Minimization of Construction Costs for an All Battery-Swapping Electric-Bus Transportation System: Comparison with an All Plug-In System

Abstract

:1. Introduction

1.1. Literature Review

1.2. Motivation and Contributions

2. System Modeling and the Calculation of Construction Costs for a Battery-Swapping Electric-Buses Transportation System

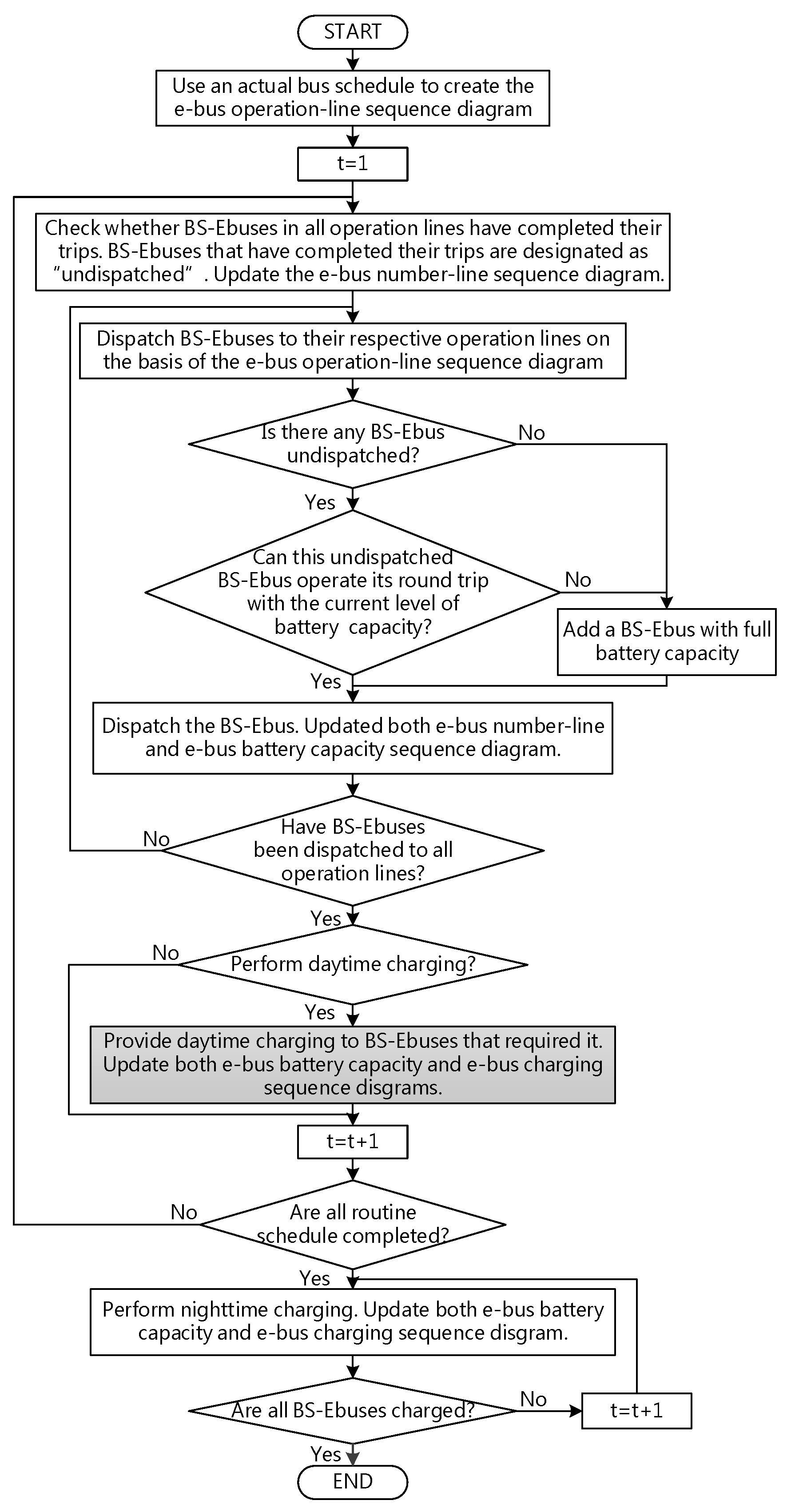

2.1. Modeling a Battery-Swapping Electric-Buses Transportation System

- (1)

- The operating models in both systems were formulated according to the existing bus schedule. However, because the two models required different durations for recharging and battery swapping, the operation–line and number–line sequence diagrams varied between the two systems.

- (2)

- Both systems required fast charging during daytime and slow charging during nighttime. Because they required different charging equipment and back-up batteries, the battery capacity and recharging sequence diagrams varied between the two systems.

- (3)

- The round-trip durations in both systems were 20 min (10 min for each one-way trip), and each bus required 10 min for changing destination signs, cleaning, and driver change before being redispatched. The PI-Ebuses were recharged immediately at the charging station in the depot upon their return, whereas the BS-Ebuses required 15 min for battery swap according to the e-bus manufacturers.

- (4)

- Identical fast- and slow-charging curves were employed in both systems. To prolong the battery life, the minimum battery capacity of the on-board batteries was maintained at ≥20% in both systems.

- (5)

- The optimization parameters of the PI-Ebus system were RBC and battery-charging time (BCT), whereas those of the BS-Ebus system were RBC and BCE.

- (6)

- The electricity costs of the two e-bus systems were calculated according to the latest price quoted by Taipower Company.

- (7)

- The research considers a complex problem spanning the life expectancy of batteries. Some assumptions have been made, including no disruptions, schedule-based operations, and installation of a unique charging point. The costs are based on expected values, and no reliability analysis was fulfilled.

- (8)

- Because of the complexity of road and traffic conditions, a microscopic simulation could not be executed in this study. The energy consumption of each e-bus line was calculated by the constant energy consumption rate per kilometer. The energy consumption rates per kilometer were 1.6 and 0.74 kWh for large and medium e-buses, respectively.

2.1.1. Battery-Swapping Process

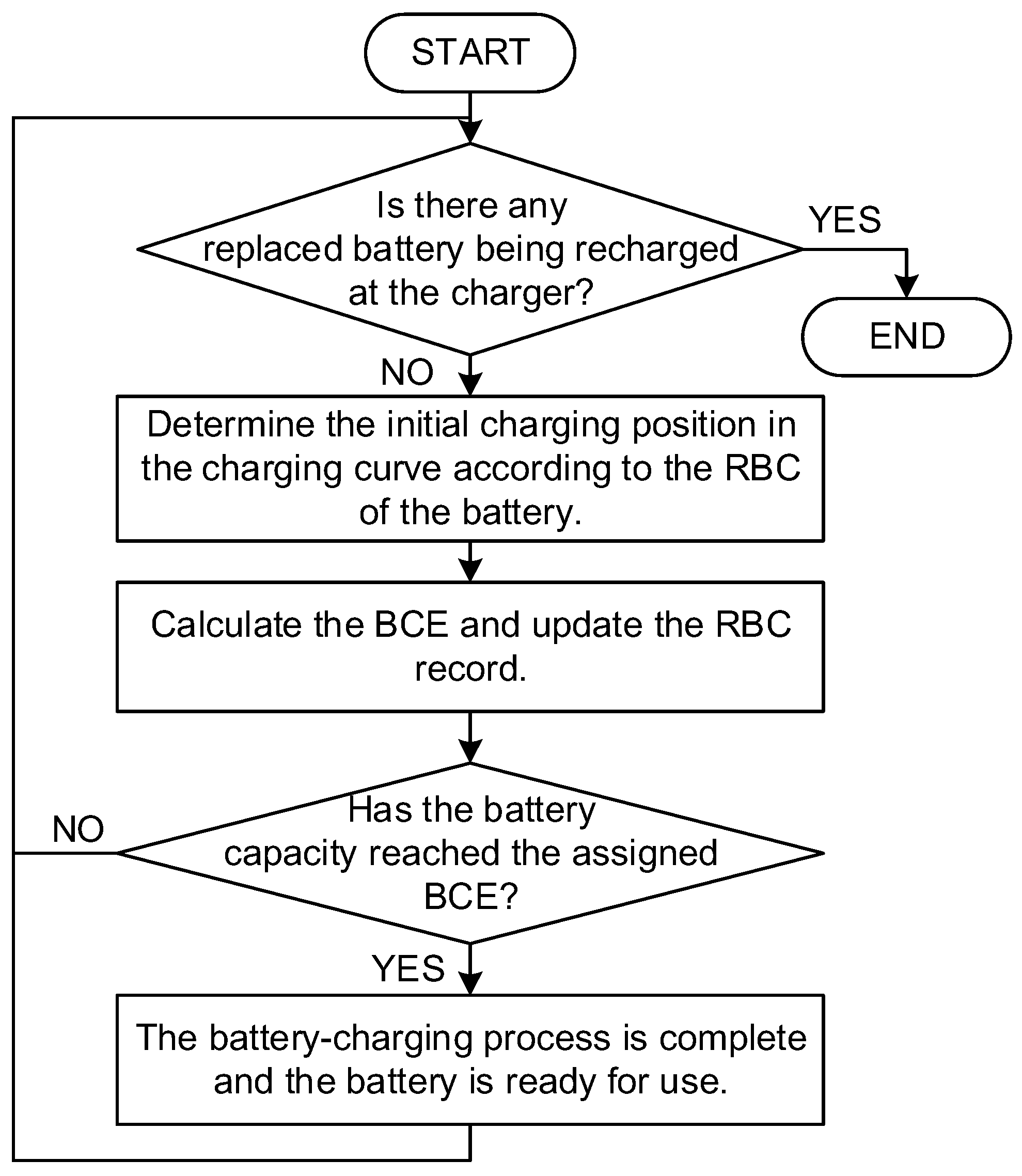

2.1.2. Battery-Charging Process

2.2. Calculation of the Construction Costs of a Battery-Swapping Electric-Buses System

- (1)

- E-bus cost: The BS-Ebus system in this study included two types of e-buses, namely medium- and large- e-buses. The bus cost was calculated by multiplying the number of buses with the price. The number of buses was determined according to the actual number of scheduled buses in the timetable.

- (2)

- On-board and additional battery costs: The minimum battery capacity of the on-board batteries was maintained at ≥20% in this study, and the installation interval of the on-board battery was set at 10% (i.e., possible battery capacities include 30%, 40%, 50%, ..., and 90%). The percentage of both on-board and back-up battery capacities of each bus was calculated to obtain the battery cost. The battery cost can be related as follows:where: : number of large and medium e-buses with different on-board battery capacities; : battery price of large and medium e-buses and : number of extra batteries based on full on-board battery capacity for large and medium e-buses.

- (3)

- Battery-charging and -swapping system cost: The batteries that were replaced during daytime were quickly recharged in the battery-swapping facilities. Each battery-swapping facility could accommodate both medium and large buses and simultaneously recharge four batteries. After all scheduled trips were completed, all on-board and back-up batteries were slow charged during nighttime, and all batteries were fully charged by the following morning before the bus schedule commenced. During the slow-charging process, each charger could simultaneously recharge two buses. The battery-charging and -swapping system costs can be related as follows:where: : number of large e-buses and battery charger unit price; : number of medium e-buses and battery charger unit price; : number of battery-swapping systems and unit price.

- (4)

- Electricity cost: Generally, the electricity rate consists of two parts, the flat and meter rates. To simplify the calculations, only the meter rate was included in this study. The meter rate includes summer and nonsummer prices, and the summer price is divided into peak and off-peak periods. The off-peak period starts at 22:30 and ends at 07:30, and the peak period starts at 07:30 and ends at 22:30. The peak price was applied to the daytime charging in this study, whereas the off-peak price was applied to the nighttime charging.

3. Optimization Methods

3.1. Optimization Variables

3.2. Particle Swarm Optimization

3.2.1. Particle Coding and Initialization

3.2.2. Particle Movement

3.2.3. Update the Best Known Particle

3.2.4. End Loop

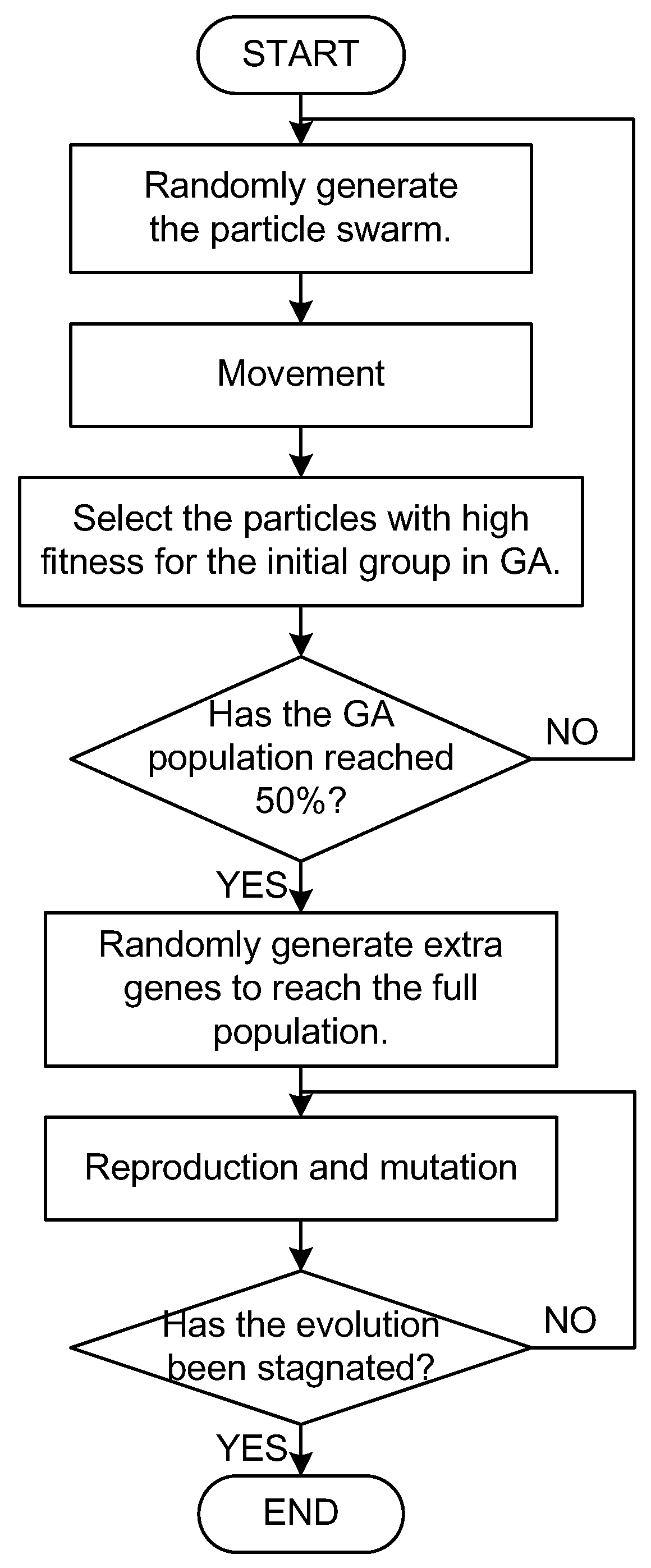

3.3. Particle Swarm Optimization–Genetic Algorithm

3.3.1. Early Stage of Optimization

3.3.2. Later Stage of Optimization

4. Results and Discussion

4.1. Penghu Bus Transportation System

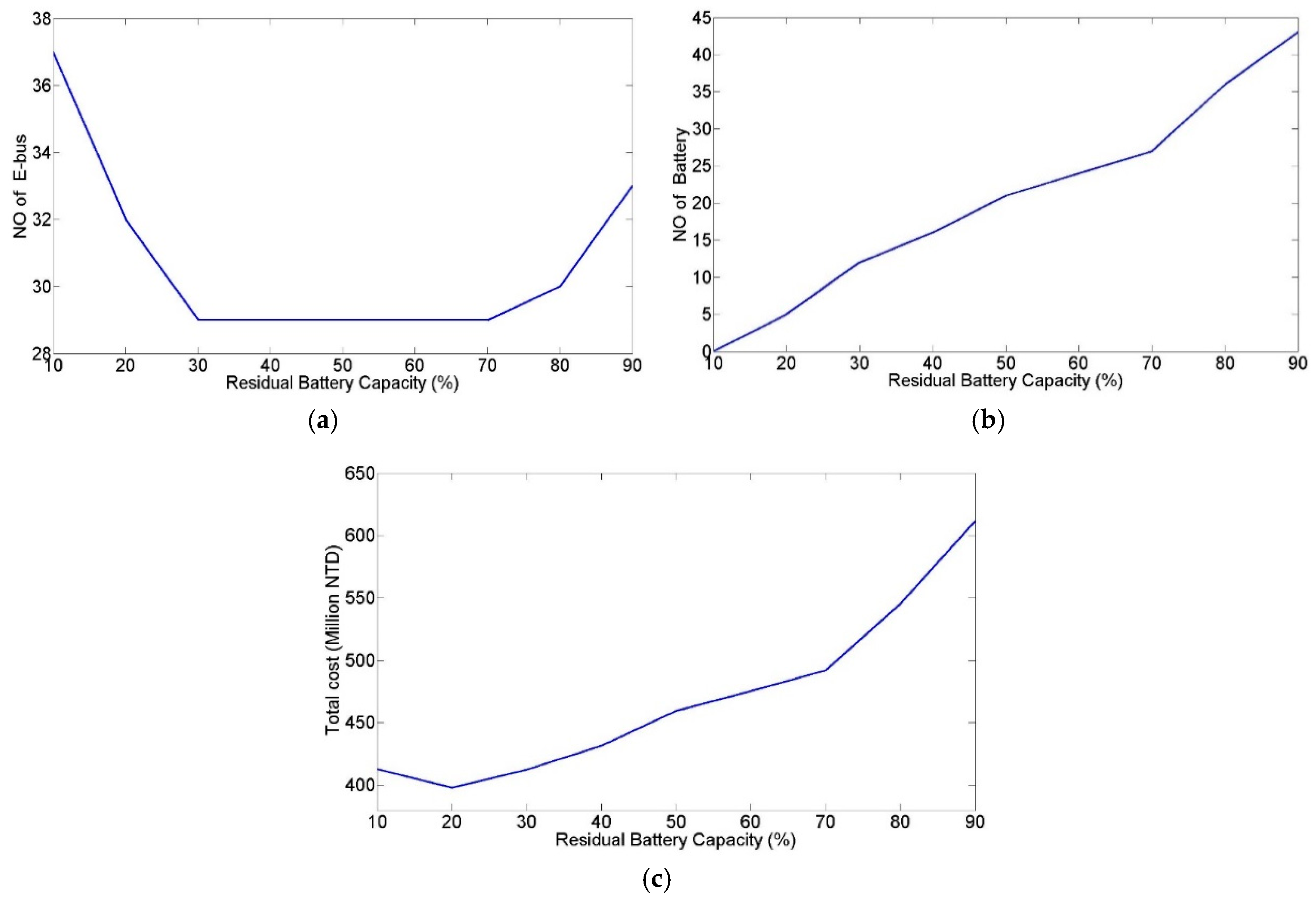

4.2. Minimization of the Construction Cost of the Battery-Swapping Electric-Busesc System

4.2.1. Case 1: No Daytime Charging

4.2.2. Case 2: Optimize the Residual Battery Capacity and Battery-Charging Energy by Using the Genetic Algorithm

4.2.3. Case 3: Optimize the Residual Battery Capacity and Battery-Charging Energy by Using the Particle Swarm Optimization–Genetic Algorithm

4.3. Comparission of Battery-Swapping Electric-Buses and Plug-In Electrice-Buses System Results

5. Conclusions

Acknowledgment

Author Contributions

Conflicts of Interest

References

- Acquaye, A.A.; Duffy, A.P. Input–output analysis of Irish construction sector greenhouse gas emissions. Build Environ. 2010, 45, 784–791. [Google Scholar] [CrossRef]

- Chang, Y.; Ries, R.J.; Wang, Y. The embodied energy and environmental emissions of construction projects in china: An economic input–output LCA model. Energy Policy 2010, 38, 6597–6603. [Google Scholar] [CrossRef]

- Peters, G.P. From production-based to consumption-based national emission inventories. Ecol. Econ. 2008, 65, 13–23. [Google Scholar] [CrossRef]

- Trappey, A.J.C.; Amy, J.C.; Trappey, C.; Hsiao, C.T.; Jerry, J.R.; Chen, L.S.; Kevin, W.P. An evaluation model for low carbon island policy: The case of Taiwan’s green transportation policy. Energy Policy 2012, 45, 510–515. [Google Scholar] [CrossRef]

- Al-Alawi, B.M.; Bradley, T.H. Review of hybrid, plug-in hybrid, and electric vehicle market modeling studies. Renew. Sustain. Energy Rev. 2013, 21, 190–203. [Google Scholar] [CrossRef]

- Sun, F.; Xiong, R. A novel dual-scale cell state-of-charge estimation approach for series-connected battery pack used in electric vehicles. J. Power Sources 2015, 274, 582–594. [Google Scholar] [CrossRef]

- Chen, Z.; Xiong, R.; Wang, C.; Cao, J. An on-line predictive energy management strategy for plug-in hybrid electric vehicles to counter the uncertain prediction of the driving cycle. Appl. Energy 2017, 185, 1663–1672. [Google Scholar] [CrossRef]

- Wang, S.; Shang, L.; Li, Z.; Deng, H.; Li, J. Online dynamic equalization adjustment of high-power lithium-ion battery packs based on the state of balance estimation. Appl. Energy 2016, 166, 44–58. [Google Scholar] [CrossRef]

- Jiang, H.R.; Zhao, T.S.; Liu, M.; Wu, M.C.; Yan, X.H. Two-dimensional SiS as a potential anode material for lithium-based batteries: A first-principles study. J. Power Sources 2016, 331, 391–399. [Google Scholar] [CrossRef]

- Wen, J.; Yu, Y.; Chen, C. A review on lithium-ion batteries safety issues: Existing problems and possible solutions. Mater. Express 2012, 2, 197–212. [Google Scholar] [CrossRef]

- Peng, P.; Jiang, F. Thermal safety of lithium-ion batteries with various cathode materials: A numerical study. Int. J. Heat Mass Transf. 2016, 103, 1008–1016. [Google Scholar] [CrossRef]

- Li, L.; You, S.; Yang, C.; Yan, B.; Song, J.; Chen, Z. Driving-behavior-aware stochastic model predictive control for plug-in hybrid electric buses. Appl. Energy 2016, 162, 868–879. [Google Scholar] [CrossRef]

- Yi, L.; He, H.; Peng, J. Hardware-in-loop simulation for the energy management system development of a plug-in hybrid electric bus. Energy Procedia 2016, 88, 950–956. [Google Scholar] [CrossRef]

- Zhang, S.; Xiong, R.; Cao, J. Battery durability and longevity based power management for plug-in hybrid electric vehicle with hybrid energy storage system. Appl. Energy 2016, 179, 316–328. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.; He, H. Battery SOC constraint comparison for predictive energy management of plug-in hybrid electric bus. Appl. Energy 2016, 194, 578–587. [Google Scholar] [CrossRef]

- Zhang, X.P.; Rao, R.; Xie, J.; Liang, Y.N. The current dilemma and future path of China’s electric vehicles. Sustainability 2014, 6, 1567–1593. [Google Scholar] [CrossRef]

- García-Villalobos, J.; Zamora, I.; Knezović, K.; Marinelli, M. Multi-objective optimization control of plug-in electric vehicles in low voltage distribution networks. Appl. Energy 2016, 180, 155–168. [Google Scholar] [CrossRef]

- Yan, J.; Xu, G.; Qian, H.; Xu, Y.; Song, Z. Model Predictive Control-Based Fast Charging for Vehicular Batteries. Energies 2011, 4, 1178–1196. [Google Scholar] [CrossRef]

- Rao, R.; Zhang, X.P.; Xie, J.; Ju, L. Optimizing electric vehicle users’ charging behavior in battery swapping mode. Appl. Energy 2015, 155, 547–559. [Google Scholar] [CrossRef]

- Bi, J.; Zhang, T.; Yu, H.; Kang, Y. State-of-health estimation of lithium-ion battery packs in electric vehicles based on genetic resampling particle filter. Appl. Energy 2016, 182, 558–568. [Google Scholar] [CrossRef]

- Blaifi, S.; Moulahoum, S.; Colak, I.; Merrouche, W. An enhanced dynamic model of battery using genetic algorithm suitable for photovoltaic applications. Appl. Energy 2016, 169, 888–898. [Google Scholar] [CrossRef]

- Gen, M.; Cheng, R. Genetic Algorithms and Engineering Design; John Wiley & Sons: New York, NY, USA, 1997. [Google Scholar]

- Montazeri-Gh, M.; Poursamad, A.; Ghalichi, B. Application of genetic algorithm for optimization of control strategy in parallel hybrid electric vehicles. J. Frankl. Inst. 2006, 343, 420–435. [Google Scholar] [CrossRef]

- Mohan, G.; Assadian, F.; Longo, S. An Optimization Framework for Comparative Analysis of Multiple Vehicle Powertrains. Energies 2013, 6, 5507–5537. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R.C. Empirical study of particle swarm optimization. In Proceedings of the 1999 Congress on Evolutionary Computation, Washington, DC, USA, 6–9 July 1999. [Google Scholar]

- Liu, D.; Wang, Y.; Shen, Y. Electric Vehicle Charging and Discharging Coordination on Distribution Network Using Multi-Objective Particle Swarm Optimization and Fuzzy Decision Making. Energies 2016, 9, 186. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R.C. Particle swarm optimization. Proc. IEEE. Int. Conf. Neural Netw. 1995, 4, 1942–1948. [Google Scholar]

- Clerc, M.; Kennedy, J. The particle swarm-explosion, stability, and convergence in a multidimensional complex space. IEEE Trans. Evol. Comput. 2002, 6, 58–73. [Google Scholar] [CrossRef]

- Chen, S.Y.; Hung, Y.H.; Wu, C.H.; Huang, S.T. Optimal energy management of a hybrid electric powertrain system using improved particle swarm optimization. Appl. Energy 2015, 160, 132–145. [Google Scholar] [CrossRef]

- Zhang, Q.; Ogren, R.M.; Kong, S.C. A comparative study of biodiesel engine performance optimization using enhanced hybrid PSO–GA and basic GA. Appl. Energy 2016, 165, 676–684. [Google Scholar] [CrossRef]

- Shi, X.H.; Lianga, Y.C.; Leeb, H.P.; Lub, C.; Wanga, L.M. An improved GA and a novel PSO-GA-based hybrid algorithm. Inf. Process Lett. 2005, 93, 255–261. [Google Scholar] [CrossRef]

- Ke, B.R.; Chung, C.Y.; Chen, Y.C. Minimizing the costs of constructing an all plug-in electric bus transportation system: A case study in Penghu. Appl. Energy 2016, 177, 649–660. [Google Scholar] [CrossRef]

- Valdivia-Gonzalez, A.; Zaldívar, D.; Fausto, F.; Camarena, O.; Cuevas, E.; Perez-Cisneros, M. A States of Matter Search-Based Approach for Solving the Problem of Intelligent Power Allocation in Plug-In Hybrid Electric Vehicles. Energies 2017, 10, 92. [Google Scholar] [CrossRef]

- Maigha; Crow, M.L. Economic Scheduling of Residential Plug-In (Hybrid) Electric Vehicle (PHEV) Charging. Energies 2014, 7, 1876–1898. [Google Scholar]

- Yang, Y.; Zhang, W.; Niu, L.; Jiang, J. Coordinated Charging Strategy for Electric Taxis in Temporal and Spatial Scale. Energies 2015, 8, 1256–1272. [Google Scholar] [CrossRef]

- Peng, L.L.; Fan, G.F.; Huang, M.L.; Hong, W.C. Hybridizing DEMD and Quantum PSO with SVR in Electric Load Forecasting. Energies 2016, 9, 221. [Google Scholar] [CrossRef]

| Price | Bus Type | |

|---|---|---|

| Large | Medium | |

| E-buses (NT$/unit) | 6,000,000 | 4,000,000 |

| On-board batteries (NT$/unit) | 2,600,000 | 1,200,000 |

| Chargers (NT$/unit) | 950,000 | 750,000 |

| Energy-filling facilities (NT$/unit) including battery-swapping equipment and battery chargers | 19,435,000 | |

| Electricity cost (NT$/kWh) | Summer: Peak 3.89 Off-peak 1.99 Nonsummer: Peak 3.79 Off-peak 1.88 | |

| System Construction | Cost Calculation | ||||

|---|---|---|---|---|---|

| E-Bus Type | Large | Medium | Item | 10-Year Cost | |

| On-board battery capacity when dispatched | Full | 5 | 0 | On-board battery cost | 117.8 |

| 90% | 1 | 0 | |||

| 80% | 13 | 0 | |||

| 70% | 5 | 0 | |||

| 60% | 2 | 1 | |||

| 50% | 0 | 1 | |||

| 40% | 1 | 0 | |||

| 30% | 2 | 1 | |||

| Number of e-buses | 29 | 3 | E-bus cost | 186 | |

| Number of extra battery modules | 5 | 0 | Extra battery cost | 26 | |

| Number of chargers | 15 | 2 | Charger cost | 15 | |

| Number of charging facilities | 1 | Facility cost | 19.4 | ||

| Nighttime BCE (kWh) | 5418.6 | 124.8 | Electricity cost | 35.7 | |

| - | Total cost | 399.9 | |||

| System Construction | Cost Calculation | ||||

|---|---|---|---|---|---|

| E-Bus Type | Large | Medium | Item | 10-Year Cost | |

| On-board battery capacity when dispatched | Full | 10 | 0 | On-board battery cost | 112.8 |

| 90% | 2 | 0 | |||

| 80% | 7 | 0 | |||

| 70% | 1 | 1 | |||

| 60% | 2 | 0 | |||

| 50% | 2 | 1 | |||

| 40% | 1 | 0 | |||

| 30% | 1 | 1 | |||

| Number of e-buses | 26 | 3 | E-bus cost | 168 | |

| Number of extra battery modules | 3 | 0 | Extra battery cost | 15.6 | |

| Number of chargers | 13 | 2 | Charger cost | 13.9 | |

| Number of charging facilities | 1 | Facility cost | 19.4 | ||

| Daily BCE (kWh) | Day | 855.8 | 0 | Electricity cost | 42.5 |

| Night | 4674.6 | 124.8 | |||

| - | Total cost | 372.2 | |||

| System Construction | Cost Calculation | |||||

|---|---|---|---|---|---|---|

| E-Bus Type | Large | Medium | Item | Decade Cost | ||

| On-board battery capacity when dispatched | Full | 7 | 0 | On-board battery cost | 108.2 | |

| 90% | 3 | 0 | ||||

| 80% | 10 | 0 | ||||

| 70% | 1 | 1 | ||||

| 60% | 1 | 0 | ||||

| 50% | 2 | 1 | ||||

| 40% | 2 | 0 | ||||

| 30% | 0 | 1 | ||||

| Number of e-buses | 26 | 3 | E-bus cost | 168 | ||

| Number of extra battery modules | 3 | 0 | Extra battery cost | 15.6 | ||

| Number of chargers | 13 | 2 | Charger cost | 13.9 | ||

| Number of charging facilities | 1 | Facility cost | 19.4 | |||

| Daily BCE (kWh) | Day | 576.4 | 0 | Electricity cost | 42.5 | |

| Night | 4875.6 | 124.8 | ||||

| - | Total cost | 367.5 | ||||

| Cost Items | PI-Ebus System | BS-Ebus System | ||||||

|---|---|---|---|---|---|---|---|---|

| Non Day-Charging [32] | Day-Charging | Non Day-Charging | Day-Charging | |||||

| PSO | GA [32] | PSO-GA | PSO | GA | PSO-GA | |||

| E-bus cost | 222 | 174 | 168 | 168 | 186 | 174 | 168 | 168 |

| On-board battery cost | 102.2 | 117.0 | 109.7 | 105.0 | 117.8 | 121.1 | 112.8 | 108.2 |

| Extra battery cost | --- | --- | --- | --- | 26 | 10.4 | 15.6 | 15.6 |

| Charger cost | 29.8 | 23.4 | 22.6 | 22.6 | 15.0 | 14.8 | 13.9 | 13.9 |

| Battery swapping system | --- | --- | --- | --- | 19.4 | 19.4 | 19.4 | 19.4 |

| Energy cost | 38.9 | 58.3 | 50.4 | 53.0 | 35.7 | 41.7 | 42.5 | 42.5 |

| Total cost | 392.9 | 372.7 | 350.7 | 348.7 | 399.9 | 381.5 | 372.2 | 367.5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, S.-C.; Ke, B.-R.; Chung, C.-Y. Minimization of Construction Costs for an All Battery-Swapping Electric-Bus Transportation System: Comparison with an All Plug-In System. Energies 2017, 10, 890. https://doi.org/10.3390/en10070890

Fang S-C, Ke B-R, Chung C-Y. Minimization of Construction Costs for an All Battery-Swapping Electric-Bus Transportation System: Comparison with an All Plug-In System. Energies. 2017; 10(7):890. https://doi.org/10.3390/en10070890

Chicago/Turabian StyleFang, Shyang-Chyuan, Bwo-Ren Ke, and Chen-Yuan Chung. 2017. "Minimization of Construction Costs for an All Battery-Swapping Electric-Bus Transportation System: Comparison with an All Plug-In System" Energies 10, no. 7: 890. https://doi.org/10.3390/en10070890

APA StyleFang, S.-C., Ke, B.-R., & Chung, C.-Y. (2017). Minimization of Construction Costs for an All Battery-Swapping Electric-Bus Transportation System: Comparison with an All Plug-In System. Energies, 10(7), 890. https://doi.org/10.3390/en10070890