Integrated Energy System Configuration Optimization for Multi-Zone Heat-Supply Network Interaction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Integrated Energy System Structure

2.2. Heat-Supply Network Structure

2.3. Heat-Supply Network Model

2.3.1. Basic Theory of Heat-Supply Network

2.3.2. Operation Cost of Heat-Supply Network Investment

2.4. CCHP Mathematical Model

2.4.1. Objective Function

2.4.2. Constraints

3. Results

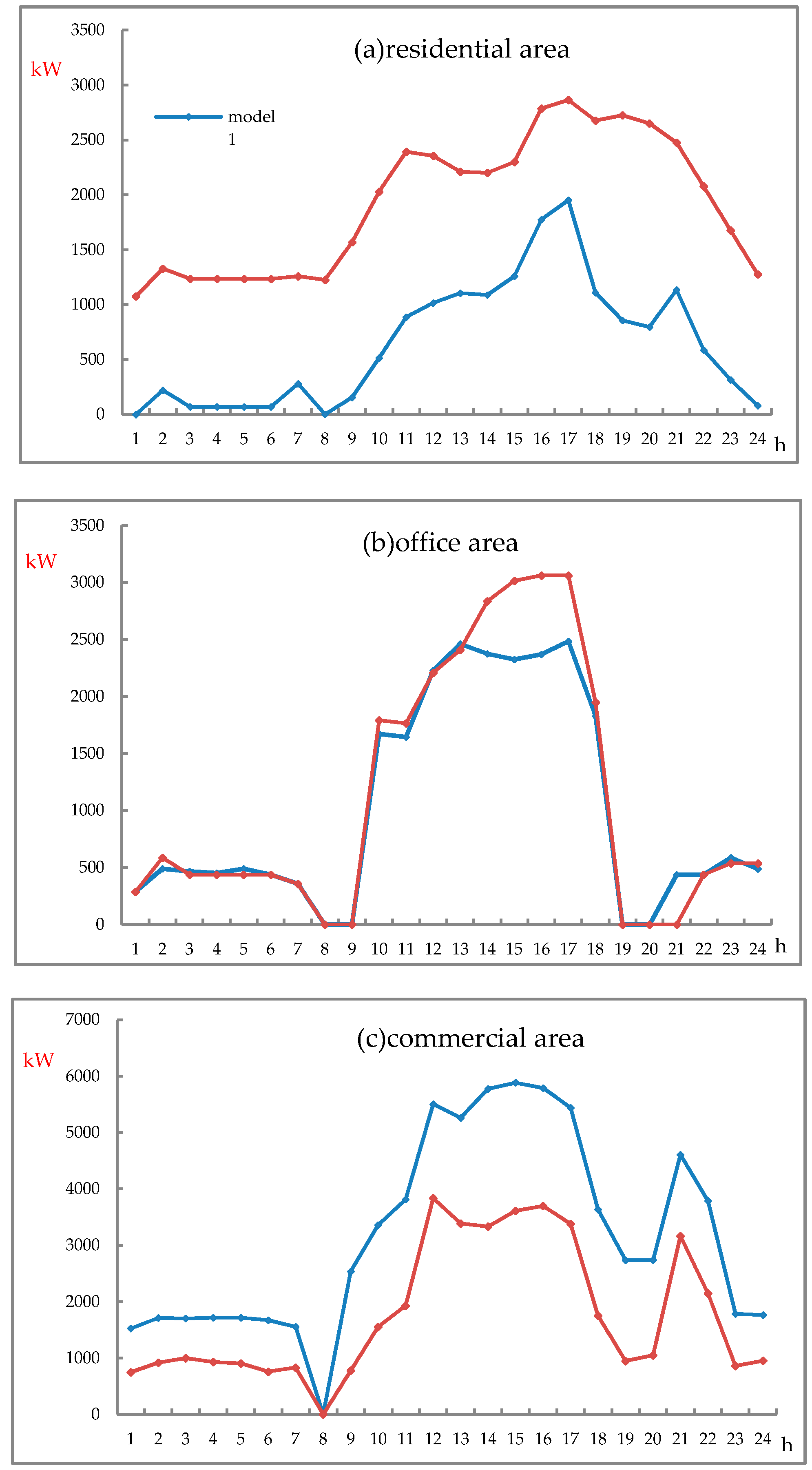

3.1. Equipment Capacity Planning

3.2. Operation Optimization

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Type | Unit Investment Cost (RMB /kW) | Single Rated Power | Conversion Efficiency |

|---|---|---|---|

| Pthemalovoltaic generator set | 10,000 | -- | 0.175 |

| Pthemalovoltaic collector | 8210 | -- | 0.56 |

| Electrical storage device | 1500 | -- | 90 |

| Absorption chiller | 1240 | -- | 1.26 |

| Electric refrigerator | 820 | -- | 4.13 |

| 1#gas turbine | 7216.3 | 1210 | 0.243 |

| 2# gas turbine | 5749.9 | 3515 | 0.279 |

| 3# gas turbine | 5429.45 | 4600 | 0.293 |

| 4# gas turbine | 5289.7 | 5740 | 0.32 |

| 1# gas boiler | 86.84 | 1300 | 0.85 |

| 2# gas boiler | 75.14 | 1950 | 0.86 |

| 3# gas boiler | 73.26 | 4560 | 0.9 |

| 4# gas boiler | 71.83 | 5200 | 0.9 |

| Area Type | Purchase Price/RMB | ||

|---|---|---|---|

| Peak Period | Flat Period | Valley Period | |

| 8:00–11:00 18:00–20:00 | 6:00–7:00 12:00–17:00 21:00–22:00 | 23:00–5:00 | |

| Residential | 0.677 | 0.377 | 0.377 |

| Office, commercial | 1.159 | 0.708 | 0.351 |

| Other Parameters | Resident | Commercial | Office |

|---|---|---|---|

| Installable area | 32,000 | 23,000 | 15,000 |

| Average sunshine intensity (kw/(M2·d)) | 0.669 | 0.669 | 0.669 |

| Average annual sunshine hours | 1970 | 1970 | 1970 |

| Period of Time | Residential Areas | Office Area | Commercial Area | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electrical Load | Themal Load | Cold Load | Solar Energy | Electrical Load | Themal Load | Cold Load | Solar Energy | Electrical Load | Themal Load | Cold Load | Solar Energy | |

| 00.00–01.00 | 1180 | 3580 | 90 | 0 | 796 | 0 | 20 | 0 | 2194 | 0 | 224 | 0 |

| 01.00–02.00 | 1194 | 3577 | 89 | 0 | 794 | 0 | 20 | 0 | 2187 | 0 | 221 | 0 |

| 02.00–03.00 | 1192 | 3589 | 101 | 0 | 795 | 0 | 20 | 0 | 2201 | 0 | 229 | 0 |

| 03.00–04.00 | 1205 | 3549 | 96 | 0 | 801 | 0 | 20 | 0 | 2195 | 0 | 231 | 0 |

| 04.00–05.00 | 1210 | 3596 | 99 | 0 | 798 | 0 | 20 | 0 | 2197 | 0 | 236 | 0 |

| 05.00–06.00 | 1211 | 3602 | 108 | 0 | 806 | 0 | 20 | 0 | 2203 | 0 | 233 | 0 |

| 06.00–07.00 | 1198 | 3607 | 191 | 960 | 802 | 0 | 20 | 450 | 2194 | 0 | 397 | 690 |

| 07.00–08.00 | 1600 | 3615 | 195 | 1280 | 813 | 0 | 30 | 600 | 2211 | 0 | 401 | 920 |

| 08.00–09.00 | 1193 | 3994 | 204 | 1600 | 1994 | 2394 | 30 | 750 | 6397 | 1794 | 410 | 1150 |

| 09.00–10.00 | 2398 | 4197 | 197 | 1920 | 4367 | 4197 | 30 | 900 | 7204 | 2798 | 408 | 1380 |

| 10.00–11.00 | 2801 | 4198 | 201 | 2240 | 4389 | 4403 | 30 | 1050 | 7581 | 3609 | 410 | 1610 |

| 11.00–12.00 | 2423 | 4200 | 200 | 2560 | 4394 | 4195 | 30 | 1200 | 7597 | 3960 | 407 | 1840 |

| 12.00–13.00 | 2418 | 4204 | 205 | 2800 | 4402 | 4011 | 30 | 1350 | 7611 | 4397 | 417 | 2070 |

| 13.00–14.00 | 2391 | 3994 | 198 | 2800 | 4396 | 4004 | 30 | 1350 | 7799 | 4001 | 410 | 2070 |

| 14.00–15.00 | 2404 | 3611 | 192 | 2240 | 4387 | 3994 | 30 | 1050 | 8001 | 4013 | 410 | 1610 |

| 15.00–16.00 | 2790 | 3603 | 103 | 1600 | 4405 | 4005 | 30 | 750 | 7994 | 3998 | 411 | 1150 |

| 16.00–17.00 | 2797 | 3598 | 105 | 960 | 4394 | 4001 | 30 | 450 | 7598 | 4005 | 407 | 690 |

| 17.00–18.00 | 2805 | 3594 | 97 | 0 | 4385 | 3997 | 30 | 0 | 7203 | 4193 | 405 | 0 |

| 18.00–19.00 | 2800 | 4003 | 100 | 0 | 2011 | 2003 | 20 | 0 | 6414 | 4197 | 230 | 0 |

| 19.00–20.00 | 2790 | 4200 | 94 | 0 | 1206 | 1000 | 20 | 0 | 6399 | 4005 | 224 | 0 |

| 20.00–21.00 | 2414 | 4189 | 96 | 0 | 8017 | 500 | 20 | 0 | 6387 | 3607 | 223 | 0 |

| 21.00–22.00 | 2006 | 4176 | 99 | 0 | 806 | 0 | 20 | 0 | 5180 | 2809 | 219 | 0 |

| 22.00–23.00 | 1600 | 4000 | 100 | 0 | 800 | 0 | 20 | 0 | 2200 | 0 | 230 | 0 |

| 23.00–24.00 | 1200 | 3600 | 100 | 0 | 800 | 0 | 20 | 0 | 2200 | 0 | 230 | 0 |

References

- Bie, C.; Wang, X.; Hu, Y. Review and prospect of energy Internet planning. Proc. CSEE 2017, 37, 6445–6462. [Google Scholar]

- Yin, S.; Ai, Q.; Zeng, S.; Wu, Q.; Hao, R.; Jiang, D. Challenges and Prospects of Energy Internet Multi-energy Distributed Optimization Research. Power Syst. Technol. 2018, 42, 1359–1369. [Google Scholar]

- Wang, W.; Wang, D.; Jia, H.; Chen, Z.; Guo, B.; Zhou, H.; Fan, M. A Summary of Steady-State Analysis of Typical Regional Integrated Energy Systems in the Background of Energy Internet. Proc. CSEE 2016, 36, 3292–3306. [Google Scholar]

- Chen, B.; Liao, Q.; Liu, D.; Wang, W.; Wang, Z.; Chen, S. A comprehensive evaluation index and method for regional integrated energy system. Autom. Electr. Power Syst. 2018, 42, 174–182. [Google Scholar]

- Moeini-Aghtaie, M.; Abbaspour, A.; Fotuhi-Firuzabad, M.; Hajipour, E. A decomposed solution to multiple-energy carriers optimal power flow. IEEE Trans. Power Syst. 2014, 29, 707–716. [Google Scholar] [CrossRef]

- Rastegar, M.; Fotuhi-Firuzabad, M.; Lehtonen, M. Home load management in a residential energy hub. Electr. Power Syst. Res. 2015, 119, 322–328. [Google Scholar] [CrossRef]

- Herrando, M.; Markides, C.N.; Hellgardt, K.A. UK-based assessment of hybrid PV and solar-thermal systems for domestic heat-supply and power: System performance. Appl. Energy 2014, 122, 288–309. [Google Scholar] [CrossRef]

- Li, Y.; Wu, M.; Zhou, H.; Wang, W.; Wang, D.; Ge, L. Discussion on several problems of regional multi-energy system based on all-energy flow model. Power Syst. Technol. 2015, 39, 2230–2237. [Google Scholar]

- Kuosa, M.; Kontu, K.; Mäkilä, T.; Lampinen, M.; Lahdelma, R. Static study of traditional and ring networks and the use of mass flow control in district themaling applications. Appl. Ther. Eng. 2013, 54, 450–459. [Google Scholar] [CrossRef]

- Li, Y.; Xun, J.; Cao, H.; Gao, C.; Zhang, X.; Zhang, J.C.W. Distribution Network Planning Strategy Based on Integrated Energy Collaborative Optimization. Power Syst. Technol. 2018, 42, 1393–1400. [Google Scholar]

- Bai, M.; Wang, Y.; Tang, W.; Wu, C.; Zhang, B. Day-time optimization scheduling of interval integrated energy system based on interval linear programming. Power Syst. Technol. 2017, 41, 3963–3970. [Google Scholar]

- Hu, R.; Ma, J.; Li, Z.; Lu, Q.; Zhang, D.; Qian, X. Optimal Configuration and Applicability Analysis of Distributed Cogeneration System. Power Syst. Technol. 2017, 41, 418–425. [Google Scholar]

- Liu, D.; Ma, H.; Wang, B.; Gao, W.; Wang, J.; Yan, B. Operational optimization of regional integrated energy system with combined themal and power supply and energy storage. Autom. Electr. Power Syst. 2018, 42, 113–120. [Google Scholar]

- Gu, W.; Lu, S.; Wang, J.; Yin, X.; Zhang, C.; Wang, Z. Multi-regional integrated energy system heat-supply network modeling and system operation optimization. Proc. CSEE 2017, 37, 1035–1046. [Google Scholar]

- Wang, J.; Gu, W.; Lu, S.; Zhang, C.; Wang, Z.; Tang, Y. Collaborative Planning of Multi-region Integrated Energy System Based on Heat-supply network Model. Autom. Electr. Power Syst. 2016, 40, 17–24. [Google Scholar]

- Xiao, X.; Kan, W.; Yang, Y.; Zhang, S.; Xiao, Y. Superstructure optimization configuration of combined energy storage system. Proc. CSEE 2012, 32, 8–15. [Google Scholar]

- Wu, H.; Wang, D.; Liu, X. Strategy Evaluation and Optimization Configuration of Solar Cooling, Cogeneration System. Power Syst. Autom. 2015, 39, 46–51. [Google Scholar]

- Gu, W.; Wu, Z.; Bo, R.; Liu, W.; Zhou, G.; Chen, W.; Wu, Z. Modeling, planning and optimal energy management of combined cooling, themaling, and power microgrid: A review. Int. J. Electr. Power Energy Syst. 2014, 54, 26–37. [Google Scholar] [CrossRef]

- Fumo, N.; Chamra, L.M. Analysis of combined cooling, themaling, and power systems based on source primary energy consumption. Appl. Energy 2010, 33, 96–100. [Google Scholar]

- Jing, Y.; Bai, H.; Zhang, J. Multi-objective optimization design and operation strategy analysis of solar cooling, themaling and power supply system. Proc. CSEE 2012, 32, 82–87. [Google Scholar]

- Lo, C.E.; Borelli, D.; Devia, F.; Schenone, C. Future distributed generation: An operational multi-objective optimization model for integrated small scale urban electrical, thermal and gas grids. Energy Convers. Manag. 2017, 143, 348–359. [Google Scholar] [CrossRef]

- Zhou, R.; Li, S.; Chen, R.; Li, H.; Yang, Y.; Chen, Y. Multi-objective Scheduling of Carbon Emissions Trading in Themal and Cold Electricity Using Fuzzy Self-Correction Particle Swarm Optimization Algorithm. Proc. CSEE 2014, 34, 6119–6126. [Google Scholar]

- Qiu, J.; Dong, Z.; Zhao, J.; Meng, K.; Zheng, Y.; Hill, D.J. Low carbon oriented expansion planning of integrated gas and power systems. IEEE Trans. Power Syst. 2015, 30, 1035–1046. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Y.; Tang, Y.; Gu, W.; Wu, X. Capacity allocation of CO2 emissions considering CO2 emissions. Proc. CSU-EPSA 2017, 29, 104–110. [Google Scholar]

- Lorestani, A.; Ardehali, M.M. Optimal integration of renewable energy sources for autonomous tri-generation combined cooling, heating and power system based on evolutionary particle swarm optimization algorithm. Energy 2018, 145, 839–855. [Google Scholar] [CrossRef]

- Yousefi, H.; Ghodusinejad, M.H.; Noorollahi, Y. GA/AHP-based optimal design of a hybrid CCHP system considering economy, energy and emission. Energy Build. 2017, 138, 309–317. [Google Scholar] [CrossRef]

- Dong, X.; Quan, C.; Jiang, T. Optimal Planning of Integrated Energy Systems Based on Coupled CCHP. Energies 2018, 11, 2621. [Google Scholar] [CrossRef]

- Ma, H.; Wang, B.; Gao, W.; Liu, D.; Sun, Y.; Liu, Z. Optimal Scheduling of an Regional Integrated Energy System with Energy Storage Systems for Service Regulation. Energies 2018, 11, 195. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, H.; Yong, M.; Huang, Y.; Zhang, F.; Wang, X. Optimal Scheduling of Integrated Energy Systems with Combined Heat and Power Generation, Photovoltaic and Energy Storage Considering Battery Lifetime Loss. Energies 2018, 11, 1676. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, X.; Li, X.; Yan, W. Probabilistic Steady-State Operation and Interaction Analysis of Integrated Electricity, Gas and Heating Systems. Energies 2018, 11, 917. [Google Scholar] [CrossRef]

| Equipment | Residential Area | Office Area | Commercial Area | One-Time Investment Cost | ||||

|---|---|---|---|---|---|---|---|---|

| Mode1 | Mode2 | Mode1 | Mode2 | Mode1 | Mode2 | Mode1 | Mode2 | |

| Gas turbine/kw | 1210 × 2 | 0 | 1210 × 2 | 1210 × 2 | 3515 | 5740 | 5513.5 | 4782.6 |

| Gas boiler/kw | 1300 | 0 | 0 | 0 | 0 | 0 | 11.3 | 0 |

| Electric refrigerator/kw | 50 | 50 | 0 | 0 | 0 | 50 | 4.1 | 8.2 |

| Absorption refrigerator/kw | 0 | 200 | 30 | 30 | 400 | 400 | 53.3 | 78.1 |

| Photovoltaic generating set/kw | 260 | 400 | 200 | 300 | 200 | 400 | 660 | 1100 |

| Electrical storage device/kw | 300 | 400 | 400 | 400 | 450 | 400 | 172.5 | 180 |

| Photovoltaic collector/kw | 450 | 650 | 150 | 0 | 150 | 0 | 615 | 533.6 |

| Total investment cost/10,000 RMB | 2413.7 | 1000 | 2118.2 | 2087.5 | 2437.8 | 3527.5 | 6969.7 | 6615 |

| Pipeline | Residential—Office | Residential—Commercial | Office—Commercial |

|---|---|---|---|

| Maximum flow | 0.011 | ||

| Pipe radius | 5 | 9 | 6 |

| Running cost of water pump | 369 | 109 | 511 |

| Cost of pipe laying (10,000 RMB) | 84.7 | 59.5 | 99.8 |

| Categories | Mode 1 (RMB) | Mode 2 (RMB) | Reduction Proportion (%) | ||||

|---|---|---|---|---|---|---|---|

| Residential Area | Office Area | Commercial Area | Residential Area | Office Area | Commercial Area | - | |

| Carbon tax | 8621 | 8483 | 19,183 | 7372 | 8464 | 19,245 | 3.32 |

| Operating cost | 51,672 | 50,999 | 107,974 | 193,368 (total) | 8.2 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, B.; Gao, G.; Xia, X.; Yang, X. Integrated Energy System Configuration Optimization for Multi-Zone Heat-Supply Network Interaction. Energies 2018, 11, 3052. https://doi.org/10.3390/en11113052

Tang B, Gao G, Xia X, Yang X. Integrated Energy System Configuration Optimization for Multi-Zone Heat-Supply Network Interaction. Energies. 2018; 11(11):3052. https://doi.org/10.3390/en11113052

Chicago/Turabian StyleTang, Bo, Gangfeng Gao, Xiangwu Xia, and Xiu Yang. 2018. "Integrated Energy System Configuration Optimization for Multi-Zone Heat-Supply Network Interaction" Energies 11, no. 11: 3052. https://doi.org/10.3390/en11113052