1. Introduction

The bio-economic framework of European Union opens up some interesting options to promote the valorisation of feedstock, until now considered as waste, such as forest and agricultural residues including chaff, straw, pruning, and stumps. Gonzalez-García et al. [

1] demonstrated that the utilization of these residues for energy production is environmentally beneficial and has a lower impact than using wooden energy crops. Such biomass is generally left in the fields, but during the last decade there has been considerable research to find a way for its valorisation, receiving international funding and support [

2].

Recently, the utilization of tree stumps as fuel is rising attention, as strategy to increase the forest potential to generate bioenergy. The stump is defined as the basal part of the tree, including the near-the-ground stem portion and the woody roots that remain after stem felling. Nowadays, stumps have gained interest as a biomass source for heat and power generation, due to the enlargement of the biofuel market and the decreasing prices for harvesting operations [

3].

In some cases, the stump removal is considered a potential threat affecting soil fertility, biological sustainability, regeneration and survival of native species. It is the case of forests, where the stumps constitute a crucial habitat for many insect groups and other organisms or microorganisms that contribute to soil biodiversity [

4]. In addition, soil damage due to compaction and removal of the essential nutrients present in stumps (e.g., N, P, K) can reduce the soil fertility [

5]. Nevertheless, the results of these studies are often contradictory, as recent literature highlighted how the soil disturbance caused by stump extraction increased the mineralization of soil organic matter and the nutrient availability [

6]. Other studies stress that stump harvesting creates better conditions for subsequent tree growth [

7], producing a favourable environment for new orchard and forest plantations, as well as improving the quality and productivity of the site preparation and planting work [

8]. However, going beyond this debate, there are certain conditions in which the removal of residual stumps is mandatory; it is the case of fruit orchards, in which the end-cycle plantations must be extracted or crushed for making space to new crops. Until now, common harvest techniques consist in the stumps removal with excavators, grinders, or extractors [

9] equipped with a stump removal head, working on the removal of the singular root time y time. The excavator operator cuts the stump into smaller pieces to break off fine roots before extracting the stump and shaking it to remove excess soil. Stump pieces are then transported to a landing area using standard forwarders modified for stump haulage.

However, as several studies stressed the potential of forest-stumps from both natural forest and Short Rotation Forestry (SRF) to be used as fuel [

10,

11,

12,

13,

14,

15,

16], a few of these works highlighted the opportunities and the impact that would be derived from the utilization of stumps deriving from orchards [

17,

18].

In case of intensive cultivations such as modern fruit orchards, these techniques become inefficient, as also demonstrated by Picchi et al. [

17]. Therefore, the frequent turnover requires that termination costs are minimized to avoid overheads for the farms.

Another concern of stump harvesting is the massive soil disturbance, with consequences for soil organic matter (SOM) decomposition and emissions of CO

2 [

19]. The stumps are normally extracted by excavators weighing 20–25 tons. To decrease extraction cost and time and reduce the soil damage, one possibility is to use light machines, towed by a tractor for single pass stump removal.

Recently, a mechanical stump eradicator manufactured by Officine Gottardo S.a.s and commercialized by La Cruz S.R.L. has been designed to solve the problem of end-life orchards removal in Italy. The machine (model SR100M) performs a continuous single-pass stump removal and represents the second version of a prototype already tested in Northern Italy on pear trees in 2012 [

17]. In that experience, the machine showed higher field capacity and lower operating cost with respect a commercial excavator used for the same operation. However, the product quality was low, because both moisture content (MC) and soil contamination of the biomass were too high to allow commercialization and immediate conversion.

Indeed, the marketability of the stumps does not depend only from the extraction costs. In fact, the scarce quality of the fuel due to the high soil contamination may compromise any opportunity of commercialization. Therefore, parallel to affordable extraction systems, low-cost solutions should be identified in order to provide a marketable fuel.

In fact, if efficient recovery systems are identified, the growing biofuel market can provide an interesting opportunity to valorize this biomass resource, giving to farmers the chance to balance the cost for extraction.

In this regard, the identification of good storage techniques before energy conversion can play a significant role in improving biomass quality, as demonstrated by studies performed wih woodchips, forest residues, and whole plants. For instance, Barontini et al. [

20] demonstrated that storing woodchips obtained from poplar tree crowns in open-air can improve the biomass quality and increase the energy yield of the product with respect the start condition. On the other hand, Lehtikangas and Jirjis [

21] verified that the storage of logging residues can increase the wood fuel quality with respect to moisture content, heating value, and ash content. Walmsley and Godbold [

22] stated that storage at the landing for up to a year allows rain and snowfall to wash off adhering soil and stones, which are fuel contaminants, and has the additional benefit of allowing the moisture content of the stump wood to decline substantially.

Hence, the authors claimed the need to identify cost-effective systems for biomass drying and cleaning before being processed into energy.

On the base of these findings, the objective of this work was to test the possibility to improve the biomass quality and the marketability of stumps of an end-cycle vineyard extracted with a specialized machine and stored in open-air piles for six months, i.e., exposed to meteorological agents.

The activity has been performed to test if the combination of such a storage system with the use of a specific machine for stump eradication would allow the farmers to increase payloads, and to obtain a product with a satisfactory quality for bio-energy production. The improvement of the biomass quality in a very affordable way would in turn determine the opportunity to exploit this still unexploited resource.

2. Materials and Methods

2.1. Test Fields

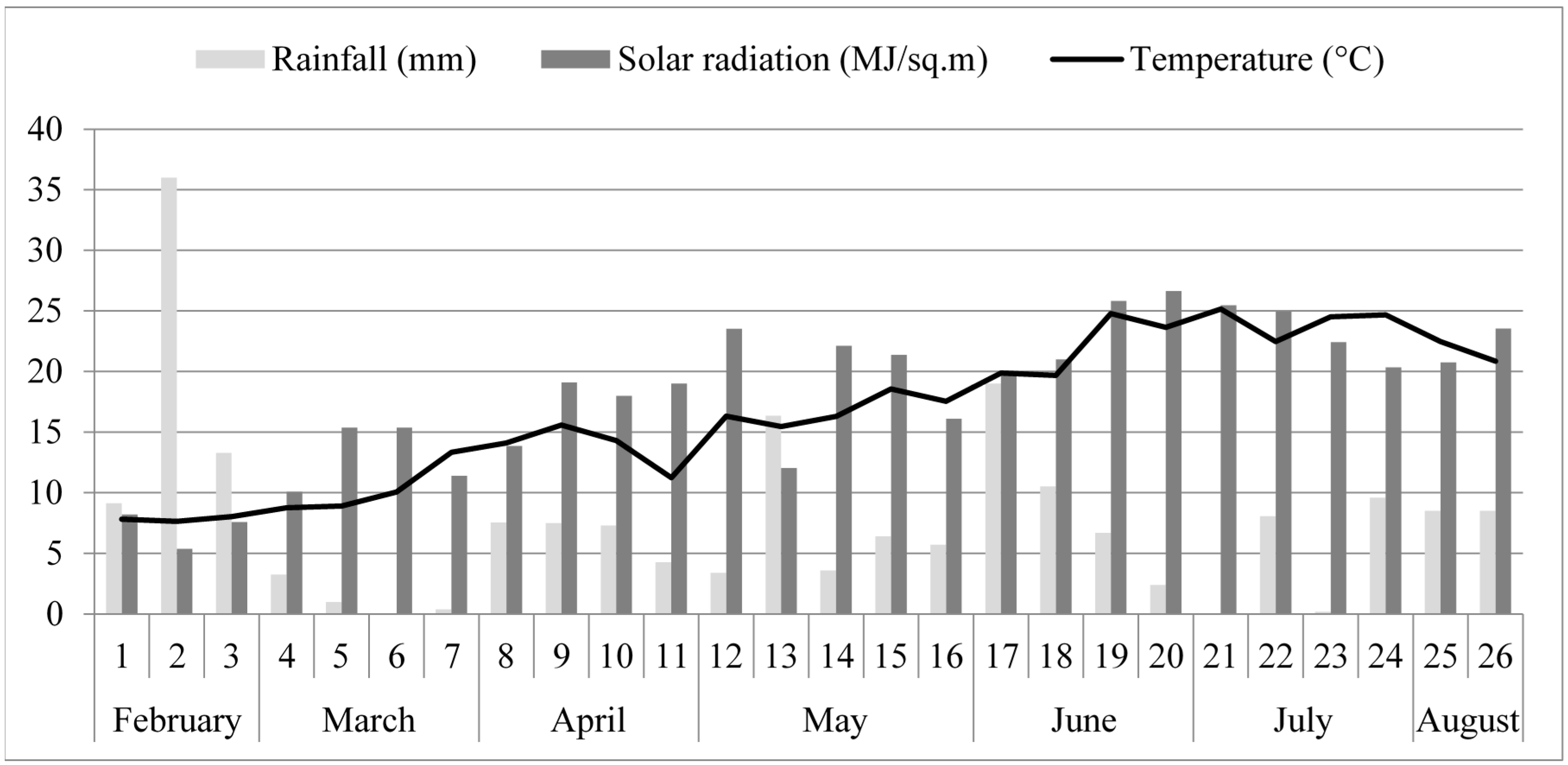

The study was conducted between February and August 2016 within the organic farm “Galileo Vini”, placed in the Northern Italy at Vazzola (45°48′23.43″ N and 12°22′03.99″ E), Treviso province. The area of the test was included in the alluvial plain of the Piave river as according to official soil map [

23], at an approximate distance of 2.5 km from the main river bank. Climatic parameters such as precipitation, mean temperature, and mean daily solar radiation were recorded during the entire storage period using a whether cab certified by the Regional Environmental Protection Agency (n. 185, Tezze–Vazzola, Italy) and placed at an approximate distance of 2.0 km from the test fields.

The stumps were extracted from two distinct plantations in two rectangular flat fields, respectively 1.31 and 0.81 ha wide. In the larger field, the vineyard plantation dated 1989 and was a mixture of wine grape varieties including Chardonnay, Verduzzo, and Cabernet growth with a crop form called Bellussi. The layout was 8 × 4 m with plants grouped in the number of fours along the row (planting density of 1 plant each 8 m2) and oriented in four opposite directions, forming a cross configuration. The second field hosted a plantation dating 1987, with a single variety (Cabernet), growth using the Geneva Double Curtain (GDC) system; the planting pattern of 4 × 1 m (planting density of 1 plant each 4 m2) resulted in one stump each linear meter along the row.

Hand texturing revealed that both test fields presented a silt-loamy texture; the area was also characterized by the presence of medium size gravels that were removed prior to cultivation to allow mechanization. The soil moisture was determined in both fields at the moment of extraction, taking five samples from each field as according to the current standard methodology [

24].

2.2. The Mechanical Extraction System

The extraction equipment was composed by a tractor Landini series 6–175 (166 Hp) and a single pass stump removal machine commercialized by La Cruz model SR100. The stump removal was composed by a iron frame, 3 cm thick, equipped frontally with two sub-soilers, 0.75 m long and spaced 1 m apart; the sub-soilers were connected at the base through a triangular horizontal blade.

Regarding functioning, during progress, the machine performs one horizontal cut with the basal blade and two vertical cuts with the sub-soilers; the working depth can be regulated by the hydraulic lift of the tractor as well as adjusted according to soil type, tractor power, and depth of the main root. As already observed in previous studies [

17], this system in compact soils determine the formation of a soil block, including the root, which is separated from the rest of the ground. Successively, the plate is lifted up through four metal rods, 2.4 m long, hinged to the triangular basal blade and leant onto a rear rotor. The rods are inclined of about 30° respect the ground and space 23 cm from each other; this allow lifting of the sound block and the roots through a continuous sliding (

Figure 1).

In loose soils, as the one of this study, the soil plate is not formed and stumps come out of the ground much cleaner. To remove the soil attached to the roots after the extraction, the machine shakes the material through a mechanism bouncing the rods up and down. In particular, the rear rotor of the machine presents pins welded in an alternative way, in correspondence of to the points where the rods are leaned on; when the rod is hit by the pin during the revolutions of the rotor, it is bounced up of about 20 cm and falls back for gravity to its foothold. Beside the pins, the rotor is equipped with curved metal teeth which allow further ground cleaning and facilitate the escape of the roots from the rear part of the machine.

Respect the previous version tested on pear orchards by Picchi et al. [

18], the transmission of this machine is entirely mechanic. The power take-off (PTO) is connected to a mechanic reducer which transfers the power to two metal chins continuously thought two pinions. The lubrication of the chin is assured by a small independent hydraulic pump mounted on the top part of the machine frame.

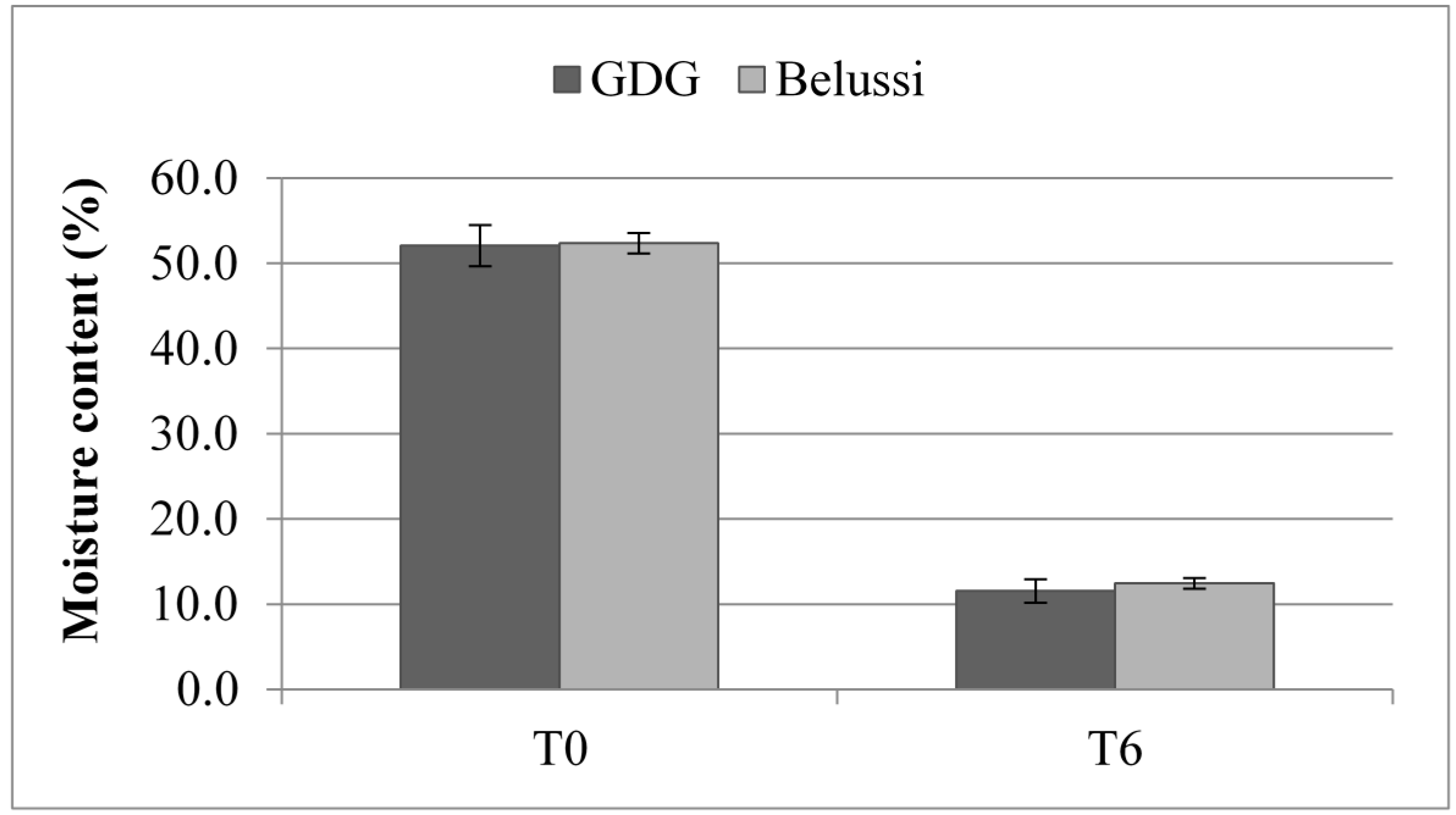

2.3. Fuel Quality Parameters before Storage and Biomass Availability

After the extraction, 25 random stumps were taken from each field (50 stumps in total) to study the initial fuel quality parameters such as MC, ash content, heating value, and soil contamination level. To determine MC, 5 stumps of Bellussi and 5 of GDC were sampled as according to the methodology proposed by Laurila and Lauhanen [

14]. Briefly, 500 g of wood in the midway between the main stump and the end of the root were cut using a chainsaw. The material was sealed in net bags and transported in the laboratory of CREA-IT (Monterotondo, Rome, Italy) together with the remaining 40 stumps to perform the analysis. In this regard, the analysis of MC was performed as according to the European standard valid for 2016 [

25], which has been recently updated in the new one EN ISO 18134-2:2017 [

26]. After the analysis, 50 g of minced samples were used for the determination of ash content and heating value as according to References [

27,

28], respectively, analyzing three replicates per each parameter.

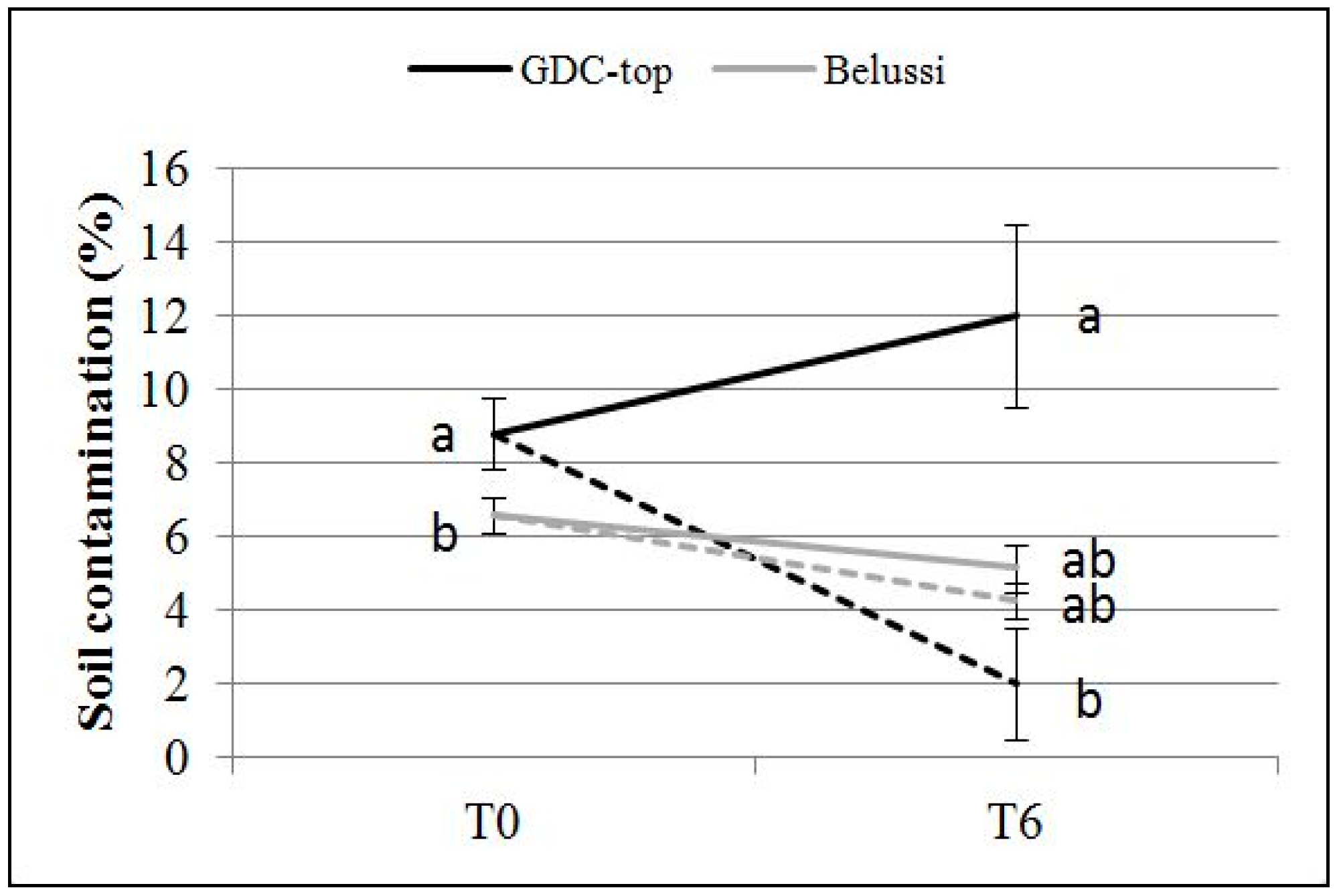

To determine the amount of soil contamination at the extraction, 20 stumps of Bellussi and 20 of GDC were weighed in the field in correspondence of the extraction point; then, each stump was numbered and transported to another area for washing with high pressure cleaner. The stumps were then left in open-air for drying and reweighed after six hours to determine the amount of soil lost.

Biomass availability per hectare was evaluated, considering the weight of these 20 clean stumps per each field and multiplying the value for the number of stumpsha−1 as according to original plant density. The results are reported on dry basis.

2.4. The Storage Test

The biomass was then transported to a storage site close to the farm, consisting in a flat area of freshly mowed lawn. Two experimental piles were formed: one using 4.3 tons of Bellussi stumps and the other using 3.5 tons of GDC stumps. Each pile was about 5 m long, 5 m wide, and 3 m high. Despite the fact that the amount of biomass used in the Bellussi pile was 0.8 tons more, the different root morphology increased the volume of the pile, making the two piles of similar shape and dimensions. In this regard, GDC stumps were characterized by a high presence of secondary roots, having diameters lower than 2 cm, while in Bellussi the secondary roots were almost absent (

Figure 2).

Piles exposition was maintained as much similar as possible in order to guarantee the same surface exposed to weathering. The pile formation occurred manually soon after the extraction (T0) with the help of a farm vehicle (fork) that was used to arrange the material on the top of the stack (

Figure 3).

After six months (T6, August), the piles were opened manually and 25 stumps per each stack were taken randomly for the determination of final fuel quality parameters—MC, ash content, and heating value. MC was determined using 5 of the 25 stumps from each pile following the procedure described for T0 [

15]. The remaining 40 stumps (20 per pile) were brought at Centro di Ricerca Ingegneria e Trasformazioni Agroalimentari of Consiglio per la ricerca in agricoltura e l’analisi dell’economia agraria (CREA IT)for chipping and laboratory analysis. The chipper utilized was the Farmi Forest CX 260, while the laboratory instruments used were respectively the Memmert drying oven UN750 for MC, the Lenton laboratory Chamber Furnace EF 11/8B for ash, and the Parr 6400 Automatic Isoperibol Calorimeter for heating value.

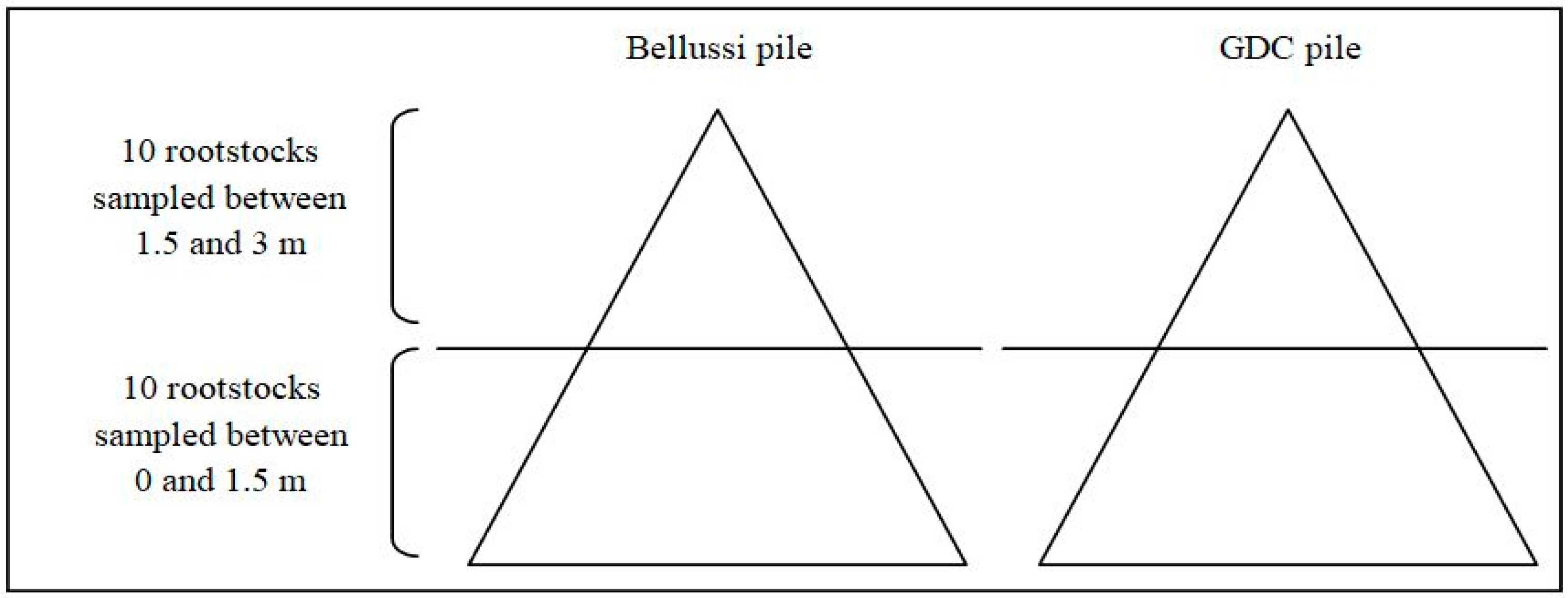

The determination of the soil contamination after storage was carried by differentiating the piles in two layers (upper layer: 1.5 m < x < 3 m; lower layer: 0 m < x < 1.5 m) and analyzing the material of each layer separately. This was done to study the effects of open-air storage on cleaning performances in the two different pile’s region, because it was expectable that soil would have accumulated largely in the lower layers of the stacks.

A number of 20 stumps were taken from each pile, respectively 10 from the upper layer and 10 from the lower layer (40 stumps taken in total), as shown in

Figure 4. Each stump was weighted, cleaned with a high pressure cleaner, left to dry for six hours, and re-weighted in location close to the storage site.

2.5. Statistical Analysis

Data were processed with PAST statistics software, version 3.15, to check the statistical significance of the difference between treatments. For the weather conditions, after checking the data for normality, a statistical analysis (Student’s t-test) was performed, confronting the temperatures of 2016 with the mean of an historical series of six years (2010–2015) taken from ARPA Veneto (n. 185, Tezze–Vazzola, Italy). The Student’s t-test was applied to the data of the stump’s weight and MC as well. The one-way analysis of variance (one-way ANOVA) was applied to the percentage of soil contamination. In this case, the analysis was conducted after arcsine transformation, in order to satisfy the normality assumption.