Study on the Tribological Characteristics of Australian Native First Generation and Second Generation Biodiesel Fuel

Abstract

:1. Introduction

2. Description of Beauty Leaf and Macadamia Biodiesel Feedstocks

3. Materials and Methods

3.1. Materials

3.2. Biodiesel Production

3.3. Characterization of Crude Oils and Biodiesels

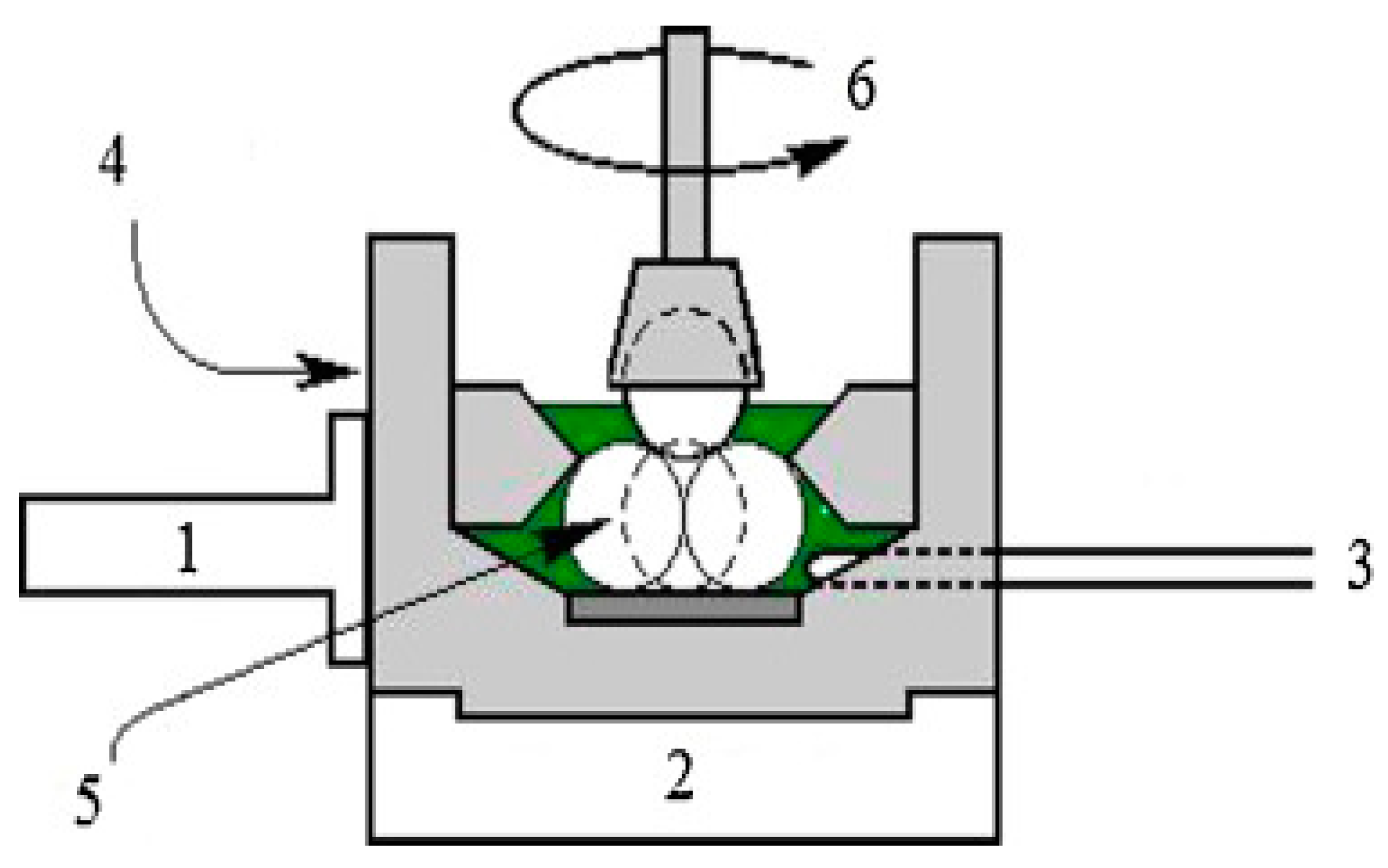

3.4. Experimental Setup and Test Procedure

3.5. Coefficient of Friction

3.6. Flash Temperature Parameter (FTP)

3.7. Wear Evaluation

3.8. SEM/EDX Analysis

3.9. Error Analysis

4. Results and Discussion

4.1. Friction Characteristics of Biodiesel Fuels

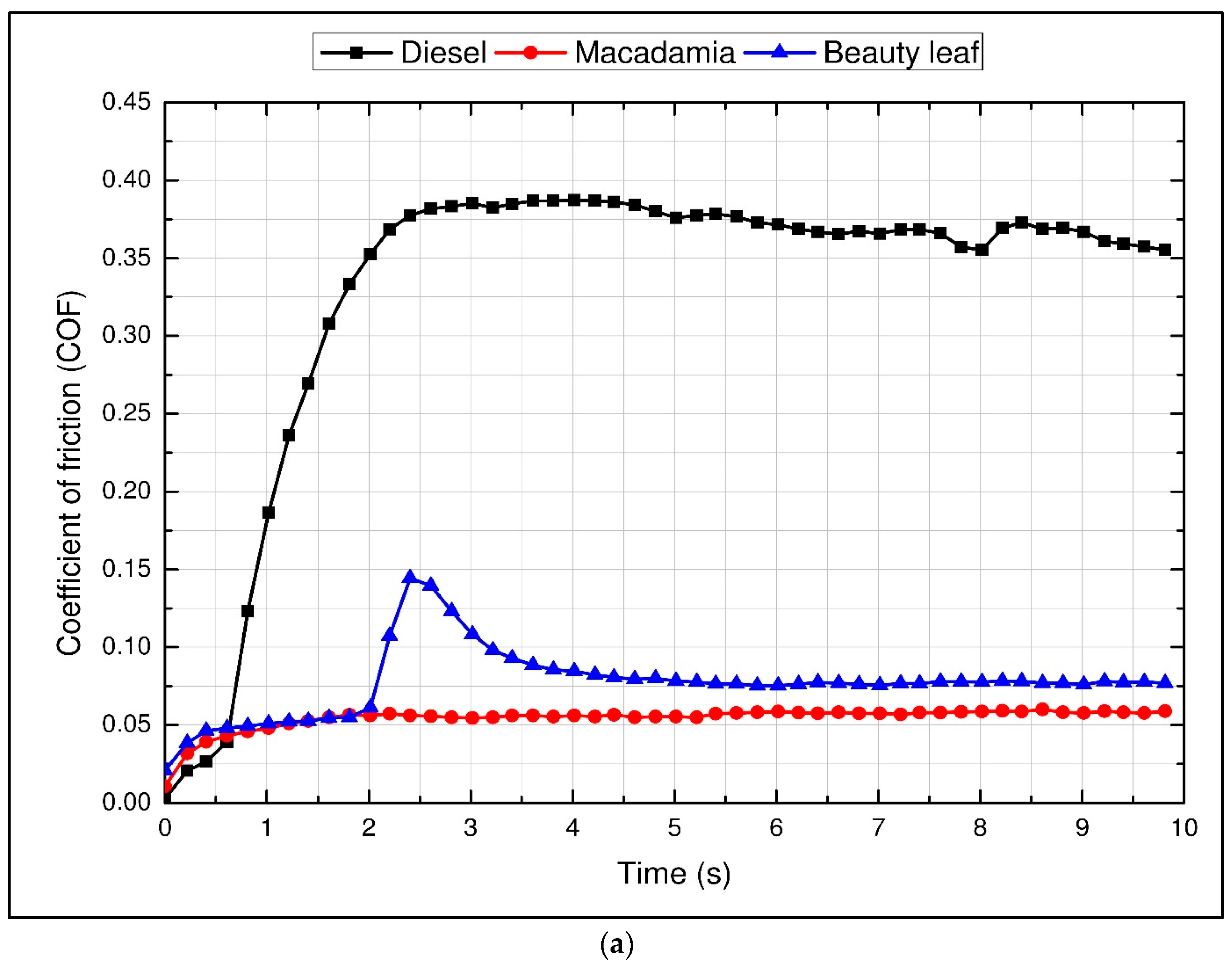

4.1.1. Friction Characteristics at Different Load and Run-In Periods (Unsteady State Condition)

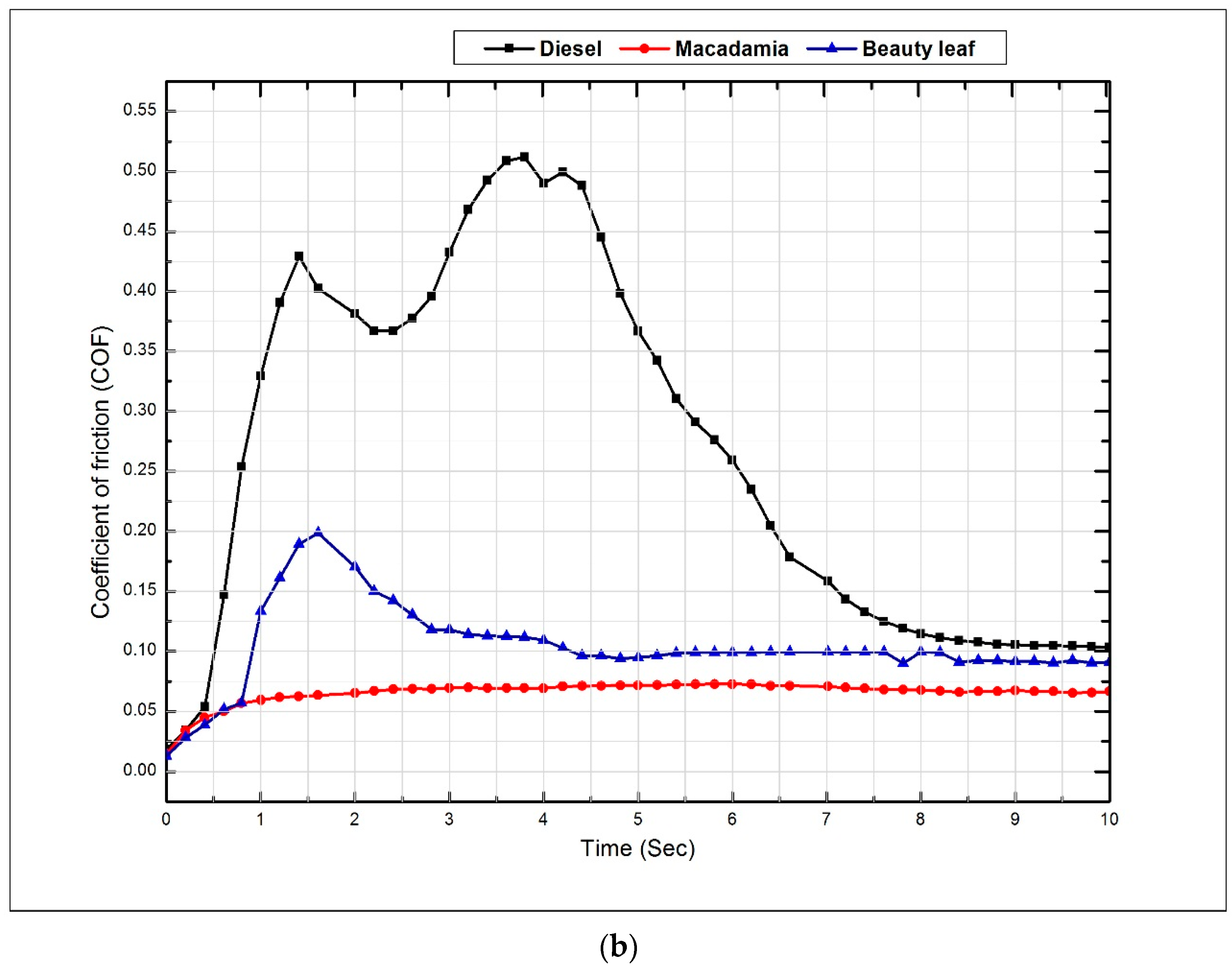

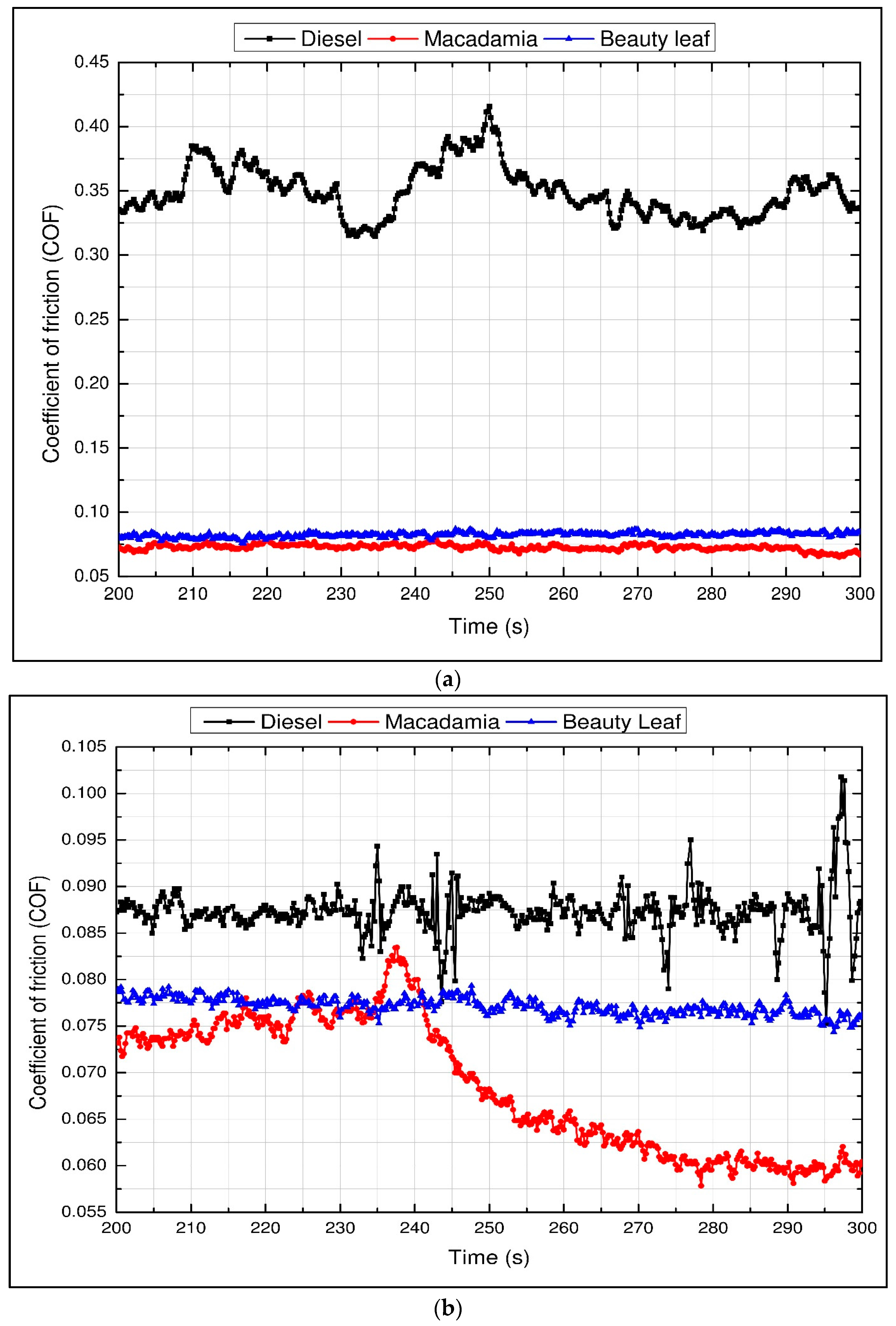

4.1.2. Friction Characteristics at Different Loads and Steady State Conditions

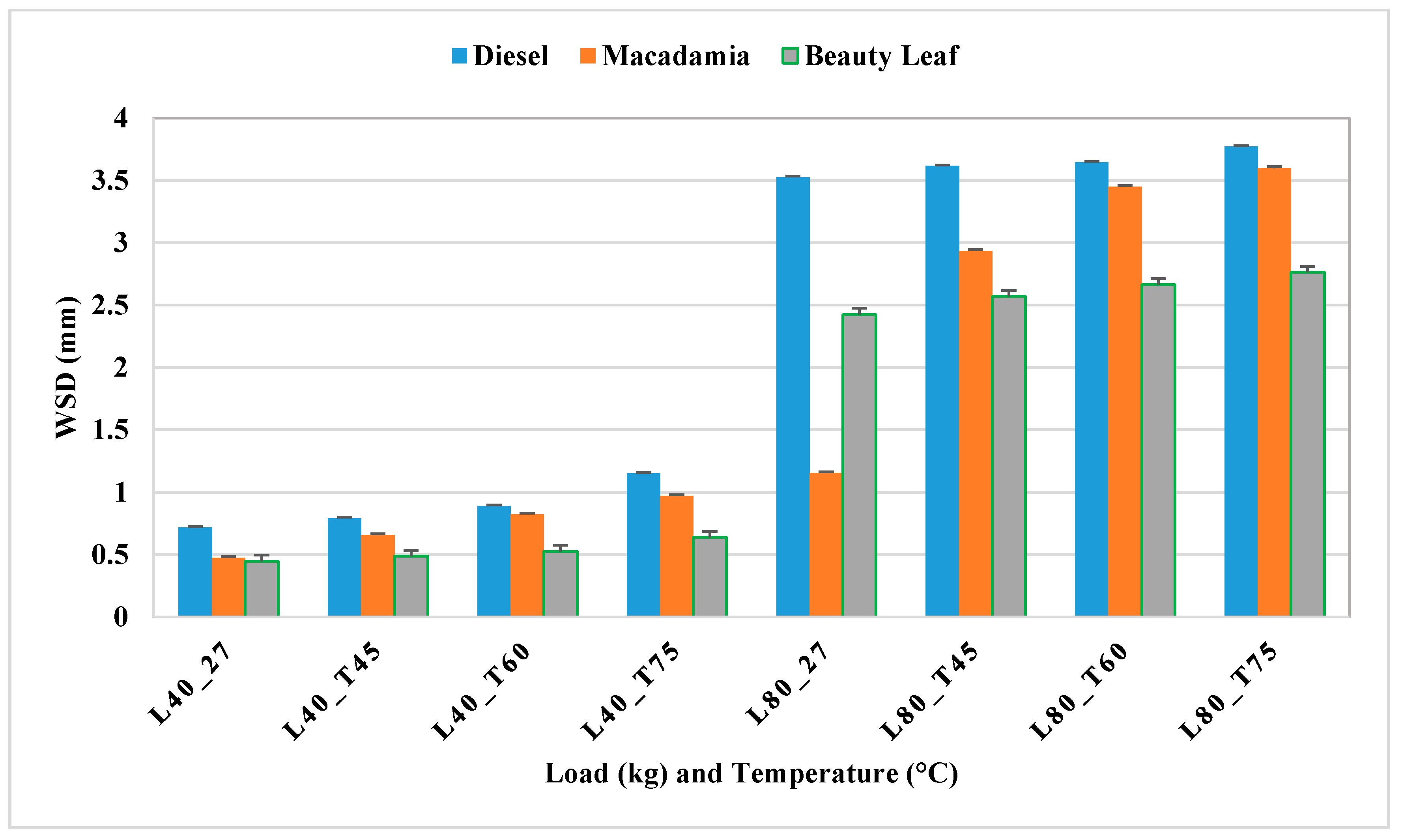

4.2. Wear Characteristics of Biodiesel Fuels at Different Loads and Temperatures

4.3. Flash Parameter Temperature at Different Loads and Temperatures

4.4. Analysis of SEM/EDX

4.4.1. Analysis of Filtering Metal Debris by SEM/EDX

4.4.2. Analysis of Worn Surfaces by SEM/EDX

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hassan, N.M.S.; Rasul, M.G.; Harch, C.A. Modelling and experimental investigation of engine performance and emissions fuelled with biodiesel produced from Australian beauty leaf tree. Fuel 2015, 150, 625–635. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Hazrat, M.A.; Liaquat, A.M.; Shahabuddin, M.; Varman, M. Prospects of biodiesel from jatropha in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 5007–5020. [Google Scholar] [CrossRef]

- Mofijur, M.; Rasul, M.G.; Hassan, N.M.S.; Masjuki, H.H.; Kalam, M.A.; Mahmudul, H.M. Assessment of physical, chemical and tribological properties of different biodiesel fuel. In Clean Energy for Sustainable Development; Rasul, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 1, pp. 441–461. [Google Scholar]

- Mofijur, M.; Rasul, M.G.; Hyde, J.; Azad, A.K.; Mamat, R.; Bhuiya, M.M.K. Role of biofuel and their binary (diesel–biodiesel) and ternary (ethanol–biodiesel–diesel) blends on internal combustion engines emission reduction. Renew. Sustain. Energy Rev. 2016, 53, 265–278. [Google Scholar] [CrossRef]

- Harch, C.A.; Rasul, M.G.; Hassan, N.M.S.; Bhuiya, M.M.K. Modelling of engine performance fuelled with second generation biodiesel. Procedia Eng. 2014, 90, 459–465. [Google Scholar] [CrossRef]

- Dai, Y.-M.; Wu, J.-S.; Chen, C.-C.; Chen, K.-T. Evaluating the optimum operating parameters on transesterification reaction for biodiesel production over a LiAlO2 catalyst. Chem. Eng. J. 2015, 280, 370–376. [Google Scholar] [CrossRef]

- Dai, Y.-M.; Chen, K.-T.; Chen, C.-C. Study of the microwave lipid extraction from microalgae for biodiesel production. Chem. Eng. J. 2014, 250, 267–273. [Google Scholar] [CrossRef]

- Rashed, M.M.; Kalam, M.A.; Masjuki, H.H.; Mofijur, M.; Rasul, M.G.; Zulkifli, N.W.M. Performance and emission characteristics of a diesel engine fueled with palm, jatropha, and moringa oil methyl ester. Ind. Crops Prod. 2016, 79, 70–76. [Google Scholar] [CrossRef]

- Azad, A.K.; Rasul, M.G.; Khan, M.M.K.; Sharma, S.C.; Mofijur, M.; Bhuiya, M.M.K. Prospects, feedstocks and challenges of biodiesel production from beauty leaf oil and castor oil: A nonedible oil sources in Australia. Renew. Sustain. Energy Rev. 2016, 61, 302–318. [Google Scholar] [CrossRef]

- Ali, O.M.; Mamat, R.; Abdullah, N.R.; Abdullah, A.A. Analysis of blended fuel properties and engine performance with palm biodiesel–diesel blended fuel. Renew. Energy 2016, 86, 59–67. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Ashrafur Rahman, S.M.; Mahmudul, H.M. Energy scenario and biofuel policies and targets in ASEAN countries. Renew. Sustain. Energy Rev. 2015, 46, 51–61. [Google Scholar] [CrossRef]

- Bhuiya, M.M.K.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Azad, A.K.; Hazrat, M.A. Prospects of 2nd generation biodiesel as a sustainable fuel—Part 2: Properties, performance and emission characteristics. Renew. Sustain. Energy Rev. 2016, 55, 1129–1146. [Google Scholar] [CrossRef]

- Sarin, A.; Arora, R.; Singh, N.P.; Sarin, R.; Malhotra, R.K.; Sharma, M.; Khan, A.A. Synergistic effect of metal deactivator and antioxidant on oxidation stability of metal contaminated Jatropha biodiesel. Energy 2010, 35, 2333–2337. [Google Scholar] [CrossRef]

- Fazal, M.A.; Haseeb, A.S.M.A.; Masjuki, H.H. Biodiesel feasibility study: An evaluation of material compatibility; performance; emission and engine durability. Renew. Sustain. Energy Rev. 2011, 15, 1314–1324. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, M.P. Stability of biodiesel and its blends: A review. Renew. Sustain. Energy Rev. 2010, 14, 667–678. [Google Scholar] [CrossRef]

- Haseeb, A.S.M.A.; Sia, S.Y.; Fazal, M.A.; Masjuki, H.H. Effect of temperature on tribological properties of palm biodiesel. Energy 2010, 35, 1460–1464. [Google Scholar] [CrossRef]

- Muñoz, M.; Moreno, F.; Monné, C.; Morea, J.; Terradillos, J. Biodiesel improves lubricity of new low sulphur diesel fuels. Renew. Energy 2011, 36, 2918–2924. [Google Scholar] [CrossRef]

- Ozioko, F.U. Synthesis and study of properties of biolubricant based on Moringa oleifera oil for industrial application. AU J. Technol. 2009, 17, 137–142. [Google Scholar]

- Sharma, B.K.; Rashid, U.; Anwar, F.; Erhan, S.Z. Lubricant properties of Moringa oil using thermal and tribological techniques. J. Therm. Anal. Calorim. 2009, 96, 999–1008. [Google Scholar] [CrossRef]

- Fazal, M.A.; Haseeb, A.S.M.A.; Masjuki, H.H. Investigation of friction and wear characteristics of palm biodiesel. Energy Convers. Manag. 2013, 67, 251–256. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Masum, B.M.; Arslan, A.; Gulzar, M. Friction and wear characteristics of Calophyllum inophyllum biodiesel. Ind. Crops Prod. 2015, 76, 188–197. [Google Scholar] [CrossRef]

- Wain, K.S.; Perez, J.M.; Chapman, E.; Boehman, A.L. Alternative and low sulfur fuel options: Boundary lubrication performance and potential problems. Tribol. Int. 2005, 38, 313–319. [Google Scholar] [CrossRef]

- Kumar, N.; Chauhan, S. Analysis of tribological performance of biodiesel. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 797–807. [Google Scholar] [CrossRef]

- Maru, M.M.; Trommer, R.M.; Cavalcanti, K.F.; Figueiredo, E.S.; Silva, R.F.; Achete, C.A. The stribeck curve as a suitable characterization method of the lubricity of biodiesel and diesel blends. Energy 2014, 69, 673–681. [Google Scholar] [CrossRef]

- Sulek, M.W.; Kulczycki, A.; Malysa, A. Assessment of lubricity of compositions of fuel oil with biocomponents derived from rape-seed. Wear 2010, 268, 104–108. [Google Scholar] [CrossRef]

- Sanjid, A.; Masjuki, H.H.; Kalam, M.A.; Rahman, S.M.A.; Abedin, M.J.; Palash, S.M. Impact of palm, mustard, waste cooking oil and Calophyllum inophyllum biofuels on performance and emission of CI engine. Renew. Sustain. Energy Rev. 2013, 27, 664–682. [Google Scholar] [CrossRef]

- Ashwath, N. Evaluating Biodiesel Potential of Australian Native and Naturalised Plant Species; Rural Industries Research and Development Corporation: Kingston, Australia, 2010. [Google Scholar]

- The Bopple Nut. Mount Bauple & District Historical Society Inc. Available online: http://www.Bauplemuseum.Com/bopple%20nut%20pub.pdf (accessed on 30 December 2015).

- Macadamia. Australian Plant Name Index (APNI), Integrated Botanical Information System (IBIS) Database (Listing by % Wildcard Matching of all Taxa Relevant to Australia). Available online: https://biodiversity.org.au/nsl/services/apni?name=Macadamia%25&max=100&display=apni&search=true (accessed on 30 December 2015).

- Knothe, G. Biodiesel derived from a model oil enriched in palmitoleic acid, macadamia nut oil. Energy Fuels 2010, 24, 2098–2103. [Google Scholar] [CrossRef]

- Rahman, M.; Rasul, M.; Hassan, N.; Hyde, J. Prospects of biodiesel production from macadamia oil as an alternative fuel for diesel engines. Energies 2016, 9, 403. [Google Scholar] [CrossRef]

- Lane, T.B. The flash temperature parameter: A criterion for assessing EP performance in the four-ball machine. J. Inst. Pet. 1957, 43, 181–188. [Google Scholar]

- Mosarof, M.H.; Kalam, M.A.; Masjuki, H.H.; Alabdulkarem, A.; Habibullah, M.; Arslan, A.; Monirul, I.M. Assessment of friction and wear characteristics of Calophyllum inophyllum and palm biodiesel. Ind. Crops Prod. 2016, 83, 470–483. [Google Scholar] [CrossRef]

- Konishi, T.; Klaus, E.; Duda, J. Wear characteristics of aluminum-silicon alloy under lubricated sliding conditions. Tribol. Trans. 1996, 39, 811–818. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Gulzar, M.; Arslan, A.; Zahid, R. Tribological characteristics of Calophyllum inophyllum–based TMP (trimethylolpropane) ester as energy-saving and biodegradable lubricant. Tribol. Trans. 2015, 58, 1002–1011. [Google Scholar] [CrossRef]

- Xu, Z.; Shi, X.; Zhai, W.; Yao, J.; Song, S.; Zhang, Q. Preparation and tribological properties of TiAl matrix composites reinforced by multilayer graphene. Carbon 2014, 67, 168–177. [Google Scholar] [CrossRef]

- Adebisi, A.A.; Maleque, M.A. Modelling aspect of corrosive wear under biodiesel. In Proceedings of the Regional Tribology Conference, Langkawi Island, Malaysia, 22–24 November 2011; Volume 6, pp. 161–168.

- Martín-Alfonso, J.E.; Valencia, C. Tribological, rheological, and microstructural characterization of oleogels based on EVA copolymer and vegetables oils for lubricant applications. Tribol. Int. 2015, 90, 426–434. [Google Scholar] [CrossRef]

- Rani, S.; Joy, M.L.; Nair, K.P. Evaluation of physiochemical and tribological properties of rice bran oil—Biodegradable and potential base stoke for industrial lubricants. Ind. Crops Prod. 2015, 65, 328–333. [Google Scholar] [CrossRef]

- Asadauskas, S.; Perez, J.M.; Duda, J.L. Oxidative stability and antiwear properties of high oleic vegetable oils. Lubr. Eng. 1996, 52, 877–882. [Google Scholar]

- Syahrullail, S.; Wira, J.Y.; Wan Nik, W.; Fawwaz, W. Friction characteristics of RBD palm olein using four-ball tribotester. Appl. Mech. Mater. 2013, 315, 936–940. [Google Scholar] [CrossRef]

- Jayadas, N.H.; Prabhakaran Nair, K.; Ajithkumar, G. Tribological evaluation of coconut oil as an environment-friendly lubricant. Tribol. Int. 2007, 40, 350–354. [Google Scholar] [CrossRef]

- Hu, J.; Du, Z.; Li, C.; Min, E. Study on the lubrication properties of biodiesel as fuel lubricity enhancers. Fuel 2005, 84, 1601–1606. [Google Scholar] [CrossRef]

- Geller, D.P.; Goodrum, J.W. Effects of specific fatty acid methyl esters on diesel fuel lubricity. Fuel 2004, 83, 2351–2356. [Google Scholar] [CrossRef]

- Mosarof, M.H.; Kalam, M.A.; Masjuki, H.H.; Alabdulkarem, A.; Ashraful, A.M.; Arslan, A.; Rashedul, H.K.; Monirul, I.M. Optimization of performance, emission, friction and wear characteristics of palm and Calophyllum inophyllum biodiesel blends. Energy Convers. Manag. 2016, 118, 119–134. [Google Scholar] [CrossRef]

- Sperring, T.; Nowell, T. Syclops—A qualitative debris classification system developed for RAF early failure detection centres. Tribol. Int. 2005, 38, 898–903. [Google Scholar] [CrossRef]

| Property | Equipment | Standard Method | Accuracy |

|---|---|---|---|

| Kinematic Viscosity | NVB Classic (Norma lab, France) | ASTM D445 | ±0.01 mm2/s |

| Density | DM40 LiquiPhysics™ Density Meter (Mettler Toledo, Switzerland) | ASTM D127 | ±0.1 kg/m3 |

| Flash Point | NPM 440 Pensky_Martens Flash Point tester (Norma Lab, France) | ASTM D93 | ±0.1 °C |

| Cloud and Pour Point | NTE 450 Cloud and Pour Point Tester (Norma Lab, France) | ASTM D2500 | ±0.1 °C |

| Acid Number | Automation Titration Rondo 20 (Mettler Toledo, Switzerland) | ASTM D664 | 0.001 mg KOH/g |

| Cold Filter Plugging Point (CFPP) | NTE 450 CFPP Tester (Norma Lab, France) | ASTM D6371 | ±0.1 °C |

| Properties | Unit | Method | Macadamia Biodiesel | Beauty Leaf Biodiesel | Australian Diesel |

|---|---|---|---|---|---|

| Kinematic Viscosity at 40 °C | mm2/s | ASTM D445 | 4.46 | 4.20 | 3.23 |

| Density at 15 °C | kg/m3 | ASTM D127 | 859.2 | 870 | 827.2 |

| Higher Heating Value | MJ/kg | ASTM 5468 | 39.90 | 39.55 | 45.30 |

| Oxidation Stability | h | - | 3.35 | 6.82 | - |

| Acid Value | mgKOH/g | ASTM D664 | 0.07 | 0.42 | - |

| Flash Point | °C | ASTM D93 | 178.5 | 106 | 68.5 |

| Pour Point | °C | ASTM D2500 | 0 | 12 | 0 |

| Cloud Point | °C | ASTM D2500 | 8 | 11 | 8 |

| CFPP | °C | ASTM D6371 | 8 | - | 5 |

| Cetane Number | - | - | 56 | 54 | 48 |

| Iodine Number | - | - | 77.85 | 85.61 | - |

| Saponification Value | - | - | 199 | 201 | - |

| Long Chain Saturated Factor | - | - | 7.24 | 11.64 | - |

| Degree of Unsaturation | - | - | 84.50 | 94.50 | - |

| Specification | Unit | Descriptions | Accuracy |

|---|---|---|---|

| Model | – | TR 30H | – |

| Speed | RPM | 300–3000 | ±1 |

| Maximum axial load | N | 10,000 | ±0.5 |

| Temperature | °C | Ambient to 100 | ±0.5 |

| Scar range | Micron | 100–4000 | ±0.5 |

| Test ball (diameter) | mm | 12.7 | – |

| Drive motor | kW | 1.5 | – |

| Power | V/Hz/VA | 380/50/3/2000 | – |

| No. | Parameters | Descriptions |

|---|---|---|

| 1. | Applied Load (kg) | 40, 80 |

| 2. | Rotation (RPM) | 1800 |

| 3. | Fuel Temperature (°C) | 27, 45, 60, 75 |

| 4. | Test Duration (s) | 300 |

| 5. | Test Ball Materials | Carbon–chromium steel (SKF) |

| 6. | Composition | 10.2% C; 0.45% Si; 0.12% P; 0.07% S; 1.46% Cr; 0.42% Mn; 0.06% Ni; 2.15% Zn and rest 85.06% Fe |

| 7. | Diameter (mm) | 12.7 |

| 8. | Hardness (HRc) | 62 |

| 9. | Surface Roughness (μm) | 0.1 Centre Line Average in Micrometers (C.L.A) |

| Condition | 1st Data | 2nd Data | 3rd Data | max | min | Accuracy | Average | Error | |

|---|---|---|---|---|---|---|---|---|---|

| +1 | −1 | ||||||||

| L40_27 | 127.58 | 113.59 | 131.10 | 131.10 | 113.59 | 132.10 | 112.59 | 122.34 | ±0.07 |

| L40_T55 | 132.92 | 110.83 | 129.32 | 132.92 | 110.83 | 133.92 | 109.83 | 121.87 | ±0.09 |

| L40_T75 | 69.80 | 73.64 | 82.50 | 82.50 | 69.80 | 83.50 | 68.80 | 76.15 | ±0.08 |

| L80_27 | 21.79 | 25.10 | 22.79 | 25.10 | 21.79 | 26.10 | 20.79 | 23.45 | ±0.07 |

| L80_T55 | 19.70 | 20.49 | 20.72 | 20.72 | 19.70 | 21.72 | 18.70 | 20.21 | ±0.03 |

| L80_T75 | 17.23 | 20.23 | 20.77 | 20.77 | 17.23 | 21.77 | 16.23 | 19.00 | ±0.09 |

| Fuel | Load 40 kg | Load 80 kg | ||||||

|---|---|---|---|---|---|---|---|---|

| 27 °C | 45 °C | 60 °C | 75 °C | 27 °C | 45 °C | 60 °C | 75 °C | |

| Diesel | 63.60 | 55.39 | 47.07 | 32.87 | 13.71 | 13.23 | 13.08 | 12.48 |

| Macadamia Biodiesel | 113.59 | 71.73 | 52.54 | 41.74 | 65.41 | 17.71 | 14.14 | 13.32 |

| Beauty Leaf Biodiesel | 123.68 | 109.68 | 98.20 | 75.00 | 23.16 | 21.35 | 20.29 | 19.30 |

| Elements | Diesel | Beauty Leaf Biodiesel | Macadamia Biodiesel |

|---|---|---|---|

| Metals elements in weight (%) | |||

| Fe | 32.93 | 19.55 | 88.95 |

| C | 52.34 | 55.52 | 8.70 |

| O | 14.73 | 24.93 | 2.35 |

| Metal elements in atomic (%) | |||

| Fe | 11.01 | 7.43 | 67.89 |

| C | 73.46 | 73.72 | 26.88 |

| O | 15.53 | 18.92 | 5.23 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.M.; Rasul, M.; Hassan, N.M.S. Study on the Tribological Characteristics of Australian Native First Generation and Second Generation Biodiesel Fuel. Energies 2017, 10, 55. https://doi.org/10.3390/en10010055

Rahman MM, Rasul M, Hassan NMS. Study on the Tribological Characteristics of Australian Native First Generation and Second Generation Biodiesel Fuel. Energies. 2017; 10(1):55. https://doi.org/10.3390/en10010055

Chicago/Turabian StyleRahman, Md Mofijur, Mohammad Rasul, and Nur Md Sayeed Hassan. 2017. "Study on the Tribological Characteristics of Australian Native First Generation and Second Generation Biodiesel Fuel" Energies 10, no. 1: 55. https://doi.org/10.3390/en10010055