1. Introduction

The multi-energy powertrain system is the most distinctive feature that makes hybrid electric vehicle (HEV) more energy efficient than the traditional vehicle, and its key technology directly determines the economy, reliability, safety and comfortability in HEV. The control of the HEV multi-energy powertrain system can be classified into two kinds of core problems. The first is the energy distribution and efficiency optimization of multi-energy sources, and the second is the dynamic torque coordination between the multi-power sources. The former aims to improve the fuel economy and reduce emissions at arbitrary driving cycles. It belongs to the research category of energy management strategy and has been widely concerned [

1,

2,

3]. By contrast, the latter, which is critical to the ride comfortability, switching rapidity and durability in HEV, is relatively less studied, but it directly determines people’s purchase intention and influences the industrialization process of HEV. In fact, in order to improve the fuel economy, frequent transitions among basic operation modes are required, such as the motor-only mode, the engine-only mode, the compound driving mode and the regenerative braking mode. However, mode transitions are often accompanied by the target torque mutation of the engine, the clutch and the motor. The vehicle impact, jitter and clutch excessive wear will appear with unfavorable coordination; thus, the comfortability and clutch durability will be influenced in the vehicle driving. In fact, torque coordination control has become not only the key problem of the HEV multi-energy powertrain system, but also a tough tradeoff commonly concerned by the business circle and the academia.

It is well known that the HEV powertrain structure is very complicated. To facilitate the torque coordination control problem, early research works neglected the clutch dynamic characteristic, which is a crucial factor to the mode transition performance. The torque compensation control strategy using the fast response ability of the motor was an early torque coordination control method [

4,

5]. The engine torque was estimated online, and the motor’s fast response characteristic was used to compensate the output torque lag of the engine to decrease the total driving torque fluctuation of the mode transition process, which could thus improve the comfortability. The advantages of this method are that it is simple and easy to realize. A model matching control (MMC) method was proposed in [

6]. The control idea was similar to the torque compensation control strategy. Compared with the torque compensation method, the motor torque demand was not simply equal to the difference between the total demand torque and the estimated engine torque, but was obtained by a model matching controller using the actual total torque and acceleration pedal as its inputs.

Taking the clutch dynamic characteristic into account, many research works handled the torque coordination problem from the perspective of state equations under different running modes. A fuzzy adaptive sliding mode approach was applied to the mode transition control in [

7], and the switched hybrid theory was applied to the control of a parallel hybrid electric vehicle drivetrain [

8]. The model predictive control (MPC) method was also used to manage HEV mode transitions in [

9,

10], in which two model predictive controllers were needed to accomplish the comfortable transition and synchronize the two drivetrain parts, which were divided by the clutch. Considering the discontinuity of the clutch, a model reference control (MRC) law was proposed to coordinate the engine torque, the clutch torque and the motor torque during the mode transition dynamic process from motor-only mode to compound driving mode [

11]. The MPC method was combined with the MRC in [

12], and good mode transition performance has been achieved in the MATLAB/Simulink environment. Only one model predictive controller was needed, which greatly reduced the calculation amount of the control strategy and was more suitable for the real-time control application. However, when the MPC method is further applied in the vehicle simulation platform, the mode transition performance is unsatisfactory, especially the vehicle jerk outdistances the recommended value, which is 10 m/s

in Germany and 17.64 m/s

in China [

13]. This motivates us to find a more practical solution to solve the torque coordination control problem.

It is worth pointing out that most of the above HEV torque coordination control methods are based on the mechanism model, whose control effect heavily depends on the modeling accuracy of the controlled process. The HEV powertrain is a multi-input and multi-output, nonlinear and strong coupling system, so it is difficult to establish its precise mechanism model. Even if the global exact mathematical model of HEV powertrain system can be obtained, the model is surely high order nonlinear, which makes it difficult to use the mechanism model-based control methods. The mechanism modeling is simplified to some extent for the convenience of controller design in the existing research, which is bound to bring about many unmodeled dynamics and a poor control effect. Although a seven-order mathematical model is used in [

9,

10], the quadratic terms proportional to vehicle speed are neglected in the resistance torque model in order to facilitate the control design; thus, the dynamic characteristics of the HEV powertrain system cannot be precisely described.

In recent years, the data-driven theory has provided a new path for the modeling and controlling of complex systems [

14,

15]. There are abundant online and offline measurement data in the HEV operation process, which provide the possibility for the realization of the data-driven modeling and control for the HEV mode transition dynamic process. As one of the efficient data-driven control methods, the data-driven predictive control (DDPC) algorithm was proposed in recent years, which combines the modeling superiority of the data-driven and the multiple-constraint handling capability of the predictive control [

16]. It was firstly proposed in [

17]. Its basic idea is to use the data-driven method to establish the data model of the controlled object and use the predictive control method to design the controller. DDPC has been used for a multidimensional blast furnace system [

18], wind power generation [

19], the distributed solar collector field [

20], biped robots [

21], a waste water system [

22], a vapor compression refrigeration cycle system [

23] and other industrial applications. Furthermore, a small quantity of application research works relative to DDPC have been used for fast and dynamic situations, such as automated manual transmission (AMT) vehicle starting [

24], dual-clutch transmission [

25] and high-speed train operation [

26]. Since the actual engine torque, the clutch torque and the motor torque and their change rates are all limited by actuator saturation, the torque coordination control of HEV powertrain is a multiple-constraint optimal control problem. Therefore, it might be a good choice to solve the HEV’s torque coordination control problem by the DDPC method.

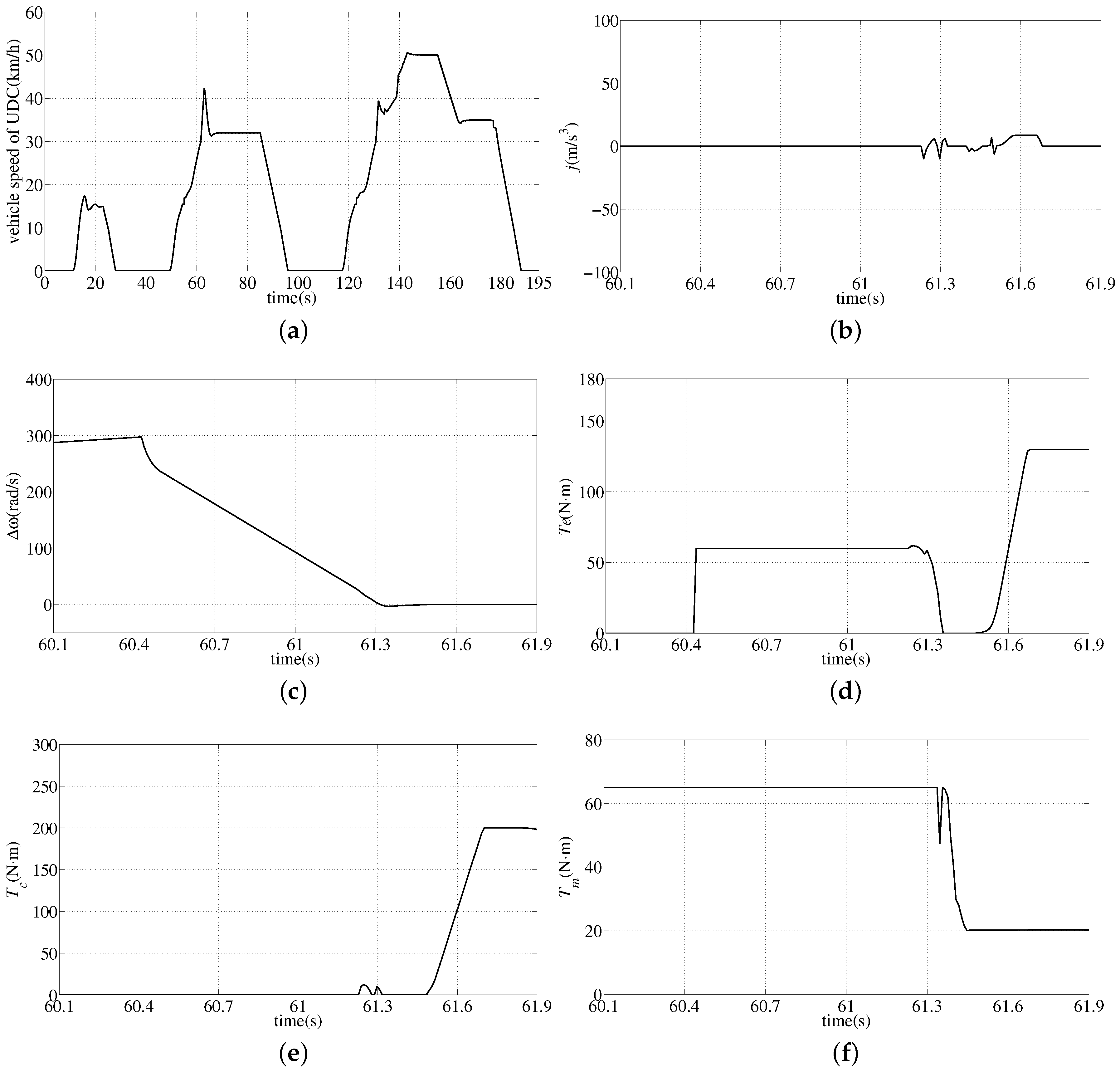

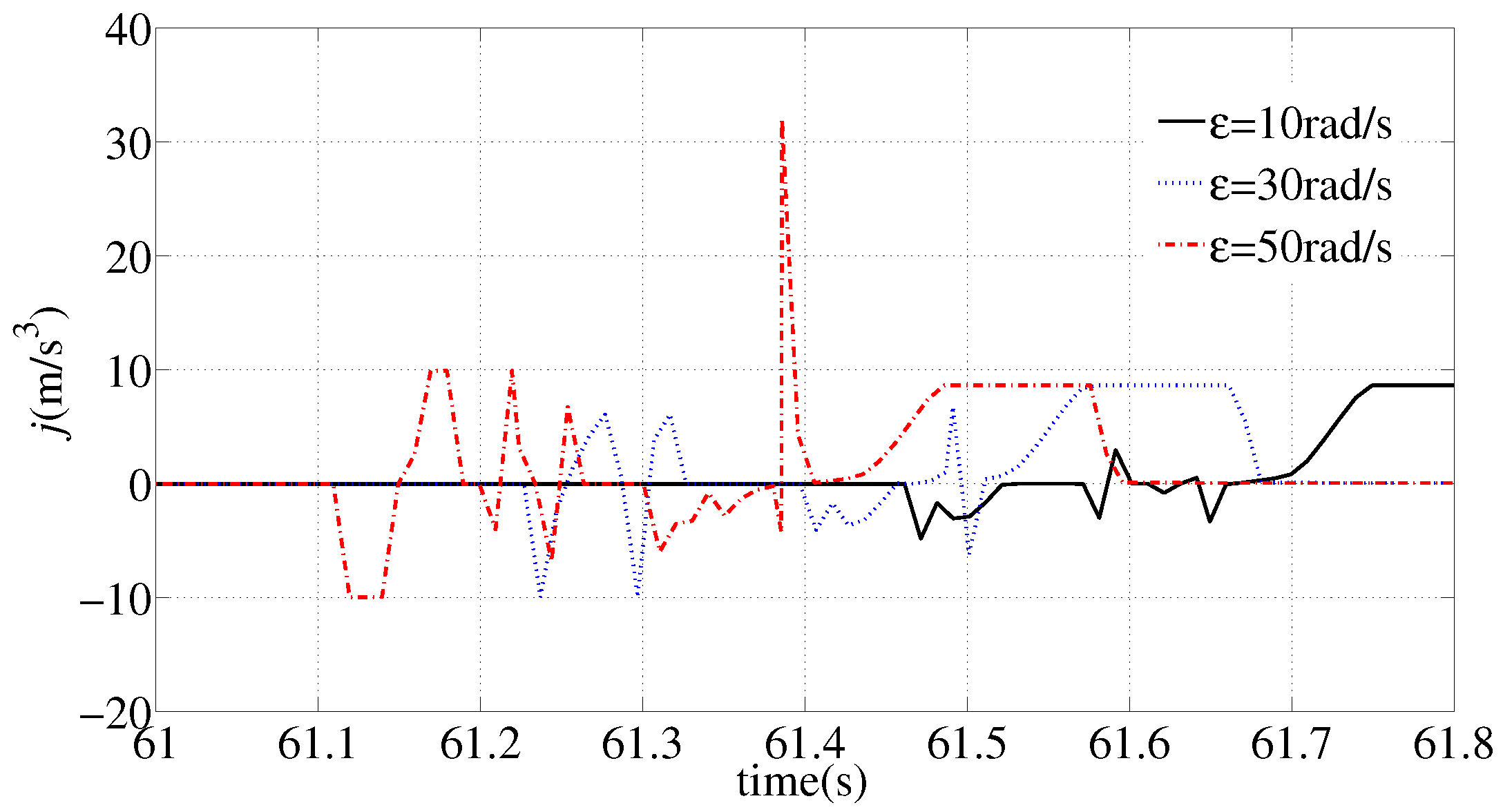

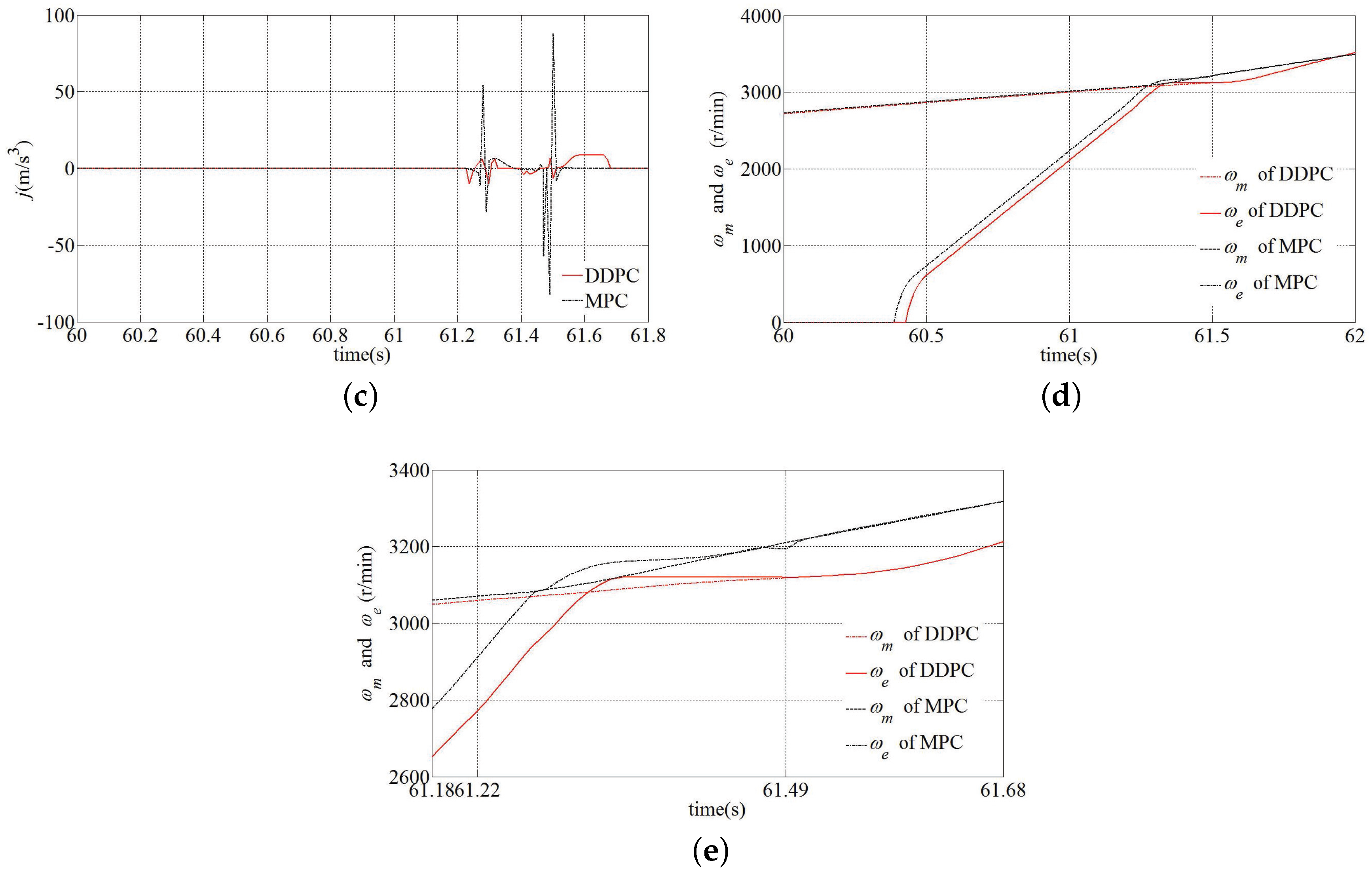

To the best of our knowledge, the proposed torque coordination control strategy based on the DDPC method is a novel contribution for the HEV dynamic process control during the mode transition process. Taking the representative mode transition process from motor-only mode to compound driving mode as an example, a data-driven predictive controller is designed for the torque coordination control problem of HEV, which overcomes the shortcomings of the traditional mechanism model-based control methods. This controller is directly obtained only based on the input-output data of HEV powertrain system, and no accurate mechanism model is required. A multi-objective function is constructed, which deals with the tradeoff between the transition rapidity and the riding comfortability. The time-domain hard constraints of the actuating units are also explicitly taken into account during the optimization control solution. The Cruise simulation results demonstrate that the designed data-driven predictive controller works very well during the mode transition process. A model predictive controller is also designed for comparison. Cruise simulation results show that the DDPC method achieves better mode transition quality compared with the MPC method, i.e., shorter transition duration, better transition comfortability (smaller vehicle jerk) and lower clutch abrasion (less frictional losses). This further validates the superiority of the DDPC method.

The remainder of this paper is organized as follows. In

Section 2, the HEV model is built in Cruise simulation software. In

Section 3, the detailed implementation of the proposed torque coordination control strategy based on DDPC method is introduced for the mode transition process from the motor-only mode to the compound mode. In

Section 4, Cruise simulation results validate the effectiveness of the proposed DDPC method and its advantages over MPC method. Finally, the concluding remarks are given in

Section 5.

2. HEV Model in Cruise and Problem Formulation

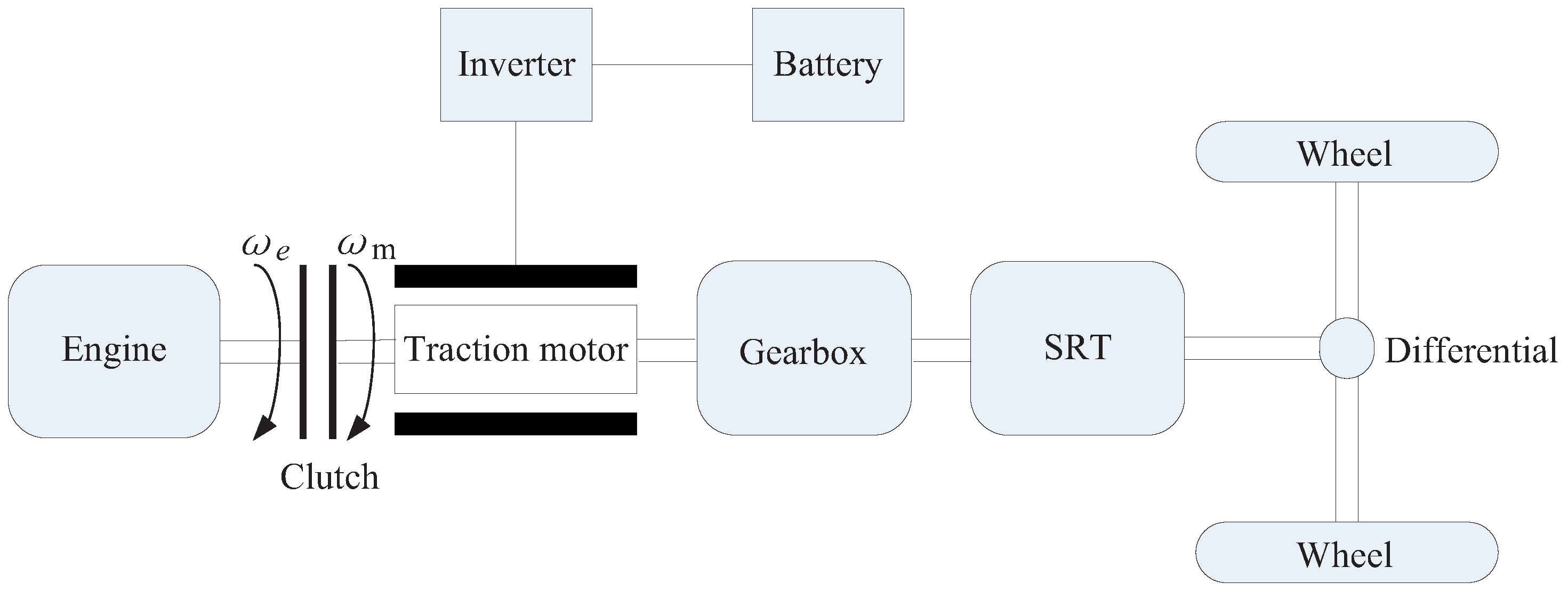

In order to obtain the input-output data, which can fully reflect HEV dynamics, a complete clutch-enabled HEV model is established in the professional automotive simulation software Cruise, which is used by Volkswagen, General Motors, Qoros and other automobile companies; the block diagram of the powertrain configuration is shown in

Figure 1. The detailed vehicle parameters are shown in

Table 1. This HEV model can well describe the HEV’s transient dynamic characteristics, e.g., the delay characteristics of engine output torque, the torsional vibration characteristics of the clutch and the driving shaft, the tire slip characteristics, etc. The engine power is delivered to the drive-line using the friction torque of the clutch. The rule-based energy management strategy is adopted in the supervisory controller.

To improve the fuel economy and reduce emissions, multiple operation modes are required, including stop mode, motor-only mode, engine-only mode, compound driving mode, regenerative brake mode, charging mode, and so on. Therefore, various mode transition dynamic processes may appear in HEV operation. The mode transition processes related to the clutch slipping phase are relatively complicated and deserve intensive study. Among these processes, the mode transition from motor-only mode to compound driving mode is the most typical dynamic process, which will be studied in this paper.

For the convenience of research, we use the vehicle speed of 27 km/h as the mode transition threshold. When the vehicle speed is lower than 27 km/h, the HEV is propelled only by the electric motor, and the two sides of the clutch are separated. When the vehicle speed exceeds 27 km/h, the two sides of the clutch remain separated; the vehicle is still propelled by the electric motor separately; and the engine is started. When the clutch slip speed is less than a given threshold , the mode transition dynamic process from motor-only mode to compound driving mode begins. The clutch enters into the slipping phase, during which time the coordination control of the engine, clutch and motor will directly determine the transition quality. When the clutch slip speed is zero, the HEV works in compound driving mode; the motor propels the HEV along with the engine; and the clutch is locked.

The indices to evaluate the torque coordination quality during the mode transition dynamic process mainly are comprised of riding comfortability, rapidity and economy.

3. Data-Driven Predictive Controller

In this section, we propose a data-driven predictive controller, which is directly based on the input-output data of the Cruise simulation platform in order to deal with the torque coordination control problem during the mode transition from motor-only mode to compound driving mode. Firstly, we deduce the subspace predictor from the state space equation in brief and get the computational formula of subspace matrices. Then, we represent the parts that can be finished offline, i.e., open-loop data sample, the identification of subspace matrices and subspace predictor verification. Finally, we translate the torque coordination control problem considering physical constraints into a quadratic programming problem; thus, we can accomplish the data-driven predictive torque coordination control online.

3.1. Derivation of the Subspace Predictor Equation

At the

k-th sampling instant, the discrete state equations of the mode transition dynamic process from motor-only mode to compound driving mode are as follows:

where

is the input variable,

is the output variable,

is the constrained output variable,

is the state variable and

,

,

,

are the state, input, output and constrained output gain matrix, respectively.

Notably, the state space Equation (1) is just used to reveal the relationship between the state space equation and the subspace predictor. The state space matrices are not required for the design of the proposed data-driven predictive controller. We are only interested in identifying the subspace matrices.

Equation (1) is a three-input three-output system for the studied mode transition dynamic process. Its input is selected as , where is the engine torque, is the clutch torque, which is proportional to the normal pressure between two sides of the clutch and can be controlled by the displacement of clutch release bearing, and is the motor torque. is selected as the system output. The engine speed and motor speed constitute the constrained output ; thus, .

The open-loop data collection of the input, the output and the constrained output

,

and

for

are collected through the Cruise simulation platform, whose details are shown in

Section 3.2.

Next, the data block Hankel matrices

,

,

,

,

and

are constructed to identify the subspace matrices, which are used to design the data-driven predictive torque coordination controller [

16].

The data block Hankel matrices

and

for

are denoted by:

The data block Hankel matrices

and

for

are constructed as follows:

where

p and

f denote the past and the future, respectively. The matrices above have

i-block rows and

j-block columns. The constrained output Hankel matrices

and

for

can be constructed in the same way. The past and future state sequences are defined as follows [

16]:

where

.

By recursive substitution of (1.a) and (1.b), the matrix output equations used in subspace identification are obtained as below:

where:

The following matrix equation can be reduced from the iteration of (1.a):

where

.

The following formula is obtained by solving the matrix Equation (

8):

where † represents the Moore-Penrose pseudo-inverse.

When (13) is substituted into (12), the following formula can be obtained:

The following formula is derived when (14) is substituted into (9):

With enough measurement data, (15) can be written as the following optimal predictive output:

where:

Equation (

16) is the subspace predictor equation. It shows that the future output can be predicted based on the past input-output data and the future input.

is the past input-output data matrix.

is the future input data matrix.

and

are the coefficient matrix of

and

, respectively.

The least-square prediction

can be found by solving the least square problem:

can be found by the orthogonal projection of the row space of

into the row space spanned by

and

:

The terms and of constrained output can be obtained in the same way as (10), (11) and (16)–(18).

3.2. Identification of Subspace Matrices

The prediction accuracy of the subspace matrix identification method is sensitive to different open-loop data. During the open-loop data collection phase, to get an accurate subspace predictor equation, we should design the input data to fully excite the system dynamics relevant to the control goal. That is to say, the designed input data should be as diverse as possible.

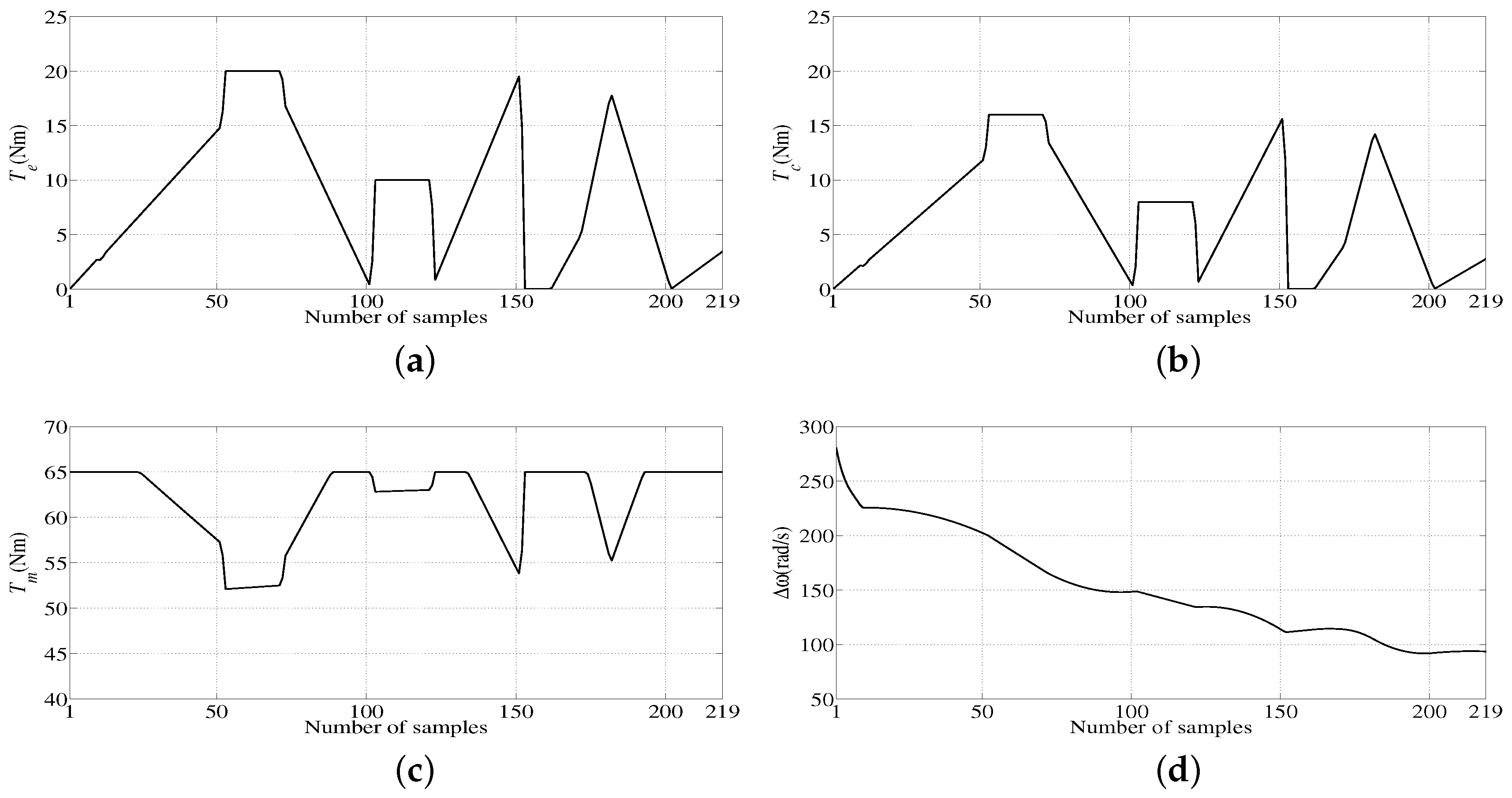

As shown in

Figure 2a–c, the input data

,

and

, which can fully excite the system characteristics of the HEV powertrain, are constructed. The system output

and constrained outputs

,

can be obtained after the input data act on the built HEV dynamics model, as shown in

Figure 2d–f. The sample time

is chosen to be 0.01 s; the number of rows

i in the input-output data matrix is chosen to be 20; and the number of columns

j in the input-output data matrix is chosen to be 180. Thus, the open-loop data at 219 sampling instants are collected during the studied mode transition dynamic process.

Based on the sampling data as shown in

Figure 2, the data block Hankel matrices

,

,

,

,

,

of input

, output

and constrained output

can be constructed. Then, the subspace matrices

,

,

and

can be solved using the corresponding formulas.

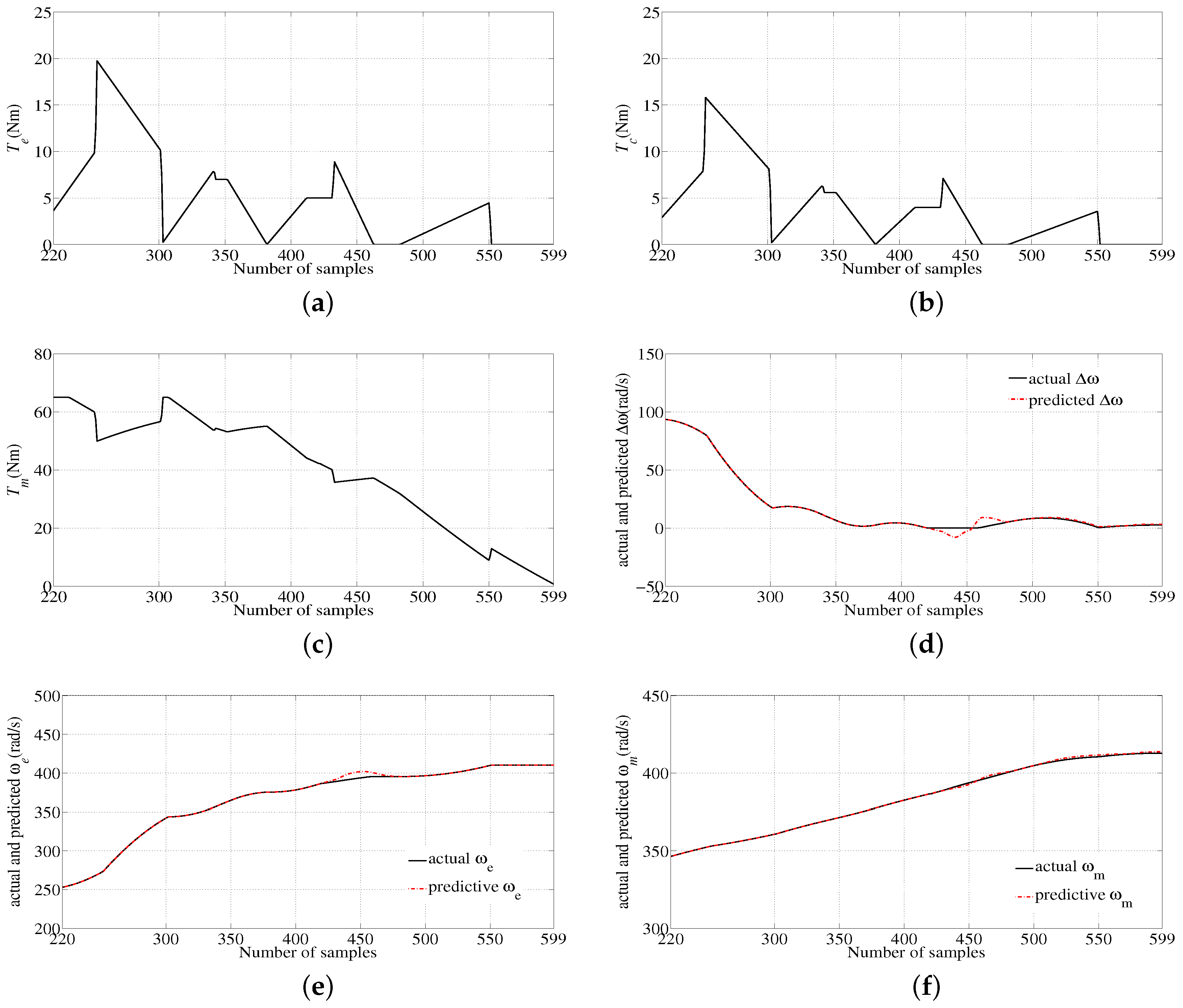

3.3. Verification of the Subspace Predictor Equation

The input-output sampling data from the 220th–599th sampling instant are used to verify the effectiveness of the identified subspace predictor equation (i.e., whether the identified subspace predictor equation can well reflect the HEV’s dynamic characteristics). The constructed fully-excited input data

,

,

and the specific identification prediction effect are shown in

Figure 3.

As shown in

Figure 3d–f, the predictive output can fit the actual output very well when

is not equal to zero. Since the data used to identify the predictive model do not include the case that

is equal to zero, a small predictive error appears when

is equal to zero. The subject investigated in this paper is the clutch slipping phase during which

is not equal to zero, so the predictive error appearing in

Figure 3 will not influence the design of the proposed data-driven predictive controller.

3.4. Description of the Optimization Problem

The control input sequence increment

to be optimized at time

k can be expressed as follows:

where:

The predictive control output sequence

is defined as follows:

and are used to represent the prediction horizon and the control horizon, respectively.

The cost function is usually defined as a quadratic form in order to make the predictive output as close as possible to a given reference output. A penalty term is added to the cost function to punish the violent changes of control variables. Therefore, considering the input and output constraints, the optimal control problem during the mode transition dynamic process from motor-only mode to compound driving mode can be described as below:

where:

In this cost function, the control objective of the first part is to force the clutch slip speed to converge to zero, which realizes the fast mode transition and reduces the wear and tear to the clutch. The control objective of the second part is to limit the torque changing rate of the engine, the clutch and the motor to ensure the mode transition comfortability. Obviously, these two control objectives are contradictory. The weighting factors and are given to trade off the two conflicting objectives. The bigger the weighting factor , the faster the mode transition process. The larger the weighting factor , the less the vehicle jerk.

is the reference sequence of within the prediction horizon, and is an adjustable parameter. The smaller is, the faster the clutch slip speed reaches zero. Thus, the clutch can finish the engagement more quickly.

3.5. Predictive Output Equation

In order to deal with the optimal control problem (19.a), the predictive output equation will be deduced in this section based on the data-driven method and the predictive control method.

To guarantee regulation with zero steady-state error for the reference input, the subspace matrix incremental input-output expressions are as follows:

and:

where:

Therefore, the optimal prediction of the future outputs can be derived as the following form:

where

is the

dynamic matrix containing the step response coefficients and formed from

:

is constructed from

, and

is the free response for the case of measured disturbances:

, , , about can be calculated in the same way as (23)–(26).

3.6. Data-Driven Predictive Controller with Constraints

The DDPC problem (19.a) is usually converted into the following quadratic programming problem:

First, the expression of

H and

G will be briefly inferred. When (21) is substituted into (19.a), the following formula can be obtained:

where

.

The last term in

J is irrelevant to

, so the cost function will be minimized if

obtains the minimum.

where:

Therefore, the optimal problem (19.a) is converted into the quadratic programming problem (27).

Then, the constraint condition matrix and b of the quadratic programming problem (27) will be inferred from (19.b)–(19.d).

Let:

the constraint conditions (19.b)–(19.d) change to the following form:

For the constraint condition (31.a),

where:

Therefore, (31.a) can be changed to the following form:

Constraint Condition (31.b) can be changed to the following form:

Constraint Condition (31.c) can be changed to the following form from (22) and (30):

Overall, the constraint condition matrices can be derived as the following form:

According to the receding horizon principle of predictive control, only the first element of

is implemented, and the calculation is repeated at each time instant. Hence, at the

k-th sampling instant, the control law is given as follows: