Equivalent Circulation Density Analysis of Geothermal Well by Coupling Temperature

Abstract

:1. Introduction

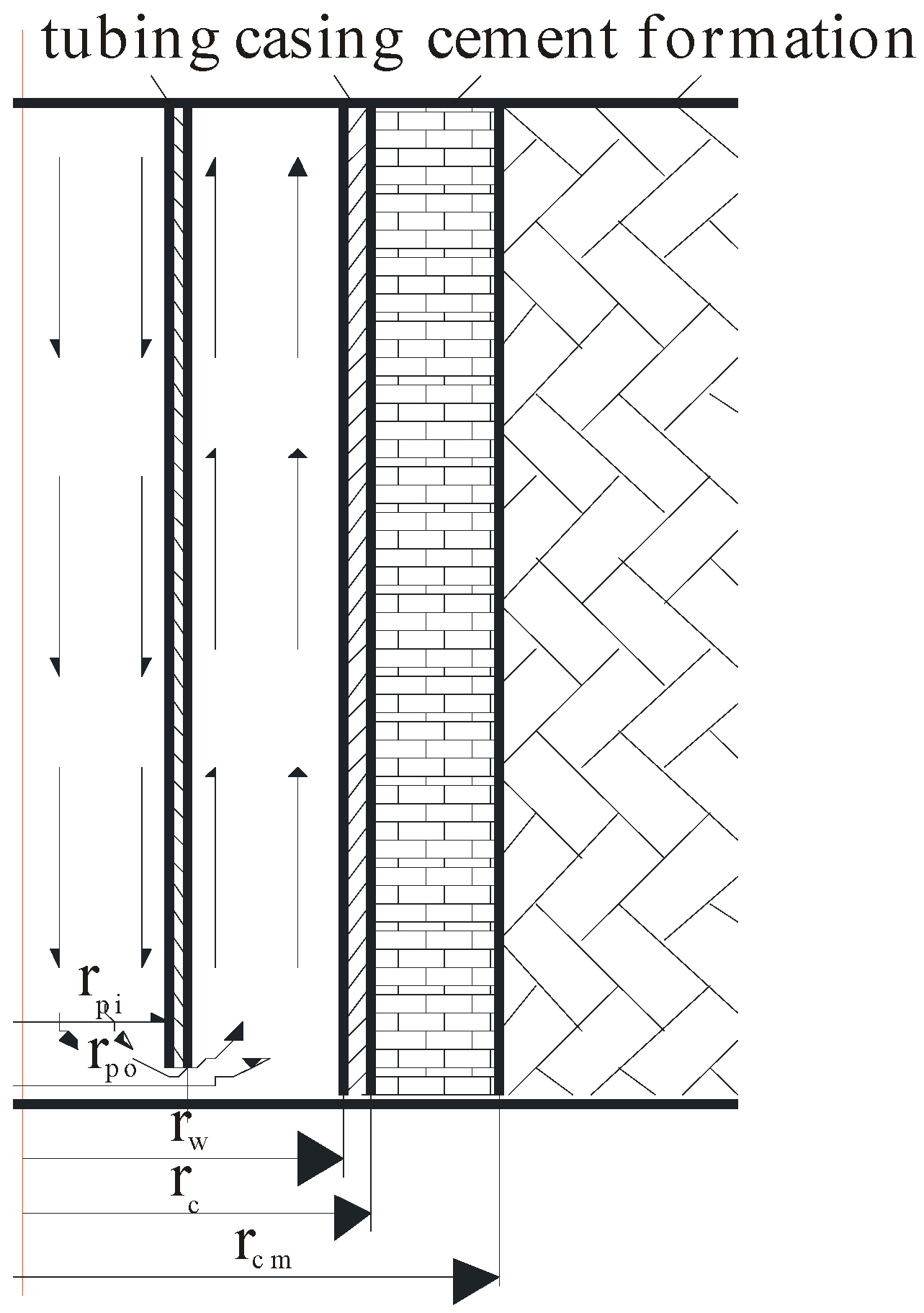

2. Methods for Temperature and Pressure Distribution in the Wellbore

2.1. Temperature Model of Wellbore

2.1.1. Assumed Condition of Model

2.1.2. Mathematical Equations

2.1.3. Initial and Boundary Conditions

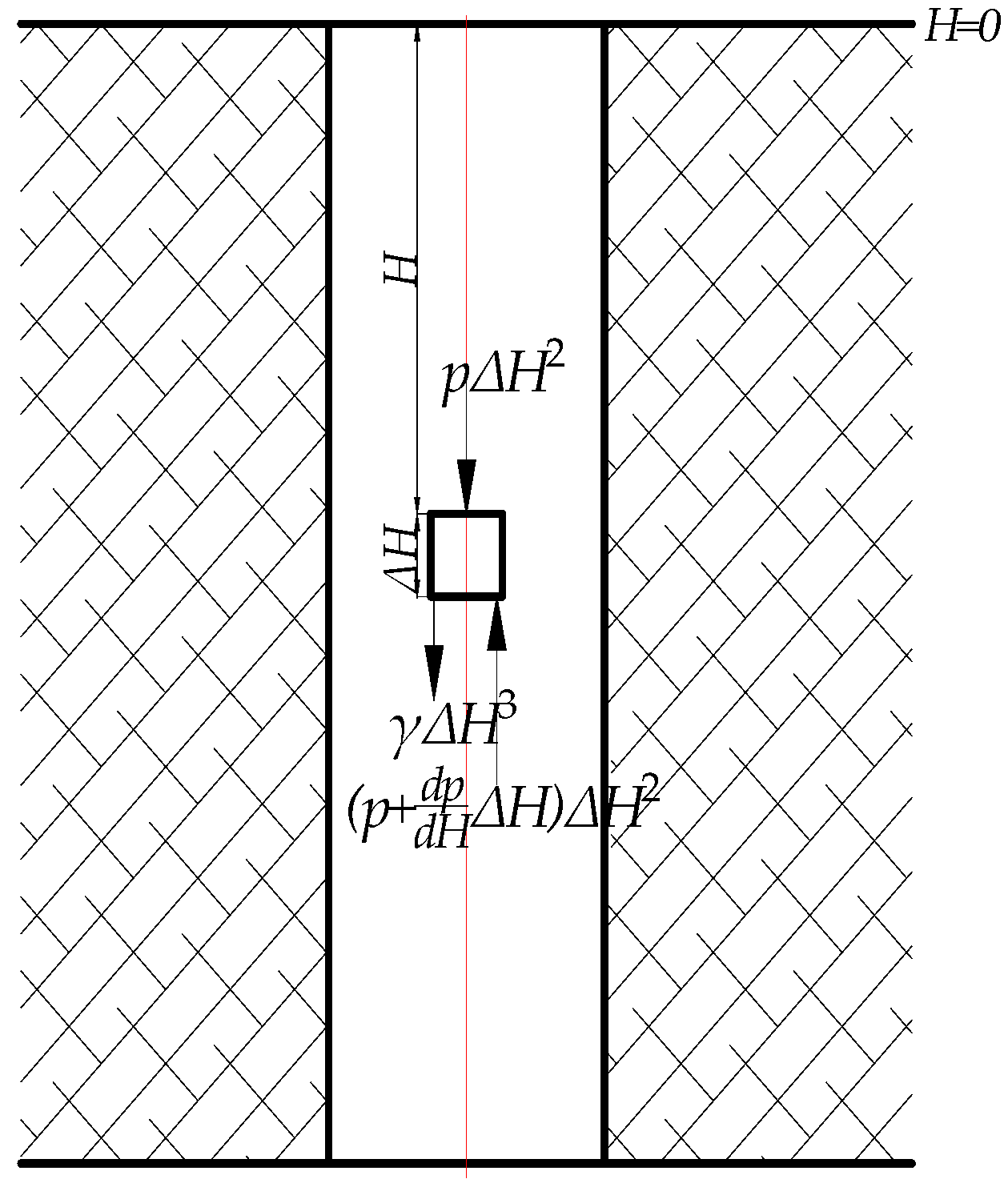

2.2. Pressure Model in the Wellbore during Circulation

2.2.1. Pressure Gradient of Circulating Drilling Fluid in the Annulus

2.2.2. Hydrostatic Pressure Gradient

2.2.3. Friction Pressure Loss

2.2.4. Iterative Method to Solve the Pressure and Temperature Models

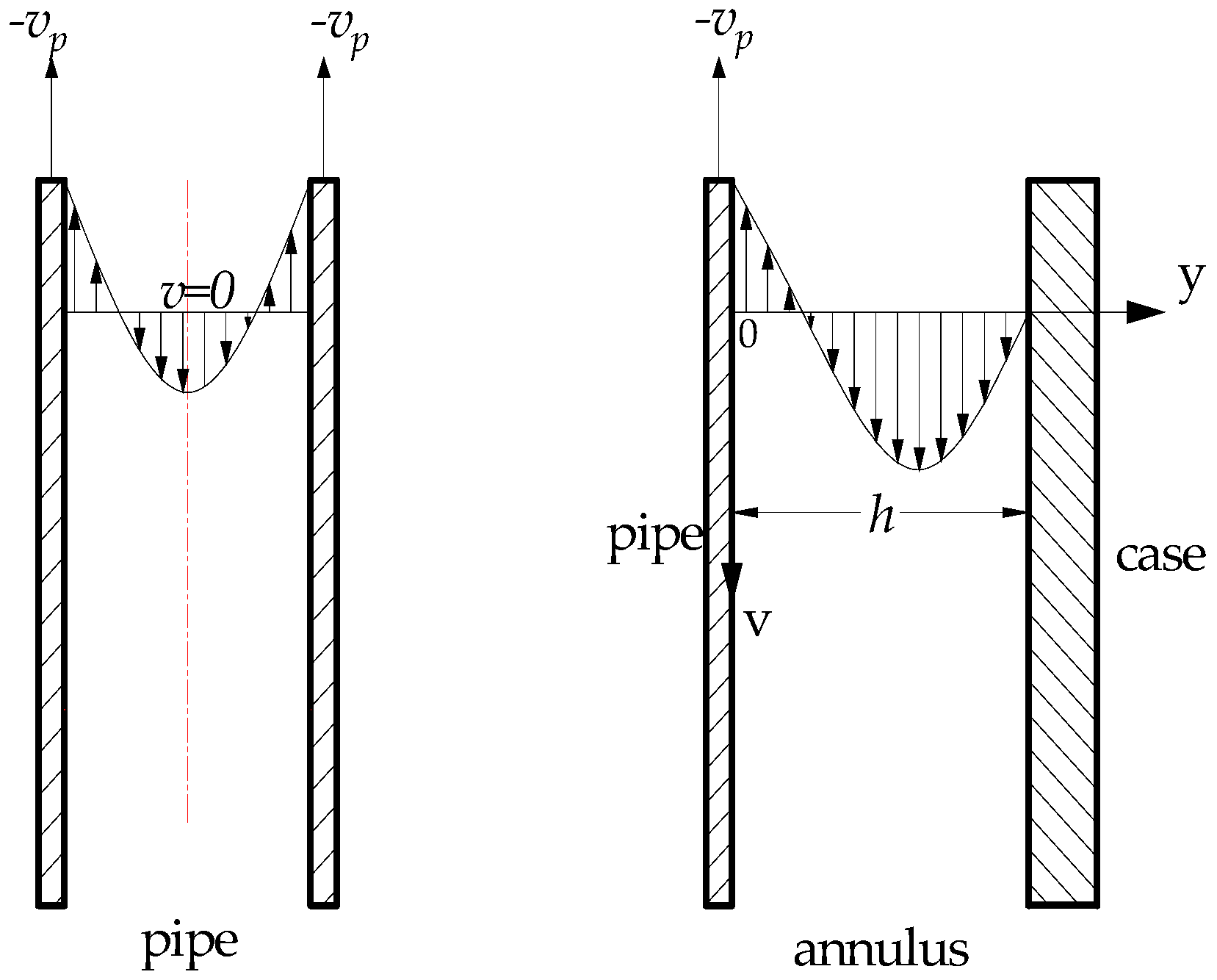

2.3. Surge Pressure

2.3.1. Initiating Circulation Pressure

2.3.2. Inertial Effects

2.3.3. Viscous Pressure Due to Vertical Pipe Movement

3. Result and Discussion

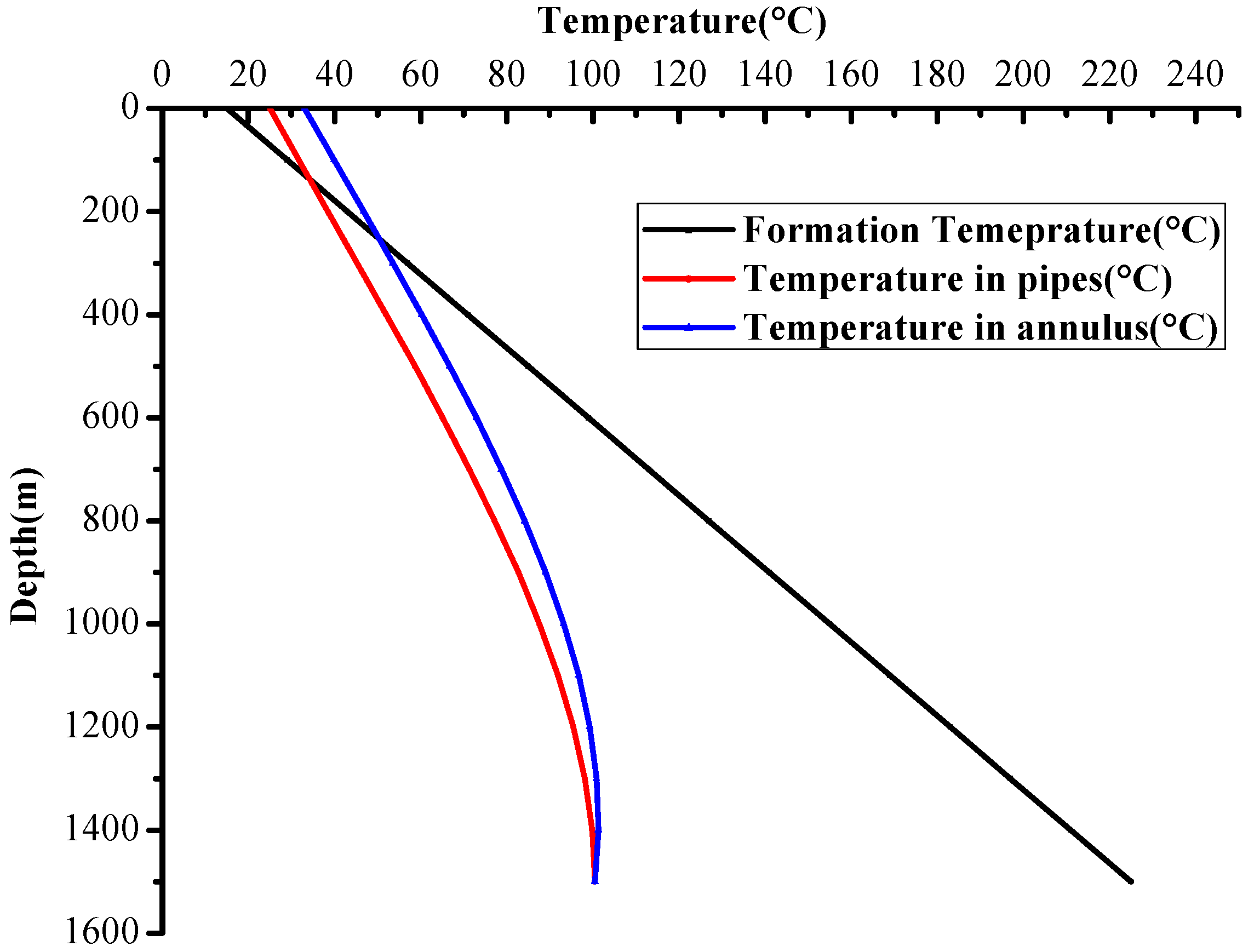

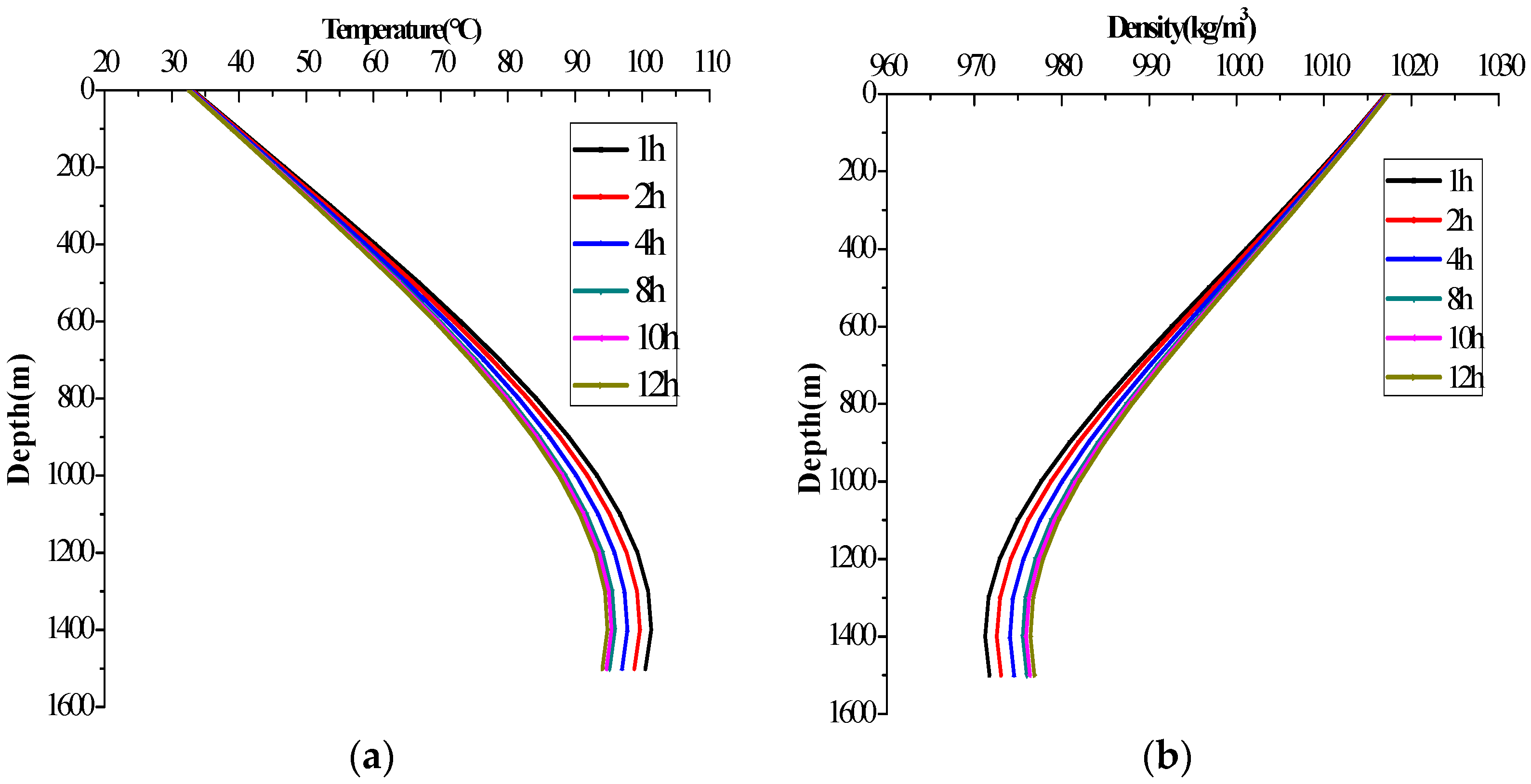

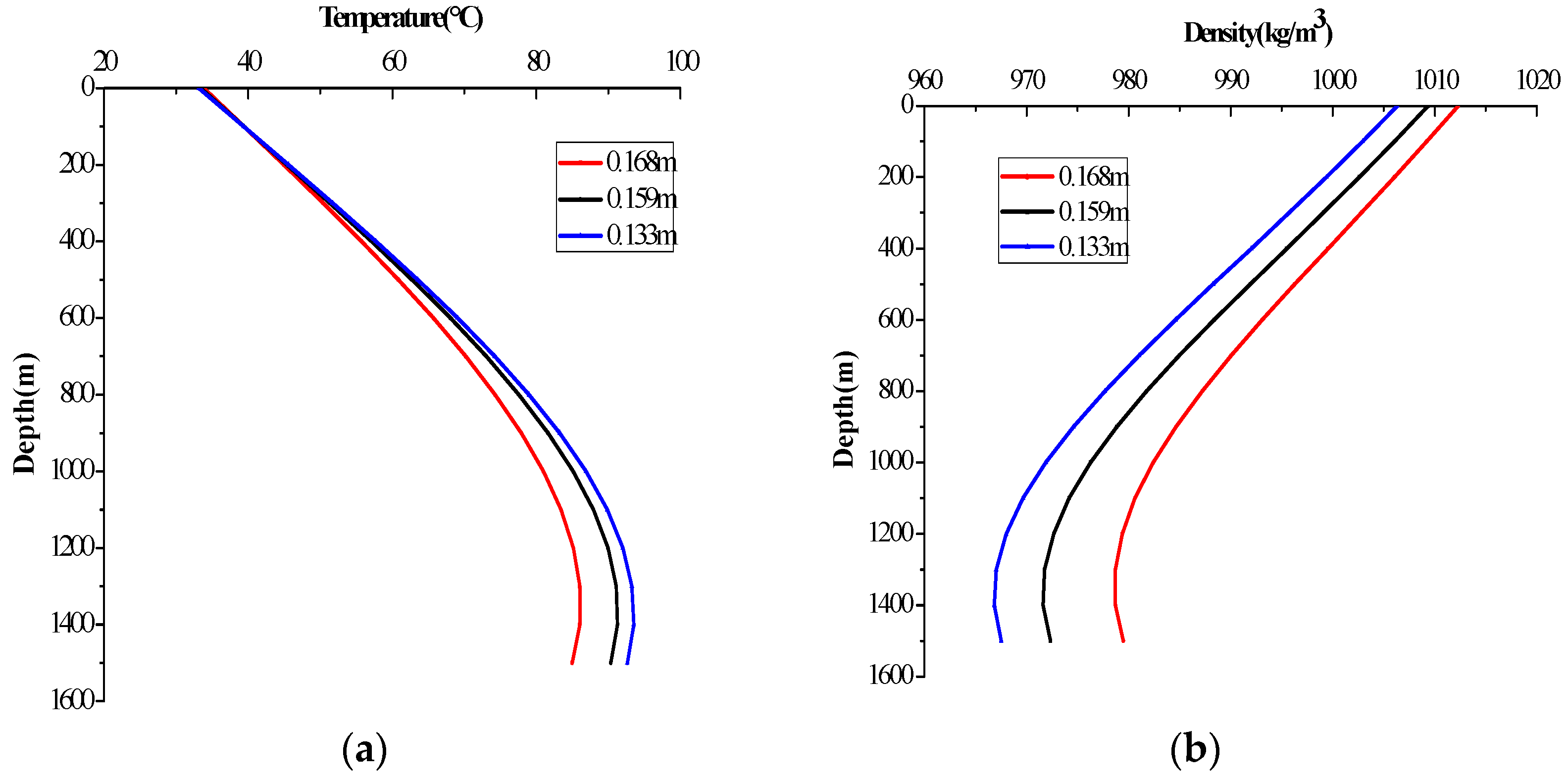

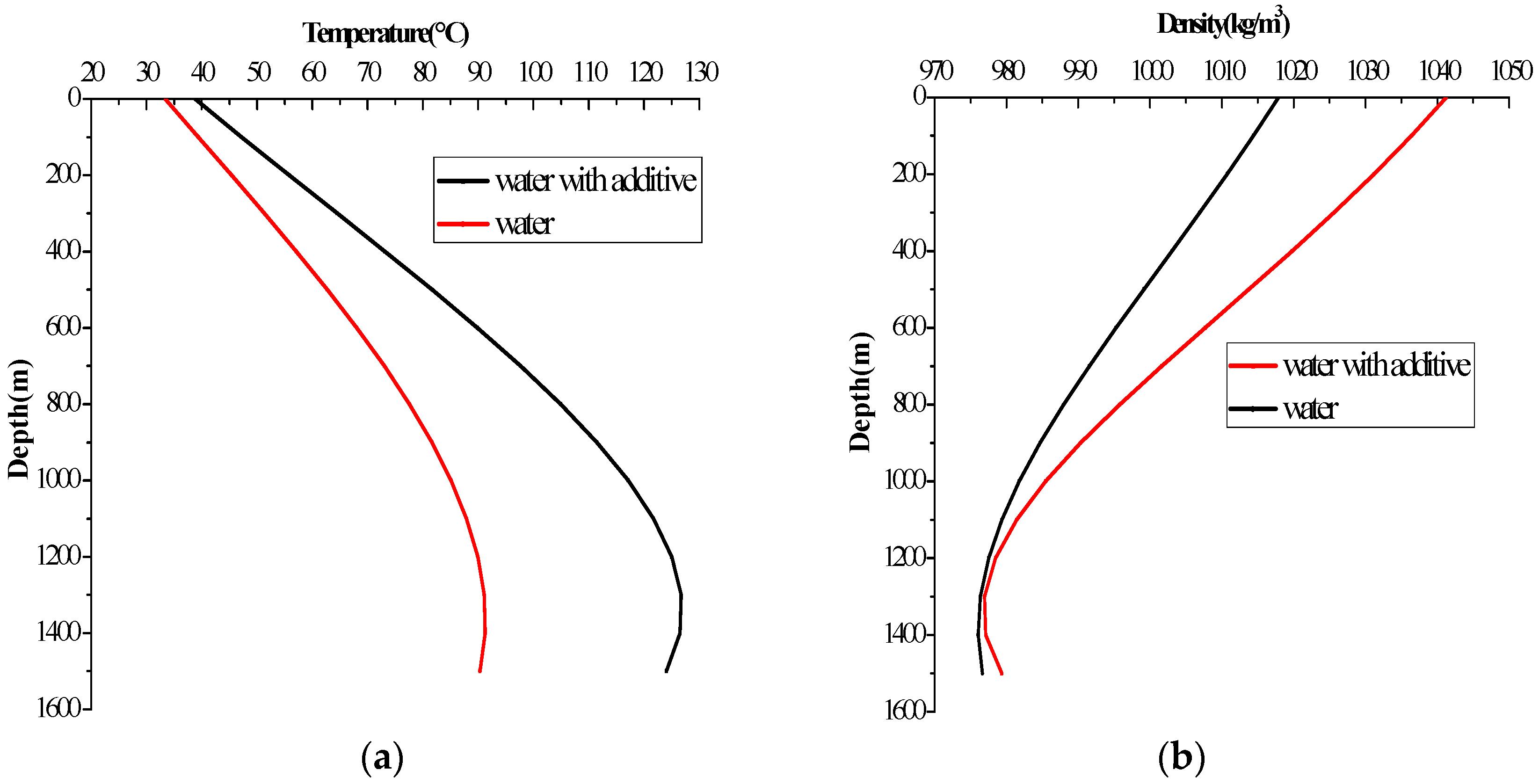

3.1. Temperature and ECD Distribution in the Wellbore

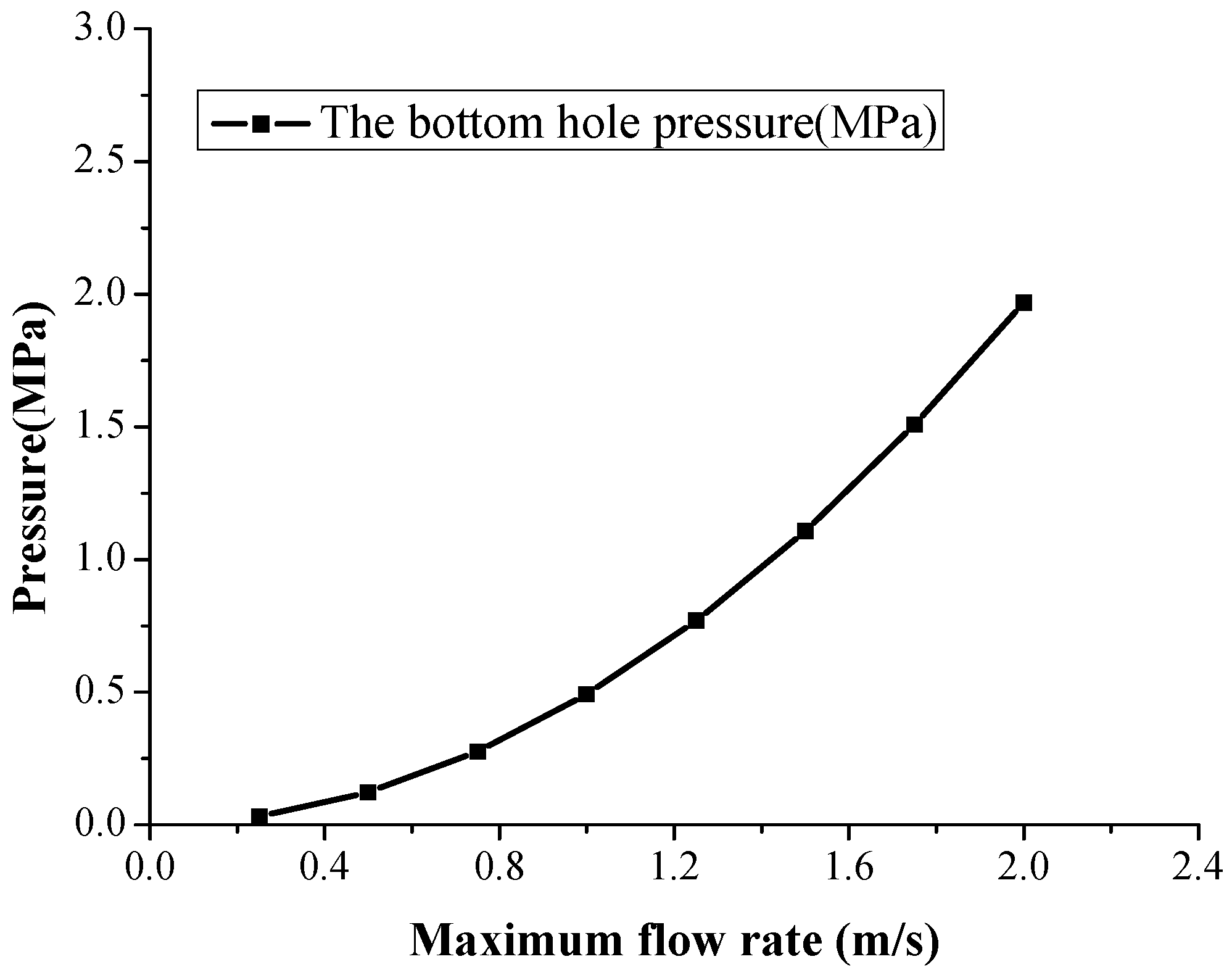

3.2. Surge Pressure Analysis

4. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Ali, K.V.; Eric, V.O. Early kick detection and well control decision-making for managed pressure drilling automation. J. Nat. Gas Sci. Eng. 2015, 27, 354–366. [Google Scholar]

- Yu, J.Y.; Bai, Z.X.; Zheng, X.H.; Zhou, D.; Li, F.Y. Controlled Pressure Drilling and the Application in High-temperature Geothermal Exploration. Explor. Eng. 2013, 40, 19–23. [Google Scholar]

- Wang, Z.Y.; Tang, S.R.; Zhou, S.G. Drilling and completion well techniques in Yangbajain Geothermal Field, Tibet. Explor. Eng. 1985, 5, 58–60. [Google Scholar]

- Ansari, A.M.; Sylvester, N.D.; Sarica, C.; Shoham, O.; Brill, J.P. A Comprehensive Mechanistic Model for Upward Two-Phase Flow in Wellbores. SPE Prod. Facil. 1994, 9, 143–151. [Google Scholar] [CrossRef]

- Peter, P.; Acuna, J.A. Implementing Mechanistic Pressure Drop Correlations in Geothermal Wellbore Simulators. In Proceedings of the World Geothermal Congress, Bali, Indonesia, 25–29 April 2010; pp. 25–29.

- Li, S.G.; Deng, J.G.; Wei, B.H.; Yu, L.J. Formation Fracture Pressure Calculation in High Temperatures Wells. Chin. J. Rock Mech. Eng. 2005, 24, 5669–5673. [Google Scholar]

- Zhong, B.; Shi, T.H.; Fang, D. Study of Pressure Balance in Deep Drilling Well. J. Southwest Pet. Inst. 1998, 20, 56–60. [Google Scholar]

- Fan, H.H.; Liu, X.S. Study on the calculation model of steady fluctuation pressure in vertical well. Oil Drill. 1993, 15, 13–18. [Google Scholar]

- Tao, Q.; Xia, H.N.; Peng, M.Q.; Li, B. Research on Surge Pressure of Casing Running in High-Temperature High-Pressure Oil Well. Fault Block Oil Gas Field 2006, 13, 58–61. [Google Scholar]

- Fu, H.C.; Liu, Y.; Sun, Z.; Ma, Y.; Ai, Z. Calculation Model of Casing Running Surge Pressure and Influence Factors Analysis. Drill. Prod. Technol. 2013, 36, 15–18. [Google Scholar]

- McMordie, W.C.; Bland, R.G.; Hauser, J.M. Effect of Temperature and Pressure on the Density of Drilling Fluids. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 26–29 September 1982; pp. 1–7.

- Hoberock, L.L.; Thomas, D.C.; Nickens, H.V. Here’s How Compressibility and Temperature Affect Bottom-Hole Mud Pressure. Oil Gas J. 1982, 12, 159–164. [Google Scholar]

- Harris, O.O.; Osisanya, S.O. Evaluation of Equivalent Circulation Density of Drilling Fluid under High-Pressure/High-Temperature Conditions. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005; pp. 1–6.

- Wang, H.G.; Liu, Y.S.; Yang, L.P. Effect of Temperature and Pressure on drilling Fluid Density in HTHP wells. Drill. Prod. Technol. 2000, 23, 56–60. [Google Scholar]

- Ramey, H.J. Wellbore heat transmission. J. Pet. Technol. 1962, 14, 427–435. [Google Scholar] [CrossRef]

- Sagar, R.K.; Dotty, D.R.; Schmidt, Z. Predicting temperature profiles in a flowing well. SPE Prod. Eng. 1991, 11, 441–448. [Google Scholar] [CrossRef]

- Willhite, G.P. Over-all heat transfer coefficients in steam and hot water injection wells. J. Pet. Technol. 1967, 5, 607–615. [Google Scholar] [CrossRef]

- Hasan, A.R.; Kabir, C.S. Modeling two-phase fluid and heat flows in geothermal wells. J. Pet. Sci. Eng. 2009, 71, 77–86. [Google Scholar] [CrossRef]

- Raymond, L.R. Temperature distribution in a circulating drilling fluid. J. Pet. Technol. 1969, 3, 333–341. [Google Scholar] [CrossRef]

- Yang, X.S.; Li, S.; Yan, J.N.; Lin, Y.X.; Wang, X. Temperature Pattern Modelling and Calculation and Analysis of ECD for Horizontal Wellbore. Drill. Fluid Complet. Fluid 2014, 31, 63–66. [Google Scholar]

- Hagoort, J.; Assocs, B.V. Ramey’s Wellbore Heat Transmission Revisited. SPE J. 2004, 9, 465–474. [Google Scholar] [CrossRef]

- Kabir, C.S.; Hasan, A.R.; Kouba, G.E.; Ameen, M. Determining Circulating Fluid Temperature in Drilling, Workover, and Well Control Operations. SPE Drill. Complet. 1996, 11, 74–79. [Google Scholar] [CrossRef]

- Hasan, A.R.; Kabir, C.S. Aspects of Wellbore Heat Transfer during Two-Phase Flow. SPE Prod. Facil. 1994, 9, 211–216. [Google Scholar] [CrossRef]

- Moore, P.L. Drilling Practices Manual; Petroleum Publishing Co.: Tulsa, OK, USA, 1974; pp. 114–123. [Google Scholar]

- Cinar, M.; Onur, M.; Satman, A. Development of a Multi-feed P-T Wellbore Model for Geothermal Wells. In Proceedings of the Thirty-First Workshop on Geothermal Reservoir Engineering, Stanford University, Stanford, CA, USA, 30 January–1 February 2006; pp. 1–6.

- Yu, H. Study the Wellbore fluctuation Pressure during Tripping Operation. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2014. [Google Scholar]

- Karstad, E.; Aadnoy, B.S. Density Behavior of Drilling Fluids During High Pressure High Temperature Drilling Operations. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology, Jakarta, Indonesia, 7–9 September 1998; pp. 227–237.

- Bourgoyne, A.T.; Chenevert, M.E.; Young, F.S. Applied Drilling Engineering; Society of Petroleum Engineers: Richardson, TX, USA, 1986; pp. 114–165. [Google Scholar]

- Burkhardt, J.A. Wellbore Pressure Surges Produced by Pipe Movement. J. Pet. Technol. 1961, 13, 559–565. [Google Scholar] [CrossRef]

- Fontenot, J.E.; Clark, R.K. An Improved Method for Calculating Swab and Surge Pressures and Circulating Pressures in a Drilling Well. Soc. Pet. Eng. J. 1972, 14, 451–462. [Google Scholar] [CrossRef]

- Zheng, X.H.; Liu, H.Y.; Ji, R.S.; Bai, Z.X. Pressure Analysis of ZK212 Well of Yangyi High Temperature Geothermal Field (Tibet, China). In Proceedings of the 6th International Conference on Applied Energy, Taipei, Taiwan, 30 May–2 June 2014; pp. 1793–1798.

| Conditions Partial Pressure | Hydrostatic Pressure | Frictional Pressure Loss | Initiating Circulation Pressure | Viscous Pressure | Inertial Wave | |

|---|---|---|---|---|---|---|

| ps | pf | pg | pV | pi | ||

| 0 | Standard static | + | ||||

| 1 | pumping | + | + | |||

| 2 | circulation | + | + | |||

| 3a | Trip out (acceleration) | + | - | - | ||

| 3b | Trip out (constant) | + | - | |||

| 3c | Trip out (decelerate) | + | - | + | ||

| 4a | Trip in (acceleration) | + | + | + | ||

| 4b | Trip in (constant) | + | + | |||

| 4c | Trip in (decelerate) | + | + | - | ||

| Position | Newtonian Model | Bingham Model | Power Law Model |

|---|---|---|---|

| Pipes | |||

| Annulus |

| Name | Density (kg/m3) | Thermal Conductivity (W/(m·K)) | Thermal Capacity (J/(kg·°C) |

|---|---|---|---|

| Sandstone | 2231 | 1.869 | 711.76 |

| Basalt | 1579 | 2.008 | 879.23 |

| Granite | 2641 | 2.821 | 837.36 |

| Cement | 2100 | 1.454 | 879.23 |

| Casing | 7848 | 45.174 | 460.55 |

| Materials | Inner Diameter (mm) | Outer Diameter(mm) |

|---|---|---|

| pipe | 139 | 159 |

| casing | 245 | 311 |

| cement | 311 | 406 |

| Depth (m) | 300 | 500 | 800 | 1000 | 1200 |

| Surge pressure (MPa) | 1.57 | 1.31 | 0.92 | 0.66 | 0.39 |

| Diameter (m) | 0.216 | 0.245 | 0.265 | 0.290 | 0.311 |

| Surge pressure (MPa) | 1.97 | 0.69 | 0.42 | 0.26 | 0.19 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, X.; Duan, C.; Yan, Z.; Ye, H.; Wang, Z.; Xia, B. Equivalent Circulation Density Analysis of Geothermal Well by Coupling Temperature. Energies 2017, 10, 268. https://doi.org/10.3390/en10030268

Zheng X, Duan C, Yan Z, Ye H, Wang Z, Xia B. Equivalent Circulation Density Analysis of Geothermal Well by Coupling Temperature. Energies. 2017; 10(3):268. https://doi.org/10.3390/en10030268

Chicago/Turabian StyleZheng, Xiuhua, Chenyang Duan, Zheng Yan, Hongyu Ye, Zhiqing Wang, and Bairu Xia. 2017. "Equivalent Circulation Density Analysis of Geothermal Well by Coupling Temperature" Energies 10, no. 3: 268. https://doi.org/10.3390/en10030268

APA StyleZheng, X., Duan, C., Yan, Z., Ye, H., Wang, Z., & Xia, B. (2017). Equivalent Circulation Density Analysis of Geothermal Well by Coupling Temperature. Energies, 10(3), 268. https://doi.org/10.3390/en10030268