1. Introduction

In recent years, the use of light-emitting diodes (LEDs) for lighting has become more popular because of their energy saving, long lifespan, compact volume, high color-rendering index and environmental benefits [

1,

2]. Although LED manufactures and leading suppliers have celebrated the advantages of LEDs in the industry publications and their catalogues [

3], the semi-spherical radiation pattern of LEDs is a drawback that renders them rarely used directly for illumination purposes that require high uniformity. To solve this problem, some secondary optical elements are utilized to redistribute light from the LED source to the target position efficiently and uniformly.

Recently, many researchers have been concentrating on the development of the LED diffusers, which can improve the cost-efficiency, energy savings and uniform distribution of LED lighting systems. In most cases, the secondary optical component is designed for a single LED [

2]. This element design involves several basic methods. Shi et al. presented the design of an LED rectangular uniform illumination lens based on the freeform optics, the lighting-energy conservation law, the edge-ray principle and Snell’s law [

4]. Rabl et al. proposed a 3D reflector for uniform far-field illumination. This reflector was designed using tailored edge-ray theory [

5]. A combination of a Fresnel lens and a micro-lens array for LED illumination was proposed by Wang et al. [

6]. The Fresnel lens for the collimation of LED irradiation and the micro-lens array for the uniform distribution of the collimated beam were designed according to geometrical optics and nonimaging optics. A group from Yonsei University, Korea, improved the illuminance uniformity, color uniformity and flux efficiency of LED illumination by using a modified Fresnel lens with an optimized groove angle [

7]. However, most methods that use secondary optics design involve complex calculations, which result in complicated and costly LED lens designs. In addition, because of the limited optical power output from a single LED, many LED lighting modules are required to illuminate a large area, and this requirement increases the cost of the total illumination system and installation. Another approach is using an LED array as a light source. For the purpose of illumination, achieving a good uniform distribution of LED array sources is important. Zhouping Su’s group proposed a numerical optimization method for designing an LED array for achieving a good uniform illumination distribution on the target plane. A simulated annealing algorithm is used to optimize an LED array arrangement. In a report from Moreno et al. [

8], different array configurations with optimum LED-to-LED spacing were used to obtain a uniform distribution. The optimum LED-to-LED spacing was achieved using the analytical method This group also designed a spherical LED array, which could distribute LED light uniformly over a large area [

9]. Whang presented a method for designing an LED array with an arbitrary view angle for a uniform illumination distribution [

10]. Zong Qin studied the uniform illumination condition for an LED array with a large view angle [

11]. Most methods for the uniform illumination of an LED array are based on the calculation and optimization of LED positions, intensities and emitting directions. Although the advantage of these methods is that they can achieve high optical efficiency because they do not use any secondary optics for redistribution, they are only suitable for some specific purposes because of the great complexity of the analytical method. These methods are difficult for wide use in indoor and outdoor lighting, which requires flexibility in design. Therefore, these studies have not been commercialized successfully on the market to date.

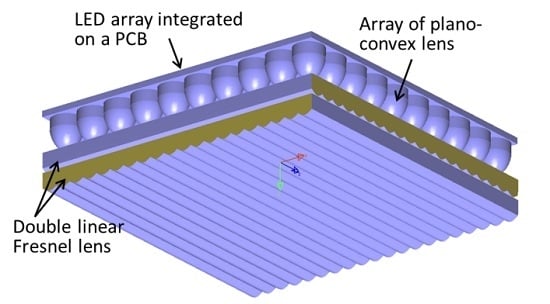

In this study, we propose an alternative approach to the uniform illumination of an LED array by designing simple secondary optics components. The LED bare chips are integrated into an array using chip-on-board (COB) technology. An array of collimators is placed on the top LED array to collect and collimate the light output from an LED array. The collimator is a plano-convex lens, which is developed with a special aspherical convex design using the freeform optics design method. The distributor was used to redistribute the LED light uniformly throughout the illumination area. The distributor was composed of two linear Fresnel lenses placed perpendicularly to each other. The linear Fresnel lens was designed by using the simultaneous multiple surface (SMS) method and the commercial MATLAB software. The simplicity and the flexibility of the design method and system configuration enable this research to be applied for various lighting purposes.

The remainder of the paper is organized as follows:

Section 2 discusses the LED illumination system design. In

Section 3, an LED illumination system is modeled by using the LightTools

TM software (Synopsys Inc., San Jose, CA, USA) to analyze the performance of this system. This section also discusses the applications for indoor and outdoor illumination purposes. The conclusions are presented in

Section 4.

3. Simulation Results and Comparison

The commercial optical simulation software LightTools

TM is utilized to design and simulate the geometrical structure of the proposed LED lighting system. The structure of the system for simulation is shown in

Figure 8. A square shape of lighting is chosen as an example to investigate the performance of the designed lighting system. As described above, the LED illumination system includes an array of LED chips, an array of plano-convex lens as a collimator and a double linear Fresnel lens as a light distributor. Lambertian LED chips are used in the simulations. Each LED generates 50 lm; therefore, the total flux of the LED array is 5000 lm. In the designed system, the Fresnel lens and collimated source are made of poly methyl methacrylate (PMMA). The double Fresnel lens for producing uniform illumination distribution in a 3 m × 3 m receiver is designed. The receiver is located 3 m away from the light source. Efficiency and uniformity are important characteristics of the lighting effect.

In the linear Fresnel lens design, the most important parameter is the size of the segment. The segment size dominates both optical efficiency and uniformity at the illumination target. To quantify the effect of segment size on the efficiency and uniformity of the system, a parametric analysis is performed while varying the number of segments of the linear Fresnel lens. Note that the linear Fresnel lens size is 100 mm × 100 mm; therefore, changing the number of segments is equivalent to changing the segment size. Based on the design principle for the linear Fresnel lens in

Section 2.3, we built a calculation program using MATLAB, which can provide the Fresnel lens surface curve based on the initial conditions such as Fresnel lens size, number of segments, illumination target size and its coordinates. Then, the Fresnel lens parameters and coordinates were imported into LightTools software to analyze the optical performance. In LightTools software, the analysis of illuminance display is based on a measurement gird. The high resolution of 200 × 200 of the mesh grid in the illumination receiver was chosen in our simulation. We generated different linear Fresnel lens structures with several different segment numbers

N ranging from 10–60 in increments of 10.

Figure 9a–c shows the effects of the illumination performances for segment numbers of 10, 20 and 30, respectively.

The uniformity equation (the following equation uniformity, Equation (4)) is utilized to calculate the uniformity

U of the light on the receiver.

Figure 10 shows the dependence of

U on the segment number

N. The higher the number of segments (or the smaller the size of the segments), the higher the optical uniformity. This can be explained by the methodology of the Fresnel design. The collimated beam output from the collimator is divided into many pieces, and each piece is redistributed and spreads over the receiver. Clearly, a smaller segment size can provide higher uniformity in the receiver.

Optical efficiency, which is defined as the ratio of the luminous flux in the receiver to the total luminous flux of the light source, is also a function of segment number

N.

Figure 10 shows the dependence of optical efficiency

η on

N together with uniformity. Efficiency decreases when segment size decreases. Optical efficiency has two types of loss effects: Fresnel loss and geometrical loss of the segment. In this proposed system, the Fresnel losses occur on the surface of the plano-convex lenses and linear Fresnel lenses. Another loss is the geometrical loss of the Fresnel lens. In an ideal case, no geometrical loss occurs when a perfect collimated beam reaches the Fresnel lens. However, our designed collimator based on plano-convex lenses provides a beam with a divergence of 7.5°. As a larger segment has a higher acceptance angle than a smaller one, the geometrical loss is smaller.

Figure 10 shows a trade-off between optical efficiency and uniformity. For different specific purposes, the parameters of the Fresnel lens should be designed appropriately.

To evaluate the advantages of our proposed lighting system, the applications for indoor lighting and street lighting are simulated, and the performances of the systems are compared with those of traditional fluorescent lamps and LED panel ceiling light. For a typical office building, the minimum illuminance required is about 500 lux, and the requirement for uniformity is 60% [

15]. In this study, we perform a simulation to evaluate the performance of the designed LED lighting system in a virtual room. The size of the room is 3 m × 3 m, and the interior is designed using LightTools

TM. The distance from the ceiling to the working plane (illumination target) is 2.7 m. The 3D view of the room’s interior is illustrated in

Figure 11a,b. The Fresnel lens parameters are calculated according to these conditions. As shown in

Figure 10, we select the Fresnel lens segment number of 30. Uniformity is achieved at 76.9% and optical efficiency at 82%. Other simulations using the traditional fluorescent lamp and the LED panel ceiling light for interior lighting were also performed for comparison. A typical fluorescent light fixture consist of a fluorescent tube and louver as shown in

Figure 12a. In our simulation, a compact fluorescent lamp (fabricated of V-shape reflector, steel material and three fluorescent tubes) was taken into consideration.

Figure 12b is a fluorescent lamp model built in LightTools. Recently, the LED panel ceiling light has been an innovative lighting product which can directly replace the conventional fluorescent lamps or light bulbs. We built a simulation model of a commercial LED flat panel light based on some parameters of the LED panel light model TLP-XX-6060 from SGSlight company (Shenzhen, China) [

16].

Figure 13a,b is an LED panel light and the dissection of its components.

Figure 14a–c shows the light distribution on the working plane by using our proposed method, the fluorescent lamp and the LED panel light.

Table 2 shows the comparison of the optical performances between three types of lighting methods. Using LED lighting for the building also overcomes inherent problems such as mercury pollution or the short lifetime of the fluorescent lamp. Although LED flat panels have been commercialized widely in recent years, current flat panel lights still have some big drawbacks. As shown in

Figure 14c, an LED flat pane provided a narrow lighting area and a hot spot [

17]. Simulation results also show that the uniformity of 39% is much lower than the standard requirement. In practice, the uniformity can be improved by increasing the number of LED panels; however, the material and installation costs also increase. Our proposed design can achieve higher lighting area and good uniformity. As shown in

Table 2, the delivery efficiency, which is defined by the ratio of luminous flux on the working plane and the light source, is 76.9%, 24% and 45.5%, corresponding to our method, the fluorescent lamp and the LED panel, respectively. In our design method, all light output from the source is delivered and distributed uniformly to the illumination target directly so that the achieved delivery efficiencies can be very high in comparison to existing methods. Our proposed system requires only 60-W LEDs with 8000 lm to delivery 6150 lm to the working plane. The fluorescent lamps, which have a very large output angle, require 300 W of electrical consumption corresponding to 21,000 lm to illuminate the working area with illumination of 500 lux. Following the

Table 2, only 5109 lm is delivered to the working plane by using fluorescent lamps with 21,000 lm, and the other part is delivered and absorbed by the room’s walls. An economic comparison is also shown in

Table 2. Using our proposed design can save five-times the electric power consumption for illumination in comparison with using of traditional fluorescent lamps. The physical dimension of our design is much smaller than others, so this may contribute to the reduction of material and installation cost.

Optical solutions for conventional street lights rarely work well with LEDs. Many newcomers, and even some big players in the street lighting business, are having difficulties finding the best solutions to meet the relevant regulations. Getting the most out of streetlights is easy, but doing it uniformly is a challenge. We conduct simulations for street lighting using our proposed method and compare the performance of our system with that of typical LED street lamps.

Figure 15a shows the visual image of a street light, and

Figure 15c illustrates the structure of a conventional street lamp. Most lighting technologies work with the light source on a symmetrical axis, and thus, conventional street lamps use an arm to direct the light source to the center of the road. This arm makes the lamp structure bulky and hinders traffic. As mentioned above, our proposed lighting method can support off-symmetrical axis lighting, and thus, this arm can be eliminated, as shown in

Figure 15b.

We carried out two simulations on our proposed design and a typical LED street lamp for comparison and evaluation. Assume that the distance from light source to the illumination surface is 10 m and the illumination area is a rectangular, 10 m × 20 m. The main goal was to illuminate a road surface area of 10 m × 20 m with a minimum illuminance of more than 20 lux, which is the standard requirement for regular vehicle traffic. Based on this initial condition, we calculated the structure of the linear Fresnel lenses as shown in

Figure 16a. The upper Fresnel lens in

Figure 16a was designed for on-axis illumination, and the lower Fresnel lens is for off-axis illumination. The ray tracing performance of one proposed street lamp module is shown in

Figure 16b. For comparison, we conducted another simulation for a typical LED street lamp. We used the design of an LED street lamp using a freeform optics lens, which is available from the LightTools software library, as shown in the exaggeration of

Figure 17.

Figure 18a is the light distribution on the illumination area of our proposed design. The light distribution on the road surface which utilized typical LED street lamp is shown in

Figure 18b.

As shown in

Figure 18b, conventional LED street lights have a high-intensity area right under the lamp, and the intensity away from the center decreases rapidly, thereby decreasing one’s ability to observe light contrasts. Ideally, street lighting should be as uniform and as visually pleasing as daylight [

18]. In our proposed system, the light was distributed uniformly on the road surface; therefore it could increase one’s ability of observation.

Table 3 shows the comparison of the performances and energy savings between two types of street lamps. Our proposed design can save 50% of the energy consumption in comparison with using a typical LED street lamp.

The uniform distribution over a road surface using our proposed design can lead to a breakthrough in solutions for LED street lighting. In terms of mass production, the linear Fresnel lens structure can allow using the extrusion molding method, which is the least costly manufacturing process. The cost efficiency of the proposed LED lighting system can be realized because of the simplicity in material, shape, form, function, manner of operation, assembly and usage, which all present obvious capabilities for commercialization.