Co-Design Based Lateral Motion Control of All-Wheel-Independent-Drive Electric Vehicles with Network Congestion

Abstract

:1. Introduction

2. Problem Formulation

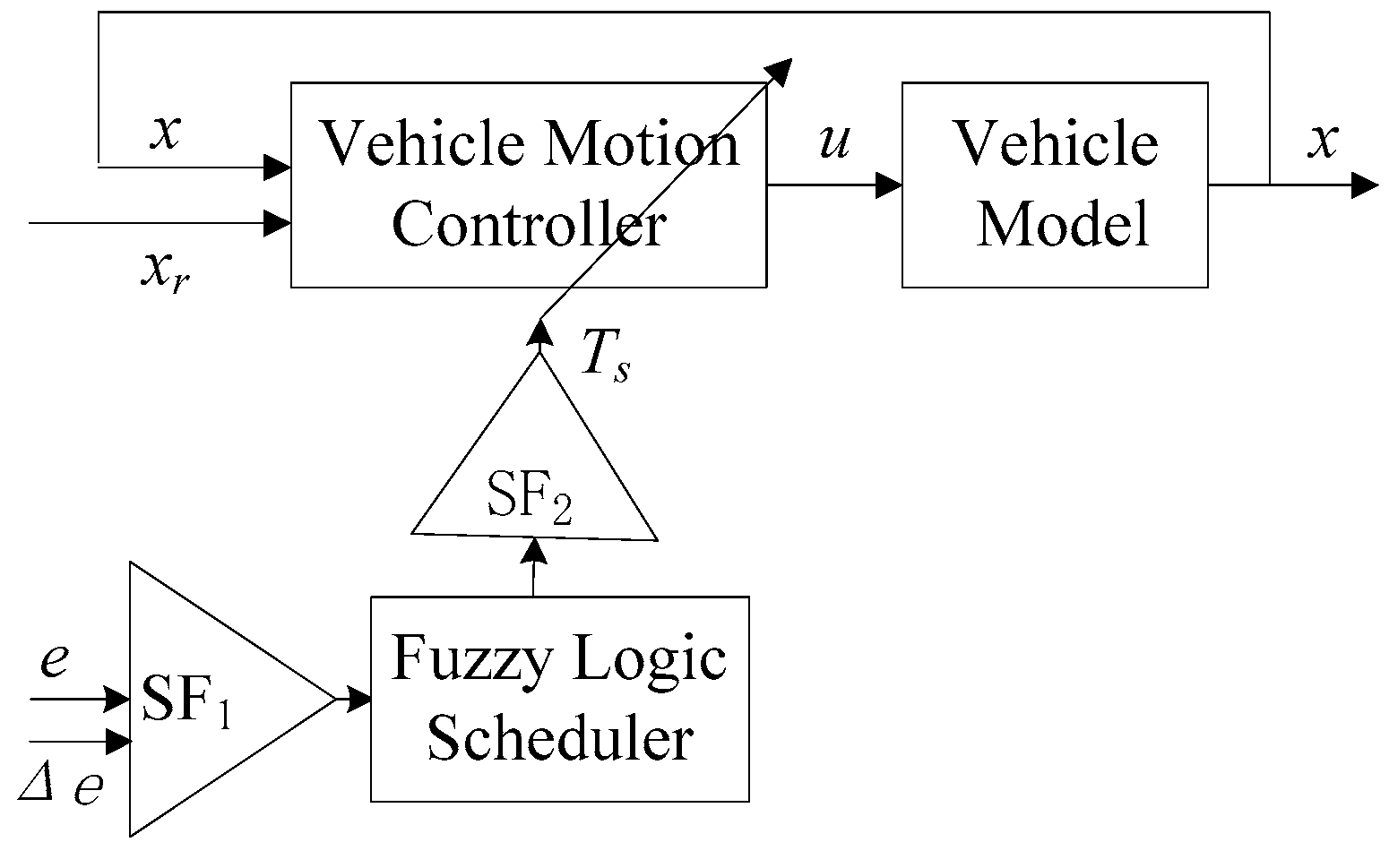

2.1. A Networked Control Architecture for the Vehicle Lateral Motion Control

2.2. Control-Orient Model of AWID-EVs with DYC

2.3. Vehicle Model with CAN-Induced Delays

2.4. The Network Utilization of CAN

3. Control Syntheses

3.1. Period-Dependent LQR Controller Design

3.2. Fuzzy-Based Dynamic Sampling Period Scheduler Design

4. Simulation Results

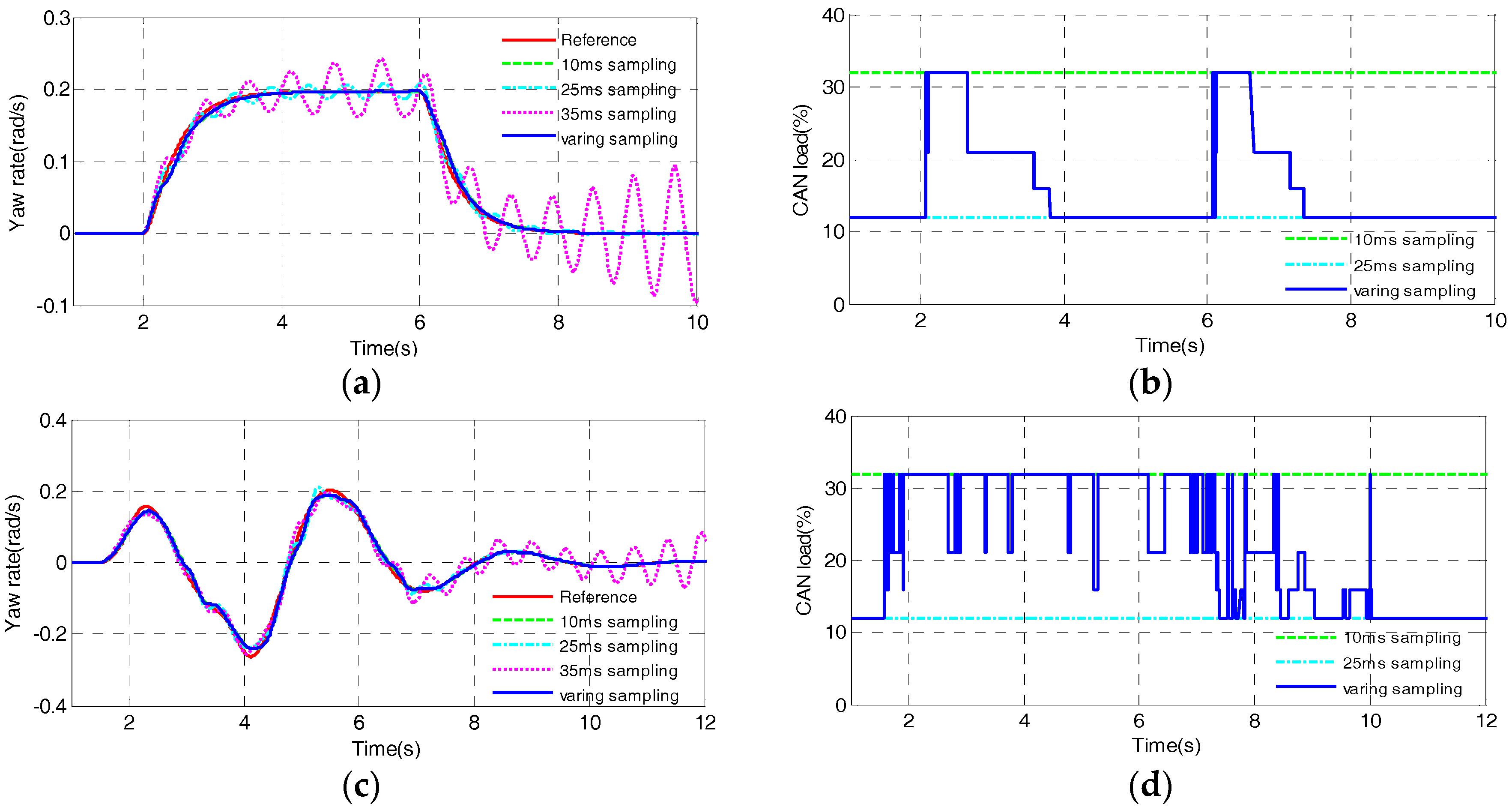

4.1. Double-Step Steering Maneuver

4.2. Double-Lane-Changing Steering Maneuver

5. Test Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gorbe, P.; Magyar, A.; Hangos, K.M. Reduction of power losses with smart grids fueled with renewable sources and applying EV batteries. J. Clean. Prod. 2012, 34, 125–137. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, H.; Fang, Z. Speed synchronization control for integrated automotive motor–transmission powertrain system with random delays. Mech. Syst. Signal Process. 2015, 64–65, 46–57. [Google Scholar] [CrossRef]

- Shuai, Z.; Zhang, H.; Wang, J.; Li, J.; Ouyang, M. Combined AFS and DYC Control of Four Wheel Independent Drive Electric Vehicles over CAN network with Time-Varying Delays. IEEE Trans. Veh. Technol. 2014, 63, 591–602. [Google Scholar] [CrossRef]

- Shuai, Z.; Zhang, H.; Wang, J.; Li, J.; Ouyang, M. Lateral motion control for four-wheel-independent-drive electric vehicles using optimal torque allocation and dynamic message priority scheduling. Control Eng. Prac. 2014, 24, 55–66. [Google Scholar] [CrossRef]

- He, H.; Peng, J.; Xiong, R.; Fan, H. An Acceleration Slip Regulation Strategy for Four-Wheel Drive Electric Vehicles Based on Sliding Mode Control. Energies 2014, 7, 3748–3763. [Google Scholar] [CrossRef]

- Park, J.; Jeong, H.; Jang, I.G.; Hwang, S.-H. Torque Distribution Algorithm for an Independently Driven Electric Vehicle Using a Fuzzy Control Method. Energies 2015, 8, 8537–8561. [Google Scholar] [CrossRef]

- Wang, R.; Hu, C.; Wang, Z.; Yan, F.; Chen, N. Integrated optimal dynamics control of 4WD4WS electric ground vehicle with tire-road frictional coefficient estimation. Mech. Syst. Signal Process. 2015, 60–61, 727–741. [Google Scholar] [CrossRef]

- Sakai, S.-I.; Sado, H.; Hori, Y. Motion Control in an Electric Vehicle with Four Independently Driven In-Wheel Motors. IEEE/ASME Trans. Mechatron. 1999, 4, 9–16. [Google Scholar] [CrossRef]

- Hori, Y.; Toyoda, Y.; Tsuruoka, Y. Traction Control of Electric Vehicle: Basic Experimental Results Using the Test EV “UOT Electric March”. IEEE Trans. Ind. Appl. 1998, 34, 1131–1138. [Google Scholar] [CrossRef]

- Hu, C.; Wang, R.; Yan, F.; Chen, N. Output Constraint Control on Path Following of Four-Wheel Independently Actuated Autonomous Ground Vehicles. IEEE Trans. Veh. Technol. 2016, 65, 4033–4043. [Google Scholar] [CrossRef]

- Song, P.; Zong, C.-F.; Tomizuka, M. A terminal sliding mode based torque distribution control for an individual-wheel-drive vehicle. J. Zhejiang Univ.-Sci. A (Appl. Phys. Eng.) 2014, 15, 681–693. [Google Scholar] [CrossRef]

- Hori, Y. Furture Vehicle Driven by Electricity and Control-Research on Four-Wheel-Motored UOT Electric March II. IEEE Trans. Ind. Electron. 2004, 51, 954–962. [Google Scholar] [CrossRef]

- Wang, R.; Wang, J. Fault-Tolerant Control With Active Fault Diagnosis for Four-Wheel Independently Driven Electric Ground Vehicles. IEEE Trans. Veh. Technol. 2011, 60, 4276–4287. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, H.; Wang, J.; Fang, Z. Robust Lateral Motion Control of Electric Ground Vehicles with Random Network-Induced Delays. IEEE Trans. Veh. Technol. 2015, 64, 4985–4995. [Google Scholar] [CrossRef]

- Wang, Y.; Fujimoto, H.; Hara, S. Torque Distribution-Based Rang Extension Control System for longitudinal motion of Electric Vehicles by LTI Modeling with Generalized Frequency Variable. IEEE/ASME Trans. Mechatron. 2016, 21, 443–452. [Google Scholar]

- Yang, X.; Wang, Z.; Peng, W. Coordinated control of AFS and DYC for vehicle handing and stability based on optimal guaranteed cost theory. Veh. Syst. Dyn. 2009, 47, 58–78. [Google Scholar] [CrossRef]

- Goodarzi, A.; Esmailzadeh, E. Design of a VDC System for All-Wheel-Independent Drive Vehicles. IEEE/ASME Trans. Mechatron. 2007, 12, 632–639. [Google Scholar] [CrossRef]

- Chen, B.-C.; Kuo, C.-C. Electronic Stability Control for Electric Vehicle with Four In-Wheel Motors. Int. J. Autom. Technol. 2014, 15, 573–580. [Google Scholar] [CrossRef]

- Novellis, L.D.; Sorniotti, A.; Gruber, P. Wheel Torque Distribution Criteria for Electric Vehicles with Torque-Vectoring Differentials. IEEE Trans. Veh. Technol. 2014, 63, 1593–1602. [Google Scholar] [CrossRef]

- Ando, N.; Fujimoto, H. Yaw-rate Control for Electric Vehicle with Active Front/Rear Steering and Driving/Braking Force Distribution of Rear Wheels. In Proceedings of the 11th IEEE International Workshop on Advanced Motion Control, Nagaoka, Japan, 21–24 March 2010. [Google Scholar]

- Li, D.; Du, S.; Yu, F. Integrated vehicle chassis control based on direct yaw moment, active steering and active stabiliser. Veh. Syst. Dyn. 2008, 46, 341–351. [Google Scholar] [CrossRef]

- Wanke, C.; Zhihao, Y.; Cheng, L. The dynamic studies of dual-motor independent drive electric vehicle with network control. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Beijing, China, 31 August–3 September 2014. [Google Scholar]

- Qin, G.; Zou, J. H∞ Control of Four Wheel Independent Drive Electric Vehicles with Random Time-Varying Delays. Math. Probl. Eng. 2015, 2015, 245493. [Google Scholar] [CrossRef]

- Cao, W.; Liu, Z.; Chang, Y.; Szumanowski, A. Direct Yaw-Moment Control of All-Wheel-Independent-Drive Electric Vehicles with Network-Induced Delays through Parameter-Dependent Fuzzy SMC Approach. Math. Probl. Eng. 2017, 2017, 5170492. [Google Scholar] [CrossRef]

- de Novellis, L.; Sorniotti, A.; Gruber, P.; Orus, J.; Fortun, J.-M.R.; Theunissen, J. Direct yaw moment control actuated through electric drivetrains and friction brakes: Theoretical design and experimental assessment. Mechatronics 2015, 26, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Yin, D.; Oh, S.; Hori, Y. A Novel Traction Control for EV Based on Maximum Transmissible Torque Estimation. IEEE Trans. Ind. Electron. 2009, 56, 2086–2094. [Google Scholar]

- Buttazzo, G.C. Rate Monotonic vs. EDF: Judgment Day. Real-Time Syst. 2005, 29, 5–26. [Google Scholar] [CrossRef] [Green Version]

- Leen, G.; Heffernan, D. TTCAN: A new time-triggered controller are network. Microprocess. Microsyst. 2002, 26, 77–94. [Google Scholar] [CrossRef]

- Cervin, A.; Henriksson, D.; Lincoln, B.; Eker, J.; Arzen, K.-E. How Does Control Timing Affect Performance? Analysis and Simulation of Timing Using Jitterbug and True Time. IEEE Control Syst. Mag. 2003, 23, 16–30. [Google Scholar] [CrossRef]

- Caruntu, C.F.; Lazar, M.; Gielen, R.H.; Bosch, P.P.J.V.D.; Cairano, S.D. Lyapunov based predictive control of vehicle drivetrains over CAN. Control Eng. Prac. 2013, 21, 1884–1898. [Google Scholar] [CrossRef]

| Symbol | Descriptions |

|---|---|

| NB | Negative Big |

| NS | Negative Small |

| ZE | Zero |

| PS | Positive Small |

| PB | Positive Big |

| Δe | ||||||

|---|---|---|---|---|---|---|

| NB | NS | ZE | PS | PB | ||

| e | NB | T1 | T1 | T2 | T1 | T1 |

| NS | T1 | T2 | T3 | T2 | T1 | |

| ZE | T2 | T3 | T4 | T3 | T2 | |

| PS | T1 | T2 | T3 | T2 | T1 | |

| PB | T1 | T1 | T2 | T1 | T1 | |

| Parameter | Description | Quantity |

|---|---|---|

| m | Vehicle mass | 1350 kg |

| IZ | Yaw moment of inertia | 1975 kg·m2 |

| lf | Front semi-wheelbase | 1.085 m |

| lr | Rear semi-wheelbase | 1.386 m |

| cf | Cornering stiffness of front tires | 58,000 N/rad |

| cr | Cornering stiffness of Rear tires | 60,000 N/rad |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, W.; Liu, H.; Lin, C.; Chang, Y.; Liu, Z.; Szumanowski, A. Co-Design Based Lateral Motion Control of All-Wheel-Independent-Drive Electric Vehicles with Network Congestion. Energies 2017, 10, 1641. https://doi.org/10.3390/en10101641

Cao W, Liu H, Lin C, Chang Y, Liu Z, Szumanowski A. Co-Design Based Lateral Motion Control of All-Wheel-Independent-Drive Electric Vehicles with Network Congestion. Energies. 2017; 10(10):1641. https://doi.org/10.3390/en10101641

Chicago/Turabian StyleCao, Wanke, Helin Liu, Cheng Lin, Yuhua Chang, Zhiyin Liu, and Antoni Szumanowski. 2017. "Co-Design Based Lateral Motion Control of All-Wheel-Independent-Drive Electric Vehicles with Network Congestion" Energies 10, no. 10: 1641. https://doi.org/10.3390/en10101641