A Comprehensive Evaluation Method for Soil Remediation Technology Selection: Case Study of Ex Situ Thermal Desorption

Abstract

:1. Introduction

2. Method and Data

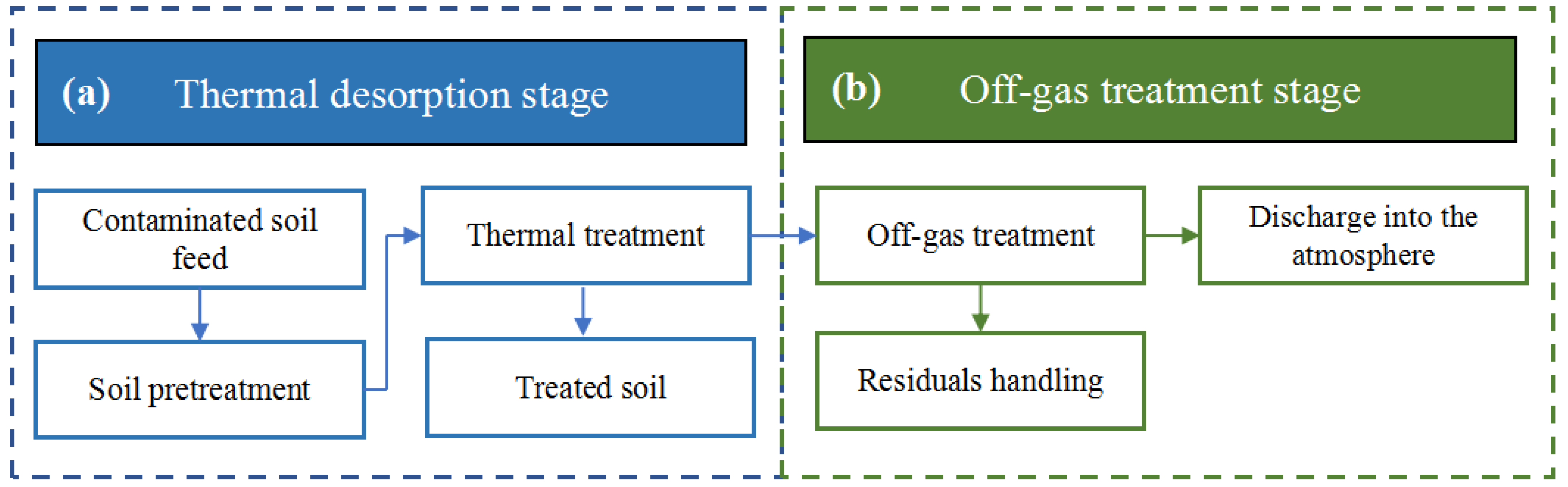

2.1. Methodological Framework

2.2. Comprehensive Evaluation Indicator System

2.2.1. Evaluation Indicators

- (1)

- Technical indicators

- (2)

- Resource indicators

- (3)

- Environmental indicators

- (4)

- Economic indicators

- (5)

- Social indicators

2.2.2. Quantification of Evaluation Indicators

2.3. Weight Determination Method

2.3.1. Weighting Calculation

2.3.2. Judgment Matrix Construction

2.3.3. Weighting Coefficient Determination

2.3.4. Consistency Test of Judgment Matrix

2.4. Comprehensive Evaluation Methodology

2.5. Data Source

3. Case Study

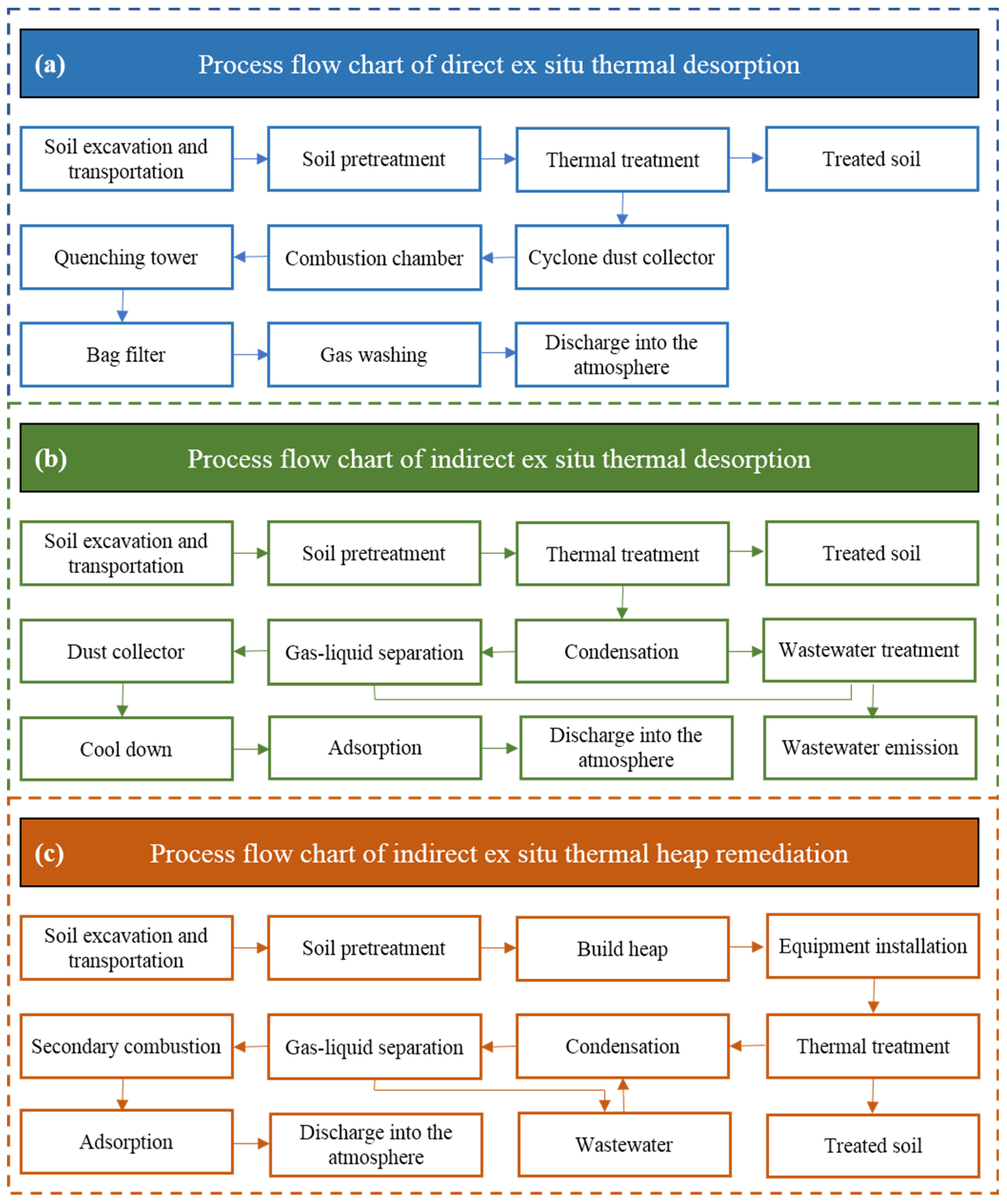

3.1. Remediation Site and Technology Selection

3.2. Results Analysis

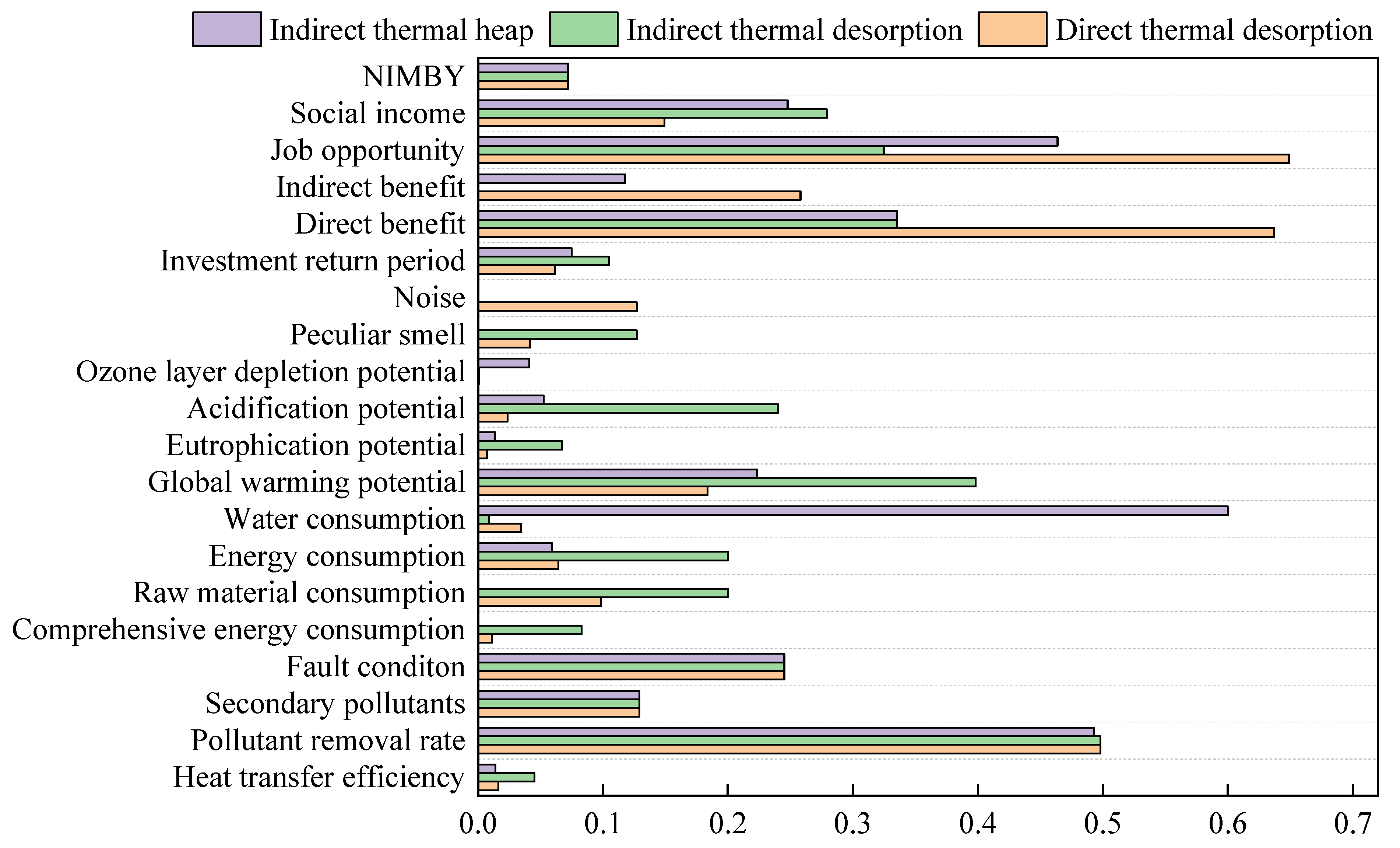

3.2.1. Indicator Performance

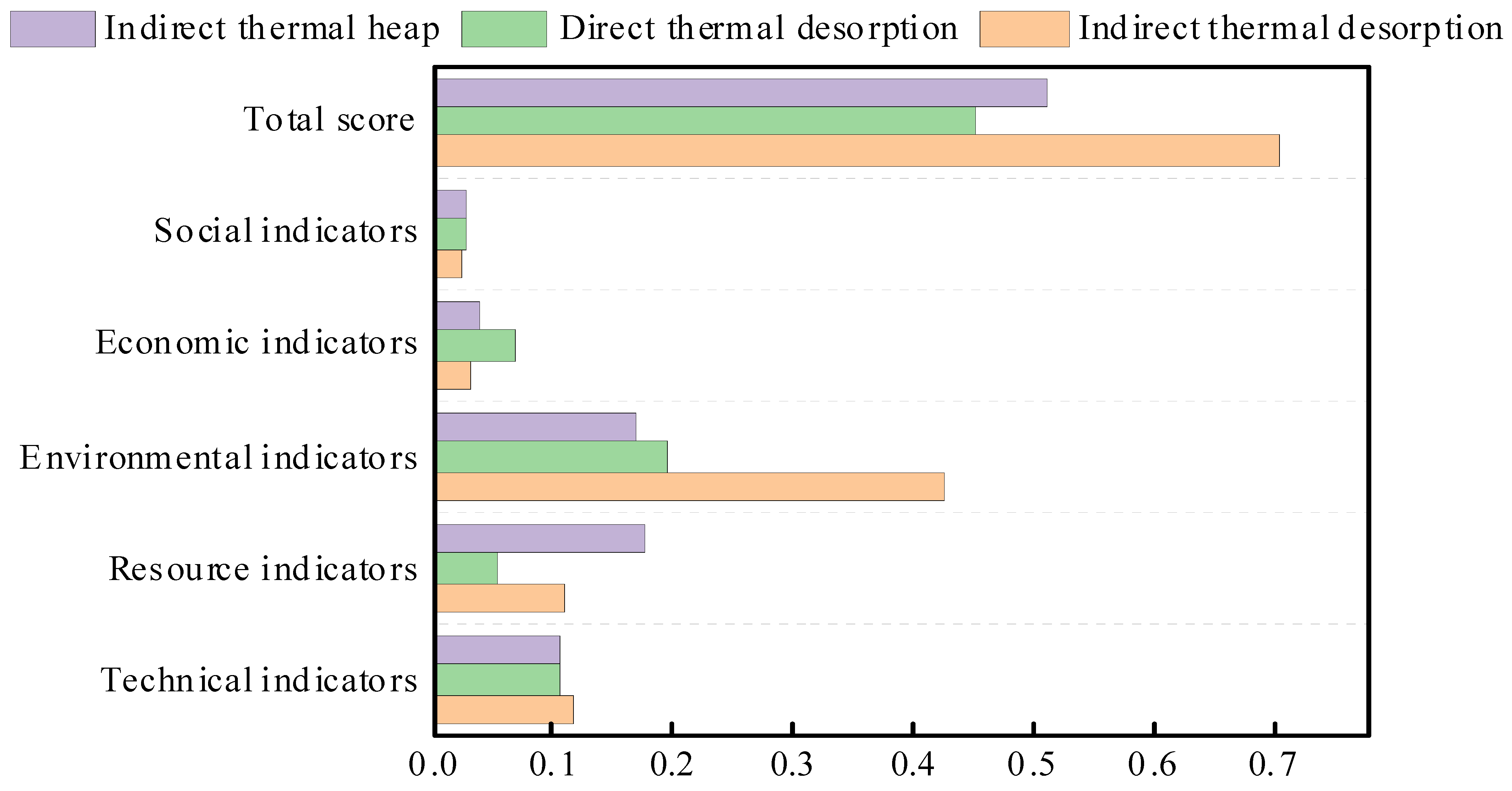

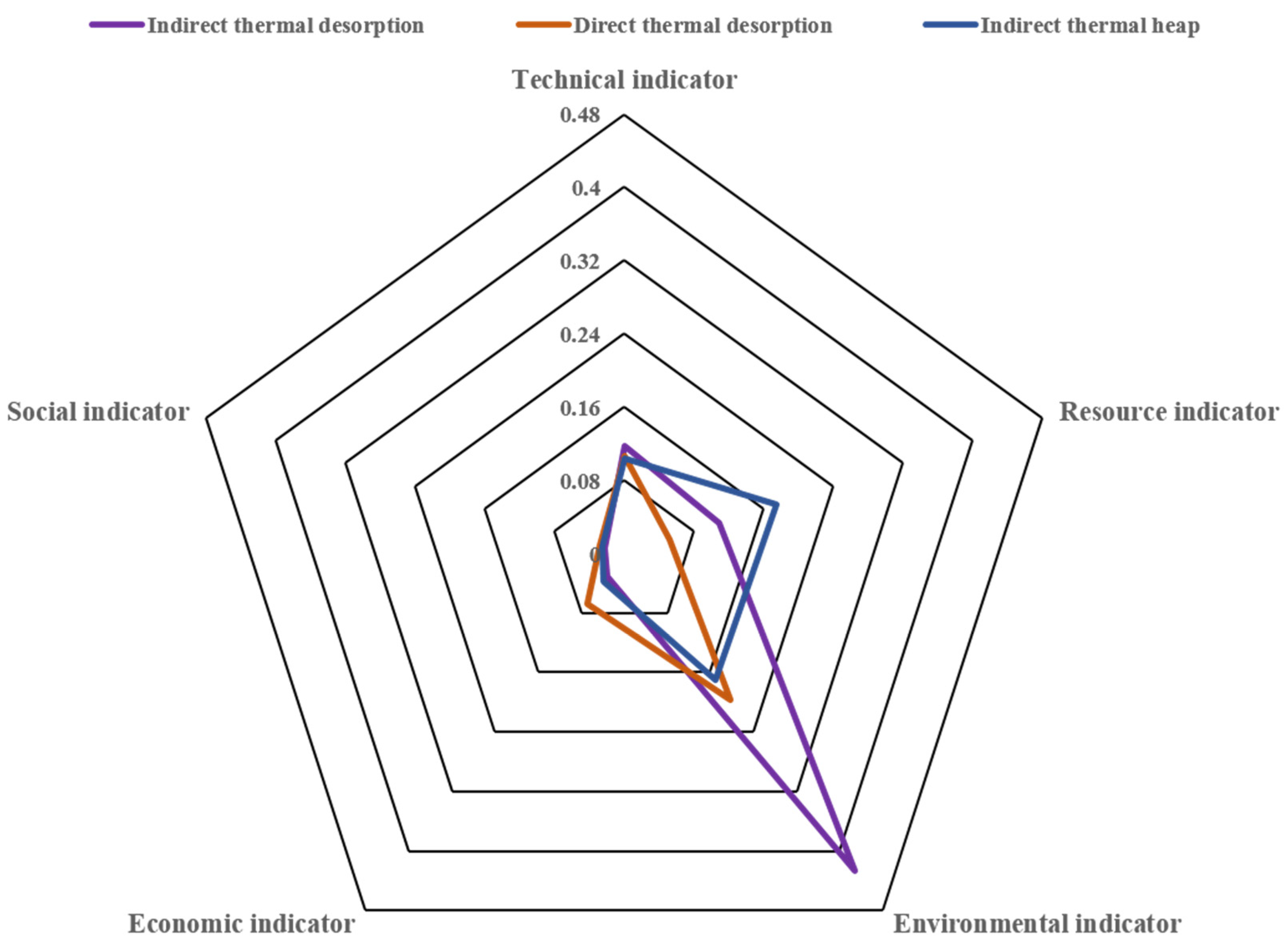

3.2.2. Dimensional Analysis

4. Discussion

4.1. Indicator System

4.2. Methodological Applicability

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Caroline, V.; Antônio, T. Sustainability in Life Cycle Analysis of Nanomaterials Applied in Soil Remediation. In The International Congress on Environmental Geotechnics; Springer: Singapore, 2018; pp. 537–543. [Google Scholar]

- Visentin, C.; da Silva Trentin, A.W.; Braun, A.B.; Thomé, A. Lifecycle assessment of environmental and economic impacts of nano-iron synthesis process for application in contaminated site remediation. J. Clean. Prod. 2019, 231, 307–319. [Google Scholar] [CrossRef]

- Harbottle, M.J.; Al-Tabbaa, A.; Evans, C.W. A comparison of the technical sustainability of in situ stabilisation/solidification with disposal to landfill. J. Hazard. Mater. 2007, 141, 430–440. [Google Scholar] [CrossRef] [PubMed]

- Dan, W. Research Status and Trends of Soil Pollution from 1999 to 2018; IOP Publishing: Bristol, UK, 2021. [Google Scholar]

- Zhao, C.; Dong, Y.; Feng, Y.; Li, Y.; Dong, Y. Thermal desorption for remediation of contaminated soil: A review. Chemosphere 2019, 221, 841–855. [Google Scholar] [CrossRef] [PubMed]

- Ding, D.; Song, X.; Wei, C.; LaChance, J. A review on the sustainability of thermal treatment for contaminated soils. Environ. Pollut. 2019, 253, 449–463. [Google Scholar] [CrossRef] [PubMed]

- Aresta, M.; Dibenedetto, A.; Fragale, C.; Giannoccaro, P.; Pastore, C.; Zammiello, D.; Ferragina, C. Thermal desorption of polychlorobiphenyls from contaminated soils and their hydrodechlorination using Pd-and Rh-supported catalysts. Chemosphere 2008, 70, 1052–1058. [Google Scholar] [CrossRef]

- Zhang, X.; Yao, A. Pilot experiment of oily cuttings thermal desorption and heating characteristics study. J. Pet. Explor. Prod. Technol. 2019, 9, 1263–1270. [Google Scholar] [CrossRef] [Green Version]

- Falciglia, P.P.; Giustra, M.G.; Vagliasindi, F. Low-temperature thermal desorption of diesel polluted soil: Influence of temperature and soil texture on contaminant removal kinetics. J. Hazard. Mater. 2011, 185, 392–400. [Google Scholar] [CrossRef]

- Gharibzadeh, F.; Kalantary, R.R.; Esrafili, A.; Ravanipour, M.; Azari, A. Desorption kinetics and isotherms of phenanthrene from contaminated soil. J. Environ. Health Sci. Eng. 2019, 17, 171–181. [Google Scholar] [CrossRef]

- Biache, C.; Mansuy-Huault, L.; Faure, P.; Munier-Lamy, C.; Leyval, C. Effects of thermal desorption on the composition of two coking plant soils: Impact on solvent extractable organic compounds and metal bioavailability. Environ. Pollut. 2008, 156, 671–677. [Google Scholar] [CrossRef]

- Troxler, W.L.; Cudahy, J.J.; Zink, R.P.; Yezzi, J.J., Jr.; Rosenthal, S.I. Treatment of nonhazardous petroleum-contaminated soils by thermal desorption technologies. Air Waste 1993, 43, 1512–1525. [Google Scholar] [CrossRef]

- Bykova, M.V.; Alekseenko, A.V.; Pashkevich, M.A.; Drebenstedt, C. Thermal desorption treatment of petroleum hydrocarbon-contaminated soils of tundra, taiga, and forest steppe landscapes. Environ. Geochem. Health 2021, 43, 2331–2346. [Google Scholar] [CrossRef] [PubMed]

- U.S. EPA. Superfund Remedy Report; Office of Land and Emergency Management: Washington, DC, USA, 2017. [Google Scholar]

- Luo, Y.; Tu, C. Twenty Years of Research and Development on Soil Pollution and Remediation in China; Springer Nature Press: Singapore, 2018. [Google Scholar]

- Shen, Z.; Chen, Y.; Li, S.; Qun, G.; Lili, G.; Wentao, J.; Peng, L.; Longjie, J.; Jia, L. Application of ex-situ thermal desorption technology and equipment in contaminated site remediation projects in China. Chin. J. Environ. Eng. 2019, 13, 2060–2073. [Google Scholar]

- Morais, S.A.; Delerue-Matos, C. A perspective on LCA application in site remediation services: Critical review of challenges. J. Hazard. Mater. 2010, 175, 12–22. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Visentin, C.; da Silva Trentin, A.W.; Braun, A.B.; Thomé, A. Application of life cycle assessment as a tool for evaluating the sustainability of contaminated sites remediation: A systematic and bibliographic analysis. Sci. Total Environ. 2019, 672, 893–905. [Google Scholar] [CrossRef]

- Owsianiak, M.; Lemming, G.; Hauschild, M.Z.; Bjerg, P.L. Assessing environmental sustainability of remediation technologies in a life cycle perspective is not so easy. ACS Publ. 2013, 47, 1182–1183. [Google Scholar] [CrossRef] [Green Version]

- Amponsah, N.Y.; Wang, J.; Zhao, L. A review of life cycle greenhouse gas (GHG) emissions of commonly used ex-situ soil treatment technologies. J. Clean. Prod. 2018, 186, 514–525. [Google Scholar] [CrossRef]

- Zhang, L. Sustainability Assessment of Solid Waste Recycling Technologies Based on Life Cycle Thinking. Master’s Thesis, University of Chinese Academy of Sciences, Beijing, China, 2021. [Google Scholar]

- Xiong, F.; Pan, J.; Lu, B.; Ding, N.; Yang, J. Integrated technology assessment based on LCA: A case of fine particulate matter control technology in China. J. Clean. Prod. 2020, 268, 122014. [Google Scholar] [CrossRef]

- Wen, Q.; Liu, G.; Wu, W.; Liao, S. Multicriteria comprehensive evaluation framework for industrial park-level distributed energy system considering weights uncertainties. J. Clean. Prod. 2021, 282, 124530. [Google Scholar] [CrossRef]

- Guo, Y. Overview of weight determination methods. Rural. Econ. Sci.—Technol. 2018, 29, 252–253. [Google Scholar]

- Saaty, R.W. The analytic hierarchy process—what it is and how it is used. Math. Model. 1987, 9, 161–176. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, M.; Qureshi, M.N.; Mallick, J.; Hasan, M.; Hussain, M. Decision support model for design of high-performance concrete mixtures using two-phase AHP-TOPSIS approach. Adv. Civ. Eng. 2019, 2019, 1696131. [Google Scholar] [CrossRef] [Green Version]

- Mamun, M.; Howladar, M.F.; Sohail, M.A. Assessment of surface water quality using fuzzy analytic hierarchy process (FAHP): A case study of Piyain River’s sand and gravel quarry mining area in Jaflong, Sylhet, 9. Sustain. Dev. 2019, 9, 100208. [Google Scholar] [CrossRef]

- Wei, Z.L.; Liu, D.J.; Liu, W.Y. Environmental impact and comprehensive benefit evaluation of energy grass based on life cycle assessment. J. Beijing Jiaotong Univ. 2013, 2, 138–143. [Google Scholar]

- Zhang, L.; Lavagnolo, M.C.; Bai, H.; Pivato, A.; Raga, R.; Yue, D. Environmental and economic assessment of leachate concentrate treatment technologies using analytic hierarchy process. Resour. Conserv. Recycl. 2019, 141, 474–480. [Google Scholar] [CrossRef]

- Ding, N.; Liu, J.; Yang, J.; Yang, D. Comparative life cycle assessment of regional electricity supplies in China. Resour. Conserv. Recycl. 2017, 119, 47–59. [Google Scholar] [CrossRef]

- Ding, N.; Liu, N.; Lu, B.; Yang, J. Life cycle greenhouse gas emissions of aluminum based on regional industrial transfer in China. J. Ind. Ecol. 2021, 25, 1657–1672. [Google Scholar] [CrossRef]

- De Percin, P.R. Application of thermal desorption technologies to hazardous waste sites. J. Hazard. Mater. 1995, 40, 203–209. [Google Scholar] [CrossRef]

- Khan, F.I.; Husain, T.; Hejazi, R. An overview and analysis of site remediation technologies. J. Environ. Manag. 2004, 71, 95–122. [Google Scholar] [CrossRef]

- Wang, B.; Wu, A.; Li, X.; Ji, L.; Sun, C.; Shen, Z.; Chen, T.; Chi, Z. Progress in fundamental research on thermal desorption remediation of organic compound-contaminated soil. Waste Dispos. Sustain. Energy 2021, 3, 83–95. [Google Scholar] [CrossRef]

| Dimensions | Indicators | Units | Indicator Definition |

|---|---|---|---|

| Technical indicators | Heat transfer efficiency | % | Heat transfer rate per unit time |

| Pollutant removal rate | % | Removal rate of target pollutants (removal rate to standard) | |

| Secondary pollutants | / | Whether to produce other secondary pollutants (produce exceed the standard, produce but not exceed, not produce) | |

| Fault condition | / | Whether it can operate stably and produce failure situations (no fault, minor fault, and serious fault affect the operation) | |

| Comprehensive energy consumption | MJ/t soil remediation | Energy consumption during operation | |

| Resource indicators | Raw materials consumption | kg/t soil remediation | Whether to consume dehydrating agents, conditioning agents, odor inhibitors, etc. |

| Energy consumption | kWh, m3, L ect./t soil remediation | Consumption of electricity, natural gas, gasoline, etc., from life cycle perspective | |

| Water consumption | m3/t soil remediation | Fresh water consumption | |

| Environmental indicators | Global warming potential | kg CO2-Equiv./t soil remediation | Life cycle assessment methodology indicator |

| Eutrophication potential | kg Phosphate-Equiv./t soil remediation | Life cycle assessment methodology indicator | |

| Acidification potential | kg SO2-Equiv./t soil remediation | Life cycle assessment methodology indicator | |

| Ozone layer depletion potential | kg R11-Equiv./t soil remediation | Life cycle assessment methodology indicator | |

| Peculiar smell | / | Peculiar smell during the implementation of technology | |

| Noise | decibel | Noise impact during implementation of technology | |

| Economic indicators | Investment return period | Year | The number of years from the time the project starts production to the time when the full construction investment is recovered |

| Direct benefit | Yuan (RMB)/t soil remediation | Net profit of remediation of unit contaminated soil | |

| Indirect benefit | Yuan (RMB)/t soil remediation | Disposal costs reduced by remediation of unit contaminated soil | |

| Social indicators | Job opportunity | person/t soil remediation | Jobs created during the operation |

| Social income | % | The income level of practitioners, the income per person per month/local average income | |

| “Not in my back yard” (NIMBY) | / | Residents or local units worry that remediation technology will bring many negative effects on health, environmental quality, and asset value |

| Importance Scale aij | Description | Importance Scale aij | Description |

|---|---|---|---|

| 1 | Two factors have the same importance | 9 | i is more important than j |

| 3 | i is slightly more important than j | 2,4,6,8 | scale median |

| 5 | i is more important than j | reciprocal | j compared to i |

| 7 | i is extremely more important than j |

| Technology | Resources | Environment | Economy | Society | |

|---|---|---|---|---|---|

| Technology | 1 | 1/3 | 1/5 | 3 | 3 |

| Resources | 3 | 1 | 1/3 | 5 | 7 |

| Environment | 5 | 3 | 1 | 7 | 9 |

| Economy | 1/3 | 1/5 | 1/7 | 1 | 5 |

| Society | 1/3 | 1/7 | 1/9 | 1/5 | 1 |

| Weight | 0.118 | 0.265 | 0.513 | 0.071 | 0.033 |

| Heat Transfer Efficiency | Pollutant Removal Rate | Secondary Pollutants | Failure Situation | Comprehensive Energy Consumption | |

|---|---|---|---|---|---|

| Heat transfer efficiency | 1 | 1/7 | 1/3 | 1/5 | 1/3 |

| Pollutant removal rate | 7 | 1 | 5 | 3 | 5 |

| Secondary pollutants | 3 | 1/5 | 1 | 1/3 | 3 |

| Fault condition | 5 | 1/3 | 3 | 1 | 3 |

| Comprehensive energy consumption | 3 | 1/5 | 1/3 | 1/3 | 1 |

| Raw Materials Consumption | Energy Consumption | Water Consumption | |

|---|---|---|---|

| Raw materials consumption | 1 | 1 | 1/3 |

| Energy consumption | 1 | 1 | 1/3 |

| Water consumption | 3 | 3 | 1 |

| Greenhouse Effect | Eutrophication | Acidification Effect | Ozone Layer Destruction | Peculiar Smell | Noise | |

|---|---|---|---|---|---|---|

| Global warming potential | 1 | 5 | 3 | 7 | 3 | 3 |

| Eutrophication potential | 1/5 | 1 | 1/3 | 3 | 1/3 | 1/3 |

| Acidification potential | 1/3 | 3 | 1 | 5 | 3 | 3 |

| Ozone layer depletion potential | 1/7 | 1/3 | 1/5 | 1 | 1/3 | 1/3 |

| Peculiar smell | 1/3 | 3 | 1/3 | 3 | 1 | 1 |

| Noise | 1/3 | 3 | 1/3 | 3 | 1 | 1 |

| Investment Return Period | Direct Benefit | Indirect Income | |

|---|---|---|---|

| Investment return period | 1 | 1/5 | 1/3 |

| Direct benefit | 5 | 1 | 3 |

| Indirect benefit | 3 | 1/3 | 1 |

| Job Opportunity | Social Income | Adjacent Effect | |

|---|---|---|---|

| Job opportunity | 1 | 3 | 7 |

| Social income | 1/3 | 1 | 5 |

| NIMBY | 1/7 | 1/5 | 1 |

| Primary Indicators | Secondary Indicators | Secondary Weight | Primary Weight |

|---|---|---|---|

| Technical indicator | Heat transfer efficiency | 0.045 | 0.118 |

| Pollutant removal rate | 0.498 | ||

| Secondary pollutants | 0.129 | ||

| Fault condition | 0.245 | ||

| Comprehensive energy consumption | 0.083 | ||

| Resource indicator | Raw materials consumption | 0.200 | 0.265 |

| Energy consumption | 0.200 | ||

| Water consumption | 0.600 | ||

| Environmental indicator | Global warming potential | 0.398 | 0.513 |

| Eutrophication potential | 0.067 | ||

| Acidification potential | 0.240 | ||

| Ozone layer depletion potential | 0.041 | ||

| Peculiar smell | 0.127 | ||

| Noise | 0.127 | ||

| Economic indicator | Investment return period | 0.105 | 0.071 |

| Direct benefit | 0.637 | ||

| Indirect benefit | 0.258 | ||

| Social indicator | Job opportunity | 0.649 | 0.033 |

| Social income | 0.279 | ||

| NIMBY | 0.072 |

| Numerical Value n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| RI | 0.00 | 0.00 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 |

| Technical Indicator | Resource Indicator | Environmental Indicator | Economic Indicator | Social Indicator | |

|---|---|---|---|---|---|

| CR | 0.066 | 0 | 0.051 | 0.037 | 0.064 |

| Data Types | Data Sources |

|---|---|

| Energy consumption and material consumption | On-site research |

| Technical specifications, failure situation, and efficiency | Provided by on-site technicians |

| Economic cost input and benefits | On-site research and project reports |

| Social employment and salary | On-site research and project reports |

| NIMBY | Survey and interview |

| Full process environmental impact base data | China localized life cycle assessment database CAS RCEES |

| Dimensions | Indicators | Secondary Indicators | Primary Indicators | ||||

|---|---|---|---|---|---|---|---|

| Direct Thermal Desorption | Indirect Thermal Desorption | Indirect Thermal Heap | Direct Thermal Desorption | Indirect Thermal Desorption | Indirect Thermal Heap | ||

| Technical indicators | Heat transfer efficiency | 0.016 | 0.045 | 0.014 | 0.106 | 0.118 | 0.104 |

| Pollutant removal rate | 0.498 | 0.498 | 0.493 | ||||

| Secondary pollutants | 0.129 | 0.129 | 0.129 | ||||

| Fault condition | 0.245 | 0.245 | 0.245 | ||||

| Comprehensive energy consumption | 0.011 | 0.083 | 0.009 | ||||

| Resource indicators | Raw material consumption | 0.099 | 0.200 | 0.001 | 0.052 | 0.108 | 0.175 |

| Energy consumption | 0.064 | 0.200 | 0.059 | ||||

| Water consumption | 0.035 | 0.009 | 0.600 | ||||

| Environmental indicators | Global warming potential | 0.184 | 0.398 | 0.223 | 0.197 | 0.427 | 0.169 |

| Eutrophication potential | 0.007 | 0.067 | 0.014 | ||||

| Acidification potential | 0.024 | 0.240 | 0.052 | ||||

| Ozone layer depletion potential | 0.0005 | 0.0009 | 0.041 | ||||

| Peculiar smell | 0.042 | 0.127 | 0 | ||||

| Noise | 0.127 | 0 | 0 | ||||

| Economic indicators | Investment return period | 0.062 | 0.105 | 0.075 | 0.068 | 0.031 | 0.037 |

| Direct benefit | 0.637 | 0.335 | 0.335 | ||||

| Indirect benefit | 0.258 | 0.068 | 0.118 | ||||

| Social indicators | Job opportunity | 0.649 | 0.325 | 0.464 | 0.028 | 0.022 | 0.026 |

| Social income | 0.149 | 0.279 | 0.248 | ||||

| NIMBY | 0.072 | 0.072 | 0.072 | ||||

| Total score | 0.452 | 0.707 | 0.511 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; He, L.; Zhang, B.; Yan, Y.; Jiao, W.; Ding, N. A Comprehensive Evaluation Method for Soil Remediation Technology Selection: Case Study of Ex Situ Thermal Desorption. Int. J. Environ. Res. Public Health 2022, 19, 3304. https://doi.org/10.3390/ijerph19063304

Li S, He L, Zhang B, Yan Y, Jiao W, Ding N. A Comprehensive Evaluation Method for Soil Remediation Technology Selection: Case Study of Ex Situ Thermal Desorption. International Journal of Environmental Research and Public Health. 2022; 19(6):3304. https://doi.org/10.3390/ijerph19063304

Chicago/Turabian StyleLi, Shuang, Liao He, Bo Zhang, Yan Yan, Wentao Jiao, and Ning Ding. 2022. "A Comprehensive Evaluation Method for Soil Remediation Technology Selection: Case Study of Ex Situ Thermal Desorption" International Journal of Environmental Research and Public Health 19, no. 6: 3304. https://doi.org/10.3390/ijerph19063304