Effects of Syngas Cooling and Biomass Filter Medium on Tar Removal

Abstract

:1. Introduction

2. Materials and Methods

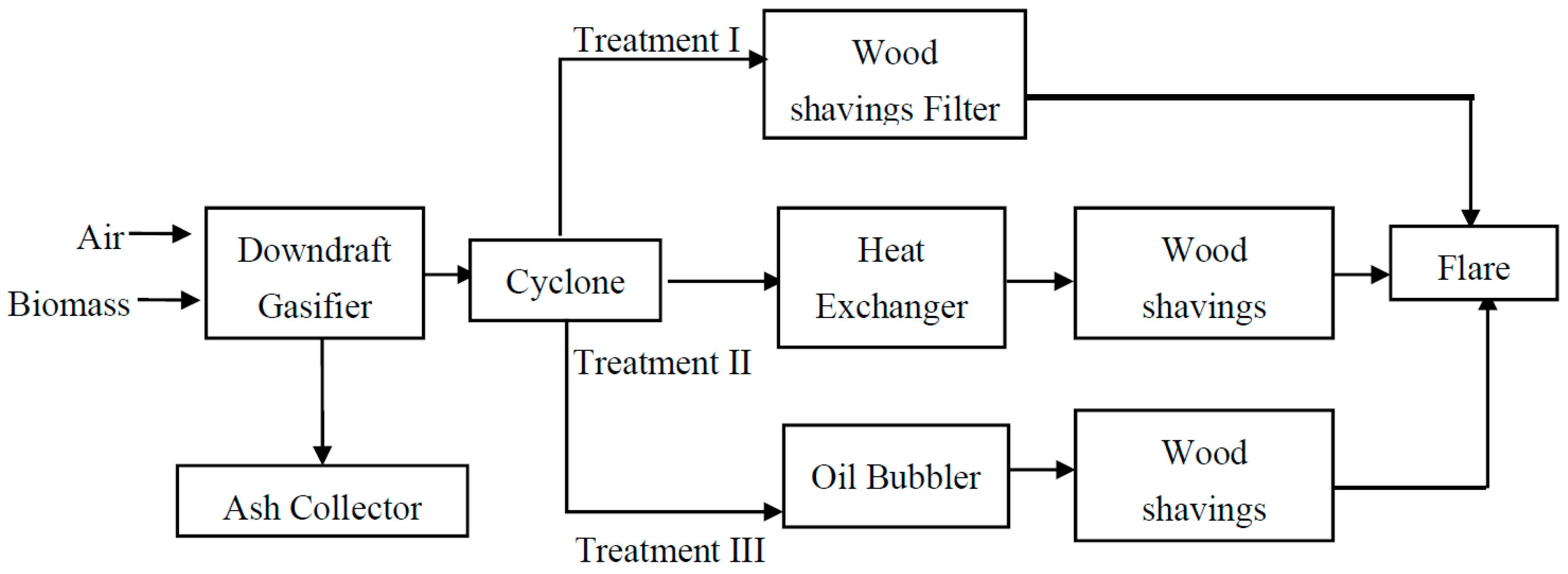

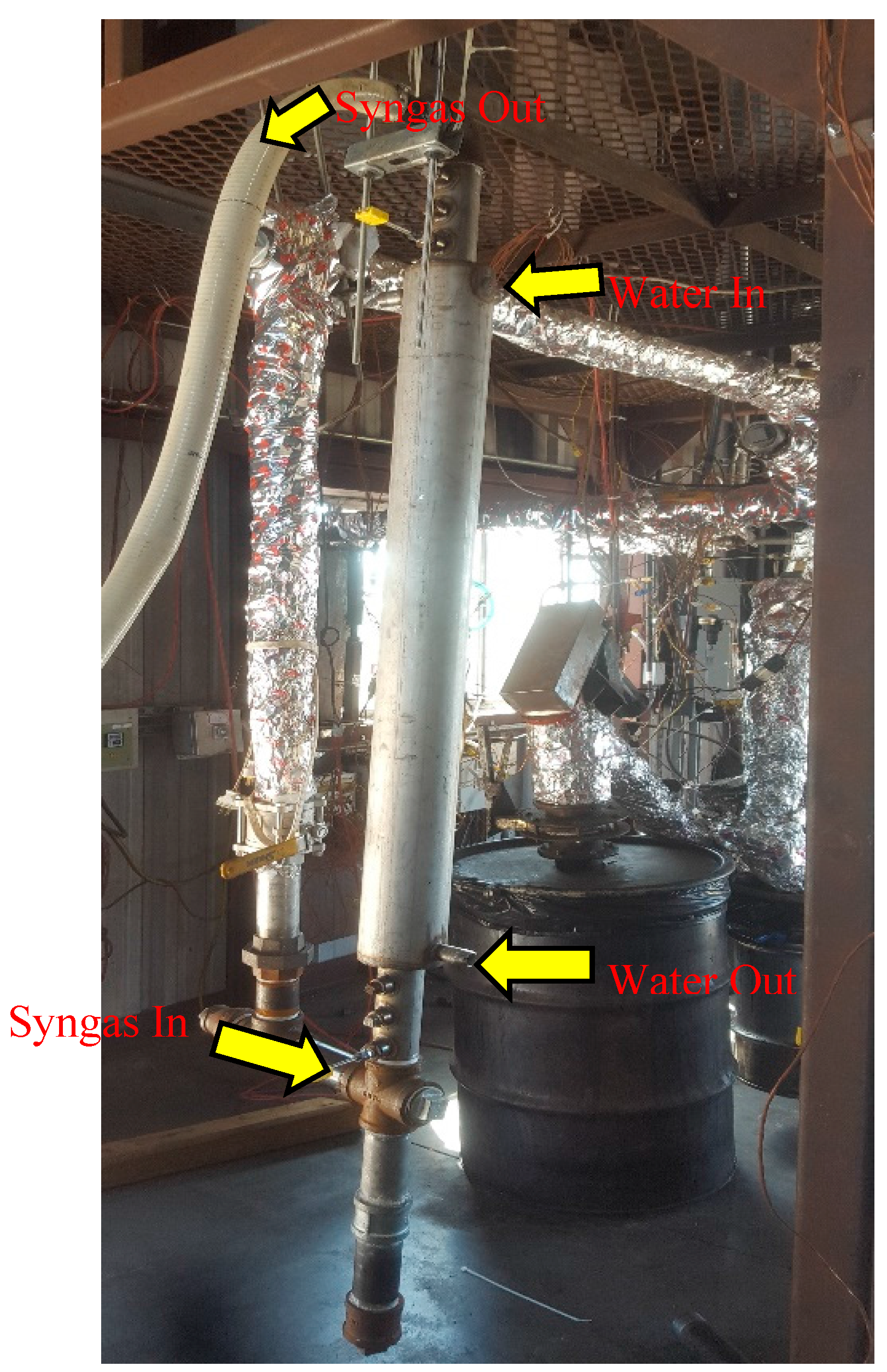

2.1. Experimental Set Up

2.2. Tar and Syngas Sampling and Analysis

3. Results and Discussion

3.1. Tar Reduction Efficiencies

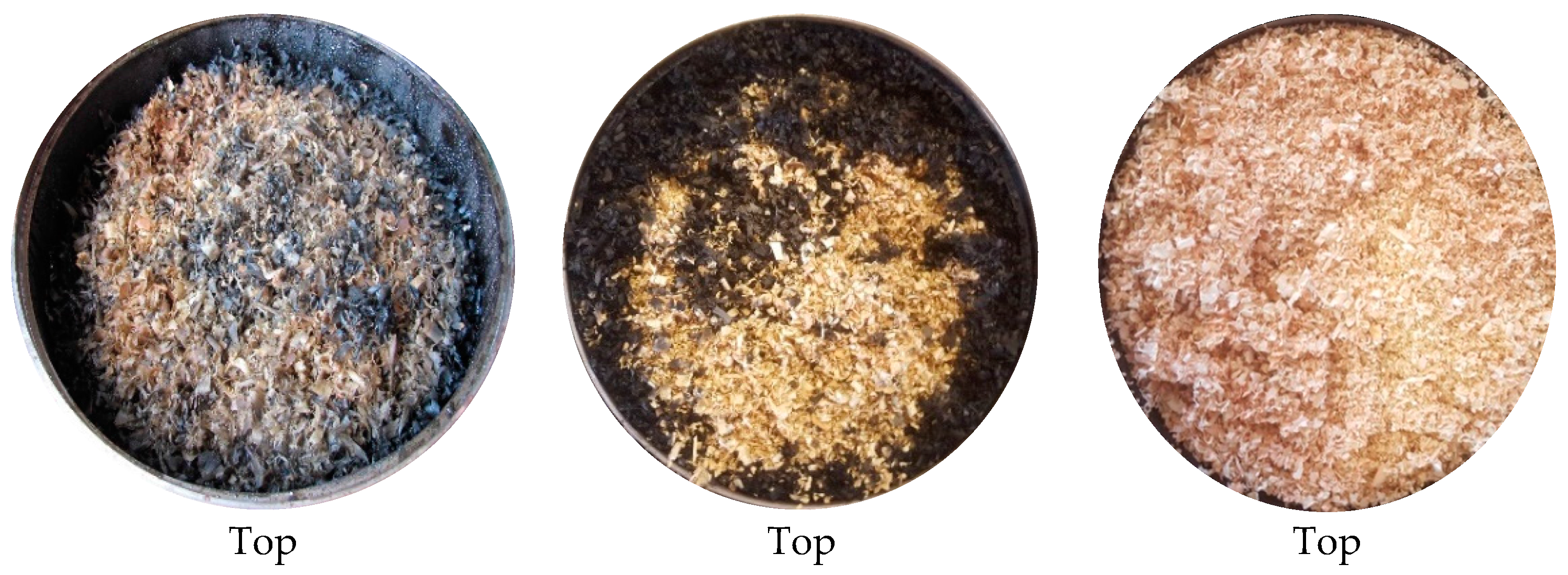

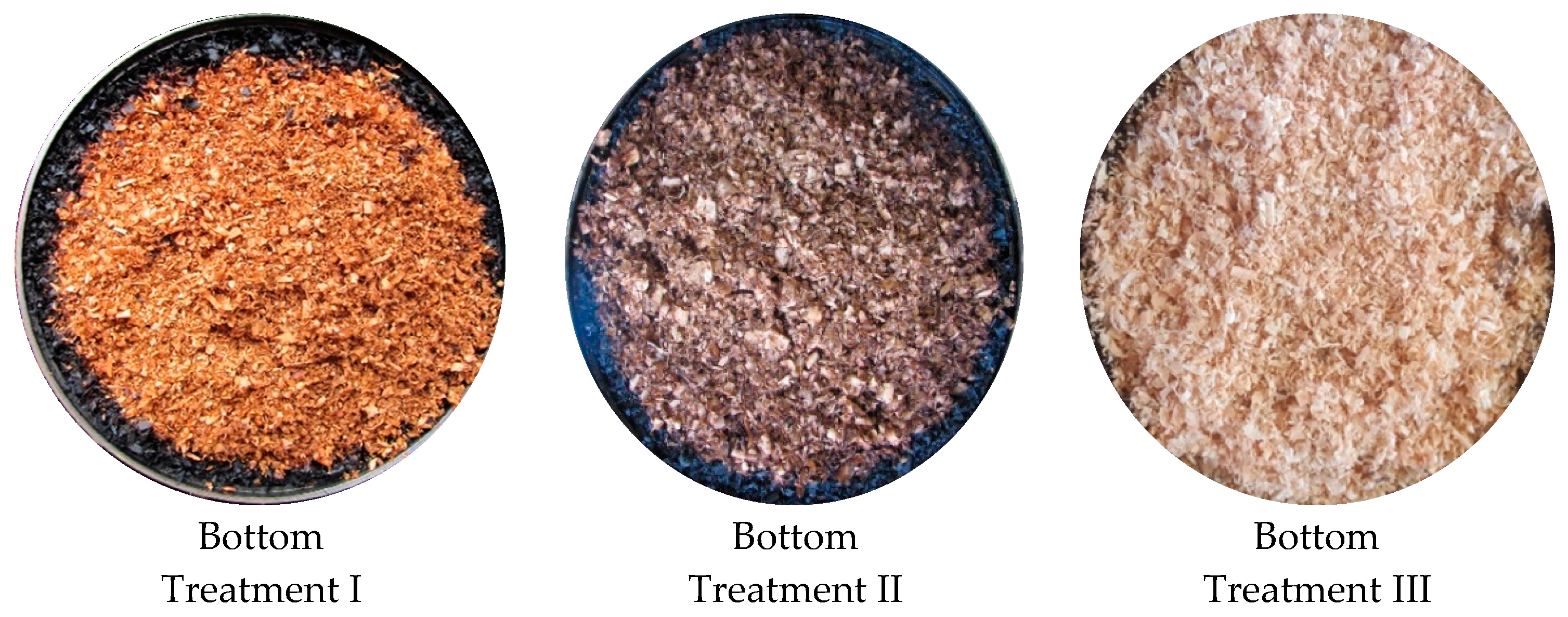

3.1.1. Tar Reduction Efficiency of Wood Shavings Filter (Treatment I)

3.1.2. Tar Reduction Efficiency of Wood Shavings Filter in Combination with Heat Exchanger (Treatment II)

3.1.3. Tar Reduction Efficiency of Wood Shavings Filter with Vegetable Oil Bubbler (Treatment III)

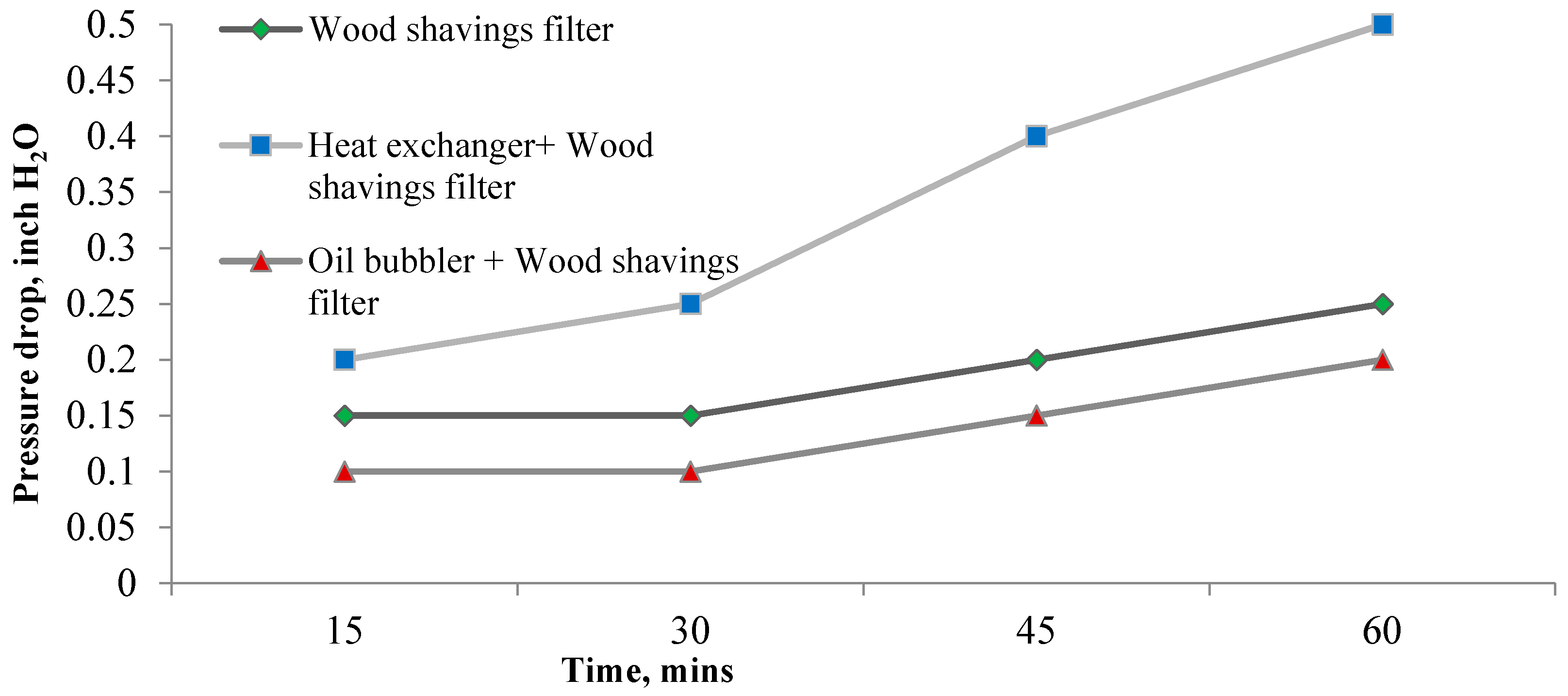

3.2. Variation of Pressure Drop across Wood Shavings Filter for the Three Treatments

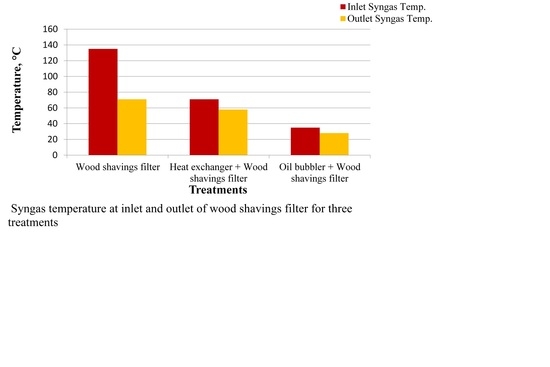

3.3. Variation of Gas Temperature at Inlet and Outlet of Wood Shavings Filter for Three Treatments

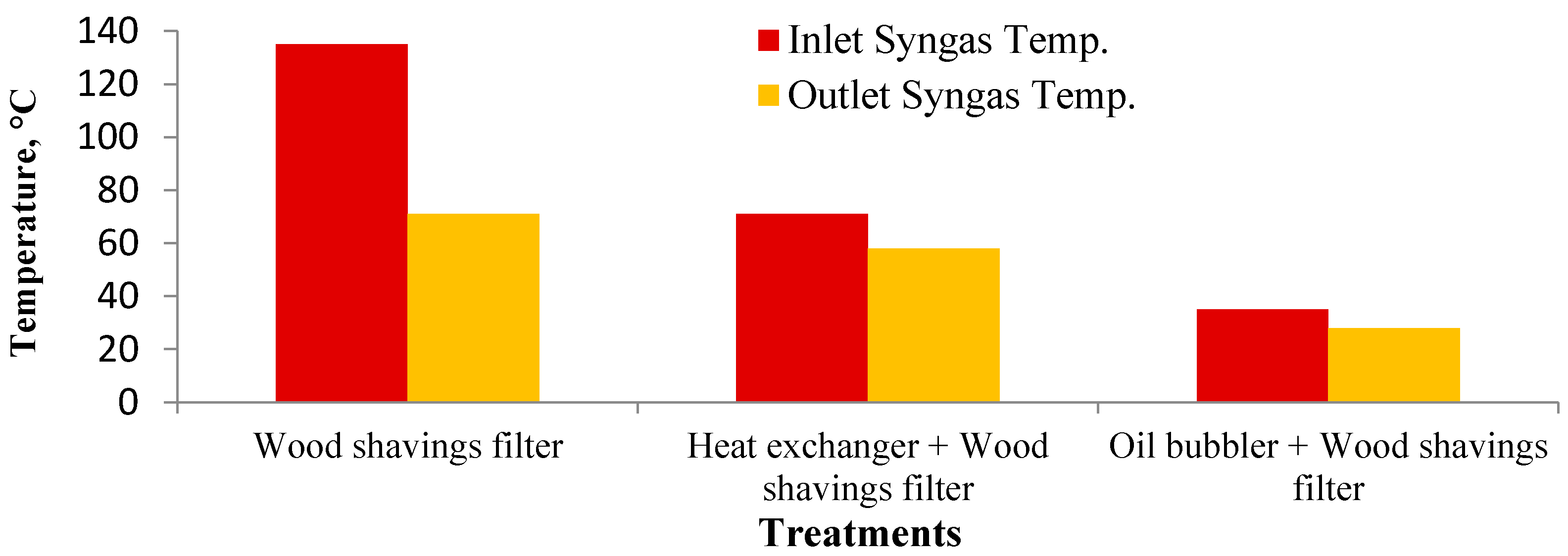

3.4. Heating Value of Syngas

4. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Srirangan, K.; Akawi, L.; Moo-Young, M.; Chou, C.P. Towards sustainable production of clean energy carriers from biomass resources. Appl. Energy 2012, 100, 172–186. [Google Scholar] [CrossRef]

- Devi, L.; Ptasinski, K.J.; Janssen, F.J. A review of the primary measures for tar elimination in biomass gasification processes. Biomass Bioenergy 2003, 24, 125–140. [Google Scholar] [CrossRef]

- Heidenreich, S.; Foscolo, P.U. New concepts in biomass gasification. Prog. Energy Combust. Sci. 2015, 46, 72–95. [Google Scholar] [CrossRef]

- Molino, A.; Chainese, S.; Musmarra, D. Biomass gasification technology: The state of the art overview. J. Energy Chem. 2016, 25, 10–25. [Google Scholar] [CrossRef]

- Anis, S.; Zainal, Z.A. Tar reduction in biomass producer gas via mechanical, catalytic and thermal methods: A review. Renew. Sustain. Energy Rev. 2011, 15, 2355–2377. [Google Scholar] [CrossRef]

- Advantages and Efficiency of Gasification. Available online: https://www.netl.doe.gov/research/coal/energy-systems/gasification/gasifipedia/clean-power (accessed on 31 January 2017).

- Ahmad, A.A.; Zawawi, N.A.; Kasim, F.H.; Inayat, A.; Khasri, A. Assessing the gasification performance of biomass: A review on biomass gasification process conditions, optimization and economic evaluation. Renew. Sustain. Energy Rev. 2016, 53, 1333–1347. [Google Scholar] [CrossRef]

- Huang, J.; Schmidt, K.G.; Bian, Z. Removal and conversion of tar in syngas from woody biomas gasification for power utilization using catalytic hydrocracking. Energies 2011, 4, 1163–1177. [Google Scholar] [CrossRef]

- Asadullah, M. Biomass gasification gas cleaning for downstream applications: A comparative critical review. Renew. Sustain. Energy Rev. 2014, 40, 118–132. [Google Scholar] [CrossRef]

- Baratieri, M.; Baggio, P.; Bosio, B.; Grigiante, M.; Longo, G.A. The use of biomass syngas in IC engines and CCGT plants: A comparative analysis. Appl. Therm. Eng. 2009, 29, 3309–3318. [Google Scholar] [CrossRef]

- Singh, R.N.; Mandovra, S.; Balwanshi, J. Performance of evaluation of “jacketed cyclone” for reduction of tar from producer gas. Int. Agric. Eng. J. 2013, 22, 1–5. [Google Scholar]

- Hasler, P.; Nussbaumer, T. Gas cleaning for IC engine applications from fixed bed biomass gasification. Biomass Bioenergy 1999, 16, 385–395. [Google Scholar] [CrossRef]

- Chainese, S.; Loipersbock, J.; Malits, M.; Rauch, R.; Hofbauer, H.; Molino, A.; Musmarra, D. Hydrogen from the high temperature water gas shift reaction with an industrial Fe/Cr catalyst using biomass gasification tar rich synthesis gas. Fuel Process. Technol. 2015, 132, 39–48. [Google Scholar] [CrossRef]

- Chainese, S.; Fail, S.; Binder, M.; Rauch, R.; Hofbauer, H.; Molino, A.; Blasi, A.; Musmarra, D. Experimental investigations of hydrogen production from CO catalytic conversion of tar rich syngas by biomass gasification. Catal. Today 2016, 277, 182–191. [Google Scholar] [CrossRef]

- Pathak, B.S.; Kapatel, D.; Bhoi, P.R.; Sharma, A.M.; Vyas, D.K. Design and development of sand bed filter for upgrading producer gas to IC engine quality fuel. Int. Energy J. 2007, 8, 15–20. [Google Scholar]

- Nakamura, S.; Unyaphan, S.; Yoshikawa, K.; Kitano, S.; Kimura, S.; Shimizu, H.; Tiara, K. Tar removal performance of bio-oil scrubber for biomass gasification. Biofuels 2014, 5, 597–606. [Google Scholar] [CrossRef]

- Rameshkumar, R.; Mayilsamy, K. A novel compact bio-filter system for a downdraft gasifier: An experimental study. AASRI Procedia 2012, 3, 700–706. [Google Scholar] [CrossRef]

- Allesina, G.; Pedrazzi, S.; Montermini, L.; Giorgini, L.; Bortolani, G.; Tartarin, P. Porous filtering media comparison through wet and dry sampling of fixed bed gasification. J. Phys. Conf. Series 2014, 547. [Google Scholar] [CrossRef]

- Pareek, D.; Joshi, A.; Narnaware, S.; Verma, V.K. Operational experience of agro-residue briquettes based power generation system of 100 kW capacity. Int. J. Renew. Energy Res. 2012, 2, 477–485. [Google Scholar]

- Henriken, U.; Ahrenfeldt, J.; Jensen, T.K.; Gobel, B.; Bentzen, J.D.; Hindsgaul, C.; Sorensen, L.H. The design, construction and operation of a 75 kW two-stage gasifier. Energy 2006, 31, 1542–1553. [Google Scholar] [CrossRef]

- Raman, P.; Ram, N.K.; Gupta, R. A dual fired downdraft gasifier system to produce cleaner gas for power generation: Design, development and performance analysis. Energy 2013, 54, 302–314. [Google Scholar] [CrossRef]

- Margaritis, N.K.; Grammelis, P.; Vera, D.; Jurado, F. Assessment of operational results of a downdraft biomass gasifier coupled with a gas engine. Proc. Soc. Behav. Sci. 2012, 48, 857–867. [Google Scholar] [CrossRef]

- Phuphukrat, T.; Namioka, T.; Yoshikawa, K. Absorptive removal of biomass tar using water and oily materials. Bioresour. Technol. 2011, 102, 543–549. [Google Scholar] [CrossRef]

- Paethanom, A.; Bartocci, P.; Alessandro, B.D.; Amico, M.D.; Testarmata, F.; Moriconi, N.; Slopiecka, K.; Yoshikawa, K.; Fantozzi, F. A low-cost pyrogas cleaning system for power generation: Scaling up from lab to pilot. Appl. Energy 2013, 111, 1080–1088. [Google Scholar] [CrossRef]

- Bhoi, P.R.; Huhnke, R.L.; Kumar, A.; Payton, M.E.; Patil, K.N.; Whiteley, J.R. Vegetable oil as a solvent for removing producer gas tar compounds. Fuel Proc. Technol. 2015, 133, 97–104. [Google Scholar] [CrossRef]

- Nakamura, S.; Siriwat, U.; Yoshikawa, K.; Kitano, S. Development of tar removal technologies for biomass gasification using the byproducts. Energy Procedia 2015, 75, 208–213. [Google Scholar] [CrossRef]

- Ahmad, N.A.; Zainal, Z.A. Performance and chemical composition of waste palm cooking oil as scrubbing medium for tar removal from biomass producer gas. J. Natural Gas Sci. Eng. 2016, 31, 256–261. [Google Scholar] [CrossRef]

- MILENA and OLGA Get together for High Efficiency and Low Tar. Available online: http://www.modernpowersystems.com/features/featuremilena-and-olga-get-together-for-high-efficiency-and-low-tar-4815584/ (accessed on 12 December 2016).

- Tarnpradab, T.; Unyaphan, S.; Takahasi, F.; Yoshikawa, K. Improvement of the biomass tar removal capacity of scrubbing oil regenerated by mechanical soild-liquid separation. Energy Fuels 2017, 31, 1564–1573. [Google Scholar] [CrossRef]

- Patil, K.N.; Huhnke, R.L.; Bellmer, D. Downdraft Gasifier with Internal Cyclonic Combustion Chamber. U.S. Patent 8,657,892 B, 25 February 2014. [Google Scholar]

- Good, J.; Ventress, L.; Knoef, H.; Zielke, U.; Hansen, P.L.; Kamp, W.V.D.; Wild, P.D.; Coda, B.; Paasen, S.V.; Kiel, J. Sampling and Analysis of Tar and Particles in Biomass Producer Gases; European Committee for Standardization (CEN): Brussels, Belgium, 2005. [Google Scholar]

- Atnaw, S.M.; Kueh, S.C.; Sulaiman, S.A. Study on tar generated from downdraft gasification of oil palm fronds. Sci. World J. 2014. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.; Srinivasan, R.; To, S.D.; Columbus, E.P. Performance and emissions of a spark-ignited engine driven generator on biomass based syngas. Bioresour. Technol. 2010, 101, 4656–4661. [Google Scholar] [CrossRef] [PubMed]

| End Use Device | Tar Acceptance Limit (g/Nm3) |

|---|---|

| Industrial gas turbine | <0.005 |

| Fuel cells | <0.001 |

| IC and diesel engines | 0.01–0.1 |

| Compressors | 0.05–0.5 |

| Parameters | Treatment I | Treatment II | Treatment III |

|---|---|---|---|

| Fuel feed rate, kg/h | 16.5 | 16 | 16.5 |

| Combustion zone temperature, °C | 719 | 700 | 703 |

| Equivalence ratio | 0.20 | 0.20 | 0.20 |

| Treatment | Raw Gas Tar Concentration (g/Nm3) | Cleaned Gas Tar Concentration (g/Nm3) |

|---|---|---|

| Wood shavings filter (I) | 78 | 70 |

| Heat exchanger + wood shavings filter (II) | 70 | 27 |

| Oil bubbler + wood shavings filter (III) | 70 | 1.9 |

| Gas components | Treatment I | Treatment II | Treatment III |

|---|---|---|---|

| H2 (% v/v) | 10.2 | 12.7 | 11.5 |

| N2 (% v/v) | 52.7 | 50.3 | 50.0 |

| O2 (% v/v) | 2.6 | 2.0 | 1.5 |

| CO (% v/v) | 12.8 | 14.0 | 14.6 |

| CH4 (% v/v) | 2.9 | 2.9 | 4.8 |

| CO2 (% v/v) | 15.6 | 14.2 | 19.1 |

| LHV (MJ·Nm−3) | 5.432 | 5.766 | 5.680 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thapa, S.; Bhoi, P.R.; Kumar, A.; Huhnke, R.L. Effects of Syngas Cooling and Biomass Filter Medium on Tar Removal. Energies 2017, 10, 349. https://doi.org/10.3390/en10030349

Thapa S, Bhoi PR, Kumar A, Huhnke RL. Effects of Syngas Cooling and Biomass Filter Medium on Tar Removal. Energies. 2017; 10(3):349. https://doi.org/10.3390/en10030349

Chicago/Turabian StyleThapa, Sunil, Prakashbhai R. Bhoi, Ajay Kumar, and Raymond L. Huhnke. 2017. "Effects of Syngas Cooling and Biomass Filter Medium on Tar Removal" Energies 10, no. 3: 349. https://doi.org/10.3390/en10030349

APA StyleThapa, S., Bhoi, P. R., Kumar, A., & Huhnke, R. L. (2017). Effects of Syngas Cooling and Biomass Filter Medium on Tar Removal. Energies, 10(3), 349. https://doi.org/10.3390/en10030349