1. Introduction and Related Work

Battery energy storage systems (BESS) are considered for a variety of applications in modern power grids [

1]. As these systems decline drastically in cost, commercial and customer interest for this type of storage is growing. As a result, the combination of residential photovoltaic (PV) systems with battery storage (“PV-battery energy storage systems”, PV-BESS) and grid connection (grid-connected PV-BESS) have attained significant growth rates [

2,

3,

4].

Such systems enable customers to avoid the retail electricity tariff for all energy fostered by surplus PV generation via buffering in the BESS, instead of selling surplus power at the feed-in tariff. This is a potentially profitable scenario in countries where the electricity retail tariff exceeds PV feed-in tariffs, e.g., Australia, Canada, regions in the USA, and multiple countries in Europe. Academia has analyzed the economic value of PV-BESS for various individual systems [

5,

6,

7], and small but positive business cases seem to be in reach for specific usage scenarios. In addition, several online tools are available free of charge and are capable of analyzing the benefit for specific BESS with respect to load and PV size variation [

8,

9,

10,

11]. These multiple approaches provide a sensitivity analysis for given BESS systems but are unable to guide residential customers to find the economically best-suited storage and inverter combination for their specific needs.

Despite the fact that PV-BESS is still a niche market at present, various automotive companies have started to enter the market and have announced products with drastically lower price tags, e.g., Tesla, Mercedes-Benz, and Nissan [

12,

13,

14], making PV-BESS potentially economic in multiple regions around the world [

4].

Interestingly, currently available and announced PV-BESS rely on different battery technologies and show a strong variation of storage size [

15]. At a first glance, there appears to be a market trend towards lithium-ion based systems with storage capacity above 5 kWh coupled with inverter sizes of nominal power (

PN) often exceeding

PN = 3 kW [

3]. Nevertheless, lead-acid (PbA) systems still hold an appreciable market share of over 10% for new system installations, and there is a strong competition within the category of lithium-ion batteries within which different cell chemistries differ significantly in performance, cost, and aging [

3].

Despite the market availability of these various systems, there is still an obvious lack of accurate quantitative assessment tools to determine return on investment (ROI)-optimal storage solutions for individual households with particular PV generation and load demand. The methods and evaluation tools presented in this paper will help to determine the best-suited storage technology and system dimensioning for a variety of BESS application settings.

While most existing studies assess the economic value of residential battery storage using sensitivity analysis, there is lack of system size optimization studies considering technology specific parameters and aging information [

16]. Nevertheless, numerous significant contributions in the literature describe the usage of optimization routines for storage dispatch and size optimization in a distinct but related context. Their overview is presented in

Table 1.

Complex optimization approaches can be applied to storage dispatch optimization in various use cases. Although this helps to reveal possible operation modes of a system, such approaches often require extensive computational resources and may fail to find a globally optimal solution.

Geth et al. [

22] show an optimization method for the best positioning and sizing of energy storage in distribution grids. Using a multi-objective optimization method, the authors find an optimized dispatch operation strategy for multiple households with respect to BESS profit generation via energy market trading. They also provide a detailed discussion of concerns of distribution system operators related to security of the energy service, e.g., using voltage control.

In a subsequent work, Tant et al. [

23] demonstrate how complex optimization methods can be applied to find the best-suited battery storage system for PV integration in a given distribution grid. The authors analyze in detail the storage dispatch optimization using PbA and lithium-ion batteries. However, this work focuses on multi-objective optimization for peak shaving and voltage regulation, rather than on aspects relevant to a single household cost optimization.

Recent work by Merei et al. [

21] concentrates on commercial applications of BESS. The authors use sensitivity analysis to study the maximization of energy self-consumption via storage integration. The techno-economic analysis reveals that, for most commercial applications, BESS is not favored economically when battery degradation is taken into account. Other previous work by Magnor and Sauer [

17] and Merei et al. [

24] analyzed the optimal sizing of storage in the context of island grids and home storage systems. A genetic algorithm-based method allows the modelling of a non-linear set of equations including battery-aging models. However, the solver results may not find a globally optimal solution to the described problem, and the studies do not provide design rules for future storage systems.

In contrast, others have used sensitivity studies to reveal the optimal size of storage system components. For example, Weniger et al. [

19] provide a detailed analysis of power conversion efficiency of state-of-art battery home storage inverters. However, this work does not consider the economic impact of component sizing. Muenzel et al. [

18] investigate the economics of residential storage systems with a dynamic programming derived operation strategy and screen payback periods achievable for several storage system sizes in Australia. Using generalized parameters for the inverter, cost, and degradation of an unspecified litium-ion battery type, they anticipate a positive return on investment in the near future. In general, such sensitivity analyses commonly fail if various parameters are to be screened and optimized at the same time.

This issue can be effectively resolved using linear optimization approaches, which have been successfully applied to energy storage optimization. For example, Lauingera et al. provide a framework for electrical and thermal storage integration in households [

20]. Based on linear programming, the energy dispatch of a residential building is optimized. However, this work does not consider the sizing optimization of storage and periphery, and battery storage aging is not part of the model.

In contrast to the aforementioned publications, this work conducts a comprehensive power flow analysis, implements technology-specific battery degradation, and presents a highly reproducible and easily adaptable linear optimization approach to assess both the cost and the maximum profit attainable for residential BESS. Parameterized with conditions matching the German regulatory framework as well as detailed cost and aging information for three commonly deployed battery technologies (a PbA and two lithium-ion systems), this approach allows the best storage type and power electronics size to be selected for households with rooftop-mounted PV generators. The presented results also provide design rules applicable to residential PV-BESS around the world.

The remainder of this paper is organized as follows:

Section 2 introduces the system layout and parameters necessary as input for the subsequent optimization procedure. The linear programming methodology, including equations and constraints for optimization, is described in

Section 3. The subsequent

Section 4 describes obtained results and discusses the findings. The final

Section 5 summarizes major conclusions and outlines possible directions for future research.

3. Linear Optimization of Photovoltaic-Battery Energy Storage Systems

The structure of the optimization problem addressed in this study can be represented by a mathematical model. The objective function and the constraints have linear relationships, meaning that the effect of changing a decision variable is proportional to its magnitude. This makes linear programming (LP) well suited to solve the optimization problem considered here, due to the linearity of the decision variable on electricity price, feed-in tariff, and other parameters. While some aspects of battery system operation are not linear, they can be linearized to fit the requirements of LP. e.g., models of BESS aging processes can be reductively applied to obtain a linearized degradation function. In addition, linear optimization provides unambiguous, repeatable results with modes and controllable computational effort, compared to other optimization methods typically based on heuristics or meta-heuristics.

The economically optimal battery storage component sizing for a household equipped with PV and an energy storage system is obtained using LP. The load demand and PV-generation profiles considered in this study cover one full year, to capture all seasons with their characteristic, distinct patterns of PV-generation, storage, and grid energy transfers. As the intent is to minimize electricity cost and maximize the revenue generation on the profit side, two types of profits are considered: the profit attainable by feeding energy into the grid, and the avoided cost stemming from the reduced need to purchase energy when a storage system is installed. On the annual cost side, a fraction of the total cost of the energy storage system is considered. This fraction is determined based on a battery storage technology-specific aging analysis as further described below. The presented cost flow analysis takes into account the discounted storage cost caused by degradation.

Data used for simulations was averaged with a resolution of

, a value that provides a reasonable compromise between the accuracy of the obtained results and computational speed [

35]. As such, the one-year simulation time frame covers a total of 35040 time intervals, indexed with variable

.

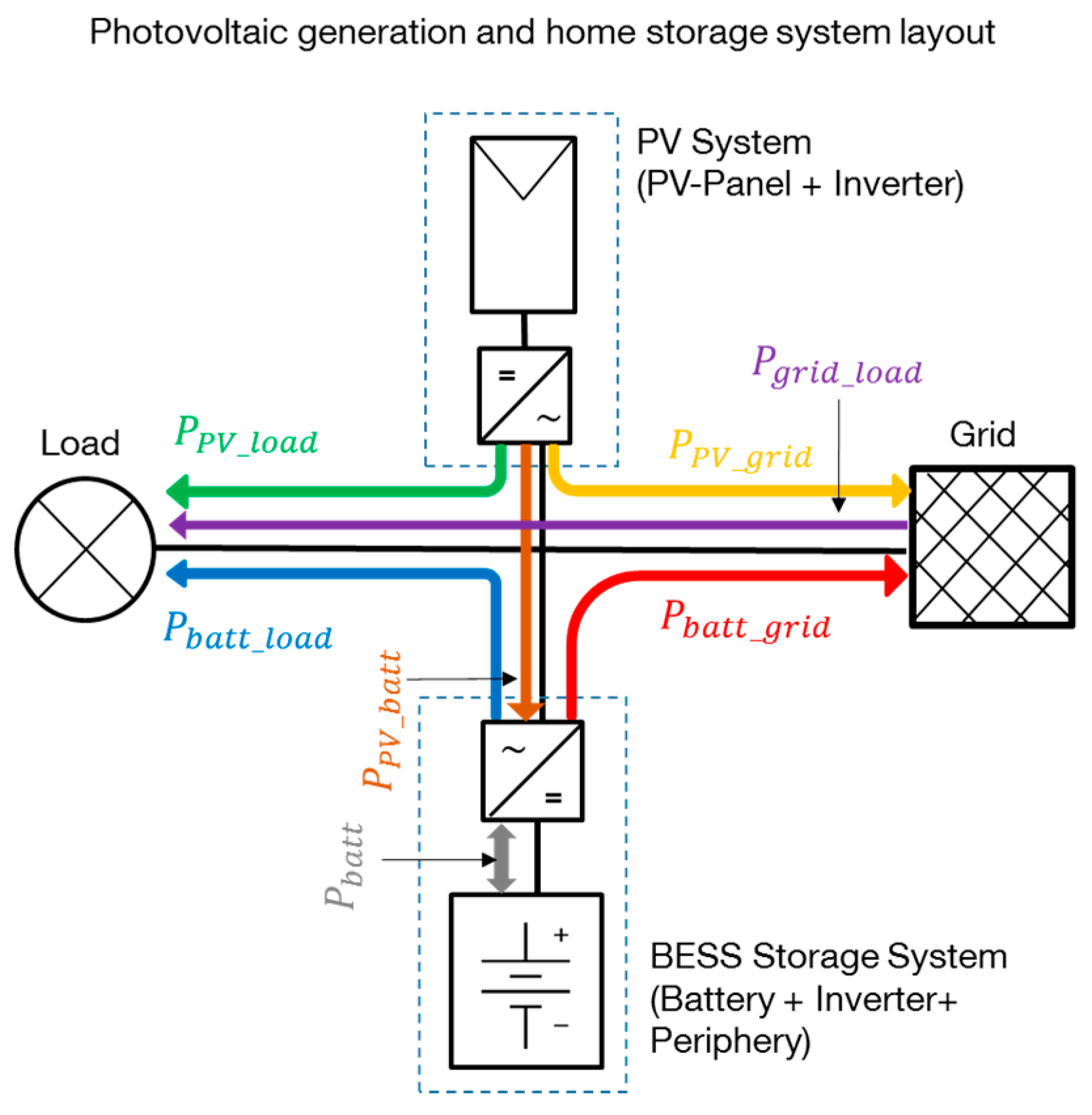

All variables and parameters considered in this study are described in

Table 5. The locally generated PV power (

) is first used to satisfy the local demand. When the local power production is greater than the demand, the surplus power is preferably transferred to the battery (

and stored for later use. If there is still additional energy available, the surplus power is injected into the grid (

) or curtailed via feed-in limitation (

). The following equation considers all power flows from the PV generator:

To avoid back-feeding of power injected into the grid from PV system owners, a feed-in limitation is enforced. Any power above the limitation threshold value must be discarded as a curtailment loss, i.e.,

To meet the electrical demand (

) the system first attempts to use power from local generation (

). If this is not sufficient, power is drained from the battery (

). As the last resource, the system draws power from the grid (

). Consequently, demand is comprised of the following three components:

The bidirectional power flow from the storage inverter to the battery is stored in an auxiliary variable (

and correlated with the inverter efficiency

:

where

is the average one-way efficiency of the inverter. The reciprocal efficiencies are the battery charge power

and the discharge power

, both limited by the nominal power flow from the inverter to the battery:

where

corresponds to the inverter nominal size. The battery energy content at time step

i (

) satisfies the recurrence relation:

where

represents the self-discharge factor of the battery and

is a conversion factor of the number of time steps per day. The energy content of the storage system is further confined by an upper boundary that decreases upon usage and aging according to the SOH:

The SOH is defined as the irreversible capacity fade over time, related to the nominal battery capacity, and

is a fraction of the total energy content of the battery installed:

For battery usage in stationary and automotive applications, it is useful to define an end of life (EOL) criterion, which is often linked to the SOH with a certain percentage value

[

36]. This percentage value also defines the time of battery replacement:

In many cases,

or

is used for automotive applications. However, lower values are often stated for less demanding residential storage applications [

6,

37]. In this study,

is used as the replacement parameter, matching e.g., the warranty conditions of the Tesla

® Powerwall product. Using the definition of

, the SOH condition reads:

The time evolution of SOH also satisfies the recurrence relation:

Using Equations (1) and (2), the calendric and cyclic aging can be estimated as:

As such, the additional cyclic aging degradation of time step

is estimated by the energy throughput in that time step (

) divided by the energy content of the system

. Additionally, it is normalized with the factor 0.5 and the technology specific cycle life indicator

. Similarly, the SOC can be expressed as:

The optimal solution must satisfy all constraints described above. It aims to reduce the overall cost by minimizing the expenses for energy purchase and the implicit cost caused by battery degradation. This cost model is divided into three components, i.e.,

subject to constraints in equations and inequalities (8)–(22).

The first component

comprises the cost of energy purchased from the grid, while the second component

is the revenue from PV energy generation exported to the grid. These two components are evaluated as follows:

where

and

are the retail electricity price and feed-in tariff, respectively. The third component estimates the home storage system degradation cost that can be represented as:

where

denotes the timespan covered with the simulation (here one year) and

the total battery aging. The full battery related cost is then calculated in consideration of the initial installation investment cost and the 22% subsidy scheme available in the German market.

For economic assessment, the cash flow for a household with the best-sized PV-BESS installed is compared against the cash flow for a household with the same PV-generation but no storage system installed. Therefore, the energy expenses, feed-in remuneration, and storage degradation cost for a PV-HESS household are related to the energy expenses and feed-in remuneration for a household with no storage:

For profitability analysis, we derive the yearly ROI that can be calculated considering the battery’s savings in each year of operation, the initial investment cost, and the storage system life:

4. Results and Discussion

Optimization was performed for the three battery technologies (PbA, LFP, and NMC) with the parameters listed in

Table 2. The load profiles were based on a reference smart meter-recorded dataset obtained from HTW Berlin and averaged to 15 min intervals [

38]. The PV-generation data was acquired for one full year (2014) using a rooftop-mounted solar generator in downtown Munich, Germany. The profile data is shown in

Appendix B. The one second resolution PV-generator output power data was normalized to the peak power of the system and preprocessed by averaging over the timeframes of 15 min. To obtain a variation of load demand and PV-generation profiles, both time series were linearly scaled to the desired values.

The linear optimization was implemented in MATLAB

® (MathWorks, Natick, MA, USA) code using a dual-simplex algorithm, which is based on a conventional simplex algorithm on the dual problem [

39]. Each one year system simulation (with co-optimization of storage and inverter size, and a 15-min time resolution for all power flows in the system) took approximately 300–800 s on a Dell

® (Dell Inc, Round Rock, TX, USA) XPS 15 system with Intel i7, depending on the number of iterations necessary for the linear optimization.

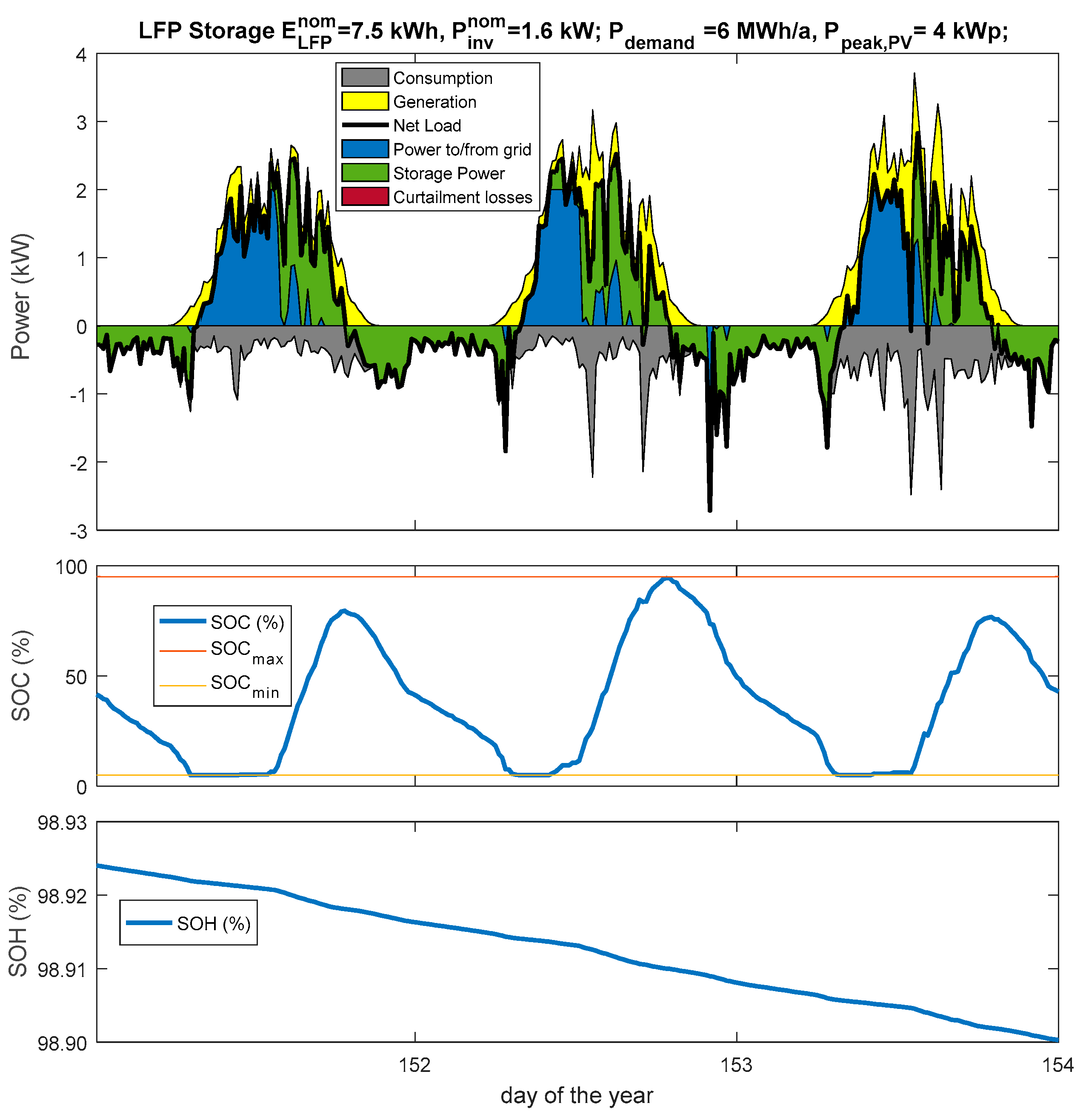

A detailed analysis is conducted for an exemplary PV-BESS system using LFP battery chemistry for a typical four-person household (annual load of 6 MWh) and a small size PV-generator (PV size of 4 kWp). For this case, the one-year optimization calculates the optimal storage size of

and inverter nominal power of

.

Figure 2 shows the power flows for an exemplary three-day period during summer (first week of June) within the system using these optimally sized components. The top panel shows the local household consumption (grey area below zero), the PV generated power (yellow area above zero), as well as power flow covered by the storage system (green area). The second and third panels show the evolution of SOC and SOH during the same time span, clearly showing the periodically changing charge level of the storage system and its gradual degradation.

It can be seen that the optimization process maximizes profit using the full capacity of the storage system: it charges the battery up to the maximum allowed SOC during daytime and fully drains it over nigh. For almost all tested scenarios, linear programming using complete data of load and generation successfully avoids curtailment losses. To achieve this optimal operation of BESS, the generated power is sometimes split. This can be observed during the second day shown in

Figure 2; power is partly fed to the grid (

) and partly used to charge the battery at a rate limited by the inverter size (

. At all times, the resulting storage charging strategy favors the lowest cost, i.e., it prefers battery usage over curtailment of energy or power exchange with the grid, whenever possible. Furthermore, self-discharge losses are kept at a minimum by charging the battery in the later period of the day (except when feed-in limitations would induce curtailment). A closer look at the spiky loads for the second day shown in the figure reveals that there are short time periods when power is drawn from the grid, despite the fact that the battery is still above its minimal SOC. This can be explained by the limited size of the inverter (here

) that does not allow full load saturation from the battery. In fact, a more powerful inverter would allow further reduction of the amount of energy drawn from the grid, but these small savings would not justify the additional cost of a larger inverter.

The third plot in

Figure 2 shows the evolution of battery degradation during the three-day timespan; a continuous degradation progress (calendric aging) superimposed to additional charge throughput dependent degradation (cyclic aging) is apparent, albeit at a very slow rate.

Over the course of one year, the investigated storage system executes 202 FEC and provides electricity cost savings of about 238 €, when compared to a household with no storage system installed. Note that the storage system does not execute a full cycle each day, a fact that is common to all storage systems and that can be mainly attributed to seasonal patterns.

Using Equation (7) for this optimally sized system, the cost of the subsidized storage system can be estimated as:

At the same time, due to the continuous calendric aging and daily cycling of the battery system, the SOH is reduced by 1.79% over the course of one year. When considering this degradation, the value of the storage system is reduced according to Equation (26):

As a result, the overall

ROI of the system is:

This calculation reveals that, for the example parameter setting chosen here (4 kWp PV and 6 MWh annual load demand), even the optimally sized LFP storage system does not provide positive ROI. A closer look at the literature on the economics of PV-BESS systems confirms that such negative ROI is well in line with other studies based on similar parameters [

5,

6]. It should be noted that in contrast to this work, most other studies discuss the scenario of future rising electricity retail prices resulting in positive ROI numbers. To achieve positive ROI for this specific storage system, the price for the 7.5 kWh battery would need to drop by about 12% at below 5100 € (instead of 5743 € assumed here).

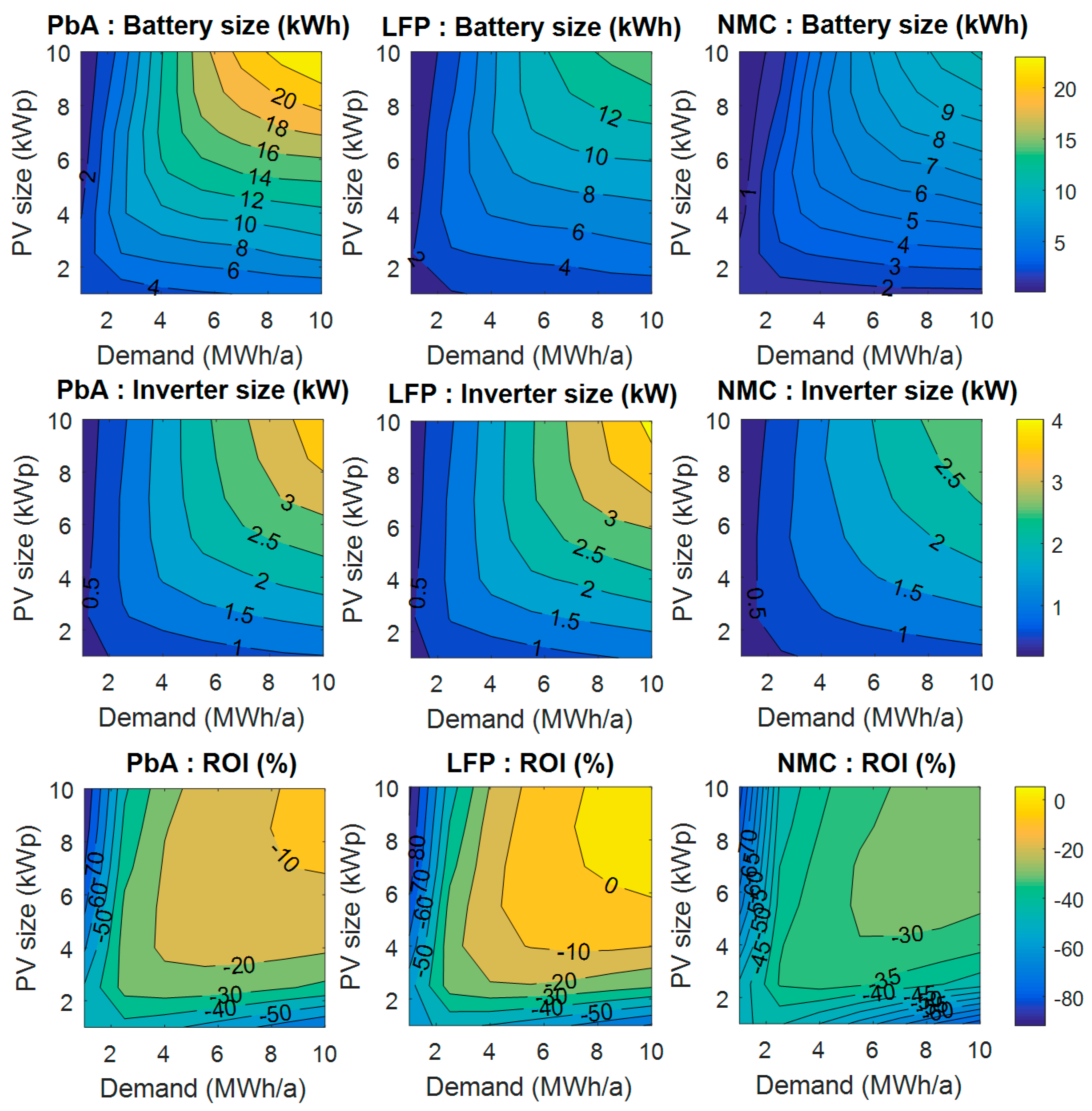

For a more systematic comparison of the three examined battery technologies, consider the group of contour plots shown in

Figure 3. Optimization runs were performed for a variety of load demand and PV-generation values using all three battery systems (PbA on the left, LFP in the middle, and NMC on the right). The upper row of plots shows the optimal size of the respective battery, whereas the three plots in the middle row reveal the optimal inverter size for each storage system. The bottom row depicts the resulting maximum attainable ROI for the three systems. They compare the profit attainable for a household with a PV-BESS against the cost and revenue for a household with a PV system only.

As an overall trend, homes with large load and PV size require BESS with increased storage and inverter size. For the PbA technology, significantly larger systems are economically favored in comparison to lithium-ion based systems. This can be attributed to a lower average price per kWh of PbA batteries compared to the alternatives. However, it should be noted that only 50% of the installed battery capacity is usable for PbA systems due to a smaller usable SOC range for this technology (see also

Table 2).

Interestingly, the optimal nominal power of the inverter systems remains low. With the cost assumed in this work, the ratio between storage capacity and nominal inverter size should be chosen at values as low as 0.25 kW/kWh for optimal ROI results. Currently, ratios of 1 kW/kWh are often used in commercial systems. Thus, this finding can be used as a guideline for cost reduction of future residential BESS.

A general trend of better ROI for large PV and high load demand can also be observed. This can be explained when analyzing the cost structure of storage with a fixed offset price for the battery housing and periphery. As such, larger installations reduce the overall cost per installed kWh of storage.

In direct comparison, and using the battery parameters chosen herein, the LFP storage systems appear to be economically superior to both NMC and PbA systems for most tested scenarios. In fact, there is a small area, for PV systems > 6 kWp and a yearly load greater than 6 MWh, where slightly positive ROI values can be achieved with today’s costs. This shows that there is a good chance of BESS becoming economically viable with PV systems in the near future. Potentially increased retail electricity tariffs will further improve the ROI of a residential storage system installed in 2016. More importantly, the prices of storage systems are rapidly declining. A recent report listed 20% annual reduction in 2015 [

3], and this cost decline is expected to continue in the following years, making future BESS likely more economically feasible. As a result, the ROI values shown here will likely turn positive within the next few years.

Refer to

Figure 4 and

Table 6 for a detailed comparison among the examined battery storage technologies. The three graphs depict the economically most favored settings in example cases with 1, 2.5, and 4 MWh annual load demand. The inset numbers in the right panel indicate the optimum sizing of battery and inverter for each simulation scenario (the first number indicates the optimum size of the storage system in kWh, the second number the nominal size of the inverter in kW). The overall shape of the ROI curves reveals the existence of scenario specific peaks. When a small PV generator is used, most generated power is used directly by local consumption. As the amounts of grid feed-in are small, storage cannot add much value to the system, and aging related costs clearly dominate the overall price of the storage systems. On the other hand, for very large PV installations, a significant portion of the local demand can be covered from PV-generation without storage. As self-supply levels are high, storage provides only small additional benefits. Interestingly, for different combinations of PV size and household power demand, PbA and NMC storage might be favored over a LFP storage solution. While for very small households the NMC system operates at the lowest cost, LFP surpasses PbA and NMC for households at 4 MWh annual load demand. For loads of 2.5 MWh LFP or PbA storage can be economically most viable, depending on the PV system size.

The fact that NMC performs best for small load demands and PV-generation can be attributed to the significantly lower fixed battery cost of NMC-based BESS systems. This advantage is most prominent for small storage system sizes (). Despite the more than 2.5-fold higher specific cost of the LFP system compared to PbA (752 €/kWh vs. 271 €/kWh), its better aging performance, higher conversion efficiency, and the increased usable SOC range makes it superior in most cases, especially if the battery has to withstand an increased number of FEC. Only for cases where the optimally sized PbA systems undergo less than or equal to 100 FEC per year, PbA may outcompete LFP, a scenario found at ratios of PV-generation to local demand of or higher.

To validate the optimization results presented in this study, we conducted 1-s resolved time series analyses of power flows using an in house developed storage assessment tool

SimSES [

5,

6]. All performed comparisons match well, confirming the validity of results and analysis presented in this paper. For example, for LFP cell chemistry, the results of one year simulations for all tested load and PV generation cases differ by less than 0.5% for SOH and less than 3% for ROI. Such small deviations can be attributed to coarser discretization of validation points within the tool (0.5 kW inverter size and 0.5 kWh storage size) and to slight differences in the storage operational strategy, which was not optimized when using the validation tool.

5. Conclusions and Future Work

This article describes a linear optimization approach to find the most cost-effective BESS dimensioning matching a variety of residential load demand and local PV generation profiles. To allow a direct comparison of one PbA and two lithium-ion batteries, the optimization problem formulated in this work maximizes the electricity cost savings while minimizing the storage specific degradation costs.

The optimization provides unambiguous, repeatable results with controllable computational effort and reveals the best suited sizing of battery storage and the inverter based on present retail price information. Within the tested scenarios, the best economical results have been attained using LFP storage systems at high load demand (>6 MWh annual demand) and local generation (>6 kWp PV generation). However, it must be clearly stated that, considering the storage degradation and price information as presented in this work, the profit attainable remains very small and peaks at ROI = 5% per anum. In fact, the ROI values remain negative for most considered scenarios. Nevertheless, a comparison of the three storage systems reveals that different storage technologies perform best for specific combinations of PV generation and local demand. Optimally sized NMC storage systems appear most economical for households with very small local demand (2 MWh/a), whereas PbA-based systems show some advantages for a mid-scale demand (2.5 MWh) and high PV generation (>7.5 kWp). At higher local electricity demand (4 MWh) coincident with higher PV generation (3 kWp), LFP batteries provide better results than PbA and NMC.

The obtained results can be used also to determine the optimal ratio of power electronics sizing (rated power of the inverter) to the installed battery capacity. For example, for a typical residential scenario of 4 kWp PV and annual local demand of 6 MWh, about 0.25 kW rated power per 1 kWh installed battery capacity shows optimal performance. This detailed analysis of optimal power-to-energy ratio could also be taken as a guideline for designing new, more cost-effective BESS products. In many actual cases, power electronic components appear to be oversized and do not properly match the needs of typical residential customers. This aspect will be of significant importance in other BESS applications, e.g., the provision of primary control reserve, industrial peak-shaving, and storage integration to micro grids. The application and extension of the method presented herein to these other applications will be tackled in the near future.

As a general remark, it is important to note that, considering the current typical cost of storage and retail energy tariff valid in Germany for 2016, most scenarios do not favor storage system installation over a sole PV system. Nevertheless, future electricity price evolution is likely to reverse this trend. The increased customer independence achieved using BESS may be profitable only in the long run under the assumption of rising retail electricity tariffs. In general, storage may provide additional value by stacking other applications, e.g., provision of uninterrupted power supply or energy market trading via cloud based pooling of battery storage systems.

Although this work uses parameters corresponding to German market conditions and regulations, the described methodology can be easily adapted to other countries that use feed-in and retail electricity tariff models, e.g., (in parts of) Australia, Canada, France, Greece, and many others. German regulations for the PV to grid feed-in limit and the complex scheme for storage systems subsidies results in various constraints and challenging model scenarios. The adaption to other regions is the subject of the present work.

This work is limited to the optimization of storage systems using historical data on specific load demand and PV generation profiles. A well parameterized energy management controller for a BESS will also need accurate forecasting of load demand and PV generation [

40] to achieve the best operation. Although such forecasting tasks are outside the scope of this work, they will be considered and used for energy management strategies in future.