1. Introduction

The crisis in Syria has deprived many of continuous and permanent access to electrical networks, so daily needs must be met through electrical energy storage, such as lead-acid and lithium-ion batteries. Given their importance, we have investigated means to maximize efficient monitoring, operation and management of battery resources.

To carry out this work, we chose lithium-ion technology. It is currently widely used in Syria to power portable electronics, such as laptop computers charged via solar bags. Moreover, compared with older battery technologies, lithium-ion batteries offer relatively high voltage, high specific energy, high specific power, no memory effect, and low self-discharge rates during storage.

An accurate model of battery dynamics should take into account multiple coefficients, such as open-circuit voltage, discharge rate, power, state of charge (SOC) and temperature.

However, it is difficult to determine or estimate battery parameters, because they are interdependent and vary over time and use. Many battery models are used to represent the battery behaviour. The most commonly used models can be divided into two categories: the electrochemical models and the electrical equivalent circuit models. The electrochemical models utilize a set of coupled non-linear differential equations to describe the pertinent transport, thermodynamic, and kinetic phenomena. The dynamical behaviour of a lithium-ion battery can be simulated correctly using the Warburg diffusion impedance with complex electrical equivalent circuits [

1,

2,

3]. However, estimating the parameters of this sophisticated model usually requires an electrochemical impedance spectrometry (EIS). EIS data are analysed by fitting to a complex electrical equivalent circuit model for different values of the SOC and the temperature.

A big capacitor with series resistance can be selected to calculate dynamic terminal voltage of the battery. Later, a model with two capacitors in parallel was developed consisting of a double layer capacitor, a bulk capacitor, a charge transfer resistance and a terminal resistance [

4]. Recently, the dual polarization model has been commonly used [

5,

6,

7,

8,

9].

There are a lot of SOC estimation methods. The commonly used methods can be generally classified into four categories, namely, the direct discharge method, the Ampere-Hour counting method, the voltage/impedance-based method, and model-based filter methods [

8,

10,

11,

12]. The extended Kalman filter (EKF) is widely used for estimating the SOC and other battery parameters related to the SOC [

13,

14,

15].

This paper proposes an experimental approach for identifying battery parameters. An EKF estimator was developed based on the Thevenin equivalent battery circuit. This recursive method can be used in real time to eliminate measurement and process noise. This hybrid approach, which is applied here to a continuous system with discrete measurements, is particularly suitable for battery systems [

16,

17,

18].

2. Dynamical Model of Battery

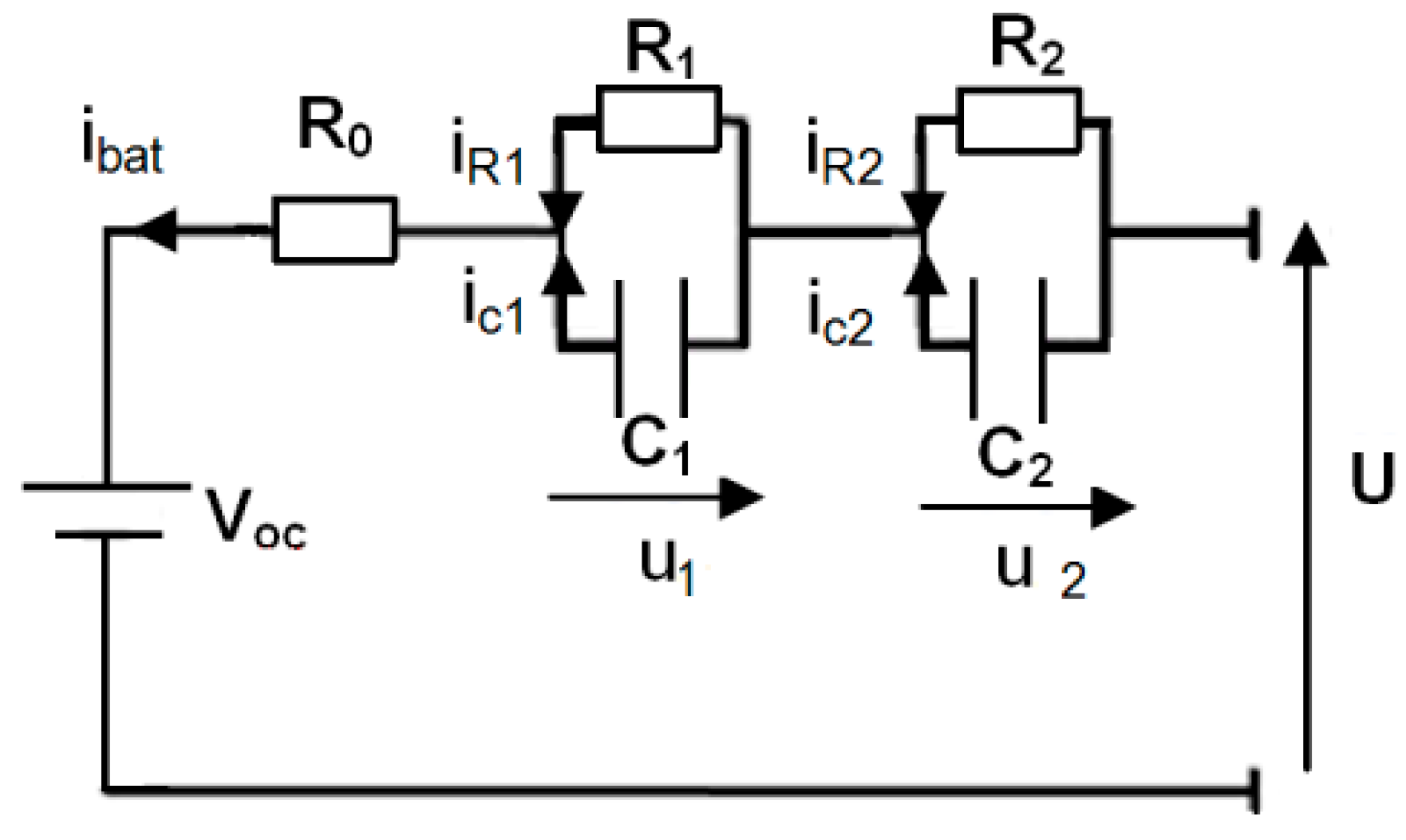

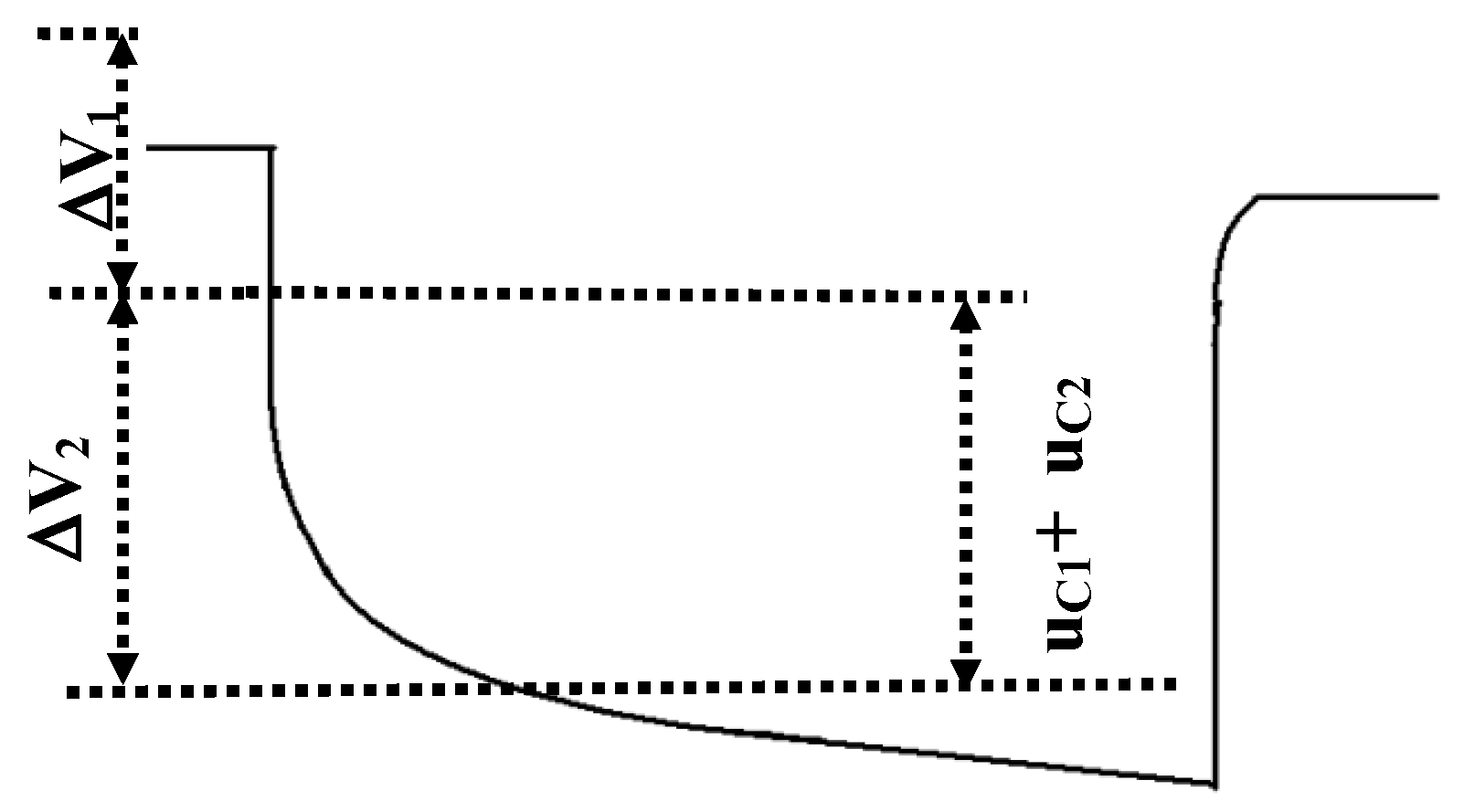

In order to describe the dynamic behaviour of a battery, we use the Thevenin equivalent circuit (dual polarization) shown in

Figure 1 [

19,

20,

21]. This battery equivalent circuit consists of two time constants

and

. The constant

characterizes the activation polarization while the constant

characterizes the concentration polarization.

The elements of the battery equivalent circuit depicted in

Figure 1 are as follows:

is the open-circuit voltage,

is the ohmic resistance of the battery's collectors and electrodes,

is the charge/discharge current and

represents the terminal voltage of the battery cell. As shown in

Figure 1, the current

flowing through resistance

can be expressed by the following equation:

Equation (1) can be rewritten as:

where

is the voltage drop due to activation polarization. Similarly, we can write the following equation in the second circuit

,

where

is the voltage drop due to mass transport (concentration polarization).

Therefore, the terminal voltage

of the cell is determined by the open-circuit voltage

and the different drops of voltage as given by Equation (4).

3. Studied Battery and Experimental Device

In order to measure the parameters of the battery, a single cell of Li-ion battery (2.15 Ah, 3.7 V) is used [

22].

Appendix A provides detailed parameters of the battery cell.

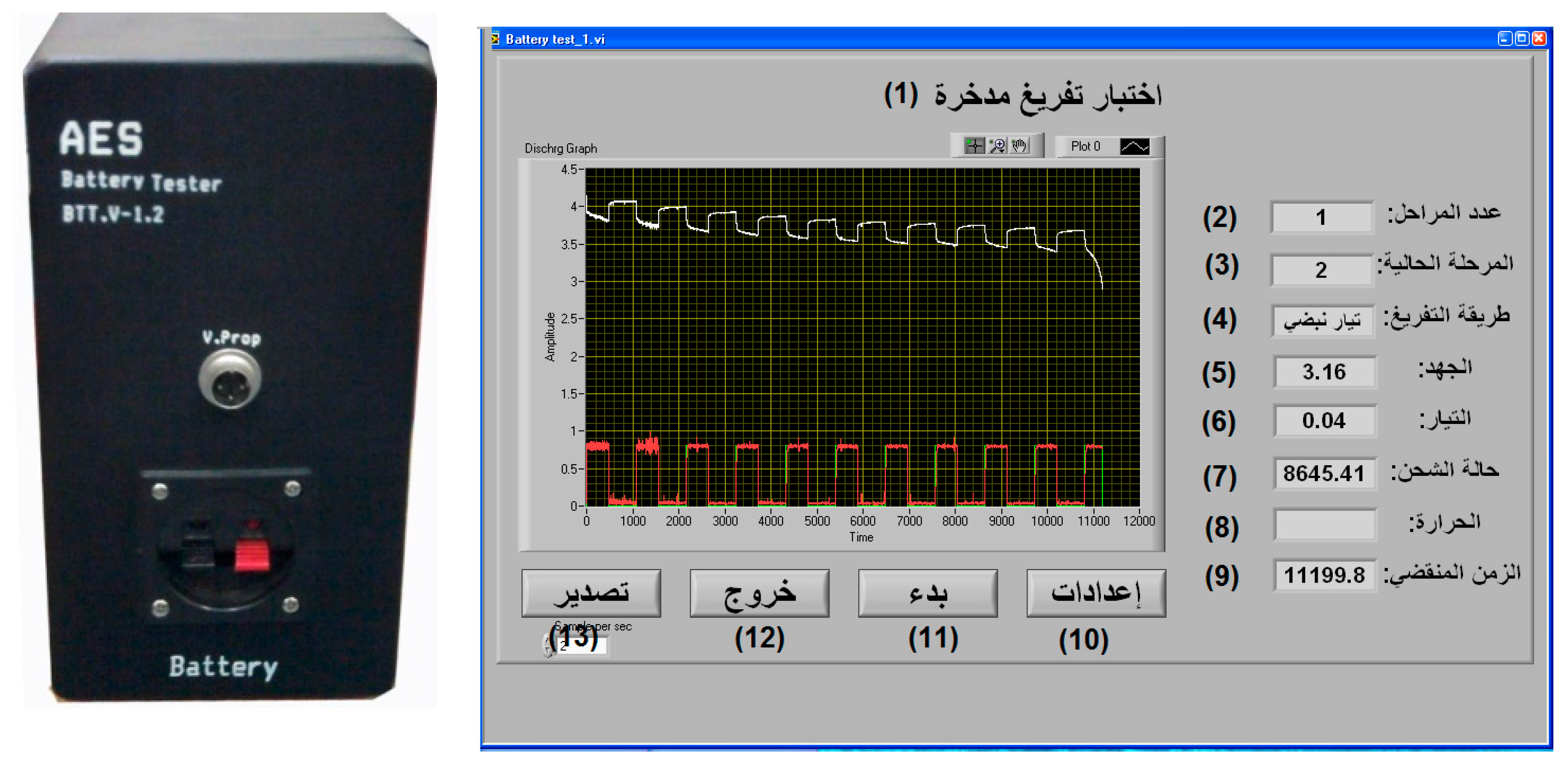

Figure 2 shows a photo of the charge/discharge experimental device which we programmed using LabView.

4. Determining Open-Circuit Voltage as a Function of SOC

Accuracy of the Thevenin circuit relies on diverse conditions, especially the

. To estimate the

during the charging/discharging of a battery, the Ampere-Hour counting (AHC) technique is used. It is the most common technique for calculating the

. The

variation during charge/discharge can be calculated as [

7,

23]:

where,

is the initial ampere-hour of battery,

is the current consumed by the parasitic reactions,

is the Coulombic efficiency, which is a function of the current and the temperature. Coulombic efficiency is the ratio of the Ampere-hours removed from a battery during discharge to the Ampere-hours required to restore the initial capacity [

24]. Before each discharge test, the battery is fully charged for more than 24 hours with the floating technique. This allows us to neglect the losses due to parasitic reactions [

25].

The first parameter in the model shown in

Figure 1 is the open-circuit voltage

. The

is usually measured at various

points as the steady-state open circuit terminal voltage. For each

point, this measurement can take many days, but in our research, we used a quick measurement technique. To measure

at various

points, the battery was discharged by injecting successive current pulses. The battery cell was discharged with a pulse current of 0.8 A (0.37 C) from full charge (

) to cut-off voltage (

) [

22]. C-rate is the discharge rate of the battery relative to its capacity. This current pulse has 480 s on-time and 600 s off-time.

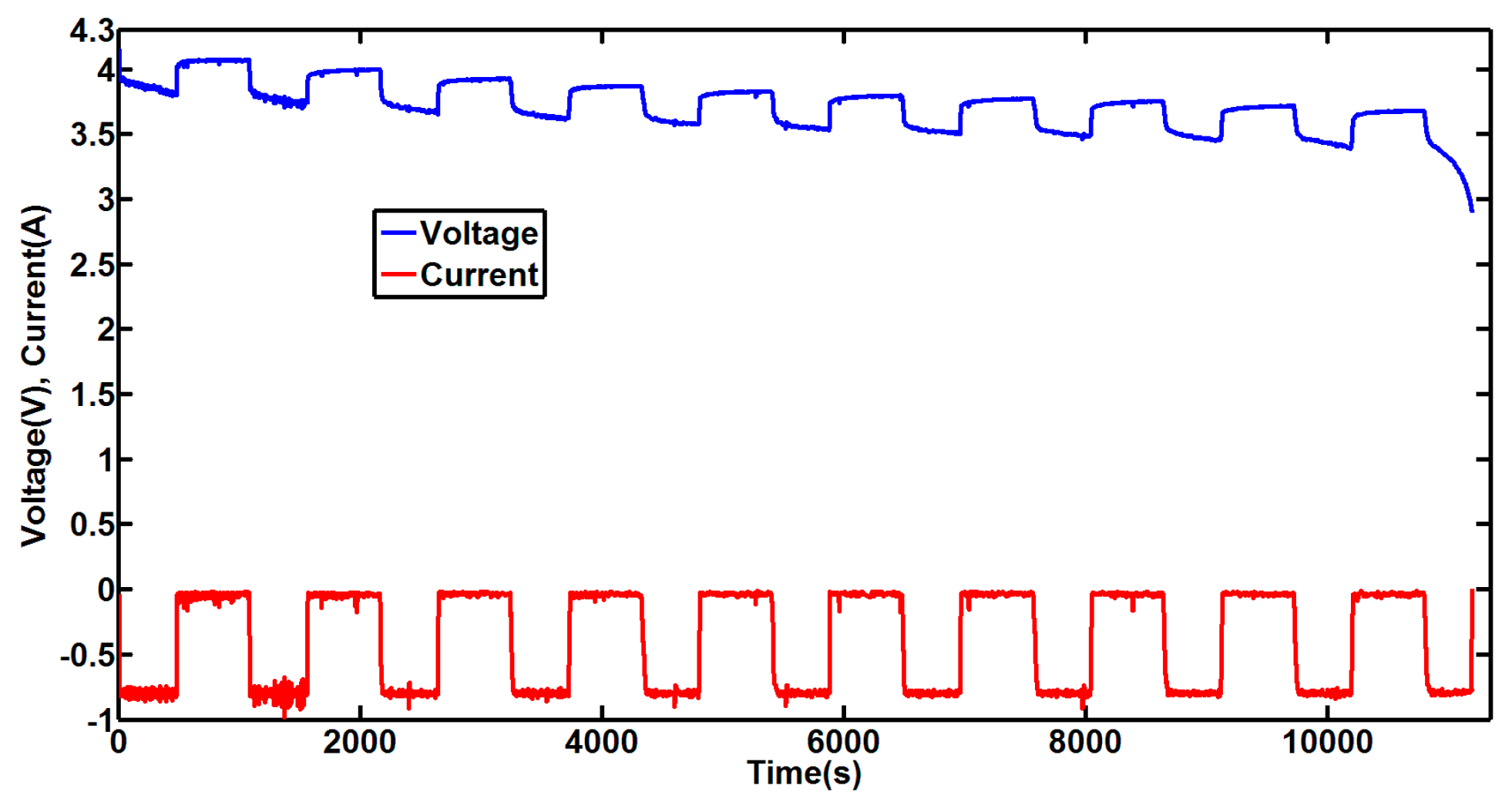

Figure 3 shows the pulse discharge current and the battery terminal voltage. The experimental data was obtained at a room temperature of 25 °C.

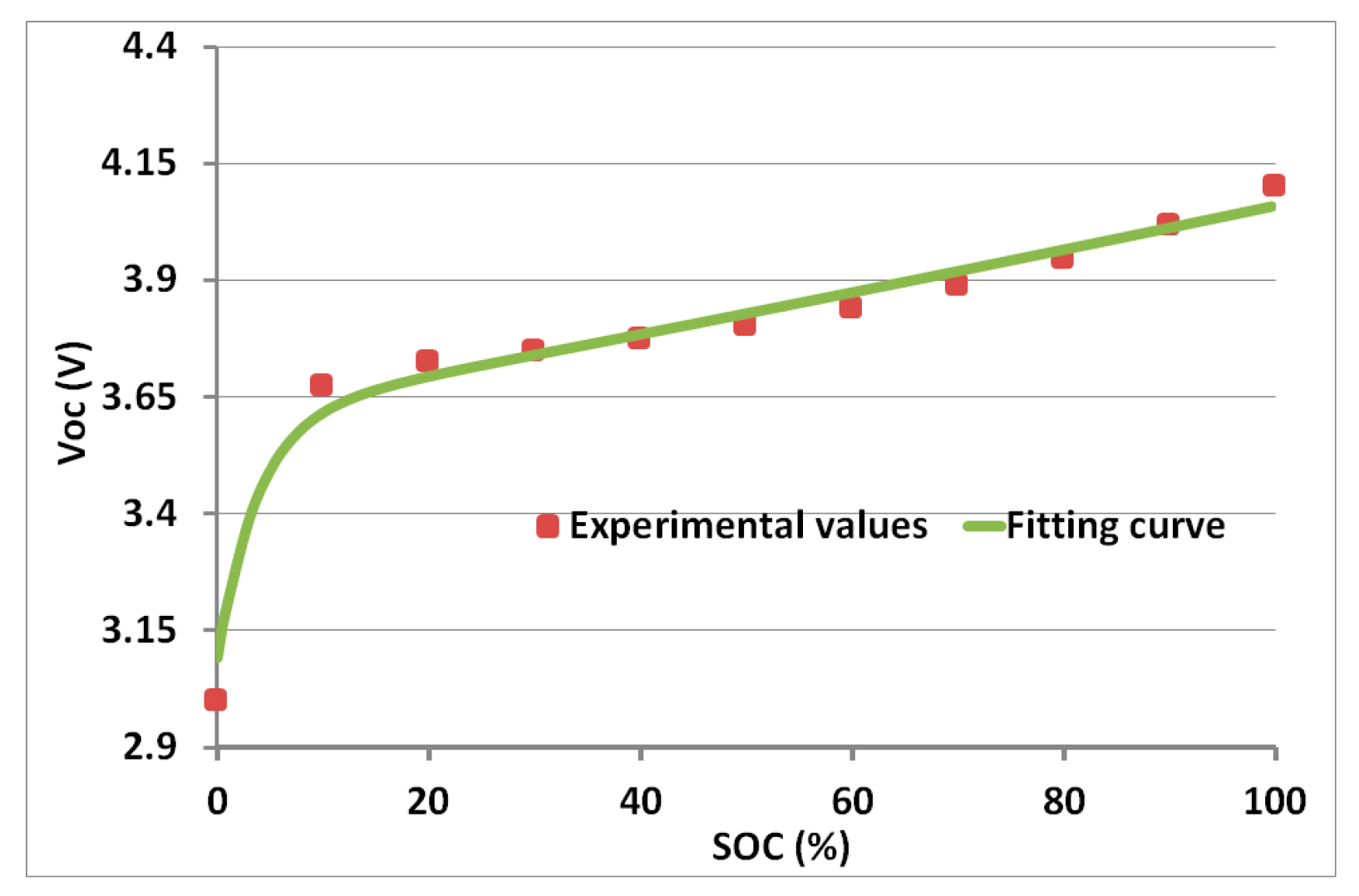

It was considered that each pulse current discharged the battery by 10%. The open-circuit voltage

was measured at equilibrium potential. The points in

Figure 4 show the

versus

. The relation between the

and the

is non-linear. The curve is steep at the beginning (for

lower than 20%) and then linear [

26,

27,

28].

It is important to include the variation of

as a function of

in the whole battery model. The experimental value is interpolated by a fitting technique (using software FindGraph). The resulting fitting function is given by:

Table 1 represents the relative fitting errors for battery parameters.

5. Identification of Model Parameters as a Function of SOC

Figure 5 shows the typical voltage response of a battery. The voltage drop may be divided into two parts. The first (

) is a vertical straight drop largely dependent on the battery’s ohmic resistance

. It can be estimated by [

29]:

The second (

) is the voltage drop based on resistances

and

. It is experimentally difficult to measure the time constants for activation and concentration separately. Moreover, some simplified hypotheses may lead to important errors. As the experimental results show, resistance

varies slightly with SOC. This concurs with publications [

8,

29,

30] showing that other parameters of the model vary non-linearly versus

.

In a single pulse, the value of the current

is either constant or zero. Therefore, the solutions for Equations (2) and (3) will be as follows:

This means that during discharge, each voltage can be represented by an exponential. We suggest using regression analysis to fit the voltage experimental data with two exponentials. Based on the experimental data, a regression analysis is conducted at each separately, and for different pulse currents (0.8, 1.2 and 1.5 A; 0.37, 0.56 and 0.7 C). Through this approach, the elements of the battery equivalent circuit can be determined.

This approach is repeated for each pulse where it is supposed that the elements

,

,

and

are independent of

only for the related pulse.

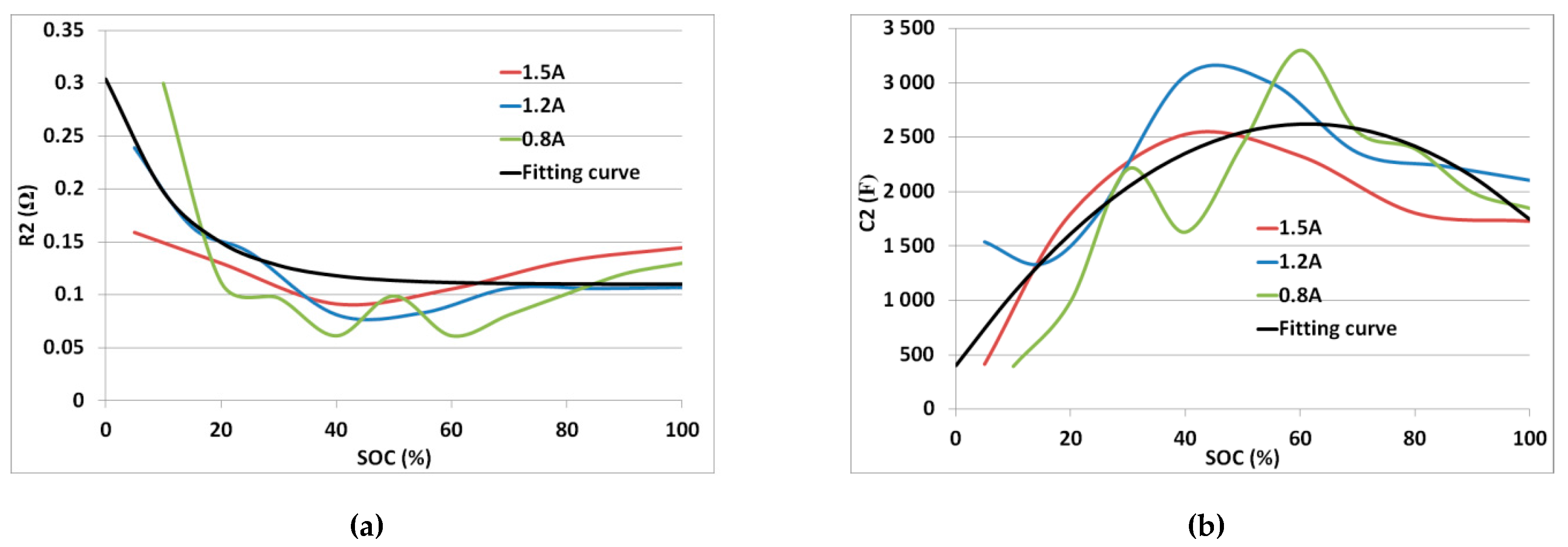

Figure 6 represents the values of the resistance

and the capacitance

as a function of

for three values of the discharge current.

The resistance

decreases roughly with the increase of

. Using fitting, the average value of

can be expressed by an exponential function as follows:

A polynomial is selected to fit the experimental values of the capacitance .

The values of the resistance

and of the capacitance

as a function of

are shown in

Figure 7 for different discharge currents. It can be seen where

is less than 20%, resistance

is higher.

Similarly, we found that the both parameters

and

can be expressed as:

where

is at or above 30%, variation is low for resistances and high for capacitances.

6. Determining the Battery Coulombic Efficiency

The battery is discharged at various constant currents in the range of 0.6–3 A (0.2–1.4 C). The experimental results are shown in

Figure 8. The discharge rate of the battery substantially affects the voltage curve—as it increases, the voltage curve shifts downward significantly. For a high discharge current (3 A), the discharge curve is deformed and the battery capacity decreases markedly.

The battery Coulombic efficiency will decrease as the discharge rate increases, as shown in

Figure 8b. There is an approximately linear relationship between the discharge current and the Coulombic efficiency. As can be noticed in

Figure 8, the effect of discharge rate on useful battery capacity is clear. It is still lower in Li-ion batteries than in lead acid batteries, however, due to the very fast redox reactions in Li-ion batteries [

31].

Since phenomena in battery systems are influenced by temperature, the model adjusts for Coulombic efficiency variation [

22,

24].

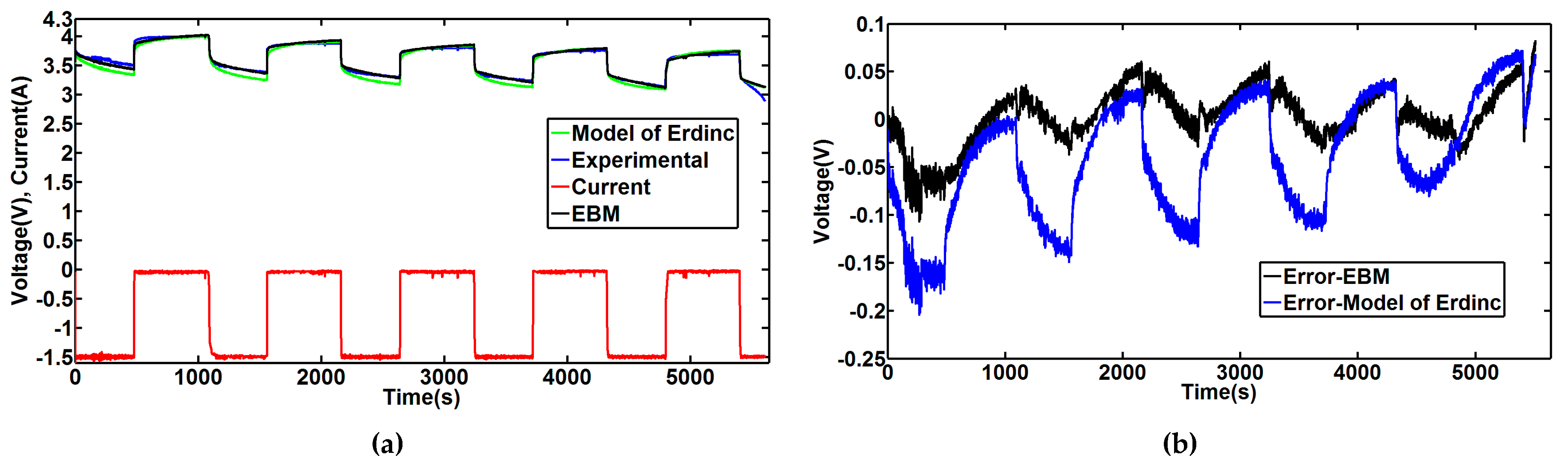

7. Comparison between Simulation and Experimental Results

Using the previous equations, an extended battery model (EBM) was built with the MATLAB/SIMULINK environment. To compare the experimental and simulated results, several tests were carried out using pulse discharge currents. The results are as follows:

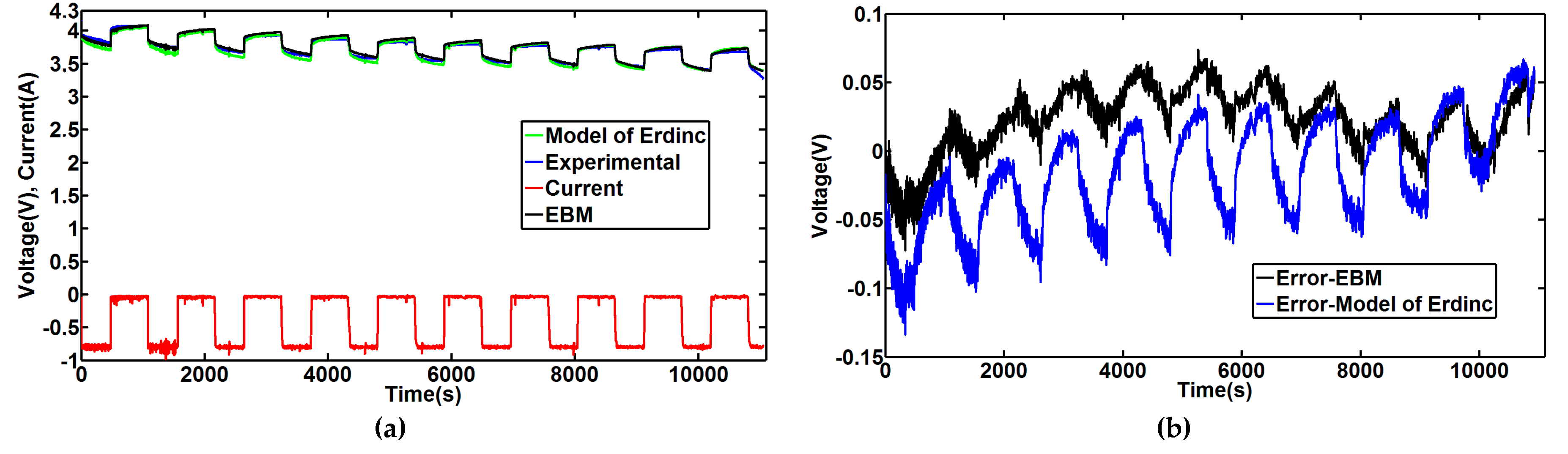

Pulse discharge current of 0.8 A (presented in

Figure 3):

Figure 9a shows the comparison between the simulation and the experimental voltages.

Figure 9b illustrates the small size of the simulation error, hardly reaching 0.06 V and remaining at less than 1% virtually throughout the test.

Pulse discharge current of 1 A (0.47 C) (180 s on-time and 60 s off-time):

Figure 10a overlays the simulated voltage and the experimental voltage curves, while

Figure 10b illustrates the small error rate.

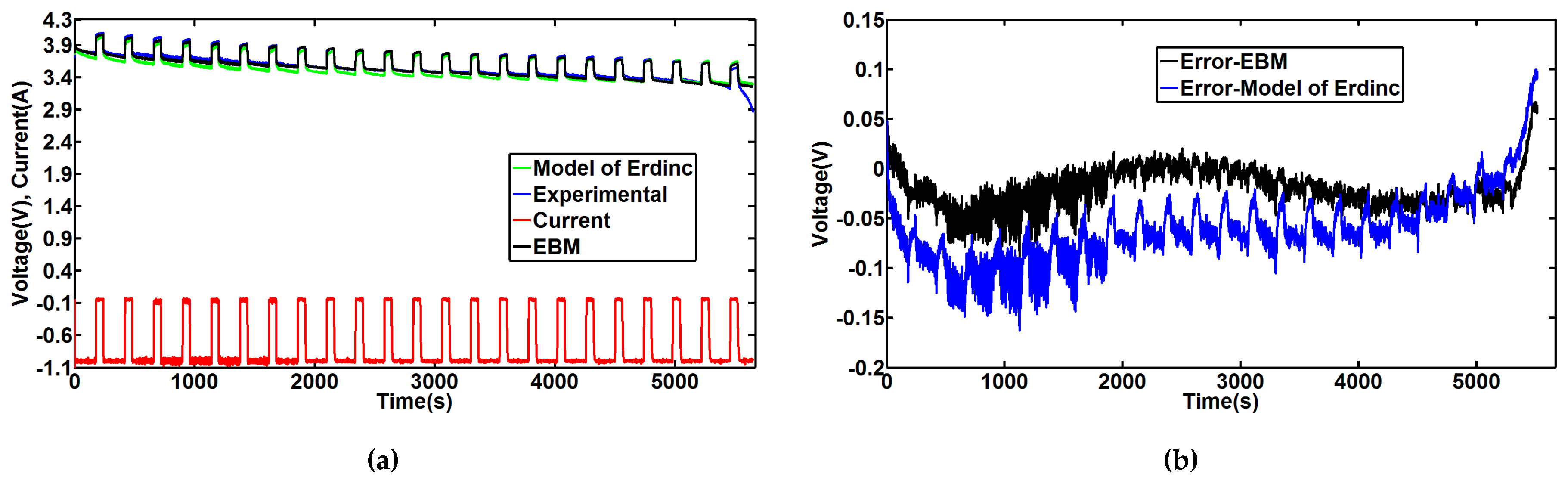

Pulse discharge current of 1.5 A (0.7 C) (480 s on-time and 600 s off-time): The comparison between the simulation and the experimental voltages is represented in

Figure 11a. It can be observed in

Figure 11b that the error rate, while still low, is slightly higher at this higher pulse discharge current, especially as the battery reaches full discharge.

The previously proposed model was used to simulate the dynamic characteristics of the lithium battery. The model’s relative accuracy was validated across a variety of voltage profiles. As the discharge current increased, however, the EBM error increased slightly. And as the battery approached full discharge, an important error emerged. This error can be explained by the sharp open-circuit voltage drop that slightly influences battery runtime. The proposed EBM model is also compared with the Erdinc model [

6] on

Figure 9,

Figure 10 and

Figure 11. These Figures clearly show that since it considers that the battery parameters slightly vary with SOC, the Erdinc model produces simulation results that are farther from the experimental results than the EBM model.

We will now examine additional steps to estimate the parameters of a real battery in real time.

8. Estimating Battery Parameters Using an Extended Kalman Filter

The Ampere Hour counting (AHC) technique used for estimating

can be accurate, but it can accumulate errors with time. Its accuracy depends very much on determining initial

, and it is subject to measurement noise [

32,

33]. To improve accuracy, an extended Kalman filter (EKF) is used. It is a nonlinear optimum state estimation method based on a continuous-time model and on discrete-time measurements. A continuous-discrete extended Kalman estimator of the lithium-ion battery is derived from the model previously built to determine the

and other parameters of a battery with less error.

,

,

,

,

,

,

and

are chosen as state-variables:

,

,

,

,

,

,

We have chosen this set of parameters because it simplifies the extended Kalman filter estimator. From Thevenin circuit equations of

Figure 1 and Equation (5) (see

Appendix B), we can write the state equations as follows:

Determination of battery parameters as a function of allows us to develop the extended Kalman filter observer to identify parameters in real-time. The derivation of time equations for the other state-variables is summarised below.

The time equation for

can be developed from Equation (12a).

Equation (12a) can be rewritten replacing

by

as:

The derivative of the constant

with respect to

can be calculated as:

Then, Equation (12b) can be rewritten as:

The resistance

is replaced as:

Finally, variable

can be expressed as follows:

Similarly, the time equation for

can developed as follows:

Likewise, we can compute variables

and

in the same manner.

The time derivative of variable

is assumed to be zero.

In such a case, we can use a continuous-discrete extended Kalman filter (CD-EKF). The system of interest is a continuous-time dynamic system with discrete-time measurements given by [

34,

35,

36]:

where

is the unmeasured “process noise” which is assumed to be a continuous-time Gaussian zero-mean white noise of covariance matrix

;

is the measurement noise which is assumed to be a discrete-time Gaussian zero-mean white noise of covariance matrix

; and

, where

is the sampling number; and

is the sampling period. The

and

are the output and input measurements.

The Kalman filter mainly involves two steps: prediction and measurement update. The predicted state

and its covariance matrix

is calculated by solving ordinary differential equations (ODE) in the form Equation (15) [

37]:

The dynamic matrix

(the Jacobian matrix of partial derivatives of function

) can be computed:

where,

The initial value of error matrix covariance

and

are given by:

The values of these matrices are provided in

Appendix A. The covariance matrix

was computed through manual testing in MATLAB.

The two Equations (18a) and (18b) are solved simultaneously with the nonlinear ODE solver [

38]. Equation (18b) is vectorised. Here, we implanted the filter (CD-EKF) in MATLAB with ODE45 Dormand-Prince variable-step differential equation solver because it implements the Runge-Kutta pair, one of the best methods for treating non-stiff general-form initial value problems for ODE. The integration is done in the interval [

,

] with the initial conditions:

and the error covariance matrix

. We compute the predicted estimate state

and the error covariance matrix

at time

[

37]. Then, we use the standard correction step of the EKF. Additionally, we calculate only the upper triangular part of the error covariance matrix including the main diagonal because of its symmetry. As a result, we have 44 equations (ODE) to solve with 44 unknown variables. Then the standard measurement update is applied at time (

). The function

deriving the observation equation is given by:

The observation matrix

can be calculated by:

where,

The Kalman gain can be computed as:

where

is the measurement noise covariance. As presented in Reference [

39], Auger et al. proposed that the value of covariance

can be set to one (

). The state estimation covariance is updated by:

We use the Kalman gain to update the state estimation:

Lastly, the process repeats itself.

9. EKF Estimator Results and Discussion

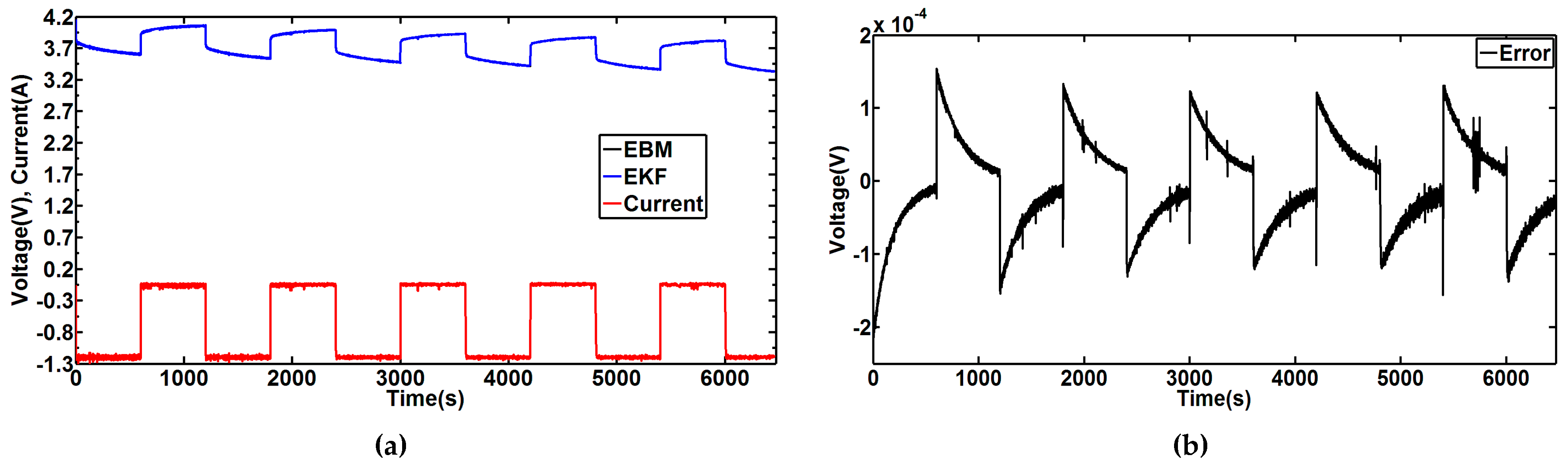

9.1. Validation using the EBM Model

Firstly, we compared the voltage estimated by the EKF with the voltage output of the EBM model, based on the same current. The battery is discharged with a current of 1.2 A (600 s on-time and 600 s off-time) as shown in

Figure 12a. This Figure shows the voltages obtained with EKF and EBM. The voltage error is lower than 0.02% as shown in

Figure 12b.

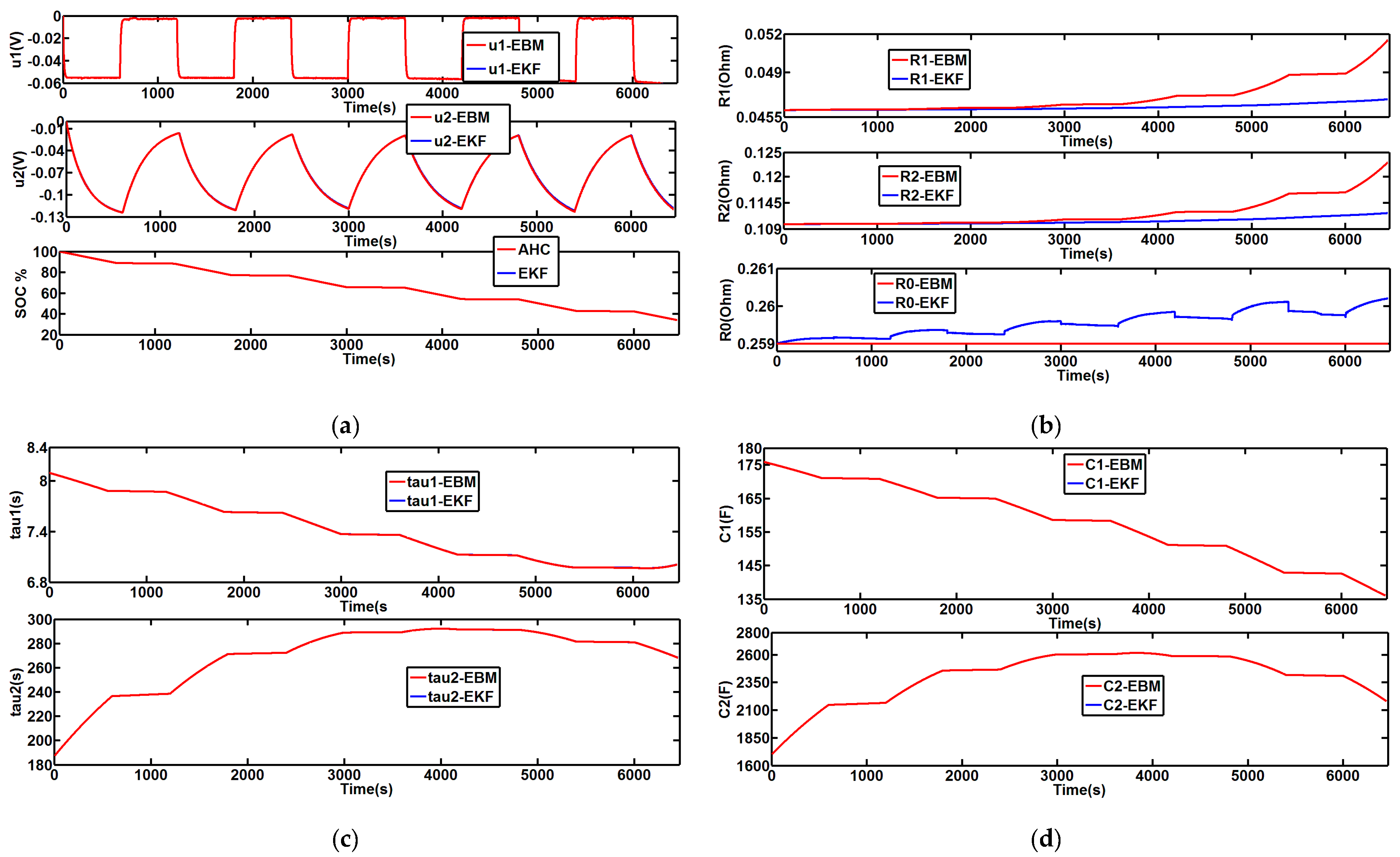

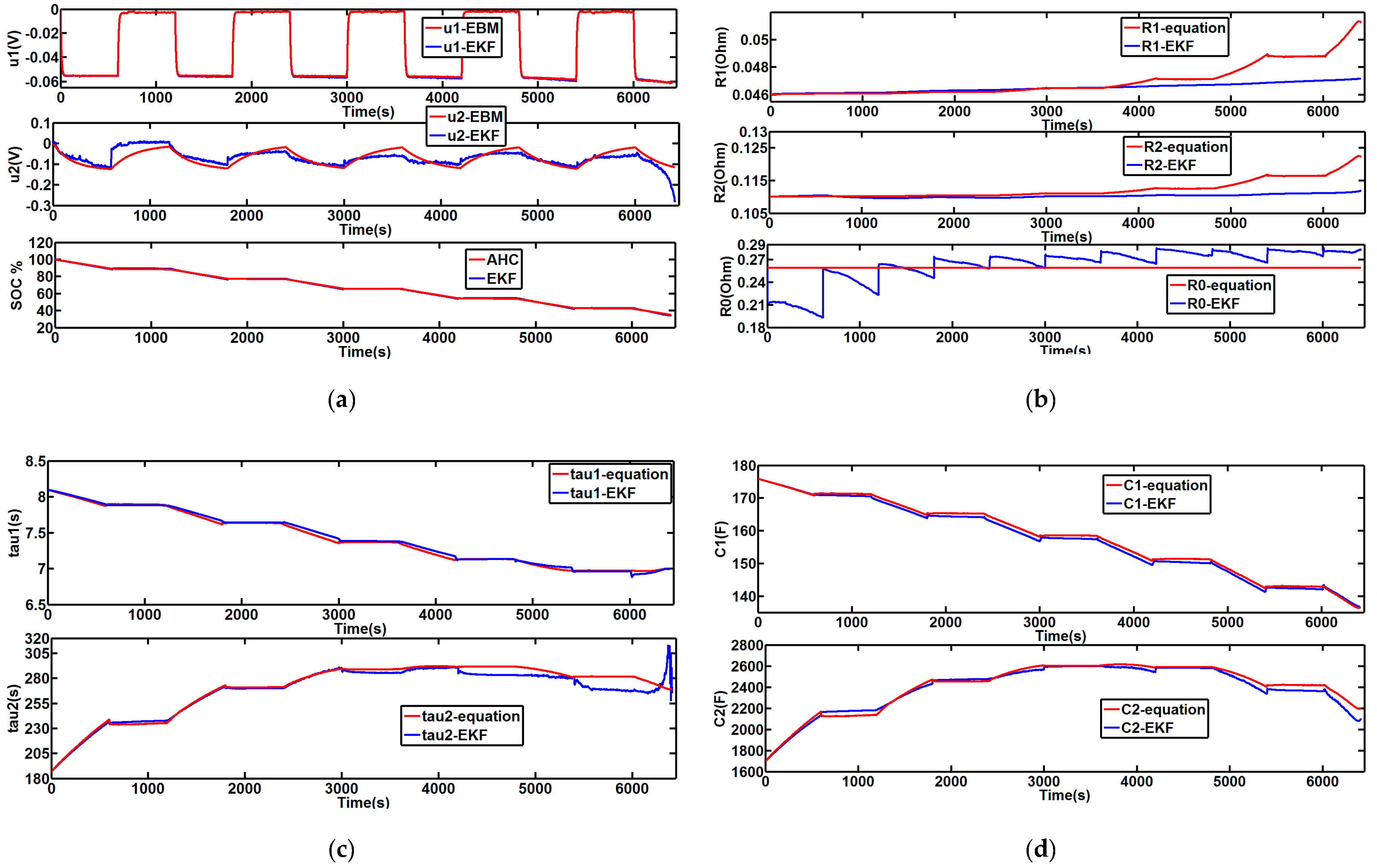

Figure 13 compares the battery parameters for the EBM with the EKF-estimated parameters (

,

,

,

,

,

and

). It is observed that the estimator can accurately identify the battery parameters of the model. For

Figure 13a,c,d, the output curves obtained with EKF and EBM are virtually identical and so are superimposed in the graphs.

These estimated parameters vary with time due to their variation with . The main observations concern the resistances which do not vary significantly with time. There is some fluctuation in resistance , but it seems to be low.

These resistances vary slightly for a interval of 30–100%; conversely, capacitances vary considerably with . These hypothetical observations can be confirmed by experimental results.

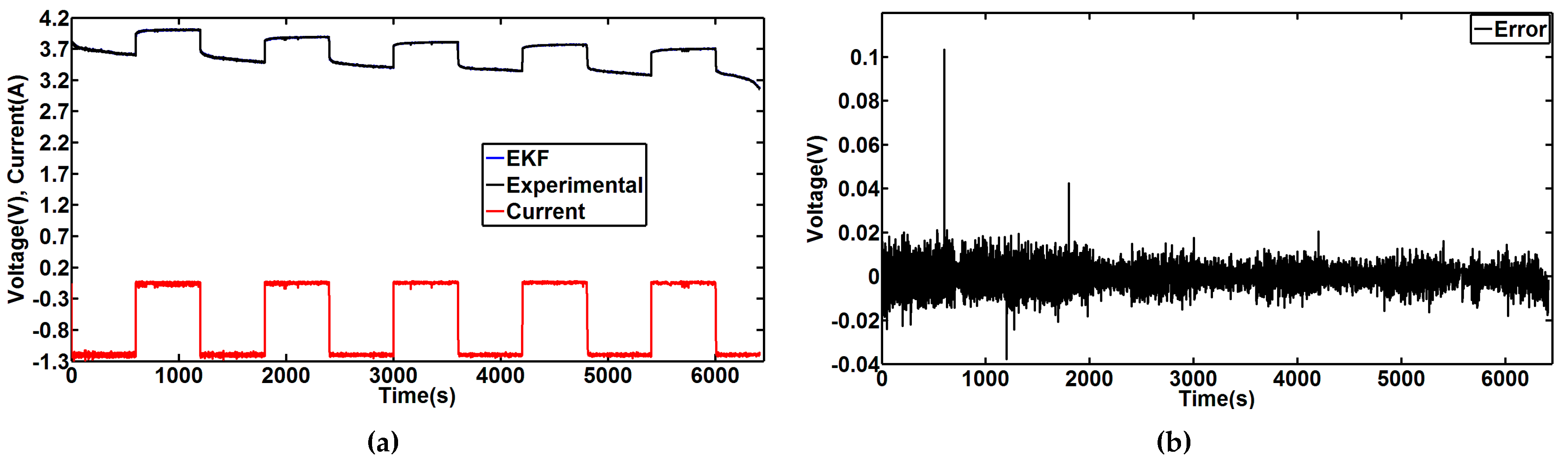

9.2. Validation using Experimental Signals

To validate the EKF observer, we used the same current profile shown previously in

Figure 12a. The battery voltage over time was measured experimentally and compared with the voltage estimated by the CD-EKF estimator. As seen in

Figure 14, the voltage with CD-EKF converges with the experimental data, and the error between these voltages is very low (on the order of 2 mV).

Figure 15 shows the variation of parameters with time. The parameters of the EKF estimator are initialized with values slightly different from the true ones. The estimated drop voltages

and

are compared with values obtained using the EBM, as presented in

Figure 15a. The first voltage drop is close to the value obtained with the EBM, but the voltage drop

is greater than

, yet it can be influenced by different coefficients, such as temperature. This can lead to errors determining the concentration parameters (

and

), particularly at the beginning of discharge.

The values for resistance and the capacitance estimated by CD-EKF are compared with those calculated by theoretical Equations (9) and (10) using the

value obtained by the estimator. These results are shown in

Figure 15a–d. The temporal change of the estimated parameters matches the calculations closely.

The main difficulties when determining these parameters usually reside at the beginning and the end of discharge. For this CD-EKF estimator, minor errors occur, especially at low

. It is found that the relative error of the estimated parameters oscillates around the zero value. Maximum error is presented in

Table 2.

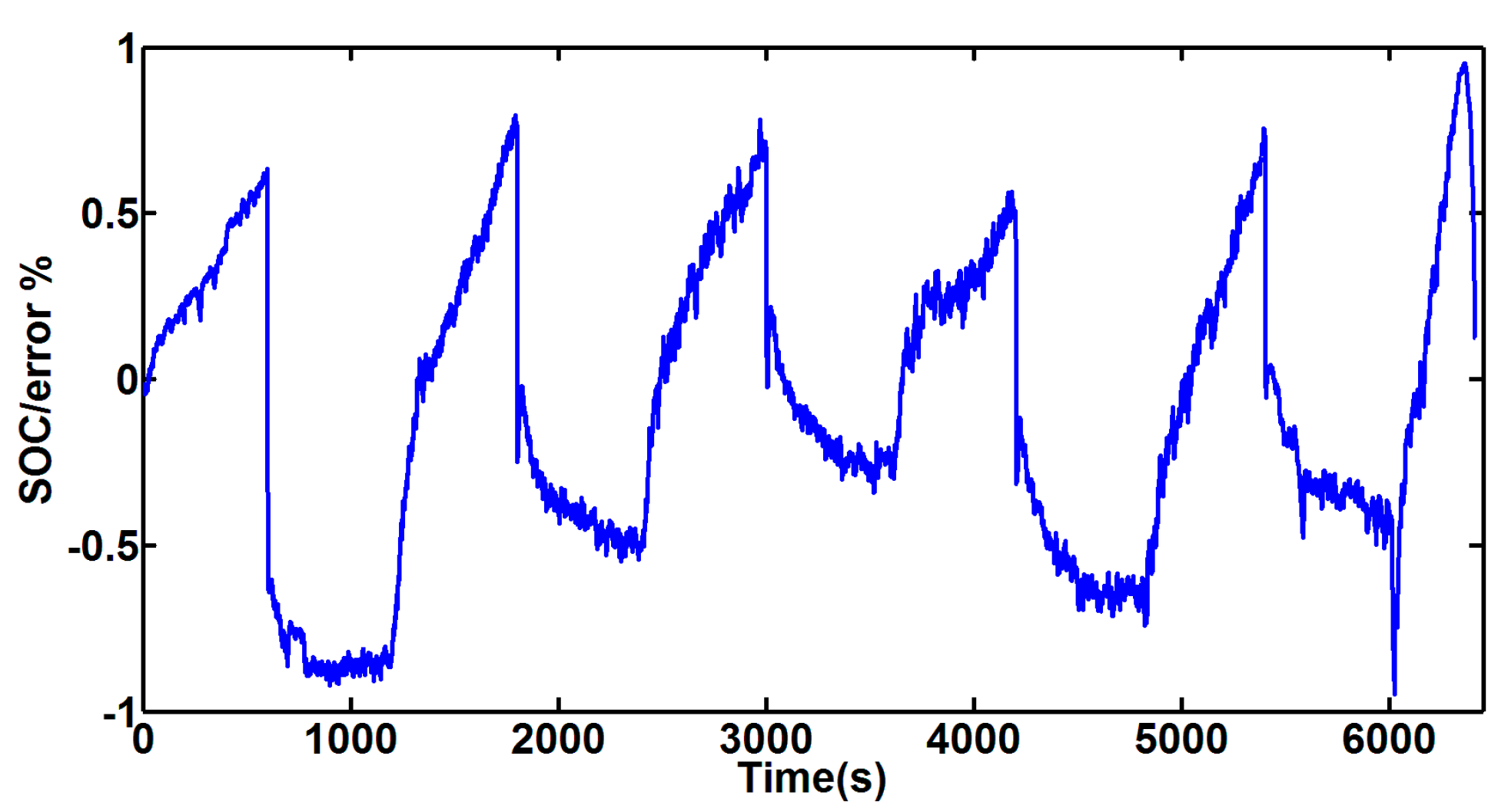

The

results estimated with EKF and AHC are compared in

Figure 15a. The

with EKF converges to the value with AHC with error lower than 1% as shown in

Figure 16.

10. Conclusions

In this paper, we propose an extended model to simplify the characterisation of battery parameters (state of charge, resistances and capacitances). This lithium-ion battery model relies on iterative measures of voltage and current as well as estimations from a continuous-discrete extended Kalman filter. We employed the pulse discharge method and fitting technique to determine battery parameters and to validate the model experimentally.

The model, established in the MATLAB environment, takes into account the effect of the discharge rate on battery parameters, and simulates the dynamic voltage behaviours of the battery well. It satisfies a trade-off between complexity and precision. However, at the end of discharge, the model becomes less precise because of increasing superposed errors and electrochemical phenomena that may take place at low voltage. For more stable estimates of the state of charge, further research can be performed to determine the time constants.

Although the model adjusts for Coulombic efficiency variation, temperature can have a substantial effect on battery behaviour and needs to be analysed more deeply.

We have developed a CD-EKF estimator based on the battery model we first derived, using an EKF observer to update parameters for ongoing, iterative input to the model. One of the great advantages of using the observer is the ability to recover from incorrect initial conditions.

Experimental results indicate that this revised CD-EKF estimator can accurately determine battery parameters throughout most of the discharge cycle. In further study, we are currently working to apply the developed estimator in real time measurements with another battery.

The estimator uses only a few equations, and should not require significant computing resources. The developed estimator can be used in various applications such as laptops, telephones and electric vehicles. We are also considering using extended Kalman filters to create an online tool for estimating the state of health of batteries online.