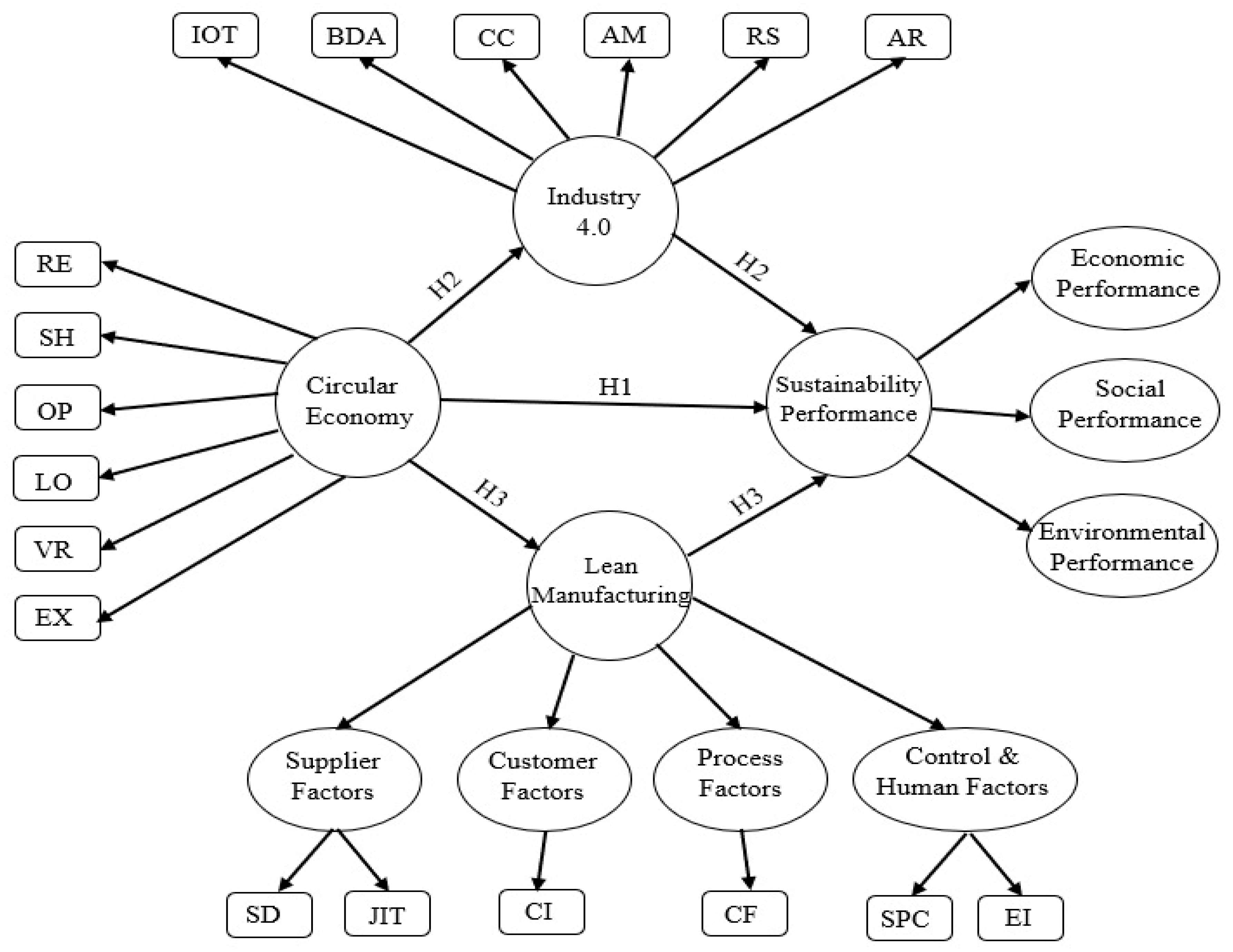

Integrated Impact of Circular Economy, Industry 4.0, and Lean Manufacturing on Sustainability Performance of Manufacturing Firms

Abstract

:1. Introduction

2. Background

2.1. Sustainability Performance

2.2. Circular Economy

2.2.1. Regenerate Criterion

2.2.2. Share Criterion

2.2.3. Optimize Criterion

2.2.4. Loop Criterion

2.2.5. Virtualize Criterion

2.2.6. Exchange Criterion

2.3. Industry 4.0 Technologies

2.3.1. IoT—Internet of Things (IOT)

2.3.2. Big Data Analytics (BDA)

2.3.3. Additive Manufacturing (AM)

2.3.4. Cloud Computing (CC)

2.3.5. Robotic Systems (RS)

2.3.6. Augmented Reality (AR)

2.4. Lean Manufacturing

2.4.1. Supplier Development (SD)

2.4.2. Just in Time (JIT)

2.4.3. Customer Involvement (CI)

2.4.4. Continuous Flow (CF)

2.4.5. Statistical Process Control (SPC)

2.4.6. Employee Involvement (EI)

3. Hypothesis Formulation

4. Materials and Method

4.1. Data Collection

4.2. Normality Test

4.3. Reliability Test

5. Results

5.1. Hypothesis Testing

5.1.1. Circular Economy vs. Sustainability Performance

5.1.2. Mediating Influence of Industry 4.0 and Lean Manufacturing on Circular Economy toward Sustainability Performance

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brundtland, G.; Khalid, M. UN Brundtland Commission Report. Our Common Future; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Elkington, J. Partnerships from Cannibals with Forks: The Triple Bottom Line of 21st-Century Business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Chouinard, Y.; Ellison, J.; Ridgeway, R. The Sustainable Economy. Harv. Bus. Rev. 2011, 89, 52–62. Available online: https://hbr.org/2011/10/the-sustainable-economy (accessed on 15 January 2019).

- Herva, M.; Franco, A.; Carrasco, E.F.; Roca, E. Review of Corporate Environmental Indicators. J. Clean. Prod. 2011, 19, 1687–1699. [Google Scholar] [CrossRef] [Green Version]

- Samuel, V.B.; Agamuthu, P.; Hashim, M.A. Indicators for Assessment of Sustainable Production: A Case Study of the Petrochemical Industry in Malaysia. Ecol. Indic. 2013, 24, 392–402. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Short, S.W.; Rana, P.; Evans, S. A Literature and Practice Review to Develop Sustainable Business Model Archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef] [Green Version]

- Gusmerotti, N.M.; Testa, F.; Corsini, F.; Pretner, G.; Iraldo, F. Drivers and Approaches to the Circular Economy in Manufacturing Firms. J. Clean. Prod. 2019, 230, 314–327. [Google Scholar] [CrossRef]

- Tukker, A. Product Services for a Resource-Efficient and Circular Economy—A Review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; Harvester Wheatsheaf: Hemel Hempstead, UK, 1990. [Google Scholar]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Laubscher, M.; Marinelli, T. Integration of Circular Economy in Business. In Proceedings of the Conference: Going Green—CARE INNOVATION 2014, Vienna, Austria, 17–20 November 2014. [Google Scholar]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef] [Green Version]

- Vermesan, O.; Friess, P.; Guillemin, P.; Gusmeroli, S.; Sundmaeker, H.; Bassi, A.; Jubert, I.S.; Mazura, M.; Harrison, M.; Eisenhauer, M.; et al. Internet of Things Strategic Research Roadmap. In Internet of Things-Global Technological and Societal Trends from Smart Environments and Spaces to Green ICT; River Publishers: Gistrup, Denmark, 2022; pp. 9–52. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Sangwan, K.S.; Bhamu, J.; Mehta, D. Development of Lean Manufacturing Implementation Drivers for Indian Ceramic Industry. Int. J. Product. Perform. Manag. 2014, 63, 569–587. [Google Scholar] [CrossRef]

- Taj, S. Lean Manufacturing Performance in China: Assessment of 65 Manufacturing Plants. J. Manuf. Technol. Manag. 2008, 19, 217–234. [Google Scholar] [CrossRef]

- Todorut, A.V.; Paliu-Popa, L.; Tselentis, V.S.; Cirnu, D. Sustainable Cost Reduction by Lean Management in Metallurgical Processes. Metalurgija 2016, 55, 846–848. [Google Scholar]

- Wong, W.P.; Wong, K.Y. Synergizing an Ecosphere of Lean for Sustainable Operations. J. Clean. Prod. 2014, 85, 51–66. [Google Scholar] [CrossRef]

- Ratnayake, R.M.C.; Chaudry, O. Maintaining Sustainable Performance in Operating Petroleum Assets via a Lean-Six-Sigma Approach: A Case Study from Engineering Support Services. Int. J. Lean Six Sigma 2017, 8, 33–52. [Google Scholar] [CrossRef]

- Camuffo, A.; De Stefano, F.; Paolino, C. Safety Reloaded: Lean Operations and High Involvement Work Practices for Sustainable Workplaces. J. Bus. Ethics 2017, 143, 245–259. [Google Scholar] [CrossRef]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J. Industry 4.0 Implies Lean Manufacturing: Research Activities in Industry 4.0 Function as Enablers for Lean Manufacturing. J. Ind. Eng. Manag. 2016, 9, 811–833. [Google Scholar] [CrossRef] [Green Version]

- Vacchi, M.; Siligardi, C.; Iveth Cedillo-González, E.; Ferrari, A.M.; Settembre-Blundo, D.; Bressanelli, G.; Adrodegari, F.; Cristina, D.; Pigosso, A.; Prida, V. Industry 4.0 and Smart Data as Enablers of the Circular Economy in Manufacturing: Product Re-Engineering with Circular Eco-Design. Sustainability 2021, 13, 10366. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fettermann, D. Implementation of Industry 4.0 and Lean Production in Brazilian Manufacturing Companies. Int. J. Prod. Res. 2017, 56, 2975–2987. [Google Scholar] [CrossRef]

- Wagner, T.; Herrmann, C.; Thiede, S. Industry 4.0 Impacts on Lean Production Systems. Procedia CIRP 2017, 63, 125–131. [Google Scholar] [CrossRef]

- Ghaithan, A.; Khan, M.; Mohammed, A.; Hadidi, L.; Ribeiro, I.; Baptista, A.J.; De Oliveira Moniz, S.; Götze, U. Impact of Industry 4.0 and Lean Manufacturing on the Sustainability Performance of Plastic and Petrochemical Organizations in Saudi Arabia. Sustainability 2021, 13, 11252. [Google Scholar] [CrossRef]

- Gardberg, N.A.; Fombrun, C.J. Corporate Citizenship: Creating Intangible Assets Across Institutional Environments. Acad. Manag. Rev. 2006, 31, 329–346. [Google Scholar] [CrossRef] [Green Version]

- Yong, J.Y.; Yusliza, M.Y.; Ramayah, T.; Chiappetta Jabbour, C.J.; Sehnem, S.; Mani, V. Pathways towards Sustainability in Manufacturing Organizations: Empirical Evidence on the Role of Green Human Resource Management. Bus. Strategy Environ. 2020, 29, 212–228. [Google Scholar] [CrossRef]

- Aggerholm, H.K.; Andersen, S.E.; Thomsen, C. Conceptualising Employer Branding in Sustainable Organisations. Corp. Commun. 2011, 16, 105–123. [Google Scholar] [CrossRef]

- Herrmann, C.; Schmidt, C.; Kurle, D.; Blume, S.; Thiede, S. Sustainability in Manufacturing and Factories of the Future. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 283–292. [Google Scholar] [CrossRef] [Green Version]

- Ellen MacArthur Foundation (EMF). Delivering the Circular Economy e A Toolkit for Policymakers. 2015. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/EllenMacArthurFoundation_PolicymakerToolkit.pdf (accessed on 28 May 2018).

- Schmidt, R.; Möhring, M.; Härting, R.C.; Reichstein, C.; Neumaier, P.; Jozinović, P. Industry 4.0—Potentials for Creating Smart Products: Empirical Research Results. Lect. Notes Bus. Inf. Process. 2015, 208, 16–27. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the Implications of Digitisation and Automation in the Context of Industry 4.0: A Triangulation Approach and Elements of a Research Agenda for the Construction Industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Xu, L.D.; He, W.; Li, S. Internet of Things in Industries: A Survey. IEEE Trans. Industr. Inform. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Huang, X. Intelligent Remote Monitoring and Manufacturing System of Production Line Based on Industrial Internet of Things. Comput. Commun. 2020, 150, 421–428. [Google Scholar] [CrossRef]

- Fosso Wamba, S.; Akter, S.; Edwards, A.; Chopin, G.; Gnanzou, D. How ‘Big Data’ Can Make Big Impact: Findings from a Systematic Review and a Longitudinal Case Study. Int. J. Prod. Econ. 2015, 165, 234–246. [Google Scholar] [CrossRef]

- Kiron, D. Organizational alignment is key to big data success. MIT Sloan Manag. Rev. 2013, 54, 1. [Google Scholar]

- Wamba, S.F.; Gunasekaran, A.; Akter, S.; Ren, S.J.-F.; Dubey, R.; Childe, S.J. Big Data Analytics and Firm Performance: Effects of Dynamic Capabilities. J. Bus. Res. 2017, 70, 356–365. [Google Scholar] [CrossRef] [Green Version]

- Hossain, M.A.; Zhumabekova, A.; Paul, S.C.; Kim, J.R. A Review of 3D Printing in Construction and Its Impact on the Labor Market. Sustainability 2020, 12, 8492. [Google Scholar] [CrossRef]

- Bajic, B.; Cosic, I.; Katalinic, B.; Moraca, S.; Lazarevic, M.; Rikalovic, A. Edge Computing vs. Cloud Computing: Challenges and Opportunities in Industry 4.0. In Proceedings of the 30th DAAAM International Sympos, Zadar, Croatia, 23–26 October 2019; DAAAM International: Vienna, Austria, 2019; pp. 864–871. [Google Scholar] [CrossRef]

- Ribeiro, J.; Lima, R.; Eckhardt, T.; Paiva, S. Robotic Process Automation and Artificial Intelligence in Industry 4.0—A Literature Review. Procedia Comput. Sci. 2021, 181, 51–58. [Google Scholar] [CrossRef]

- Bahrin, M.A.K.; Othman, M.F.; Azli, N.H.N.; Talib, M.F. Industry 4.0: A Review on Industrial Automation and Robotic. J. Teknol. 2016, 78, 137–143. [Google Scholar]

- Park, C.S.; Lee, D.Y.; Kwon, O.S.; Wang, X. A Framework for Proactive Construction Defect Management Using BIM, Augmented Reality and Ontology-Based Data Collection Template. Autom. Constr. 2013, 33, 61–71. [Google Scholar] [CrossRef]

- Pierdicca, R.; Frontoni, E.; Pollini, R.; Trani, M.; Verdini, L. The Use of Augmented Reality Glasses for the Application in Industry 4.0. In Augmented Reality, Virtual Reality, and Computer Graphics, Proceedings of the 4th International Conference, AVR 2017, Ugento, Italy, 12–15 June 2017; Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer International Publishing: Cham, Switzerland, 2017; pp. 389–401. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Lean Manufacturing: Context, Practice Bundles, and Performance; Lean Manufacturing: Context, Practice Bundles, and Performance. J. Oper. Manag. 2003, 21, 129–149. [Google Scholar] [CrossRef] [Green Version]

- Shah, R.; Ward, P.T. Defining and Developing Measures of Lean Production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Martínez-Jurado, P.J.; Moyano-Fuentes, J. Lean Management, Supply Chain Management and Sustainability: A Literature Review. J. Clean. Prod. 2014, 85, 134–150. [Google Scholar] [CrossRef]

- Karim, A.; Arif-Uz-Zaman, K. A Methodology for Effective Implementation of Lean Strategies and Its Performance Evaluation in Manufacturing Organizations. Bus. Process Manag. J. 2013, 19, 169–196. [Google Scholar] [CrossRef]

- Azadegan, A.; Patel, P.C.; Zangoueinezhad, A.; Linderman, K. The effect of environmental complexity and environmental dynamism on lean practices. J. Oper. Manag. 2013, 31, 193–212. [Google Scholar] [CrossRef]

- General Authority for Statistics in Saudi General Authority for Statistics in Saudi Arabia 2017. Available online: http://Stats.Gov.Sa (accessed on 10 June 2020).

- Sideridis, G.; Simos, P.; Papanicolaou, A.; Fletcher, J. Using Structural Equation Modeling to Assess Functional Connectivity in the Brain: Power and Sample Size Considerations. Educ. Psychol. Meas. 2014, 74, 733–758. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leguina, A. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM). Int. J. Res. Method Educ. 2015, 38, 220–221. [Google Scholar] [CrossRef]

- Falk, R.F.; Miller, N.B. A Primer for Soft Modeling; University of Akron Press: Akron, OH, USA, 1992. [Google Scholar]

- Wallace, R.S.O.; Mellor, C.J. Nonresponse Bias in Mail Accounting Surveys: A Pedagogical Note. Br. Account. Rev. 1988, 20, 131–139. [Google Scholar] [CrossRef]

- Hopkins, K.D.; Weeks, D.L. Tests for Normality and Measures of Skewness and Kurtosis: Their Place in Research Reporting. Educ. Psychol. Meas. 1990, 50, 717–729. [Google Scholar] [CrossRef]

- Curran, P.J.; West, S.G.; Finch, J.F. The Robustness of Test Statistics to Nonnormality and Specification Error in Confirmatory Factor Analysis. Psychol. Methods 1996, 1, 16. [Google Scholar] [CrossRef]

- Wolf, E.J.; Harrington, K.M.; Clark, S.L.; Miller, M.W. Sample Size Requirements for Structural Equation Models: An Evaluation of Power, Bias, and Solution Propriety. Educ. Psychol. Meas. 2013, 73, 913–934. [Google Scholar] [CrossRef] [PubMed]

- Cronbach, L.J. Coefficient Alpha and the Internal Structure of Tests. Psychometrika 1951, 16, 297–334. [Google Scholar] [CrossRef] [Green Version]

- Chin, W.W. The partial least squares approach to structural equation modeling. Mod. Methods Bus. Res. 1998, 295, 295–336. [Google Scholar]

- Almatari, A.; Ghaithan, A.; Mohammed, A.; Hadidi, L.A. Exploring the Influence of Project Management Offices in Project-Based Organizations in Saudi Arabia. Int. J. Inf. Technol. Proj. Manag. 2022, 13, 1–19. [Google Scholar] [CrossRef]

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the Circular Economy: A Proposed Research Agenda and Original Roadmap for Sustainable Operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart Factories in Industry 4.0: A Review of the Concept and of Energy Management Approached in Production Based on the Internet of Things Paradigm. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar] [CrossRef]

| Symbol | Description | Skewness | Kurtosis |

|---|---|---|---|

| RE1 | Our organization has established or is planning to establish the usage of circular supplies (e.g., using renewable energy or consuming bio-based materials in the production process) | −0.875 | 0.340 |

| RE2 | Our organization has established or is planning to establish the consumption of recycled raw materials into production process | −0.830 | −0.013 |

| SH1 | Our organization has established or is planning to establish the extension of product life cycle through maintenance and repair | −0.849 | −0.089 |

| SH2 | Our organization has established or is planning to establish shared use, access, or ownership between consumers and/or businesses | −0.901 | 0.266 |

| SH3 | Our organization has established or is planning to establish creating value from waste and find new ways to reuse within the same firm or in a different industry/application | −0.684 | −0.302 |

| OP1 | Our organization has established or is planning to establish production upon demand and secured orders | −0.619 | −0.524 |

| OP2 | Our organization has established or is planning to establish waste elimination in supply chains and production processes | −0.767 | −0.316 |

| OP3 | Our organization has established or is planning to establish the collection, reuse, refurbishing, and resale of used products | −1.186 | 0.915 |

| LO | Our organization has established or is planning to establish restoring a product or its components to a “brand new” quality | −1.043 | 1.060 |

| VR | Our organization has established or is planning to establish shifting from physical to virtual activities, services, or processes | −0.745 | 0.411 |

| EX | Our organization has established or is planning to establish replacing old materials with advanced materials or adopting new production technologies | −0.762 | 0.026 |

| CC | Our organization has established or is planning to establish cloud computing | −0.648 | −0.197 |

| BDA | Our organization has established or is planning to establish big data analytics (the process of analyzing large data to uncover hidden patterns and correlations) | −0.777 | 0.376 |

| IOT | Our organization has established or is planning to establish internet of things | −0.667 | −0.056 |

| AM | Our organization has established or is planning to establish additive manufacturing (technology which enables the manufacturing of the most complex components through digital models and 3D printing) | −0.860 | 0.275 |

| RS | Our organization has established or is planning to establish robotic systems | −0.562 | −0.358 |

| AR | Our organization has established or is planning to establish augmented reality (e.g., append virtual information to the real world to simulate consumer experience) | −0.513 | −0.426 |

| SD | Our organization established strategic alliances with suppliers and is committed to the development to gain mutual success | −0.808 | 0.428 |

| JIT | Suppliers emphasized on just in time delivery to reduce delays in production flow and minimize inventory levels | −0.966 | 0.898 |

| CI | Our organization established customer involvement channels for continuous improvement objectives | −1.069 | 1.169 |

| CF | Our organization established mechanisms that enable and ease the continuous flow of products | −0.630 | −0.393 |

| SPC | Statistical process control is utilized on the production floor to measure process variability | −0.721 | 0.261 |

| EI | Our shop floor personnel contribute significantly to problem-solving activities and drive suggestion schemes | −0.784 | 0.325 |

| EP1 | Our organization reduced costs of production | −0.810 | 0.340 |

| EP2 | Our organization improved profits | −0.810 | 0.585 |

| EP3 | Our organization reduced product development costs | −0.690 | 0.402 |

| EP4 | Our organization decreased energy consumption costs | −0.622 | −0.044 |

| EP5 | Our organization reduced rejection and rework costs | −0.951 | 0.930 |

| SP1 | Our organization improved working environment and people’s morale | −0.685 | 0.405 |

| SP2 | Our organization prioritize the health and safety of employees | −0.619 | 0.110 |

| SP3 | Our organization improved labor relations | −0.478 | −0.240 |

| EVP1 | Our organization established the reduction of solid, liquid, and energy wastes | −0.751 | 0.135 |

| EVP2 | Our organization established the reduction of gas emissions | −0.716 | 0.001 |

| EVP3 | Our organization established the reduction of hazardous material consumption | −0.622 | −0.255 |

| Factor | AVE | CR | α | Factor | AVE | CR | α |

|---|---|---|---|---|---|---|---|

| RE | 0.73 | 0.92 | 0.88 | AR | 0.77 | 0.91 | 0.7 |

| SH | 0.72 | 0.93 | 0.9 | SD | 0.68 | 0.93 | 0.64 |

| OP | 0.75 | 0.9 | 0.83 | JIT | 0.65 | 0.92 | 0.64 |

| LO | 0.74 | 0.94 | 0.93 | CI | 0.76 | 0.9 | 0.75 |

| VR | 0.83 | 0.91 | 0.8 | CF | 0.77 | 0.91 | 0.79 |

| EX | 0.73 | 0.91 | 0.87 | SPC | 0.72 | 0.89 | 0.73 |

| CC | 0.62 | 0.91 | 0.88 | EI | 0.71 | 0.92 | 0.72 |

| BDA | 0.8 | 0.89 | 0.74 | EP | 0.65 | 0.9 | 0.78 |

| IOT | 0.72 | 0.91 | 0.85 | SP | 0.68 | 0.91 | 0.69 |

| AM | 0.67 | 0.86 | 0.66 | EVP | 0.76 | 0.91 | 0.61 |

| RS | 0.63 | 0.92 | 0.7 |

| Hypothesis | Std. Beta (β) | T-Value | p-Value | Result |

|---|---|---|---|---|

| H1 | 0.674 | 12.854 | 0.000 | Validated |

| H2 | 0.149 | 3.342 | 0.001 | Full mediation exists |

| H3 | 0.333 | 5.718 | 0.000 | Full mediation exists |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghaithan, A.M.; Alshammakhi, Y.; Mohammed, A.; Mazher, K.M. Integrated Impact of Circular Economy, Industry 4.0, and Lean Manufacturing on Sustainability Performance of Manufacturing Firms. Int. J. Environ. Res. Public Health 2023, 20, 5119. https://doi.org/10.3390/ijerph20065119

Ghaithan AM, Alshammakhi Y, Mohammed A, Mazher KM. Integrated Impact of Circular Economy, Industry 4.0, and Lean Manufacturing on Sustainability Performance of Manufacturing Firms. International Journal of Environmental Research and Public Health. 2023; 20(6):5119. https://doi.org/10.3390/ijerph20065119

Chicago/Turabian StyleGhaithan, Ahmed M., Yasser Alshammakhi, Awsan Mohammed, and Khwaja Mateen Mazher. 2023. "Integrated Impact of Circular Economy, Industry 4.0, and Lean Manufacturing on Sustainability Performance of Manufacturing Firms" International Journal of Environmental Research and Public Health 20, no. 6: 5119. https://doi.org/10.3390/ijerph20065119