Evaluation of Interface Defects in Inaccessible Reactor Shrink Fit Nozzle Welds Using Ultrasonic Waves

Abstract

:1. Introduction

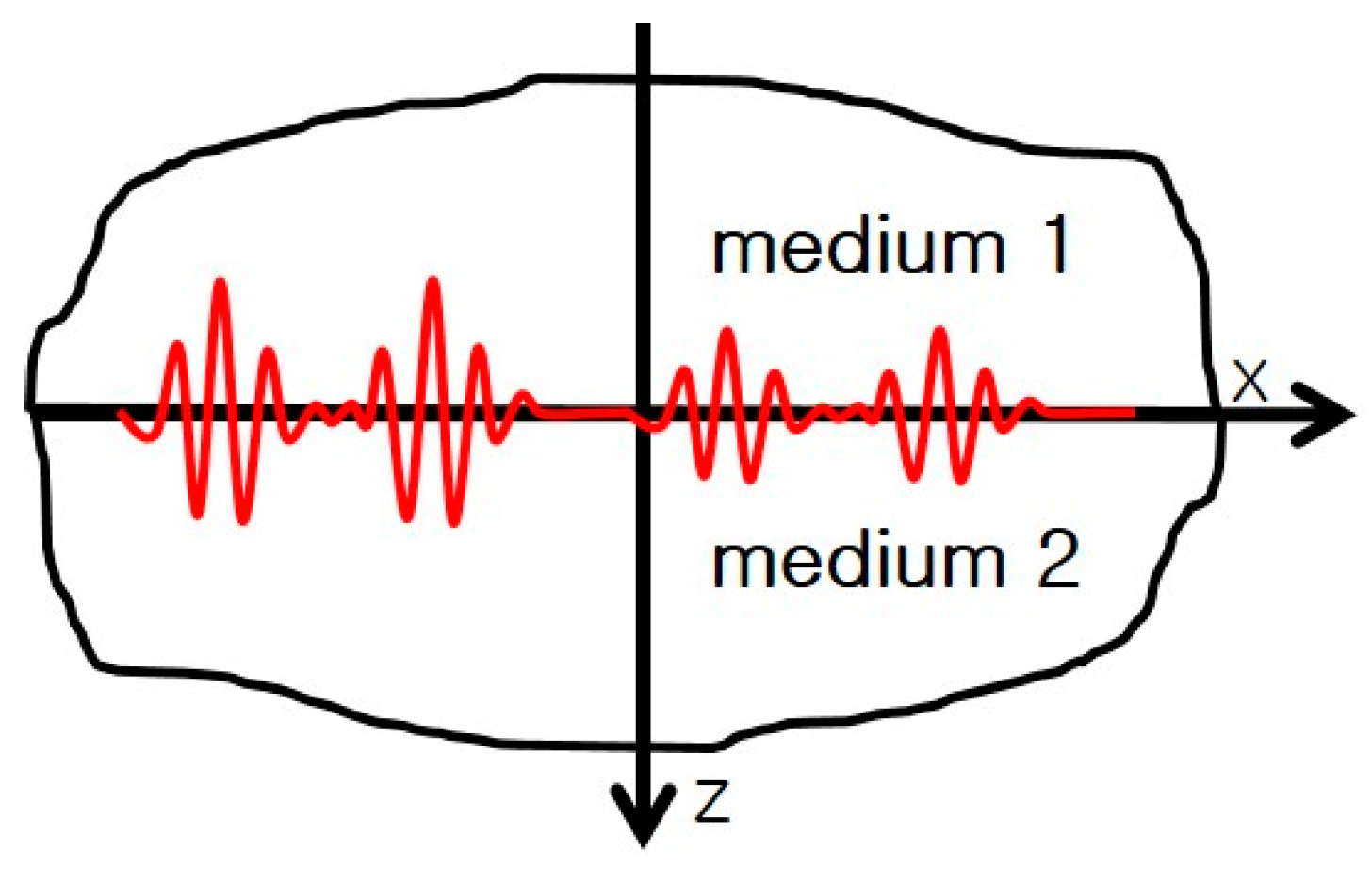

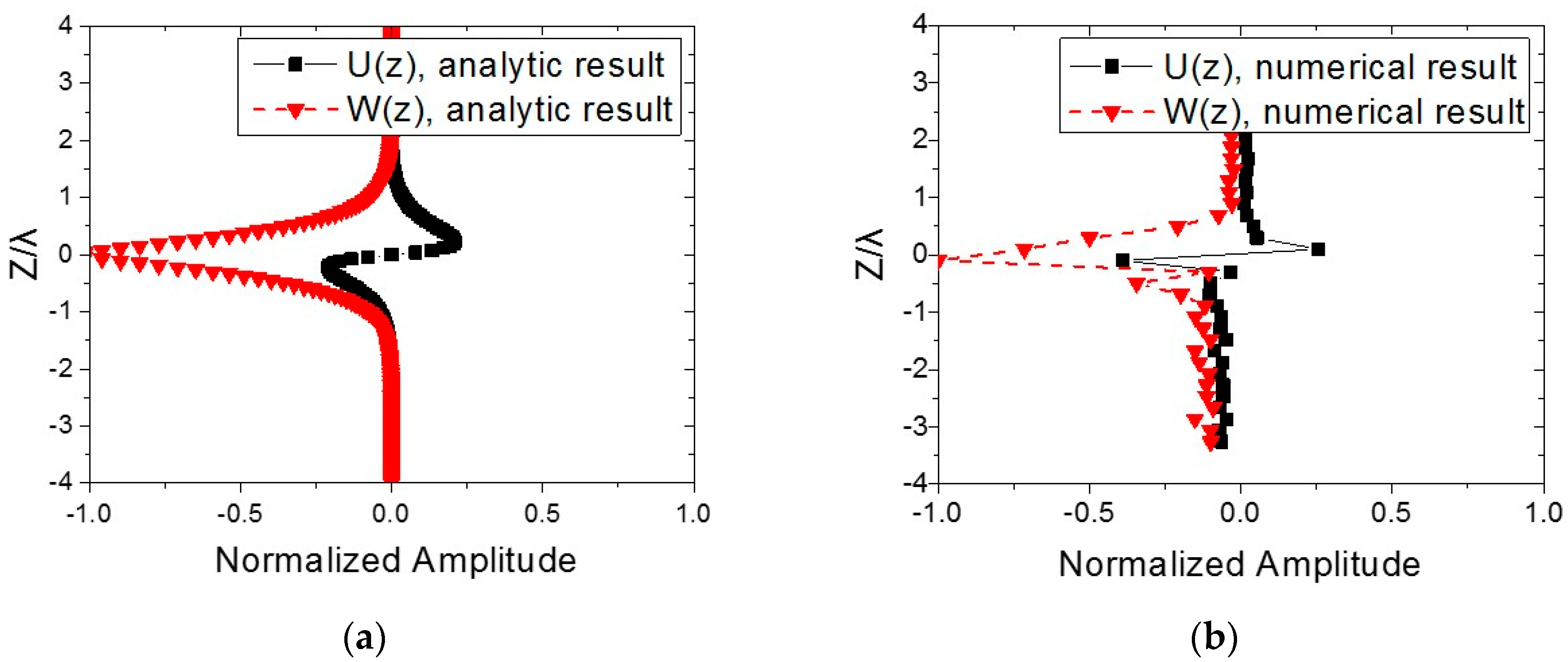

2. Interface Wave Propagation Theory

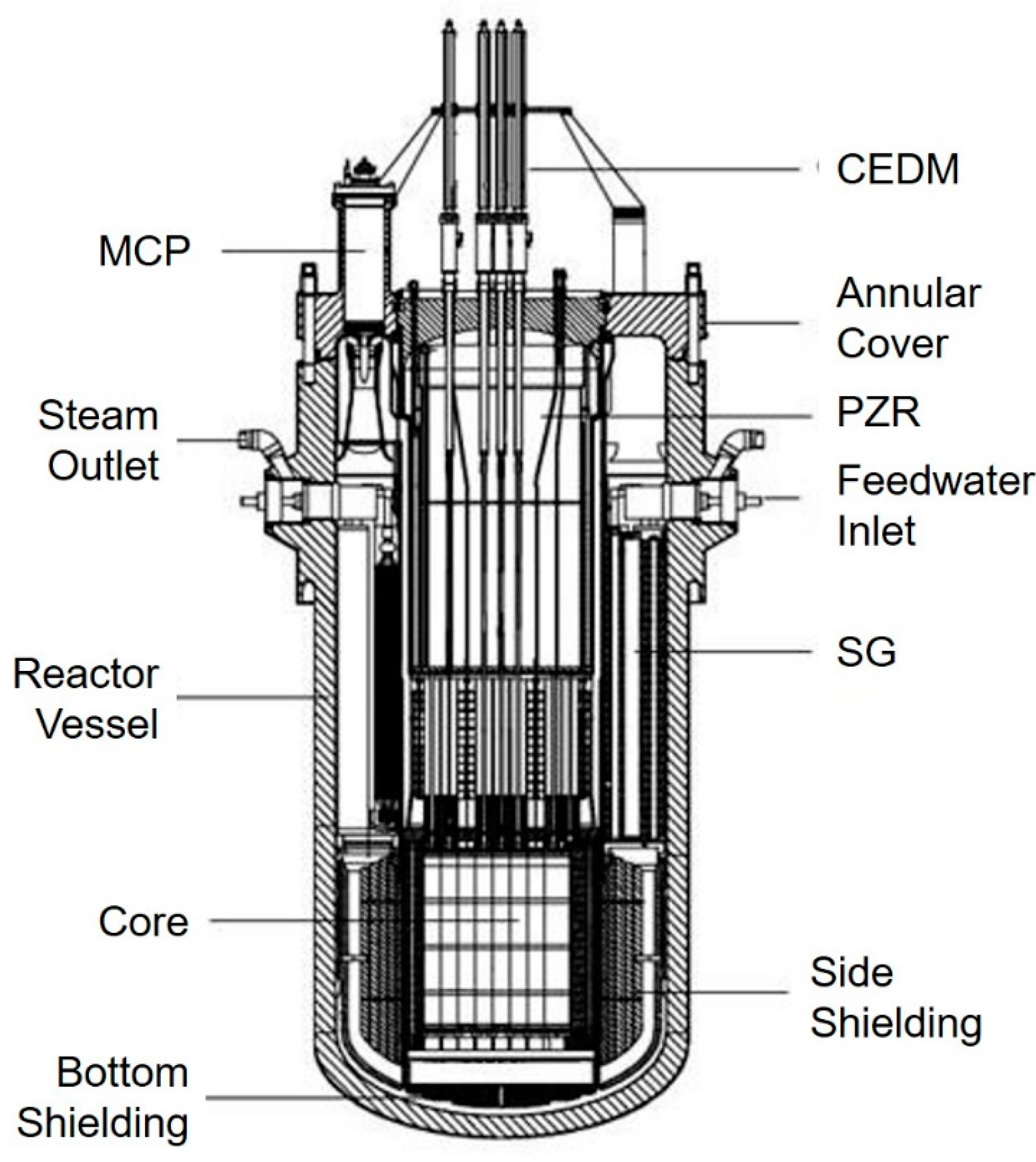

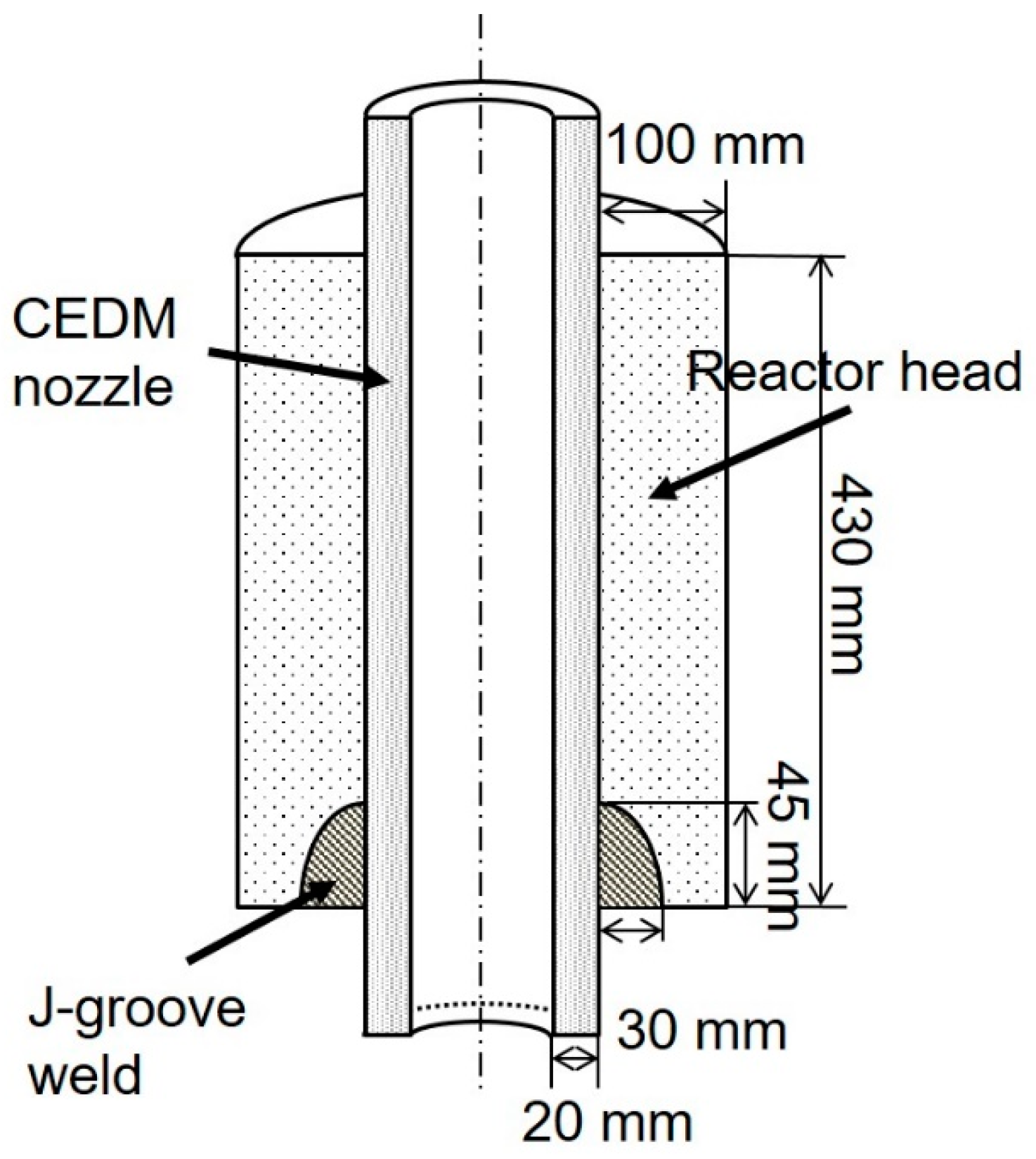

3. Nuclear Reactor Head Nozzle Model

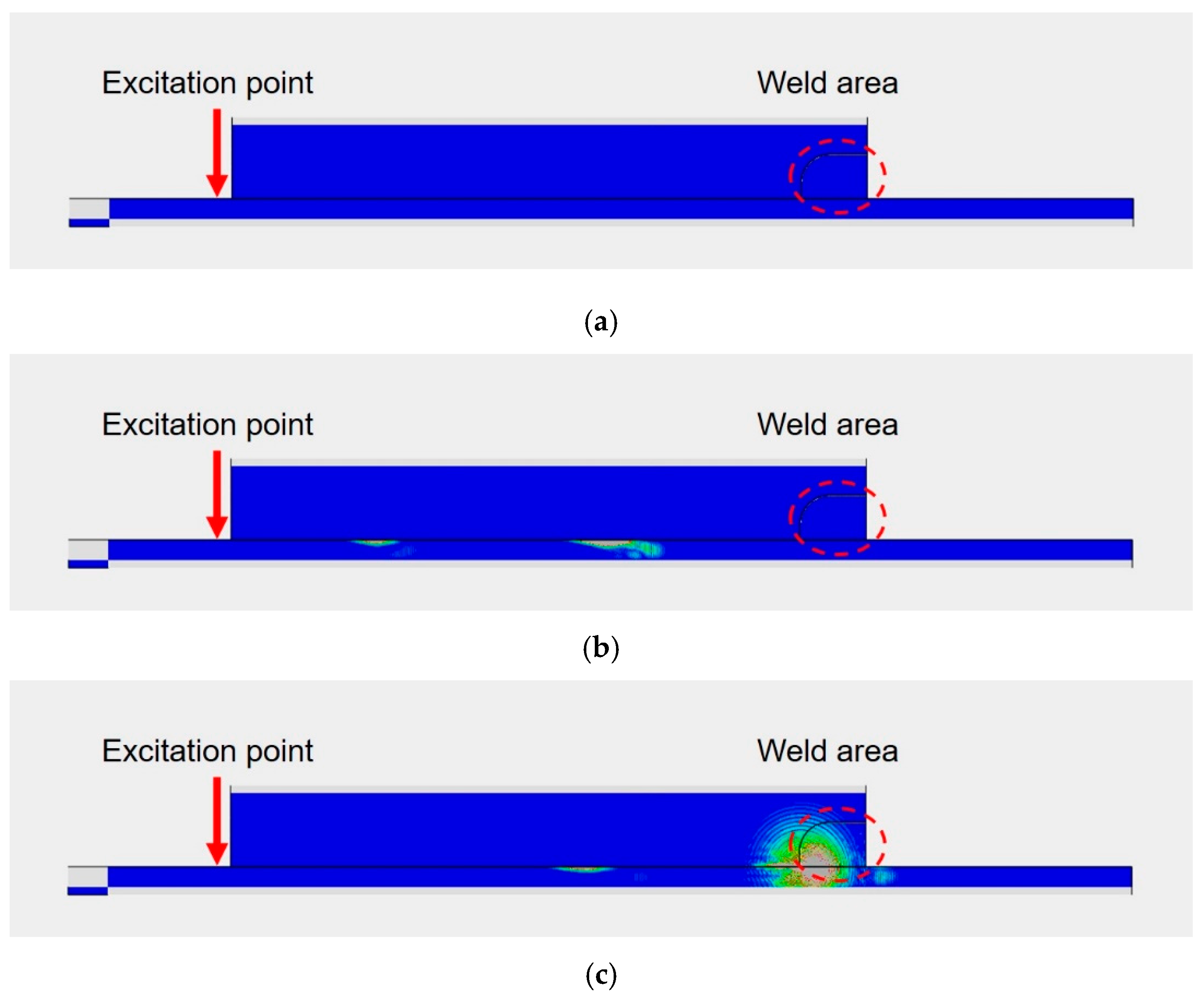

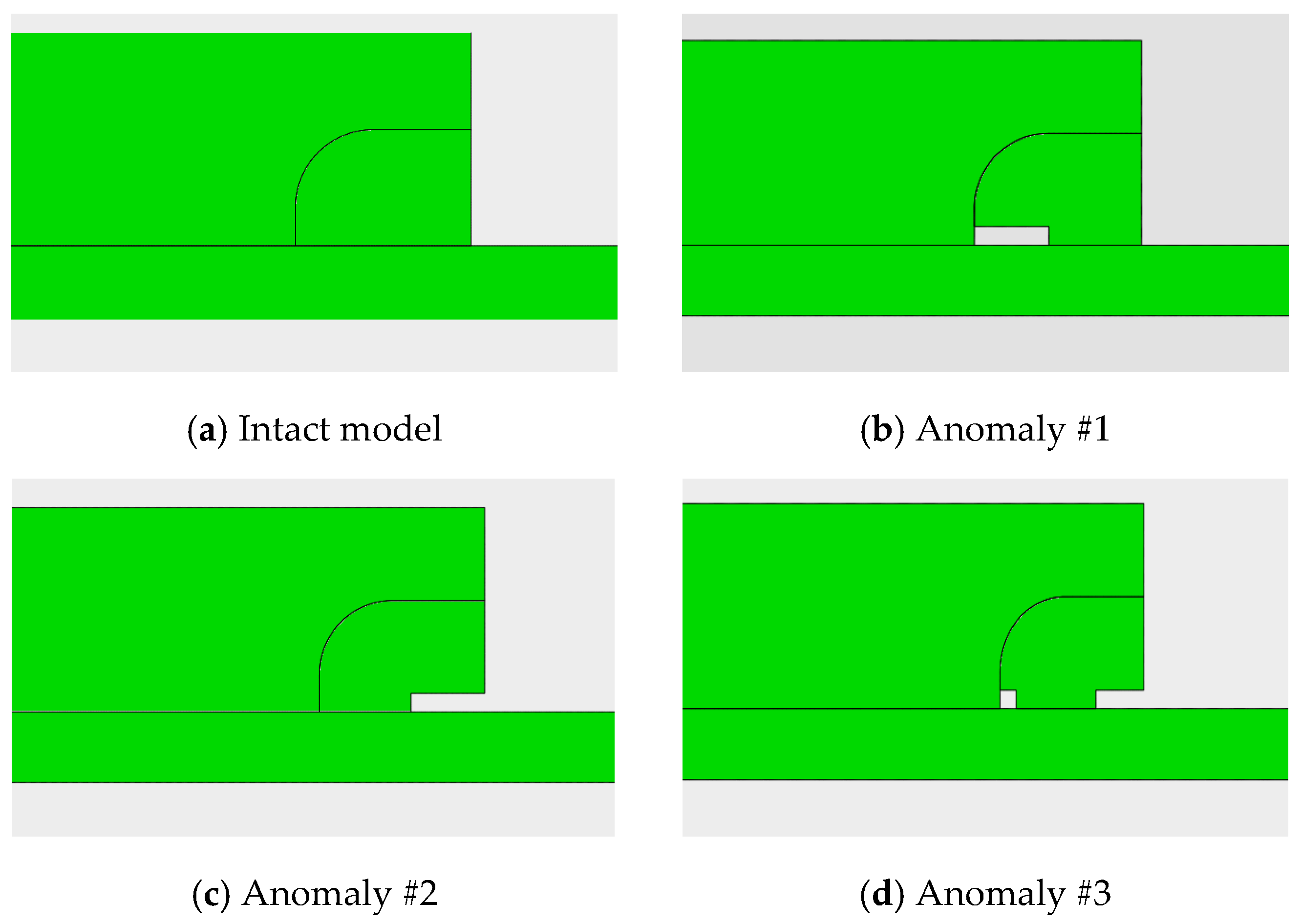

3.1. Finite Element Model Analyis for Reactor Nozzle

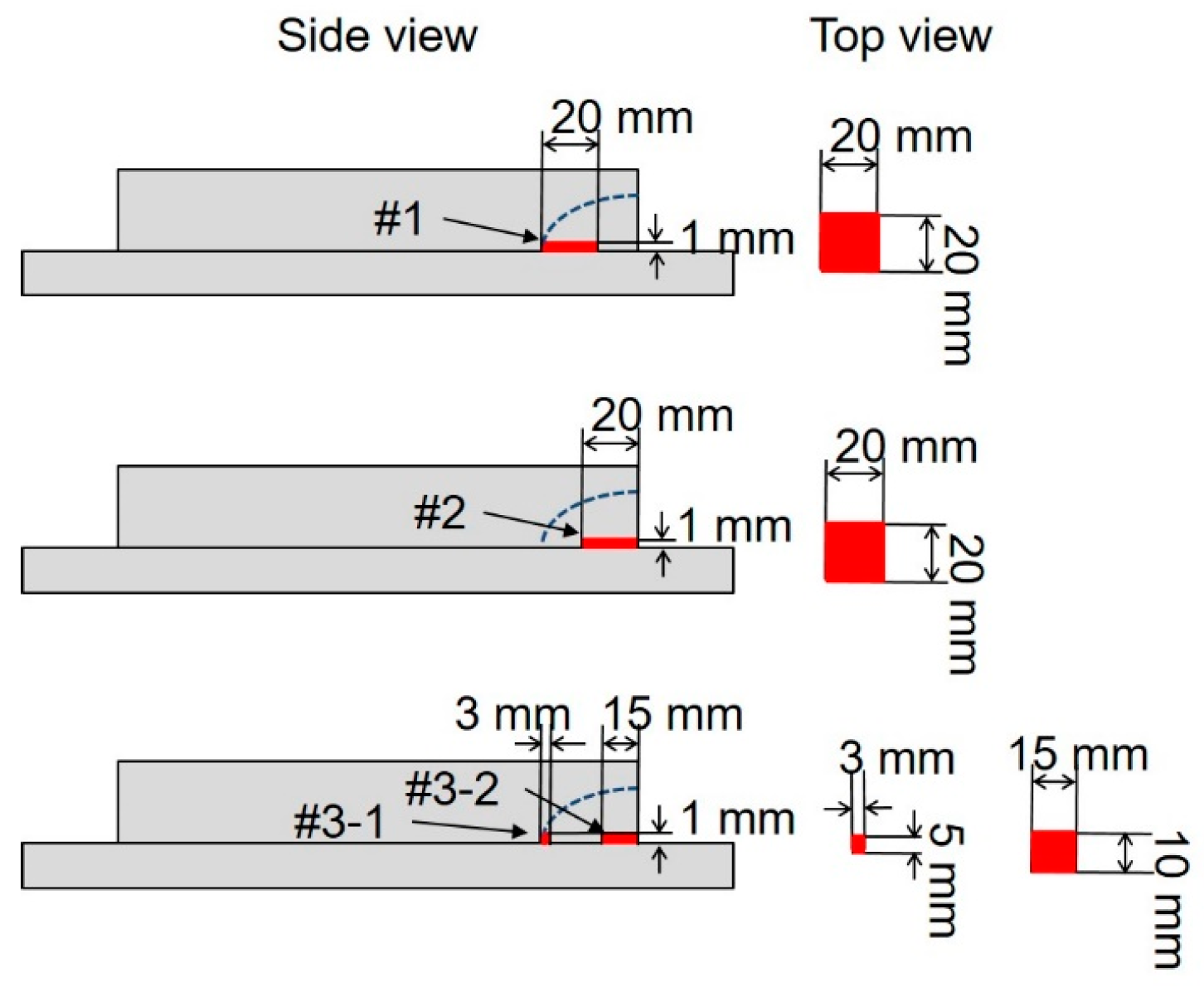

3.2. Experimental Setup and Specimen

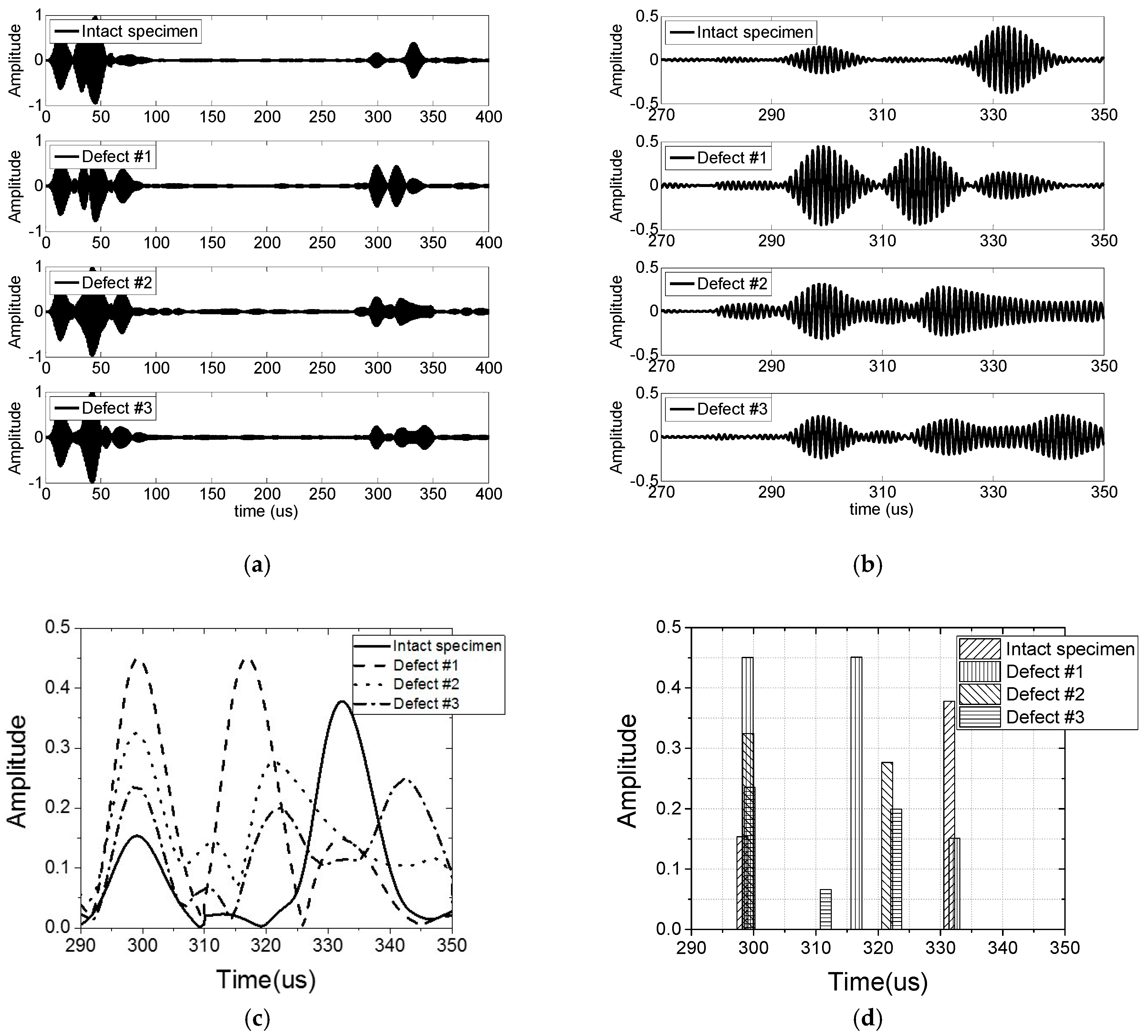

4. Discussion

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gofuku, A. Integrated diagnostic technique for nuclear power plants. Nucl. Eng. Technol. 2014, 46, 725–736. [Google Scholar] [CrossRef]

- Yamamoto, S.; Semboshi, J.; Sugawara, A.; Ochiai, M.; Tsuchihashi, K.; Adachi, H.; Higuma, K. Phased array ultrasonic inspection technique for cast austenitic stainless steel parts of nuclear power plants. In Proceedings of the 24th International Conference on Nuclear Engineering, Charlotte, NC, USA, 26–30 June 2016. [Google Scholar]

- Lee, J.-H.; Lee, M.-R.; Kim, J.-T.; Luk, V.; Jung, Y.-H. A study of the characteristics of the acoustic emission signals for condition monitoring of check valves in nuclear power plants. Nucl. Eng. Des. 2006, 236, 1411–1421. [Google Scholar] [CrossRef]

- Ghosh, A.; Varde, P.; Satheesh, C. Prognostics & health management of swing type check valves. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 374–382. [Google Scholar]

- Alleyne, D.; Cawley, P. The excitation of lamb waves in pipes using dry-coupled piezoelectric transducers. J. Nondestruct. Eval. 1996, 15, 11–20. [Google Scholar] [CrossRef]

- Rose, J.L.; Cho, Y.; Ditri, J.J. Cylindrical guided wave leakage due to liquid loading. Rev. Prog. Quant. Nondestruct. Eval. 1994, 13, 259. [Google Scholar]

- Cheong, Y.-M.; Lee, D.-H.; Jung, H.-K. Ultrasonic guided wave parameters for detection of axial cracks in feeder pipes of phwr nuclear power plants. Ultrasonics 2004, 42, 883–888. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Lee, H.; Lim, H.J.; Kim, N.; Yeo, H.; Sohn, H. Development of a fiber-guided laser ultrasonic system resilient to high temperature and gamma radiation for nuclear power plant pipe monitoring. Meas. Sci. Technol. 2013, 24. [Google Scholar] [CrossRef]

- Van Velsor, J.; Royer, R.; Owens, S.; Rose, J. A magnetostrictive phased array system for guided wave testing and structural health monitoring of pipe. Mater. Eval. 2013, 71, 11. [Google Scholar]

- Kang, S.-S.; Hwang, S.-S.; Kim, H.-P.; Lim, Y.-S.; Kim, J.-S. The experience and analysis of vent pipe PWSCC (primary water stress corrosion cracking) in pwr vessel head penetration. Nucl. Eng. Des. 2014, 269, 291–298. [Google Scholar] [CrossRef]

- Rose, J.L.; Rajana, K.M.; Carr, F.T. Ultrasonic guided wave inspection concepts for steam generator tubing. Mater. Eval. 1994, 52, 307–311. [Google Scholar]

- Xin, J.; Lei, N.; Udpa, L.; Udpa, S.S. Rotating field eddy current probe with bobbin pickup coil for steam generator tubes inspection. NDT E Int. 2013, 54, 45–55. [Google Scholar] [CrossRef]

- Pasadas, D.J.; Rocha, T.J.; Ramos, H.G.; Ribeiro, A.L. Remote field eddy current inspection of metallic tubes using GMR sensors. In Proceedings of the IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Minneapolis, MN, USA, 6–9 May 2013; pp. 296–299. [Google Scholar]

- Hwang, W.; Bae, S.; Kim, J.; Kang, S.; Kwag, N.; Lee, B. Acoustic emission characteristics of stress corrosion cracks in a type 304 stainless steel tube. Nucl. Eng. Technol. 2015, 47, 454–460. [Google Scholar] [CrossRef]

- Nishiyamaa, N.; Kotakeb, S.; Uzawa, M. In-service inspection and repair program for commercialized sodium-cooled fast reactor. In Proceedings of the International Conference on Fast Reactors and Related Fuel Cycles (FR 2009), Kyoto, Japan, 7–11 December 2009; Volume 357. [Google Scholar]

- Shin, H.; Seo, Y.C.; Jung, K.M.; Lee, S.U.; Kim, S.; Park, K.S. Development of guide system for a reactor head maintenance robot. In Proceedings of the Transactions of the Korean Nuclear Society Autumn Meeting, Busan, Korea, 27–28 October 2005. [Google Scholar]

- Liu, Q.; Wang, G.; Dong, Y.; Liu, P.; Sun, J.; Wu, X.; Xu, Y. A novel nuclear station inspection robot. In Proceedings of the 4th IEEE International Conference on Information Science and Technology, Shenzhen, China, 26–28 April 2014; pp. 678–681. [Google Scholar]

- Schmidt, D.; Berns, K. Climbing robots for maintenance and inspections of vertical structures—A survey of design aspects and technologies. Robot. Auton. Syst. 2013, 61, 1288–1305. [Google Scholar] [CrossRef]

- Kim, S.; Kim, C.H.; Bae, Y.-G.; Na, H.; Jung, S. NDT inspection mobile robot with spiral driven mechanism in pipes. In Proceedings of the 44th International Symposium on Robotics (ISR), Seoul, Korea, 24–26 October 2013. [Google Scholar]

- Lee, J.-H.; Han, S.; Ahn, J.; Kim, D.-H.; Moon, H. Two-module robotic pipe inspection system with emats. Smart Struct. Syst. 2014, 13, 1041–1063. [Google Scholar] [CrossRef]

- Lee, J.; Cho, Y.; Park, J.-P.; Rose, J.L.; Huh, H.; Park, K.-B.; Kim, D.-O. A study on nondestructive evaluation technique by the use of interface guided waves on shrink fit structure. Aip Conf. Proc. 2014, 1581, 353–357. [Google Scholar]

- Lee, J.; Park, J.; Cho, Y. A novel ultrasonic nde for shrink fit welded structures using interface waves. Ultrasonics 2016, 68, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Scholte, J. The range of existence of rayleigh and stoneley waves. Geophys. J. Int. 1947, 5, 120–126. [Google Scholar] [CrossRef]

- Yu, L.; Tian, Z. Case study of guided wave propagation in a one-side water-immersed steel plate. Case Stud. Nondestruct. Test. Eval. 2015, 3, 1–8. [Google Scholar] [CrossRef]

- Pistone, E.; Rizzo, P. On the use of an array of ultrasonic immersion transducers for the nondestructive testing of immersed plates. Nondestruct. Test. Eval. 2015, 30, 26–38. [Google Scholar] [CrossRef]

- Pistone, E.; Li, K.; Rizzo, P. Noncontact monitoring of immersed plates by means of laser-induced ultrasounds. Struct. Health Monit. 2013, 12, 549–565. [Google Scholar] [CrossRef]

- Cegla, F.; Cawley, P.; Lowe, M. Material property measurement using the quasi-scholte mode—A waveguide sensor. J. Acoust. Soc. Am. 2005, 117, 1098–1107. [Google Scholar] [CrossRef]

- Cegla, F.; Cawley, P.; Lowe, M. Fluid bulk velocity and attenuation measurements in non-newtonian liquids using a dipstick sensor. Meas. Sci. Technol. 2005, 17. [Google Scholar] [CrossRef]

- Stoneley, R. Elastic waves at the surface of separation of two solids. Proc. R. Soc. Lond. 1924, 106, 416–428. [Google Scholar] [CrossRef]

- Rauch, D. On the role of bottom interface waves in ocean seismo-acoustics: A review. In Ocean Seismo-Acoustics; Springer: New York, NY, USA, 1986; pp. 623–641. [Google Scholar]

- Meegan, G.; Hamilton, M.; Il’inskii, Y.A.; Zabolotskaya, E. Nonlinear stoneley and scholte waves. J. Acoust. Soc. Am. 1999, 106, 1712–1723. [Google Scholar] [CrossRef]

- Declercq, N.F.; Degrieck, J.; Briers, R.; Leroy, O. Diffraction of homogeneous and inhomogeneous plane waves on a doubly corrugated liquid/solid interface. Ultrasonics 2005, 43, 605–618. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Qiang, L.; Lu, T.; Geng, X.; Li, M. A stoneley wave method to detect interlaminar damage of metal layer composite pipe. Front. Mech. Eng. 2015, 10, 89–94. [Google Scholar] [CrossRef]

- Moiseyenko, R.P.; Declercq, N.F.; Laude, V. Guided wave propagation along the surface of a one-dimensional solid-fluid phononic crystal. J. Phys. D Appl. Phys. 2013, 46. [Google Scholar] [CrossRef]

- Rose, J.L. Ultrasonic Guided Waves in Solid Media; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Achenbach, J. Wave Propagation in Elastic Solids; Elsevier: Amsterdam, The Netherlands, 1984. [Google Scholar]

| Frequency | 1 MHz |

| Wavelength | 0.0027 m |

| Mesh Size | 0.00027 m |

| Element Type | CPE4R (plane strain conditions) |

| Defect | Axial Size (mm) | Circumferential Size (mm) | Radius Size (mm) |

|---|---|---|---|

| #1 | 20 | 20 | 1 |

| #2 | 20 | 20 | 1 |

| #3-1 | 3 | 5 | 1 |

| #3-2 | 15 | 10 | 1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Cho, Y. Evaluation of Interface Defects in Inaccessible Reactor Shrink Fit Nozzle Welds Using Ultrasonic Waves. Energies 2017, 10, 589. https://doi.org/10.3390/en10050589

Lee J, Cho Y. Evaluation of Interface Defects in Inaccessible Reactor Shrink Fit Nozzle Welds Using Ultrasonic Waves. Energies. 2017; 10(5):589. https://doi.org/10.3390/en10050589

Chicago/Turabian StyleLee, Jaesun, and Younho Cho. 2017. "Evaluation of Interface Defects in Inaccessible Reactor Shrink Fit Nozzle Welds Using Ultrasonic Waves" Energies 10, no. 5: 589. https://doi.org/10.3390/en10050589

APA StyleLee, J., & Cho, Y. (2017). Evaluation of Interface Defects in Inaccessible Reactor Shrink Fit Nozzle Welds Using Ultrasonic Waves. Energies, 10(5), 589. https://doi.org/10.3390/en10050589