Digitisation and the Circular Economy: A Review of Current Research and Future Trends

Abstract

:1. Introduction

1.1. Background of Study

1.1.1. The Circular Economy

1.1.2. Industry 4.0

1.2. Relevance of the Theme

1.3. Contributions of Review Papers

1.4. Problem Description

1.5. Research Question and Novelty of Research

- How can the synthesis of digital technologies with circular approaches support I4.0 in enabling the transition towards a CE?

- How can a synergistic and integrative CE-DT framework offer direction for policymakers and industrialists and guidance to academia for future CE-I4.0 research?

1.6. Objective of Paper

- To provide a precise investigation of the development of Industry 4.0 and CE in research by conducting a systematic literature review integrating key terms from CE and I4.0.

- To identify trends and gaps from the systematic literature review and research to develop a synergistic and integrative framework to provide an overview for future research.

- To present identified suggestions to academia, industry, and policymakers for future CE-I4.0 research.

- As I4.0 contains a variety and growing number of sub-groups, domains, and technologies [28,50] and the CE possesses a number of approaches (Reuse, Reduce, Remanufacturing, Recycling, Repurpose, Recover, Repair, Refurbish, and Refuse) [11], it is important to refer to key concepts relating to I4.0 and CE in order to synthesize and build a consistent and integrative framework.

- As I4.0 domains and technologies advance, their uses within the CE increase further.

1.7. Structure of Paper

2. Review Methodology

3. Paper Selection Methodology

4. Descriptive Analysis of the Literature

4.1. Circular Economy Papers Across Period under Review

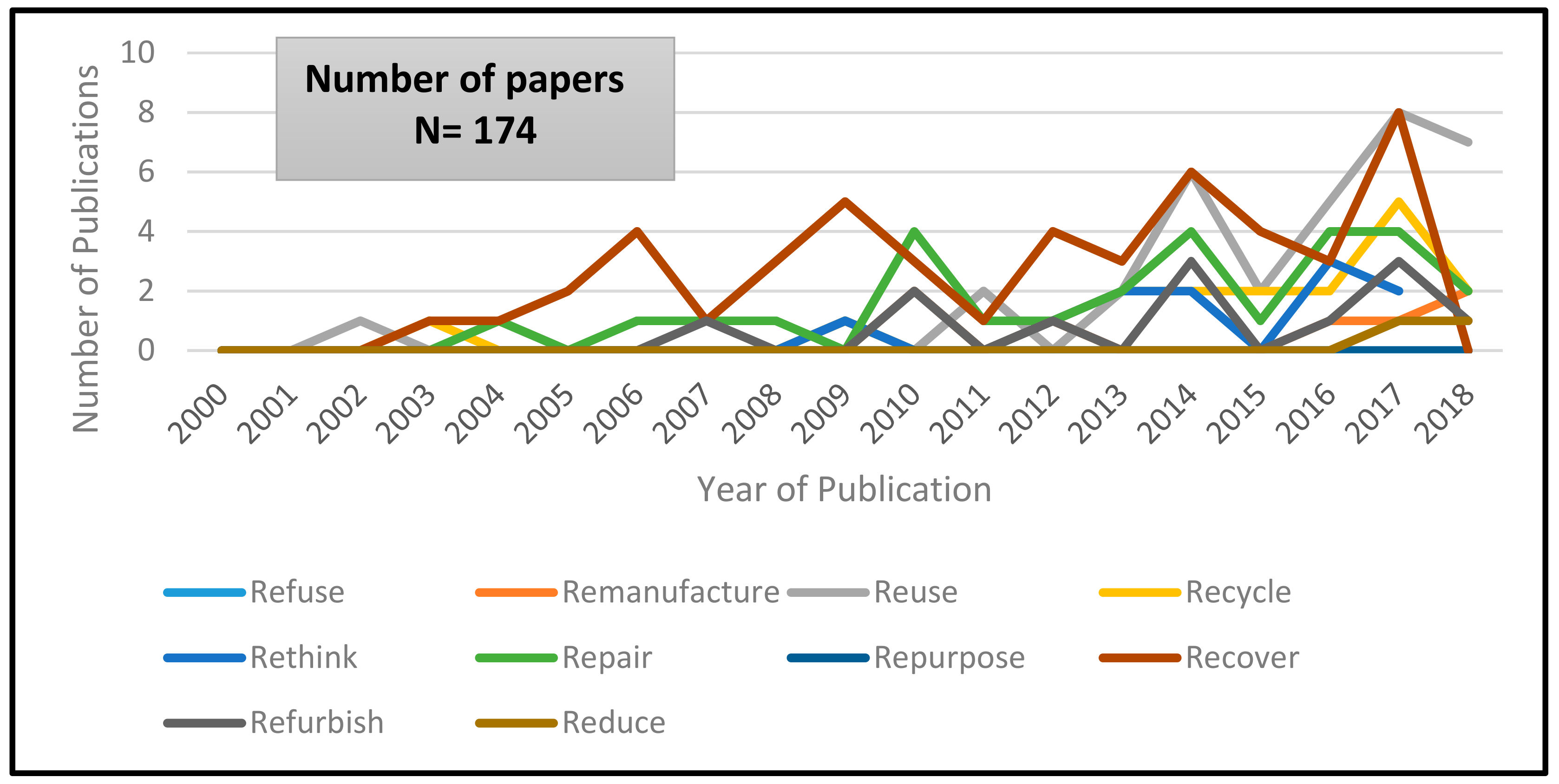

4.2. Circular Approaches Papers Across Years of Publication

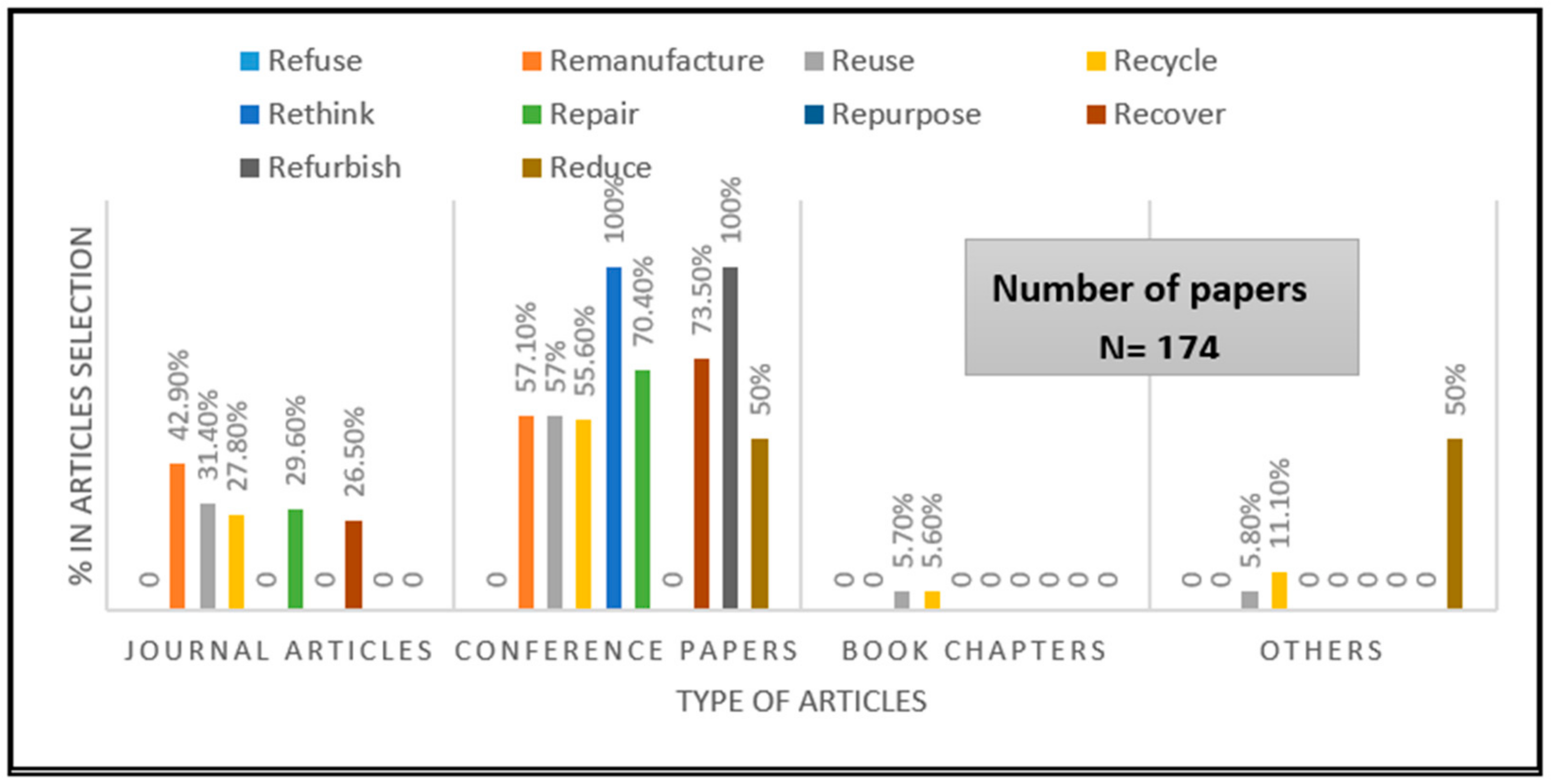

4.3. Papers across Journals and Conference Papers

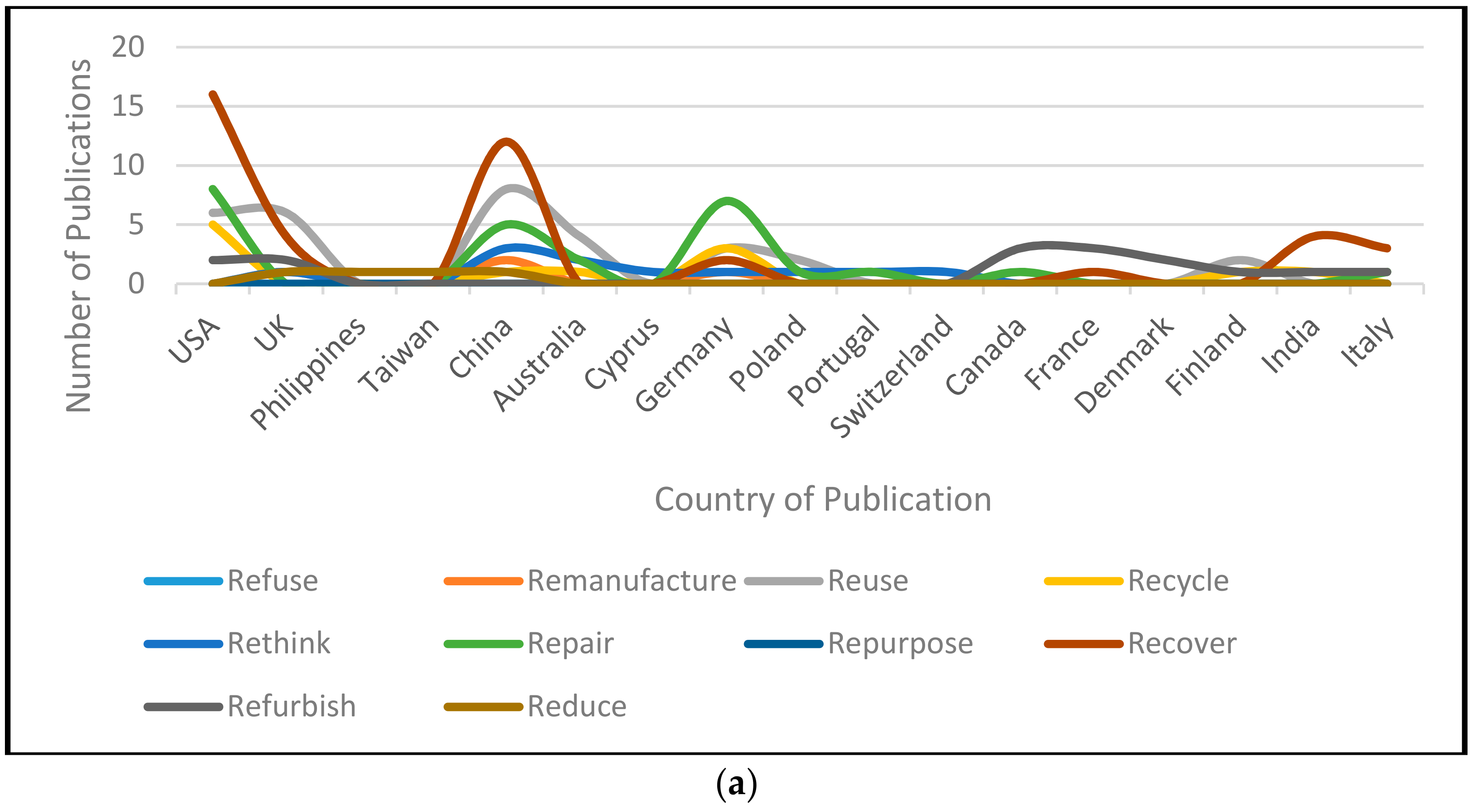

4.4. Papers by Geographical Distribution

4.5. Papers Across Subject Area

5. Content Analysis and Framework Design

5.1. Analyzing the Aspect of Multidisciplinary Research in I4.0 for CE Research

5.2. Industry 4.0 and Digital Technologies

5.3. Analysis of Trend by Means of Technology Life Cycle (TLC)

5.4. Technological Infrastructure Important for a CE-DT Integration

5.5. Digital Intelligence to Enable a CE-I4.0 Integration

6. Conclusions

6.1. Implication for Academia, Policy Makers, Industry and End-Users

6.2. Research Conclusions

6.3. Limitations and Recommendations for Future Study

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sachs, J. The Age of Sustainable Development; Columbia University Press: New York, NY, USA, 2015. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Meadows, D.H.; Randers, J.; Meadows, D.L. The Limits to Growth: The 30-Year Update; Routledge: London, UK, 2009. [Google Scholar]

- Jackson, T. Prosperity without Growth: Economics for a Finite Planet; Earthscan: London, UK; New York, NY, USA, 2009. [Google Scholar]

- Banerjee, A.; Duflo, E. Poor Economics: A Radical Rethinking of the Way to Fight Global Poverty; PublicAffairs: New York, NY, USA, 2011. [Google Scholar]

- Clark, W.C.; Crutzen, P.J.; Schellnhuber, H.J. Science for Global Sustainability: Toward a New Paradigm. CID Working Paper No. 120. 2005. Available online: http://www.cid.harvard.edu/cidwp/120.htm (accessed on 3 October 2018).

- Rockstrom, J.; Steffen, W.; Noone, K.; Persson, A.; Chapin, F.S., III; Lambin, E.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.; et al. Planetary boundaries: Exploring the safe operating space for humanity. Ecol. Soc. 2009, 14, 32. [Google Scholar] [CrossRef]

- Esposito, M.; Tse, T.; Soufani, K. Introducing a Circular Economy: New Thinking with New Managerial and Policy Implications. Calif. Manag. Rev. 2018, 60, 5–19. [Google Scholar] [CrossRef]

- Sauvé, S.; Bernard, S.; Sloan, P. Environmental Sciences, Sustainable Development and Circular Economy: Alternative concepts for trans-disciplinary research. Environ. Dev. 2015, 17, 48–56. [Google Scholar] [CrossRef]

- Siegel, A.; Bautista, R. Retail Horizons: Envisioning the Future of the Retail Industry; Forum for the Future and Retail Industry Leaders Association: Arlington, VA, USA, 2014. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Ormazabal, M.; Prieto-Sandoval, V.; Puga-Leal, R.; Jaca, C. Circular Economy in Spanish SMEs: Challenges and opportunities. J. Clean. Prod. 2018, 185, 157–167. [Google Scholar] [CrossRef]

- De Vries, B.J.M.; Petersen, A.C. Conceptualizing sustainable development. An assessment methodology connecting values, knowledge, worldviews and scenarios. Ecol. Econ. 2009, 68, 1006–1019. [Google Scholar] [CrossRef]

- Gladek, E. The Seven Pillars of the Circular Economy. Available online: https://www.greenbiz.com/article/7-pillars-circular-economy (accessed on 30 September 2018).

- Lieder, M.; Asif, F.M.A.; Rashid, A. Towards Circular Economy implementation: An agent-based simulation approach for business model changes. Auton. Agents Multi-Agent Syst. 2017, 31, 1377–1402. [Google Scholar] [CrossRef]

- Nobre, G.C.; Tavares, E. Scientific literature analysis on big data and internet of things applications on circular economy: A bibliometric study. Scientometrics 2017, 111, 463–492. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Pearce, D.; Turner, K. Economics of Natural Resources and the Environment; Johns Hopkins University Press: Baltimore, MD, USA, 1990; 378p, Available online: https://books.google.co.uk/books/about/Economics_of_Natural_Resources_and_the_E.html?id=ex8vaG6m4RMC&redir_esc=y (accessed on 30 September 2018).

- Lacy, P.; Rutqvist, J. Waste to Wealth; Palgrave Macmillan: Basingstoke, UK, 2016; p. 159. [Google Scholar]

- Lund, R.T. Remanufacturing: The Experience of the United States and Implications for Developing Countries; World Bank: Washington, DC, USA, 1984; 126p, Available online: http://documents.worldbank.org/curated/en/792491468142480141/Remanufacturing-the-experience-of-the-United-States-and-implications-for-developing-countries (accessed on 30 September 2018).

- Yuan, Z.; Bi, J.; Moriguichi, Y. The Circular Economy: A New Development Strategy in China. J. Ind. Ecol. 2006, 10, 4–8. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Jaca, C.; Ormazabal, M. Towards a consensus on the circular economy. J. Clean. Prod. 2018, 179, 605–615. [Google Scholar] [CrossRef]

- Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013.

- Hunt, R. Design for a Circular Economy in Industry 4.0. In Designing for the Circular Economy; Charter, M., Ed.; Routledge: London, UK, 2018; pp. 221–231. [Google Scholar]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Wang, L.; Törngren, M.; Onori, M. Current status and advancement of cyber-physical systems in manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Thames, L.; Schaefer, D. Software-defined Cloud Manufacturing for Industry 4.0. Procedia CIRP 2016, 52, 12–17. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.D.F.R.; Ramos, L.F.P. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Kagermann, H. Change Through Digitization—Value Creation in the Age of Industry 4.0. In Management of Permanent Change; Albach, H., Meffert, H., Pinkwart, A., Ralf, R., Eds.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2015; pp. 23–32. [Google Scholar]

- Shamim, S.; Cang, S.; Yu, H.; Li, Y. Examining the feasibilities of Industry 4.0 for the hospitality sector with the lens of management practice. Energies 2017, 10, 499. [Google Scholar] [CrossRef]

- Tsai, W.-H. Green production planning and control for the textile industry by using mathematical programming and industry 4.0 techniques. Energies 2018, 11, 2072. [Google Scholar] [CrossRef]

- Bányai, T. Real-Time Decision Making in First Mile and Last Mile Logistics: How Smart Scheduling Affects Energy Efficiency of Hyperconnected Supply Chain Solutions. Energies 2018, 11, 1833. [Google Scholar] [CrossRef]

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). IPCC Special Report on the Impacts of Global Warming of 1.5 °C—Summary for Policy Makers. October 2018. Available online: http://www.ipcc.ch/report/sr15/ (accessed on 22 October 2018).

- United Nations. The Sustainable Development Goals Report; United Nations Publications: New York, NY, USA, 2017; pp. 1–56. [Google Scholar]

- Lee, R.P.; Keller, F.; Meyer, B. A concept to support the transformation from a linear to circular carbon economy: Net zero emissions, resource efficiency and conservation through a coupling of the energy, chemical and waste management sectors. Clean Energy 2017, 1, 102–113. [Google Scholar] [CrossRef]

- Circle Economy. The Circularity Gap Report. 2018. Available online: https://docs.wixstatic.com/ugd/ad6e59_c497492e589c4307987017f04d7af864.pdf (accessed on 17 September 2018).

- Kharas, H. The Emerging Middle Class in Developing Countries; OECD Development Centre Working Paper Series; OECD: Paris, France, 2010; pp. 1–52. [Google Scholar]

- Hoornweg, D.; Bhada, P. What a Waste: A Global Review of Solid Waste Management; Urban Development Series Knowledge Papers; World Bank: Washington, DC, USA, 2012; p. 44. [Google Scholar]

- MacArthur, E. Towards the Circular Economy: A Opportunities for the Consumer Goods Sector; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Chiarello, F.; Trivelli, L.; Bonaccorsi, A.; Fantoni, G. Extracting and mapping industry 4.0 technologies using wikipedia. Comput. Ind. 2018, 100, 244–257. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2015, 114, 11–32. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the business models for circular economy-towards the conceptual framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing Around Prolonging Resource Productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef] [Green Version]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Masi, D.; Day, S.; Godsell, J. Supply Chain Configurations in the Circular Economy: A Systematic Literature Review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef]

- Núñez-Cacho, P.; Molina-Moreno, V.; Corpas-Iglesias, F.A.; Cortés-García, F.J. Family Businesses Transitioning to a Circular Economy Model: The Case of “Mercadona”. Sustainability 2018, 10, 538. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards The Circular Economy; 596/09-08-2013; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2017, 135, 190–201. [Google Scholar] [CrossRef]

- Moreno, M.; Charnley, F. Can Re-distributed Manufacturing and Digital Intelligence Enable a Regenerative Economy? An Integrative Literature Review. In Sustainable Design and Manufacturing; Theobald, P., Ed.; Springer: Cham, Switzerland, 2014; pp. 563–575. [Google Scholar]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Tseng, M.L.; Tan, R.R.; Chiu, A.S.F.; Chien, C.F.; Kuo, T.C. Circular economy meets industry 4.0: Can big data drive industrial symbiosis? Resour. Conserv. Recycl. 2018, 131, 146–147. [Google Scholar] [CrossRef]

- Antikainen, M.; Uusitalo, T.; Kivikytö-Reponen, P. Digitalisation as an Enabler of Circular Economy. Procedia CIRP 2018, 73, 45–49. [Google Scholar] [CrossRef]

- Pagoropoulos, A.; Pigosso, D.C.A.; McAloone, T.C. The Emergent Role of Digital Technologies in the Circular Economy: A Review. Procedia CIRP 2017, 64, 19–24. [Google Scholar] [CrossRef] [Green Version]

- Jabbour, C.J.C.; De Sousa Jabbour, A.B.L. Green Human Resource Management and Green Supply Chain Management: Linking two emerging agendas. J. Clean. Prod. 2016, 112, 1824–1833. [Google Scholar] [CrossRef]

- Sarkis, J.; Gonzalez-Torre, P.; Adenso-Diaz, B. Stakeholder pressure and the adoption of environmental practices: The mediating effect of training. J. Oper. Manag. 2010, 28, 163–176. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Pagell, M.; Shevchenko, A. Why research in sustainable supply chain management should have no future. J. Supply Chain Manag. 2013, 50, 44–55. [Google Scholar] [CrossRef]

- Zuo, Z.; Zhao, K. The more multidisciplinary the better?—The prevalence and interdisciplinarity of research collaborations in multidisciplinary institutions. J. Informetr. 2018, 12, 736–756. [Google Scholar] [CrossRef]

- Yang, S.; Aravind Raghavendra, M.R.; Kaminski, J.; Pepin, H. Opportunities for Industry 4.0 to Support Remanufacturing. Appl. Sci. 2018, 8, 1177. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Policy Report; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017.

- Industry 4.0—Opportunities behind the Challenge. UNIDO Background Paper. 2017. Available online: https://www.unido.org/gc17/industry40 (accessed on 7 August 2018).

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef] [Green Version]

- Short, J. The Art of Writing a Review Article. J. Manag. 2009, 35, 1312–1317. [Google Scholar] [CrossRef]

- Ruschel, E.; Santos, E.A.P.; Loures, E.F.R. Industrial maintenance decision-making: A systematic literature review. J. Manuf. Syst. 2017, 45, 180–194. [Google Scholar] [CrossRef]

- Thelwall, M. Dimensions: A competitor to Scopus and the Web of Science? J. Informetr. 2018, 12, 430–435. [Google Scholar] [CrossRef] [Green Version]

- Mongeon, P. The journal coverage of Web of Science and Scopus: A comparative analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- EBP. What Is a Boolean Operator? 2013, pp. 1–2. Available online: http://library.alliant.edu/ (accessed on 12 October 2018).

- Joshi, K.; Venkatachalam, A.; Jawahir, I.S. A new methodology for transforming 3R concept into 6R concept for improved product sustainability. In Proceedings of the IV Global Conference on Sustainable Product Development and Life Cycle Engineering, Sao Carlos, Brazil, 3–6 October 2006. [Google Scholar]

- Okorie, O.; Turner, F.; Charnley, M.; Moreno, M.; Tiwari, A. A review of data driven approaches for Circular Economy in manufacturing. In Proceedings of the 18th European Roundtable for Sustainable Consumption and Production, ERSCP, Skiathos Island, Greece, 1–5 October 2017; pp. 120–131. [Google Scholar]

- Van Buren, N.; Demmers, M.; van der Heijden, R.; Witlox, F. Towards a circular economy: The role of Dutch logistics industries and governments. Sustainability 2016, 8, 647. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Mackenzie, S.B.; Bachrach, D.G.; Podsakoff, N.P. The influence of management journals in the 1980s and 1990s. Strateg. Manag. J. 2005, 26, 473–488. [Google Scholar] [CrossRef]

- Pittaway, L.; Robertson, M.; Munir, K.; Denyer, D.; Neely, A. Networking and innovation: A systematic review of the evidence 200. Int. J. Manag. Rev. 2004, 5–6, 137–168. [Google Scholar] [CrossRef]

- Roehrich, J.K.; Lewis, M.A.; George, G. Are public-private partnerships a healthy option? A systematic literature review. Soc. Sci. Med. 2014, 113, 110–119. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cerchione, R.; Esposito, E. A systematic review of supply chain knowledge management research: State of the art and research opportunities. Int. J. Prod. Econ. 2016, 182, 276–292. [Google Scholar] [CrossRef]

- Schulze, M.; Nehler, H.; Ottosson, M.; Thollander, P. Energy management in industry—A systematic review of previous findings and an integrative conceptual framework. J. Clean. Prod. 2016, 112, 3692–3708. [Google Scholar] [CrossRef]

- Moreno, M.; Braithwaite, N.; Cooper, T. Moving beyond the circular economy. In Proceedings of the Going Green—Care Innovation 2014, Schoenbrunn Palace Conference Centre, Vienna, Austria, 17–20 November 2014; Moreno, M.A., Braithwaite, N., Cooper, T., Eds.; Nottingham Trent University: Vienna, Austria, 2014; pp. 1–10. Available online: http://www.researchgate.net/publication/281115672 (accessed on 8 October 2018).

- Fernández, G.; Zhang, K. Evaluation of most Suitable Electronic Waste Recycling Components from Economic and Environmental Point of View. Interdiscip. J. Res. Bus. 2012, 1, 1–10. [Google Scholar]

- Roets, L.; Botma, Y. Challenges and opportunities nurses experienced to turn conference presentations into journal articles. Int. J. Afr. Nurs. Sci. 2018, 9, 9–13. [Google Scholar] [CrossRef]

- Zhang, L.; Glänzel, W. Proceeding papers in journals versus the ‘regular’ journal publications. J. Informetr. 2012, 6, 88–96. [Google Scholar] [CrossRef]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving’leapfrog development’. Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. [Google Scholar] [CrossRef]

- Hauser, W.; Lund, R. The Remanufacturing Industry: Anatomy of a Giant, Report. 2008. Available online: http://www.bu.edu/reman/OrderAnatomy.htm (accessed on 12 September 2018).

- Engineering and Physical Sciences Research Council. Manufacturing a Circular Economy: A Position Statement on Circular Economy Research in the UK; EPSRC: Swindon, UK, 2015; pp. 1–19. [Google Scholar]

- European Commission. Circular Economy Package: Questions & Answers. 2015. Available online: http://europa.eu/rapid/press-release_MEMO-15-6204_en.htm (accessed on 12 July 2018).

- König, B.; Diehl, K.; Tscherning, K.; Helming, K. A framework for structuring interdisciplinary research management. Res. Policy 2013, 42, 261–272. [Google Scholar] [CrossRef]

- Thompson Klein, J. Prospects for transdisciplinarity. Futures 2004, 36, 515–526. [Google Scholar] [CrossRef]

- López-Benítez, M.; Drysdale, T.D.; Hadfield, S.; Maricar, M.I. Prototype for multidisciplinary research in the context of the Internet of Things. J. Netw. Comput. Appl. 2017, 78, 146–161. [Google Scholar] [CrossRef] [Green Version]

- Huutoniemi, K.; Thompson, J.; Bruun, H.; Hukkinen, J. Analyzing interdisciplinarity: Typology and indicators. Res. Policy 2010, 39, 79–88. [Google Scholar] [CrossRef]

- Sheng, J.; Amankwah-Amoah, J.; Wang, X. A multidisciplinary perspective of big data in management research. Int. J. Prod. Econ. 2017, 191, 97–112. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. From ‘smart objects’ to ‘social objects’: The next evolutionary step of the internet of things. IEEE Commun. Mag. 2014, 52, 97–105. [Google Scholar] [CrossRef]

- Zanella, A.; Bui, N.; Castellani, A.; Vangelista, L.; Zorzi, M. Internet of Things for Smart Cities. IEEE Internet Things J. 2014, 1, 22–32. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef]

- Weyer, S.; Schmitt, M.; Ohmer, M.; Gorecky, D. Towards Industry 4.0—Standardization as the crucial challenge for highly modular, multi-vendor production systems. IFAC-PapersOnLine 2015, 48, 579–584. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Yu, C.; Xu, X.; Lu, Y. Computer-Integrated Manufacturing, Cyber-Physical Systems and Cloud Manufacturing—Concepts and relationships. Manuf. Lett. 2015, 6, 5–9. [Google Scholar] [CrossRef]

- Xu, L.D.; He, W.; Li, S. Internet of things in industries: A survey. IEEE Trans. Ind. Inform. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Holmström, J.; Holweg, M.; Khajavi, S.H.; Partanen, J. The direct digital manufacturing (r)evolution: Definition of a research agenda. Operations Management Research. Oper. Manag. Res. 2016, 9, 1–10. [Google Scholar] [CrossRef]

- Koch, V.; Kuge, S.; Geissbauer, R.; Schrauf, S. Industry 4.0—Opportunities and challenges of the industrial internet. Strategy PwC 2014, 13, 1–51. [Google Scholar]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design: A Systematic Approach; Wallace, K., Blessing, L., Eds.; Springer-Verlag London Limited: London, UK, 2007. [Google Scholar]

- Brockhoff, K. A Test for the Product Life Cycle. Econometrica 1967, 35, 472–484. Available online: https://www.jstor.org/stable/1905649?seq=1#page_scan_tab_contents (accessed on 28 September 2018). [CrossRef]

- Easingwood, C. Product life cycle patterns for new industrial goods. R D Manag. 1988, 18, 23–32. [Google Scholar] [CrossRef]

- Taylor, M.; Taylor, A. The technology life cycle: Conceptualization and managerial implications. Int. J. Prod. Econ. 2012, 140, 541–553. [Google Scholar] [CrossRef] [Green Version]

- Sood, A.; Tellis, G.J. Technological Evolution and Radical Innovation. J. Mark. 2005, 69, 152–168. [Google Scholar] [CrossRef] [Green Version]

- Kim, B. Managing the transition of technology life cycle. Technovation 2003, 23, 371–381. [Google Scholar] [CrossRef]

- Ernst, H. The Use of Patent Data for Technological Forecasting: The Diffusion of CNC-Technology in the Machine Tool Industry. Small Bus. Econ. 1997, 9, 361–381. [Google Scholar] [CrossRef]

- McGahan, A.M.; Argyres, N.; Baum, J.A.C. Context, technology and strategy: Forging new perspectives on the industry life cycle. In Business Strategy over the Industry Lifecycle; Joel, A.C., Baum, A.M.M., Eds.; Emerald Group Publishing Limited: Bingley, UK, 2004; pp. 1–21. [Google Scholar]

- Yu, D.; Hang, C.C. A Reflective Review of Disruptive Innovation Theory. Int. J. Manag. Rev. 2010, 12, 435–452. [Google Scholar] [CrossRef]

- Abernathy, W.J.; Utterback, J.M. Patterns of innovation in technology. Technol. Rev. 1978, 50, 40–47. [Google Scholar]

- Murmann, J.P.; Frenken, K. Toward a systematic framework for research on dominant designs, technological innovations, and industrial change. Res. Policy 2006, 35, 925–952. [Google Scholar] [CrossRef] [Green Version]

- Sick, N.; Bröring, S.; Figgemeier, E. Start-ups as technology life cycle indicator for the early stage of application: An analysis of the battery value chain. J. Clean. Prod. 2018, 201, 325–333. [Google Scholar] [CrossRef]

- Bornkessel, S.; Bröring, S.; (Onno) Omta, S.W.F. Crossing industrial boundaries at the pharma-nutrition interface in probiotics: A life cycle perspective. PharmaNutrition 2016, 4, 29–37. [Google Scholar] [CrossRef] [Green Version]

- Kushnir, D.; Sandén, B.A. Multi-level energy analysis of emerging technologies: A case study in new materials for lithium ion batteries. J. Clean. Prod. 2011, 19, 1405–1416. [Google Scholar] [CrossRef]

- Orlikowski, W.J.; Gash, D.C. Technological Frames: Making Sense of Information Technology in Organisations. ACM Trans. Inf. Syst. 1994, 12, 174–207. [Google Scholar] [CrossRef]

- Huenteler, J.; Schmidt, T.S.; Ossenbrink, J.; Hoffmann, V.H. Technology life-cycles in the energy sector—Technological characteristics and the role of deployment for innovation. Technol. Forecast. Soc. Chang. 2016, 104, 102–121. [Google Scholar] [CrossRef]

- Roy, R.; Stark, R.; Tracht, K.; Takata, S.; Mori, M. Continuous maintenance and the future—Foundations and technological challenges. CIRP Ann. Manuf. Technol. 2016. [Google Scholar] [CrossRef] [Green Version]

- Ness, D.; Swift, J.; Ranasinghe, D.C.; Xing, K.; Soebarto, V. Smart steel: New paradigms for the reuse of steel enabled by digital tracking and modelling. J. Clean. Prod. 2015, 98, 292–303. [Google Scholar] [CrossRef]

- Bergesen, J.D.; Heath, G.A.; Gibon, T.; Suh, S. Thin-film photovoltaic power generation offers decreasing greenhouse gas emissions and increasing environmental co-benefits in the long term. Environ. Sci. Technol. 2014, 48, 9834–9843. [Google Scholar] [CrossRef]

- Peng, L.L.; Li, J.W.; Bin, Z. The Application of Digital Technology in the Recycling of Old Industrial Buildings. Adv. Mater. Res. 2014, 653–656. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Xiong, G.; Cang, D. Application of digital technologies about water network in steel industry. Resour. Conserv. Recycl. 2011, 55, 755–759. [Google Scholar] [CrossRef]

- Chu, L.K.; Shi, Y.; Lin, S.; Sculli, D.; Ni, J. Fuzzy chance-constrained programming model for a multi-echelon reverse logistics network for household appliances. J. Oper. Res. Soc. 2010, 61, 551–560. [Google Scholar] [CrossRef]

- Hottenstein, F. Digital Technologies for Automated Optical Sorting of Recycled Glass. Glass 2003, 80, 260. [Google Scholar]

- Shan, Z.; Qin, S.; Liu, Q.; Liu, F. Key manufacturing technology & equipment for energy saving and emissions reduction in mechanical equipment industry. Int. J. Precis. Eng. Manuf. 2012, 13, 1095–1100. [Google Scholar] [CrossRef]

- Lau, H.C.W.; Tang, C.X.H.; Lee, C.K.M.; Ho, G.T.S. A generic object-based support system for manufacturing processes. Int. J. Prod. Dev. 2007, 4. [Google Scholar] [CrossRef]

- Gu, Q.; Ji, J. Fuzzy chance-constrained programming model for the integrated logistics network of remanufacturing/manufacturing system. Control Theory Appl. 2005, 22. Available online: https://www.researchgate.net/publication/265983215_Fuzzy_chance-constrained_programming_model_for_the_integrated_logistics_network_of_remanufacturingmanufacturing_system (accessed on 12 October 2018).

- Rojek, G.; Regulski, K.; Wilk-Kołodziejczyk, D.; Kluska-Nawarecka, S.; Jakowiec, K.; Smolarek-Grzyb, A. Methods of Computational Intelligence in the Context of Quality Assurance in Foundry Products. Arch. Foundry Eng. 2016, 16, 11–16. [Google Scholar] [CrossRef] [Green Version]

- Kern, H.; Stefan, F.; Fähnrich, K.P.; Dimitrieski, V. A mapping-based framework for the integration of machine data and information systems. In Proceedings of the 8th IADIS International Conference Information Systems 2015 (IS 2015), Madeira, Portugal, 14–16 March 2015; pp. 113–120. Available online: http://www.scopus.com/inward/record.url?eid=2-s2.0-84944145438&partnerID=tZOtx3y1 (accessed on 12 October 2018).

- Shafiq, S.I.; Sanin, C.; Toro, C.; Szczerbicki, E. Virtual Engineering Object (VEO): Toward experience-based design and manufacturing for industry 4.0. Cybern. Syst. 2015, 46, 35–50. [Google Scholar] [CrossRef]

- Li, W.; Guo, C.F.; Tang, X.Q. Research on the integrated system of digital design/manufacturing/ management in aeroplane process equipments. Mater. Sci. Forum 2009, 1, 626–627. [Google Scholar] [CrossRef]

- Rana, A.; Lehal, G.S. Unique Sense: Smart Computing Prototype for Industry 4.0 Revolution with IOT and Bigdata Implementation Model. Indian J. Sci. Technol. 2015, 8, 1–4. [Google Scholar] [CrossRef]

- Huang, G.O.; Zhang, Y.; Dai, Q.Y.; Ho, O.; Xu, F.J. Agent-based workflow management for RFID-enabled real-time reconfigurable manufacturing. In Collaborative Design and Planning for Digital Manufacturing; Springer: London, UK, 2009; pp. 341–364. [Google Scholar]

- Jing, Z.; Jianping, W.; Guo, Z.; Yunsheng, Z. Service-oriented design and implementation strategy of real-time distributed embedded control software. In Proceedings of the 2008 27th Chinese Control Conference (CCC 2008), Kunming, China, 16–18 July 2008; pp. 393–397. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Growth within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015; 100p. [Google Scholar]

- Tukker, A. Product services for a resource-ef fi cient and circular economy e a review. J. Clean. Prod. 2013, 97, 76–91. [Google Scholar] [CrossRef]

- Janeček, V. Ownership of personal data in the Internet of Things. Comput. Law Secur. Rev. 2018, 34, 1039–1052. [Google Scholar] [CrossRef]

- Kaplan, S.; Tripsas, M. Thinking about technology: Applying a cognitive lens to technical change. Res. Policy 2008, 37, 790–805. [Google Scholar] [CrossRef]

- Von Hippel, E.A. Lead Users: A Source of Novel Product Concepts. Manag. Sci. 1986, 32, 791–805. [Google Scholar] [CrossRef]

- Pereira, J.L.; Oliveira, E.S. Process-based Information Systems: Technological Infrastructure and Development Issues. Procedia Comput. Sci. 2016, 100, 872–877. [Google Scholar] [CrossRef]

- Duarte Neto, J.G.; Soares Machado, M.A.; Monteiro Gomes, L.F.A.; Caldeira, A.M.; Valentim Sallum, F.S. Investments in a New Technological Infrastructure: Decision Making Using the ELECTRE-TRI Methodology. Procedia Comput. Sci. 2017, 122, 194–199. [Google Scholar] [CrossRef]

- DPWorkshop. Digital Preservation Management: Implementing Short-term Strategies for Long-Term Problems. 2018. Available online: http://www.dpworkshop.org/dpm-eng/program/techinf.html (accessed on 21 October 2018).

- Liao, K.; Tu, Q. Leveraging automation and integration to improve manufacturing performance unde certainty. J. Manuf. Technol. Manag. 2008, 19, 38–51. [Google Scholar] [CrossRef]

- Molina-Moreno, V.; Leyva-Díaz, J.; Sánchez-Molina, J. Pellet as a Technological Nutrient within the Circular Economy Model: Comparative Analysis of Combustion Efficiency and CO and NOx Emissions for Pellets from Olive and Almond Trees. Energies 2016, 9, 777. [Google Scholar] [CrossRef]

- Moreno, M.; Court, R.; Campbell, C.; Wright, M.; Charnley, F. Opportunities for re-distributed manufacturing and digital intelligence as enablers of a circular economy: The Four Lens Framework. Int. J. Sustain. Eng. 2016, 1–18. [Google Scholar] [CrossRef]

- Davis, K.; Christodoulou, J.; Seider, S.; Gardner, H. The Theory of Multiple Intelligences. Ann. Dyslexia 1987, 37, 19–35. [Google Scholar] [CrossRef]

- Adams, N.B. Digital intelligence fostered by technology. J. Technol. Stud. 2004, 30, 93–97. [Google Scholar] [CrossRef]

- Schmidt, F.L. Select on Intelligence. Handbook of Principles of Organizational Behavior; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Cismaru, D.M.; Gazzola, P.; Ciochina, R.S.; Leovaridis, C. The rise of digital intelligence: challenges for public relations education and practices. Kybernetes 2018, 47, 1924–1940. [Google Scholar] [CrossRef]

- Ichihashi, H.; Ishida, M.; Shiga, A.; Kitamura, M.; Suzuki, T.; Suenobu, K. The catalysis of vapor-phase Beckmann rearrangement for the production of ε-caprolactam. Catal. Surv. Asia 2003, 7, 261–270. [Google Scholar] [CrossRef]

- Echeverría, J.; Tabarés, R. Artificial Intelligence, Cybercities and Technosocieties. Minds Mach. 2017, 27, 473–493. [Google Scholar] [CrossRef]

- Rußmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries; Industry 4.0 Boston Consulting Group: Boston, MA, USA, 2015. [Google Scholar]

- Schumacher, A.; Erol, S.; Sihn, W. A Maturity Model for Assessing Industry 4.0 Readiness and Maturity of Manufacturing Enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Wee, D.; Breunig, M.; Kelly, R.; Mathis, R. Industry 4.0 after the Initial Hype—Where Manufacturers are Finding Value and How They Can Best Capture It; McKinsey & Company: New York, NY, USA, 2016; p. 32. [Google Scholar]

- Agrawal, D.; Bernstein, P.; Bertino, E.; Dayal, U.; Franklin, M.; Gehrke, J.; Haas, L.; Halevy, A.; Han, J.; Jagadish, H.V.; et al. Challenges and Opportunities with Big Data; Purdue University Press Journals e-Pubs: West Lafayette, IN, USA, 2011. [Google Scholar]

| ## | Authors | Focus | Journal | Circ. Approach in Keywords/Sections |

|---|---|---|---|---|

| 1 | Ghiselli et al., (2016) [43] | Review of 155 articles on the CE | Journal of Cleaner Production | Recycling, Reuse, Remanufacturing |

| 2 | Murray et al., (2017) [44] | Comparison of CE concept and sustainable business | Journal of Business Ethics | Recycling |

| 3 | Lieder and Rashid (2016) [45] | A review of CE in the context of manufacturing industry | Journal of Cleaner Production | Reduction, Reuse, Remanufacturing |

| 4 | Lewandowski (2016) [46] | A review (conceptualisation) of business models for CE | Sustainability MDPI | - |

| 5 | Geissdoerfer et al., (2017) [2] | A review of CE and sustainability | Journal of Cleaner Production | - |

| 6 | Sauvé et al., (2016) [9] | Comparison of CE concept and sustainable business | Environmental Development | - |

| 7 | Blomsma and Brennan (2017) [47] | Explanation of the emergence of the CE concept | Journal of Industrial Ecology | - |

| 8 | Su et al., (2012) [48] | Review of CE implementation | Journal of Cleaner Production | |

| 9 | Kirchher et al., (2017) [11] | Comparison and analysis of 114 CE definitions | Resources, Conservation & Recycling | Reduce, Reuse, Recycle, Recover |

| 10 | Nobre et al., (2017) [16] | Big data and IOT | Scientometrics | - |

| 11 | Masi et al., (2017) [49] | Supply Chain | Sustainability | - |

| 12 | Nunez-Cacho et al., (2018) [50] | Family business and transitioning to a CE Model | Sustainability | Reuse, Reduce, Recycle, Recover |

| Item | Description |

|---|---|

| Time Period | January 2000 to June 2018 (Search was performed in June, 2018) |

| Boolean Operators | AND between keywords; OR between Database search fields. |

| Search fields | “Industry 4.0”; “Digital Technologies”; “Digital Intelligence”; “Circular Economy”; “Reuse”; “Recycl*”; “Remanufacture”; “Repair”; “Repurpose”; “Rethink”; “Recover”; “Recover Energy”; “Refuse”; “Refurbish”; “Reduce” |

| Language | English |

| Availability | Articles available online as full text |

| Research Discipline | Engineering; Business; the Sciences excluding Medical Science. |

| Exclusion Criteria | Articles unrelated to search words; |

| Publication type | Peer-reviewed academic journals; conference papers. |

| Selection Criteria | Tasks Performed |

|---|---|

| 1st selection criterion: Focus of abstract | The focus is on the title and abstract in materials which relate to the research context identified for this research. Papers outside this criterion were removed. |

| 2nd selection criterion: focus of paper | Papers focusing on Circular Economy and each of the 9R’s were identified and considered. Papers with a missing abstract, broken links, were excluded. |

| 3rd selection criterion: citation method | Papers not included in the selected academic database (SCOPUS) but cited in the literature found on industry 4.0, circular economy, and circular approaches were considered. |

| Search String Keyword | Initial Result | After Exclusion Criteria |

|---|---|---|

| “Circular Econom*” | 15 | 12 |

| “Remanufactur*” | 9 | 7 |

| “Reuse” | 59 | 35 |

| “Recycl*” | 44 | 18 |

| “Recover” OR “Recover Energy” | 137 | 49 |

| “Repair” | 65 | 27 |

| “Reduc*” AND “Circular Economy” | 3 | 2 |

| “Refuse” | 4 | 0 |

| “Repurpose” | 0 | 0 |

| “Rethink” | 66 | 11 |

| “Refurbish*” | 18 | 13 |

| Technology | Description | Resources in Use |

|---|---|---|

| Cyber-physical systems | Enables automation, monitoring and control of processes and objects in real time [26] | Controllers and sensor systems [26] |

| Cloud Manufacturing | Virtual portals which create a shared network of manufacturing resources and capabilities offered as services [100] | The Internet |

| Internet of Things (IoT) | A computational system which collects and exchanges data acquired from electronic devices [99] | Radio-frequency identification (RFID) technology tags, sensors, barcodes, smartphones [100,101] |

| Additive Manufacturing | Represents agile and connected prototyping of parts of products on a large scale, enabling customization [102] | 3D printers |

| Era of Ferment | Dominant Design | Era of Incremental Change | Discontinuity | |

|---|---|---|---|---|

| Technological perspective | Greater or lesser variation takes place on product or process. Specific I4.0 domains are introduced, e.g., sensor-enabled product to enable recycling. | A dominant design is achieved or not. A particular technology becomes dominant over others in specific CE approaches. | Dominant design from SLR includes reuse, recycle, remanufacture, and repair. Inertia develops around these CE approaches. | A new I4.0 technology emerges or not [140]. |

| Economic perspective | Mechanism Mechanism: Technical breakthroughs in CE-DT integrated areas are likely to come from areas where research is highest. Predicted Outcomes: Variation here is not random but strategic. | Mechanism: A dominant design linking I4.0 domain to CE approach will be driven by econ-omies of scale, interdisciplinary interaction, and industry. Predicted outcomes: Dominant technology for CE approach. | Predicted Outcomes: I4.0 technology linked to CE approach is expected to remain dominant. Future technologies and research are expected to be built around this outcome. | When existing I4.0 to CE approach technology reaches a point of diminishing returns, a new technology will emerge [140], e.g., from Bar code to RFID. |

| Organizational perspective | Mechanism: Technical variety is driven by exogenous stochastic technological advances [141]. Predicted Outcome: Variation is random. | Mechanism: emergence of dominant design is driven by subject area (engineering and computer sciences Figure 9). Predicted Outcomes: Dominant design spons-ored by a dominant community is expected. | Mechanism: CE-DT results from industry-academic demand, existing CE approach, and procedures. Technological progress is expected to rapidly increase due to the competing stakeholders and countries. | Mechanism: Stakeholders from academia, industry, and govern-ment bring capabilities to bear. Predicted outcome: As evident by number of papers in Figure 6, research in CE-DT research will grow, with technologies outpac-ing CE approaches |

| Cognitive perspective (framework adaptation) | Mechanisms: Technical variation is driven by agents such as academia, industry, government policy-makers, and customer. End-users guide the design and interpretation of various CE-DT technologies and trends. | Mechanisms: The prerequisite for achieving a dominant design is end-user feedback. Why should this CE-DT device be used? Is it user friendly? How would the device interact with other users? Has the data collection & analysis been defined? | Mechanisms: Adoption and flexibility of I4.0 technologies may be fairly easy across dominant CE approaches. | Mechanisms: CE and I4.0 are emerging research areas, hence any discontinuity of existing technology will be due to a newer, more efficient technology. |

| Stakeholder | A Concise Definition | Research Trend for Integrated CE-I4.0 Future Research |

|---|---|---|

| Academia | Research institutions, universities, scholarly institutes | (a) To investigate and map CE approaches to specific I4.0 technology; (b) to investigate, capture, categorize, and rank value from CE-I4.0 implementation within industry; (c) to identify possible barriers to CE-I4.0 implementation and suggest ways of overcoming these barriers; (d) to identify opportunities for I4.0 to support each of the 9R’s CE approach; (e) to provide a definition for the CE within an integrative CE-I4.0 context; (f) future research in this area could include intersecting (and important) research areas such as supply chain and cybersecurity; (g) to study CE-I4.0 development within selected areas, for example, countries and regions. |

| Industry | Manufacturing, environmental, health-related industries, etc. Research and Development units within industries. | (a) To identify and categorize various emerging I4.0 devices and intelligence under the technologies (smart manufacturing) as identified in [99] and link them to use in CE approach; (b) to identify links between CE approaches, I4.0, and environmental implications; (c) identification of dominant design where industry standards emerge; (d) to investigate CE-I4.0 implementation at theoretical, practical, and strategic level. |

| Policy-makers | National governments, regional governmental units, policy-making institutions (e.g., the United Nations, UN) | (a) To clarify data ownership with Industry and academia. (b) As done with CE research to synthesize a common template and industrial policy for CE-I4.0 used. (c) To drive for multidisciplinary research for CE-I4.0 research |

| End-User | User of product or service. Customer who has purchased and shall use product or service. | (a) Can help in carrying out interviews, surveys in order to define “lead-user” and “potential users”; (b) various support shall be implemented to ensure that used and operational data is captured by user in order to implement circularity on products or services (for example, product manual). |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okorie, O.; Salonitis, K.; Charnley, F.; Moreno, M.; Turner, C.; Tiwari, A. Digitisation and the Circular Economy: A Review of Current Research and Future Trends. Energies 2018, 11, 3009. https://doi.org/10.3390/en11113009

Okorie O, Salonitis K, Charnley F, Moreno M, Turner C, Tiwari A. Digitisation and the Circular Economy: A Review of Current Research and Future Trends. Energies. 2018; 11(11):3009. https://doi.org/10.3390/en11113009

Chicago/Turabian StyleOkorie, Okechukwu, Konstantinos Salonitis, Fiona Charnley, Mariale Moreno, Christopher Turner, and Ashutosh Tiwari. 2018. "Digitisation and the Circular Economy: A Review of Current Research and Future Trends" Energies 11, no. 11: 3009. https://doi.org/10.3390/en11113009