Robust Tracking Controller for a DC/DC Buck-Boost Converter–Inverter–DC Motor System

Abstract

:1. Introduction

2. DC/DC Buck-Boost Converter–Inverter–DC Motor System

3. Hierarchical Controller

- High level control. This is a differential flatness-based control, , and is related to the inverter–DC motor subsystems. This control ensures the required voltage so that the bidirectional angular velocity trajectory tracking task can be achieved, i.e., .

- Low level control. In order to solve the voltage tracking on the Buck-Boost converter subsystem, i.e., , an alternative model of the converter is used along with the differential flatness approach to generate the control .

- Integration of controls. The controls designed in items A and B are interconnected through an inner control-loop, giving rise to the hierarchical controller.

3.1. High Level Control

3.2. Low Level Control

3.3. Integration of Controls

4. Experimental Results

- Hierarchical controller (designed in Section 3):withwhere the gains and are given, respectively, by

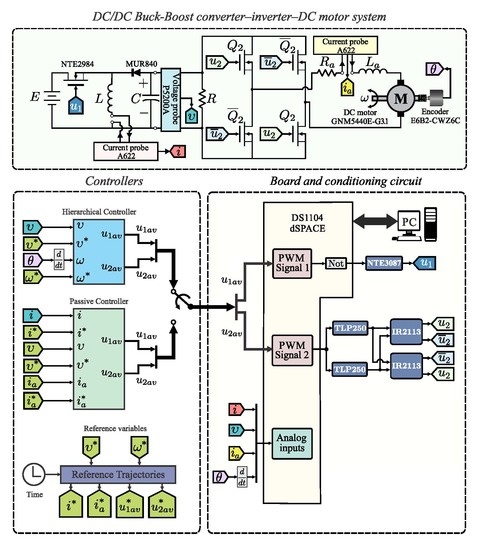

4.1. Experimental Testbed

- DC/DC Buck-Boost converter–inverter–DC motor system. This block corresponds to the built prototype of the system under study. Regarding the DC/DC Buck-Boost converter, according to [31], the following parameters are considered:Whereas, four IRF640 transistors and two circuit-drivers IR2113 were used for the inverter. Related to the DC motor, an ENGEL GNM5440E-G3.1 (, ) is used whose parameters are:

- Board and conditioning circuit. This block electrically isolates the DS1104 board from the power stage via the NTE3087 and TLP250 optocouplers. Also, this block drives the converter and inverter when generating, through PWM1 and PWM2, the switched inputs and , respectively.

- Controllers. In this block, the synthesis and programming of the hierarchical controller Equations (32) and (33) and the passive controller Equations (36) and (37) is carried-out via Matlab-Simulink. The corresponding program is shown in Figure 3, where the following four stages are observed: (i) Signals acquisition, (ii) Reference variables, (iii) Hierarchical controller, and (iv) Passive controller.

4.2. Experimental Results

4.2.1. Experiment 1

4.2.2. Experiment 2

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Erenturk, K. Hybrid control of a mechatronic system: Fuzzy logic and grey system modeling approach. IEEE/ASME Trans. Mechatron. 2007, 12, 703–710. [Google Scholar] [CrossRef]

- Silva-Ortigoza, R.; García-Sánchez, J.R.; Hernández-Guzmán, V.M.; Márquez-Sánchez, C.; Marcelino-Aranda, M. Trajectory tracking control for a differential drive wheeled mobile robot considering the dynamics related to the actuators and power stage. IEEE Latin Am. Trans. 2016, 14, 657–664. [Google Scholar] [CrossRef]

- García-Sánchez, J.R.; Tavera-Mosqueda, S.; Silva-Ortigoza, R.; Antonio-Cruz, M.; Silva-Ortigoza, G.; de Jesus Rubio, J. Assessment of an avarage tracking controller that considers all the subsystems involved in a WMR: Implementation via PWM or sigma-delta modulation. IEEE Latin Am. Trans. 2016, 14, 1093–1102. [Google Scholar] [CrossRef]

- García-Sánchez, J.R.; Silva-Ortigoza, R.; Tavera-Mosqueda, S.; Márquez-Sánchez, C.; Hernández-Guzmán, V.M.; Antonio-Cruz, M.; Silva-Ortigoza, G.; Taud, H. Tracking control for mobile robots considering the dynamics of all their subsystems: Experimental implementation. Complexity 2017, 2017, 1–18. [Google Scholar] [CrossRef]

- Onoda, S.; Emadi, A. PSIM-based modeling of automotive power systems: Conventional, electric, and hybrid electric vehicles. IEEE Trans. Veh. Technol. 2004, 53, 390–400. [Google Scholar] [CrossRef]

- Linares-Flores, J.; Sira-Ramírez, H.; Cuevas-López, E.F.; Contreras-Ordaz, M.A. Sensorless passivity based control of a DC motor via a solar powered Sepic converter-full bridge combination. J. Power Electron. 2011, 11, 743–750. [Google Scholar] [CrossRef]

- Kumar, C.K.; Kumar, A.N. Analysis of conducted EMI with a standalone solar-powered DC motor. Turk. J. Electr. Eng. Comput. Sci. 2013, 21, 1260–1271. [Google Scholar] [CrossRef]

- Ahmad, M.A.; Ismail, R.M.T.R.; Ramli, M.S. Control strategy of Buck converter driven DC motor: A comparative assessment. Austral. J. Basic Appl. Sci. 2010, 14, 4893–4903. [Google Scholar]

- Bingöl, O.; Paçaci, S. A virtual laboratory for neural network controlled DC motors based on a DC-DC Buck converter. Int. J. Eng. Educ. 2012, 28, 713–723. [Google Scholar]

- Sira-Ramírez, H.; Oliver-Salazar, M.A. On the robust control of Buck-converter DC-motor combinations. IEEE Trans. Power Electron. 2013, 28, 3912–3922. [Google Scholar] [CrossRef]

- Silva-Ortigoza, R.; García-Sánchez, J.R.; Alba-Martínez, J.M.; Hernández-Guzmán, V.M.; Marcelino-Aranda, M.; Taud, H.; Bautista-Quintero, R. Two-stage control design of a Buck converter/DC motor system without velocity measurements via a Σ-Δ-modulator. Math. Probl. Eng. 2013, 2013, 1–11. [Google Scholar] [CrossRef]

- Silva-Ortigoza, R.; Márquez-Sánchez, C.; Carrizosa-Corral, F.; Antonio-Cruz, M.; Alba-Martínez, J.M.; Saldaña-González, G. Hierarchical velocity control based on differential flatness for a DC/DC Buck converter-DC motor system. Math. Probl. Eng. 2014, 2014. [Google Scholar] [CrossRef]

- Silva-Ortigoza, R.; Hernández-Guzmán, V.M.; Antonio-Cruz, M.; Muñoz-Carrillo, D. DC/DC Buck power converter as a smooth starter for a DC motor based on a hierarchical control. IEEE Trans. Power Electron. 2015, 30, 1076–1084. [Google Scholar] [CrossRef]

- Kumar, S.G.; Thilagar, S.H. Sensorless load torque estimation and passivity based control of Buck converter fed DC motor. Sci. World J. 2015, 2015. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Guzmán, V.M.; Silva-Ortigoza, R.; Muñoz-Carrillo, D. Velocity control of a brushed DC–motor driven by a DC to DC Buck power converter. Int. J. Innov. Comp. Inf. Control 2015, 11, 509–521. [Google Scholar]

- Khubalkar, S.; Chopade, A.; Junghare, A.; Aware, M.; Das, S. Design and realization of stand-alone digital fractional order PID controller for Buck converter fed DC motor. Circuits Syst. Signal Process. 2016, 35, 2189–2211. [Google Scholar] [CrossRef]

- Rigatos, G.; Siano, P.; Wira, P.; Sayed-Mouchaweh, M. Control of DC-DC converter and DC motor dynamics using differential flatness theory. Intell. Ind. Syst. 2016, 2, 371–380. [Google Scholar] [CrossRef]

- Nizami, T.K.; Chakravarty, A.; Mahanta, C. Design and implementation of a neuro-adaptive backstepping controller for Buck converter fed PMDC-motor. Control Eng. Pract. 2017, 58, 78–87. [Google Scholar] [CrossRef]

- Linares-Flores, J.; Reger, J.; Sira-Ramírez, H. Load torque estimation and passivity-based control of a Boost-converter/DC-motor combination. IEEE Trans. Control Syst. Technol. 2010, 18, 1398–1405. [Google Scholar] [CrossRef]

- Alexandridis, A.T.; Konstantopoulos, G.C. Modified PI speed controllers for series-excited DC motors fed by DC/DC Boost converters. Control Eng. Pract. 2014, 23, 14–21. [Google Scholar] [CrossRef]

- Konstantopoulos, G.C.; Alexandridis, A.T. Enhanced control design of simple DC-DC Boost converter-driven DC motors: Analysis and implementation. Electr. Power Compon. Syst. 2015, 43, 1946–1957. [Google Scholar] [CrossRef]

- Sönmez, Y.; Dursun, M.; Güvenç, U.; Yilmaz, C. Start up current control of Buck-Boost convertor-fed serial DC motor. Pamukkale Univ. J. Eng. Sci. 2009, 15, 278–283. [Google Scholar]

- Linares-Flores, J.; Barahona-Avalos, J.L.; Sira-Ramírez, H.; Contreras-Ordaz, M.A. Robust passivity-based control of a Buck-Boost-converter/DC–motor system: An active disturbance rejection approach. IEEE Trans. Ind. Appl. 2012, 48, 2362–2371. [Google Scholar] [CrossRef]

- Jiménez-Toribio, E.E.; Labour-Castro, A.A.; Muñiz-Rodríguez, F.; Pérez-Hernández, H.R.; Ortiz-Rivera, E.I. Sensorless control of Sepic and Ćuk converters for DC motors using solar panels. In Proceedings of the IEEE International Electric Machines and Drives Conference, IEMDC 2009, Miami, FL, USA, 3–6 May 2009; pp. 1503–1510. [Google Scholar]

- Silva-Ortigoza, R.; Alba-Juárez, J.N.; García-Sánchez, J.R.; Antonio-Cruz, M.; Hernández-Guzmán, V.M.; Taud, H. Modeling and Experimental Validation of a Bidirectional DC/DC Buck Power Electronic Converter-DC Motor System. IEEE Latin Am. Trans. 2017, 15, 1043–1051. [Google Scholar] [CrossRef]

- Silva-Ortigoza, R.; Alba-Juárez, J.N.; García-Sánchez, J.R.; Hernández-Guzmán, V.M.; Sosa-Cervantes, C.Y.; Taud, H. A sensorless passivity-based control for the DC/DC Buck converter–inverter–DC motor system. IEEE Latin Am. Trans. 2016, 14, 4227–4234. [Google Scholar] [CrossRef]

- Hernández-Márquez, E.; García-Sánchez, J.R.; Silva-Ortigoza, R.; Antonio-Cruz, M.; Hernández-Guzmán, V.M.; Taud, H.; Marcelino-Aranda, M. Bidirectional tracking robust controls for a DC/DC Buck converter-DC motor system. Complexity 2018, in press. [Google Scholar]

- García-Rodríguez, V.H.; Silva-Ortigoza, R.; Hernández-Márquez, E.; García-Sánchez, J.R.; Taud, H. DC/DC Boost converter–inverter as driver for a DC motor: Modeling and experimental verification. Energies 2018, 11, 2044. [Google Scholar] [CrossRef]

- Silva-Ortigoza, R.; García-Rodríguez, V.H.; Hernández-Márquez, E.; Ponce, M.; García-Sánchez, J.R.; Alba-Juárez, J.N.; Silva-Ortigoza, G.; Pérez, H.J. A trajectory tracking control for a Boost converter–inverter–DC motor combination. IEEE Latin Am. Trans. 2018, 16, 1008–1014. [Google Scholar] [CrossRef]

- Hernández-Márquez, E.; Silva-Ortigoza, R.; García-Sánchez, J.R.; García-Rodríguez, V.H.; Alba-Juárez, J.N. A new “DC/DC Buck-Boost converter–DC motor” system: Modeling and experimental validation. IEEE Latin Am. Trans. 2017, 15, 2043–2049. [Google Scholar] [CrossRef]

- Hernández-Márquez, E.; Silva-Ortigoza, R.; García-Sánchez, J.R.; Marcelino-Aranda, M.; Saldaña-González, G. A DC/DC Buck-Boost converter–inverter–DC motor system: Sensorless passivity-based control. IEEE Access 2018, 6, 31486–31492. [Google Scholar] [CrossRef]

- Hernández-Guzmán, V.M.; Antonio-Cruz, M.; Silva-Ortigoza, R. Linear state feedback regulation of a Furuta pendulum: Design based on differential flatness and root locus. IEEE Access 2016, 4, 8721–8736. [Google Scholar] [CrossRef]

- Antonio-Cruz, M.; Hernández-Guzmán, V.M.; Silva-Ortigoza, R. Limit cycle elimination in inverted pendulums: Furuta pendulum and pendubot. IEEE Access 2018, 6, 30317–30332. [Google Scholar] [CrossRef]

- Márquez-Sánchez, C.; Silva-Ortigoza, R.; García-Sánchez, J.R.; Hernández-Guzmán, V.M.; Antonio-Cruz, M.; Marcelino-Aranda, M.; Silva-Ortigoza, G. An embedded hardware for implementation of a tracking control in WMRs. IEEE Latin Am. Trans. 2018, 16, 1835–1842. [Google Scholar] [CrossRef]

- Sira-Ramírez, H.; Agrawal, S.K. Differentially Flat Systems; Marcel Dekker: New York, NY, USA, 2004; ISBN 0-8247-5470-0. [Google Scholar]

- Sira-Ramírez, H.; Lischinsky-Arenas, P. Differential algebraic approach in non-linear dynamical compensator design for d.c.-to-d.c. power converters. Int. J. Control 1991, 54, 111–133. [Google Scholar] [CrossRef]

- Sira-Ramírez, H.; Silva-Ortigoza, R. Control Design Techniques in Power Electronics Devices; Springer: London, UK, 2006; ISBN 978-1-84628-458-8. [Google Scholar]

- Hernández-Márquez, E.; Silva-Ortigoza, R.; García-Sánchez, J.R.; Antonio-Cruz, M.; Taud, H.; Carrizosa-Corral, F.; Marcelino-Aranda, M. Alternative mathematical models for the DC/DC Buck-Boost converter. In Proceedings of the 2017 International Conference on Mechatronics, Electronics and Automotive Engineering, ICMEAE 2017, Cuernavaca, Mexico, 21–24 November 2017; pp. 104–107. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Márquez, E.; Avila-Rea, C.A.; García-Sánchez, J.R.; Silva-Ortigoza, R.; Silva-Ortigoza, G.; Taud, H.; Marcelino-Aranda, M. Robust Tracking Controller for a DC/DC Buck-Boost Converter–Inverter–DC Motor System. Energies 2018, 11, 2500. https://doi.org/10.3390/en11102500

Hernández-Márquez E, Avila-Rea CA, García-Sánchez JR, Silva-Ortigoza R, Silva-Ortigoza G, Taud H, Marcelino-Aranda M. Robust Tracking Controller for a DC/DC Buck-Boost Converter–Inverter–DC Motor System. Energies. 2018; 11(10):2500. https://doi.org/10.3390/en11102500

Chicago/Turabian StyleHernández-Márquez, Eduardo, Carlos Alejandro Avila-Rea, José Rafael García-Sánchez, Ramón Silva-Ortigoza, Gilberto Silva-Ortigoza, Hind Taud, and Mariana Marcelino-Aranda. 2018. "Robust Tracking Controller for a DC/DC Buck-Boost Converter–Inverter–DC Motor System" Energies 11, no. 10: 2500. https://doi.org/10.3390/en11102500