Performance Characteristics of Solid-Desiccant Evaporative Cooling Systems

Abstract

:1. Introduction

2. Solid-Desiccant Evaporative Cooling System—Overview

3. Computer Modeling Analysis of System Performance

3.1. Computer Modelling Setup

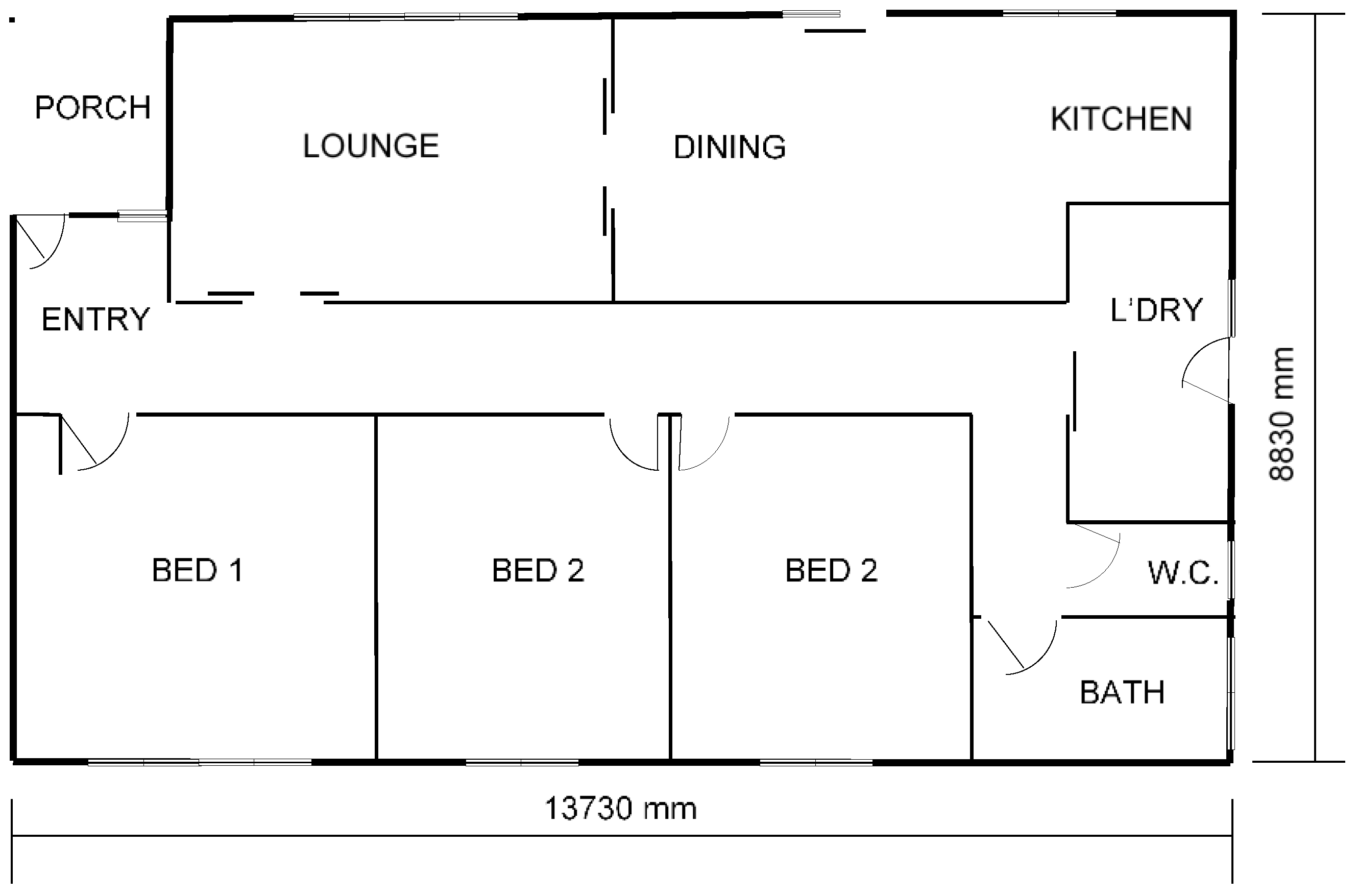

3.2. Reference House

3.3. Room Set Point Temperature-Design Indoor Temperature

4. Results and Discussion

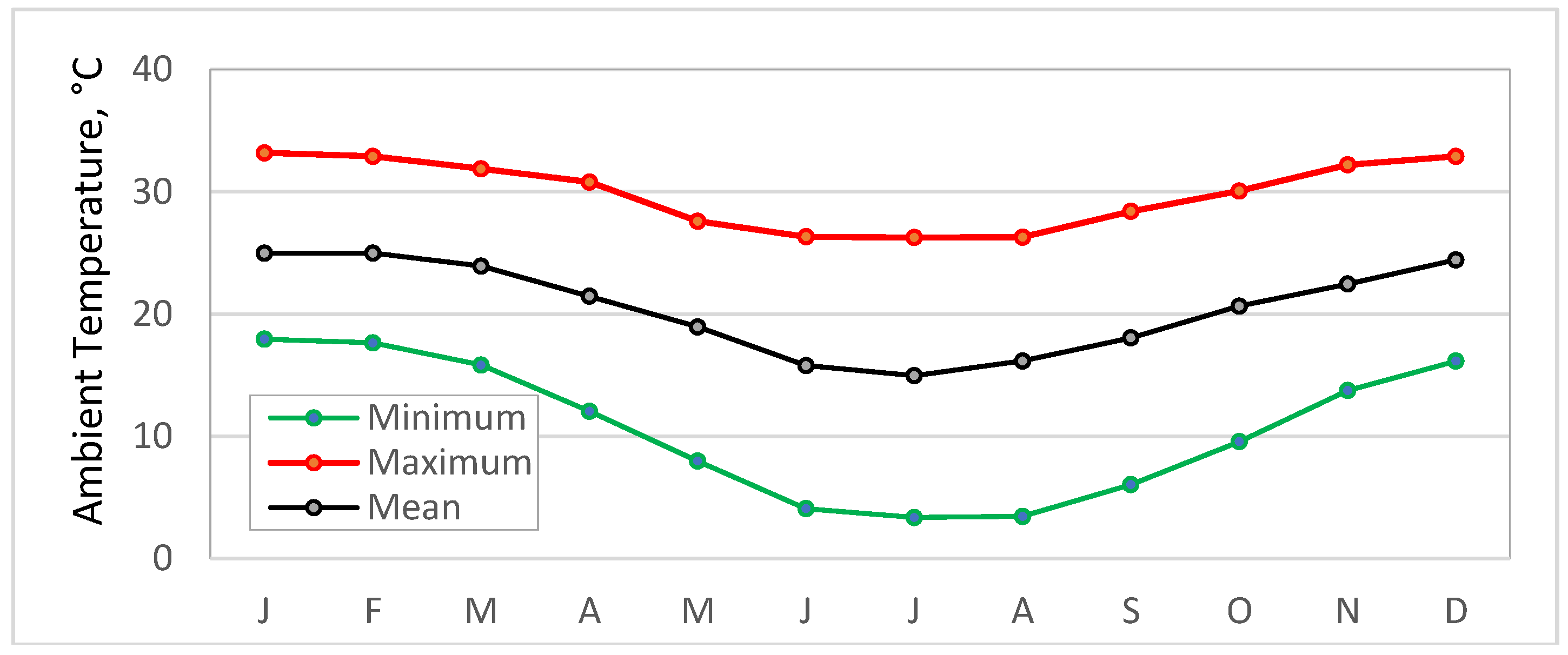

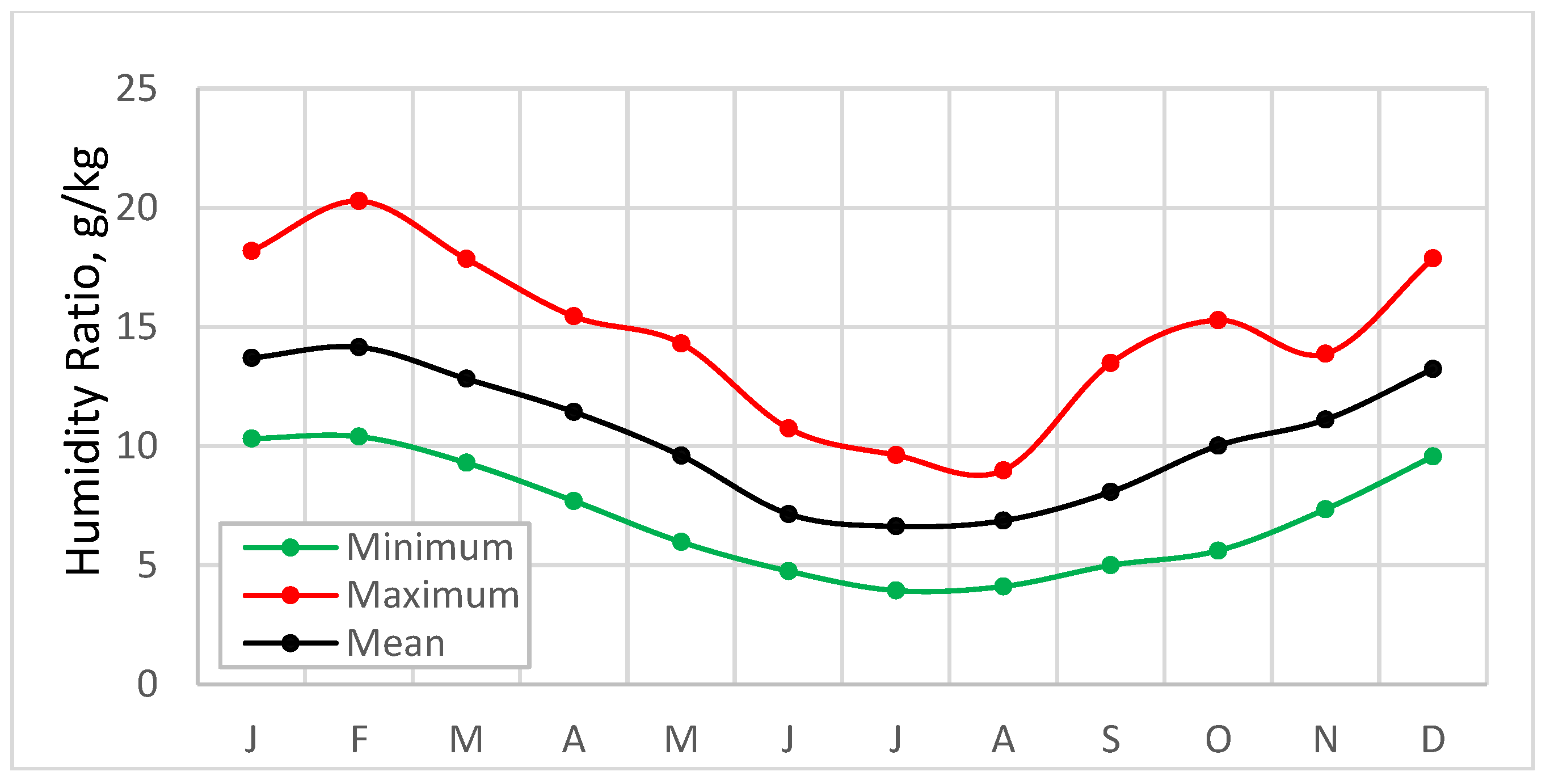

4.1. Temperature, Humidity, and Irradiance Profiles

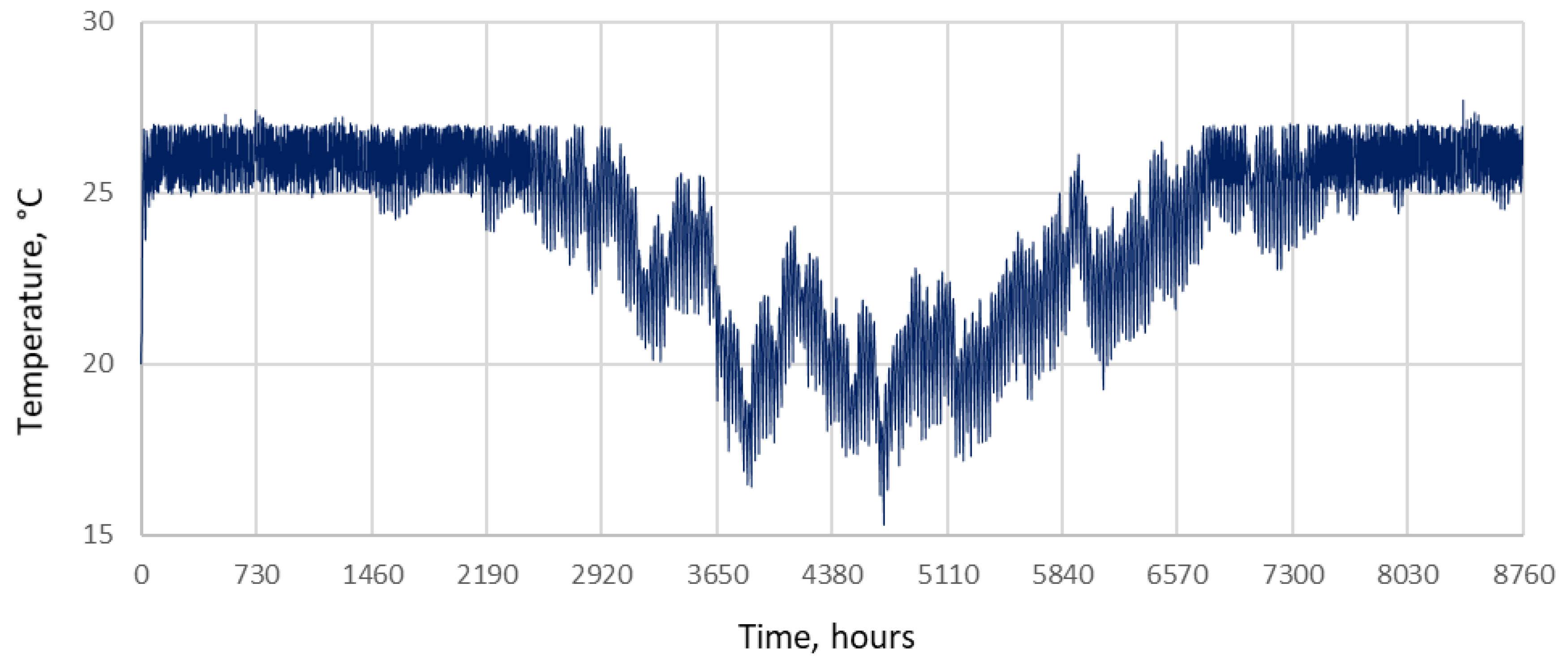

4.2. Living-Room and Bedroom Temperature and Humidity Profiles

4.3. Cooling-Energy Demand

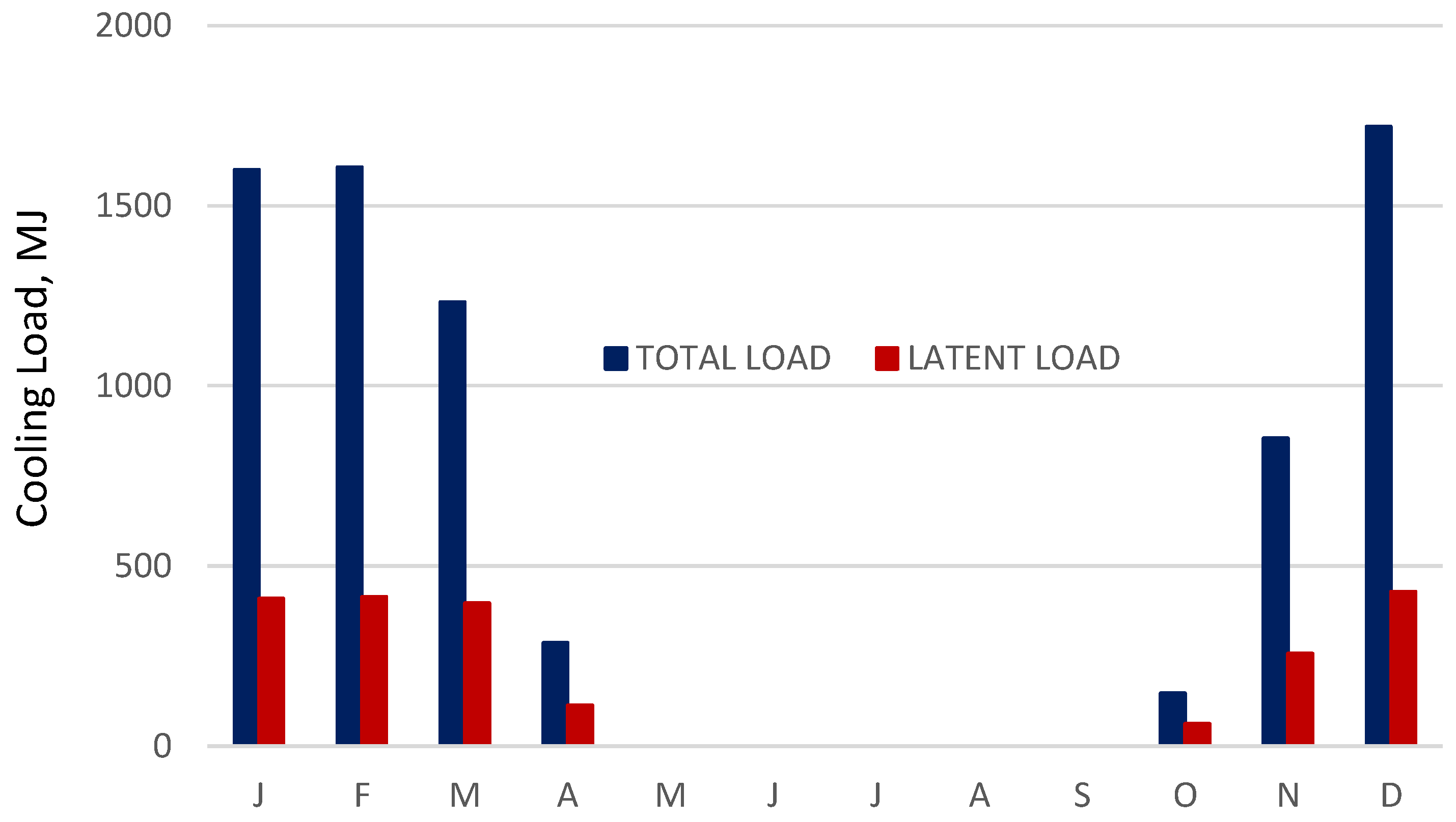

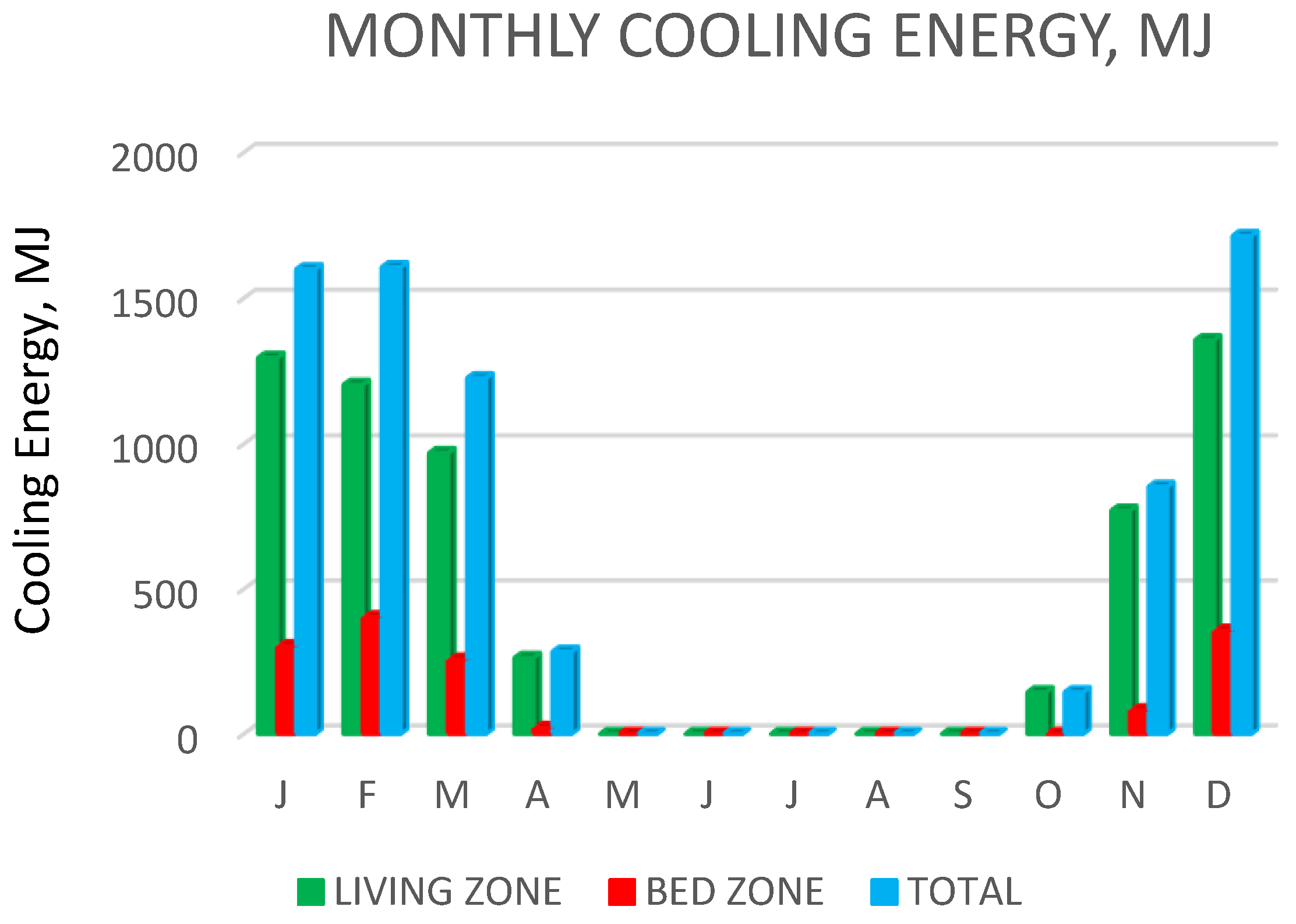

4.3.1. Cooling Demand During Normal Operation

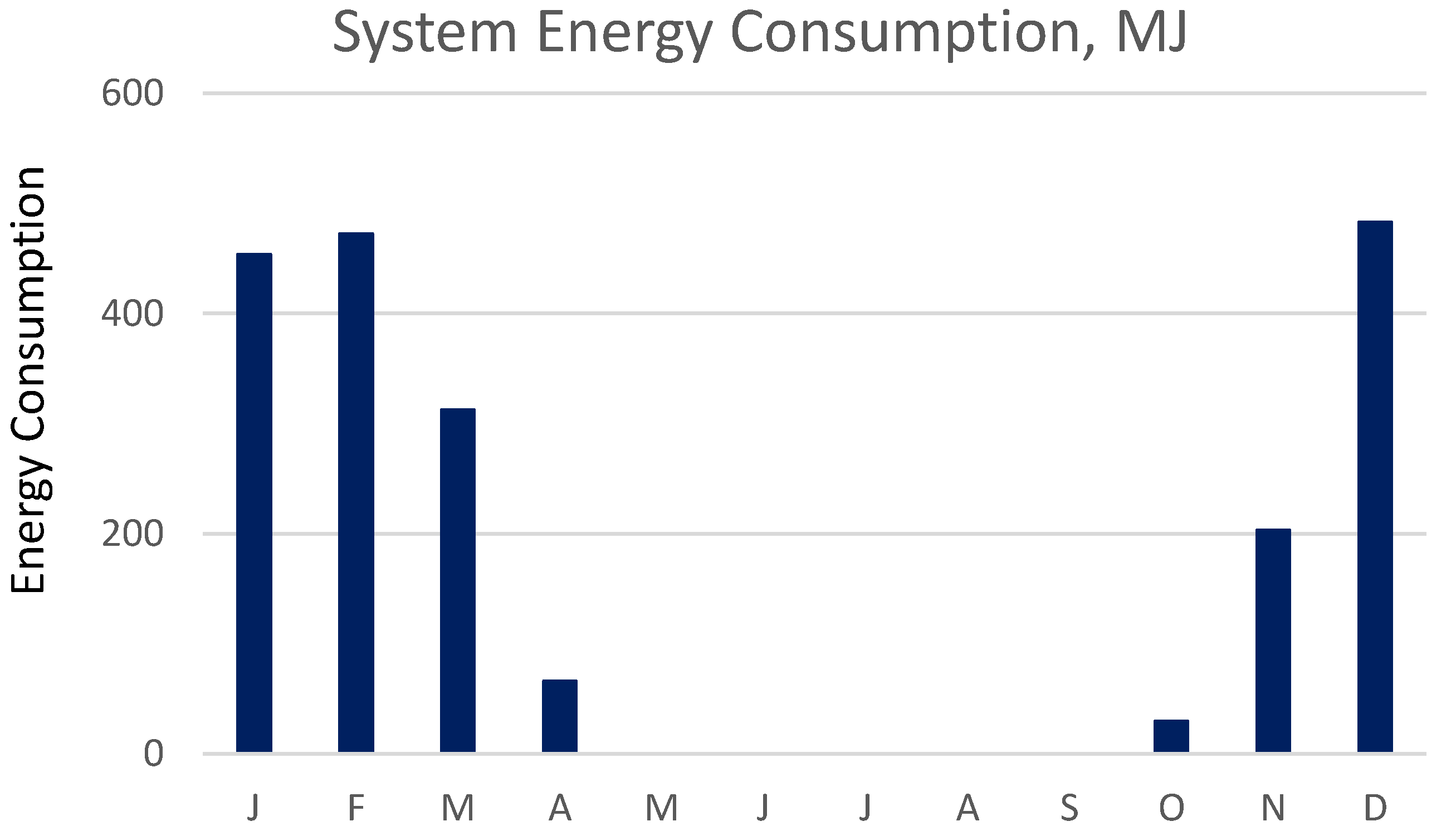

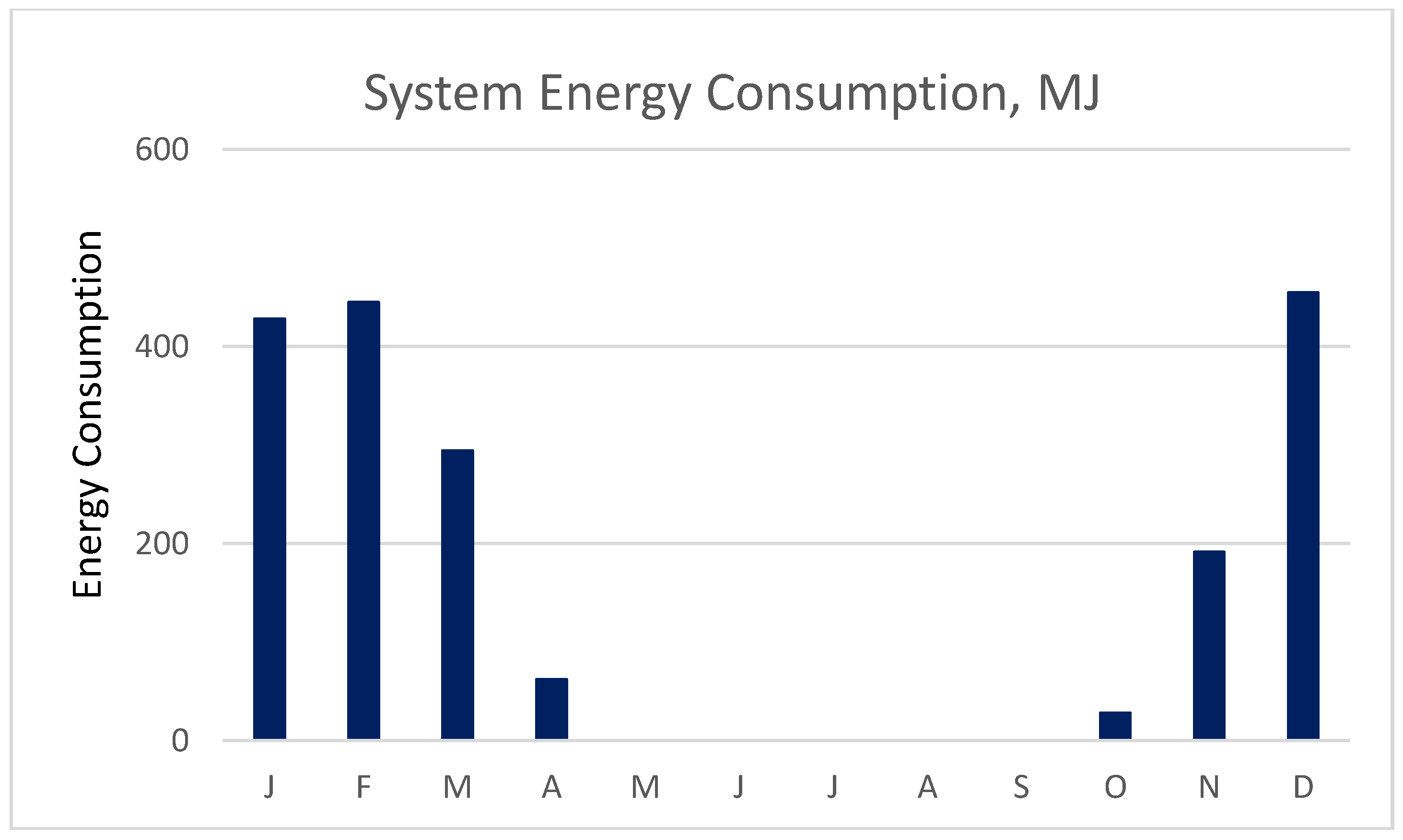

4.3.2. System’s Electrical Energy Consumption

4.3.3. Humidity Levels in Air-Conditioned Spaces

4.3.4. Impact of the Economy Cycle on Cooling Energy Consumption and Comfort

5. Conclusions and Recommendations

- The study based on the TRNSYS supplied weather data, which seem confirmed by other observations, found that the sensible cooling demand is the predominant load, while the monthly latent load during the cooling periods represents about 20% of the total cooling load. This, however, is still significant in terms of providing comfort to the occupants of the house.

- The number of hours where plots of humidity ratio vs. temperature are within the comfort zone during the cooling season are quite significant. During these hours, occupants can rely on the natural ventilation or economy cycle for thermal provision by allowing outside air entering the room though open windows or doors.

- Likewise, the number of hours where plots of humidity ratio vs. temperature are outside the comfort zone during the cooling season are equally quite significant. During most of these hours, the proposed desiccant evaporative cooling system can technically provide thermal comfort, and its thermal performance is comparable to refrigerative cooling systems. Specifically, the following is the summary of the findings:

- -

- About half of the plots of temperature vs. humidity ratio during system operation fall beyond the upper acceptable boundary. The system’s capability to provide suitable temperature and humidity air levels supplied to the room is dependent on the performance of ‘exhaust components’ of the systems, namely, the evaporative cooling system, energy-recovery system, and heat-regeneration system.

- -

- The heat required to regenerate the desiccant on the exhaust side can be quite significant. Therefore, the availability of a cheap or waste-heat source is essential in making this system economically viable.

- -

- It is observed that the admission of some return air to the conditioned space, as normally practiced in conventional cooling systems to save energy, seems to have some, albeit limited, benefit in this system. This is because while the return air reduced the system’s burden on the supply side in terms of temperature and humidity, the exhaust side requires raising the temperature for regeneration purposes. In this particular study, the optimum ratio of return air and supply admitted to the room and that which returns to the exhaust side for treatment is 50:50.

- -

- For the Brisbane climate, the introduction of an economy cycle seems to not be very prospective since periods in which it is applicable are mostly at night, when people may be expected to opt for natural ventilation.

- The values of some of the parameters can significantly affect system performance, especially the humidity level of the conditioned space. These include saturation effectiveness of the evaporative cooler and the energy-recovery device. The proper selection of these values should be considered in the design stage of the system.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kohlenbach, P.; Dennis, M. Solar Cooling in Australia: The Future of Air Conditioning? Ecolibrium 2010, 12, 32–38. [Google Scholar]

- Narayanan, R. Developmnet of a Thermally-Driven Solid Desiccnat System for Dehumidification Cooling. Ph.D. Thesis, University of South Australia, Adelaide, Australia, 2012. [Google Scholar]

- Saman, W.; Halawa, E. NATHERS-Peak Load Performance Module Research; Institute of Sustainable Systems and Technologies: Adelaide, Australia, 2009. [Google Scholar]

- Piccolo, A.; Siclari, R.; Rando, F.; Cannistraro, M. Comparative Performance of Thermoacoustic Heat Exchanges with Different Pore Geometries in Oscillatory Flow. Implementation of Experimental Techniques. Appl. Sci. 2017, 7, 784. [Google Scholar] [CrossRef]

- American Society of Heating Refrigerating and Air-Conditioning Engineers. Green Guide-Design, Construction and Operation of Sustainable Buildings; American Society of Heating, Refrigerating and Air-Conditioning Engineers: New York City, NY, USA, 2010. [Google Scholar]

- Henning, H.M. Solar assisted air conditioning of buildings—An overview. Appl. Therm. Eng. 2007, 27, 1734–1749. [Google Scholar] [CrossRef]

- Narayanan, R.; Saman, W.Y.; White, S.D.; Goldsworthy, M. Comparative study of different desiccant wheel designs. Appl. Therm. Eng. 2011, 31, 1613–1620. [Google Scholar] [CrossRef]

- Narayanan, R. Heat-Driven Cooling Technologies. In The Clean Energy for Sustainable Development: Comparisons and Contrasts of New Approaches; Elsevier: London, UK, 2017; Chapter 7; pp. 191–212. [Google Scholar]

- Narayanan, R.; Saman, W.Y.; White, S.D.; Goldsworthy, M. Modeling and Parametric Analysis of Silica-gel Desiccant Wheels. In Proceedings of the International Institute of Refrigeration Gustav Lorentzen Conference, Sydney, Australia, 12–14 April 2010. [Google Scholar]

- Balaras, C.A.; Grossman, G.; Henning, H.M.; Infante Ferreira, C.A.; Podesser, E.; Wang, L.; Wiemken, E. Solar air conditioning in Europe-An overview. Renew. Sustain. Energy Rev. 2007, 11, 299–314. [Google Scholar] [CrossRef]

- Narayanan, R. Investigation of geometry effects of channels of a silica-gel desiccant wheel. Energy Procedia 2017, 110, 20–25. [Google Scholar] [CrossRef]

- Saman, W.; Bruno, F.; Tay, S. Technical Research on Evaporative Air Conditioners and Feasibility of Rating and their Energy Performance; Technical Report for SA Department for Transport, Energy and Infrastructure: Adelaide, Australia, 2010. [Google Scholar]

- Parsons, R. Ashrae Handbook Fundamentals; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2005. [Google Scholar]

- Saman, W.; Bruno, F.; Liu, M. Technical Background Research on Evaporative Air Conditioners and Feasibility of Rating Their Water Consumption; University of South Australia: Adelaide, Australia, 2009. [Google Scholar]

- Brisbane, Queensland. Available online: http://www.weatherbase.com/weather/weather-summary.php3?s=87549&cityname=Brisbane,+Queensland,+Australia&units (accessed on 14 April 2018).

- Ma, Y.; Guan, L.; Brown, R. Techno-economic Analysis of a Solar Desiccant-Evaporative Cooling System with Different Collector Types for Australian Office Buildings. In Proceedings of the 2015 Asia-Pacific Solar Research Conference, Sydney, Australia, 4–6 December 2015. [Google Scholar]

- Ma, Y.; Saha, S.C.; Miller, W.; Guan, L. Comparison of Different Solar-Assisted Air Conditioning Systems for Australian Office Buildings. Energies 2017, 10, 1463. [Google Scholar] [CrossRef]

- Narayanan, R.; Saman, W.; White, S.D. A non-adiabatic desiccant wheel: Modeling and experimental validation. Appl. Therm. Eng. 2013, 61, 178–185. [Google Scholar] [CrossRef]

- A Transient Systems Simulation Program. Available online: http://sel.me.wisc.edu/trnsys (accessed on 22 September 2018).

- Delsante, A.E. Computer User Manual for Program Cheetah: A Thermal Design Tool for Small Buildings; Commonwealth Scientific and Industrial Research Organisation: Canberra, Australia, 1987. [Google Scholar]

- Vakilaltojjar, S.M. Phase Change Thermal Storage System for Space Heating and Cooling. Ph.D. Thesis, University of South Australia, Adelaide, Australia, 2012. [Google Scholar]

- Halawa, E. Thermal Performance Analysis of a Roof Integrated Solar Heating System Incorporating Phase Change Thermal Storage. Ph.D. Thesis, University of South Australia, Adelaide, Australia, 2005. [Google Scholar]

- ASHRAE Inc. ANSI/ASHRAE Standard 55, Thermal Environmental Conditions for Human Occupancy; ASHRAE Inc.: Atlanta, GE, USA, 2010. [Google Scholar]

- The Australian Institute of Refrigeration Air Conditioning and Heating. Design Guide DA20 Humid Tropical Air Conditioning; The Australian Institute of Refrigeration Air Conditioning and Heating: Melbourne, Australia, 2017. [Google Scholar]

- AS 2913-2000: Evaporative Air Conditioning Equipment–Standards Australia. Available online: https://www.saiglobal.com/PDFTemp/Previews/OSH/as/as2000/2900/2913.pdf (accessed on 20 September 2018).

- Skills Workshop—HVAC and R Optimisation—Ventilation and airflow, Part 1 of 2—VAC and R Nation. Available online: www.hvacrnation.com.au (accessed on 22 September 2015).

| °C | 35 | 53 | 27 | 20 | Temp | |||||

| → | DW | → | ERW | → | DEC | → | Sup. Side | |||

| g/kg | 11 | 6 | 6 | 8.5 | Humidity Ratio | |||||

| °C | 48 | 75 | 45 | 20 | 27 | Temp | ||||

| ← | DW | ← | REG | ← | ERW | ← | DE | ← | Exhaust | |

| g/kg | 19 | 13 | 13 | 13 | 11 | Hum | ||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narayanan, R.; Halawa, E.; Jain, S. Performance Characteristics of Solid-Desiccant Evaporative Cooling Systems. Energies 2018, 11, 2574. https://doi.org/10.3390/en11102574

Narayanan R, Halawa E, Jain S. Performance Characteristics of Solid-Desiccant Evaporative Cooling Systems. Energies. 2018; 11(10):2574. https://doi.org/10.3390/en11102574

Chicago/Turabian StyleNarayanan, Ramadas, Edward Halawa, and Sanjeev Jain. 2018. "Performance Characteristics of Solid-Desiccant Evaporative Cooling Systems" Energies 11, no. 10: 2574. https://doi.org/10.3390/en11102574