Nuclear Magnetic Resonance Measurement of Oil and Water Distributions in Spontaneous Imbibition Process in Tight Oil Reservoirs

Abstract

:1. Introduction

2. Experiments

2.1. Materials

2.2. Experimental Setup

2.3. Experimental Procedures

- (1)

- Prepare short core samples, I01, I02, I03, and I04, with a length of 2.521 cm for SI experiments.

- (2)

- Clean, dry, and measure the petrophysical properties, shown in Table 1, of the short core samples.

- (3)

- Evacuate the four cores in a sealed container and saturate them with simulated oil. Then, place the core in the core holder and inject 20 pore volumes of simulated oil into the core at a constant injection rate of 0.005 mL/min to ensure these cores are fully saturated with simulated oil.

- (4)

- Remove core from the core holder and age in simulated oil for 48 h to restore the native wettability.

- (5)

- Remove cores from the simulated oil, carefully wipe the simulated oil from the core surface. Conduct SI tests using cores I02, I03, and I04 using the improved imbibition cell and simulated formation water without MnCl2.

- (6)

- Place core I01 in the NMR apparatus for testing its transverse relaxation time (T2) spectrum in the state of saturated oil. Put the core I01 into Amott cell so that it is immersed in simulated formation water with MnCl2. Because it is inconvenient to frequently remove core I01 for NMR tests, the Amott cell is used in this test instead of the improved imbibition cell.

- (7)

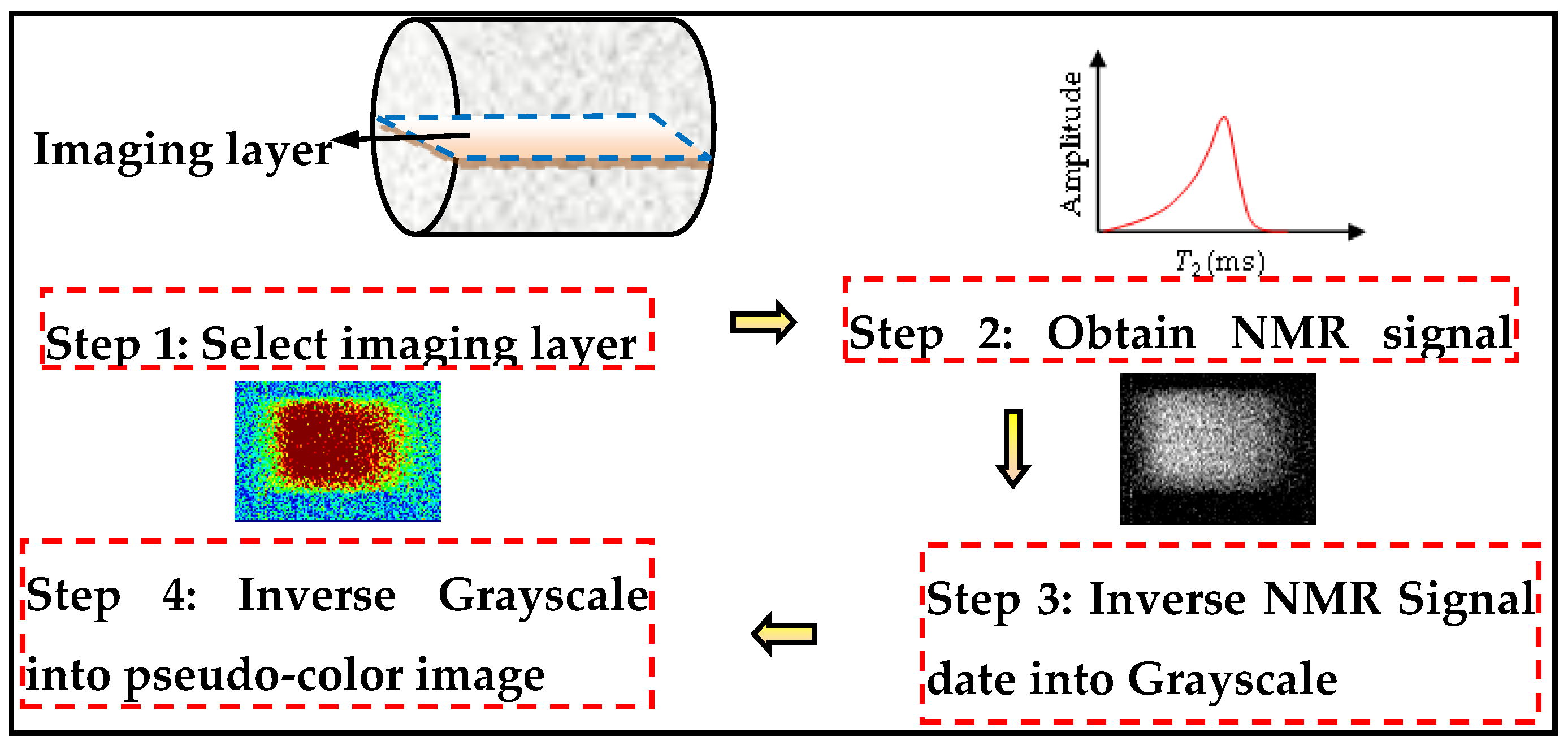

- Measure the T2 spectrum (core I01) at different time intervals, such as 1 h, 4 h and 10 h, using NMR. Collect MRI of the core at the same times.

- (8)

- Clean and dry the core I01 after the SI experiment is completed. Perform MICP to obtain the pore size.

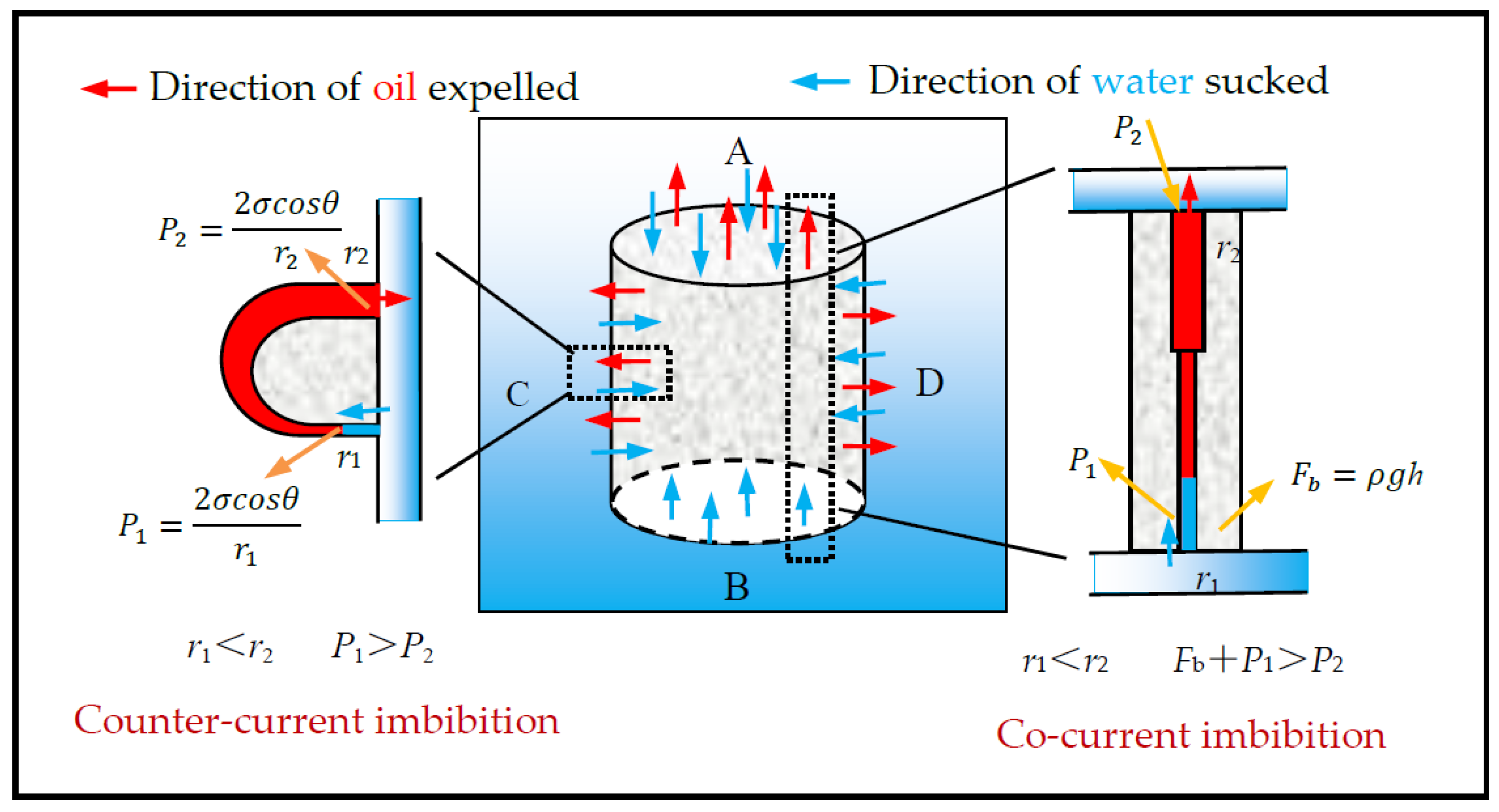

3. Experimental Analysis Fundamental Theory

3.1. NMR Theory

3.2. Relationship Between T2 Spectrum and Pore Throat Radius

4. Results and Discussions

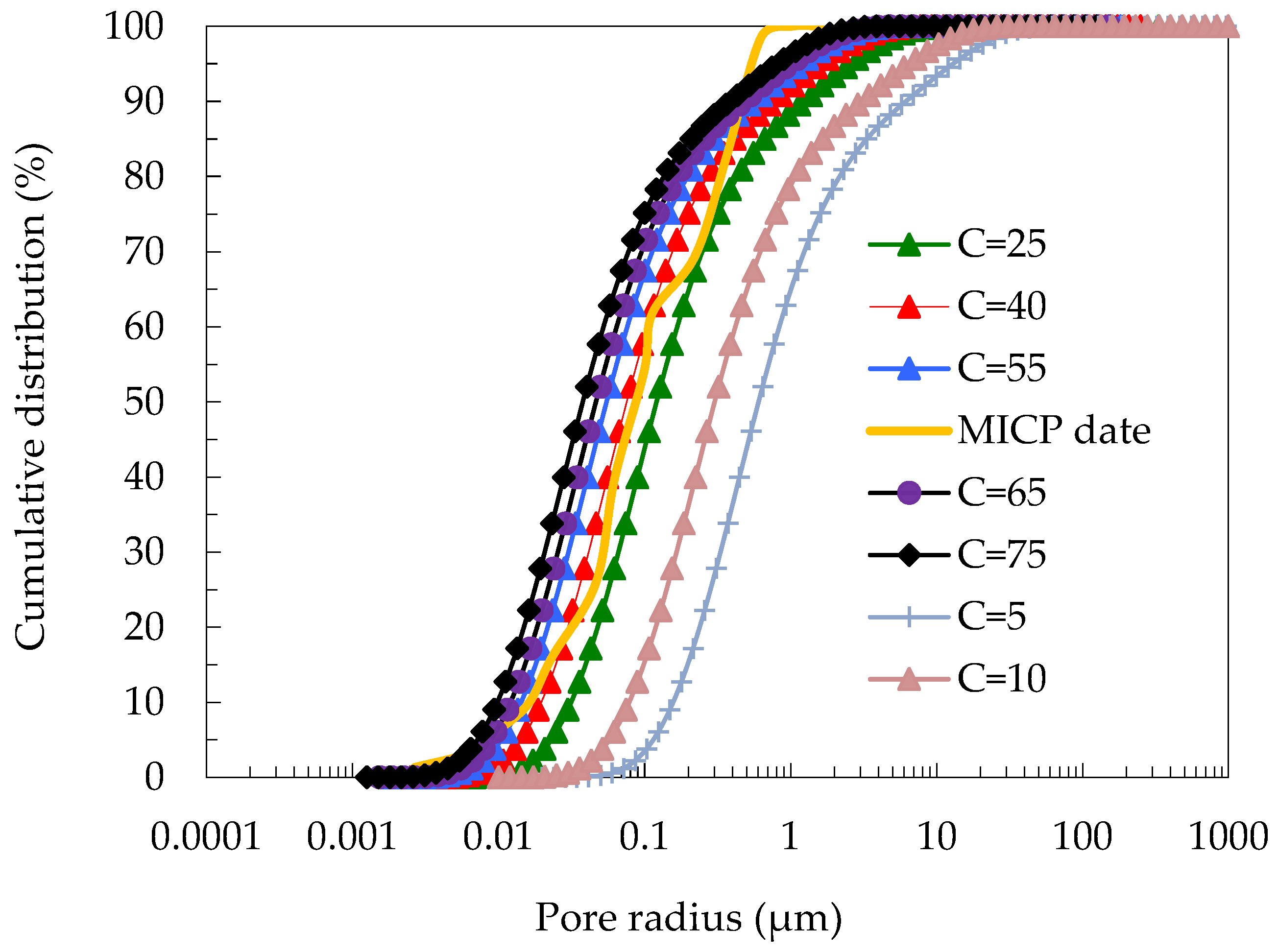

4.1. Pore Radius Distribution

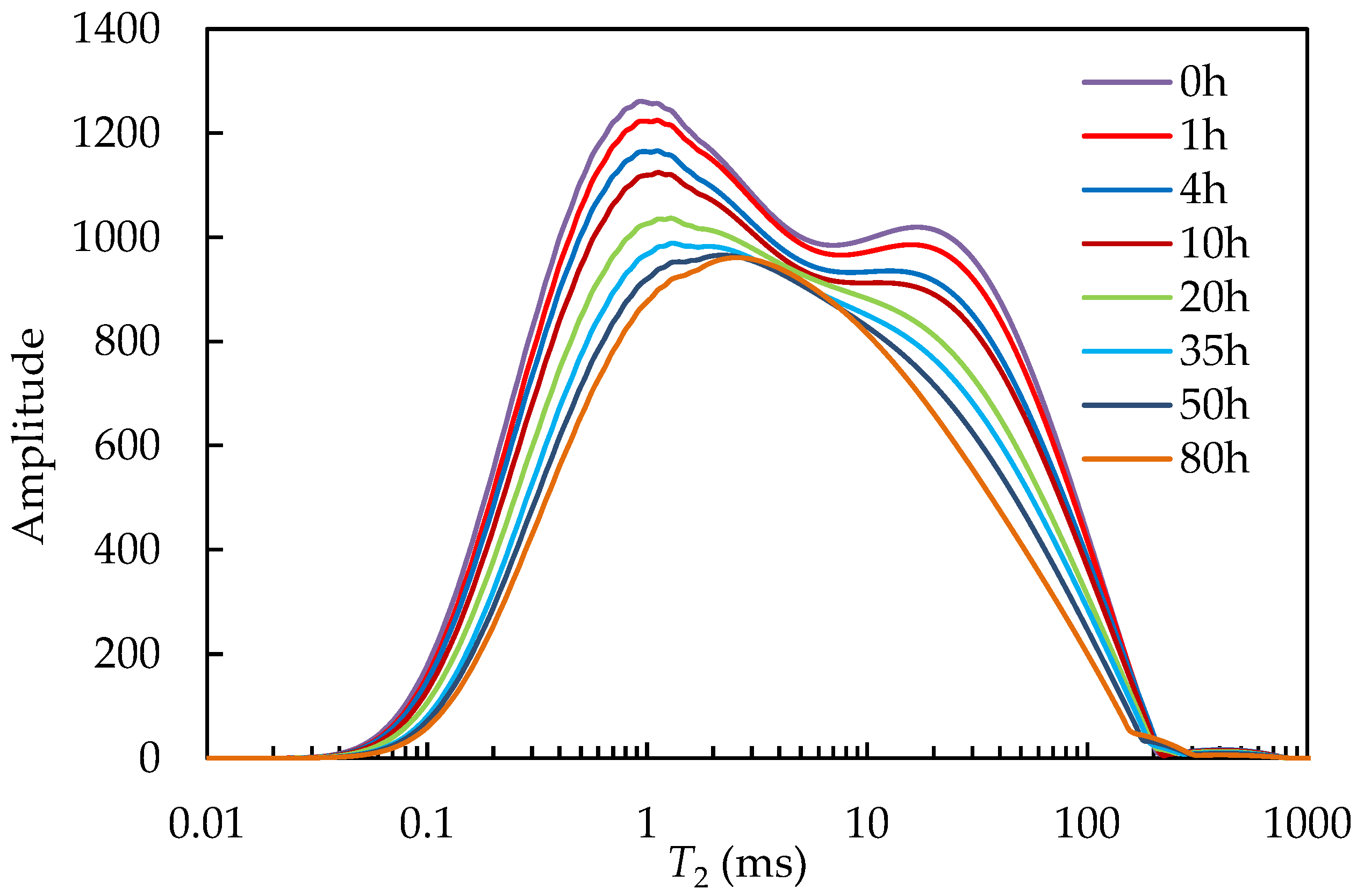

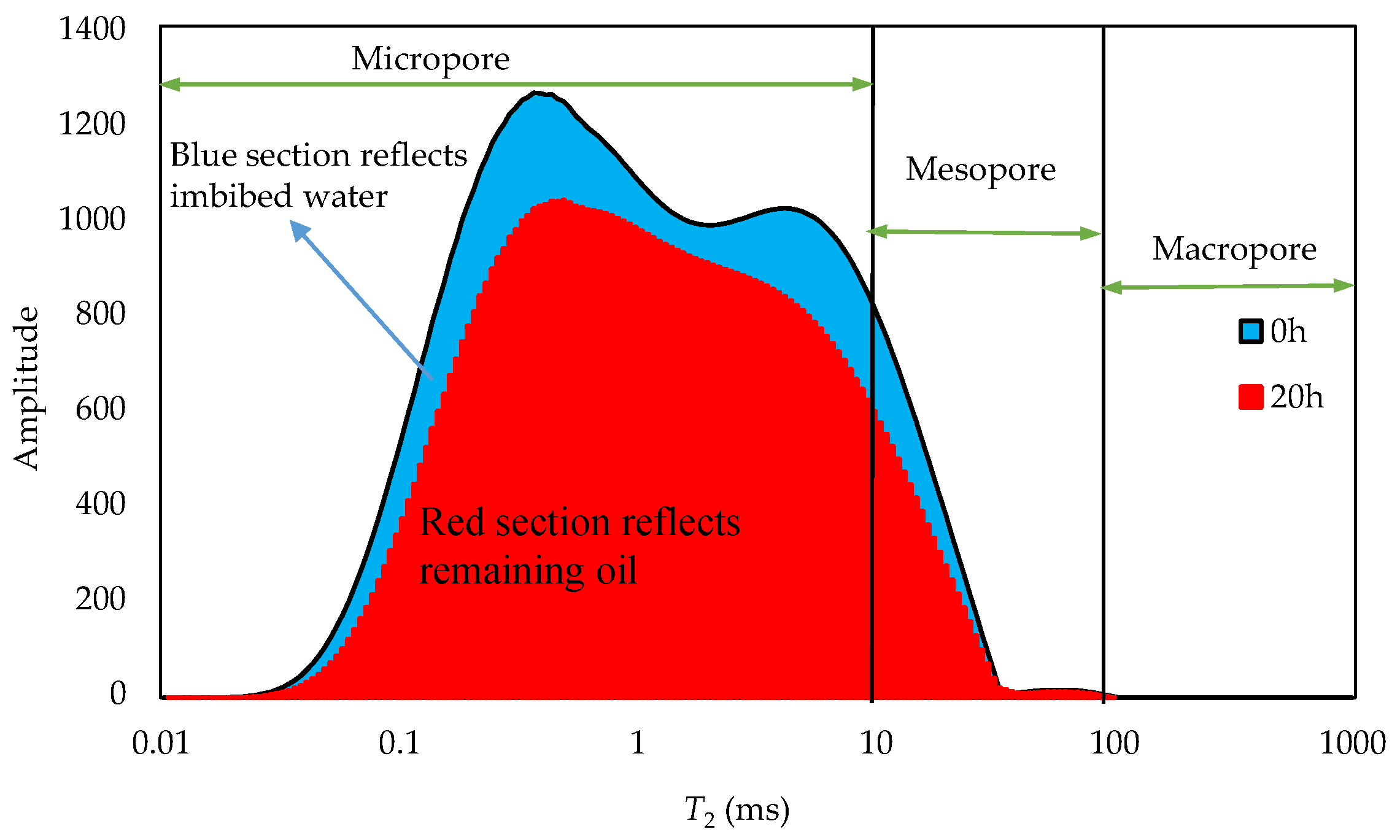

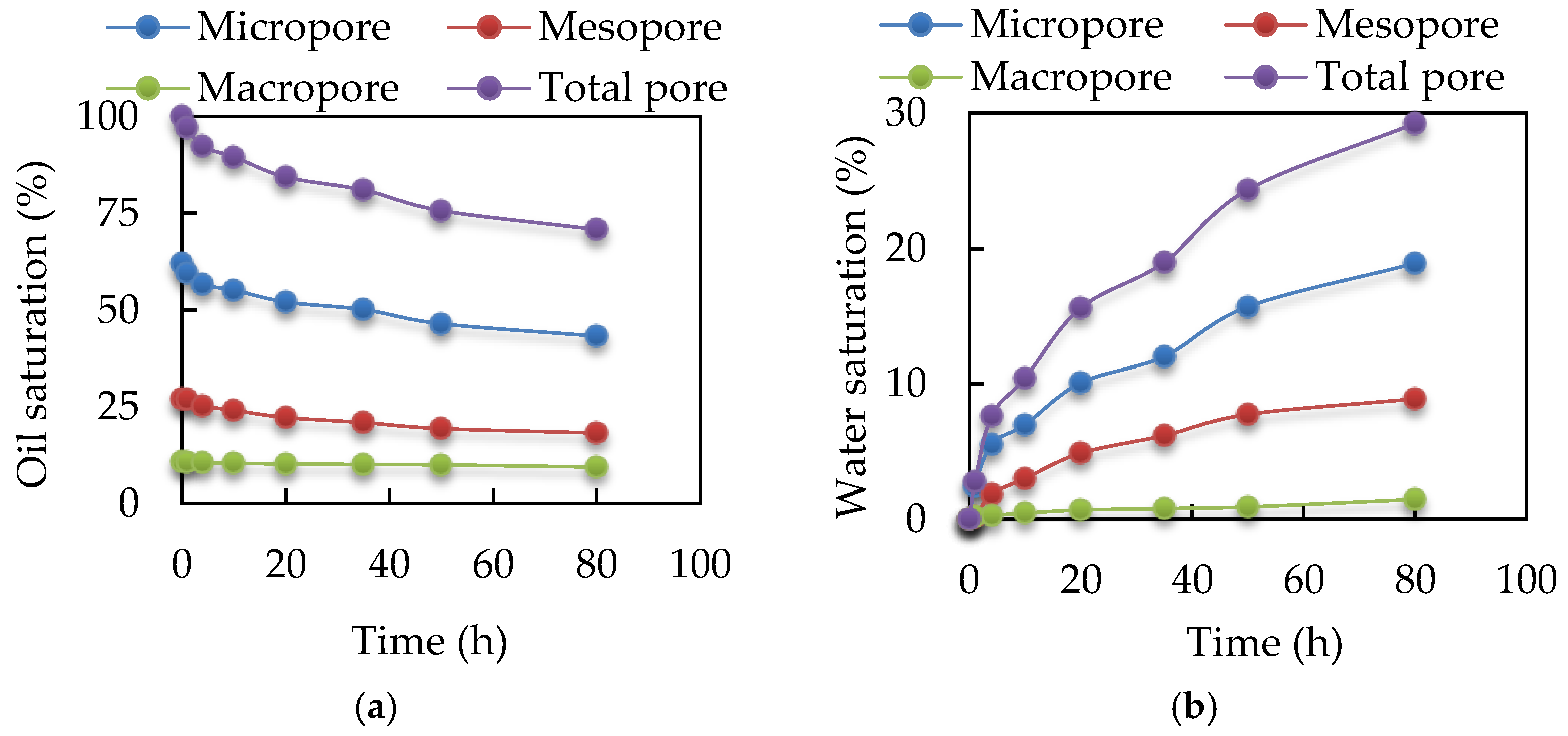

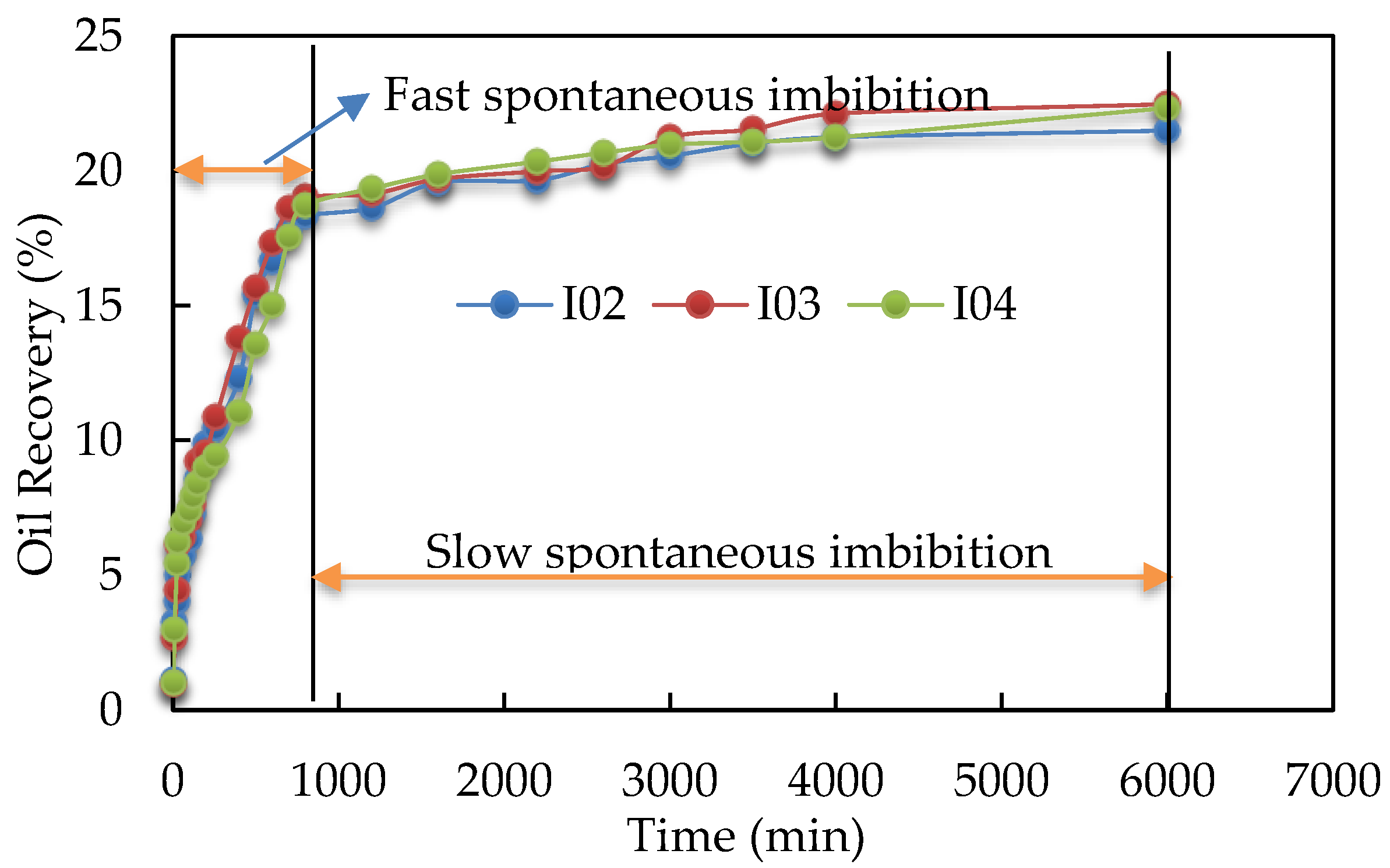

4.2. NMR Results

4.3. MRI Results

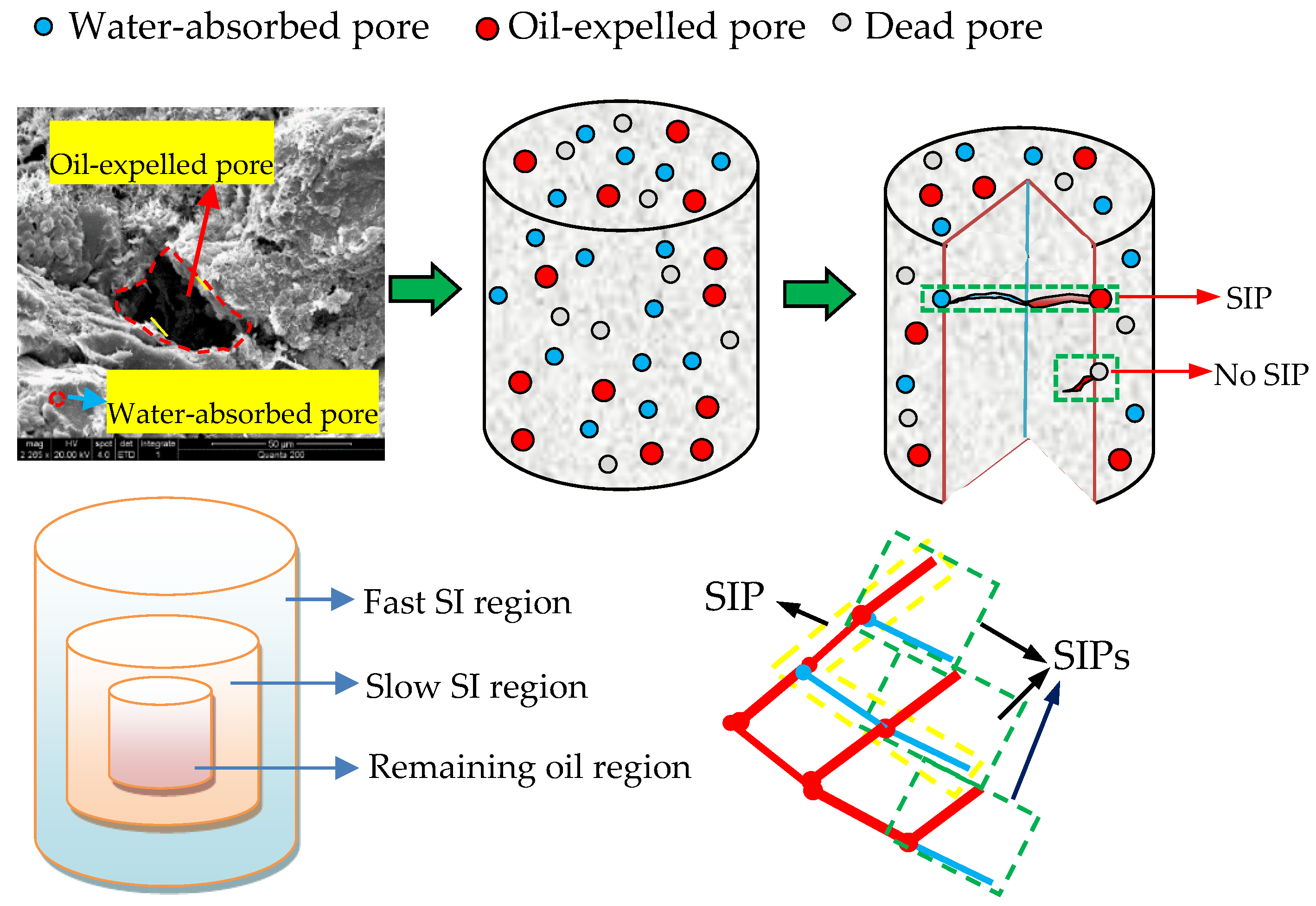

4.4. Spontaneous Imbibition Pathway

5. Conclusions

- The water absorbed into the micropores and mesopores will drive away their original saturated oil, which will enter the large pores hydraulic communication and cause the original saturated oil in the macro pores to escape the core.

- MRI results can effectively demonstrate the distribution of oil and water during the SI process. The development of the SI front can be seen by performing NMI on different stages of SI. MRI results clearly show that the remaining oil accumulates in the central region of the core because a large amount of water is absorbed in the late stage of SI, and the water in the pores gradually connects to form a water shield that blocks the flow of the oil phase.

- We propose a new concept termed spontaneous imbibition pathway, which is the essential cause of the rate of SI. The surface of the core tends to form many SIPs, so the rate of SI is fast. The deep core does not easily form many SIPs, so the rate of SI is slow. Although the SIP theory we proposed can explain the reason for the rate of SI. However, the formation mechanism and quantitative calculation of the SIP have not been studied, which is the focus of our next research.

- The advantage of NMR technology is that it can be visualized for SI. However, it needs to combine the Amott cell. The whole research process needs to take out and put the core sample from the Amott cell multiple times, so that will cause experimental errors. How to combine the Amott cell and NMR to form an integrated device is the next development direction.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, H.; Ma, F.; Tong, X.; Liu, Z.; Zhang, X.; Wu, Z.; Li, D.; Wang, B.; Xie, Y.; Yang, L. Assessment of global unconventional oil and gas resources. Pet. Explor. Dev. 2016, 43, 925–940. [Google Scholar] [CrossRef]

- Zhao, H.; Lai, Z.; Firoozabadi, A. Sorption hysteresis of light hydrocarbons and carbon dioxide in shale and kerogen. Sci. Rep. 2017, 7, 16209. [Google Scholar] [CrossRef] [PubMed]

- Jin, Z.; Firoozabadi, A. Phase behavior and flow in shale nanopores from molecular simulations. Fluid Phase Equilib. 2016, 430, 156–168. [Google Scholar] [CrossRef]

- Dejam, M.; Hassanzadeh, H.; Chen, Z. Pre-Darcy flow in porous media. Water Res. Resour. 2017, 53, 8187–8210. [Google Scholar] [CrossRef]

- Zhang, L.; Kou, Z.; Wang, H.; Zhao, Y.; Dejam, M.; Guo, J.; Du, J. Performance analysis for a model of a multi-wing hydraulically fractured vertical well in a coalbed methane gas reservoir. J. Pet. Sci. Eng. 2018, 166, 104–120. [Google Scholar] [CrossRef]

- Dejam, M.; Hassanzadeh, H.; Chen, Z. Semi-analytical solution for pressure transient analysis of a hydraulically fractured vertical well in a bounded dual-porosity reservoir. J. Hydrol. 2018, 565, 289–301. [Google Scholar] [CrossRef]

- Yao, S.; Zeng, F.; Liu, H.; Zhao, G. A semi-analytical model for multi-stage fractured horizontal wells. J. Hydrol. 2013, 507, 201–212. [Google Scholar] [CrossRef]

- Wang, H.; Liao, X.; Lu, N.; Cai, Z.; Liao, C.; Dou, X. A study on development effect of horizontal well with SRV in unconventional tight oil reservoir. J. Energy Inst. 2014, 87, 114–120. [Google Scholar] [CrossRef]

- Shariatpanahi, S.F.; Strand, S.; Austad, T. Evaluation of water-based enhanced oil recovery (EOR) by wettability alteration in a low-permeable fractured limestone oil reservoir. Energy Fuels 2010, 24, 5997–6008. [Google Scholar] [CrossRef]

- Kathel, P.; Mohanty, K.K. Wettability alteration in a tight oil reservoir. Energy Fuels 2013, 27, 6460–6468. [Google Scholar] [CrossRef]

- Li, J.; Yu, W.; Guerra, D.; Wu, K. Modeling wettability alteration effect on well performance in Permian basin with complex fracture networks. Fuel 2018, 224, 740–751. [Google Scholar] [CrossRef]

- Akin, S.; Schembre, J.M.; Bhat, S.K.; Kovscek, A.R. Spontaneous imbibition characteristics of diatomite. J. Pet. Sci. Eng. 2000, 25, 149–165. [Google Scholar] [CrossRef]

- Schechter, D.S.; Zhou, D.; Orr, F.M., Jr. Low IFT drainage and imbibition. J. Pet. Sci. Eng. 1994, 11, 283–300. [Google Scholar] [CrossRef]

- Li, K.; Horne, R. An analytical scaling method for spontaneous imbibition in gas/water/rock systems. SPE J. 2004, 9, 322–329. [Google Scholar] [CrossRef]

- Ghosh, P.; Kishore, K.M. Novel application of cationic surfactants for foams with wettability alteration in oil-wet low-permeability carbonate rocks. SPE J. 2018, 2, 1126–1139. [Google Scholar] [CrossRef]

- Brownscombe, E.R.; Dyes, A.B. Water-imbibition displacement can it release reluctant spraberry oil? Oil Gas. J. 1952, 11, 64–265. [Google Scholar]

- Aronofsky, J.S.; Jenkins, R. A simplified analysis of unsteady radial gas flow. J. Pet. Technol. 1954, 6, 23–28. [Google Scholar] [CrossRef]

- Dehghanpour, H.; Lan, Q.; Saeed, Y.; Fei, H.; Qi, Z. Spontaneous imbibition of brine and oil in gas shales: Effect of water adsorption and resulting microfractures. Energy Fuels 2013, 27, 3039–3049. [Google Scholar] [CrossRef]

- Makhanov, K.; Habibi, A.; Dehghanpour, H.; Kuru, E. Liquid uptake of gas shales: A workflow to estimate water loss during shut-in periods after fracturing operations. J. Unconv. Oil Gas. Res. 2014, 7, 22–32. [Google Scholar] [CrossRef]

- Yildiz, H.O.; Gokmen, M.; Cesur, Y. Effect of shape factor, characteristic length, and boundary conditions on spontaneous imbibition. J. Pet. Sci. Eng. 2006, 53, 158–170. [Google Scholar] [CrossRef]

- Tinni, A.; Odusina, E.; Sulucarnain, I.; Sondergeld, C.H.; Rai, C.S. Nuclear-Magnetic-Resonance Response of Brine, Oil, and Methane in Organic-Rich Shales. SPE Res. Eval. Eng. 2015, 18, 400–406. [Google Scholar] [CrossRef]

- Meng, M.; Ge, H.; Ji, W.; Wang, X. Research on the auto-removal mechanism of shale aqueous phase trapping using low field nuclear magnetic resonance technique. J. Pet. Sci. Eng. 2016, 137, 63–73. [Google Scholar] [CrossRef]

- Glantz, R.; Hilpert, M. Tight dual models of pore spaces. Adv. Water Resour. 2008, 31, 787–806. [Google Scholar] [CrossRef]

- Chen, S.; Kim, K.H.; Qin, F.; Watson, A.T. Quantitative NMR imaging of multiphase flow in porous media. Magn. Reson. Imaging 1992, 10, 815–826. [Google Scholar] [CrossRef]

- Borgia, G.C.; Fantazzini, P. Nonmobile water quantified in fully saturated porous materials by magnetic resonance relaxation and electrical resistivity measurements. J. Appl. Phys. 1994, 75, 7562–7564. [Google Scholar] [CrossRef]

- Straley, C.; Matteson, A.; Feng, S.; Schwartz, L.M.; Kenyon, W.E.; Banavar, J.R. Magnetic resonance, digital image analysis, and permeability of porous media. Appl. Phys. Lett. 1998, 51, 1146–1148. [Google Scholar] [CrossRef]

- Williams, J.L.A.; Taylor, D.G. Measurements of viscosity and permeability of two phase miscible fluid flow in rock cores. Magn. Reson. Imaging 1994, 12, 317–318. [Google Scholar] [CrossRef]

- Borgia, G.C.; Bortolotti, V.; Brancolini, A.; Brown, R.J.S.; Fantazzini, P. Developments in core analysis by NMR measurements. Magn. Reson. Imaging 1996, 14, 751–760. [Google Scholar] [CrossRef]

- Toumelin, E.; Torres-Verdín, C.; Sun, B.; Dunn, K. Limits of 2D NMR interpretation techniques to quantify pore size, wettability, and fluid type: A numerical sensitivity study. SPE J. 2006, 11, 354–363. [Google Scholar] [CrossRef]

- Halperin, W.P.; Bhattacharja, S.; D’Orazio, F. Relaxation and dynamical properties of water in partially filled porous materials using NMR techniques. Magn. Reson. Imaging 1991, 9, 733–737. [Google Scholar] [CrossRef]

- Wang, W.; Guo, H.; Ye, Z. The evaluation of development potential in low permeability oilfield by the aid of NMR movable fluid detecting technology. Acta Pet. Sin. 2001, 22, 40–44. [Google Scholar]

- Li, J.; Zhou, K.; Zhang, Y.; Xu, Y. Experimental study of rock porous structure damage characteristics under condition of freezing-thawing cycles based on nuclear magnetic resonance technique. Chin. J. Rock Mech. Eng. 2012, 31, 1208–1214. [Google Scholar]

- Guan, Z.; Xie, C.; Dong, H.; Luo, G. 3D Imaging and Visualization Technology of Micro Pore Structure in Porous Media. Geol. Sci. Technol. Inform. 2009, 28, 115–121. [Google Scholar]

- Rouquerol, J.; Everett, A.D.H.; Fairbridge, C.; Haynes, M.; Pernicone, N.; Ramsay, J.D.F.; Sing, K.S.W.; Unger, K.K. Guidelines for the characterization of porous solids. Stud. Surf. Sci. Catal. 1994, 87, 1–9. [Google Scholar]

- Zhu, W.; Ju, Y.; Zhao, M.; Chen, Q.; Yang, Z. Spontaneous imbibition mechanism of flow through porous media and water flooding in low-permeability fractured sandstone reservoir. Acta Pet. Sin. 2002, 23, 56–59. [Google Scholar]

- Lai, F.; Li, Z.; Wei, Q.; Zhang, T.; Zhao, Q. Experimental investigation of spontaneous imbibition in tight reservoir with nuclear magnetic resonance testing. Energy Fuels 2016, 30, 8932–8940. [Google Scholar] [CrossRef]

- Wang, X.; Peng, X.; Zhang, S.; Du, Z.; Zeng, F. Characteristics of oil distributions in forced and spontaneous imbibition of tight oil reservoir. Fuel 2018, 224, 280–288. [Google Scholar] [CrossRef]

- Wu, R.; Yang, S.; Wang, M.; Lv, D.; Kou, G. Experimental study on static imbibition of tight sandstone. J. Liaoning Shihua Univ. 2017, 37, 24–29. [Google Scholar]

- Purcell, E.M.; Torrey, H.C.; Pound, R.V. Resonance absorption by nuclear magnetic moments in a solid. Phys. Rev. 1946, 69, 37–38. [Google Scholar] [CrossRef]

- Lyu, C.; Ning, Z.; Wang, Q.; Chen, M. Application of NMR T2 to pore size distribution and movable fluid distribution in tight sandstones. Energy Fuels 2018, 32, 1395–1405. [Google Scholar] [CrossRef]

- Li, H.; Zhu, J.; Guo, H. Methods for calculating pore radius distribution in rock from NMR T2 spectra. Chin. J. Magn. Reson. 2008, 25, 273–280. [Google Scholar]

- Liu, Z.; Li, Y.; Cui, M.; Wang, F.; Prasiddhianti, A.G. Pore-scale investigation of residual oil displacement in surfactant–polymer flooding using nuclear magnetic resonance experiments. Pet. Sci. 2016, 13, 91–99. [Google Scholar] [CrossRef] [Green Version]

- Xiao, P.; Leng, X.; Xiao, H.; Sun, L.; Zhang, H.; Mei, S.; Zhang, H. Investigation effect of wettability and heterogeneity in water flooding and on microscopic residual oil distribution in tight sandstone cores with NMR technique. Open Phys. 2017, 15, 544–550. [Google Scholar] [CrossRef] [Green Version]

- Tian, X.; Cheng, L.; Cao, R.; An, N.; Zhang, M.; Wang, Y. Characteristics of boundary layer in micro and nano throats of tight sandstone oil reservoirs. Chin. J. Comput. Phys. 2016, 33, 717–725. [Google Scholar]

| Sample No. | Length (cm) | Diameter (cm) | Porosity (%) | Permeability (10−3μm2) | Pore Volume (cm3) |

|---|---|---|---|---|---|

| I01 | 5.353 | 2.521 | 9.94 | 0.0761 | 2.655 |

| I02 | 5.441 | 2.521 | 8.81 | 0.0644 | 2.391 |

| I03 | 5.454 | 2.521 | 7.56 | 0.0621 | 2.057 |

| I04 | 5.278 | 2.521 | 8.42 | 0.0682 | 2.217 |

| pH | Cation (mg/L) | Anion (mg/L) | Total Salinity (mg/L) | Water Type | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| K+ | Na+ | Ca2+ | Mg2+ | Ba2+ | Sr2+ | HCO3− | Cl− | |||

| 7.31 | 2643 | 2711 | 241 | 42 | 55 | 61 | 313 | 8641 | 14,707 | CaCl2 |

| T2 Relaxation Time, ms | Pore Radius, μm | Pore Type |

|---|---|---|

| T2 ≤ 10 | Pore radius ≤ 0.26 | Micropore |

| 10 < T2 ≤ 100 | 0.26 < Pore radius ≤ 2.56 | Mesopore |

| T2 > 100 | Pore radius > 2.56 | Macropore |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nie, X.; Chen, J. Nuclear Magnetic Resonance Measurement of Oil and Water Distributions in Spontaneous Imbibition Process in Tight Oil Reservoirs. Energies 2018, 11, 3114. https://doi.org/10.3390/en11113114

Nie X, Chen J. Nuclear Magnetic Resonance Measurement of Oil and Water Distributions in Spontaneous Imbibition Process in Tight Oil Reservoirs. Energies. 2018; 11(11):3114. https://doi.org/10.3390/en11113114

Chicago/Turabian StyleNie, Xiangrong, and Junbin Chen. 2018. "Nuclear Magnetic Resonance Measurement of Oil and Water Distributions in Spontaneous Imbibition Process in Tight Oil Reservoirs" Energies 11, no. 11: 3114. https://doi.org/10.3390/en11113114