; width: 900 mm; height: 800 mm |

| Material Name | Thermal Storage Coefficient W/(m2·K) | Specific Heat Capacity (J/kg·K) | Density (kg/m3) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|

| Tile | 6.23 | 1406 | 1800 | 0.43 |

| Waterproof coiled materials | 3.302 | 1470 | 600 | 0.17 |

| Cement mortar | 11.37 | 1050 | 1800 | 0.93 |

| Lime cement mortar | 10.75 | 1050 | 1700 | 0.87 |

| Clay porous brick masonry | 6.602 | 1356 | 850 | 0.52 |

| Wood | 3.575 | 2510 | 500 | 0.14 |

| Air | - | - | 1.27 | - |

| Aluminum | 191.495 | 920 | 2700 | 203 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Dewancker, B.; Chen, S. Study on Passive Heating Involving Firewalls with an Additional Sunlight Room in Rural Residential Buildings. Int. J. Environ. Res. Public Health 2021, 18, 11147. https://doi.org/10.3390/ijerph182111147

Yang S, Dewancker B, Chen S. Study on Passive Heating Involving Firewalls with an Additional Sunlight Room in Rural Residential Buildings. International Journal of Environmental Research and Public Health. 2021; 18(21):11147. https://doi.org/10.3390/ijerph182111147

Chicago/Turabian StyleYang, Simin, Bart Dewancker, and Shuo Chen. 2021. "Study on Passive Heating Involving Firewalls with an Additional Sunlight Room in Rural Residential Buildings" International Journal of Environmental Research and Public Health 18, no. 21: 11147. https://doi.org/10.3390/ijerph182111147