Coupled Effects of Moisture Content and Inherent Clay Minerals on the Cohesive Strength of Remodelled Coal

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Description and Preparation

2.2. Apparatus and Procedures

2.2.1. Direct Shear Test

2.2.2. X-ray Diffraction Observations

3. Results and Discussion

3.1. Direct Shear Test Results and Discussion

3.1.1. Shear Stress-Displacement Curves

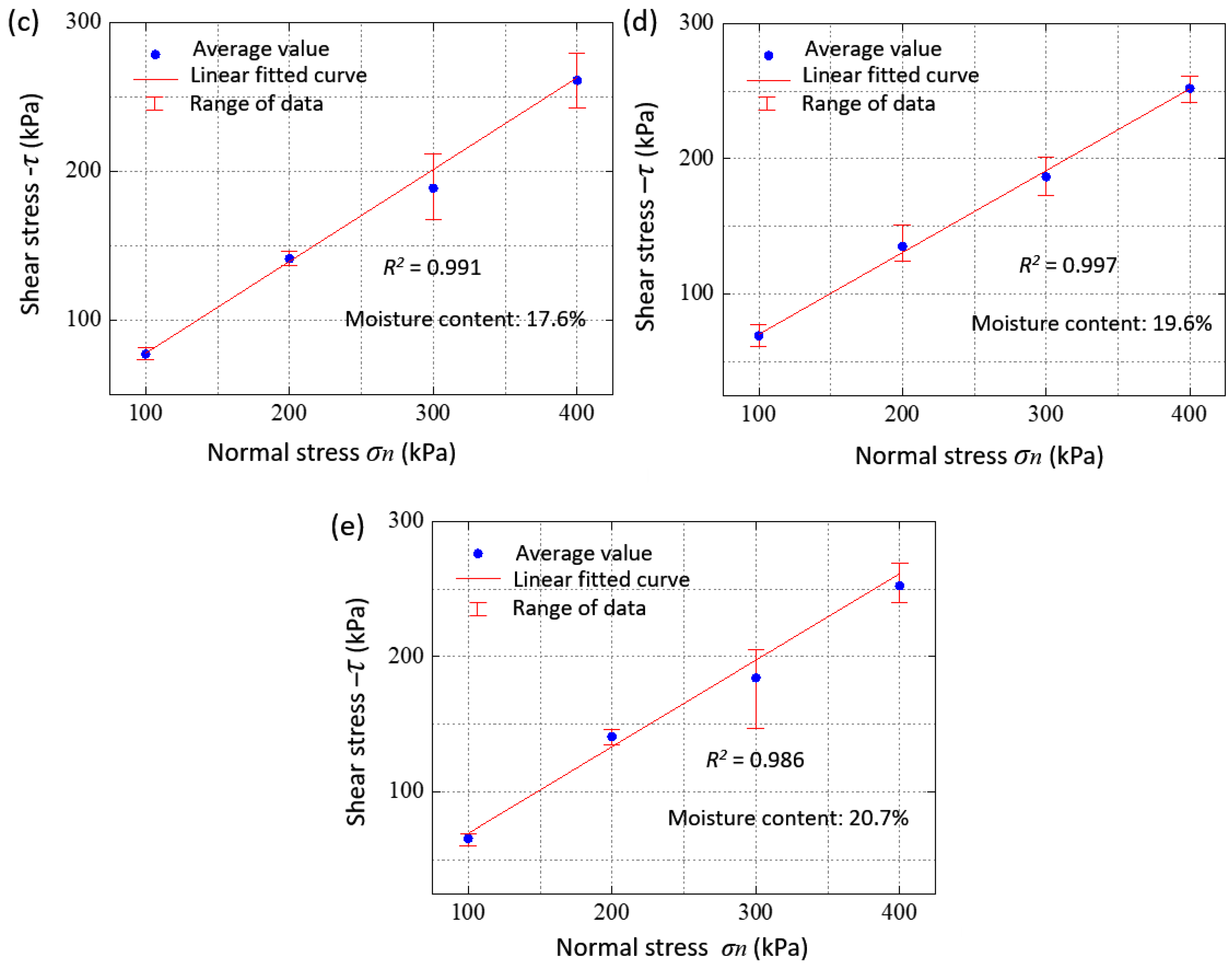

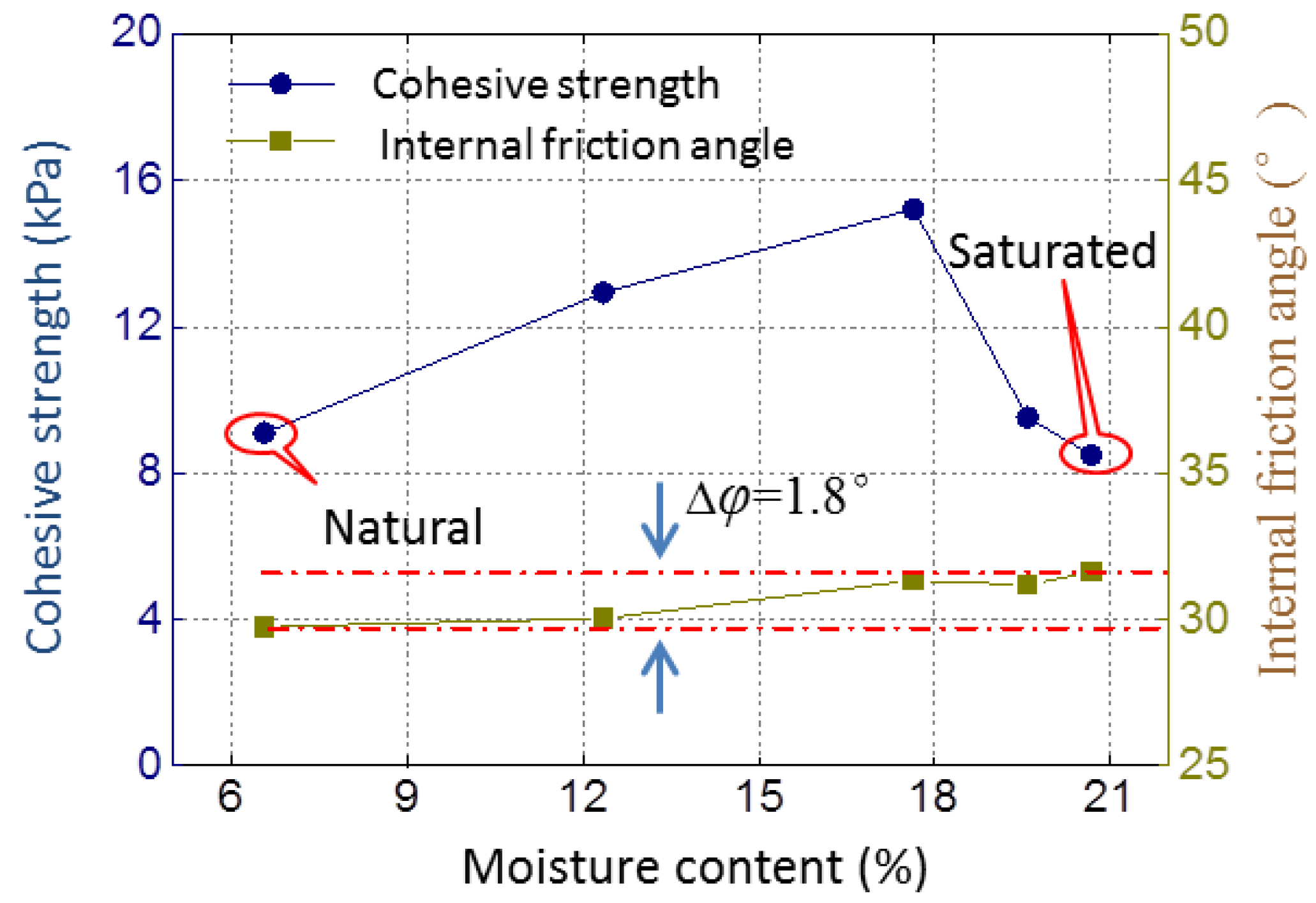

3.1.2. Physical Properties Based on Mohr-Coulomb Failure Criterion

3.2. Effect of Moisture Content on Inherent Clay Minerals

3.3. Discussion about the Sunction Stress and Cohesive Strength of Remodelled Coal

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Molinda, G.; Mark, C. Ground failures in coal mines with weak roof. Electron. J. Geotech. Eng. 2010, 15, 547–588. [Google Scholar]

- Shi, N.; Huang, Z. Application of longwall top coal caving in challenging geological conditions. In Proceedings of the World Congress on Mechanical, Chemical, and Material Engineering, Barcelona, Spain, 20–21 July 2015; p. 354. [Google Scholar]

- Si, G.; Durucan, S.; Jamnikar, S.; Lazar, J.; Abraham, K.; Korre, A.; Shi, J.Q.; Zavšek, S.; Mutke, G.; Lurka, A. Seismic monitoring and analysis of excessive gas emissions in heterogeneous coal seams. Int. J. Coal Geol. 2015, 149, 41–54. [Google Scholar] [CrossRef]

- Karimi, M. Mineral Impurities in Coal Combustion; Hemisphere Publishing Corp.: Carlsbad, CA, USA, 1985; pp. 141–181. [Google Scholar]

- Kang, T.H.; Zhang, J.P.; Bai, S.W. Theoretical study and application of weakening top coal using water pre-infusion in fully mechanized sublevel caving mining. Chin. J. Rock Mech. Eng. 2004, 23, 2615–2621. [Google Scholar]

- Lu, Y.; Zhou, Z.; Ge, Z.; Zhang, X.; Li, Q. Coupling effect of intruding water and inherent gas on coal strength based on the improved (mohr-coulomb) failure criterion. Minerals 2016, 6, 118. [Google Scholar] [CrossRef]

- Pan, J.F.; Ning, Y.; Lan, H.; Peng, Y.W.; Xia, Y.X.; Wei, X.Z.; Wang, S.W. Water injection methods in coal bed based on experiments of water immersion time effect of qianqiu coal samples with burst trend. J. China Coal Soc. 2012, 37, 19–25. [Google Scholar]

- Guo, B.B.; Chen, G.X. Experimental study on relationship between water content and shear strength parameters of soft rock in coal mine. Saf. Coal Mines 2013, 44, 4–7. [Google Scholar]

- Wang, L.; Zhu, C.; Yin, Z.; Hou, J. Research on soft coal mechanics characteristic test for moisture content effect. J. Min. Saf. Eng. 2016, 33, 1145–1151. [Google Scholar]

- Hu, X.; Hong, B.N.; Du, Q.; Meng, Y.M. Influence of water contents on shear strength of coal-bearing soil. Rock Soil Mech. 2009, 30, 2291–2294. [Google Scholar]

- Fredlund, D.G.; Xing, A. Equations for the soil-water characteristic curve. Can. Geotech. J. 1994, 31, 521–532. [Google Scholar] [CrossRef]

- Casini, F.; Serri, V.; Springman, S.M. Hydromechanical behaviour of a silty sand from a steep slope triggered by artificail rainfall: From unsaturated to saturated conditions. Can. Geotech. J. 2013, 50, 28–40. [Google Scholar] [CrossRef] [Green Version]

- Casini, F.; Vassallo, R.; Mancuso, C.; Desideri, A. Application to a compacted soil of a cam clay model extended to unsaturated conditions. In Proceedings of the 1st European Conference on Unsaturated Soils. Advances in Geo-Engineering (E-UNSAT), Durham, UK, 2–4 July 2008; pp. 609–615. [Google Scholar]

- Casini, F. Fundamentals of the hydromechanical behavior of multiphase granular materials. In New Frontiers in Oil and Gas Exploration; Springer International Publishing: Cham, Switzerland, 2016; pp. 461–486. [Google Scholar]

- Fredlund, D.G.; Rahardjo, H. An Overview of Unsaturated Soil Behaviour; Geotechnical special publication, ASCE publishing: Dallas, TX, USA, 1993; pp. 1–31. [Google Scholar]

- Casini, F.; Minder, P.; Springman, S.M. Shear Strength of An Unsaturated Silty Sand; Unsaturated Soils-Proceedings of the 5th International Conference on Unsaturated Soils: Barcelona, Spain, 2011; pp. 211–216. [Google Scholar]

- D’Onza, F.; Gallipoli, D.; Wheeler, S.; Casini, F.; Vaunat, J.; Khalili, N.; Laloui, L.; Mancuso, C.; Mašín, D.; Nuth, M. Benchmark of constitutive models for unsaturated soils. Géotechnique 2011, 61, 283–302. [Google Scholar] [CrossRef] [Green Version]

- Ciervo, F.; Casini, F.; Papa, M.N.; Rigon, R. Some remarks on bimodality effects of the hydraulic properties on shear strength of unsaturated soils. Vadose Zone J. 2015, 14, 1–12. [Google Scholar] [CrossRef]

- Lu, N.; Likos, W.J. Suction stress characteristic curve for unsaturated soil. J. Geotech. Geoenviron. Eng. 2006, 132, 131–142. [Google Scholar] [CrossRef]

- Casini, F. Consequences on water retention properties of double-porosity features in a compacted silt. Acta Geotech. 2012, 7, 139–150. [Google Scholar] [CrossRef] [Green Version]

- Ma, D.; Miao, X.X.; Wu, Y.; Bai, H.B.; Wang, J.G.; Rezania, M.; Huang, Y.H.; Qian, H.W. Seepage properties of crushed coal particles. J. Pet. Sci. Eng. 2016, 146, 297–307. [Google Scholar]

- Ma, D.; Rezania, M.; Yu, H.S.; Bai, H.B. Variations of hydraulic properties of granular sandstones during water inrush: Effect of small particle migration. Eng. Geol. 2017, 217, 61–70. [Google Scholar] [CrossRef]

- Helwany, S. Applied Soil Mechanics with Abaqus Applications; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Ma, D.; Li, Q.; Hall, M.; Wu, Y. Experimental investigation of stress rate and grain size on gas seepage characteristics of granular coal. Energies 2017, 10, 527. [Google Scholar] [CrossRef]

- Kemper, W.D.; Rosenau, R.C. Soil cohesion as affected by time and water content. Soil Sci. Soc. Am. J. 1984, 48, 1001–1006. [Google Scholar] [CrossRef]

- Moayed, R.Z.; Alibolandi, M.; Alizadeh, A. Specimen size effects on direct shear test of silty sands. Int. J. Geotech. Eng. 2017, 11, 198–205. [Google Scholar]

- Huang, K.; Wan, J.W.; Chen, G.; Zeng, Y. Testing study of relationship between water content and shear strength of unsaturated soils. Rock Soil Mech. 2012, 23, 2600–2606. [Google Scholar]

- Cokca, E.; Erol, O.; Armangil, F. Effects of compaction moisture content on the shear strength of an unsaturated clay. Geotech. Geol. Eng. 2004, 22, 285–297. [Google Scholar] [CrossRef]

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key parameters for strength control of artificially cemented soils. J. Geotech. Geoenviron. Eng. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- Liu, Q.Y.; Zhu, Z.Q. Shear characteristics of siltized intercalation in red sandstone at different water contents. J. Shenyang Univ. Technol. 2012, 34, 220–235. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Brusewitz, G.H. Angle of internal friction and cohesion of consolidated ground marigold petals. Trans. ASAE 2001, 44, 1255–1259. [Google Scholar]

- Mouazen, A.M.; Ramon, H.; Jde, B. Effects of bulk density and moisture content on selected mechanical properties of sandy loam soil. Biosyst. Eng. 2002, 83, 217–224. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Cao, W.; Li, X.; Xiong, C. Influence of water content on mechanical properties of rock in both saturation and drying processes. Rock Mech. Rock Eng. 2016, 49, 3009–3025. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Chen, L.; Cao, W.; Zhao, Y.; Xiong, C. Influence of cyclic wetting and drying on physical and dynamic compressive properties of sandstone. Eng. Geol. 2017, 220, 1–12. [Google Scholar] [CrossRef]

- Zhang, H.; Wan, Z.; Ma, D.; Zhang, Y.; Cheng, J.; Zhang, Q. Experimental investigation on the strength and failure behavior of coal and synthetic materials under plane-strain biaxial compression. Energies 2017, 10, 500. [Google Scholar] [CrossRef]

- Odom, I.E. Smectite clay minerals: Properties and uses. Philos. Trans. R. Soc. Lond. 1984, 311, 391–409. [Google Scholar] [CrossRef]

- Polzer, W.L.; Hem, J.D. The dissolution of kaolinite. J. Geophys. Res. Atmos. 1965, 70, 6233–6240. [Google Scholar] [CrossRef]

- Magaritz, M.; Luzier, J.E. Water-rock interactions and seawater-freshwater mixing effects in the coastal dunes aquifer, coos bay, oregon. Geochim. Cosmochim. Acta 1985, 49, 2515–2525. [Google Scholar] [CrossRef]

- Whitney, G. Role of water in the smectite-to-illite reaction. Clays Clay Miner. 1990, 38, 343–350. [Google Scholar] [CrossRef]

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

| Coal Seam | W (%) | A (%) | V (%) | FC (%) | S (%) | CV (MJ/Kg) |

|---|---|---|---|---|---|---|

| NO. 2 | 0.85 | 28.35 | 22.97 | 68.73 | 3.89 | 34.47 |

| Group Number | Moisture Content (%) | Density (kg/m3) | Normal Load (kPa) | Shear Velocity (mm/min) |

|---|---|---|---|---|

| G-1 | 6.6 | 1.30 | 100, 200, 300, 400 | 2.4 |

| G-2 | 12.3 | 1.35 | ||

| G-3 | 17.6 | 1.45 | ||

| G-4 | 19.6 | 1.55 | ||

| G-5 | 20.7 | 1.65 |

| References | Materials | Range of Moisture Content (%) | Trend of Cohesive Strength |

|---|---|---|---|

| Wang et al. [9] | Coal | 1.57–6.55 | [1.57–3.07] increase; [3.07–6.55] decease |

| Hu et al. [10] | Coal-bearing soil | 8.5–20.6 | [8.5–20.6] decease |

| Cokca et al. [28] | Unsaturated clay | 18–28 | [18–23] increase; [23–28] decease |

| Consoli et al. [29] | Cemented soils | 4.0–13.5 | [4.0–10] increase; [10–13.5] decease |

| Liu and Zhu [30] | Mudstone | 10–20 | [10–13] increase; [13–20] decease |

| Huang et al. [27] | Soil | 3.0–27.5 | [3.0–12.0] increase; [12.0–27.5] decease |

| Minerals | Chemical Formula | Introduction |

|---|---|---|

| Kaolinite | Al2Si2O5(OH)4 | Easily broken and can be moulded or shaped, especially when wet. However, it does not expand when contacts with water. |

| Smectite | (Al,Mg)2[Si4O10](OH)2·nH2O | An absorbent clay that can absorb large quantities of water, swelling to many times their original volume, and give rise to permanent suspensions of gel-like masses. |

| Illite | K0.75(Al1.75R)[Si3.5Al0.5O10](OH)2 | A non-expanding clay and the capability of absorbing water is weaker than that of Smectite. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Wan, Z.; Ma, D.; Zhang, B.; Zhou, P. Coupled Effects of Moisture Content and Inherent Clay Minerals on the Cohesive Strength of Remodelled Coal. Energies 2017, 10, 1234. https://doi.org/10.3390/en10081234

Zhang H, Wan Z, Ma D, Zhang B, Zhou P. Coupled Effects of Moisture Content and Inherent Clay Minerals on the Cohesive Strength of Remodelled Coal. Energies. 2017; 10(8):1234. https://doi.org/10.3390/en10081234

Chicago/Turabian StyleZhang, Hongwei, Zhijun Wan, Dan Ma, Bo Zhang, and Peng Zhou. 2017. "Coupled Effects of Moisture Content and Inherent Clay Minerals on the Cohesive Strength of Remodelled Coal" Energies 10, no. 8: 1234. https://doi.org/10.3390/en10081234