Insulation Resistance Monitoring Algorithm for Battery Pack in Electric Vehicle Based on Extended Kalman Filtering

Abstract

:1. Introduction

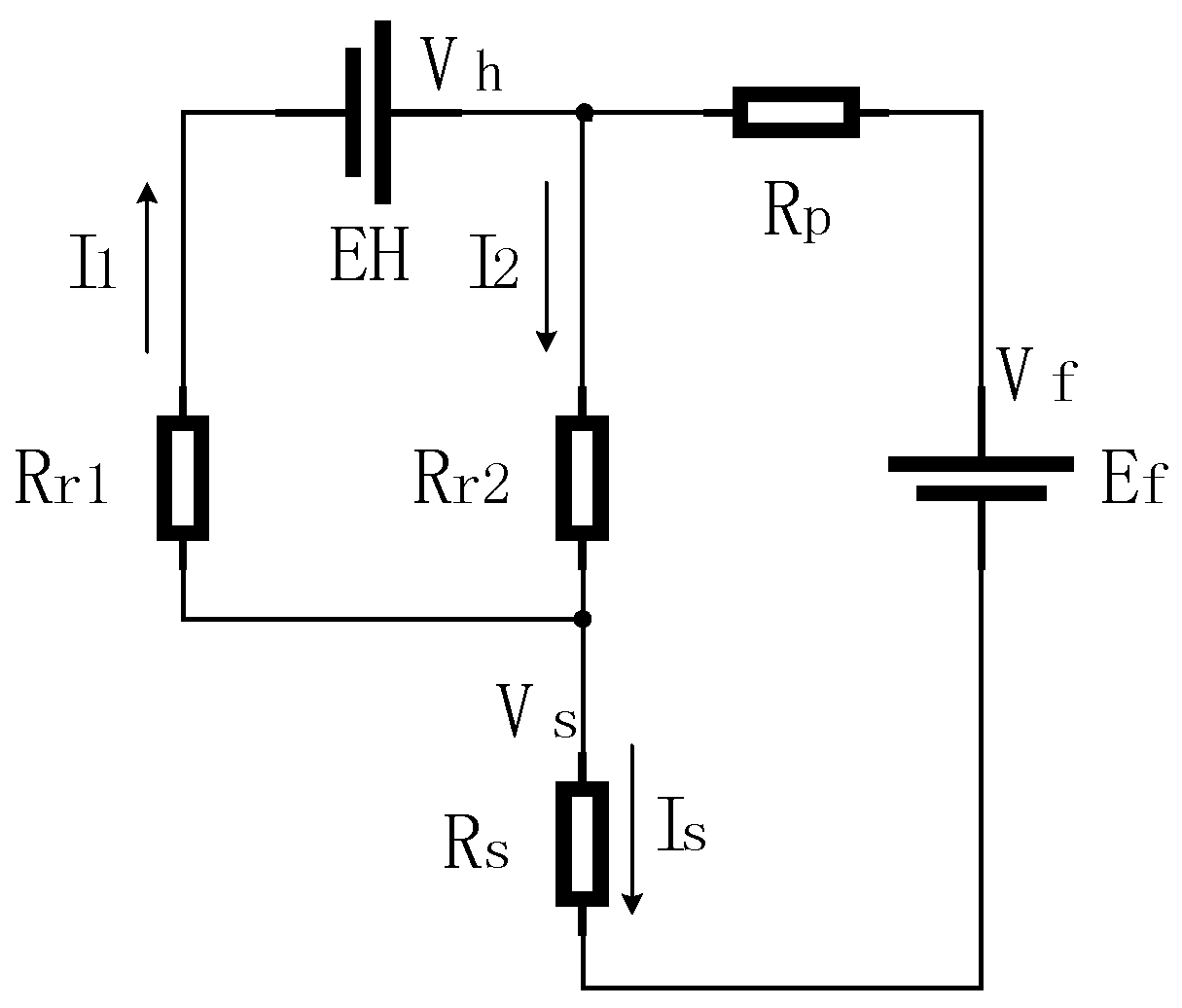

2. Mechanism of the Low-Voltage, Low-Frequency Signal Injection Method Monitoring Circuit

3. Design of the Discrete Extended Kalman Filter

- is the noise-driven matrix,

- is the process noise with an average value of 0 and a variance of Q, and

- is white Gaussian noise with an average value of 0 and a variance of R.

- (1)

- Initial state X(0) and P0.

- (2)

- Time update, which includes the state space update and covariance of the error update:where is the predicted state at step k, is the previous estimated state at step k−1, is the predicted error covariance at step k, and is the estimated error covariance at step k−1.

- (3)

- Measurement update, which involves Kalman gain calculation, state estimation measurement update, and error covariance update:where is the Kalman gain, is the predicted output, and is the measured output.

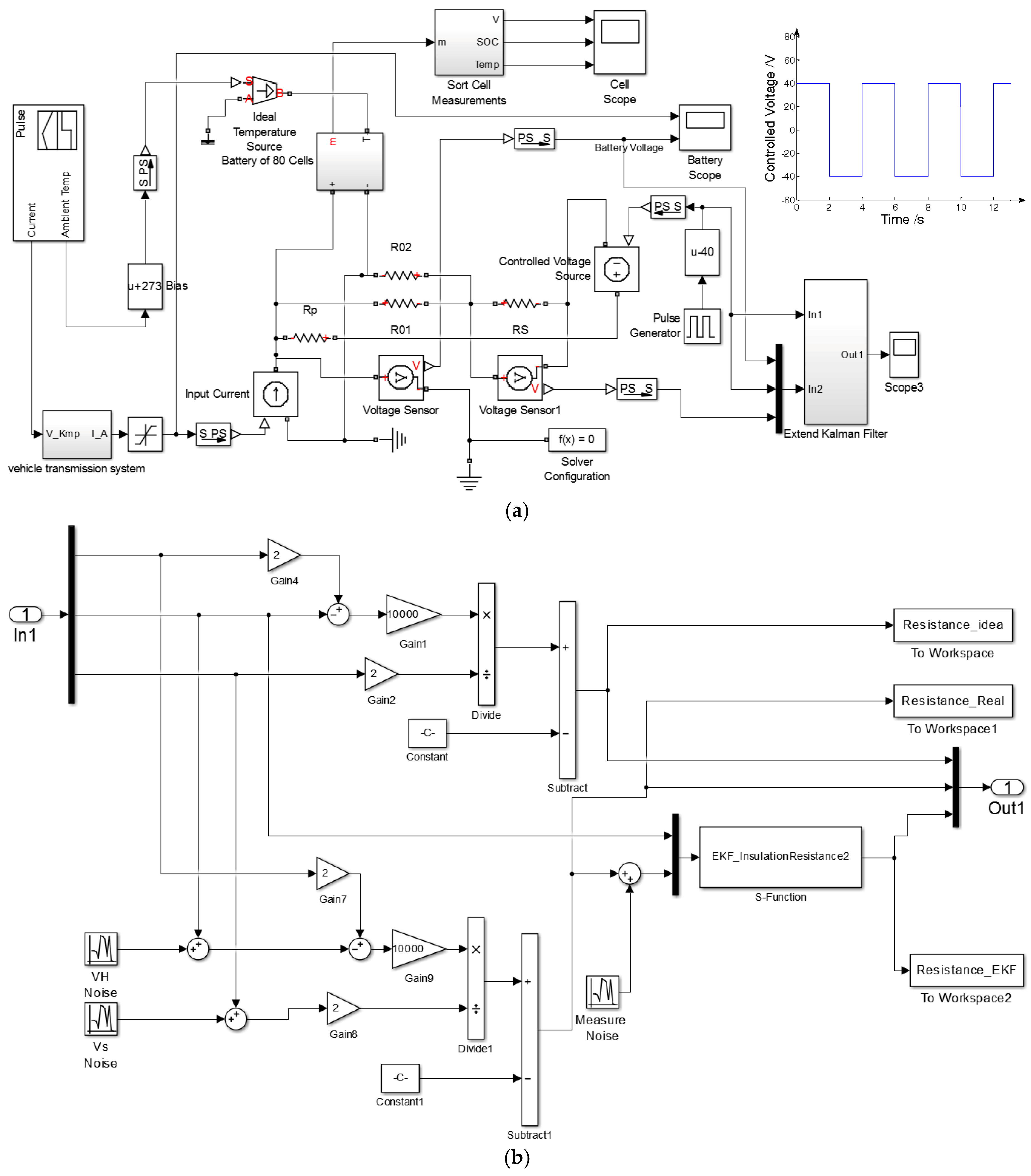

4. Matlab Simulation Model and Analysis

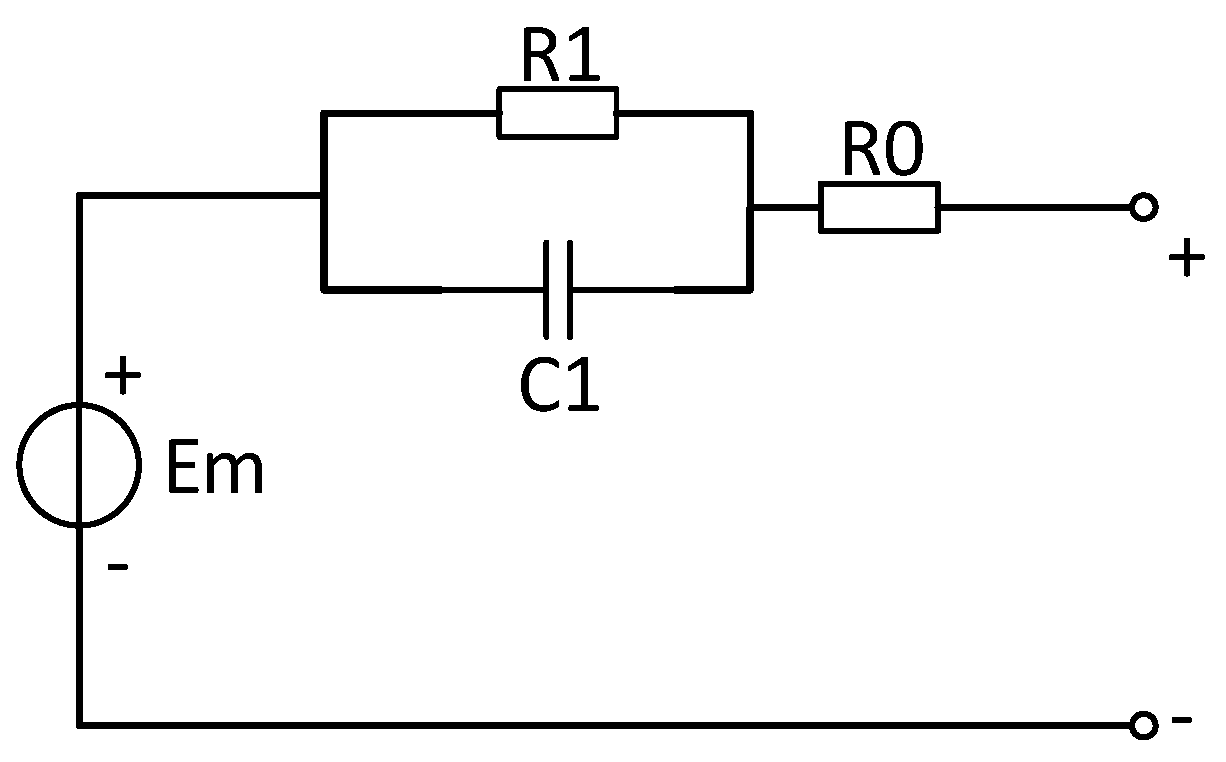

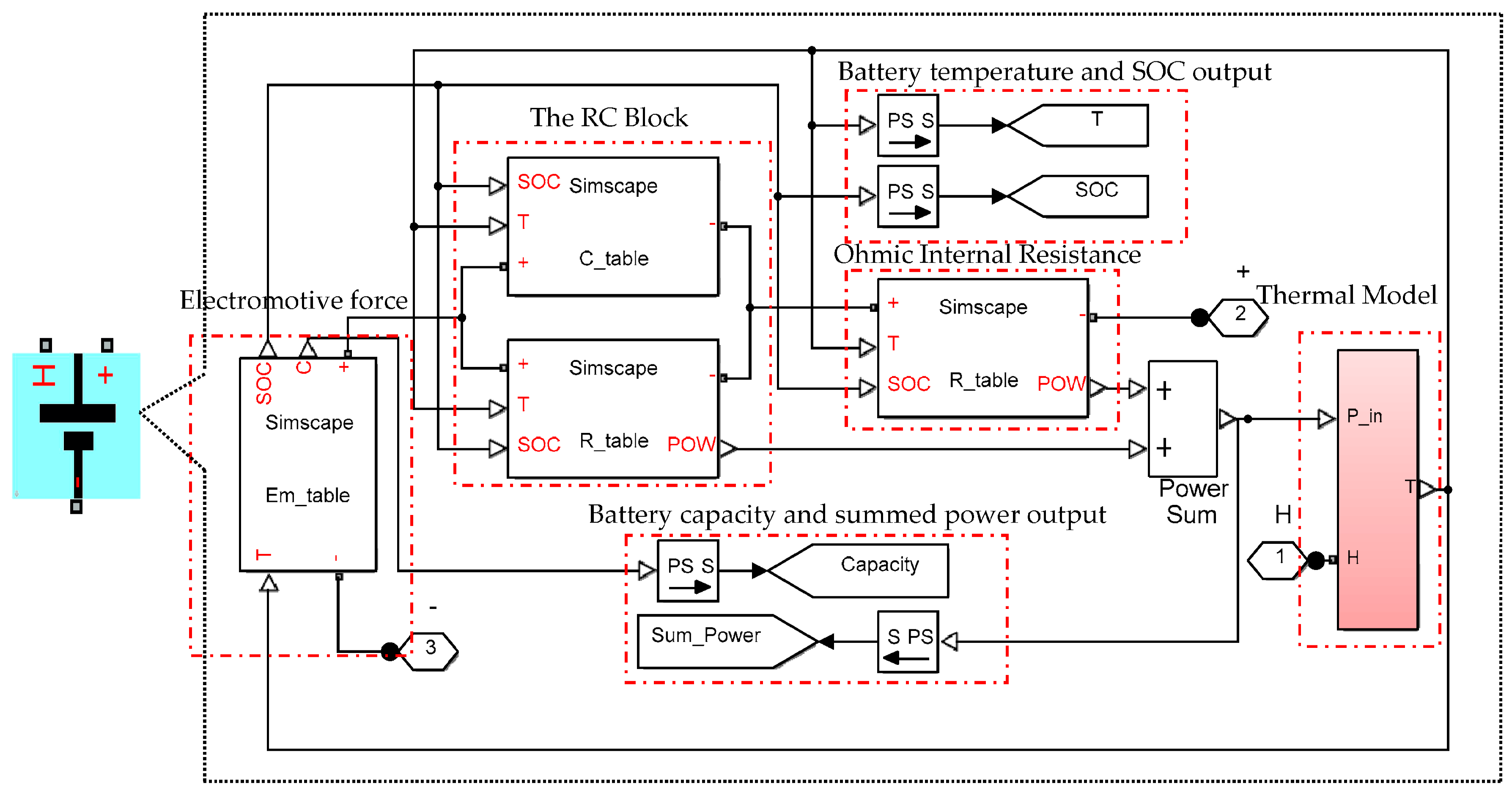

4.1. Simscape Battery Cell Model

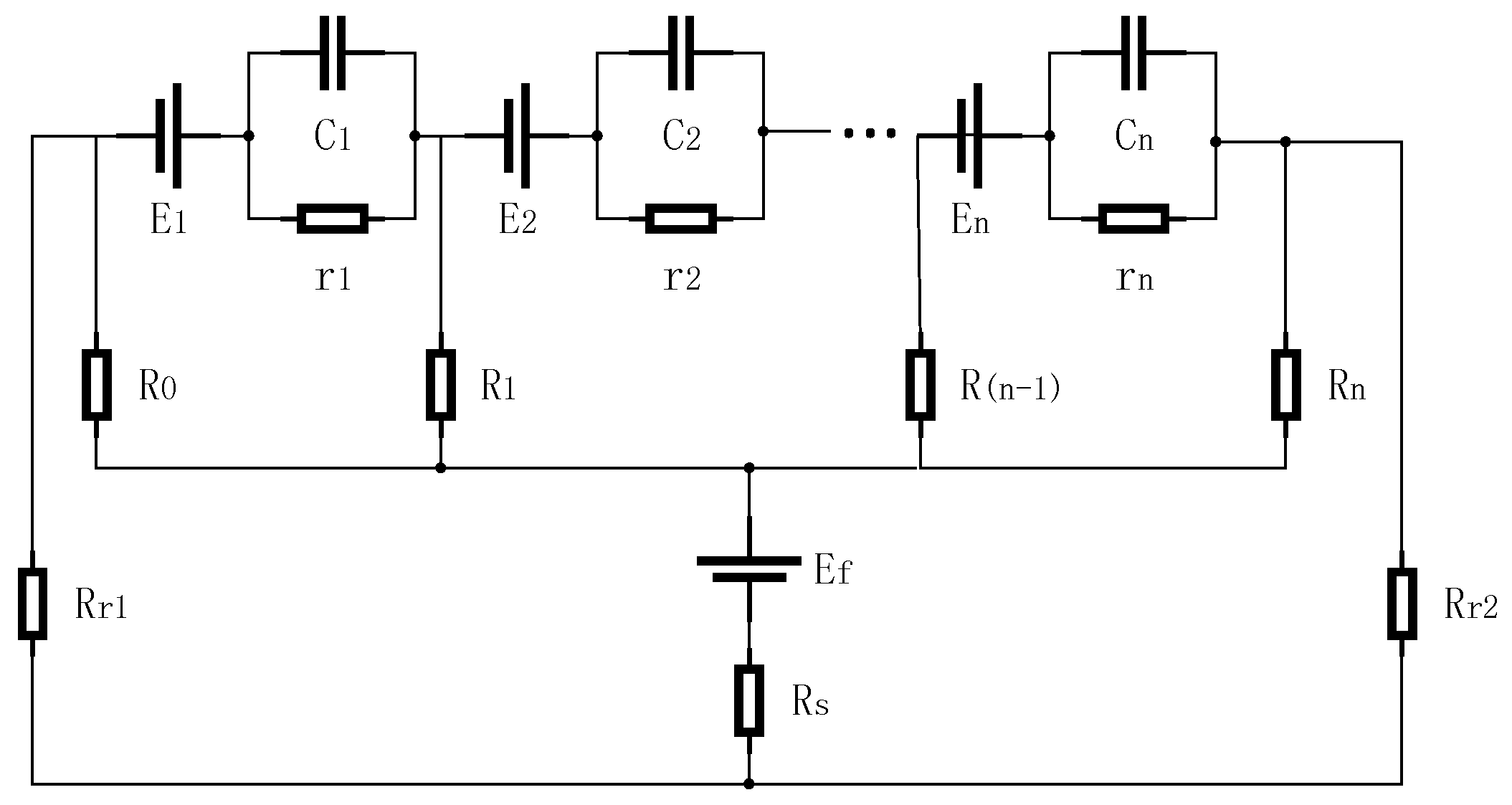

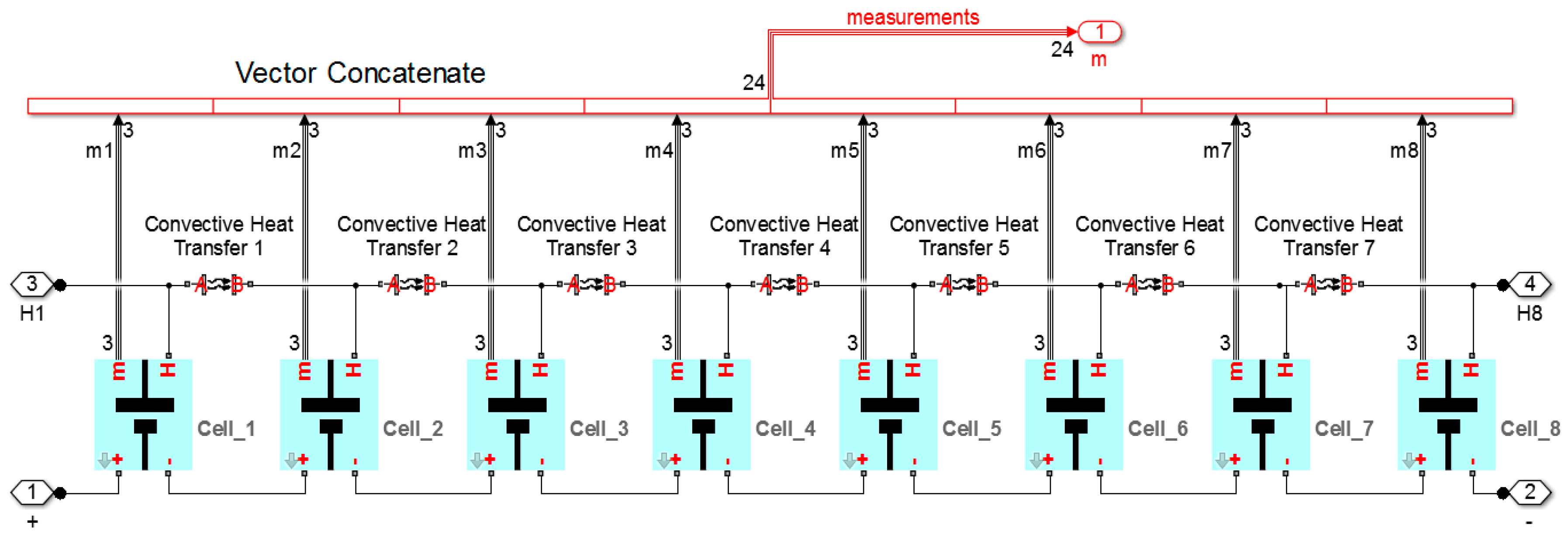

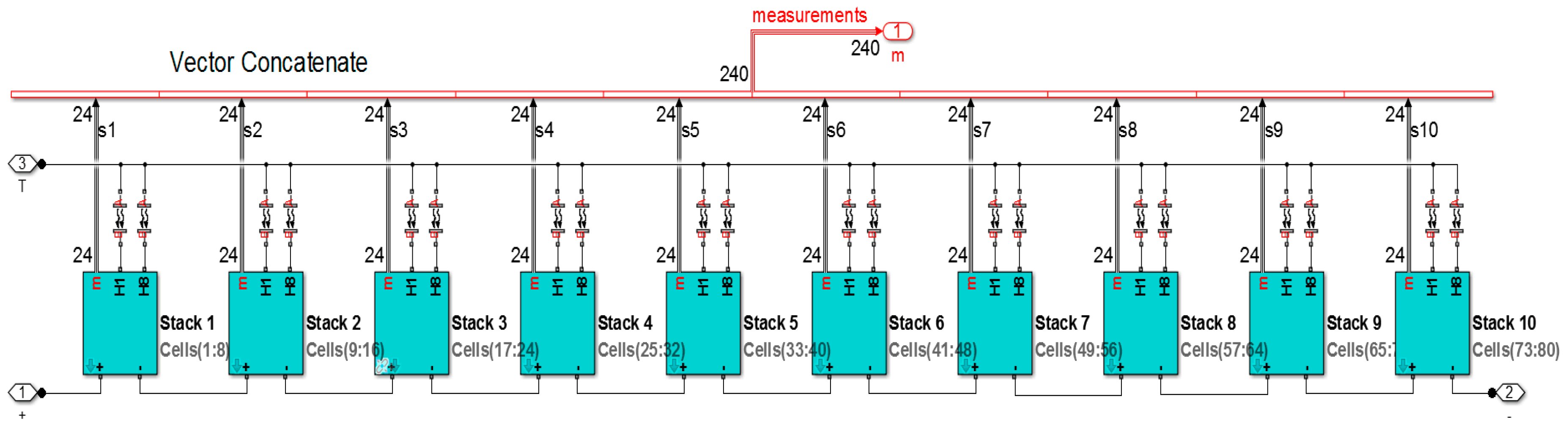

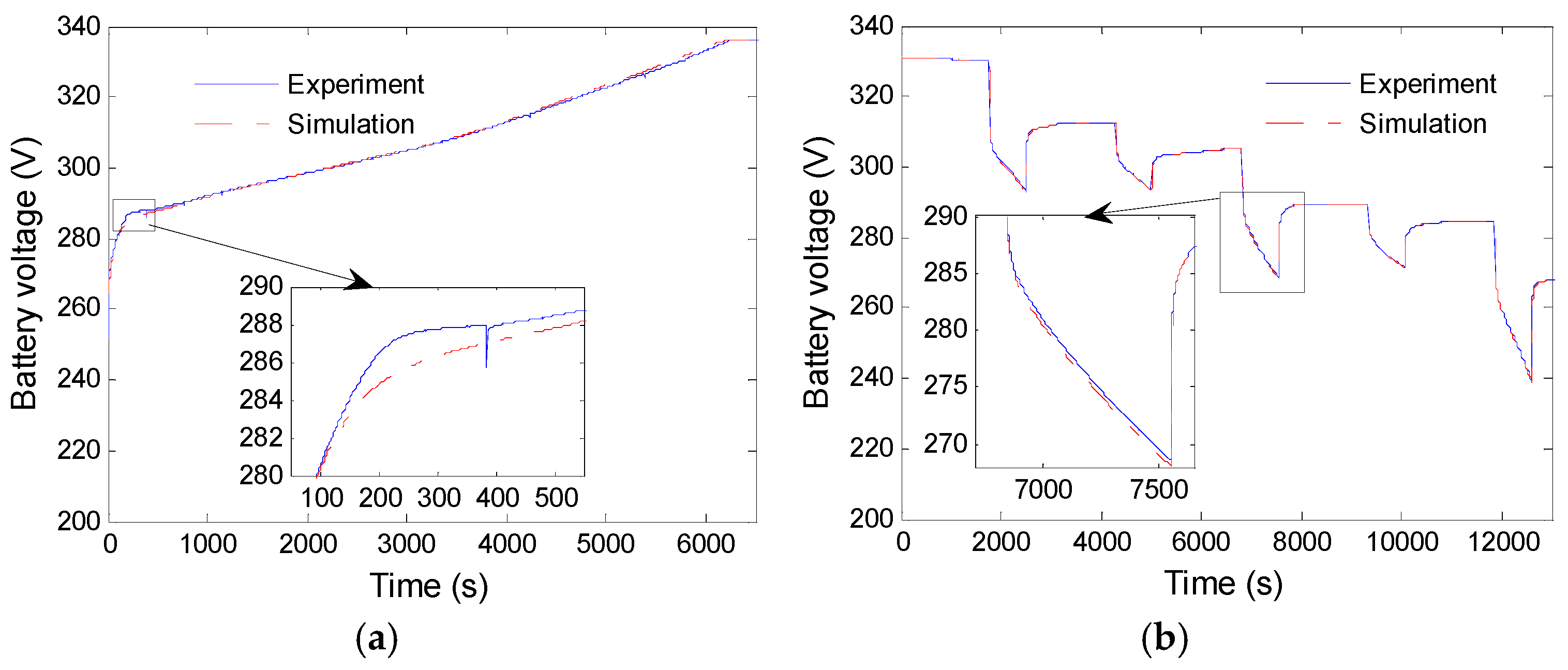

4.2. Battery Pack Model

4.3. Insulation Resistance Monitoring Model

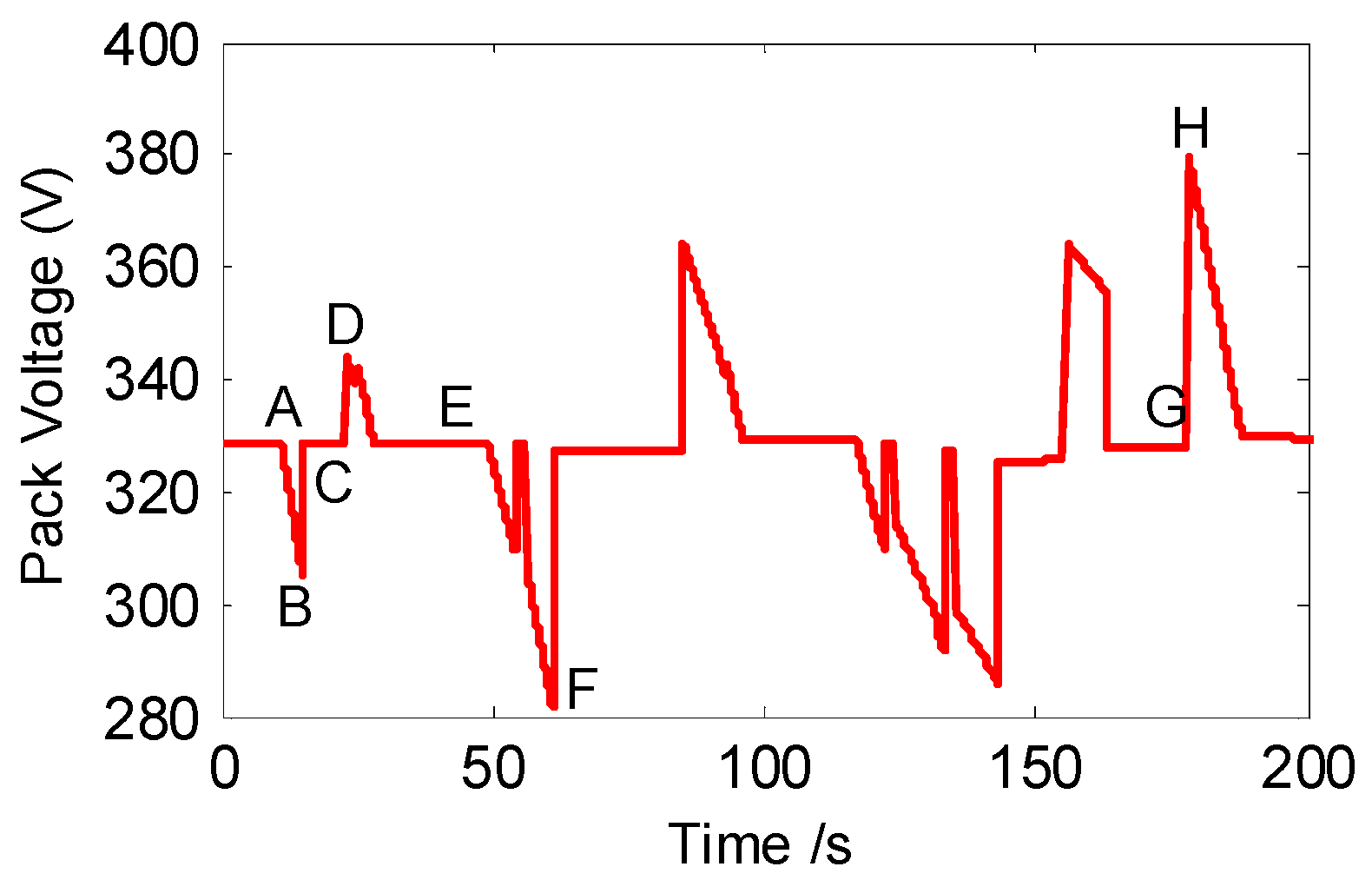

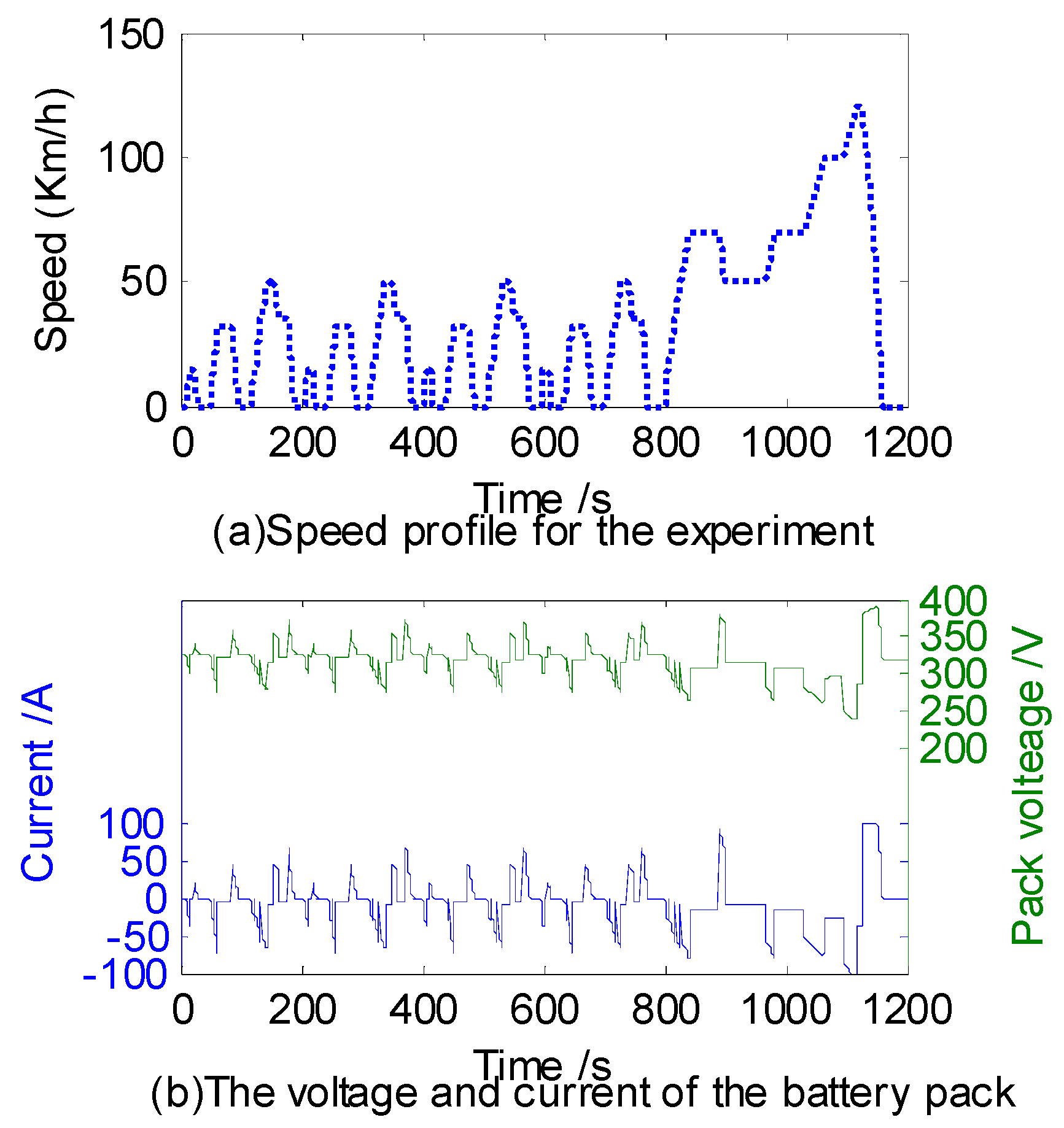

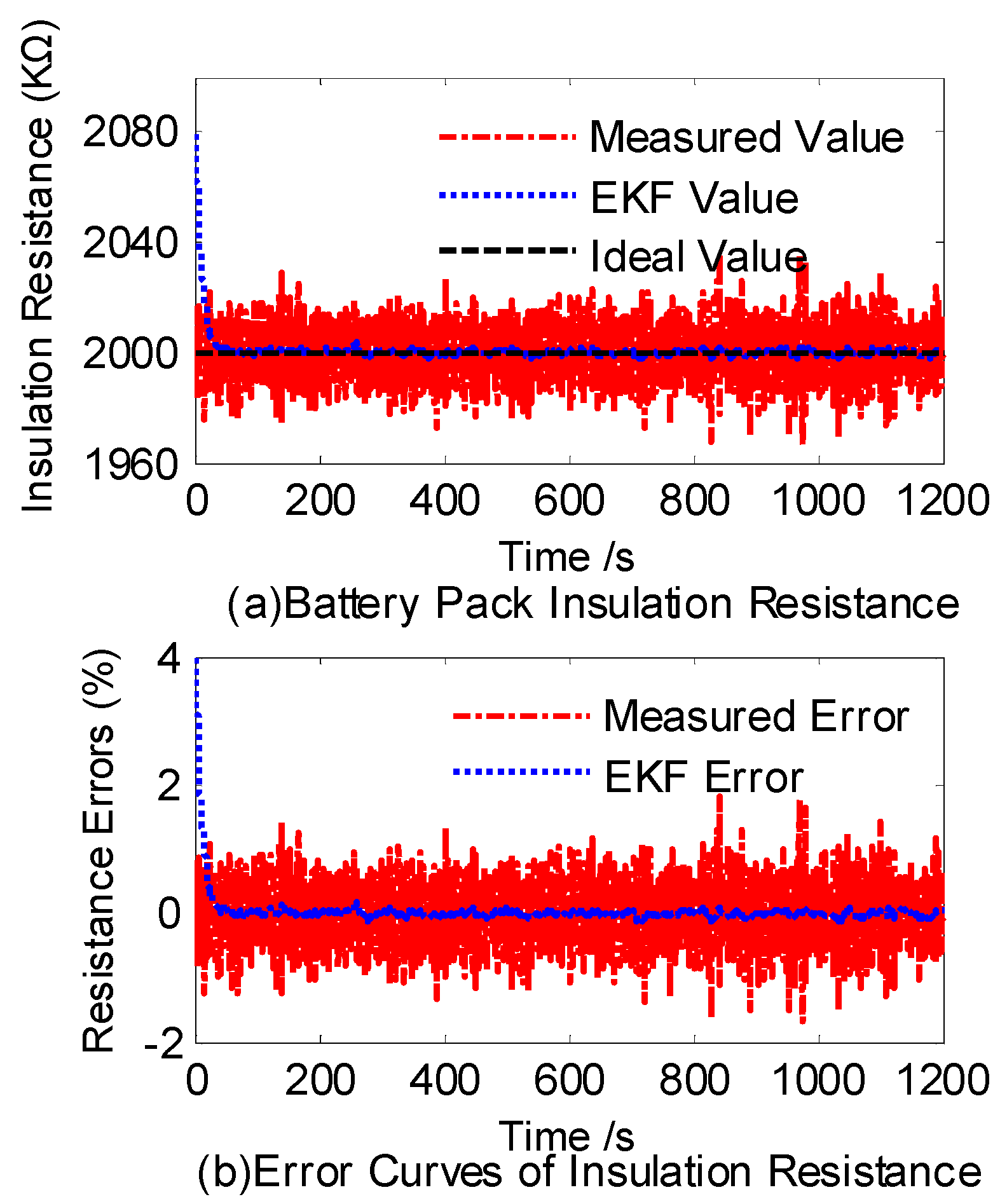

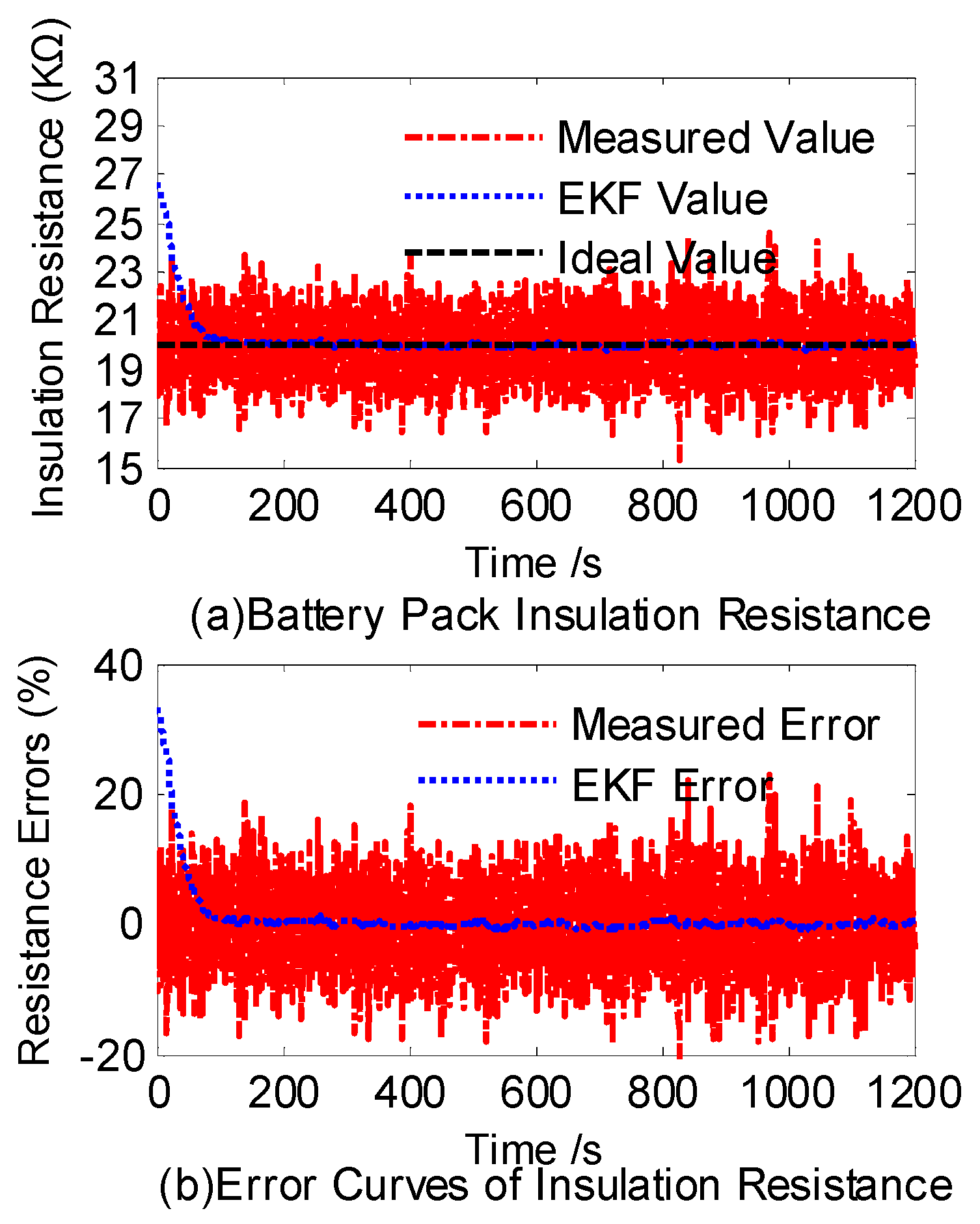

5. Analysis of Bench Test Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jiang, J.S.; Ji, H. Study of Insulation Monitoring Device for DC System Based on Multi-switch Combination. In Proceedings of the 2009 Second International Symposium on Computational Intelligence and Design, Changsha, China, 12–14 December 2009. [Google Scholar]

- Li, C.S.; Luo, S.H.; Cole, C.; Spiryagin, M. An overview: Modern techniques of railway vehicle on-board health monitoring system. Veh. Syst. Dyn. 2017, 55, 1045–1070. [Google Scholar] [CrossRef]

- Wu, Z.-J.; Wang, L.-F. A novel insulation resistance monitoring device for Hybrid Electric Vehicle. In Proceedings of the 2008 IEEE Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–4. [Google Scholar]

- Wei, X.; Bi, L.; Sun, Z. A method of insulation failure detection on electric vehicle based on FPGA. In Proceedings of the 2008 IEEE Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008. [Google Scholar]

- Piao, C.; Cong, T. Study on isolation monitoring of High-voltage battery system. Appl. Mech. Mater. 2010, 44–47, 571–575. [Google Scholar] [CrossRef]

- Zhang, G.; Jiang, J.-C.; Zhang, W.-G.; Zhang, C.-P.; Zhou, X.-Y. Research on online insulation detection in electric vehicle based on leakage current. J. Beijing Inst. Technol. 2011, 20 (Suppl. 2), 19–23. [Google Scholar]

- Jingxin, L.; Zhiqiang, W.; Yanqiang, F.; Yunyan, W.; Jiuchun, J. Research on insulation resistance on-line monitoring for electric vehicle. In Proceedings of the ICEMS 2005: 8th International Conference on Electrical Machines and Systems, Nanjing, China, 27–29 September 2005; pp. 814–817. [Google Scholar]

- Sepasi, S.; Ghorbani, R.; Liaw, B.Y. A novel on-board state-of-charge estimation method for aged Li-ion batteries based on model adaptive extended Kalman filter. J. Power Sources 2014, 245, 337–344. [Google Scholar] [CrossRef]

- Chen, Z.; Li, X.Y.; Shen, J.W.; Yan, W.S.; Xiao, R.X. A novel state of charge estimation algorithm for lithium-ion battery packs of electric vehicles. Energies 2016, 9, 15. [Google Scholar] [CrossRef]

- Xiong, R.; Gong, X.; Mi, C.C.; Sun, F. A robust state-of-charge estimator for multiple types of lithium-ion batteries using adaptive extended Kalman filter. J. Power Sources 2013, 243, 805–816. [Google Scholar] [CrossRef]

- Barillas, J.K.; Li, J.H.; Gunther, C.; Danzer, M.A. A comparative study and validation of state estimation algorithms for Li-ion batteries in battery management systems. Appl. Energy 2015, 155, 455–462. [Google Scholar] [CrossRef]

- Bressel, M.; Hilairet, M.; Hissel, D.; Bouamama, B.O. Extended Kalman filter for prognostic of proton exchange membrane fuel cell. Appl. Energy 2016, 164, 220–227. [Google Scholar] [CrossRef]

- Laroche, E.; Sedda, E.; Durieu, C. Methodological insights for online estimation of induction motor parameters. IEEE Trans. Control Syst. Technol. 2008, 16, 1021–1028. [Google Scholar] [CrossRef]

- Mohamed, M.R.; Ahmad, H.; Abu Seman, M.N.; Razali, S.; Najib, M.S. Electrical circuit model of a vanadium redox flow battery using extended Kalman filter. J. Power Sources 2013, 239, 284–293. [Google Scholar] [CrossRef]

- Hoffmann, N.; Fuchs, F.W. Minimal invasive equivalent grid impedance estimation in inductive-resistive power networks using extended Kalman filter. IEEE Trans. Power Electron. 2014, 29, 631–641. [Google Scholar] [CrossRef]

- Barre, A.; Deguilhem, B.; Grolleau, S.; Gerard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Maher, K.; Yazami, R. A study of lithium ion batteries cycle aging by thermodynamics techniques. J. Power Sources 2014, 247, 527–533. [Google Scholar] [CrossRef]

- Nejad, S.; Gladwin, D.T.; Stone, D.A. A systematic review of lumped-parameter equivalent circuit models for real-time estimation of lithium-ion battery states. J. Power Sources 2016, 316, 183–196. [Google Scholar] [CrossRef]

- Nikolian, A.; Firouz, Y.; Gopalakrishnan, R.; Timmermans, J.-M.; Omar, N.; van den Bossche, P.; van Mierlo, J. Lithium ion batteries—Development of advanced electrical equivalent circuit models for nickel manganese cobalt lithium-ion. Energies 2016, 9, 360. [Google Scholar] [CrossRef]

- Huria, T.; Ceraolo, M.; Gazzarri, J.; Jackey, R. High fidelity electrical model with thermal dependence for characterization and simulation of high power lithium battery cells. In Proceedings of the 2012 IEEE International Electric Vehicle Conference, Greenville, SC, USA, 4–8 March 2012. [Google Scholar]

- Guo, X.; Kang, L.; Yao, Y.; Huang, Z.; Li, W. Joint estimation of the electric vehicle power battery state of charge based on the least squares method and the Kalman filter algorithm. Energies 2016, 9, 100. [Google Scholar] [CrossRef]

- Wang, Y.J.; Zhang, C.B.; Chen, Z.H. An adaptive remaining energy prediction approach for lithium-ion batteries in electric vehicles. J. Power Sources 2016, 305, 80–88. [Google Scholar] [CrossRef]

- Farmann, A.; Waag, W.; Sauer, D.U. Adaptive approach for on-board impedance parameters and voltage estimation of lithium-ion batteries in electric vehicles. J. Power Sources 2015, 299, 176–188. [Google Scholar] [CrossRef]

- Seaman, A.; Dao, T.-S.; McPhee, J. A survey of mathematics-based equivalent-circuit and electrochemical battery models for hybrid and electric vehicle simulation. J. Power Sources 2014, 256, 410–423. [Google Scholar] [CrossRef]

- Gong, X.; Xiong, R.; Mi, C.C. Study of the characteristics of battery packs in electric vehicles with parallel-connected lithium-ion battery cells. IEEE Trans. Ind. Appl. 2015, 51, 1872–1879. [Google Scholar] [CrossRef]

- Sepasi, S.; Roose, L.R.; Matsuura, M.M. Extended Kalman filter with a fuzzy method for accurate battery pack state of charge estimation. Energies 2015, 8, 5217–5233. [Google Scholar] [CrossRef]

- Wang, L.M.; Cheng, Y.; Zhao, X.L. A LiFePO4 battery pack capacity estimation approach considering in-parallel cell safety in electric vehicles. Appl. Energy 2015, 142, 293–302. [Google Scholar] [CrossRef]

| Simulation No. | System Impedance RF (KΩ) | Measure Noise Variance | Maximum Absolute Error (Ω) | Root Mean Square Error (Ω) | ||

|---|---|---|---|---|---|---|

| without EKF | with EKF | without EKF | with EKF | |||

| 1 | 2000 | 800 | 4780.3 | 1426.4 | 1974.5 | 589.7 |

| 2 | 2000 | 80 | 723.7 | 205.6 | 277.3 | 77.9 |

| 3 | 20 | 800 | 4780.3 | 427.8 | 1879.1 | 206.4 |

| 4 | 20 | 80 | 723.7 | 143.9 | 256.2 | 38.5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, C.; Shao, Y.; Song, S.; Peng, S.; Zhou, F.; Chang, C.; Wang, D. Insulation Resistance Monitoring Algorithm for Battery Pack in Electric Vehicle Based on Extended Kalman Filtering. Energies 2017, 10, 714. https://doi.org/10.3390/en10050714

Song C, Shao Y, Song S, Peng S, Zhou F, Chang C, Wang D. Insulation Resistance Monitoring Algorithm for Battery Pack in Electric Vehicle Based on Extended Kalman Filtering. Energies. 2017; 10(5):714. https://doi.org/10.3390/en10050714

Chicago/Turabian StyleSong, Chuanxue, Yulong Shao, Shixin Song, Silun Peng, Fang Zhou, Cheng Chang, and Da Wang. 2017. "Insulation Resistance Monitoring Algorithm for Battery Pack in Electric Vehicle Based on Extended Kalman Filtering" Energies 10, no. 5: 714. https://doi.org/10.3390/en10050714

APA StyleSong, C., Shao, Y., Song, S., Peng, S., Zhou, F., Chang, C., & Wang, D. (2017). Insulation Resistance Monitoring Algorithm for Battery Pack in Electric Vehicle Based on Extended Kalman Filtering. Energies, 10(5), 714. https://doi.org/10.3390/en10050714