Study on the Optimization and Oxygen-Enrichment Effect of Ventilation Scheme in a Blind Heading of Plateau Mine

Abstract

:1. Introduction

2. Numerical Analysis

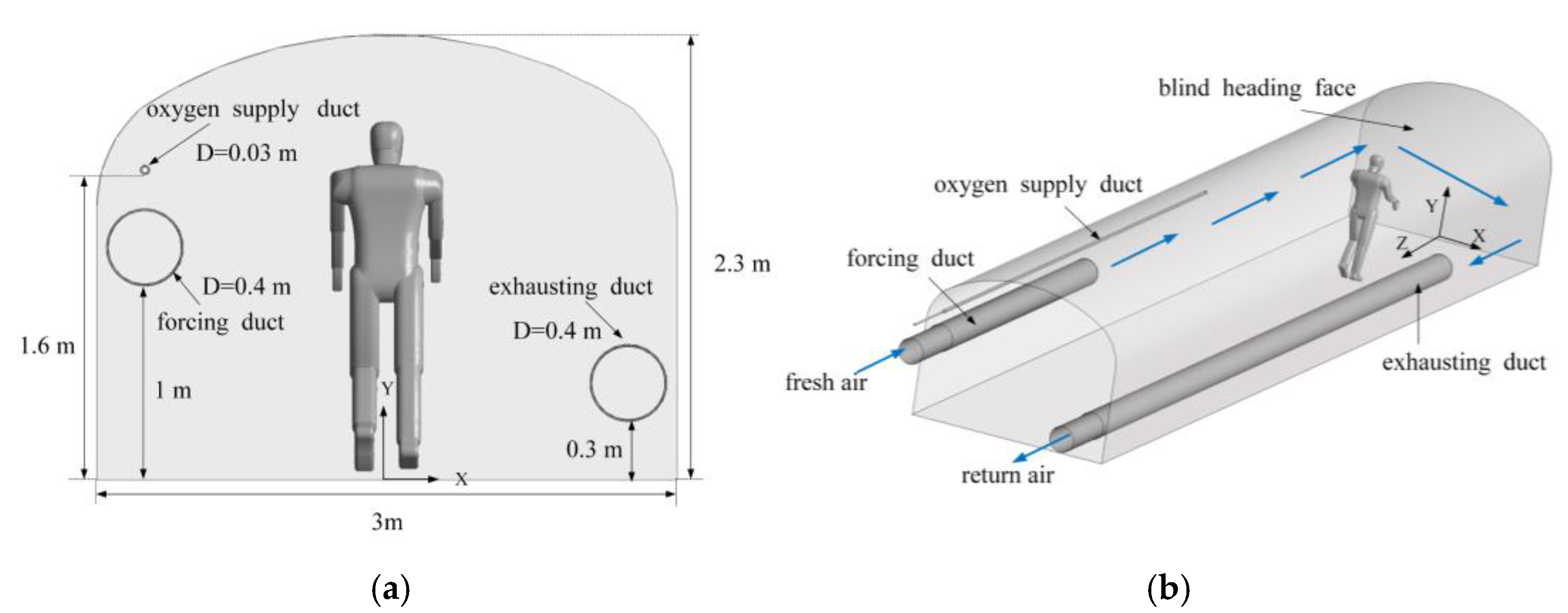

2.1. Physical Model

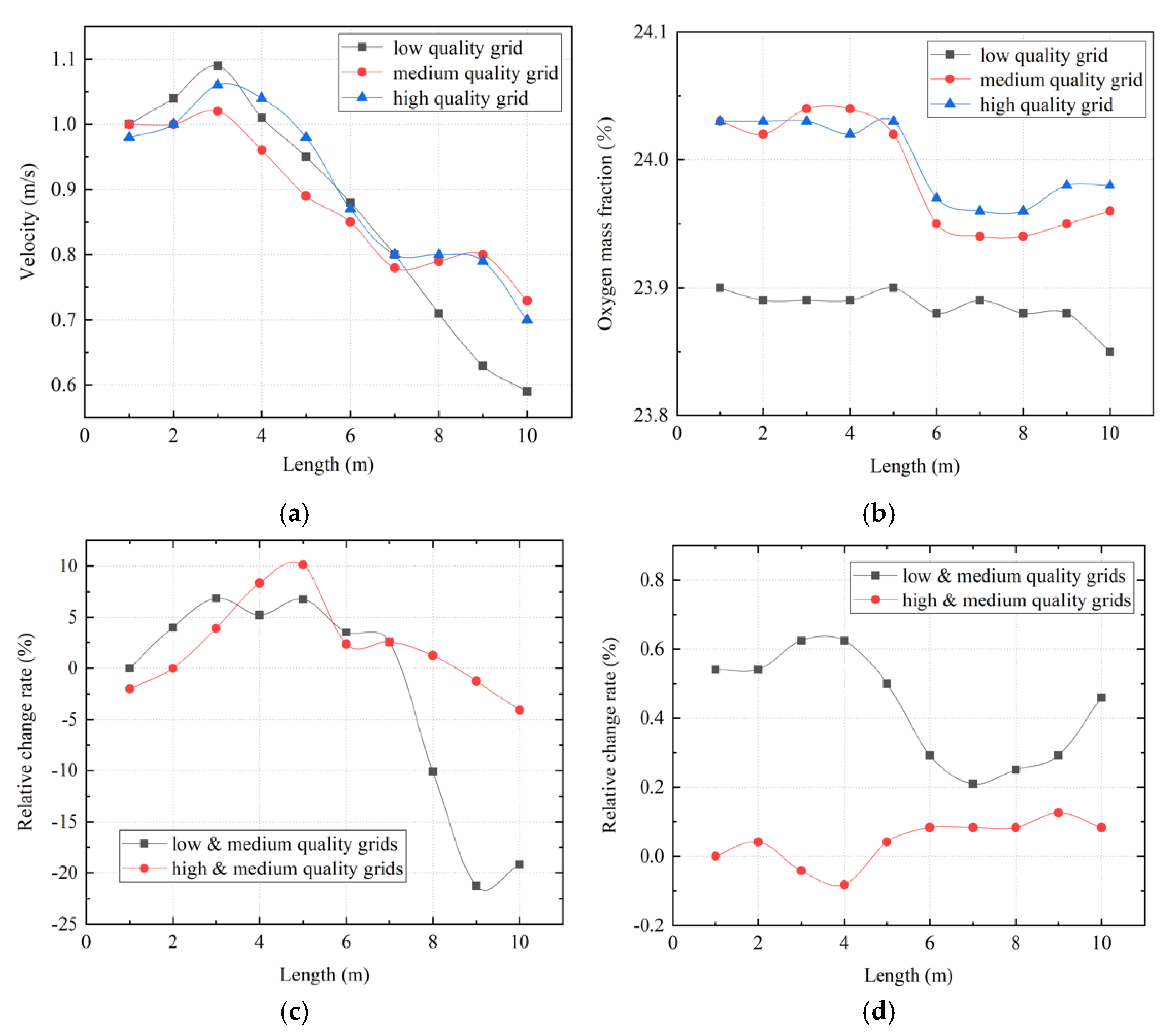

2.2. Grid Generation and Independence Tests

2.3. Boundary Conditions and Turbulence Model

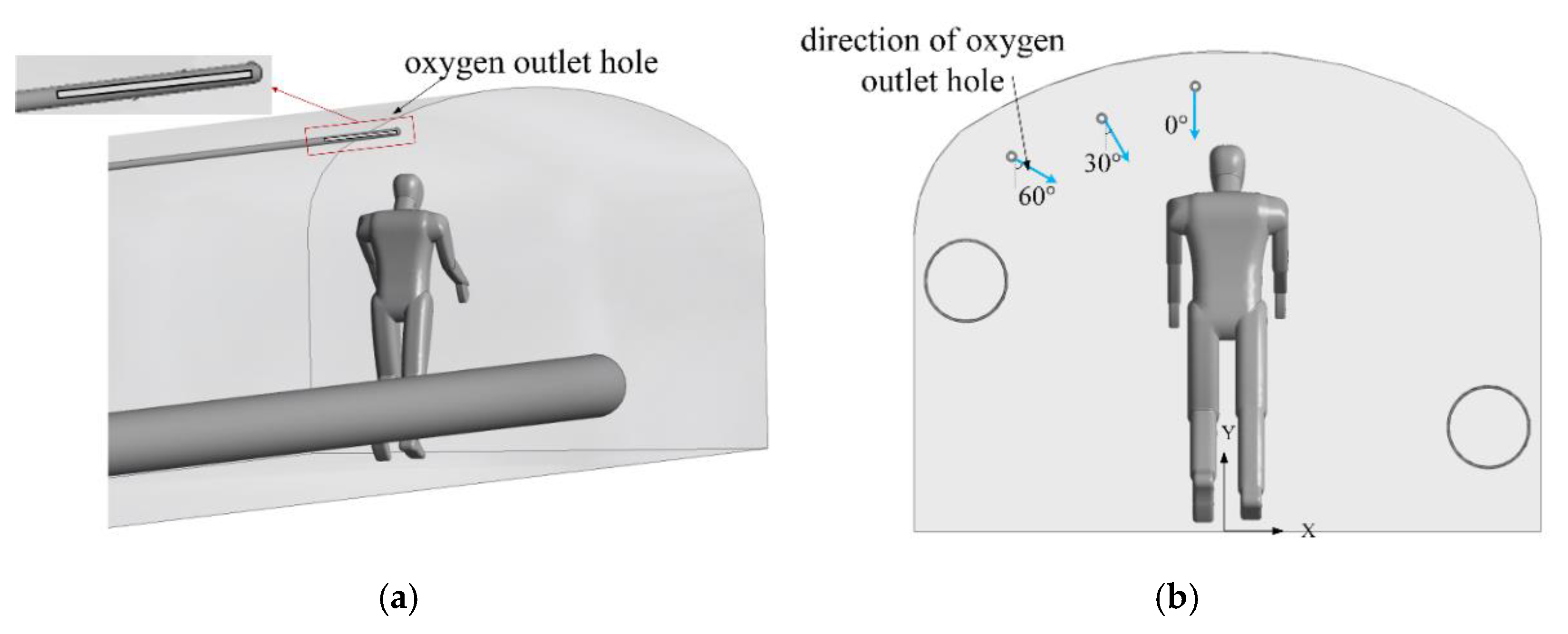

2.4. Optimization Scheme of Oxygen Supply Duct Outlet

3. Results and Discussion

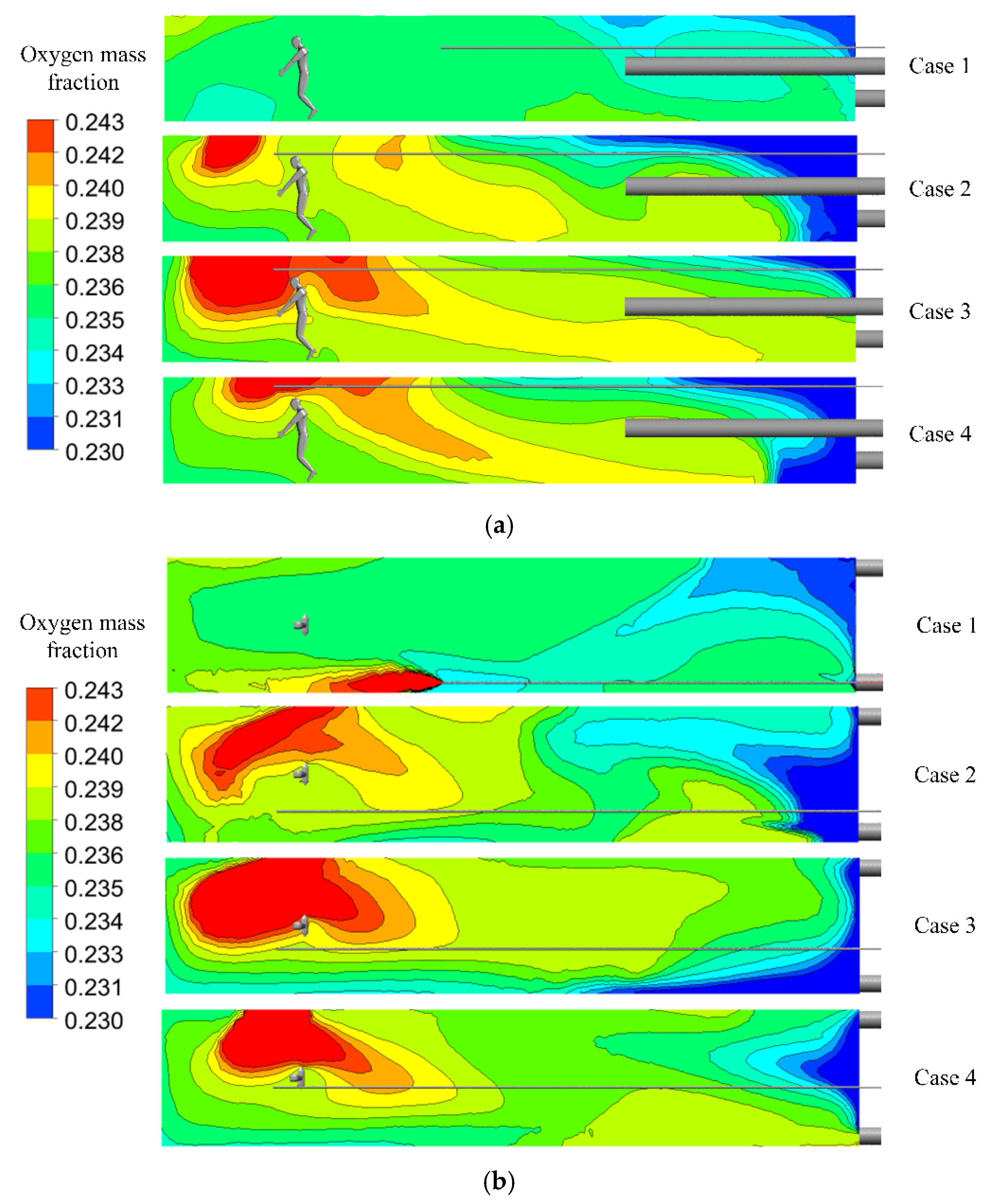

- Case 1: when the oxygen was ejected through the outlet of the oxygen supply duct, the velocity direction of oxygen flow was towards the blind heading face, and was affected by the airflow in the roadway. A high concentration of oxygen accumulated on the left wall of the roadway, failing to diffuse sufficiently to the human body. The oxygen mass fraction around the human body ranges from 23.6–23.8%, and the effect of oxygen enrichment is not ideal.

- Using a slit air outlet, the distribution range of oxygen in the working area of the roadway increased, and the oxygen mass fraction increased significantly, with more concentrated oxygen around the human body. Case 3 presented the optimal result among the five comparisons, with a larger distribution area of high-concentration oxygen; hence, it was applied in the following study.

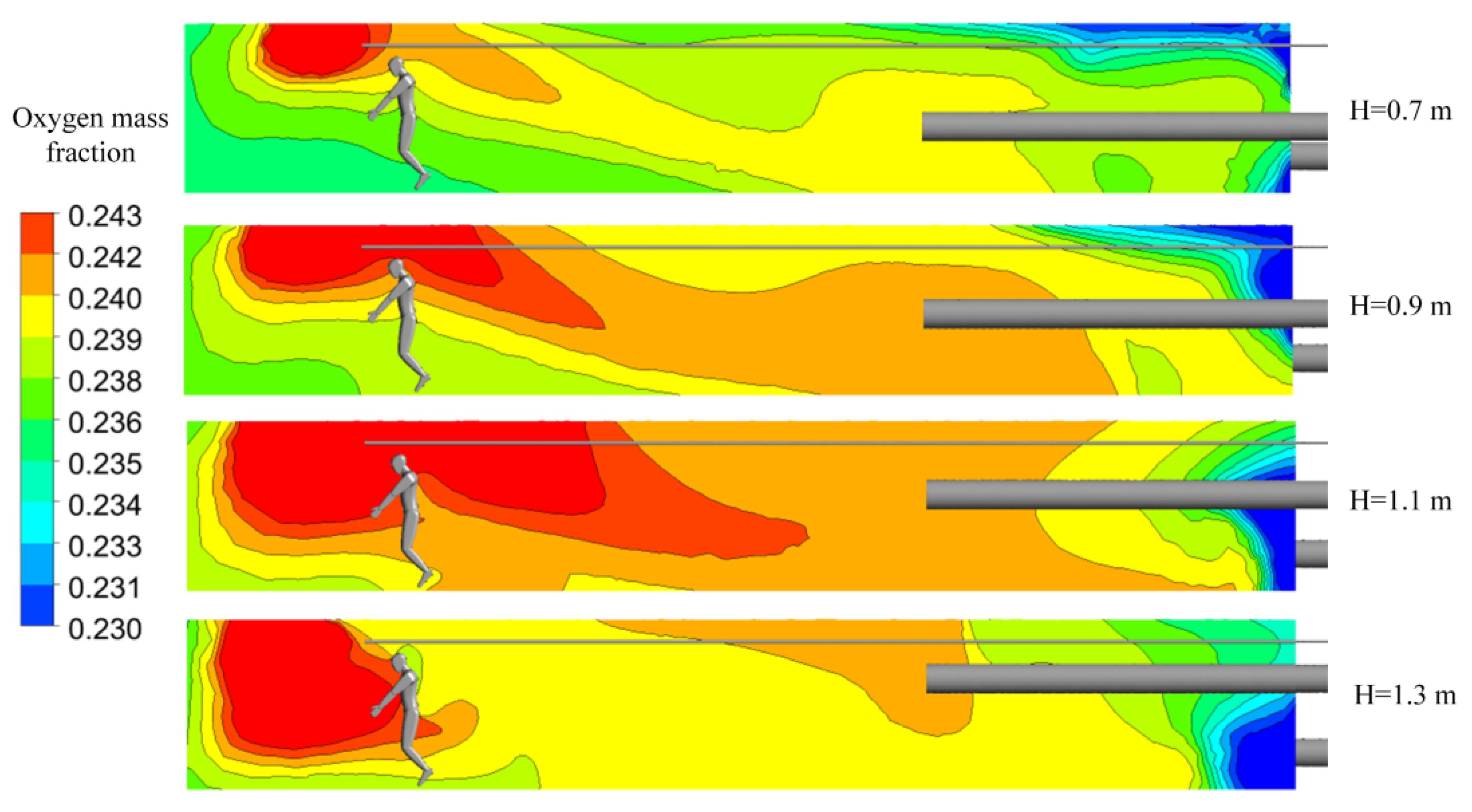

- With an increase in oxygen supply duct height, oxygen mass distribution presented two stages. The concentration area of concentrated oxygen moved from the left side of the roadway to the right side, and the distribution range of high-concentration oxygen first increased and then decreased. All these phenomena are related to the airflow driven by forcing ducts. When the oxygen supply duct is lower in height, it is closer to the forcing duct, which is easily affected by the entrainment effect by the jet of the forcing duct, diffusing air to the tunneling face. When the height of the oxygen supply duct is too high, it is difficult to spread oxygen to the floor due to the extrusion of the airflow.

4. Stability Analysis of Oxygen-Enrichment Effect

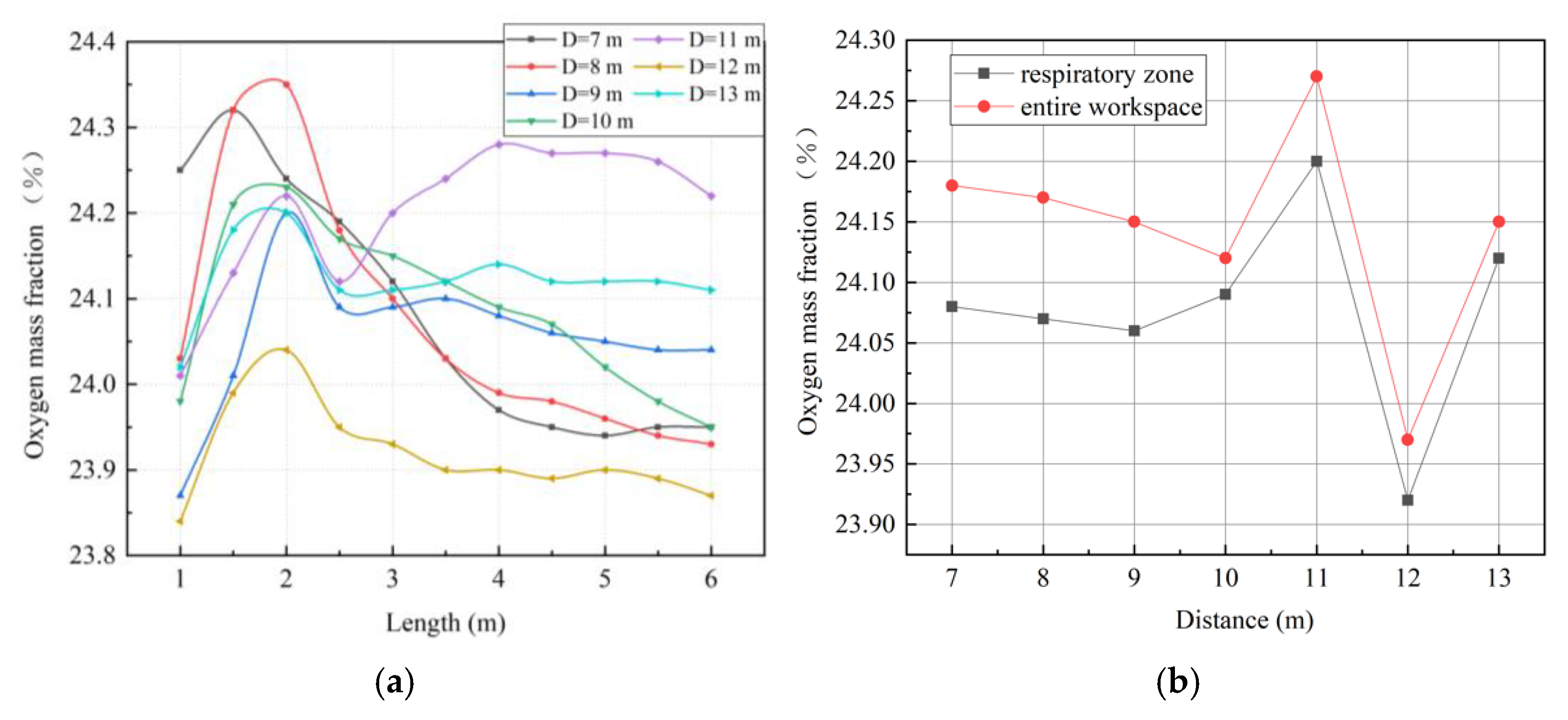

4.1. Forcing Duct Position

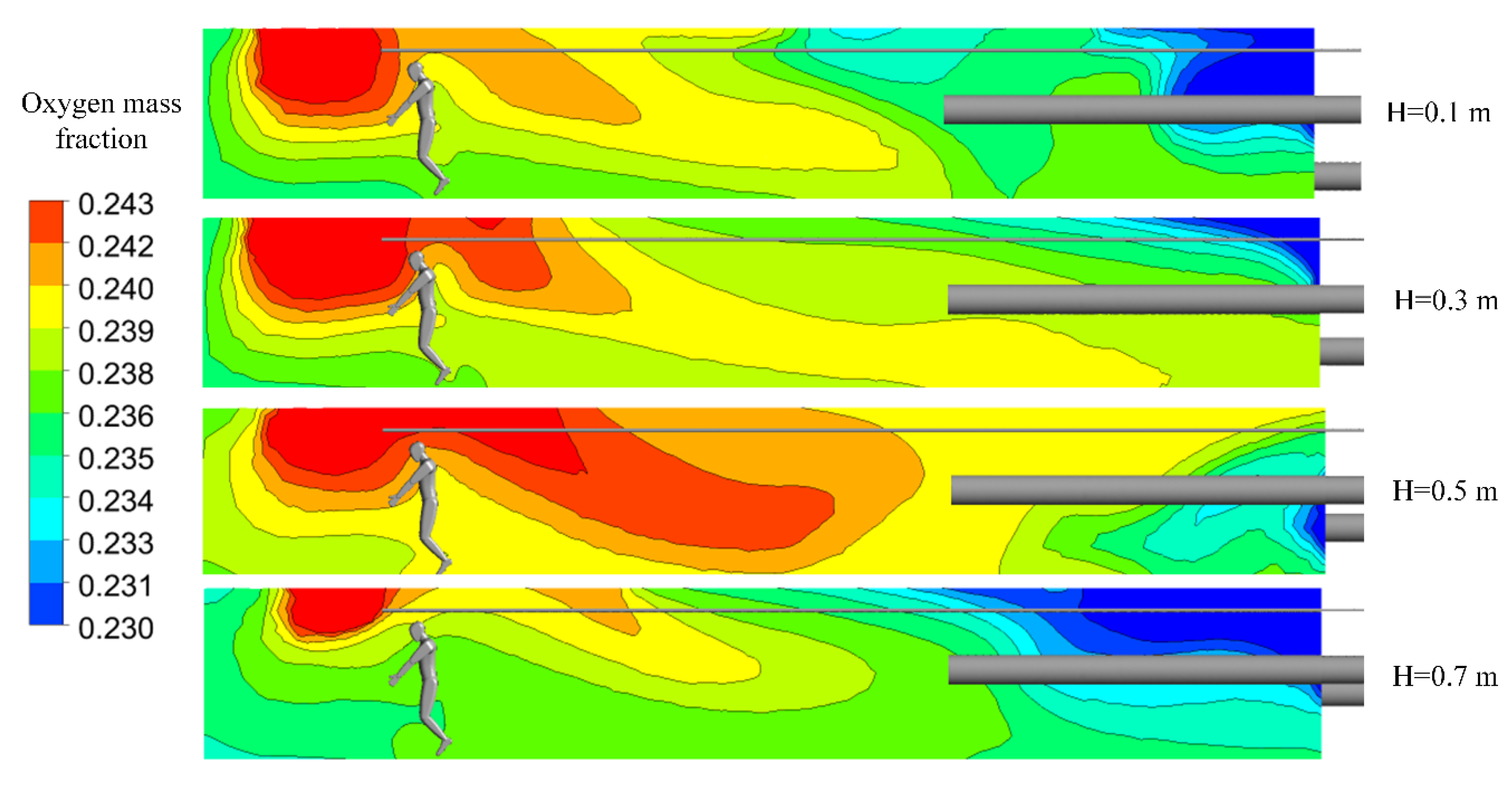

4.1.1. Height between Forcing Duct and Roadway Floor

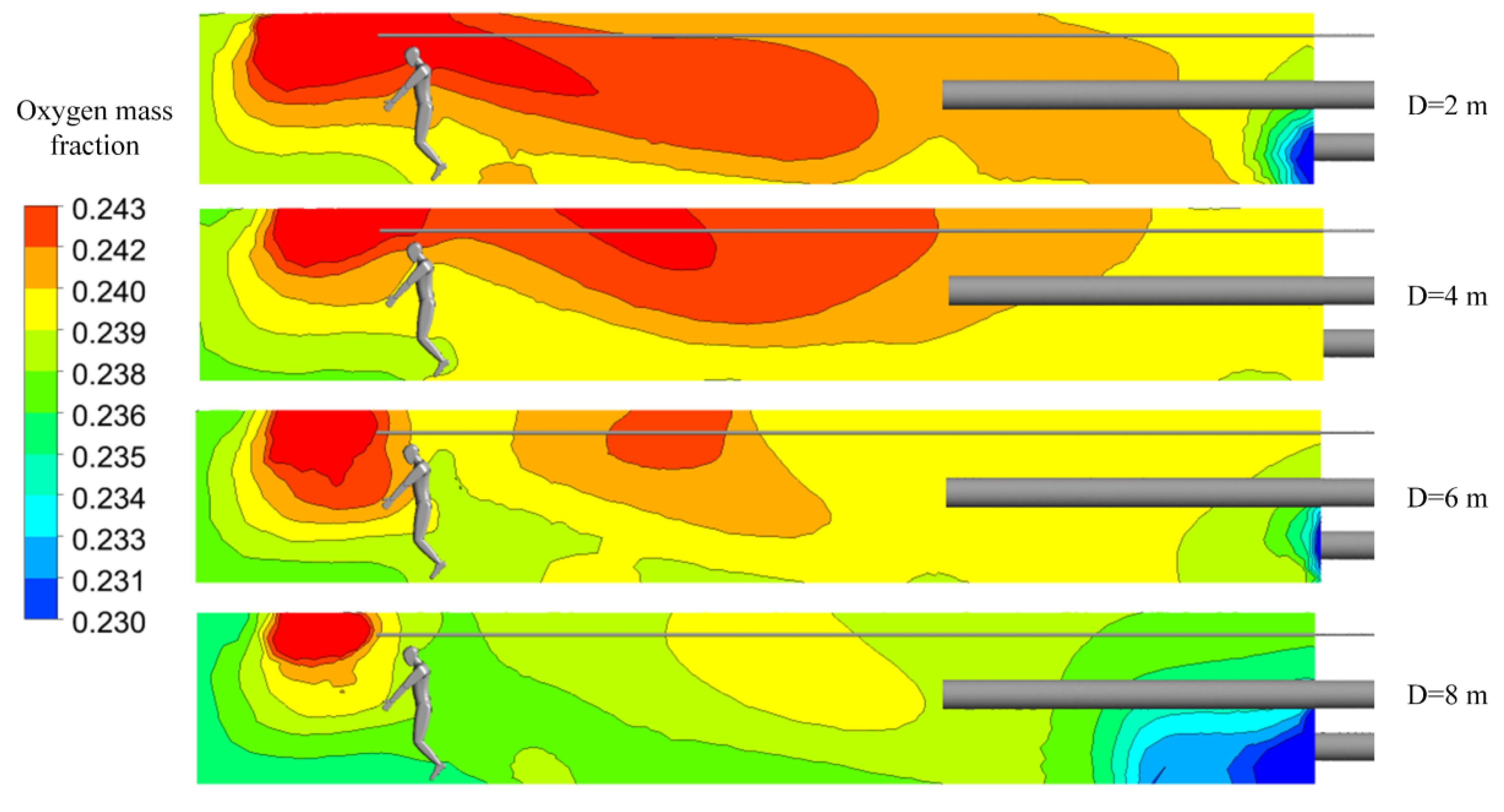

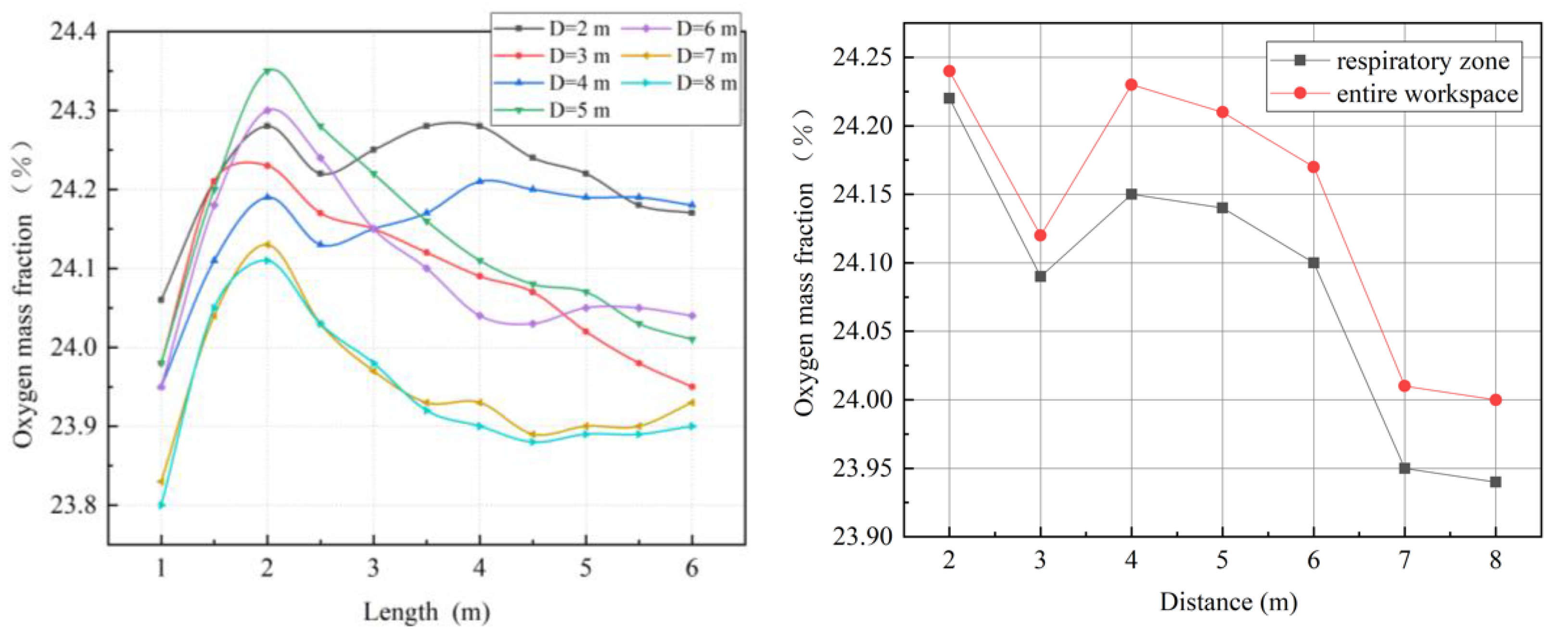

4.1.2. Distance between Forcing Duct Outlet and Blind Heading Face

4.2. Exhausting Duct Position

4.2.1. Height between Exhausting Duct and Roadway Floor

4.2.2. Distance between Exhausting Duct Inlet and Blind Heading Face

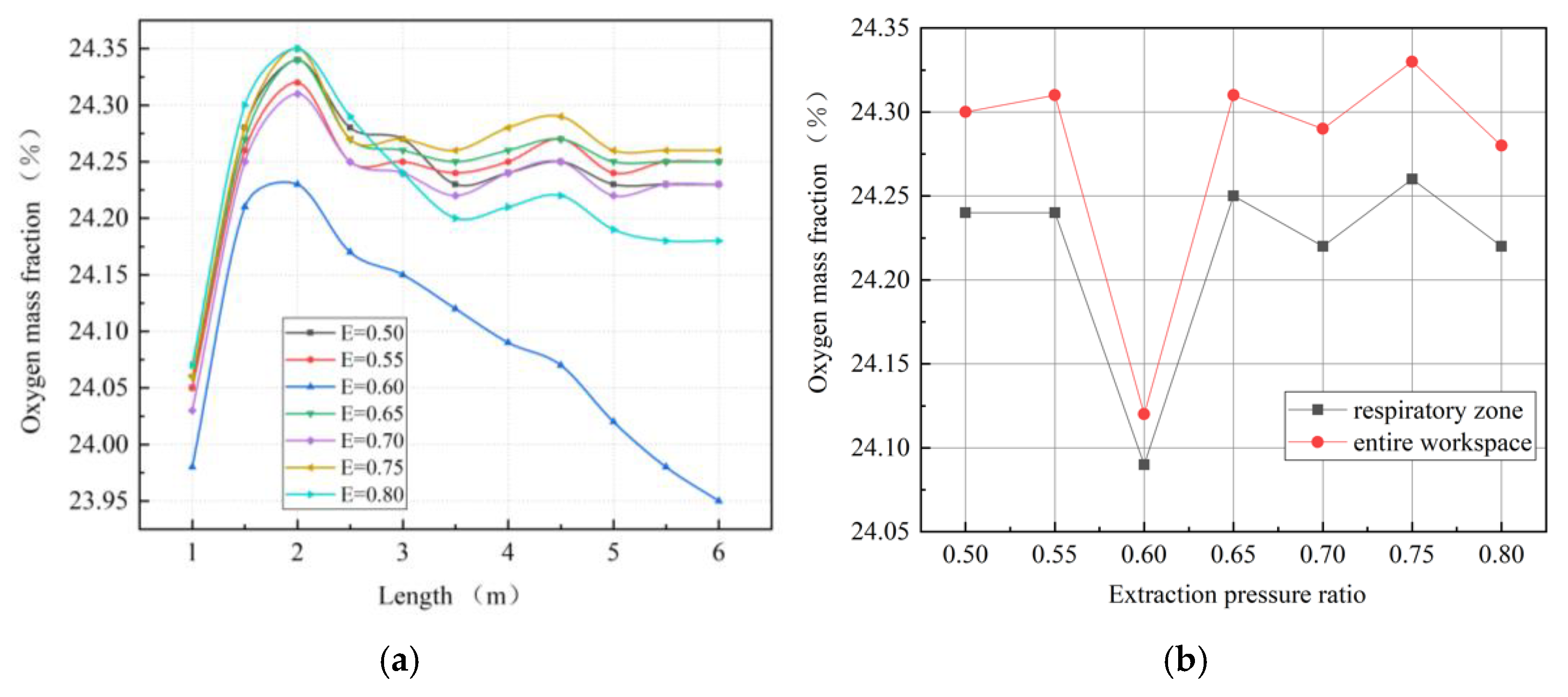

4.3. Extraction Pressure Ratio

5. Degree of Influence on Oxygen Enrichment Factors

6. Conclusions

- Using a slit air outlet, the diffusion and distribution range of oxygen in the working area of the roadway were larger than that of the traditional oxygen supply method, and the oxygen mass fraction increased significantly, with more concentrated oxygen around mine workers’ bodies. When the direction of the oxygen outlet hole is 30° and its height above the roadway floor is 1.95 m, the oxygen-enrichment effect is better than other forms of oxygen supply duct outlets.

- The forcing duct position, exhausting duct position, and extraction pressure ratio have obvious influence on oxygen-enrichment effects. The influences of these factors on the oxygen distribution are complex and non-monotonous; they initially affect the flow characteristics of air flow in the roadway, hence affecting the oxygen distribution. Based on grey relational analysis results, the main factors that influence the correlation degree of the oxygen distribution in the blind heading of a plateau metal mine, in descending order, are as follows: the forcing duct position, the extraction pressure ratio, and the exhausting duct position. The position of the forcing duct has greater influence on the oxygen distribution in the main working area of the roadway.

- This paper is mainly a theoretical and feasibility analysis, and can be considered as a preliminary study on oxygen supply in blind headings of plateau mines. In future research, environmental factors and actual working conditions should also be considered, in order to improve the model setting as well as complete the optimization of the artificial oxygen supply system.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, K.; Du, F. Coal-gas compound dynamic disasters in China: A review. Process Saf. Environ. Prot. 2020, 133, 1–17. [Google Scholar] [CrossRef]

- Yu, S.W.; Duan, H.R.; Cheng, J.H. An evaluation of the supply risk for China’s strategic metallic mineral resources. Resour. Policy 2021, 70, 101891. [Google Scholar] [CrossRef]

- Bian, S.Z.; Jin, J.; Li, Q.N.; Yu, J.; Tang, C.F.; Rao, R.S.; Yu, S.Y.; Zhao, X.H.; Qin, J.; Huang, L. Hemodynamic characteristics of high-altitude headache following acute high altitude exposure at 3700 m in young Chinese men. J. Headache Pain 2015, 16, 13. [Google Scholar] [CrossRef] [Green Version]

- Bacaloni, A.; Zamora Saa, M.C.; Sinibaldi, F.; Steffanina, A.; Insogna, S. Respiratory parameters at varied altitudes in intermittent mining work. Int. J. Occup. Med. Environ. Health 2018, 31, 129–138. [Google Scholar] [CrossRef]

- Butler, G.J.; Al-Waili, N.; Passano, D.V.; Ramos, J.; Chavarri, J.; Beale, J.; Allen, M.W.; Lee, B.Y.; Urteaga, G.; Salom, K. Altitude mountain sickness among tourist populations: A review and pathophysiology supporting management with hyperbaric oxygen. J. Med. Eng. Technol. 2011, 35, 197–207. [Google Scholar] [CrossRef]

- Guo, C.; Xu, J.F.; Wang, M.N.; Yan, T.; Yang, L.; Sun, Z.T. Study on oxygen supply standard for physical health of construction personnel of high-altitude tunnels. Int. J. Environ. Res. Public Health 2016, 13, 64. [Google Scholar] [CrossRef] [Green Version]

- Wu, P.; Yang, F.; Zheng, J.L.; Wei, Y.Q. Evaluating the highway tunnel construction in western sichuan plateau considering vocational health and environment. Int. J. Environ. Res. Public Health 2019, 16, 4671. [Google Scholar] [CrossRef] [Green Version]

- Shen, G.H.; Wu, X.M.; Tang, C.; Yan, Y.L.; Liu, J.; Guo, W.; Jing, D.; Lei, T.; Tian, Y.; Xie, K.N.; et al. An oxygen enrichment device for lowlanders ascending to high altitude. Biomed. Eng. Online 2013, 12, 100. [Google Scholar] [CrossRef] [Green Version]

- Shen, G.H.; Xie, K.N.; Yan, Y.L.; Jing, D.; Tang, C.; Wu, X.M.; Liu, J.; Sun, T.; Zhang, J.B.; Luo, E.P. The role of oxygen-increased respirator in humans ascending to high altitude. Biomed. Eng. Online 2012, 11, 49. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.N.; Yan, G.F.; Yu, L.; Xie, W.Q.; Dai, Y. Effects of different artificial oxygen-supply systems on migrants’ physical and psychological reactions in high-altitude tunnel construction. Build. Environ. 2019, 149, 458–467. [Google Scholar] [CrossRef]

- West, J.B. Commuting to high altitude: Value of oxygen enrichment of room air. High Alt. Med. Biol. 2002, 3, 223–235. [Google Scholar] [CrossRef] [PubMed]

- West, J.B. Potential use of oxygen enrichment of room air in mountain resorts. High Alt. Med. Biol. 2002, 3, 59–64. [Google Scholar] [CrossRef] [Green Version]

- West, J.B. Oxygen enrichment of room air to improve well-being and productivity at high altitude. Int. J. Occup. Environ. Health 1999, 5, 187–193. [Google Scholar] [CrossRef] [PubMed]

- Barash, I.A.; Beatty, C.; Powell, F.L.; Prisk, G.K.; West, J.B. Nocturnal oxygen enrichment of room air at 3800 meter altitude improves sleep architecture. High Alt. Med. Biol. 2001, 2, 525–533. [Google Scholar] [CrossRef]

- Li, Y.L.; Liu, Y.S. Oxygen enrichment and its application to life support systems for workers in high-altitude areas. Int. J. Occup. Environ. Health 2014, 20, 207–214. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Z.J.; Zhao, S.Q.; Li, R.R.; Huang, Y.; Xu, Y.; Song, P. Increasing Oxygen Mass Fraction in Blind Headings of a Plateau Metal Mine by Oxygen Supply Duct Design: A CFD Modelling Approach. Math. Prob. Eng. 2020, 2020, 8541909. [Google Scholar] [CrossRef]

- Li, Z.J.; Wang, J.J.; Zhao, S.Q.; Xu, Y. The effect of oxygen supply and oxygen distribution on single-head tunnel with different altitudes under mixed ventilation. Indoor Built Environ. 2021, 31, 972–987. [Google Scholar] [CrossRef]

- Li, Z.J.; Li, R.R.; Xu, Y.; Xu, Y.Y. Study on the Oxygen Enrichment Effect of Individual Oxygen-Supply Device in a Tunnel of Plateau Mine. Int. J. Environ. Res. Public Health 2020, 17, 5934. [Google Scholar] [CrossRef]

- Liu, Y.F.; Song, Z.Y.; Song, C.; Wang, D.J. A novel point source oxygen supply method for sleeping environment improvement at high altitudes. Build. Simul. 2021, 14, 1843–1860. [Google Scholar] [CrossRef]

- Diego, I.; Torno, S.; Torano, J.; Menendez, M.; Gent, M. A practical use of CFD for ventilation of underground works. Tunn. Undergr. Space Technol. 2011, 26, 189–200. [Google Scholar] [CrossRef]

- Jang, C.B.; Choi, S.W. Simulation and Damage Analysis of an Accidental Jet Fire in a High-Pressure Compressed Pump Shelter. Saf. Health Work 2017, 8, 42–48. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, W.; Cheng, Y.P.; Liu, H.Y.; Fang, Z.M.; Li, X.C.; Zhao, R. Permeability model of gob based on sigmoid function and application in the airflow field simulation. J. Min. Saf. Eng. 2017, 34, 1232–1239. [Google Scholar]

- Niu, Y.H.; Deng, J.; Zhou, X.Q.; Cheng, C.X.; Tian, Z.J. Law of gas accumulation and analysis of danger of gas explosion during sealing fire zone in coal mine. J. Cent. South Univ. 2013, 44, 3918–3924. [Google Scholar]

- Shi, G.Q.; Wang, D.M.; Zhong, X.X.; Wang, Y.W.; Gu, J.J. CFD simulation of oxidation zones distribution in goaf of fully−mechanized caving face. J. Min. Saf. Eng. 2010, 27, 568–571. [Google Scholar]

- Shi, G.Q.; Hu, F.K.; Wang, D.M.; Wang, S.L. Unsteady simulation on distribution of three zones for spontaneous combustion in goaf areas. J. China Univ. Min. Technol. 2014, 43, 189–194. [Google Scholar]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. CFD simulation of methane dispersion and innovative methane management in underground mining faces. Appl. Math. Modell. 2014, 38, 3467–3484. [Google Scholar] [CrossRef]

- Park, J.; Park, S.; Lee, D.-K. CFD modeling of ventilation ducts for improvement of air quality in closed mines. Geosyst. Eng. 2016, 19, 177–187. [Google Scholar] [CrossRef]

- Garcia-Diaz, M.; Sierra, C.; Miguel-Gonzalez, C.; Pereiras, B. A discussion on the effective ventilation distance in dead-end tunnels. Energies 2019, 12, 3352. [Google Scholar] [CrossRef] [Green Version]

- Cao, C.; Zhao, J.Y.; Ding, H.G. Ventilation system arrangement in large cross-section tunnels:a CFD simulation based on direct initial concentration assessment. Int. J. Environ. Health Res. 2019, 29, 489–499. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Hu, P.; Han, Z.C.; Chen, J.H. Effect of heading face ventilation arrangement on regulation of dust distribution. J. Cent. South Univ. 2018, 49, 2264–2271. [Google Scholar]

- Huang, R.; Shen, X.; Wang, B.; Liao, X.P. Migration characteristics of CO under forced ventilation after excavation roadway blasting: A case study in a plateau mine. J. Clean. Prod. 2020, 267, 122094. [Google Scholar] [CrossRef]

- Wang, W.H.; Zhang, C.F.; Yang, W.Y.; Xu, H.; Li, S.S.; Li, C.; Ma, H.; Qi, G.S. In Situ measurements and CFD numerical simulations of thermal environment in blind headings of underground mines. Processes 2019, 7, 313. [Google Scholar] [CrossRef] [Green Version]

- Chen, T.; Li, Y.Z.; Xu, Z.S.; Kong, J.; Liang, Y.; Wang, B.L.; Fan, C.G. Study of the optimal pitch angle of jet fans in road tunnels based on turbulent jet theory and numerical simulation. Build. Environ. 2019, 165, 106390. [Google Scholar] [CrossRef]

- Hua, Y.; Nie, W.; Wei, W.L.; Liu, Q.; Liu, Y.H.; Peng, H.T. Research on multi-radial swirling flow for optimal control of dust dispersion and pollution at a fully mechanized tunnelling face. Tunn. Undergr. Space Technol. 2018, 79, 293–303. [Google Scholar] [CrossRef]

- Xu, G.; Luxbacher, K.D.; Ragab, S.; Xu, J.L.; Ding, X.H. Computational fluid dynamics applied to mining engineering: A review. Int. J. Min. Reclam. Environ. 2017, 31, 251–275. [Google Scholar] [CrossRef]

| Type | Min | Max | Average | Standard Deviation |

|---|---|---|---|---|

| Skewness | 6.89 × 10−7 | 0.90 | 0.23 | 0.12 |

| Orthogonal quality | 0.18 | 0.99 | 0.86 | 0.08 |

| Type | Parameter |

|---|---|

| Forcing duct outlet | Inlet velocity, 8 m/s |

| Exhausting duct outlet | Inlet velocity, 4.8 m/s |

| Oxygen supply duct outlet | Inlet velocity, 12 m/s |

| Roadway exit | Outflow, 66.614 Kpa |

| Other walls | Wall |

| Temperature | 288.15 K |

| Air density | 0.8064 kg/m3 |

| Case | Height above the Roadway Floor/m | Distance from the Left wall/m | Direction of Oxygen Outlet Hole |

|---|---|---|---|

| Case 2 | 1.80 | 0.60 | 60° |

| Case 3 | 1.90 | 1.00 | 30° |

| Case 4 | 2.00 | 1.40 | 0° |

| Influencing Factors | Height between Forcing Duct and Roadway Floor | Distance between Forcing Duct Outlet and Blind Heading Face | Height between Exhausting Duct and Roadway Floor | Distance between Exhausting Duct Inlet and Blind Heading Face | Extraction Pressure Ratio |

|---|---|---|---|---|---|

| Correlation coefficient | 0.9767 | 0.9500 | 0.8191 | 0.8422 | 0.8636 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Li, R.; Xu, Y.; Xu, Y. Study on the Optimization and Oxygen-Enrichment Effect of Ventilation Scheme in a Blind Heading of Plateau Mine. Int. J. Environ. Res. Public Health 2022, 19, 8717. https://doi.org/10.3390/ijerph19148717

Li Z, Li R, Xu Y, Xu Y. Study on the Optimization and Oxygen-Enrichment Effect of Ventilation Scheme in a Blind Heading of Plateau Mine. International Journal of Environmental Research and Public Health. 2022; 19(14):8717. https://doi.org/10.3390/ijerph19148717

Chicago/Turabian StyleLi, Zijun, Rongrong Li, Yu Xu, and Yuanyuan Xu. 2022. "Study on the Optimization and Oxygen-Enrichment Effect of Ventilation Scheme in a Blind Heading of Plateau Mine" International Journal of Environmental Research and Public Health 19, no. 14: 8717. https://doi.org/10.3390/ijerph19148717