Dynamic Charging of Electric Vehicle with Negligible Power Transfer Fluctuation

Abstract

:1. Introduction

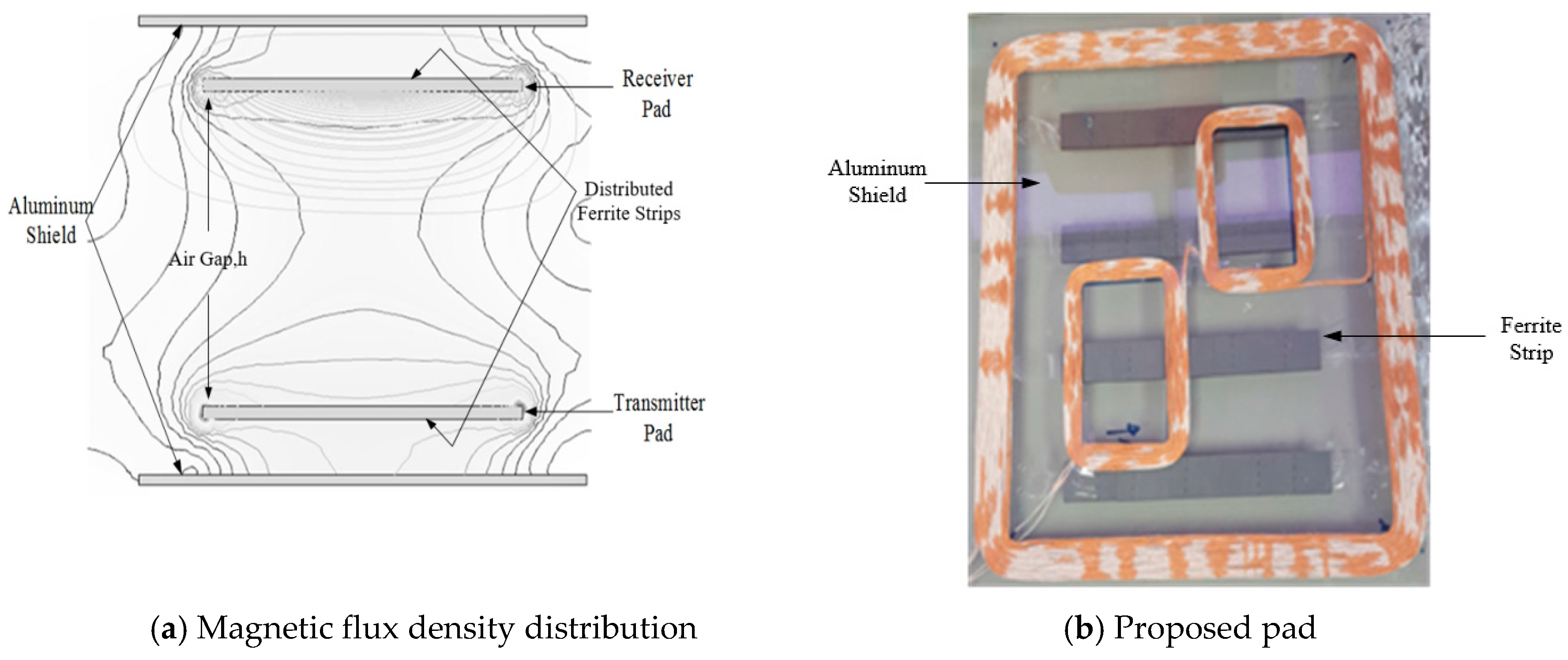

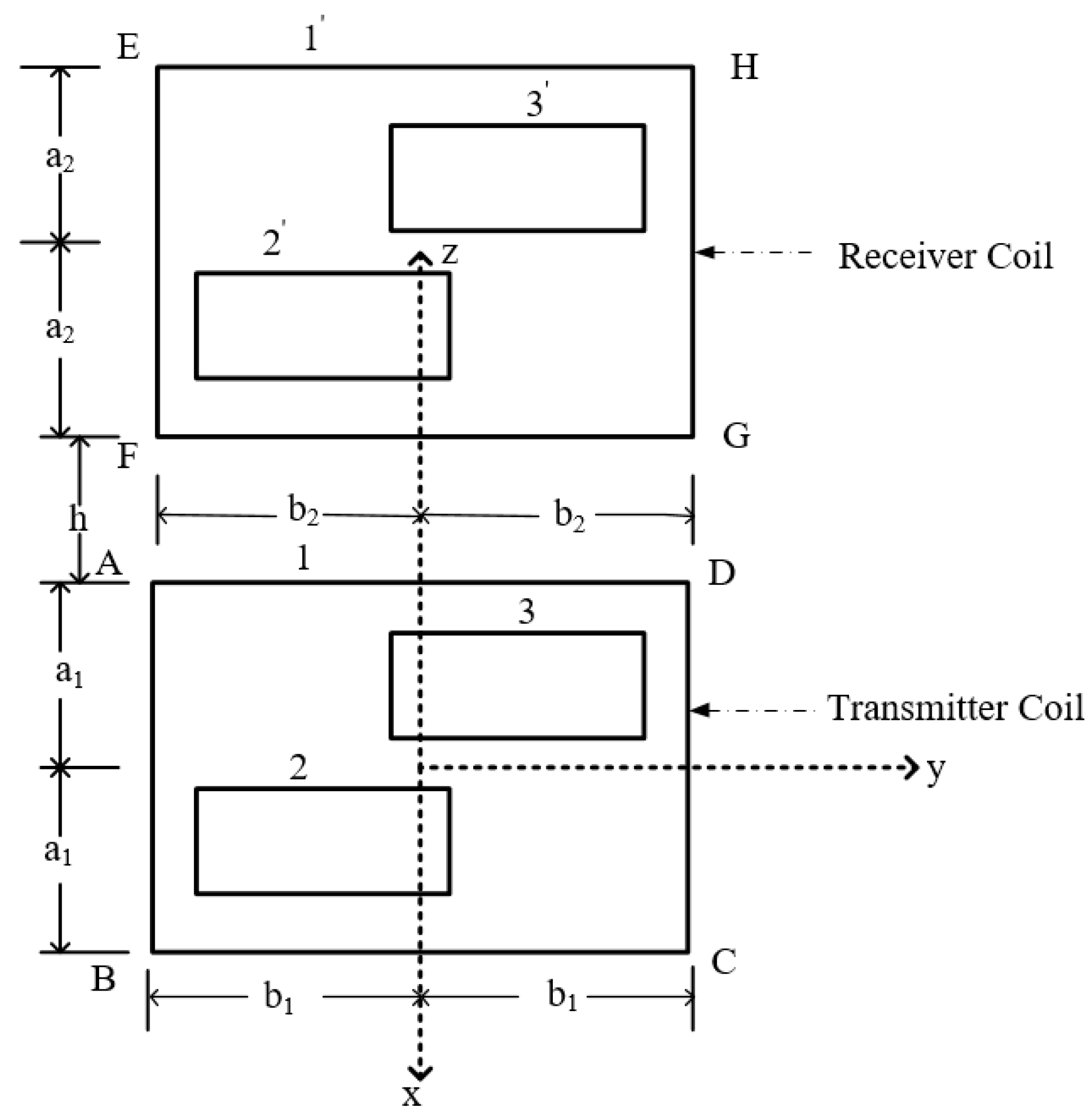

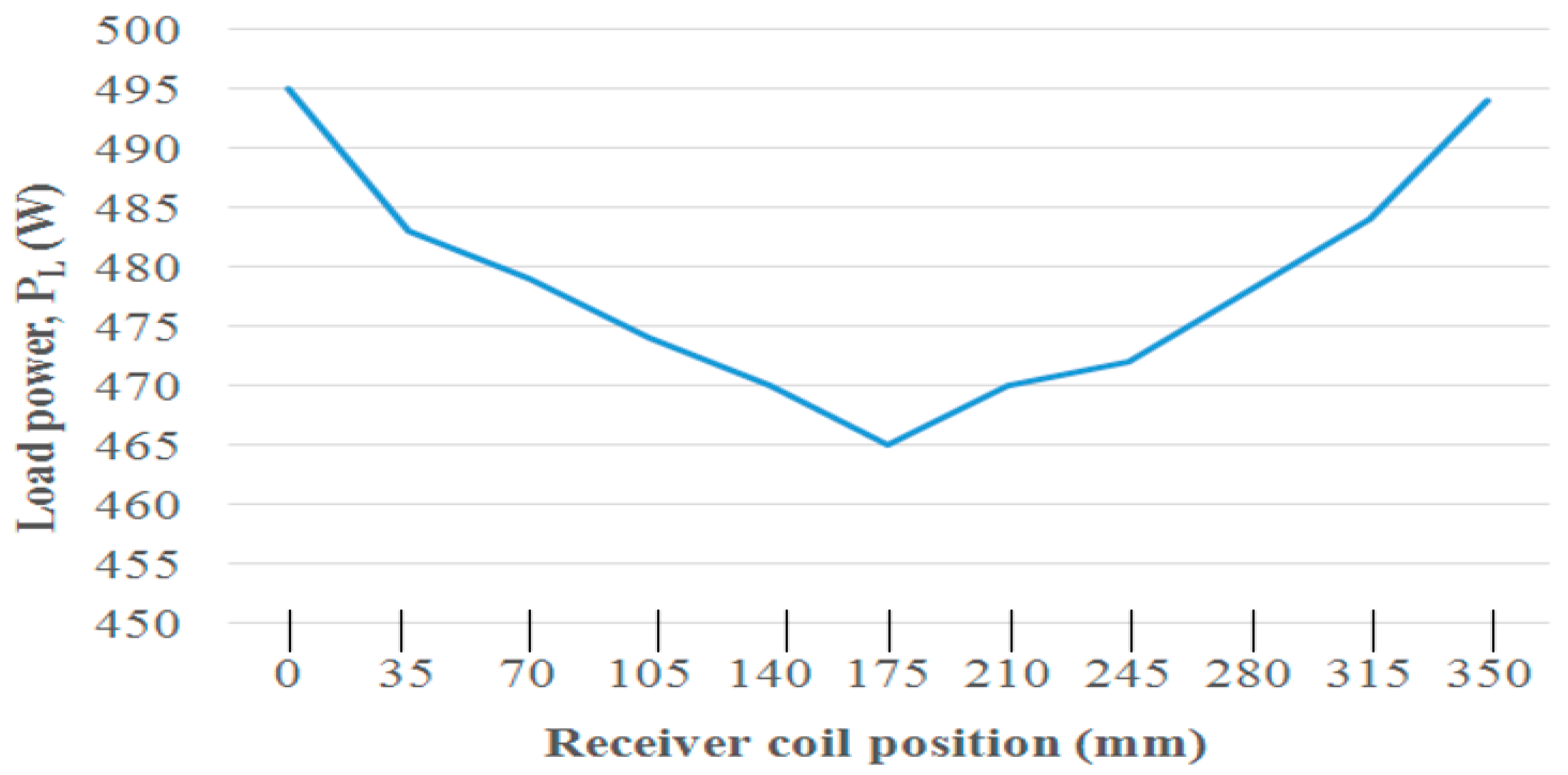

2. Proposed Magnetic Pad Structure

- The receiver pad is identical to one part of the extended DD transmitter pad.

- Mutual inductances under perpendicular segments are negligible.

- Transient conditions for all switching states are not changed significantly from one transmitter pad to another.

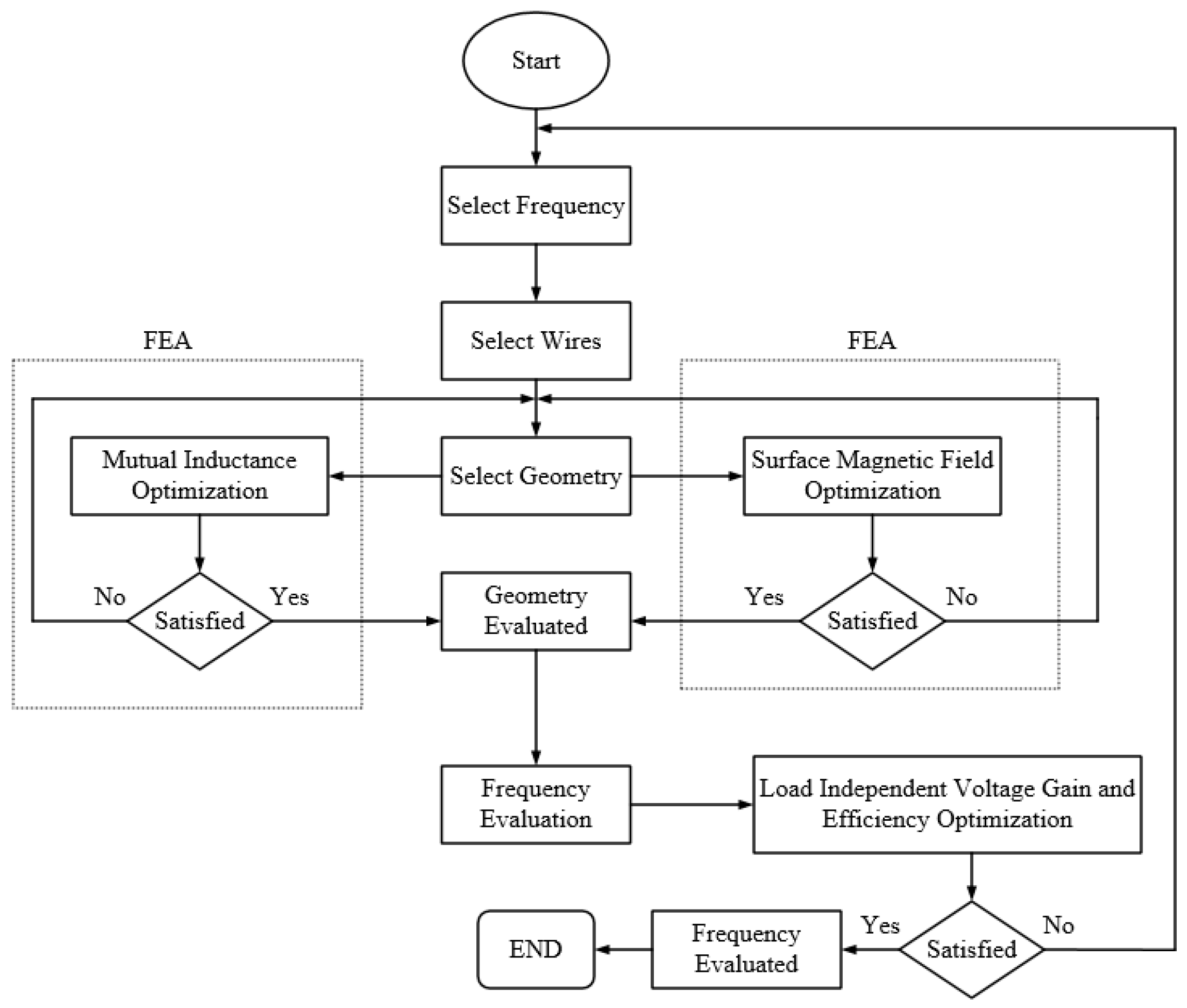

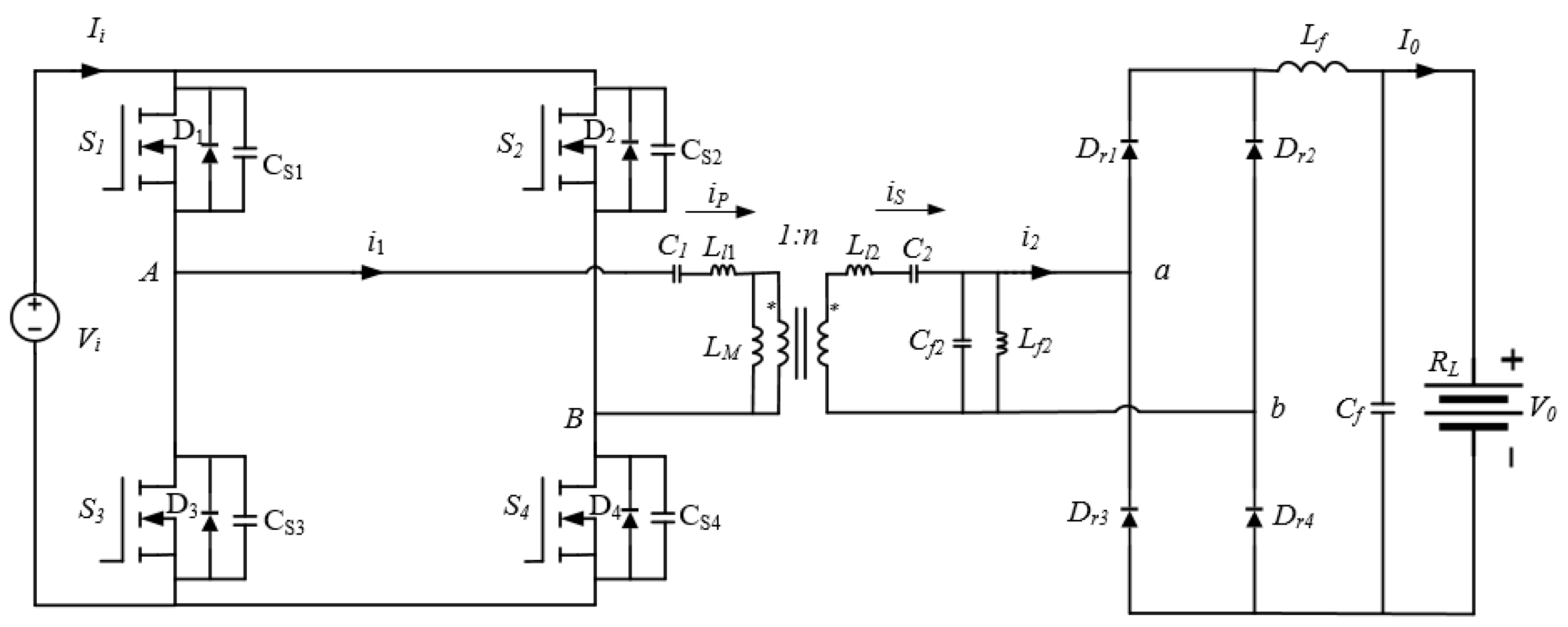

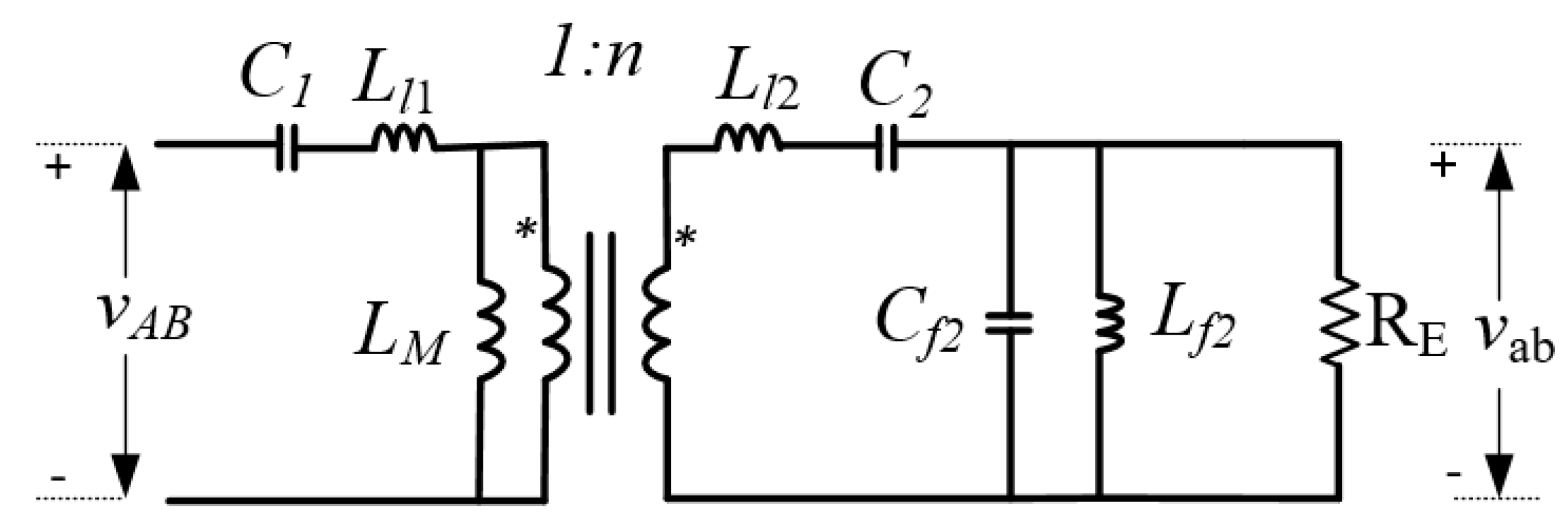

3. Analysis of the Proposed Topology

3.1. Finite Element Analysis of Proposed Pad

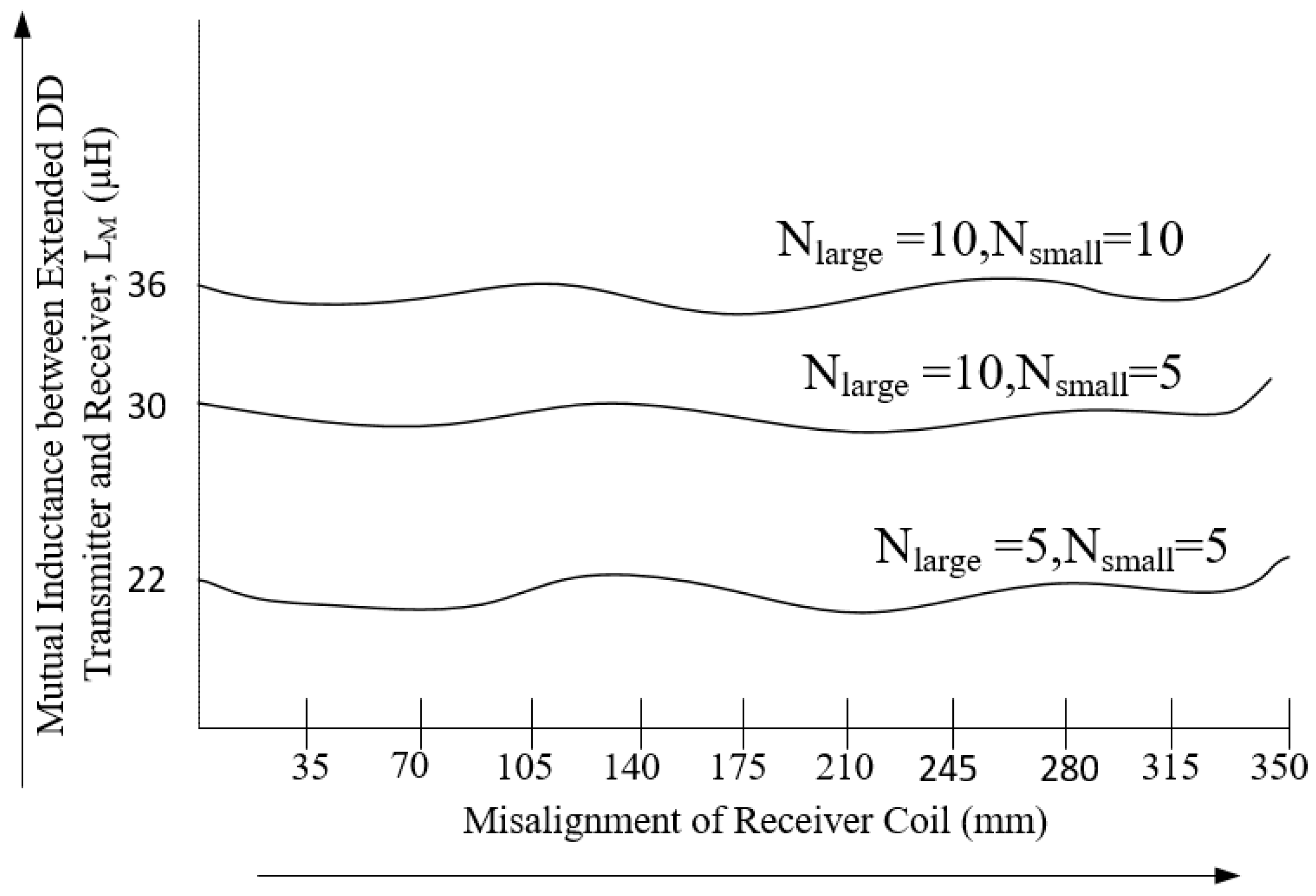

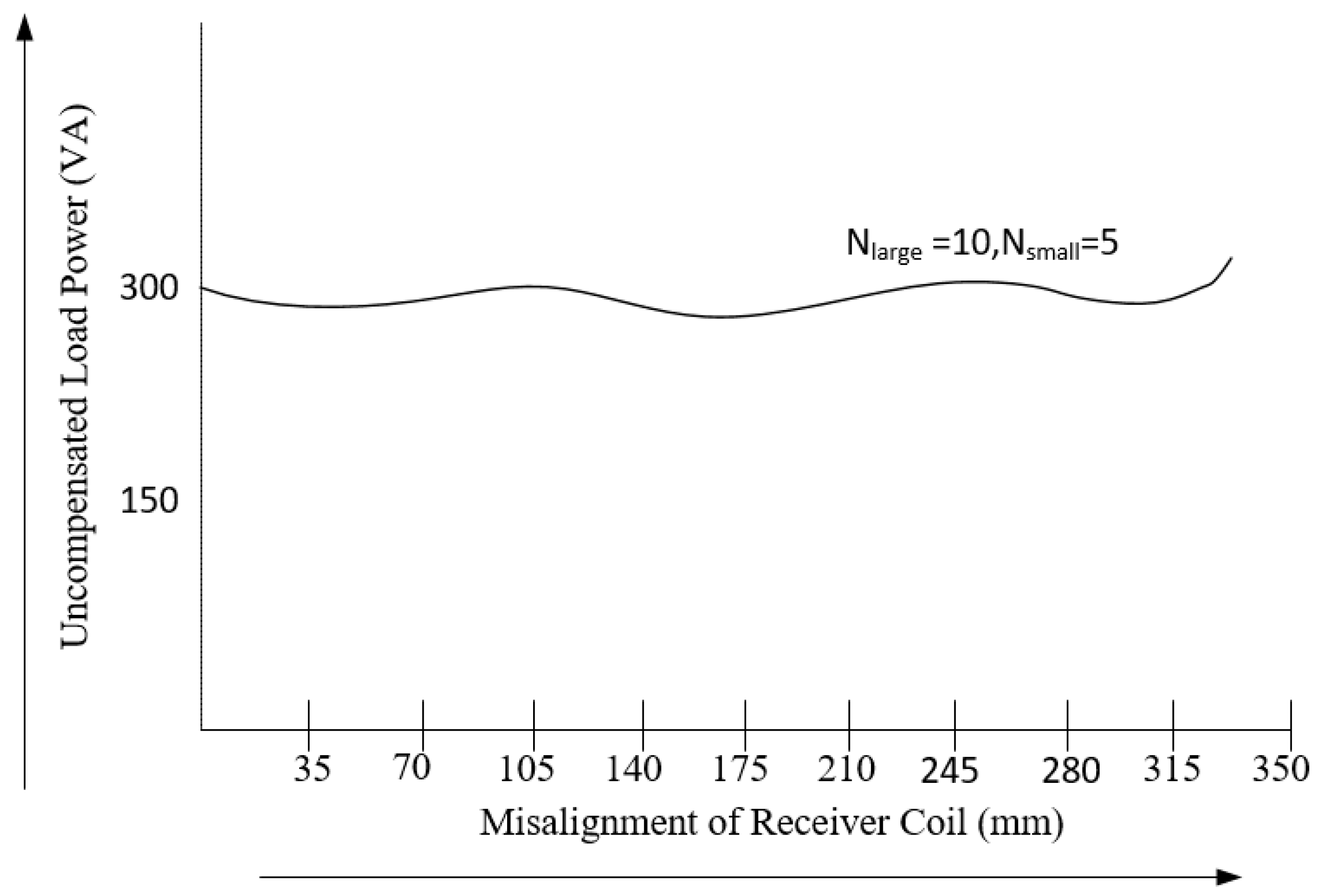

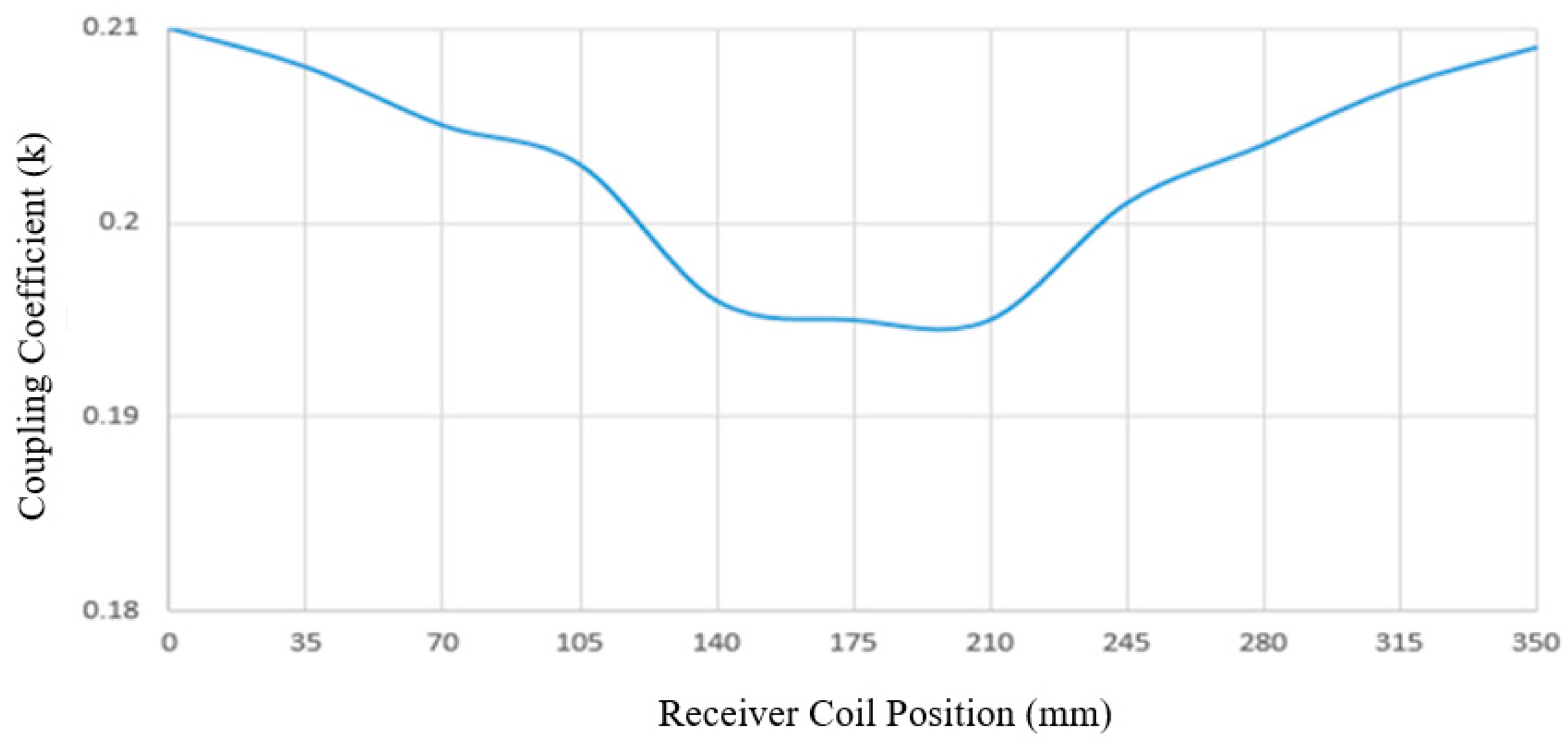

3.2. Mutual Inductance and Coupling Coefficient

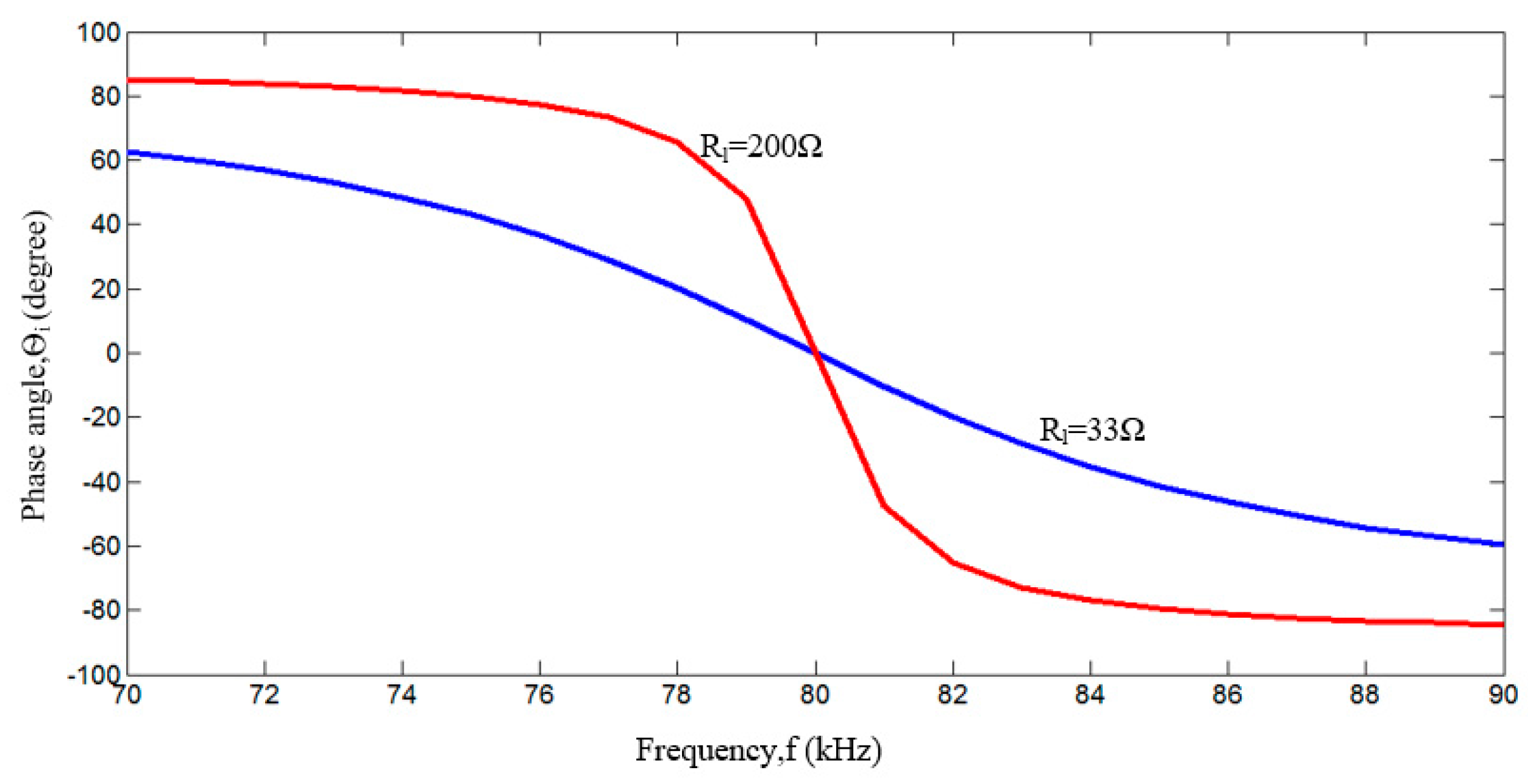

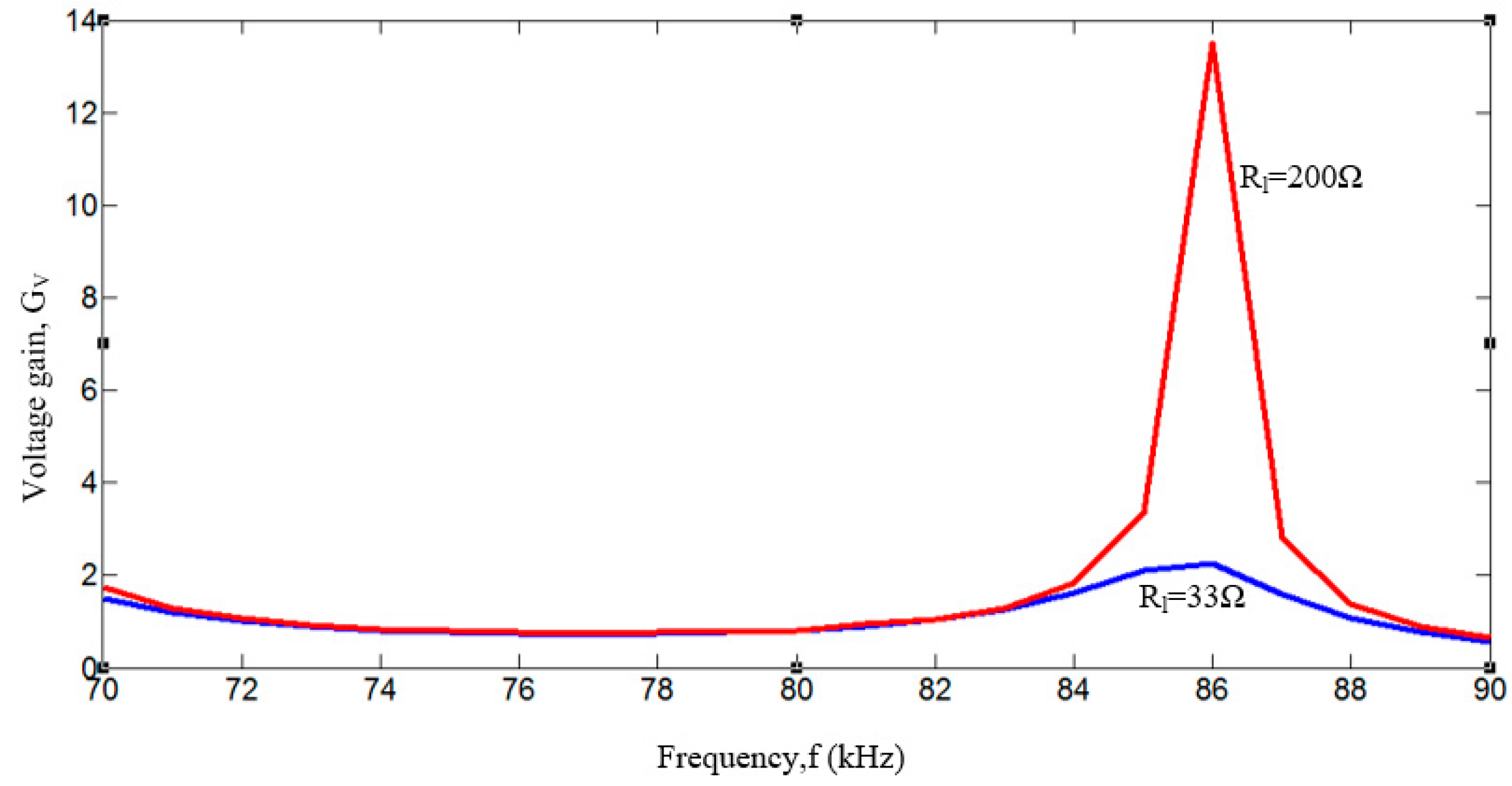

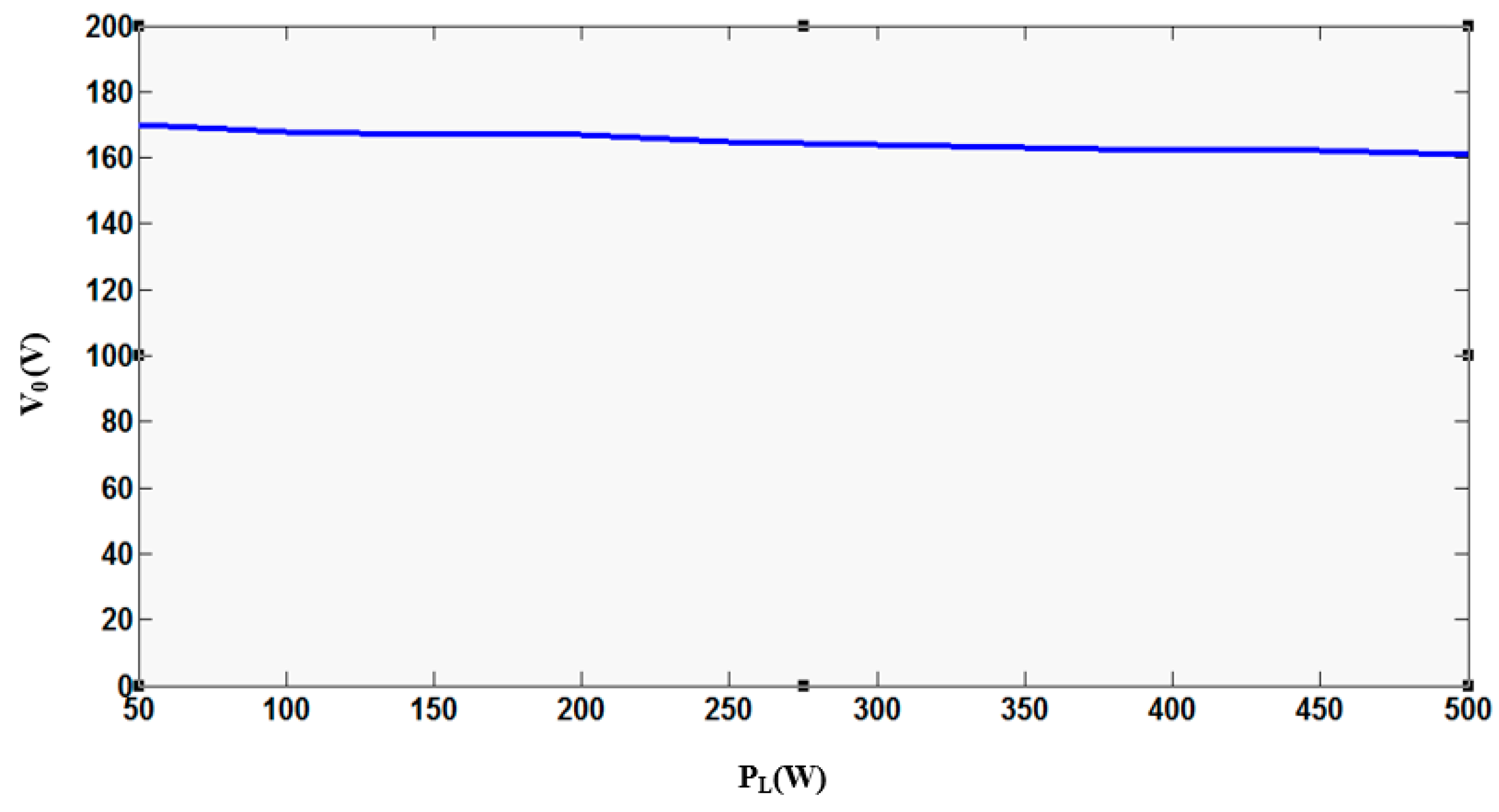

3.3. Load Independent Voltage Gain

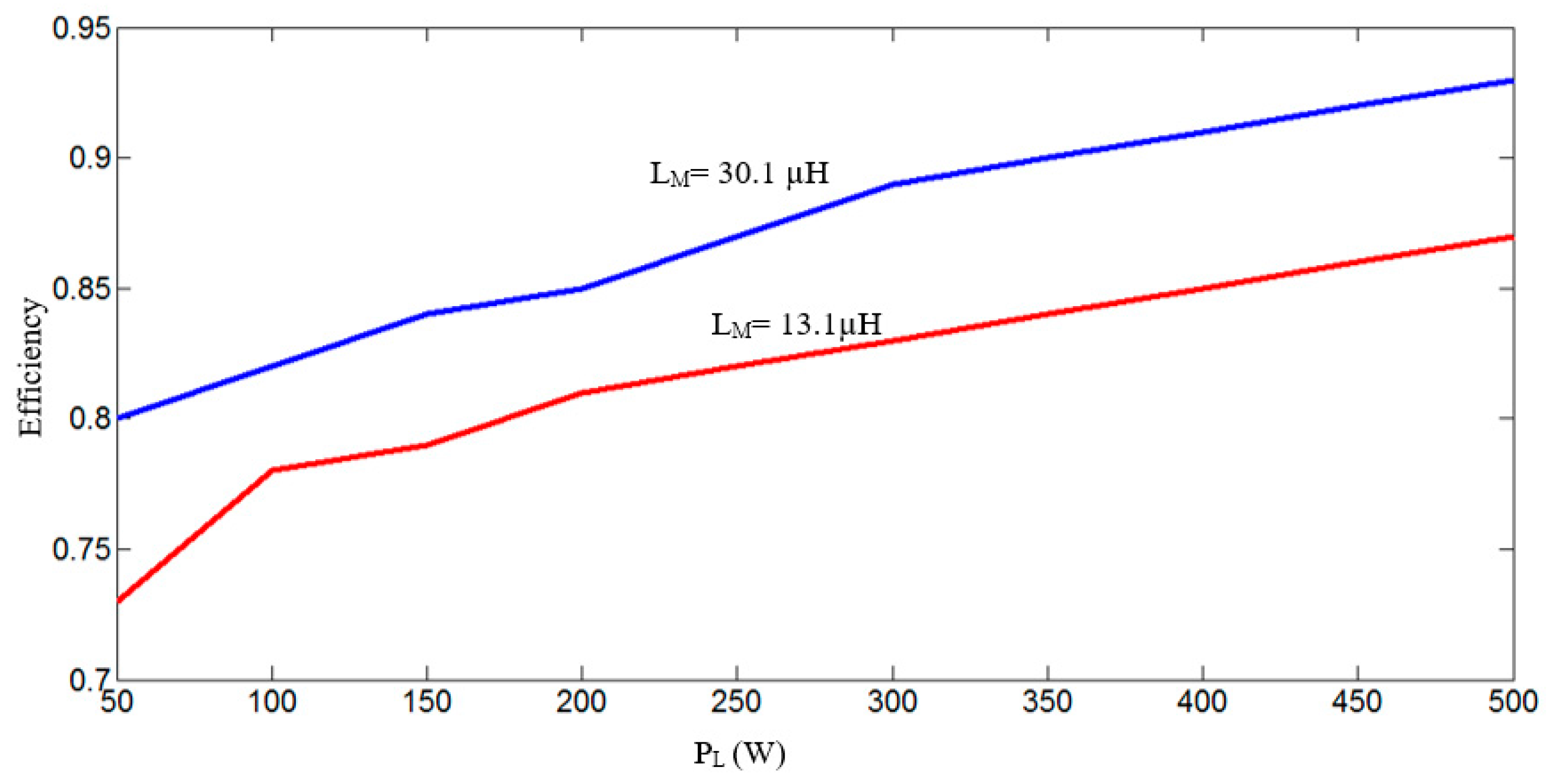

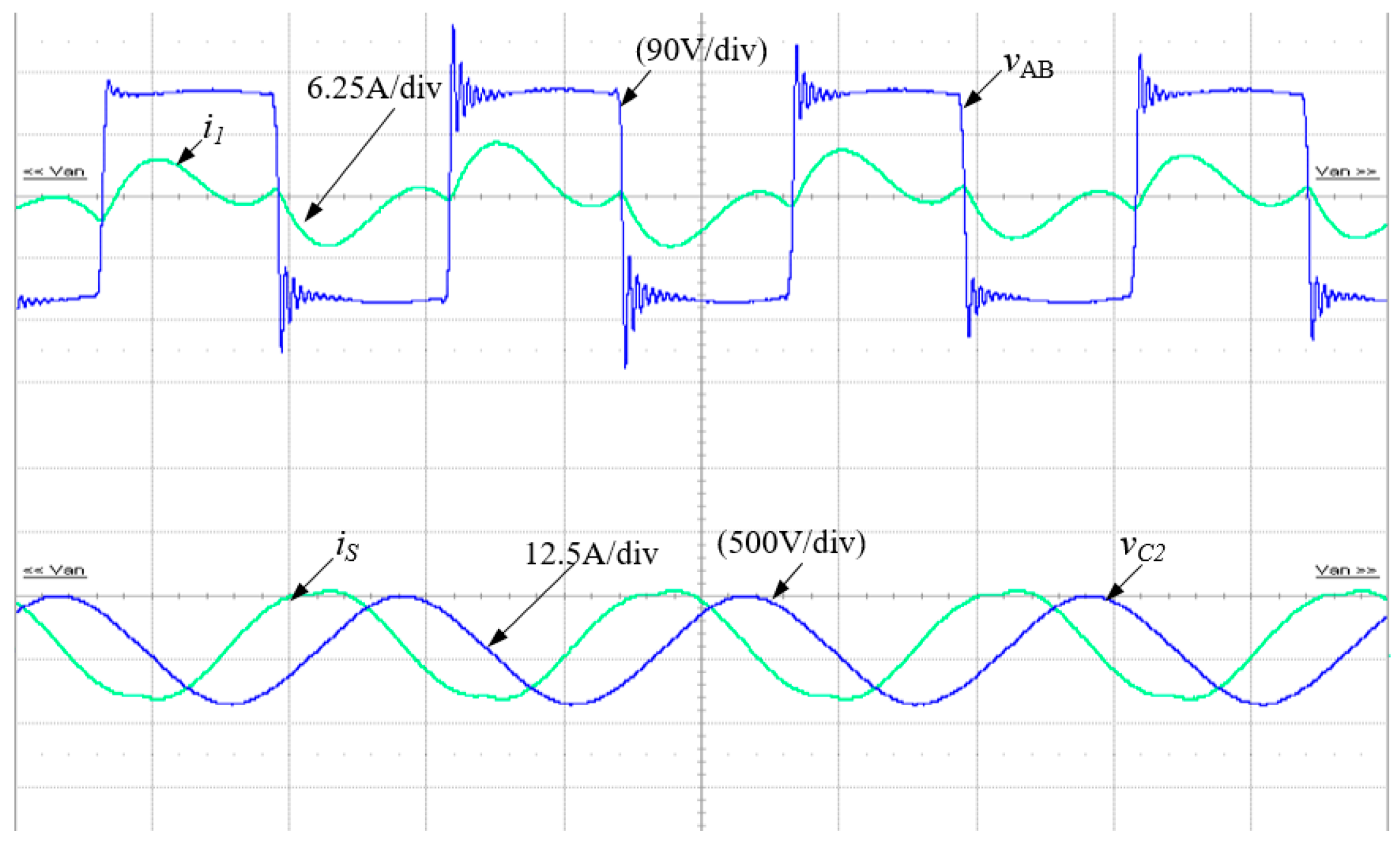

4. Experimental Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jeong, S.; Jang, Y.J.; Kum, D. Economic Analysis of the dynamic charging electric vehicle. IEEE Trans. Power Electron. 2015, 30, 6368–6377. [Google Scholar] [CrossRef]

- Jan-Mou, L.; Jones, P.T.; Onar, O.; Starke, M. Coupling electric vehicles and power grid through charging-in-motion and connected vehicle technology. In Proceedings of the IEEE Electric Vehicle Conference (IEVC), Florence, Italy, 17–19 December 2014. [Google Scholar]

- Gilchrist, A.; Wu, H.; Sealy, K. Novel system for wireless in-motion EV charging and disabled vehicle removal. In Proceedings of the IEEE Electric Vehicle Conference (IEVC), Greenville, SC, USA, 4–8 March 2012. [Google Scholar]

- Stamati, T.E.; Bauer, P. On-road charging of electric vehicles. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Metro Detroit, MI, USA, 16–19 June 2013. [Google Scholar]

- Prasanth, V.; Bauer, P. Study of misalignment for on road charging. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Metro Detroit, MI, USA, 16–19 June 2013. [Google Scholar]

- Zhang, W.; Wong, S.-C.; Tse, C.K.; Chen, Q. An optimized track length in roadway inductive power transfer systems. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 598–608. [Google Scholar] [CrossRef]

- Kalwar, A.K.; Mekhilef, S.; Seyedmahmoudian, M.; Horan, B. Coil design for high misalignment tolerant inductive power transfer system for EV charging. Energies. 2016, 9, 937. [Google Scholar] [CrossRef]

- Bosshard, R.; Kolar, J.W.; Muhlethaler, J.; Stevanovic, I.; Wunsch, B.; Canales, F. Modeling and η-α-pareto optimization of inductive power transfer coils for electric vehicles. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 50–64. [Google Scholar] [CrossRef]

- Kalwar, A.K.; Aamir, M.; Uddin, K.M.; Mekhilef, S. A new coil design for enhancement in misalignmenttolerance of wireless charging system. In Proceedings of the Students Conference on Research and Development (SCOReD), Kuala Lumpur, Malaysia, 13–14 December 2015. [Google Scholar]

- Elliott, G.A.J.; Covic, G.A.; Kacprzak, D.; Boys, J.T. A new concept: Asymmetrical pick-ups for inductively coupled power transfer monorail systems. IEEE Trans. Magn. 2006, 42, 3389–3391. [Google Scholar] [CrossRef]

- Shin, J.; Shin, S.; Kim, Y.; Ahn, S.; Lee, S.; Jung, G.; Jeon, S.-J.; Cho, D.-H. Design and implementation of shaped magnetic-resonance-based wireless power transfer system for roadway-powered moving electric vehicles. IEEE Trans. Ind. Electron. 2014, 61, 1179–1192. [Google Scholar] [CrossRef]

- Prasanth, V.; Bauer, P. Distributed IPT systems for dynamic powering: Misalignment analysis. IEEE Trans. Ind. Electron. 2014, 61, 6013–6021. [Google Scholar] [CrossRef]

- Pijl, F.F.A.v.d.; Castilla, M.; Bauer, P. Adaptive sliding-mode control for a multiple-user inductive power transfer system without need for communication. IEEE Trans. Ind. Electron. 2013, 60, 271–279. [Google Scholar] [CrossRef]

- Onar, O.C.; Miller, J.M.; Campbell, S.; Coomer, C.; White, C.; Seiber, L. A novel wireless power transfer for in-motion EV/PHEV charging. In Proceedings of the Twenty-Eighth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013. [Google Scholar]

- Onar, O.C.; Miller, J.M.; Campbell, S.; Coomer, C.; White, C.; Seiber, L.; Sepe, R.; Steyerl, A. Demonstrating dynamic wireless charging of an electric vehicle: The benefit of electrochemical capacitor smoothing. IEEE Power Electron. Magn. 2014, 1, 12–24. [Google Scholar]

- Sampath, J.P.K.; Vilathgamuwa, D.M.; Alphones, A. Efficiency enhancement for dynamic wireless power transfer system with segmented transmitter array. IEEE Trans. Transp. Electrif. 2015, 2, 76–85. [Google Scholar] [CrossRef]

- Miller, J.M.; Jones, P.T.; Jan-Mou, L.; Onar, O.C. ORNL experience and challenges facing dynamic wireless power charging of EV’s. IEEE Circuits Sys. Mag. 2015, 15, 40–53. [Google Scholar] [CrossRef]

- Kibok, L.; Pantic, Z.; Lukic, S.M. Reflexive field containment in dynamic inductive power transfer systems. IEEE Trans. Power Electron. 2014, 29, 4592–4602. [Google Scholar]

- Chen, L.; Nagendra, G.R.; Boys, J.T.; Covic, G.A. Double-coupled systems for IPT roadway applications. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 37–49. [Google Scholar] [CrossRef]

- Budhia, M.; Covic, G.A.; Boys, J.T. Design and optimization of circular magnetic structures for lumped inductive power transfer systems. IEEE Trans. Power Electron. 2011, 26, 3096–3108. [Google Scholar] [CrossRef]

- Budhia, M.; Boys, J.T.; Covic, G.A.; Chang-Yu, H. Development of a single-sided flux magnetic coupler for electric vehicle ipt charging systems. IEEE Trans. Ind. Electron. 2013, 60, 318–328. [Google Scholar] [CrossRef]

- Covic, G.A.; Kissin, M.L.G.; Kacprzak, D.; Clausen, N.; Hao, H. A bipolar primary pad topology for EV stationary charging and highway power by inductive coupling. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Phoenix, AZ, USA, 17–22 September 2011. [Google Scholar]

- Budhia, M.; Covic, G.A.; Boys, J.T.; Chang-Yu, H. Development and evaluation of single sided flux couplers for contactless electric vehicle charging. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Phoenix, AZ, USA, 17–22 September 2011. [Google Scholar]

- Zhu, Q.; Wang, L.; Guo, Y.; Liao, C.; Li, F. Applying LCC compensation network to dynamic wireless EV charging system. IEEE Trans. Ind. Electron. 2016, 63, 6557–6567. [Google Scholar] [CrossRef]

- Wen, F.; Huang, X. Optimal magnetic field shielding method by metallic sheets in wireless power transfer system. Energies 2016, 9, 733. [Google Scholar] [CrossRef]

- Chen, Z.; Jing, W.; Huang, X.; Tan, L.; Chen, C.; Wang, W. A promoted design for primary coil in roadway-powered system. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Greenhouse, H.M. Design of planar rectangular microelectronic inductors. IEEE Trans. Parts Hybrids Packag. 1974, 10, 101–109. [Google Scholar] [CrossRef]

- Cheng, Y.; Shu, Y. A new analytical calculation of the mutual inductance of the coaxial spiral rectangular coils. IEEE Trans. Magn. 2014, 50, 1–6. [Google Scholar] [CrossRef]

- Hou, J.; Chen, Q.; Yan, K.; Ren, X.; Wong, S.C.; Tse, C.K. Analysis and control of S/SP compensation contactless resonant converter with constant voltage gain. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Denver, CO, USA, 15–19 September 2013. [Google Scholar]

- Budhia, M.; Covic, G.A.; Boys, J.T. A new IPT magnetic coupler for electric vehicle charging systems. In Proceedings of the 36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010. [Google Scholar]

- Li, S.; Mi, C.C. Wireless power transfer for electric vehicle applications. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 4–17. [Google Scholar]

- Zaheer, A.; Kacprzak, D.; Covic, G.A. A bipolar receiver pad in a lumped IPT system for electric vehicle charging applications. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012. [Google Scholar]

- Saponara, S. Distributed measuring system for predictive diagnosis of uninterruptible power supplies in safety-critical applications. Energies 2016, 9, 327. [Google Scholar] [CrossRef]

- Saponara, S.; Fanucci, L.; Bernardo, F.; Falciani, A. Predictive diagnosis of high-power transformer faults by networking vibration measuring nodes with integrated signal processing. IEEE Trans. Instrum. Meas. 2016, 65, 1749–1760. [Google Scholar] [CrossRef]

- Costantino, N.; Serventi, R.; Tinfena, F.; D’Abramo, P.; Chassard, P.; Tisserand, P.; Saponara, S.; Fanucci, L. Design and test of an HV-CMOS intelligent power switch with integrated protections and self-diagnostic for harsh automotive applications. IEEE Trans. Ind. Electron. 2011, 58, 2715–2727. [Google Scholar] [CrossRef]

- Saponara, S.; Bacchillone, T. Network architecture, security issues, and hardware implementation of a home area network for smart grid. J. Comput. Netw. Commun. 2012, 2012, 534512. [Google Scholar] [CrossRef]

| Design Specifications | Value |

|---|---|

| Resonant frequency | f = 80 kHz |

| Parameters of IPT transformer | n = 1, Ll1 = 165.9 µH, Ll2 = 82.05 µH, LM = 30.1 µH, k = 0.203 |

| Compensating inductor | Lf2 = 20 µH |

| Resonant capacitors | C1 = 23.86 nF, C2 = 48.24 nF, Cf2 = 329.27 nF |

| Load resistance | RL = 33–200 Ω |

| Load power | PL = 500 W |

| Air gap | h = 140 mm |

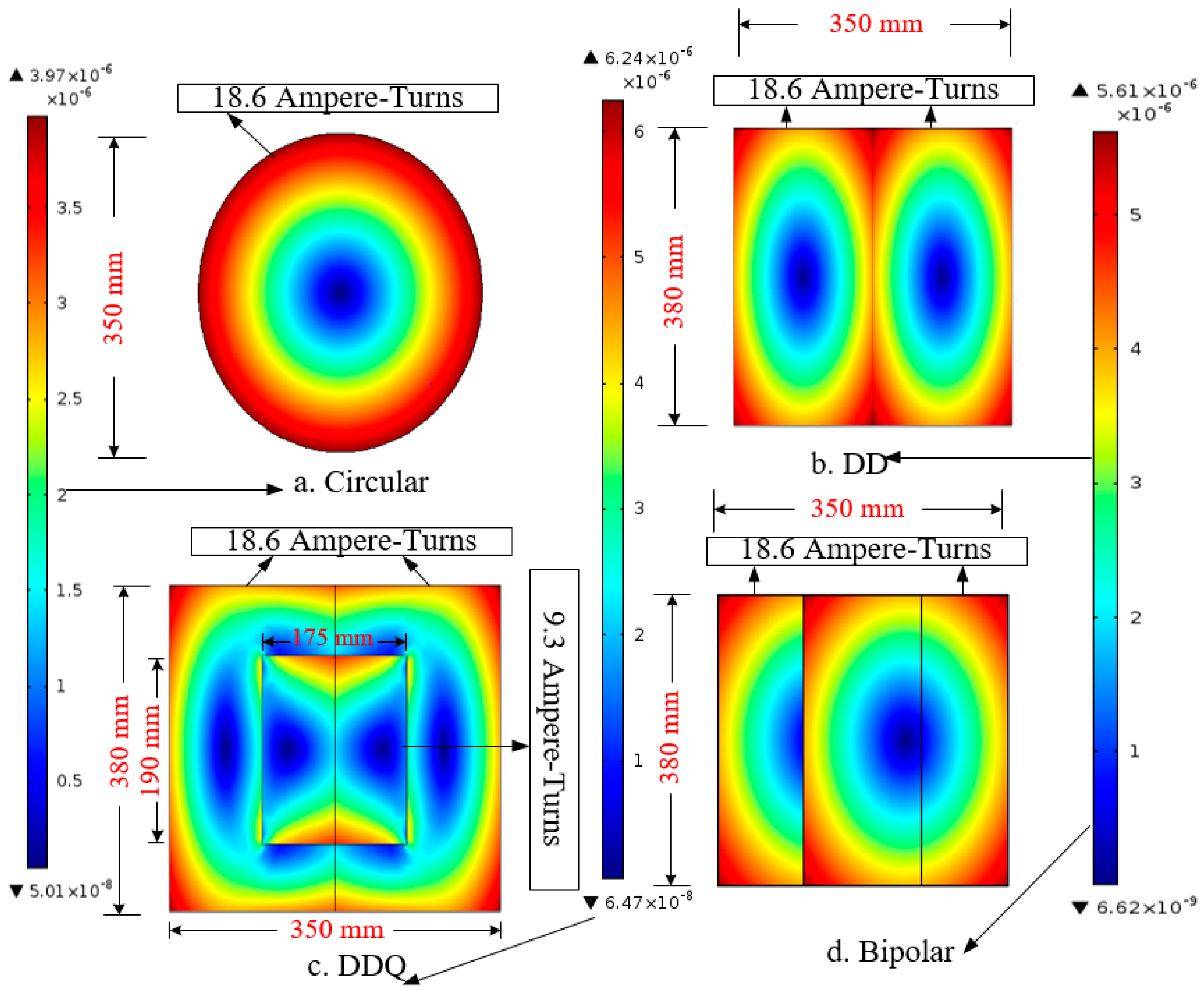

| Coil Topology | Evaluation Criteria | |||

|---|---|---|---|---|

| Overview | Flux Path Height | Polarization | Null Zones of Power Transfer with Horizontal Offset | |

| Circular |  | 1/4 of the pad diameter [30] | Not polarized | Occurs at about 38% of the pad diameter [23] |

| DD |  | 1/2 of the pad length [23,31] | Polarized | Creates at about 34% of the pad length [21] |

| DDQ |  | 2 times of circular with an extra single sided flux path [23] | Polarized | Occurs at about 77% of the pad length [32] |

| Bipolar |  | 2 times of circular | Polarized | Similar to DDQ [32] |

| Proposed |  | 1/2.5 of the pad length | Smaller sections are polarized | Not happens for extended DD transmitter |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alam, M.M.; Mekhilef, S.; Seyedmahmoudian, M.; Horan, B. Dynamic Charging of Electric Vehicle with Negligible Power Transfer Fluctuation. Energies 2017, 10, 701. https://doi.org/10.3390/en10050701

Alam MM, Mekhilef S, Seyedmahmoudian M, Horan B. Dynamic Charging of Electric Vehicle with Negligible Power Transfer Fluctuation. Energies. 2017; 10(5):701. https://doi.org/10.3390/en10050701

Chicago/Turabian StyleAlam, Md Morshed, Saad Mekhilef, Mehdi Seyedmahmoudian, and Ben Horan. 2017. "Dynamic Charging of Electric Vehicle with Negligible Power Transfer Fluctuation" Energies 10, no. 5: 701. https://doi.org/10.3390/en10050701