Using Grass Cuttings from Sports Fields for Anaerobic Digestion and Combustion

Abstract

:1. Introduction

2. Results and Discussion

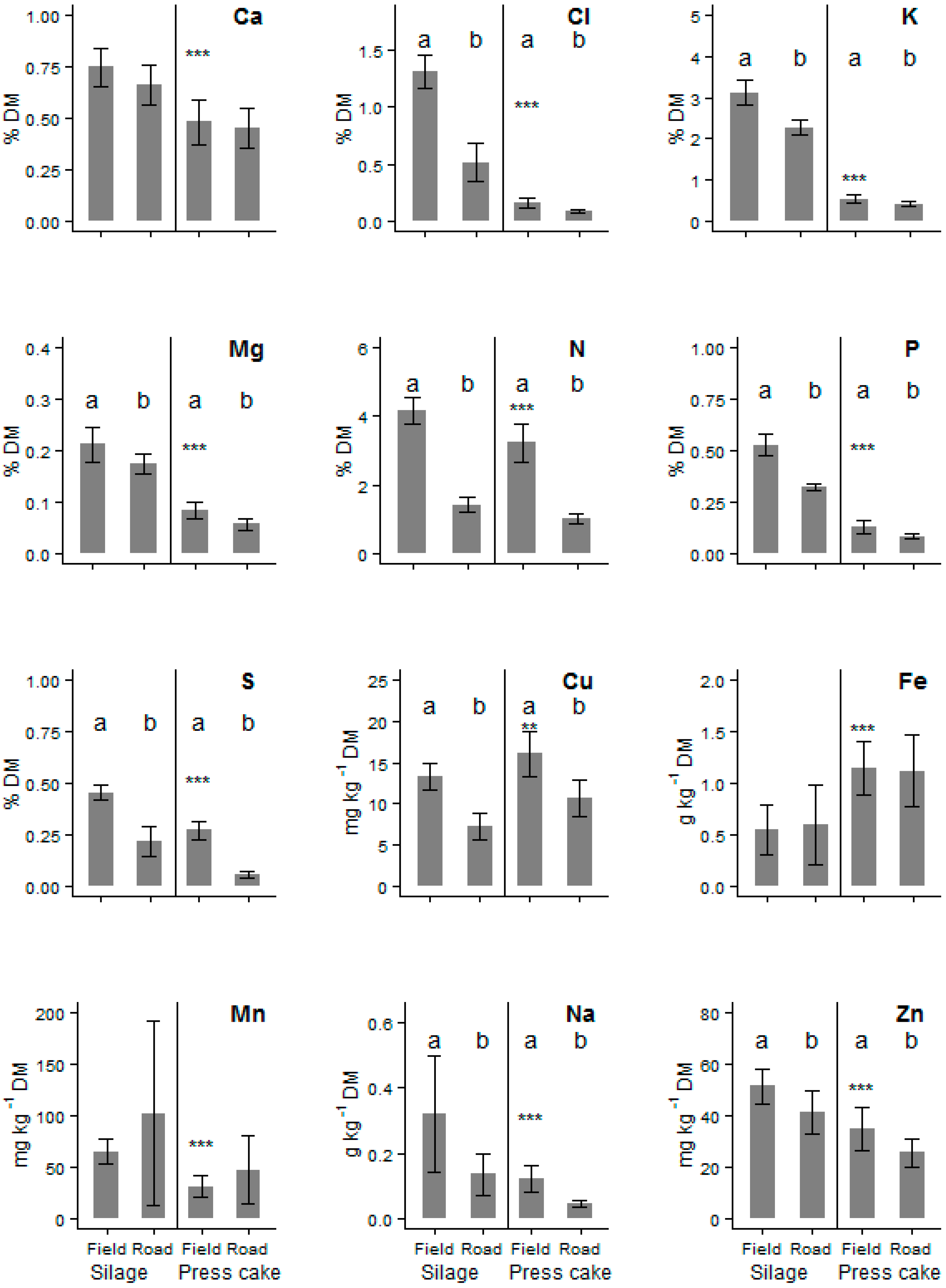

2.1. Elemental Composition of Silage and Press Cake

2.2. Combustion Related Properties of Silage and Press Cake

2.3. Anaerobic Digestion Related Properties of Silage and Press Fluid

2.4. Economic and Ecological Potential of Biomass from Sports Fields as a Substrate for Bioenergy Generation

3. Materials and Methods

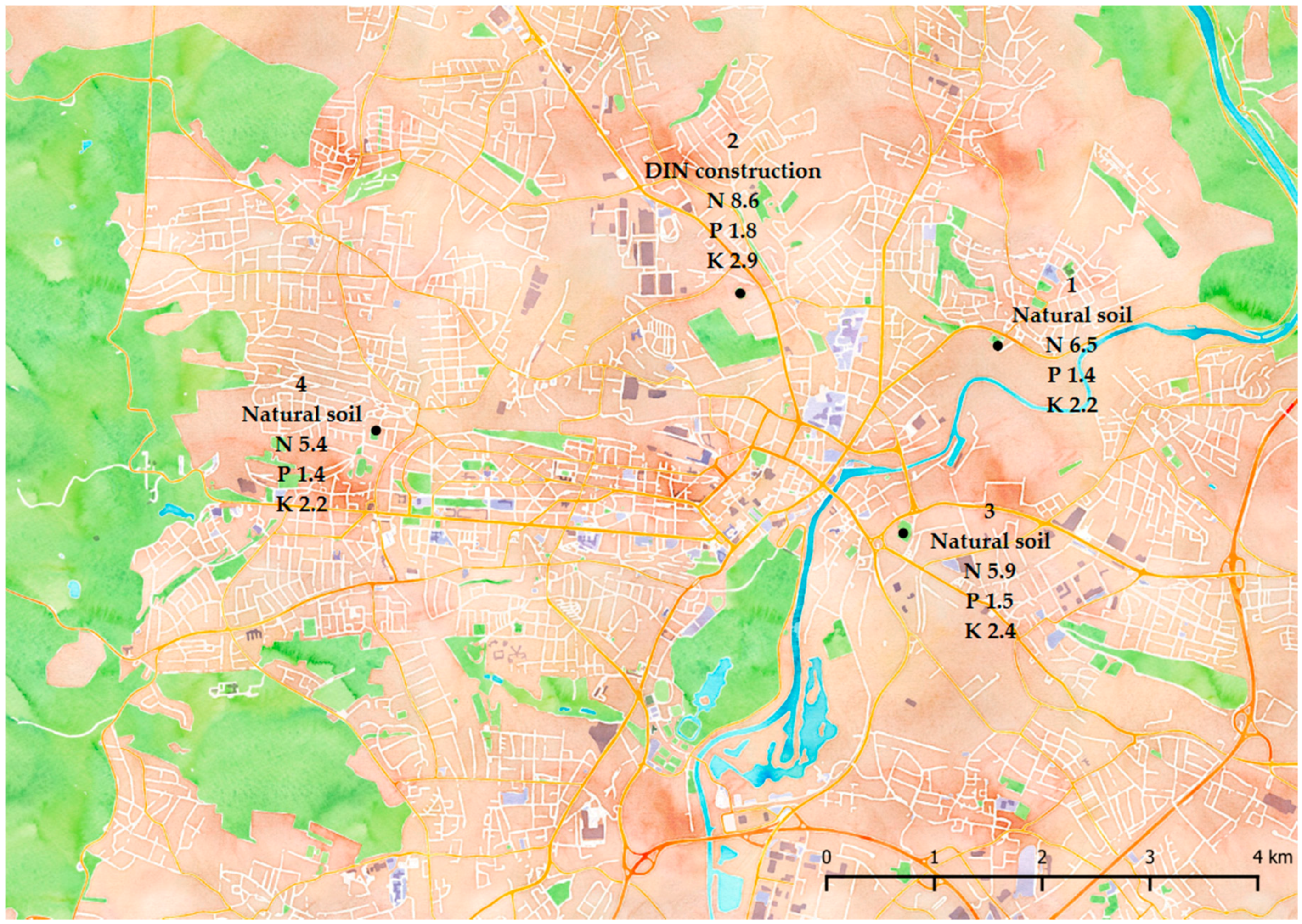

3.1. Sampling

3.2. Processing

3.3. Anaerobic Digestion

3.4. Chemical Analysis

3.5. Further Calculations and Statistics

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pick, D.; Dieterich, M.; Heintschel, S. Biogas Production Potential from Economically Usable Green Waste. Sustainability 2012, 4, 682–702. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R., Jr.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Bühle, L.; Dürl, G.; Hensgen, F.; Urban, A.; Wachendorf, M. Effects of hydrothermal conditioning and mechanical dewatering on ash melting behaviour of solid fuel produced from European semi-natural grasslands. Fuel 2014, 118, 123–129. [Google Scholar] [CrossRef]

- Sommersacher, P.; Brunner, T.; Obernberger, I. Fuel Indexes: A Novel Method for the Evaluation of Relevant Combustion Properties of New Biomass Fuels. Energy Fuels 2012, 26, 380–390. [Google Scholar] [CrossRef]

- Thamsiriroj, T.; Murphy, J.D. Difficulties Associated with Monodigestion of Grass as Exemplified by Commissioning a Pilot-Scale Digester. Energy Fuels 2010, 24, 4459–4469. [Google Scholar] [CrossRef]

- Prochnow, A.; Heiermann, M.; Plöchl, M.; Linke, B.; Idler, C.; Amon, T.; Hobbs, P. Bioenergy from permanent grassland—A review: 1. Biogas. Bioresour. Technol. 2009, 100, 4931–4944. [Google Scholar] [CrossRef] [PubMed]

- Hensgen, F.; Richter, F.; Wachendorf, M. Integrated generation of solid fuel and biogas from green cut material from landscape conservation and private households. Bioresour. Technol. 2011, 102, 10441–10450. [Google Scholar] [CrossRef] [PubMed]

- Prochnow, A.; Heiermann, M.; Plöchl, M.; Amon, T.; Hobbs, P. Bioenergy from permanent grassland—A review: 2. Combustion. Bioresour. Technol. 2009, 100, 4945–4954. [Google Scholar] [CrossRef] [PubMed]

- McEniry, J.; O’Kiely, P. Anaerobic methane production from five common grassland species at sequential stages of maturity. Bioresour. Technol. 2013, 127, 143–150. [Google Scholar] [CrossRef] [PubMed]

- Geber, U. Cutting frequency and stubble height of reed canary grass (Phalaris arundinacea L.): Influence on quality and quantity of biomass for biogas production. Grass Forage Sci. 2002, 57, 389–394. [Google Scholar] [CrossRef]

- Triolo, J.M.; Pedersen, L.; Qu, H.; Sommer, S.G. Biochemical methane potential and anaerobic biodegradability of non-herbaceous and herbaceous phytomass in biogas production. Bioresour. Technol. 2012, 125, 226–232. [Google Scholar] [CrossRef] [PubMed]

- Piepenschneider, M.; de Moor, S.; Hensgen, F.; Meers, E.; Wachendorf, M. Element concentrations in urban grass cuttings from roadside verges in the face of energy recovery. Environ. Sci. Pollut. Res. 2015, 22, 7808–7820. [Google Scholar] [CrossRef] [PubMed]

- El-Nashaar, H.; Griffith, S.; Steiner, J.; Banowetz, G. Mineral concentration in selected native temperate grasses with potential use as biofuel feedstock. Bioresour. Technol. 2009, 100, 3526–3531. [Google Scholar] [CrossRef] [PubMed]

- McEniry, J.; Finnan, J.; King, C.; O’Kiely, P. The effect of ensiling and fractionation on the suitability for combustion of three common grassland species at sequential harvest dates. Grass Forage Sci. 2012, 67, 559–568. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Barnthaler, G. Chemical properties of solid biofuels—Significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Nitsche, M.; Nurmatov, N.; Hensgen, F.; Wachendorf, M. Heavy Metals and Polycyclic Aromatic Hydrocarbons in Urban Leaf Litter Designated for Combustion. Energies 2017, 10, 298. [Google Scholar] [CrossRef]

- McEniry, J.; King, C.; O’Kiely, P. Silage fermentation characteristics of three common grassland species in response to advancing stage of maturity and additive application. Grass Forage Sci. 2014, 69, 393–404. [Google Scholar] [CrossRef]

- Bühle, L.; Hensgen, F.; Donnison, I.; Heinsoo, K.; Wachendorf, M. Life cycle assessment of the integrated generation of solid fuel and biogas from biomass (IFBB) in comparison to different energy recovery, animal-based and non-refining management systems. Bioresour. Technol. 2012, 230–239. [Google Scholar] [CrossRef] [PubMed]

- Piepenschneider, M.; Nurmatov, N.; Bühle, L.; Hensgen, F.; Wachendorf, M. Chemical Properties and Ash Slagging Characteristics of Solid Fuels from Urban Leaf Litter. Waste Biomass Valoriz. 2016, 7, 625–633. [Google Scholar] [CrossRef]

- Khalsa, J.; Döhling, F.; Berger, F. Foliage and Grass as Fuel Pellets–Small Scale Combustion of Washed and Mechanically Leached Biomass. Energies 2016, 9, 361. [Google Scholar] [CrossRef]

- Piepenschneider, M.; Bühle, L.; Hensgen, F.; Wachendorf, M. Energy recovery from grass of urban roadside verges by anaerobic digestion and combustion after pre-processing. Biomass Bioenergy 2016, 85, 278–287. [Google Scholar] [CrossRef]

- Herrmann, C.; Prochnow, A.; Heiermann, M.; Idler, C. Biomass from landscape management of grassland used for biogas production: Effects of harvest date and silage additives on feedstock quality and methane yield. Grass Forage Sci. 2014, 69, 549–566. [Google Scholar] [CrossRef]

- Stadt Kassel. Sport in Kassel. 2016. Available online: http://www.kassel.de/miniwebs/sport_in_kassel/20757/index.html (accessed on 14 January 2017).

- London Playing Fields Foundation. Who We Are. 2016. Available online: http://lpff.org.uk/About/Who-We-Are (accessed on 28 December 2016).

- Hidaka, T.; Arai, S.; Okamoto, S.; Uchida, T. Anaerobic co-digestion of sewage sludge with shredded grass from public green spaces. Bioresour. Technol. 2013, 130, 667–672. [Google Scholar] [CrossRef] [PubMed]

- OpenStreetMap contributors. Open Layers Plugin. Available online: http://www.openstreetmap.de (accessed on 10 January 2017).

- Zerr, W. Versuchsanlage zur energetischen Beurteilung von Substraten und Kofermentaten für Biogasanlagen. Umweltwissenschaften Schadstoff Forschung 2006, 18, 219–227. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure. VDI 4630 Vergärung Organischer Stoffe: Substratcharakterisierung, Probenahme, Stoffdatenerhebung, Gärversuche; Beuth: Berlin, Germany, 2006. [Google Scholar]

- Van Soest, P.J.; Wine, R.H. Use of detergents in the analysis of fibrous feeds. IV. Determination of plant cell-wall constituents. J. Assoc. Off. Anal. Chem. 1967, 50, 50–55. [Google Scholar]

- Porter, M.G.; Murray, R.S. The volatility of components of grass silage on oven drying and the inter-relationship between dry-matter content estimated by different analytical methods. Grass Forage Sci. 2001, 56, 405–411. [Google Scholar] [CrossRef]

- Weißbach, F.; Kuhla, S. Substance losses in determining the dry matter content of silage and green fodder: Arising errors and possibilities of correction. Übers. Tierernährung 1995, 23, 189–214. [Google Scholar]

- Friedl, A.; Padouvas, E.; Rotter, H.; Varmuza, K. Prediction of heating values of biomass fuel from elemental composition. Anal. Chim. Acta 2005, 544, 191–198. [Google Scholar] [CrossRef]

- R Core Team. R: A language and Environment; R Foundation for Statistical Computing: Vienna, Austria, 2013. [Google Scholar]

| Silage from Sports Field | Press Cake from Sports Field | Silage from Urban Roadside Verges 1 | Press Cake from Urban Roadside Verges 1 | Coniferous Wood without Bark 2 | |

|---|---|---|---|---|---|

| Number of samples | 18 | 18 | 10 | 10 | not given |

| C (% DM) | 45.76 ± 1.01 b | 48.40 ± 1.28 a | 45.72 | 46.66 | 51 |

| H (% DM) | 5.37 ± 0.09 b | 5.98 ± 0.18 a | 6.35 | 6.43 | 6.3 |

| Ash (% DM) | 14.54 ± 2.02 a | 7.60 ± 2.00 b | 10.84 | 6.89 | 0.3 |

| K2O/CaO | 3.66 ± 0.68 a | 1.00 ± 0.25 b | 2.86 | 0.88 | 0.38 |

| 2S/Cl | 0.78 ± 0.09 b | 3.94 ± 1.13 a | 0.93 | 8.63 | 4.44 |

| HHV (MJ·kg−1 DM) | 18.57 ± 0.40 b | 19.61 ± 0.55 a | 17.97 | 18.68 | 20.42 |

| LHV (MJ·kg−1 DM) | 17.51 ± 0.40 b | 18.43 ± 0.52 a | 16.72 | 17.41 | 19.18 |

| Parameter | Silage from Sports Fields | Press Fluid from Sports Fields | Silage from Urban Roadside Verges 1 | Press Fluid from Urban Roadside Verges 1 |

|---|---|---|---|---|

| Number of samples | 18 | 17 3 | 10 | 10 |

| NDF (% DM) | 44.47 ± 4.76 | - 2 | 57.04 | - |

| ADF (% DM) | 24.07 ± 1.95 | - | 33.84 | - |

| ADL (% DM) | 1.24 ± 0.26 | - | 4.50 | - |

| Dry matter (% FM) | 32.79 ± 11.05 a | 2.48 b ± 0.72 | 25.99 | 1.41 |

| Volatile solids (% DM) | 87.27 ± 2.50 a | 78.04 b ± 3.48 | 93.9 | 93.9 |

| Methane concentration (% of biogas) | 58.38 ± 3.64 b | 64.13 a ± 4.18 | 56 | 60 |

| Methane yield (lN·kg−1 VS) | 291.86 ± 34.36 b | 340.10 a ± 56.73 | 221 | 292 |

| Species | Sports Field | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Agrostis spec. | - | - | 30 | - |

| Elymus repens | - | - | 10 | - |

| Lolium perenne | 65 | 20 | 55 | 40 |

| Poa spec. | 20 | 85 | 45 | 70 |

| Bellis perennis | - | 10 | - | - |

| Plantago major | - | - | 10 | 5 |

| Polygonum aviculare | - | - | 10 | - |

| Taraxacum spec. | - | 5 | 5 | - |

| Trifolium repens | 40 | 30 | 10 | 10 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nitsche, M.; Hensgen, F.; Wachendorf, M. Using Grass Cuttings from Sports Fields for Anaerobic Digestion and Combustion. Energies 2017, 10, 388. https://doi.org/10.3390/en10030388

Nitsche M, Hensgen F, Wachendorf M. Using Grass Cuttings from Sports Fields for Anaerobic Digestion and Combustion. Energies. 2017; 10(3):388. https://doi.org/10.3390/en10030388

Chicago/Turabian StyleNitsche, Meike, Frank Hensgen, and Michael Wachendorf. 2017. "Using Grass Cuttings from Sports Fields for Anaerobic Digestion and Combustion" Energies 10, no. 3: 388. https://doi.org/10.3390/en10030388