Simulation Study on the Effects of DC Electric Field on Insulator Surface Pollution Deposit

Abstract

:1. Introduction

2. Analysis of Insulator String Electric Field and Electric Force

2.1. Electric Field Simualtion

2.2. Electric Force Calculation

3. Effects of the DC Electric Field on the Pollution Particle’s Motion

- (1)

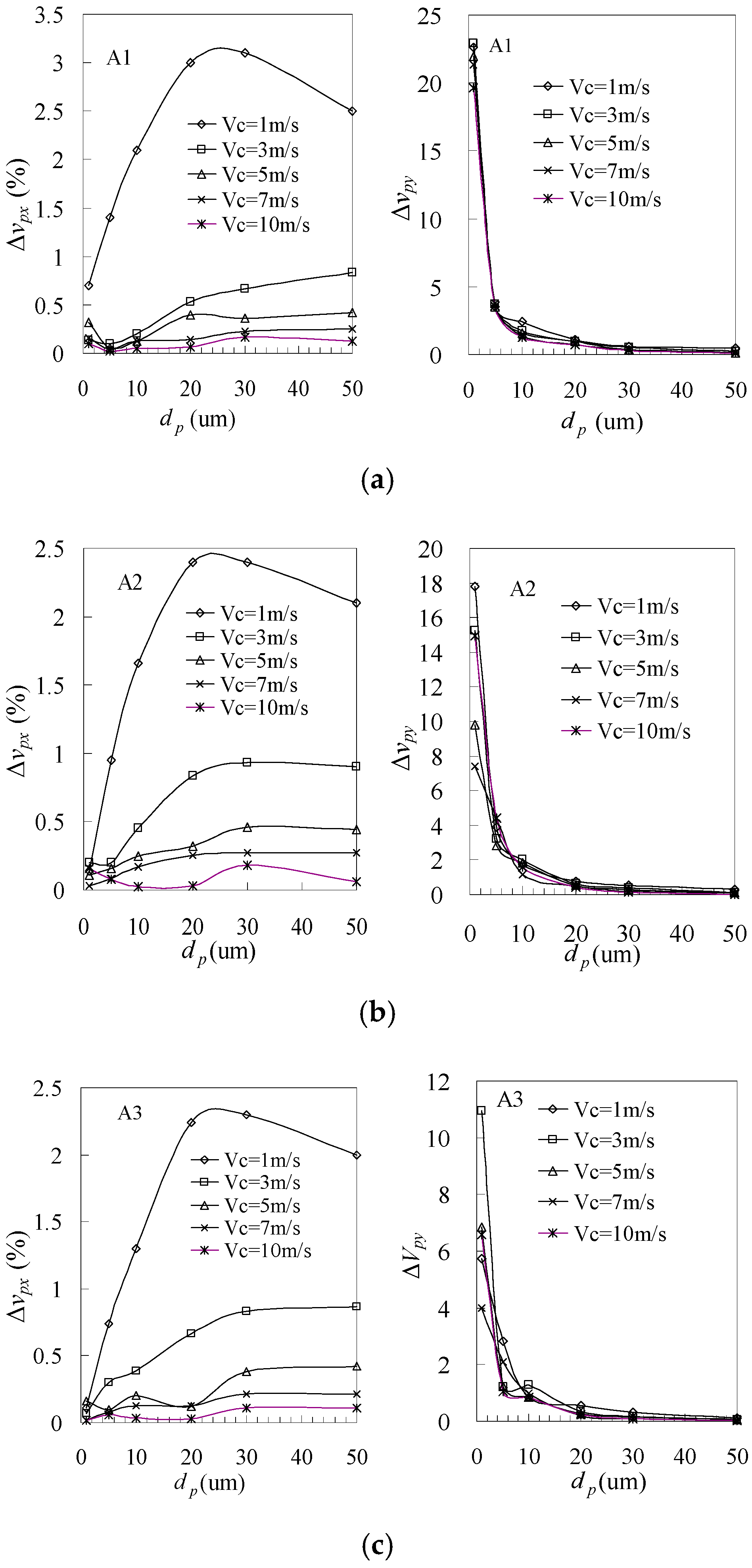

- Under DC electric field, their horizontal moving speed vpx does not change much, the increasing rate is only within 5%. The lower the wind speed, the higher the Δvpx values of particles. This is mainly because when wind velocity is low, the function of air drag force on the particles is weakened, in which case the electric force is relatively distinct and easily accelerates the particle motion.

- (2)

- Particles’ vertical velocity component is greatly affected by the DC electric field. The vertical component of the end speed increased by 0.5–23 times when dp is within 1–50 μm, obviously higher than that of the horizontal component. The smaller the particle diameter, the more outstanding the particle velocity increases in the vertical direction. The increasing rate drops rapidly when dp increases from 1 to 20 μm, and then remains gentle. This is mainly because gravity is proportional to the third power of dp, while the electric force is proportional to the square of dp.

- (3)

- The end speed of particles moving across electric field is associated with the colliding position. The increasing rate of the particles’ end speed is higher if the colliding position is closer to the insulator string (such as A1). This is because it takes a longer time and distance for particles to get closer to the insulator string, in which case the electric force will have a greater effect on the particles’ motion.

4. Effects of DC Electric Field on the Insulator Pollution Degree

- (1)

- The ratio ck presents a decreasing trend with the increment of wind speed, which means the higher the wind speed, the weaker the DC electric field aggravating pollution degree. This is due to higher wind speed, resulting in larger air drag force, which obscures the electric field force.

- (2)

- Additionally, the ratio ck varies obviously with particle diameter dp. The value of the particle capture coefficient ratio ck when dp is 50 μm is always the lowest compared to other conditions (dp = 1 μm, 5 μm, 10 μm, 20 μm), meaning that the DC electric field has less of an effect on the pollution increment when the particle diameter is larger, which is in good accordance with previous analyses. Combined with the results shown in Figure 5, it can be deduced that the critical particle diameter when the air flow field controls the pollution particle deposition more than the DC electric field may be close to 20 μm.

- (3)

- The particle capture coefficient ratio ck is in the range of 1.04 to 1.98 when dp is within 1–50 μm and the wind velocity within 1–5 m/s, very close to the field measurement results of the DC pollution ratio k (within 1.2–1.7), as shown in Table 2. In such a case ck can be used to reflect the pollution degree increment of insulators under DC. In this way the complicated field measurement work can be saved to some degree.

5. Conclusions

- (1)

- The main function of the electric field on insulator contamination is that it changes the particles’ vertical motion during its deposition process from outside to the insulator’s surface, especially when dp is within 1–20 μm. The particle’s vertical speed can increase to 0.5–23 times by electric force, which significantly accelerates the particles’ deposition process and benefits contamination.

- (2)

- The particle capture coefficient ratio ck of DC to non-energized conditions is in the range of 1.04 to 1.98 when dp is within 1–50 μm and wind velocity is within 1–5 m/s, very close to the one-year period field test results of the DC pollution ratio k (within 1.2–1.7) for the ±800 kV line.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jiang, X.; Yuan, J.; Zhang, Z.; Hu, J.; Shu, L. Study on Pollution Flashover Performance of Short Samples of Composite Insulators Intended for ±800 kV UHV DC. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 1192–1200. [Google Scholar] [CrossRef]

- Lin, Y.; Hao, Y.P.; Li, L.C.; Zhao, Y.M. Comparison of pollution flashover performance of porcelain long rod, disc type, and composite UHVDC insulators at high altitudes. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1053–1059. [Google Scholar]

- Baker, A.C.; Farzaneh, M.; Gorur, R.S.; Gubanski, S.M.; Hill, R.J.; Karady, G.G.; Schneider, H.M. Insulator selection for AC overhead lines with respect to contamination. IEEE Trans. Power Deliv. 2009, 24, 1633–1641. [Google Scholar] [CrossRef]

- Ravelomanantsoa, N.; Farzaneh, M.; Chisholm, W.A. A Simulation Method for Winter Pollution Contamination of HV Insulators. In Proceedings of the 2011 Electrical Insulation Conference (EIC), Annapolis, MD, USA, 5–8 June 2011; pp. 373–376. [Google Scholar]

- Sun, J.; Gao, G.; Zhou, L.; Wu, G. Pollution accumulation on rail insulator in high-speed aerosol. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 731–738. [Google Scholar]

- Zhang, Z.; Zhang, D.; Jiang, X.; Liu, X. Study on natural contamination performance of typical types of insulators. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1901–1909. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, W.; You, J.; Jiang, X.; Zhang, D.; Bi, M.; Wu, B.; Wu, J. Influence factors in contamination process of XP-160 insulators based on computational fluid mechanics. IET Gener. Transm. Distrib. 2016, 10, 4140–4148. [Google Scholar] [CrossRef]

- Lampe, W.; Höglund, T.; Nellis, C.; Renner, P.; Stearns, R. Long-term tests of HVDC insulators under natural pollution conditions at the Big Eddy Test Center. IEEE Trans. Power Deliv. 1989, 4, 248–259. [Google Scholar] [CrossRef]

- Horenstein, M.N.; Melcher, J.R. Particle Contamination of High Voltage DC Insulators below Corona Threshold. IEEE Trans. Dielectr. Electr. Insul. 1979, 16, 297–305. [Google Scholar] [CrossRef]

- Lv, Y.; Li, J.; Zhan, X.; Pang, G. A simulation study on pollution accumulation characteristics of XP13-160 porcelain suspension disc insulator. IEEE Trans. Dielectr. Electric Insul. 2016, 23, 2196–2206. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, X.; Wu, G. Simulation and Analysis of Contamination Depositing Characteristic of Roof Insulator. In Proceedings of the 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016; pp. 1–4. [Google Scholar]

- Chao, Y.; Huang, F.; Zhao, S.; Wang, C.; Wang, F.; Yue, Y. Study on natural pollution accumulating characteristics of cap and pin suspension ceramic insulator with composite shed of DC 500 kV transmission line in central China. In Proceedings of the 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016; pp. 1–4. [Google Scholar]

- Liu, Q. Investigation on natural contamination deposition ofinsulators on ±500 kV DC transmission lines in different environments. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013; pp. 347–349. [Google Scholar]

- Jiang, X.; Shu, L.; Sun, C. Power System Pollution and Iced Insulation; Chinese Electric Power Press: Beijing, China, 2009. (In Chinese) [Google Scholar]

- Jayaratne, E.R.; J-Fatokun, F.O.; Morawska, L. Air ion concentrations under overhead high-voltage transmission lines. Atmos. Environ. 2008, 42, 1846–1856. [Google Scholar] [CrossRef] [Green Version]

- Ling, X.; Jayaratne, R.; Morawska, L. The relationship between airborne small ions and particles in urban environments. Atmos. Environ. 2013, 79, 1–6. [Google Scholar] [CrossRef]

- White, H.J. Industrial Electrostatic Precipitators; Addison-Wesley: Boston, MA, USA, 1963. [Google Scholar]

- IEC 60815-4-2016. Selection and Dimensioning of High-Voltage Insulators Intended for Use in Polluted Conditions—Part 4: Insulators for d.c Systems; British Standards: London, UK, 2016. [Google Scholar]

- Su, Z.; Fan, J.; Gu, C.; Zhou, J. The research of pollution level prediction method of HVDC converter stations. Proc. CSEE 2007, 27, 1–5. [Google Scholar]

| Insulator Type | Structure Height (mm) | Shed Diameter (mm) | Creepage Distance (mm) |

|---|---|---|---|

| XP-160 | 155 | 255 | 305 |

| Tower Number | DC-Energized String | Non-Energized String | DC Pollution Ratio k | |||

|---|---|---|---|---|---|---|

| ESDD | NSDD | ESDD | NSDD | By ESDD | By NSDD | |

| No. 1 | 0.075 | 0.245 | 0.049 | 0.165 | 1.52 | 1.48 |

| No. 2 | 0.031 | 0.097 | 0.024 | 0.119 | 1.24 | 0.81 |

| No. 3 | 0.055 | 0.195 | 0.035 | 0.115 | 1.58 | 1.69 |

| Wind Velocity | Particle Capture Coefficient Ratio ck | ||||

|---|---|---|---|---|---|

| dp = 1 μm | dp = 5 μm | dp = 10 μm | dp = 20 μm | dp = 50 μm | |

| VC = 1 m/s | 1.28 | 1.47 | 1.76 | 1.98 | 1.26 |

| VC = 2 m/s | 1.17 | 1.42 | 1.72 | 1.62 | 1.13 |

| VC = 5 m/s | 1.11 | 1.14 | 1.26 | 1.12 | 1.04 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Zhang, Z.; Jiang, X.; Shu, L.; Wu, B. Simulation Study on the Effects of DC Electric Field on Insulator Surface Pollution Deposit. Energies 2018, 11, 626. https://doi.org/10.3390/en11030626

Zhang D, Zhang Z, Jiang X, Shu L, Wu B. Simulation Study on the Effects of DC Electric Field on Insulator Surface Pollution Deposit. Energies. 2018; 11(3):626. https://doi.org/10.3390/en11030626

Chicago/Turabian StyleZhang, Dongdong, Zhijin Zhang, Xingliang Jiang, Lichun Shu, and Bin Wu. 2018. "Simulation Study on the Effects of DC Electric Field on Insulator Surface Pollution Deposit" Energies 11, no. 3: 626. https://doi.org/10.3390/en11030626

APA StyleZhang, D., Zhang, Z., Jiang, X., Shu, L., & Wu, B. (2018). Simulation Study on the Effects of DC Electric Field on Insulator Surface Pollution Deposit. Energies, 11(3), 626. https://doi.org/10.3390/en11030626