A Novel High Step-Up DC-DC Converter with Coupled Inductor and Switched Clamp Capacitor Techniques for Photovoltaic Systems

Abstract

:1. Introduction

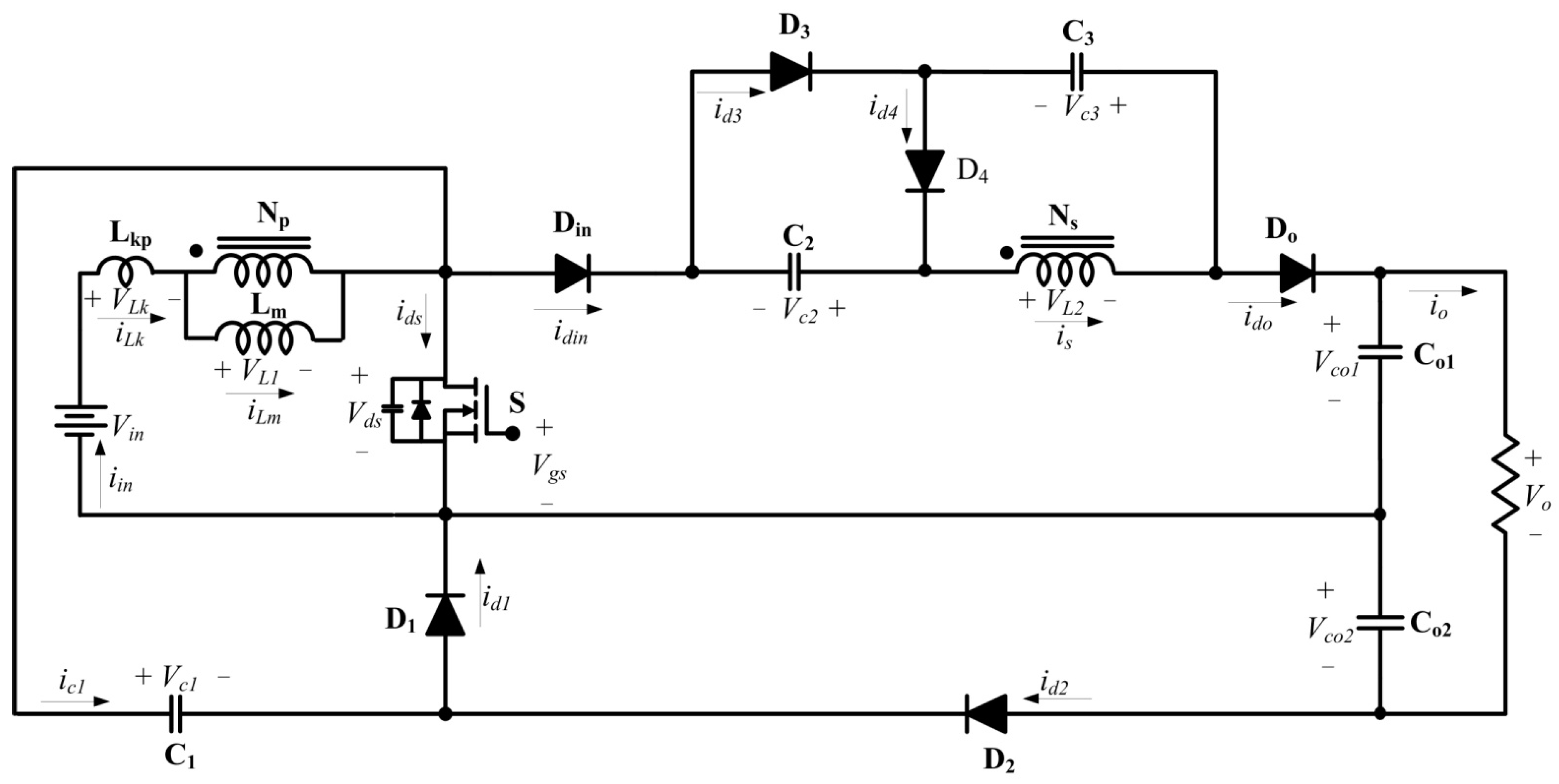

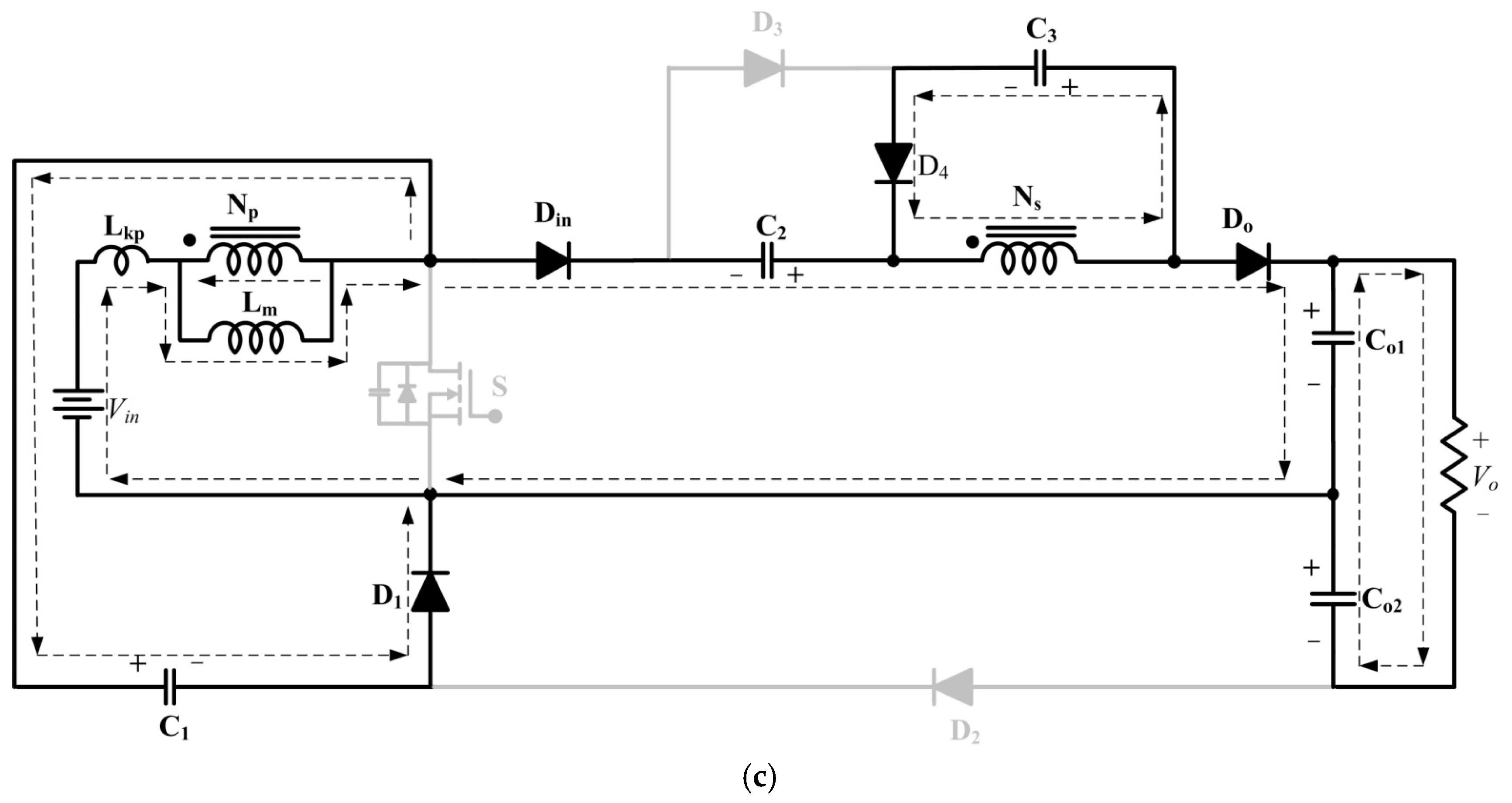

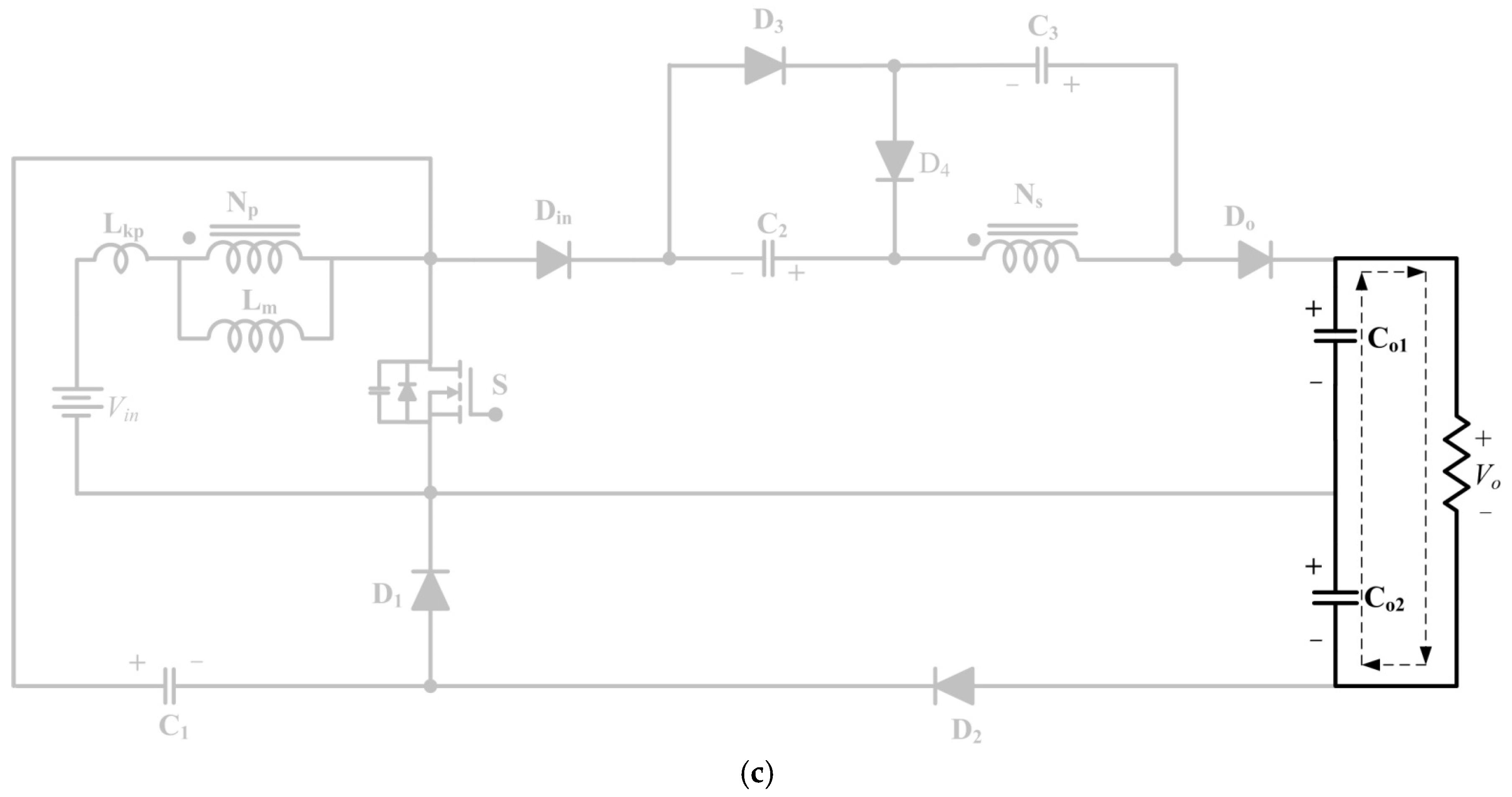

2. Operation Principle of the Proposed Converter

- Capacitors C1–C3 and Co1–Co2 are sufficiently large. Therefore, Vc1–Vc3 and Vco1–Vco2 are considered constant during an operation.

- Power devices are ideal components, and the parasitic capacitors of power devices are not neglected.

- The magnetizing inductance is Lm and leakage inductance is Lk; the coupling coefficient of the coupled inductor is k and is equal to Lm/(Lm+Lk).

- The turn ratio n is equal to Ns/Np.

- The proposed converter operation can be divided into the continuous conduction mode (CCM) and discontinuous conduction mode (DCM). The detail analysis is as follows:

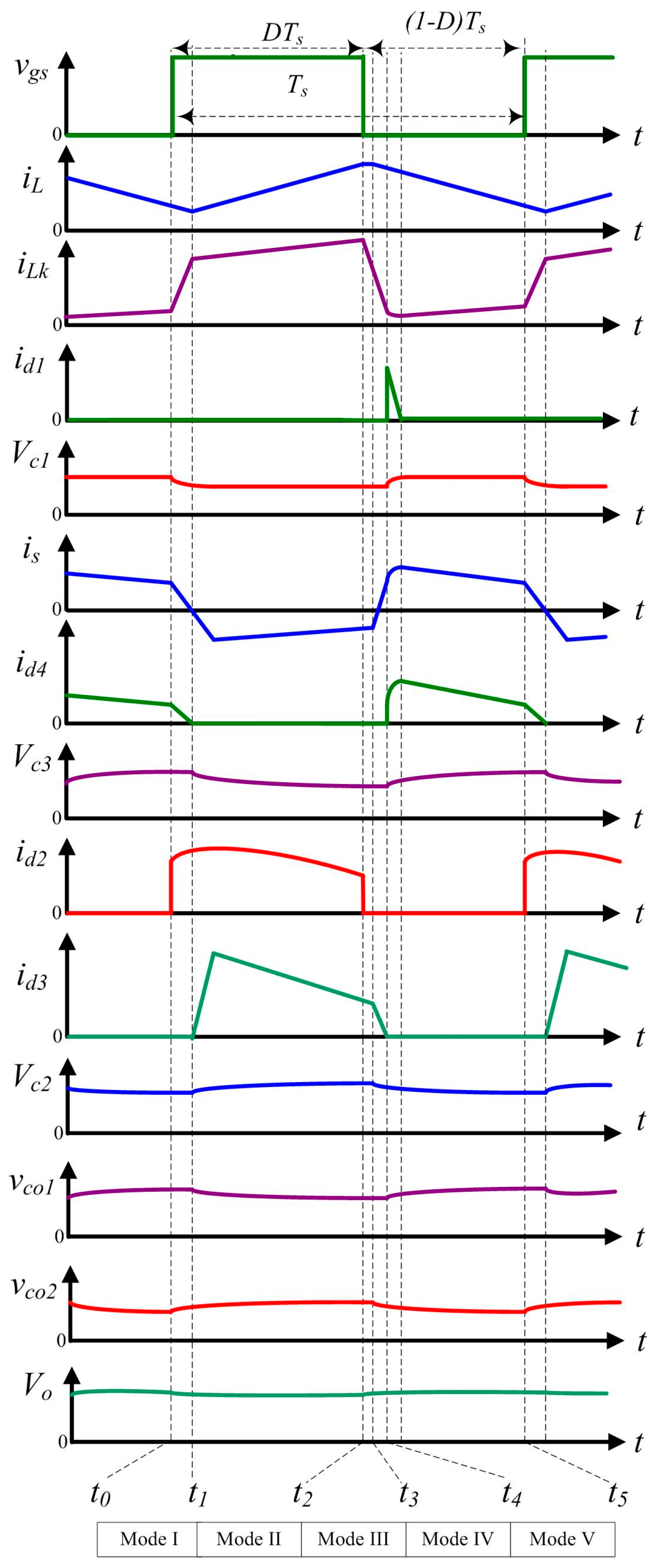

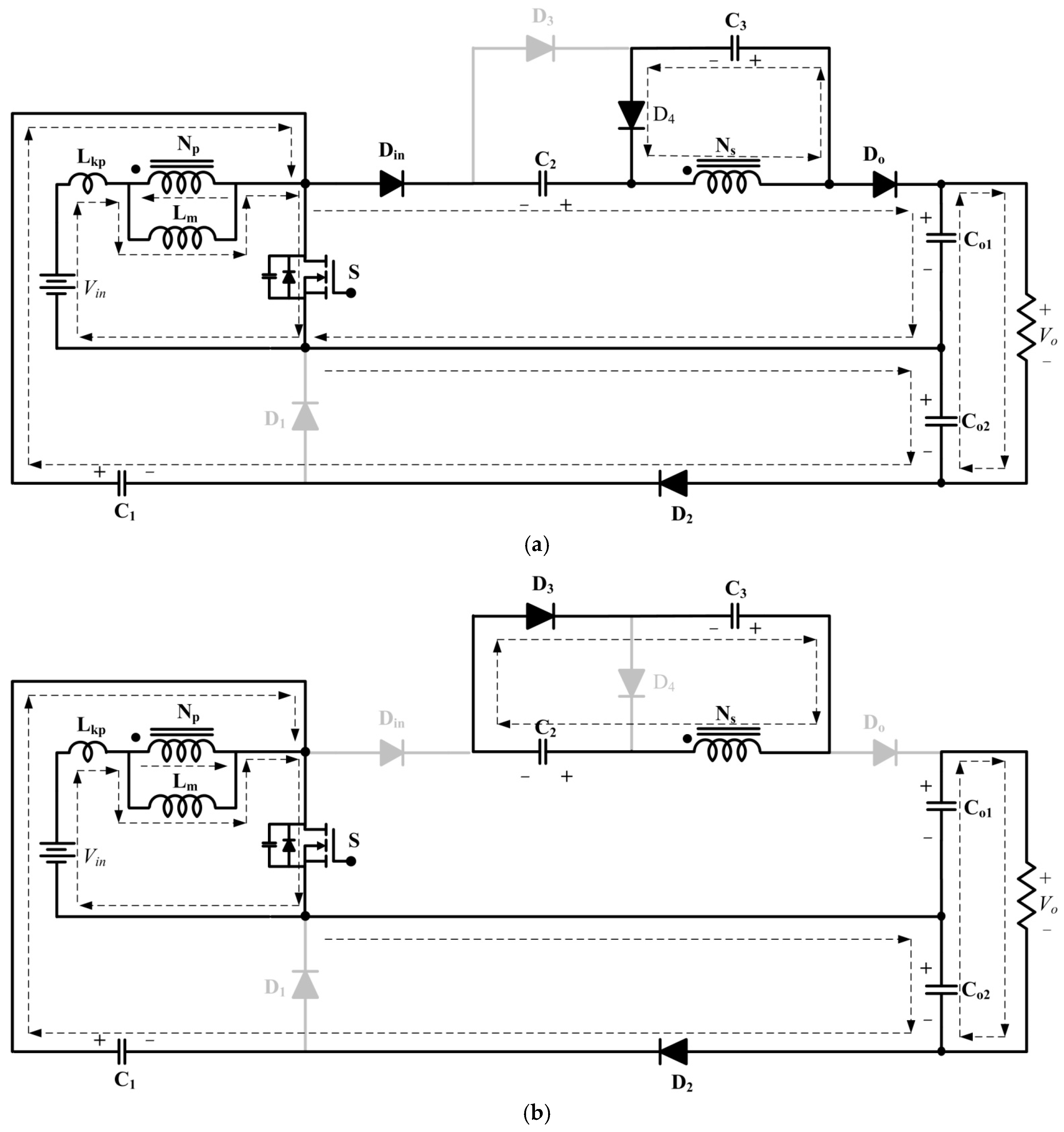

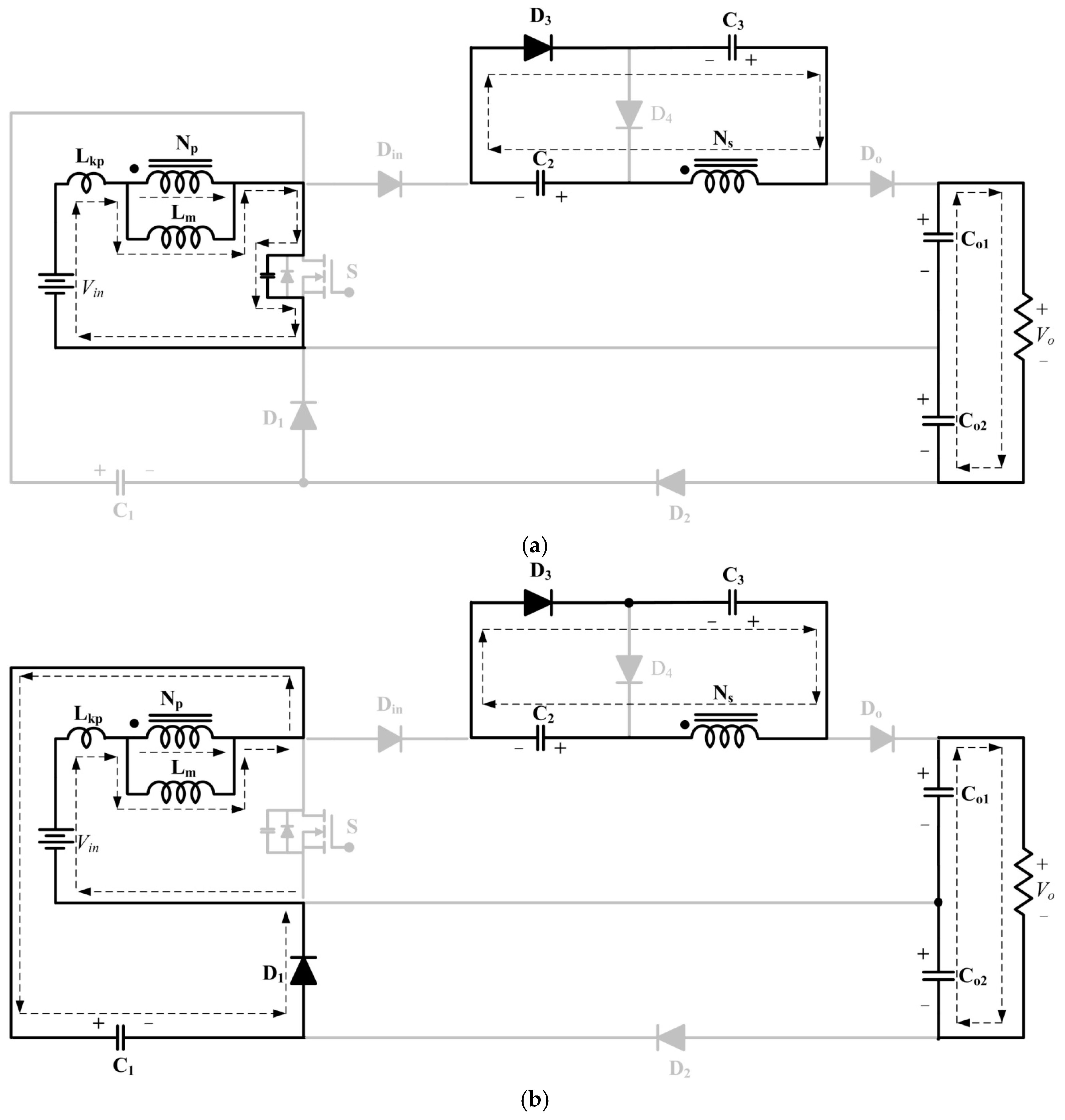

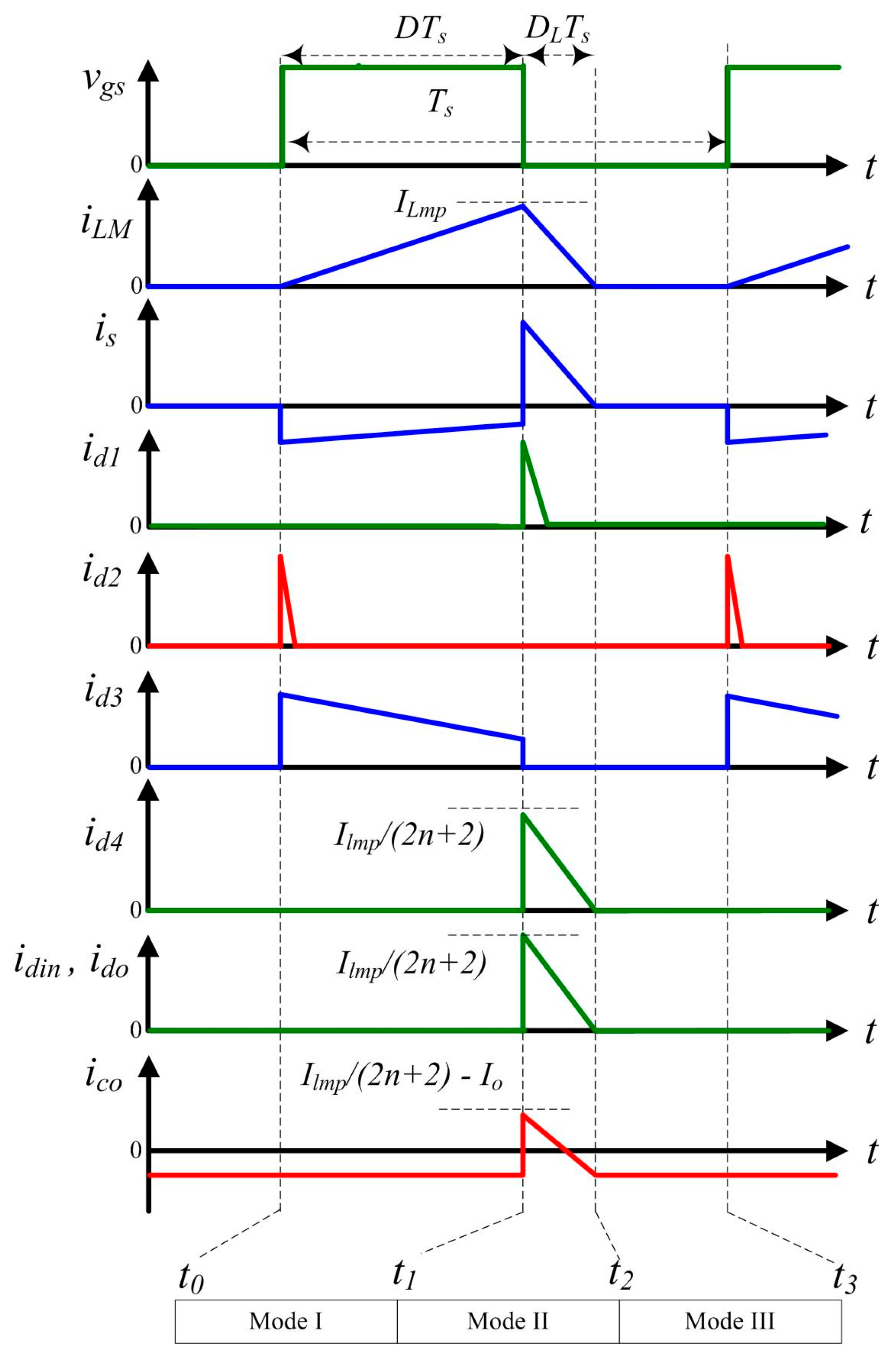

2.1. CCM Operation

2.2. DCM Operation

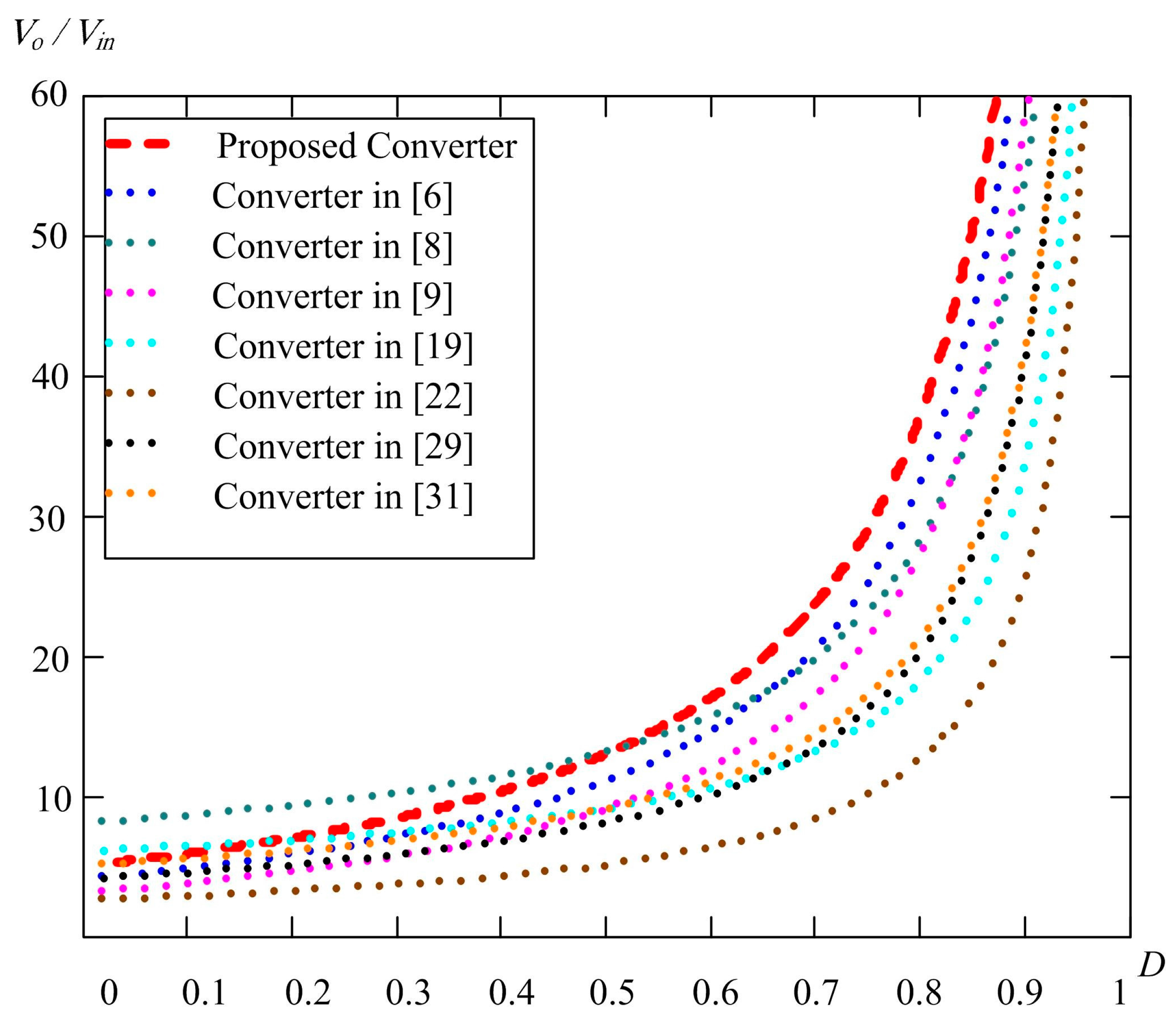

3. Steady-State Analysis of the Proposed Converter

3.1. CCM Operation

3.2. DCM Operation

3.3. Boundary Operating Condition between the CCM and the DCM

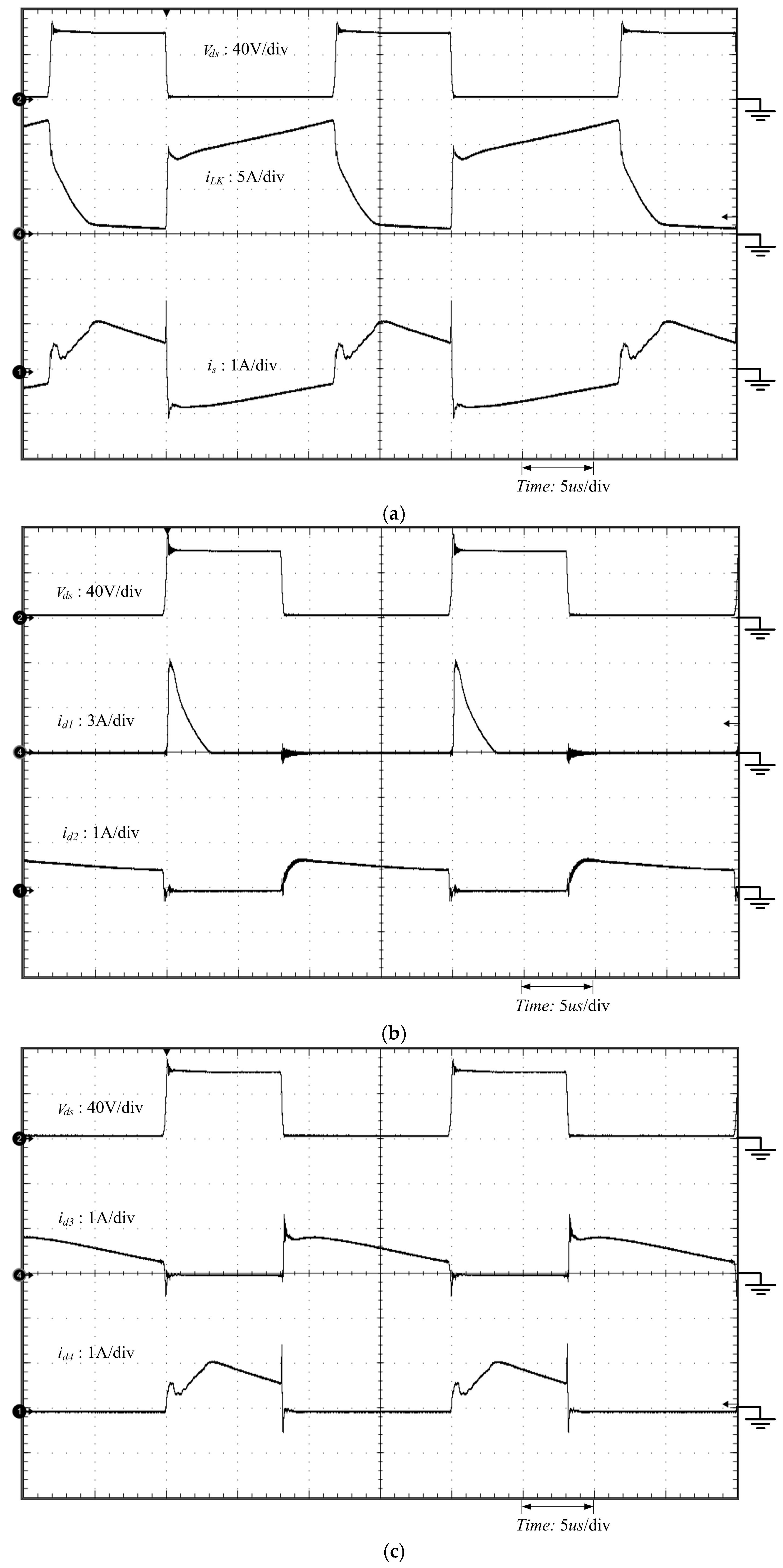

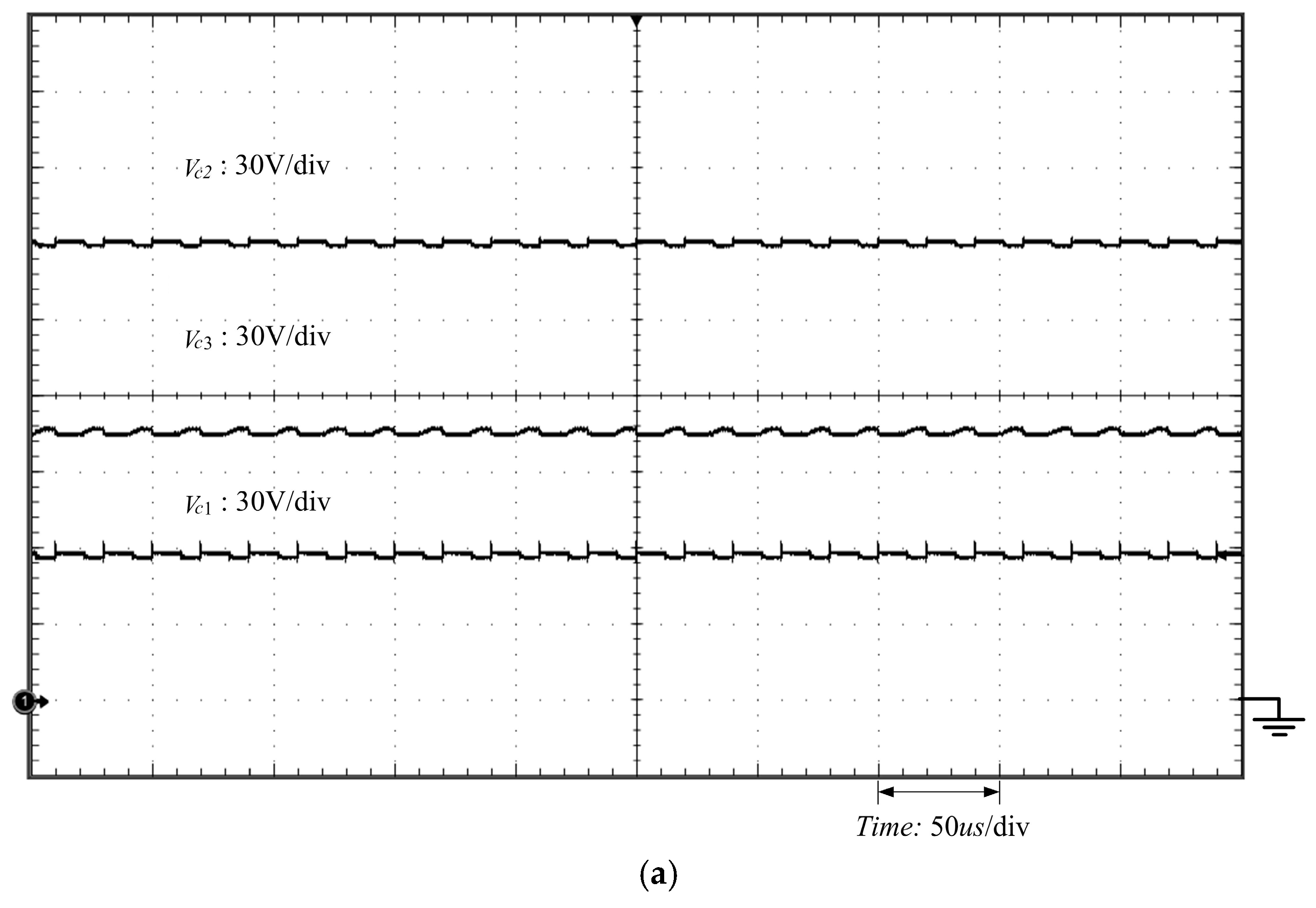

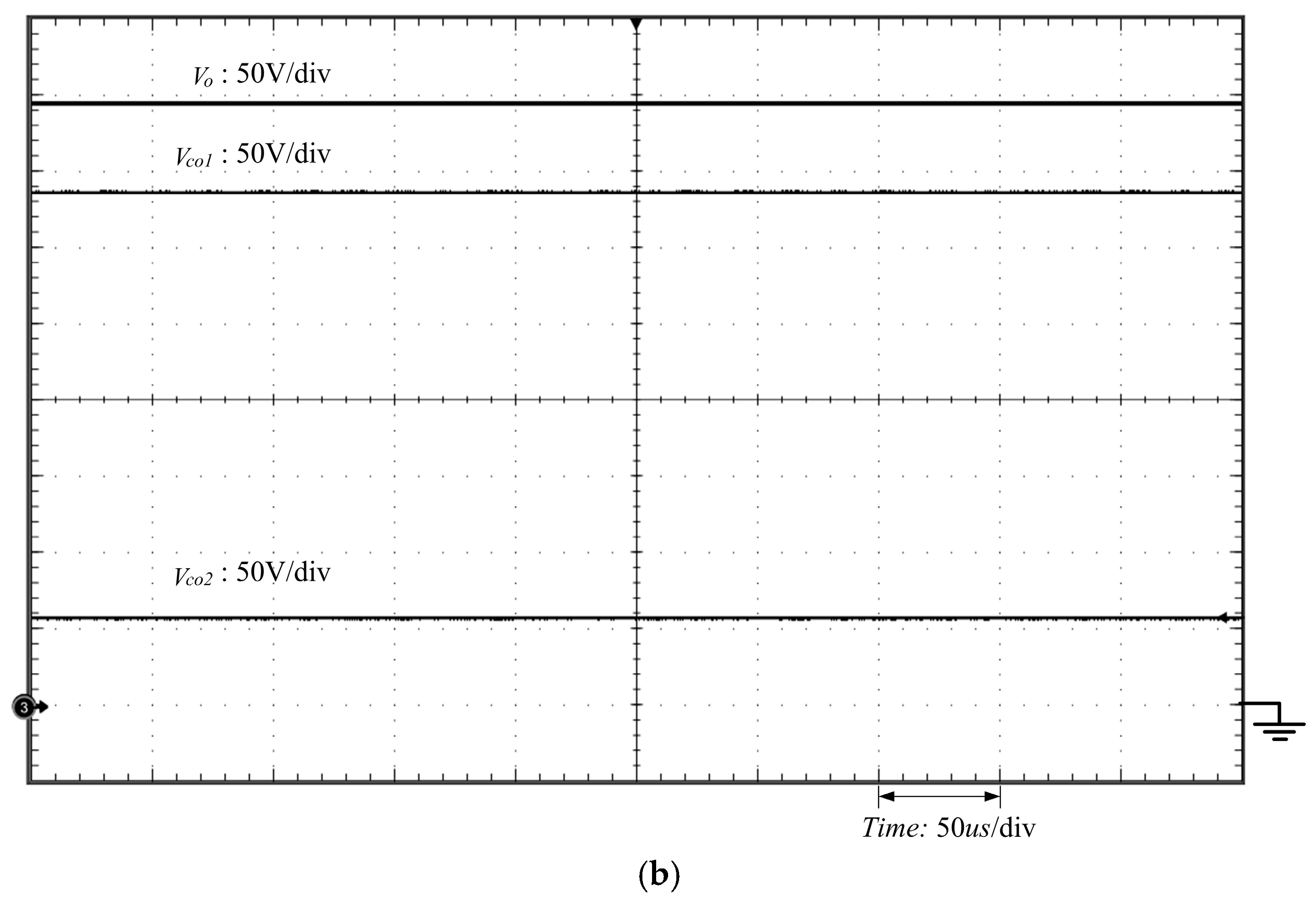

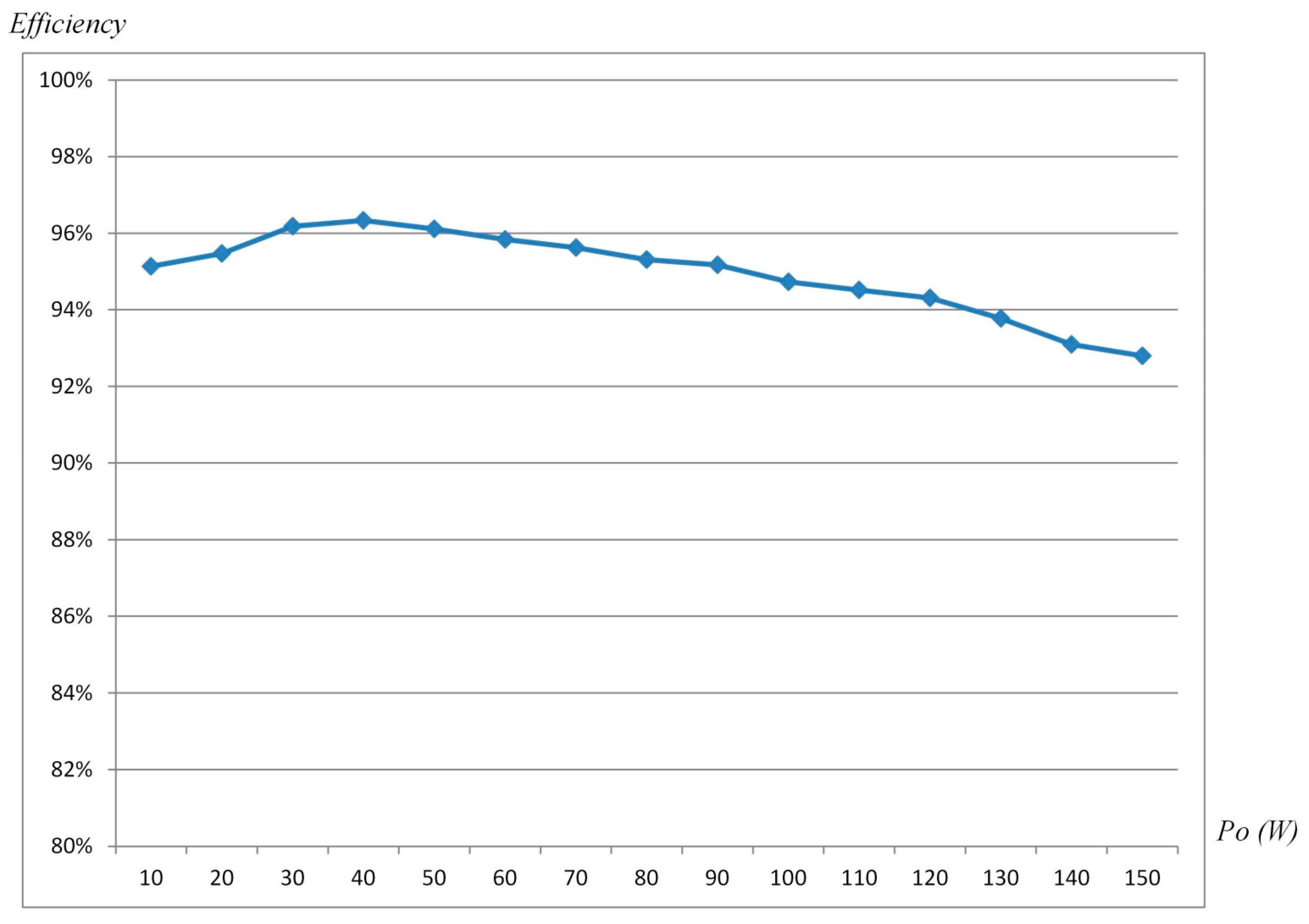

4. Design and Experiment of the Proposed Converter

- Input DC voltage : 24 V.

- Output DC voltage .

- Maximum output power: 150 W.

- Switch frequency: 50 kHz.

- Switch: IXTH130N10T.

- Diodes: D1–D3, Do: DSEI 30-10A; Din and D4: 25JPE40.

- Capacitors: C1 and Cco2: 100 /100 V, C2: 100 /250 V, C3: 100 /100 V, and Co1: 220 /400 V aluminium capacitors.

- Transformer: ETD-49 core PC-32, Np:Ns = 1:3, Lm = 32 μH and Lk = 0.22 μH; .

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Anders, L.; Peter, U.C.; Ben, M.; Glenn, A.M.; David, P.; Valentina, R.; Alexander, R. The multimillennial sea-level commitment of global warming. Proc. IEEE Natl. Acad. Sci. USA 2016, 110, 13745–13750. [Google Scholar]

- Wei, C.L.; Shih, M.H. Design of a switched-capacitor DC-DC converter with a wide input voltage range. IEEE Trans. Circuits Syst. I 2013, 60, 1648–1656. [Google Scholar] [CrossRef]

- Chang, C.H.; Chang, E.C.; Cheng, H.L. A high-efficiency solar array simulator implemented by an LLC resonant DC-DC converter. IEEE Trans. Power Electron. 2013, 28, 3039–3046. [Google Scholar] [CrossRef]

- Shen, J.M.; Jou, H.L.; Wu, J.C. Novel transformerless grid-connected power converter with negative grounding for photovoltaic generation system. IEEE Trans. Power Electron. 2012, 27, 1819–1829. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, K.; Feng, L.L.; Wu, H.F.; Xing, Y. A family of neutral point clamped full-bridge topologies for transformerless photovoltaic grid-tied inverters. IEEE Trans. Power Electron. 2013, 28, 730–739. [Google Scholar] [CrossRef]

- Baek, J.W.; Ryoo, M.H.; Kim, T.J.; Yoo, D.W.; Kim, J.S. High boost converter using voltage multiplier. In Proceedings of the 31st Annual Conference of IEEE Industrial Electronics Society (IECON 2005), Raleigh, NC, USA, 6–10 November 2005; pp. 567–572.

- Wai, R.J.; Duan, R.Y. High-efficiency power conversion for low power fuel cell generation system. IEEE Trans. Power Electron. 2005, 20, 847–856. [Google Scholar] [CrossRef]

- Hsieh, Y.P.; Chen, J.F.; Liang, T.J.; Yang, L.S. Novel high step-up DC-DC converter for distributed generation system. IEEE Trans. Ind. Electron. 2013, 60, 1473–1482. [Google Scholar] [CrossRef]

- Hsieh, Y.P.; Chen, J.F.; Liang, T.J.; Yang, L.S. Analysis and implementation of a novel single-switch high step-up DC-DC converter. IET Power Electron. 2012, 5, 11–21. [Google Scholar] [CrossRef]

- Ajami, A.; Ardi, H.; Farakhor, A. A novel high step-up DC/DC converter based on integrating coupled inductor and switched-capacitor techniques for renewable energy applications. IEEE Trans. Power Electron. 2015, 30, 4255–4263. [Google Scholar] [CrossRef]

- Luo, F.L.; Ye, H. Positive output multiple-lift push-pull switched-capacitor Luo-converters. IEEE Trans. Ind. Electron. 2004, 51, 594–602. [Google Scholar] [CrossRef]

- Abutbul, O.; Gherlitz, A.; Berkovih, Y.; Ioinovici, A. Step-up switching-mode converter with high voltage gain using a switched-capacitor circuit. IEEE Trans. Circuits Syst. I 2003, 50, 1098–1102. [Google Scholar] [CrossRef]

- Hsieh, Y.P.; Chen, J.F.; Liang, T.J.; Yang, L.S. Novel high step up DC-DC converter with coupled-inductor and switched-capacitor techniques. IEEE Trans. Ind. Electron. 2012, 59, 998–1007. [Google Scholar] [CrossRef]

- Axelrod, B.; Berkovich, Y. Switched coupled-inductor cell for DC-DC converters with very large conversion ratio. IET Power Electron. 2011, 4, 309–315. [Google Scholar]

- Duan, R.Y.; Lee, J.D. High-efficiency bidirectional DC-DC converter with coupled inductor. IET Power Electron. 2012, 5, 115–123. [Google Scholar] [CrossRef]

- Changchien, S.K.; Liang, T.J.; Chen, J.F.; Yang, L.S. Step-up DC-DC converter by coupled inductor and voltage-lift technique. IET Power Electron. 2013, 3, 369–378. [Google Scholar] [CrossRef]

- Hsieh, Y.P.; Chen, J.F.; Yang, L.S.; Wu, C.Y.; Liu, W.S. High-conversion-ratio bidirectional DC-DC converter with coupled inductor. IEEE Trans. Ind. Electron. 2014, 61, 210–222. [Google Scholar] [CrossRef]

- Zhao, Q.; Lee, F.C. High-efficiency, high Step-up DC-DC converters. IEEE Trans. Power Electron. 2003, 18, 65–73. [Google Scholar] [CrossRef]

- Lee, J.H.; Liang, T.L.; Chen, J.F. Isolated coupled-inductor-integrated DC-DC converter with nondissipative snubber for solar energy applications. IEEE Trans. Ind. Electron. 2014, 61, 3337–3348. [Google Scholar] [CrossRef]

- Hsieh, Y.P.; Chen, J.F.; Liang, T.J.; Yang, L.S. Novel high step-up DC-DC converter with coupled-inductor and switched-capacitor techniques for a sustainable energy system. IEEE Trans. Power Electron. 2011, 26, 3481–3490. [Google Scholar] [CrossRef]

- Siwakoti, Y.P.; Blaabjerg, F.; Loh, P.C. Ultra-step-up DC-DC converter with integrated autotransformer and coupled inductor. In Proceedings of the 2016 IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 20–24 March 2016; pp. 1872–1877.

- Liang, T.J.; Lee, J.H.; Chen, S.M.; Chen, J.F.; Yang, L.S. Novel isolated high step-up DC-DC converter with voltage lift. IEEE Trans. Power Electron. 2013, 60, 1483–1491. [Google Scholar] [CrossRef]

- Chen, Y.T.; Tsai, M.H.; Liang, R.H. DC-DC converter with high voltage gain and reduce switch stress. IET Power Electron. 2014, 7, 2564–2571. [Google Scholar] [CrossRef]

- Lin, B.R.; Dong, J.Y. Analysis and implementation of an active clamping zero-voltage turn-on switching/zero-current turn-off switching converter. IET Power Electron. 2010, 3, 429–437. [Google Scholar] [CrossRef]

- Zhao, Q.; Tao, F.; Hu, Y.; Lee, F.C. Active-clamp DC/DC converters using magnetic switches. In Proceedings of the Sixteenth Annual IEEE Applied Power Electronics Conference and Exposition (APEC 2001), Anaheim, CA, USA, 4–8 March 2002; pp. 946–952.

- Tseng, K.C.; Liang, T.J. Analysis of integrated boost-flyback step-up converter. IEEE Proc. Inst. Elect. Eng. Electric. Power Appl. 2005, 151, 217–225. [Google Scholar]

- Wai, R.J.; Duan, R.Y.; Jheng, K.H. High-efficiency bidirectional DC-DC converter with high-voltage gain. IET Power Electron. 2012, 5, 173–184. [Google Scholar] [CrossRef]

- Kuo, P.H.; Liang, T.J.; Tseng, K.C.; Chen, J.F.; Chen, S.M. An isolated high step-up forward/flyback active-clamp converter with output voltage lift. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition (ECCE), Atlanta, GA, USA, 12–16 September 2010; pp. 542–548.

- Wai, R.J.; Liu, L.W.; Duan, R.Y. High-efficiency voltage-clamped DC-DC converter with reduced reverse-recovery current and switch-Voltage stress. IEEE Trans. Ind. Electron. 2006, 53, 272–280. [Google Scholar]

- Wu, T.F.; Lai, Y.S.; Hung, J.C.; Chen, Y.M. Boost converter with coupled inductors and buck-boost type of active clamp. IEEE Trans. Ind. Electron. 2008, 55, 154–162. [Google Scholar] [CrossRef]

- Wai, R.J.; Lin, C.Y.; Duan, R.Y.; Chang, Y.R. High-efficiency DC-DC converter with high voltage gain and reduced switch stress. IEEE Trans. Ind. Electron. 2007, 54, 354–364. [Google Scholar] [CrossRef]

- Muhammad, M.; Armstrong, M.; Elgendy, M.A. A nonisolated interleaved boost converter for high-voltage gain applications. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 352–362. [Google Scholar] [CrossRef]

- Muhammad, M.; Armstrong, M.; Elgendy, M. Non-isolated DC-DC converter for high-step-up ratio applications. In Proceedings of the 2015 17th European Conference on Power Electronics and Applications (EPE'15 ECCE-Europe), Geneva, Switzerland, 8–10 September 2015; pp. 1–10.

- Muhammad, M.; Armstrong, M.; Elgendy, M.A. Non-isolated, high gain, boost converter for power electronic applications. In Proceedings of the 8th IET International Conference on Power Electronics, Machines and Drives (PEMD 2016), Glasgow, UK, 19–21 April 2016.

| Converters | No. of Components | Efficiency | Vin/Vout | Voltage Gain ( Vo/Vin) |

|---|---|---|---|---|

| proposed converter | 6 diodes, | 96.20% | Vin = 24 V, | |

| 5 capacitors | Vo = 400 V | |||

| [6] | 3 diodes, | NA | Vin = 48 V, | |

| 3 capacitors | Vo = 380 V | |||

| [8] | 4 diodes, | 95.88% | Vin = 24 V, | |

| 4 capacitors | Vo = 400 V | |||

| [9] | 4 diodes, | 96.70% | Vin = 24 V, | |

| 4 capacitors | Vo = 400 V | |||

| [19] | 5 diodes, | 95.70% | Vin = 24 V, | |

| 4 capacitors | Vo = 200 V | |||

| [22] | 5 diodes, | 96.20% | Vin = 24 V, | |

| 3 capacitors | Vo = 200 V | |||

| [29] | 5 diodes, | 96.50% | Vin = 27–37.5 V, | |

| 3 capacitors | Vo = 200 V | |||

| [31] | 3 diodes, | 95.20% | Vin = 27–36.5 V, | |

| 3 capacitors | Vo = 200 V |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wong, Y.-S.; Chen, J.-F.; Liu, K.-B.; Hsieh, Y.-P. A Novel High Step-Up DC-DC Converter with Coupled Inductor and Switched Clamp Capacitor Techniques for Photovoltaic Systems. Energies 2017, 10, 378. https://doi.org/10.3390/en10030378

Wong Y-S, Chen J-F, Liu K-B, Hsieh Y-P. A Novel High Step-Up DC-DC Converter with Coupled Inductor and Switched Clamp Capacitor Techniques for Photovoltaic Systems. Energies. 2017; 10(3):378. https://doi.org/10.3390/en10030378

Chicago/Turabian StyleWong, Yong-Seng, Jiann-Fuh Chen, Kuo-Bin Liu, and Yi-Ping Hsieh. 2017. "A Novel High Step-Up DC-DC Converter with Coupled Inductor and Switched Clamp Capacitor Techniques for Photovoltaic Systems" Energies 10, no. 3: 378. https://doi.org/10.3390/en10030378