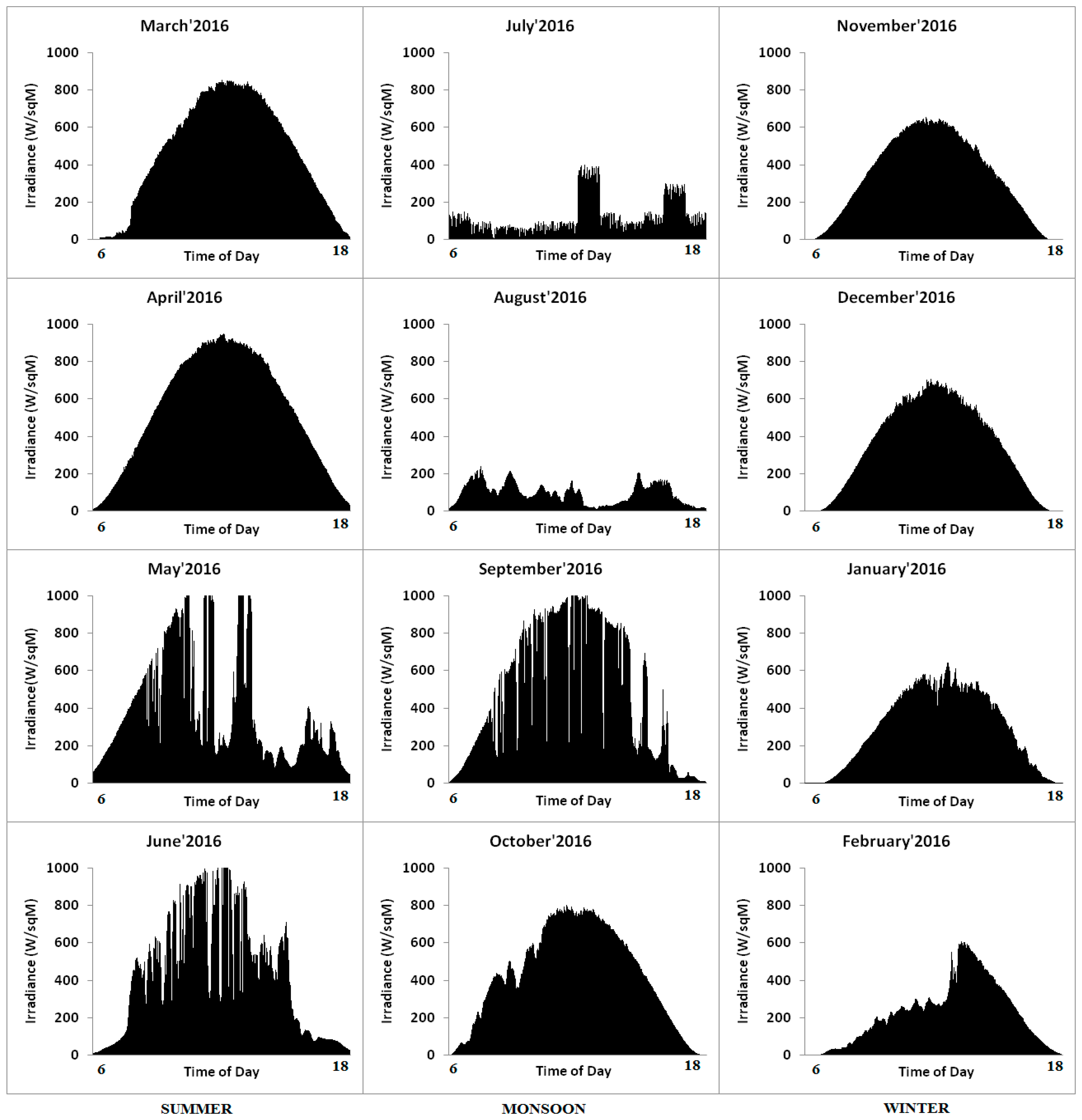

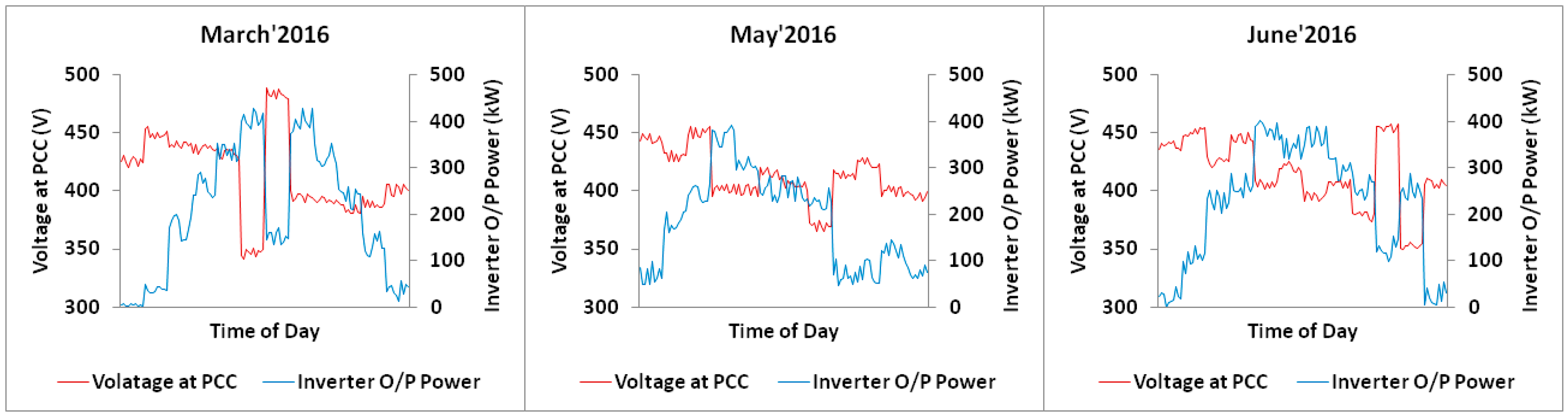

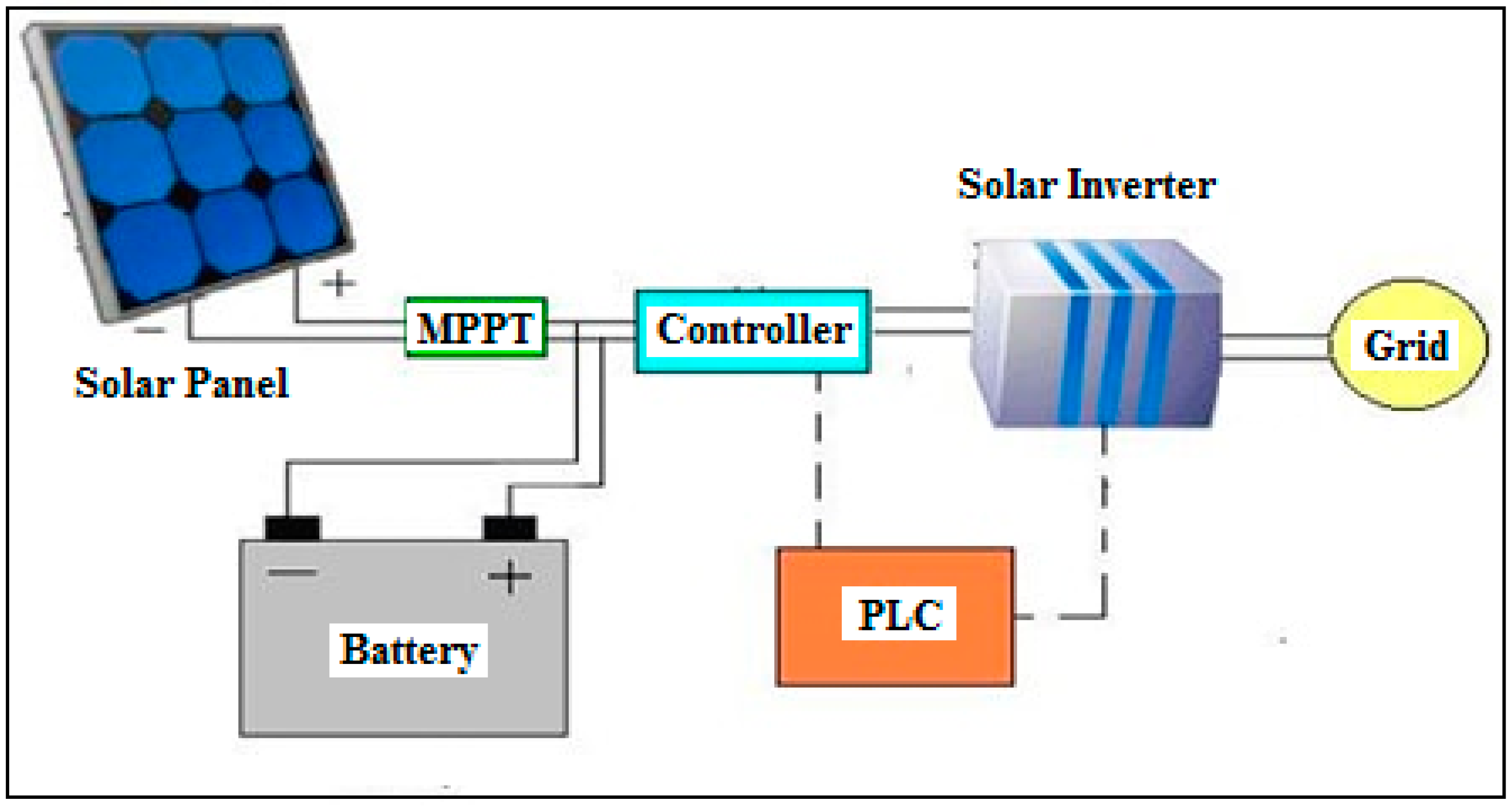

As a follow up of Paris Conference agreement many countries around the world including India have initiated massive programs for establishing thousands of Mega Watt (MW) solar photovoltaic (PV) installations throughout the country in next five to ten years. It is envisaged that hundreds of kilo Watt (kW) of decentralized solar PV power plants in the range of 10 kW to 500 kW or more will be installed in these countries and connected to the local distribution grids. It is also noticed that the solar irradiance level fluctuates seasonally in a significant manner due to the local weather conditions. Such a high penetration level of solar PV and the high rate of change of PV output power due to fluctuation in irradiance can destabilize the distribution system in terms of voltage level leading to outages and unavailability of electricity to the connected loads. However very few studies have been done so far to take account of the frequency and duration of these outages since under the present practice and regulations it is essential to implement remote monitoring system to monitor the inverter parameters such as instantaneous power and energy generation. No provision has been incorporated to monitor and log the voltage at the point of common coupling (PCC), so it is difficult to calculate the energy losses due to the grid voltage outage. In this paper a methodology has been proposed by which the availability of solar power is confirmed at the PCC by incorporating a solar smoother along with storage within the system. Two professional software packages have been used, namely PSCAD (4.5, Manitoba HVDC Research Centre, Winnipeg, MB, Canada) and PVsyst (6.6.4, University of Geneva, Geneva, Switzerland), to simulate the grid voltage instability at the PCC and yearly energy generation from a solar PV plant respectively. Kamaruzzaman et al. [

1] studied the impact of a grid-connected photovoltaic (PV) system on static and dynamic voltage stability. To quantify the effect an analytical technique has also been implemented. Intermittency of high ramp-rated solar irradiance can cause fluctuation in the PV output due to cloud passing, as studied by Alam et al. [

2]. The variation of voltage is more predominant for a weak distribution grid with high PV penetration. This fluctuation can be smoothened by a proper control mechanism of the energy storage devices. In their work, Jewell and Ramakumar [

3] discussed that the power captured by a utility-based dispersed solar photovoltaic generator varied with the fluctuation of incident solar radiation on the utility service area. A load flow program has been simulated to study the impact of distributed residential PV generation on the utility. Maximum PV penetration relative to steady-state voltage and overcurrent has been found in different locations at the distribution feeder investigated by Hoke et al. [

4]. A mitigation technique has also been proposed. Transient and steady-state performance of a photovoltaic system connected to a large utility grid have been investigated by Wang and Lin [

5] using a novel approach based on an eigen value method. In their work, Srisaen and Sangswang [

6] studied the consequences of PV system installation location on the power quality of the distribution system. It has been concluded from the simulation results that implementation of the PV grid-connected system could improve the power quality of a distribution feeder. To increase the reliability of PV-based generation some modifications to existing inverter technology have been proposed by Johnson et al. [

7]. The significant instantaneous ramp rates have been investigated using both the standard method of calculating ramp rates at discrete time intervals and using the piecewise linear approximation method. Jayasekara et al. [

8] in their work have proposed a management technique for distributed battery storage that enhances the capability of distribution networks to utilize PV generation. For energy forecasts optimal daily energy profiles for each storage unit have also been calculated on a one day ahead schedule. The impact of high PV penetration on low voltage distribution system with high X/R ratio, and long tap changing delay has been studied by Yan and Saha [

9]. They also proposed that the distribution networks can be operated with low PV penetration without voltage stability problem due to cloud passing. For high penetration the reactive power support from a PV inverter can be used to mitigate this voltage stability. In his work, Marcos et al. [

10] has discussed a new control scheme (step control) in relation to two strategies—ramp control and moving average—to smooth out PV power fluctuations due to cloud coverage. A technique to calculate the storage capacity requirement for three different control strategies has also been implemented. The design of control systems for PV systems with extremely fast variation of weather conditions and necessary regulations has been investigated by Yan and Saha [

11]. Fast maximum power point tracking (MPPT) is not an appropriate option to solve the high penetration problem because it may create power surges with solar radiation increases of which can create network overvoltage, and breaker tripping problems, etc., so, a new control scheme has been described to control PV power ramping up and whole system becomes smooth. The adverse impact of large scale solar PV installation on the utility grid has been discussed by Omran et al. [

12]. This study also reveals that if the penetration level of the solar PV becomes high then this can have a negative impact on the grid network. Three methods to mitigate these problems have been proposed such as connecting battery storage with the existing PV plant, connecting dump loads and curtailment of power from the solar PV source. By implementing these methods the financial benefits at the consumers’ end have been discussed. Barelli et al. [

13] have discussed the requirement of energy storage for grid stability and safety due to heavy penetration of solar PV installations. This paper simulated the dynamic behaviour of a hybrid energy storage system coupled to a solar PV system and residential load. The result summarizes the evaluation of instantaneous behavior of each component along with the impact of fluctuation of the power on the battery and grid. The effects of passing clouds on the utility-connected battery backup PV system has been studied through radial basis function and back propagation network techniques by Giraud and Salameh [

14]. Moreover, the effect of random clouds on the developed network model is simulated through an artificial neural network and standard linear model and compared with the experimental results. This model can be used for designing and engineering utility-connected PV systems. Chalmers et al. evaluated the effect of solar PV generation on utility operation [

15]. The characteristics of various performance parameters of the system were also examined. Datta et al. [

16] discussed three different control methods for PV output power smoothing to reduce frequency fluctuation, first is fuzzy reasoning-based, the second is an energy storage-based one and the third is a simple coordination-based control method. The results of the three studies have been compared with the MPPT-based control method and found effective in mitigating fluctuations. A Gaussian-based algorithm for smoothing the power fluctuation from renewable energy-based plants has been proposed by Addisu et al. [

17]. By implementing this algorithm the optimum sizing of the Energy Storage System (ESS) has also been determined and compared the result with the moving average method. Up to a 34% improvement in power smoothness and a 19% improvement of battery sizing has been achieved. Different innovative strategies for minimizing the ESS capacity for MW level PV plants have been proposed by Parra et al. in this work [

18]. The results of the proposed strategies have also been validated through simulation and operational PV plant data. It is easier for transmission system operators to handle short term power fluctuations due to intermittency of the PV system. Recently Sarkar et al. [

19] considered the dependence of voltage instability in the distribution grid on the ratio of PV penetration and connected load. However to the best of the knowledge of the authors no work has been reported so far where the loss of energy availability in the distribution grid due to the irradiance fluctuation of the connected PV power plant has been computed methodically and the role of solar smoother in minimizing the loss of energy has been analyzed in depth. In this paper a methodology is first proposed to estimate the of energy non-availability in the distribution grid with heavy penetration of solar power and high fluctuation of irradiance. Next a mitigation technique is demonstrated by designing a suitable solar smoother. Finally a detailed case study is undertaken to validate the proposed methodology.

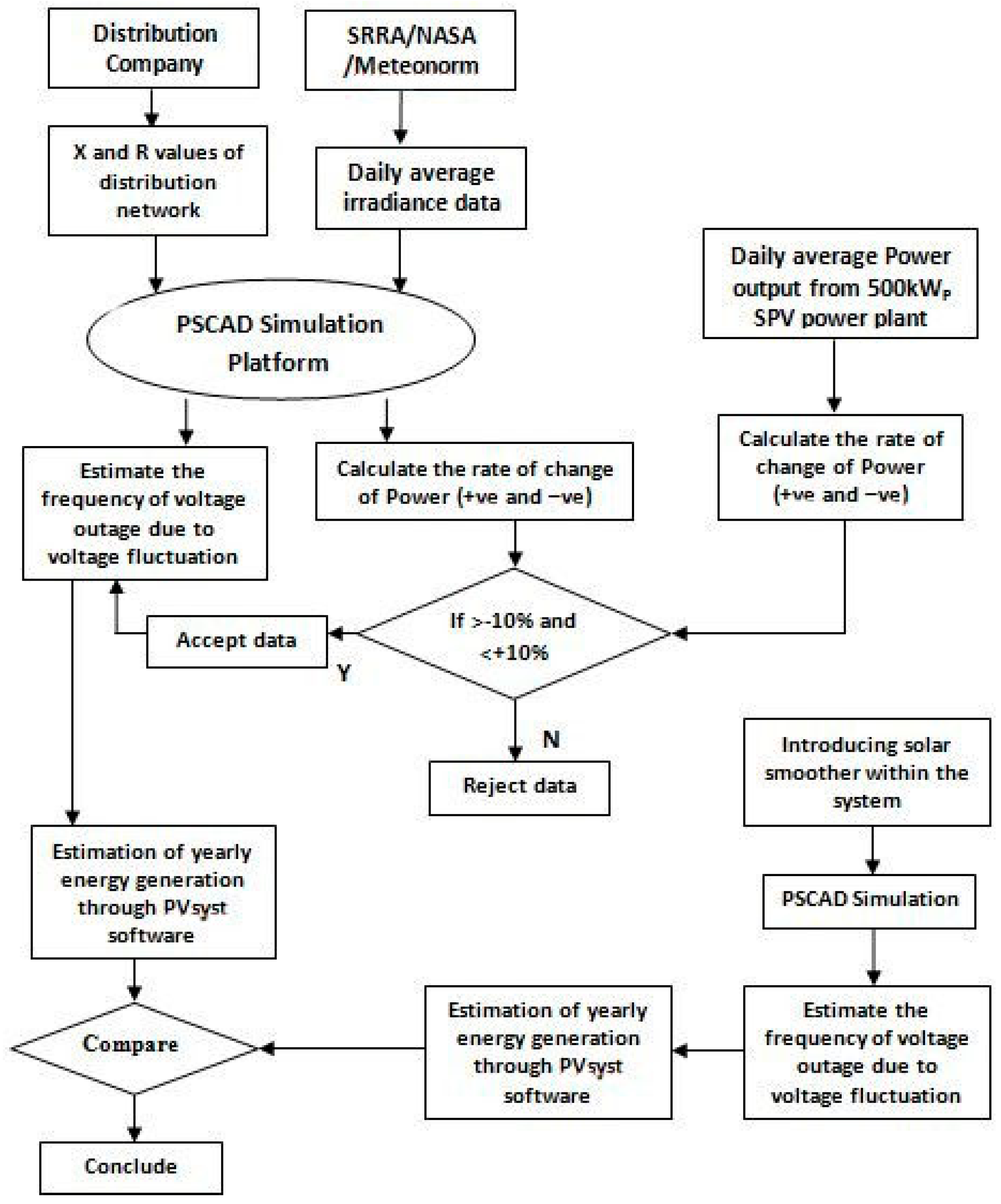

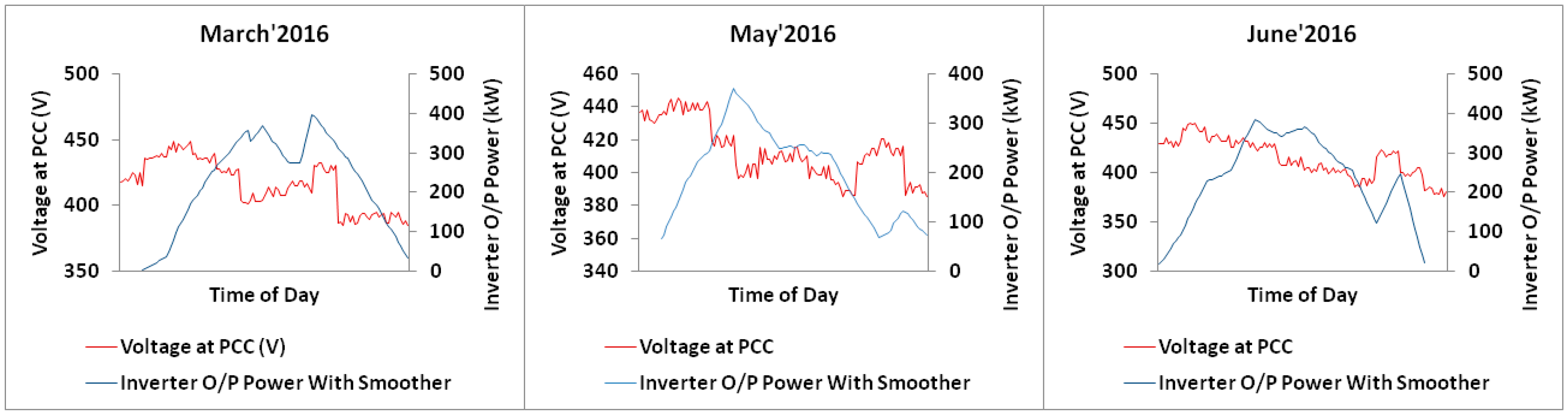

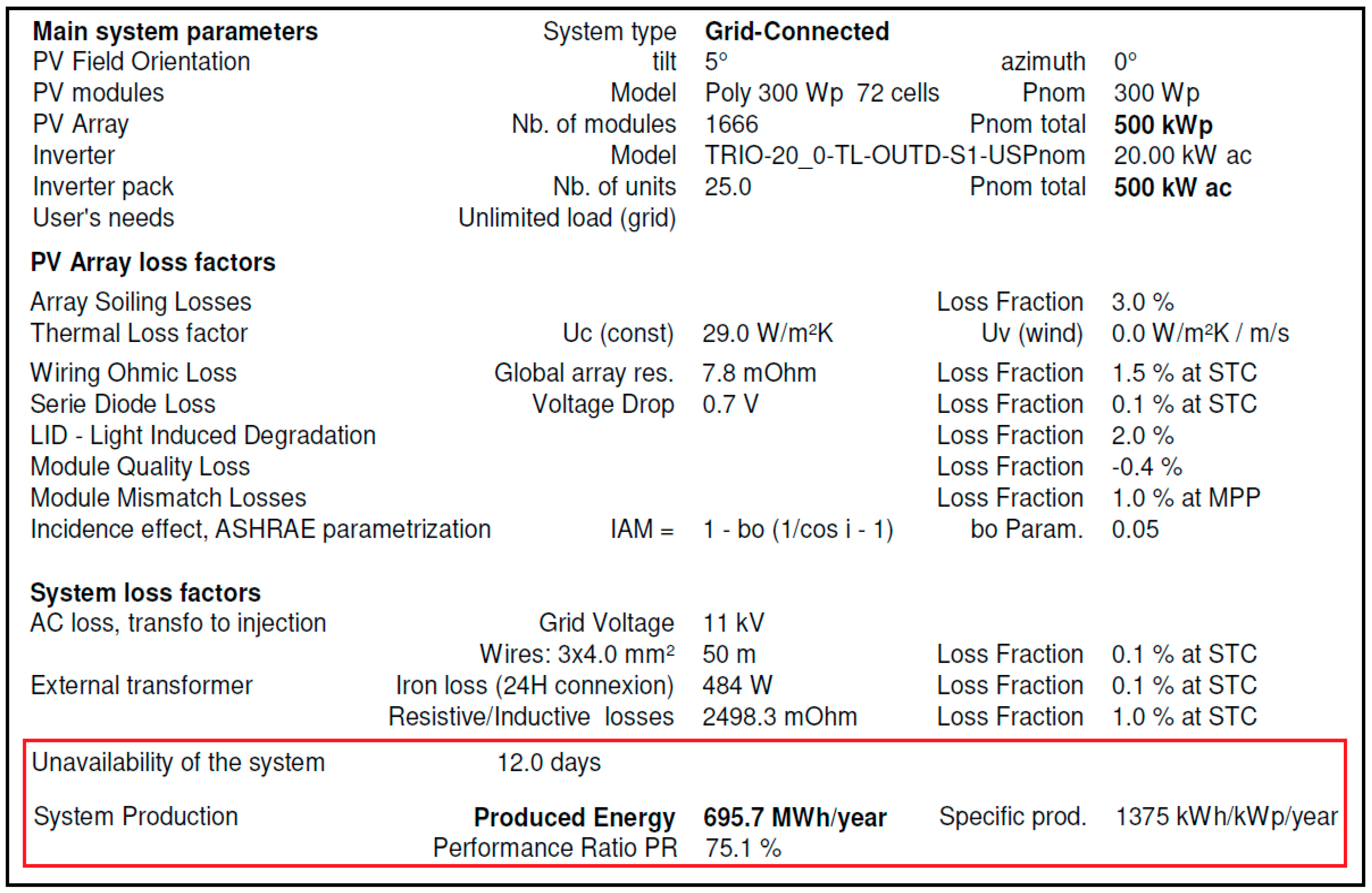

The impact of high penetration of solar PV on the electrical dynamics of the distribution grid has been estimated using the PSCAD simulation platform. The amount of energy non-availability at the grid end with and without solar smoother is demonstrated by using a PVsyst simulation. It has been found that the energy availability is improved by 4.86% throughout the year after using the proposed solar smoother technology.

Further, the proposed solar smoother technology helps in minimizing significant electricity tariff financial losses by mitigating the probability of energy non-availability at the consumer end. The rest is divided into seven sections. This

Section 1 describes the Introduction.

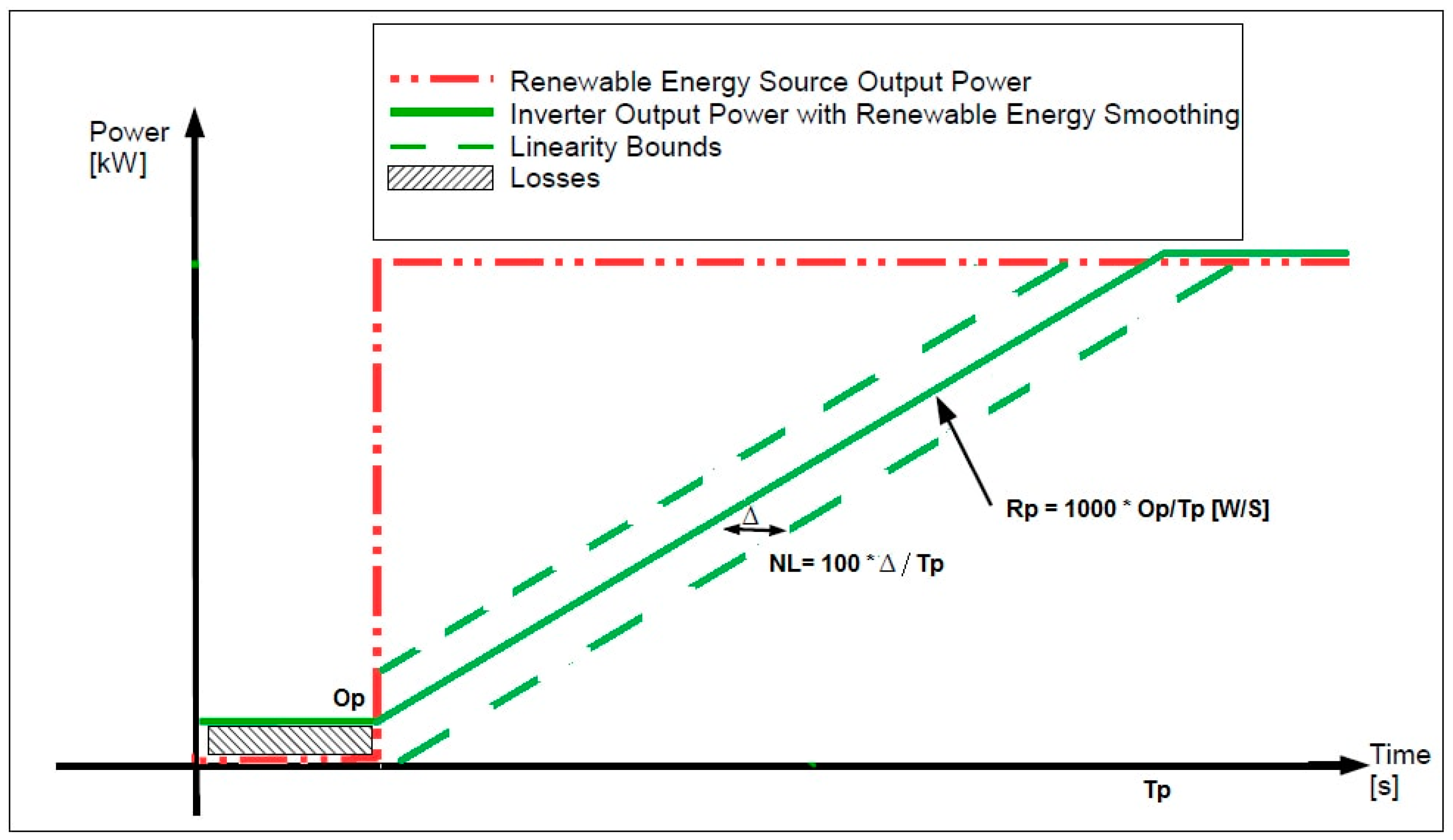

Section 2 describes the effect of ramp up and ramp down of irradiance which leads to a voltage fluctuation in the distribution grid.

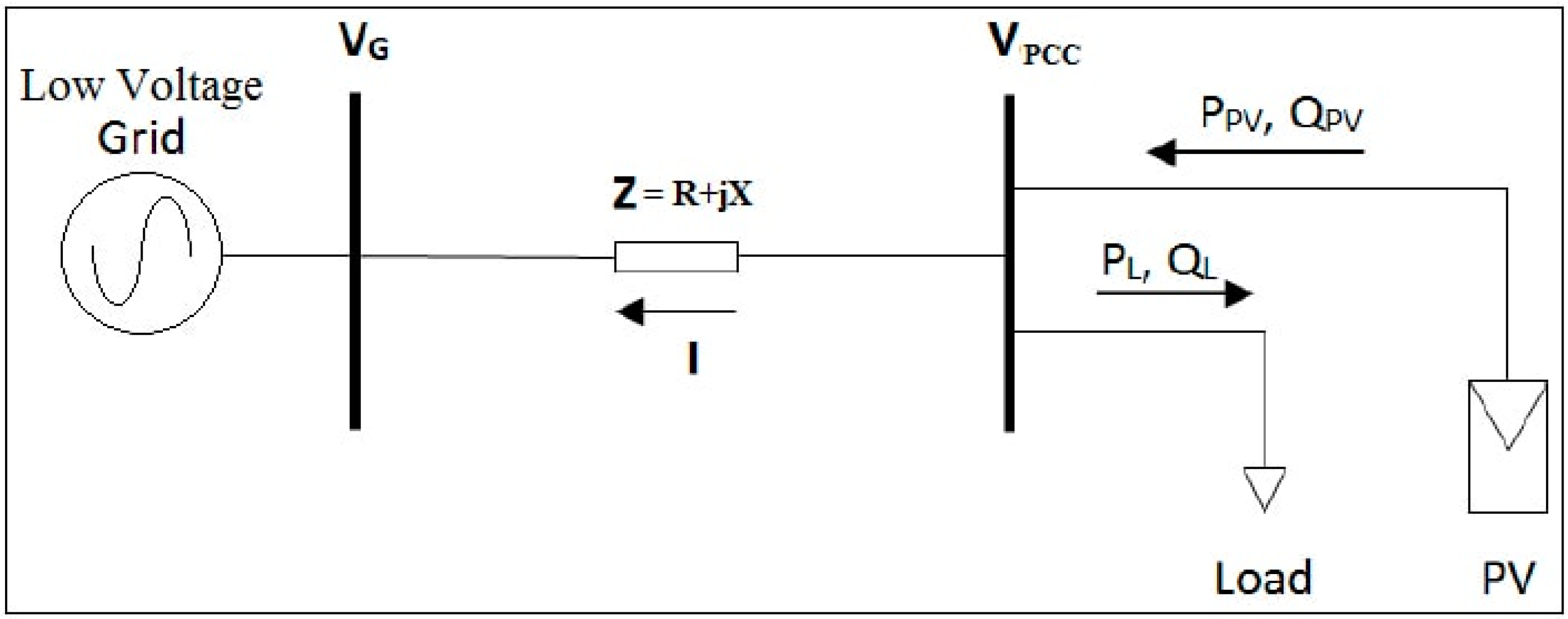

Section 3 describes the modeling of the system.

Section 4 describes the methodology of the system.

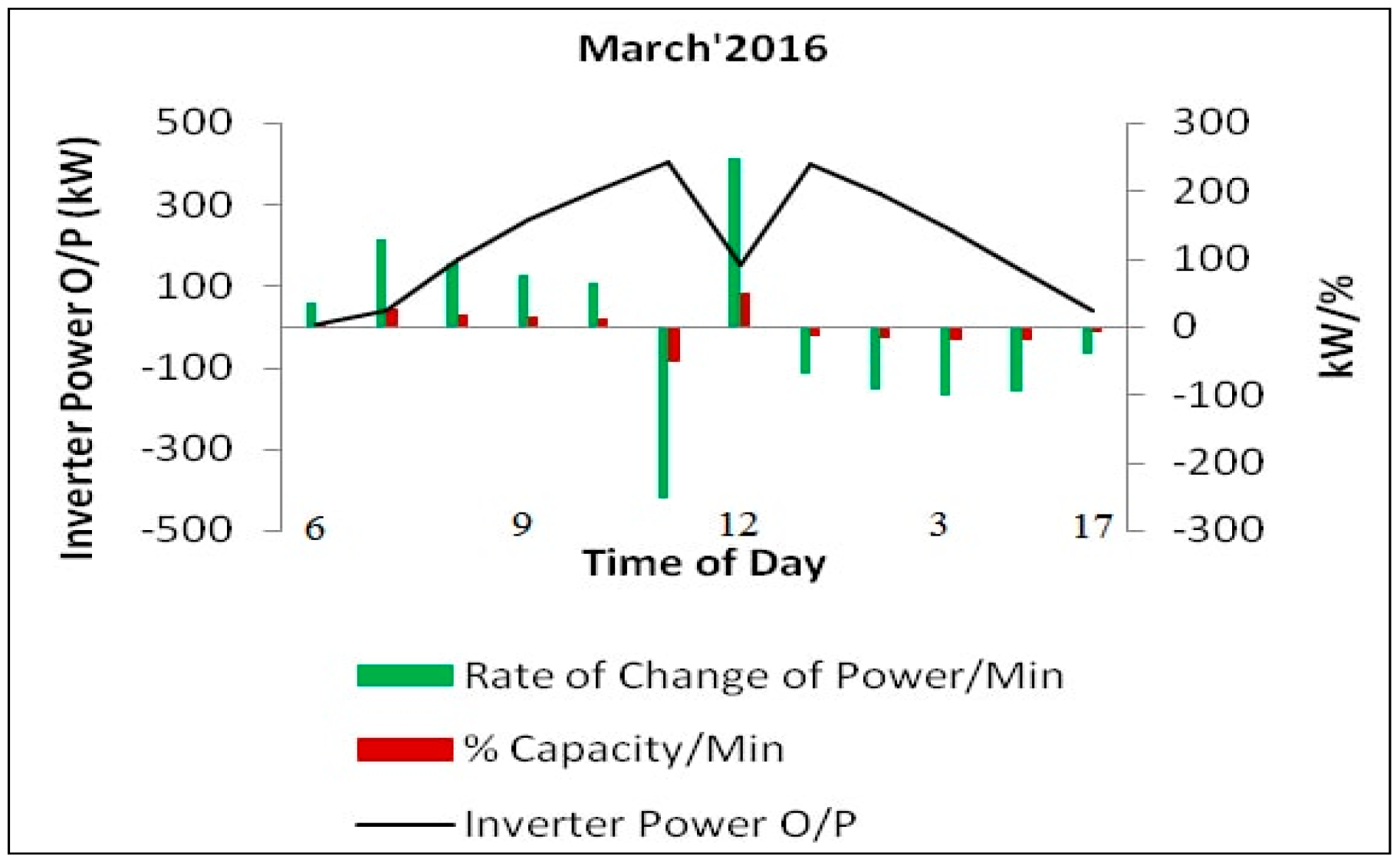

Section 5 describes the case study of 500 kWp solar PV system installed in Kolkata, India, where the energy non-availability has been estimated using the proposed methodology and then validated though actual observations of field data.

Section 6 discusses the financial issues.

Section 7 presents the conclusions of the paper.