Thermal Performance through Heat Retention in Integrated Collector-Storage Solar Water Heaters: A Review

Abstract

:1. Introduction

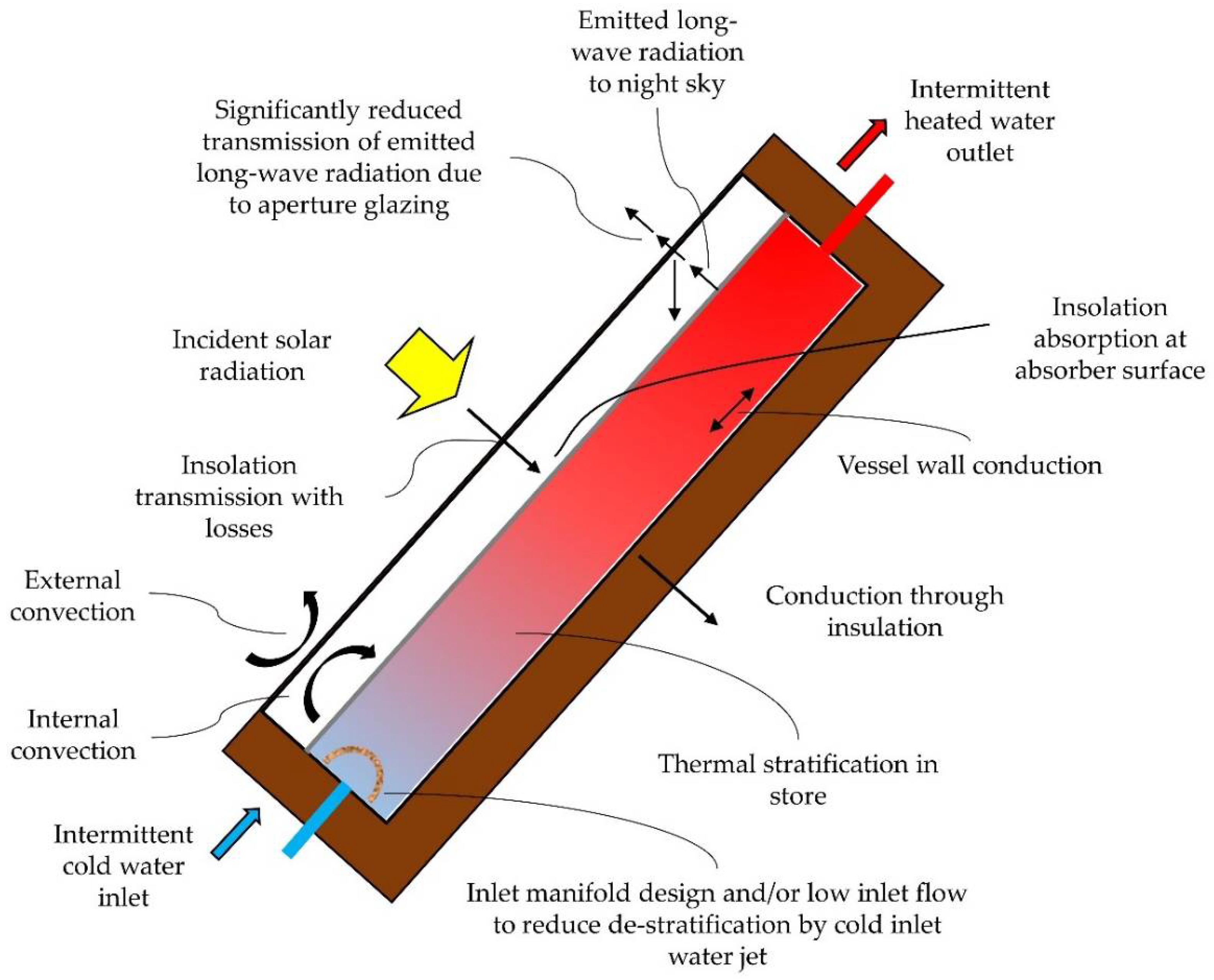

2. Background

3. Heat Gain and Retention Strategies

3.1. Additional Insulation

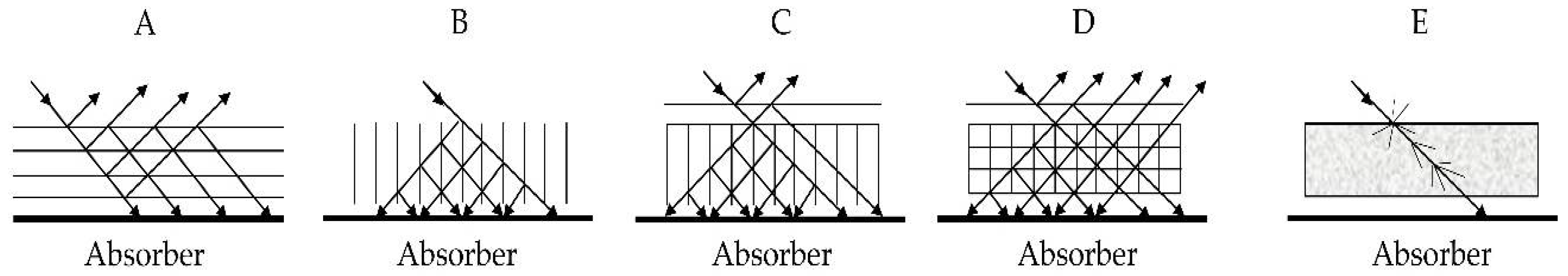

3.1.1. Transparent Insulation Materials (TIMs)

3.1.2. Opaque Insulation

3.1.3. Night Cover

3.2. Auxiliary Heating

Legionella/Freezing

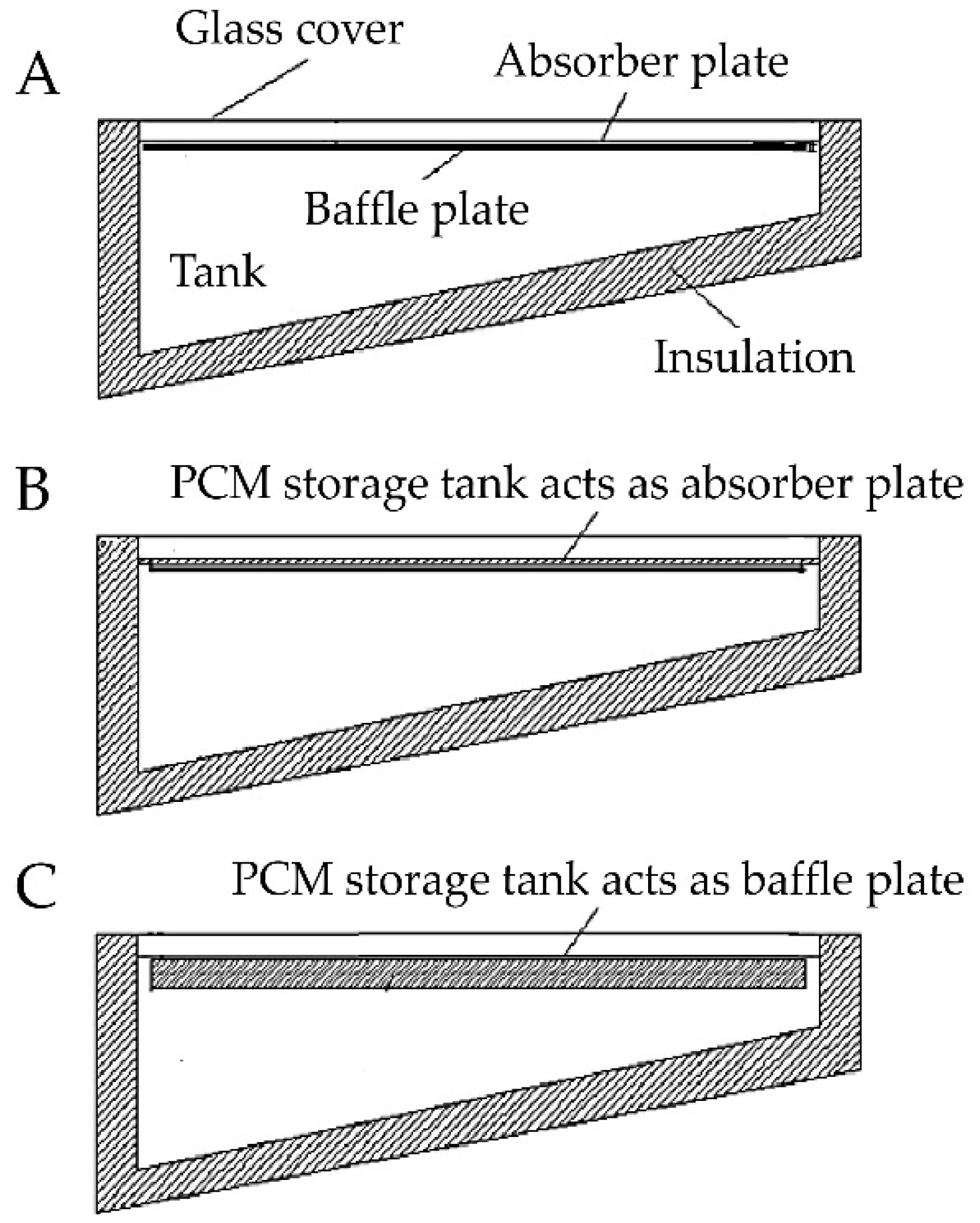

3.3. Baffle Plate/Inner Sleeve

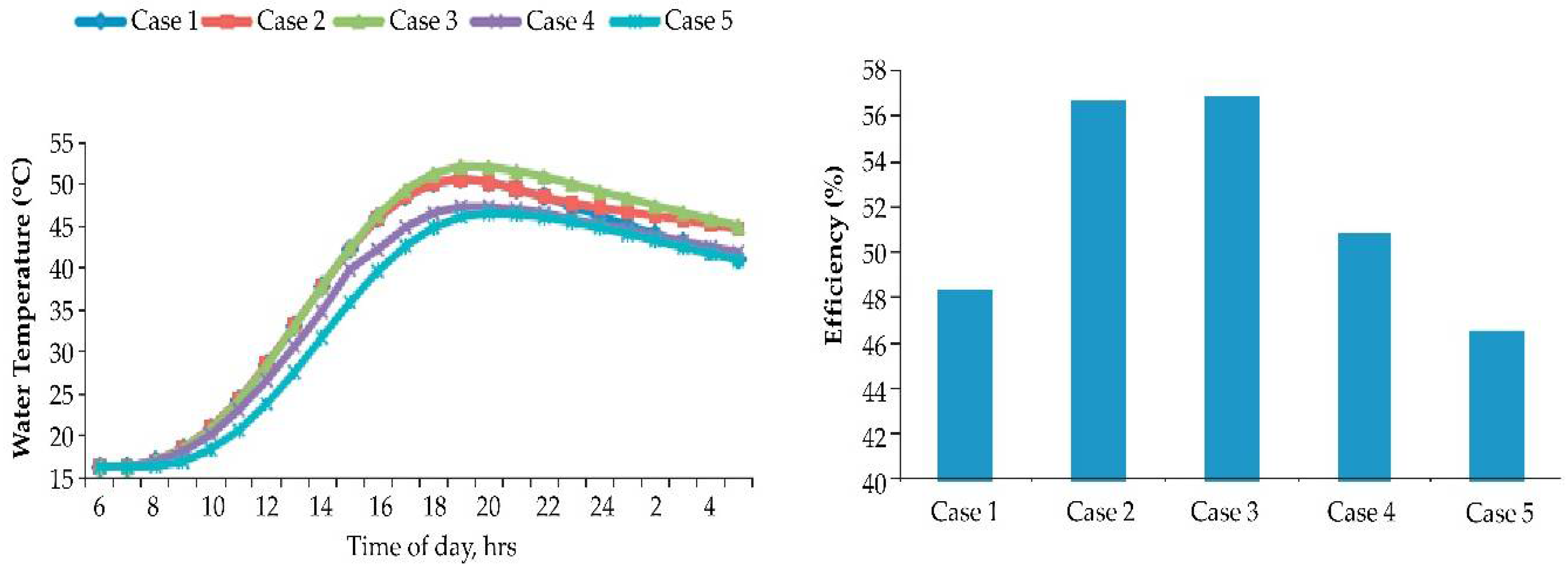

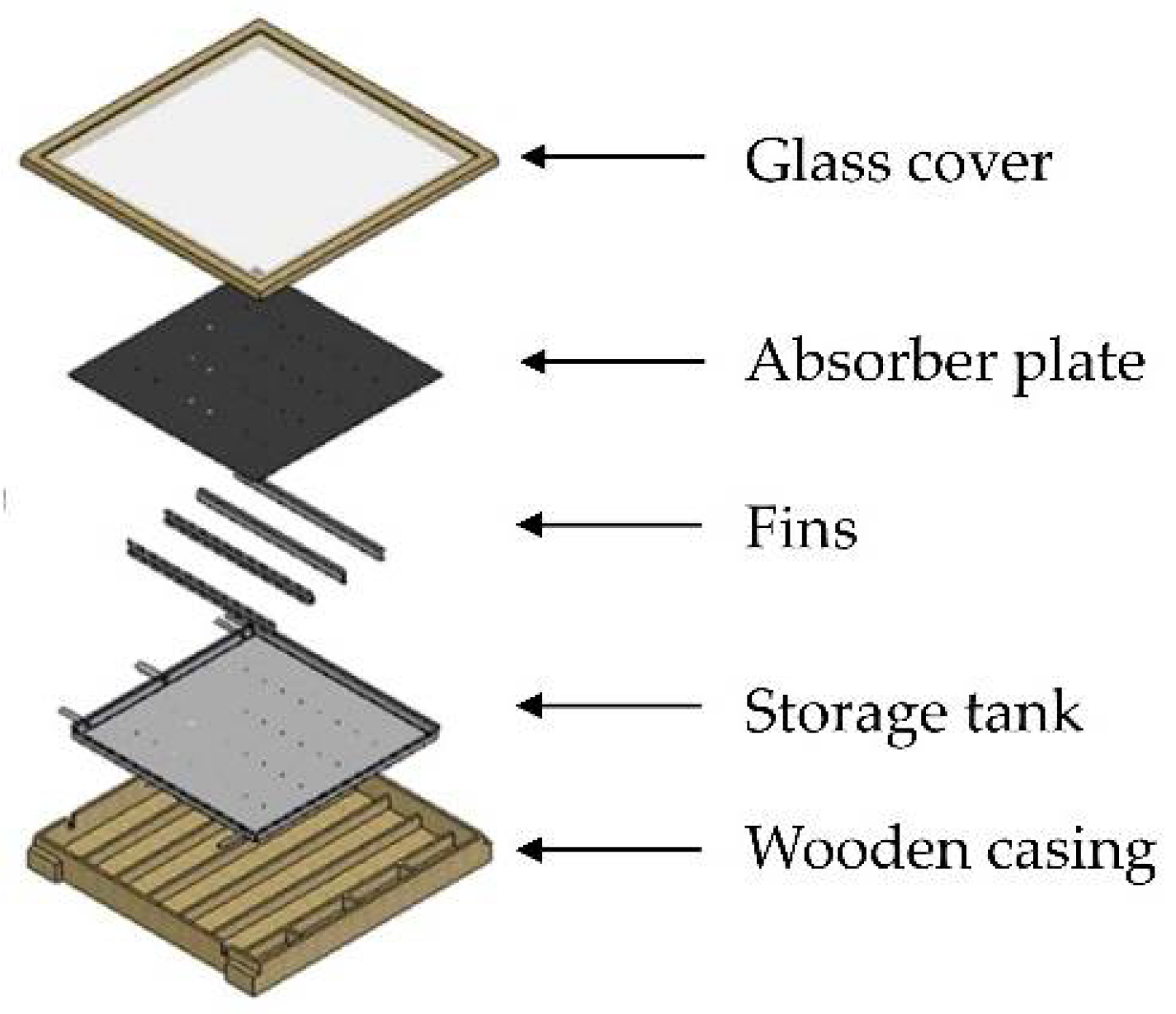

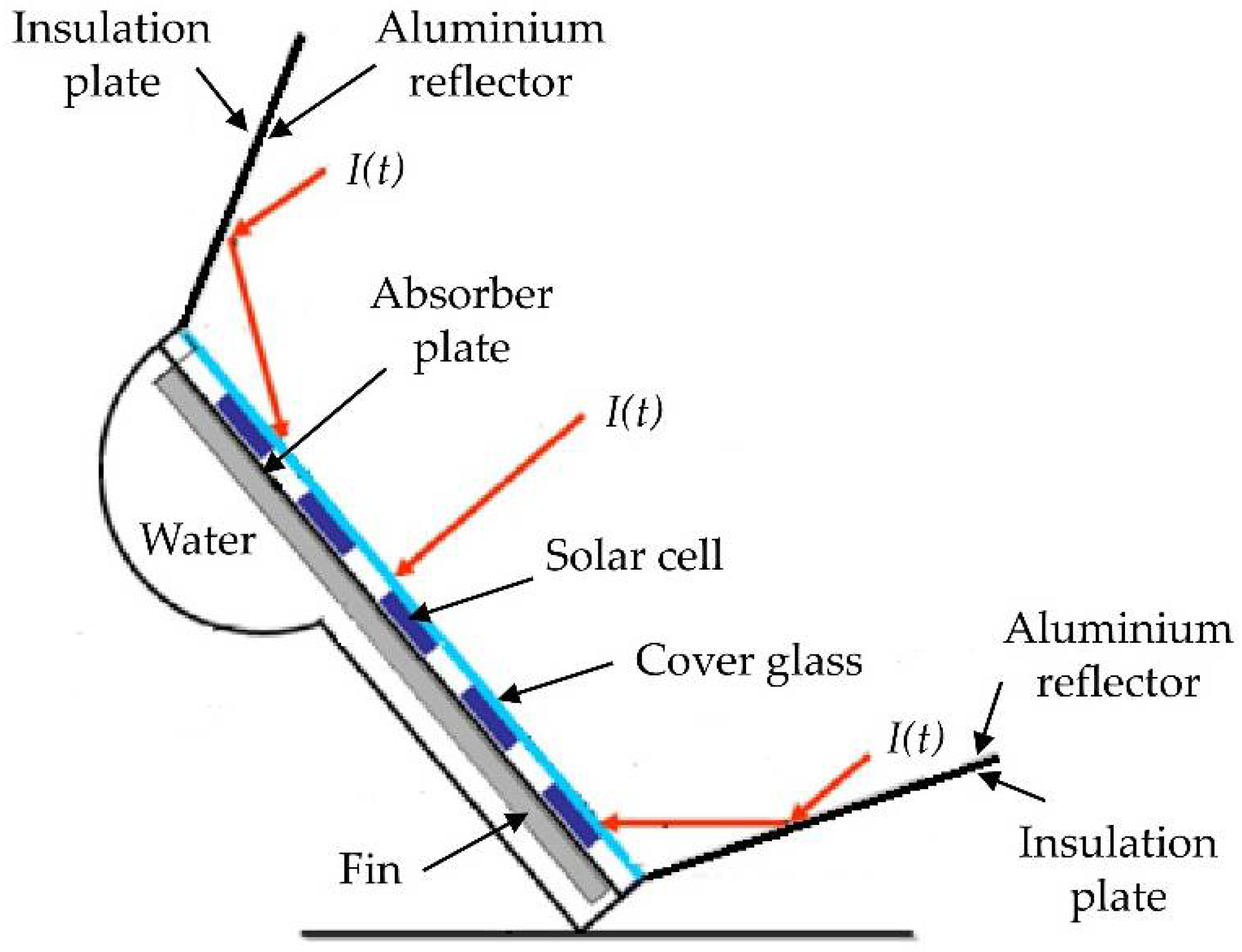

3.4. Fins

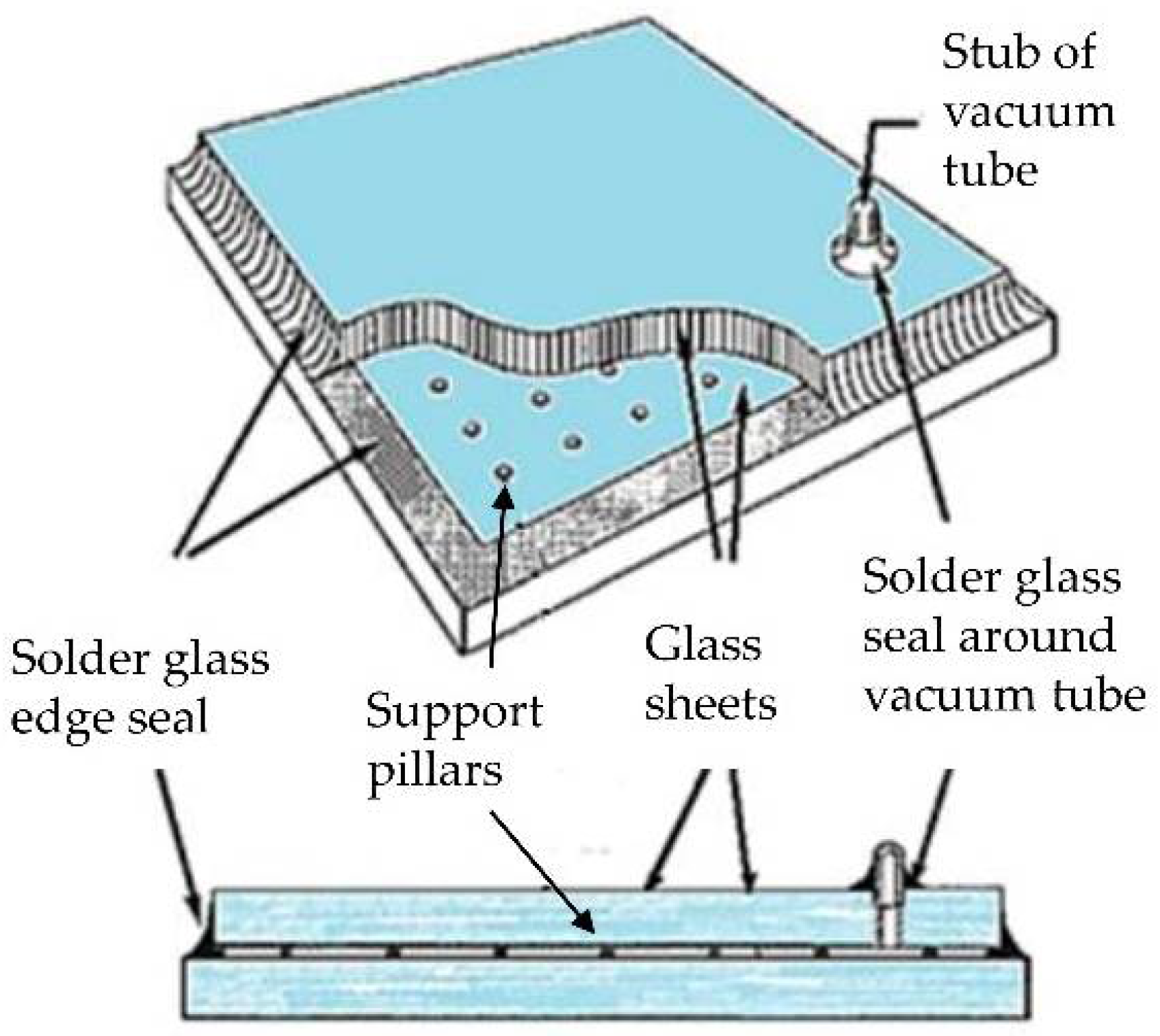

3.5. Glazing

3.5.1. Glazing Layers

3.5.2. Selective Coatings/Glazing Material

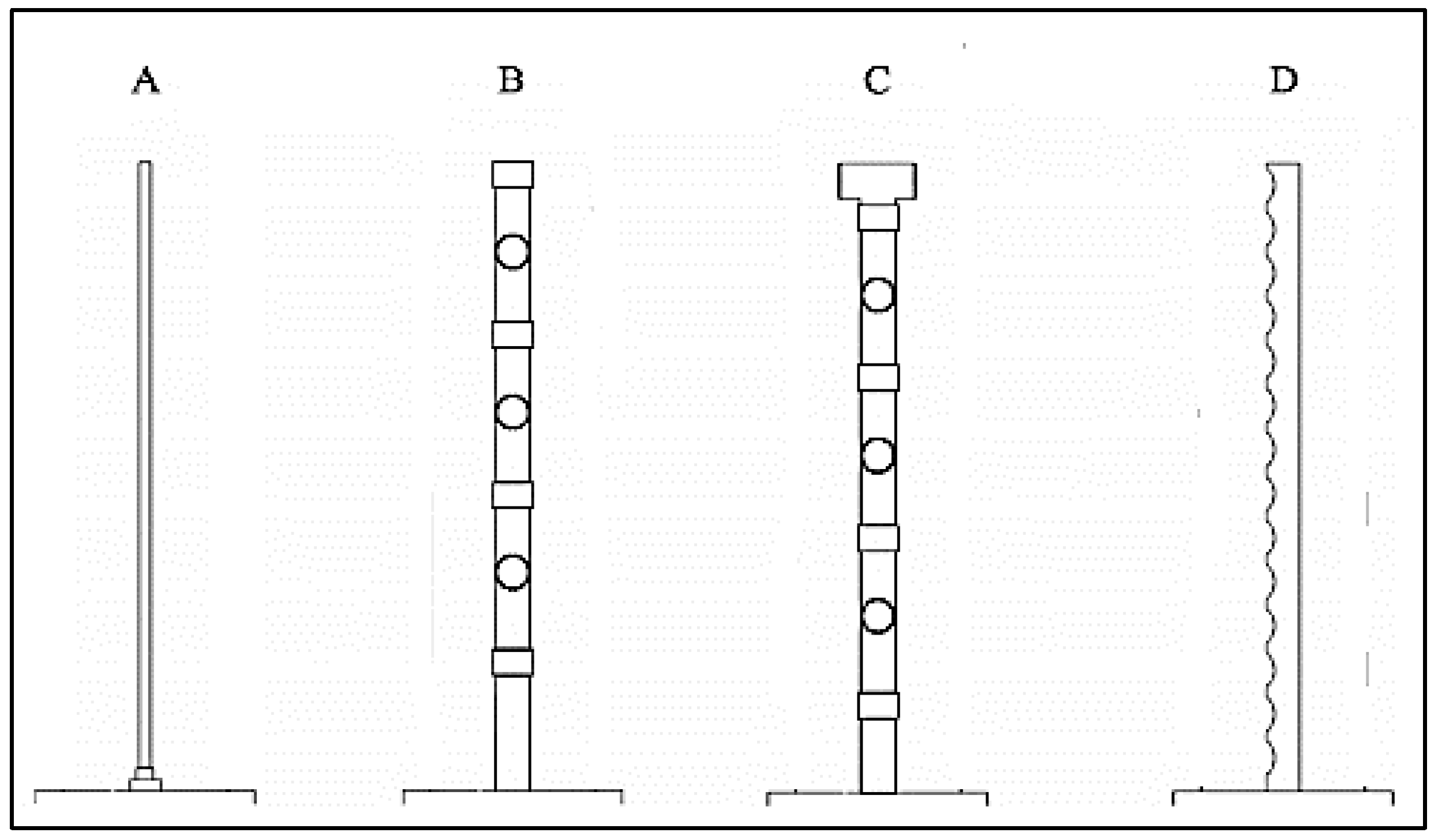

3.6. Inlet Pipe Configuration

3.7. Phase Change Materials (PCM)

3.8. Reflectors

3.9. Selective Absorber Surfaces

3.10. Storage Tank/Collector Material

3.10.1. Metals

3.10.2. Polymer and Composite Materials

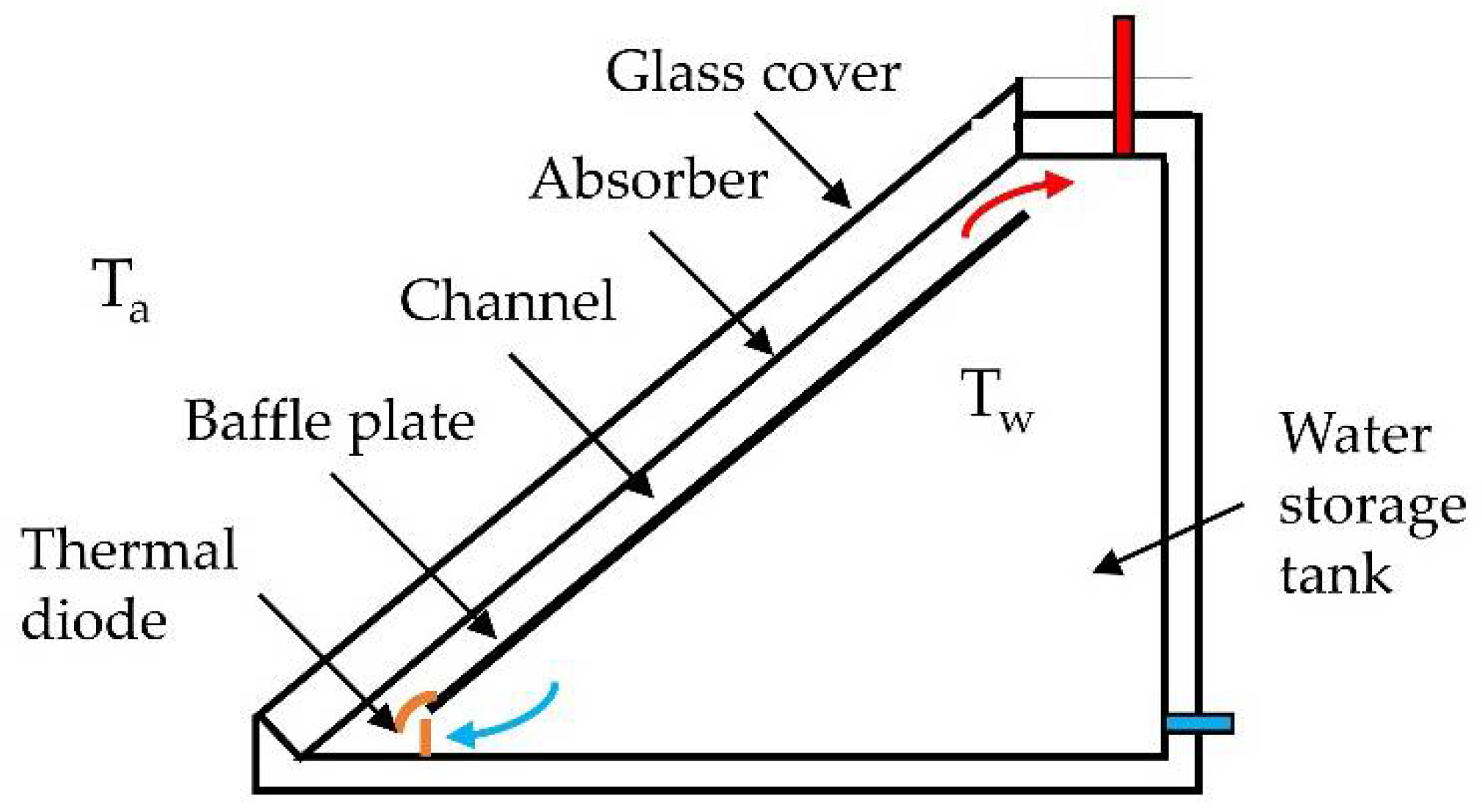

3.11. Thermal Diodes

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| CFD | computational fluid dynamics |

| CPC | compound parabolic concentrator |

| FPTU | flat plate thermosyphonic units |

| GHG | greenhouse gas |

| ICPCSSWH | integrated compound parabolic concentrator storage solar water heater |

| ICS | integrated collector-storage |

| ICSSWH | integrated collector-storage solar water heater |

| PCM | phase change materials |

| PV | Photovoltaic |

| PV/T | photovoltaic-thermal |

| SCS | solar combi system |

| SWH | solar water heater |

| TIMs | transparent insulation materials |

References

- United Nations. Paris Agreement; United Nations: New York, NY, USA, 2015; p. 3. [Google Scholar]

- Ellabban, O.; Abu-Rub, H.; Blaabjerg, F. Renewable energy resources: Current status, future prospects and their enabling technology. Renew. Sustain. Energy Rev. 2014, 39, 748–764. [Google Scholar] [CrossRef]

- Wheelhouse, P. Draft Scottish Energy Strategy: The Future of Energy in Scotland. 2017. Available online: http://www.gov.scot/Publications/2017/01/3414/downloads (accessed on 24 January 2018).

- Jaisankar, S.; Ananth, J.; Thulasi, S.; Jayasuthakar, S.T.; Sheeba, K.N. A comprehensive review on solar water heaters. Renew. Sustain. Energy Rev. 2011, 15, 3045–3050. [Google Scholar] [CrossRef]

- Kemp, C.M. Climax Solar Water Heater. US Patent no. 451384, 28 April 1891. [Google Scholar]

- Smyth, M.; Eames, P.C.; Norton, B. Integrated collector storage solar water heaters. Renew. Sustain. Energy Rev. 2006, 10, 503–538. [Google Scholar] [CrossRef]

- United Nations. Kyoto Protocol to the United Nations Framework Kyoto Protocol to the United Nations Framework. Rev. Eur. Community Int. Environ. Law 1998, 7, 214–217. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2014: Mitigation of Climate Change; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Currie, J.; Garnier, C.; Muneer, T.; Grassie, T.; Henderson, D. Modelling bulk water temperature in integrated collector storage systems. Build. Serv. Eng. 2008, 29, 203–218. [Google Scholar] [CrossRef] [Green Version]

- Kumar, R.; Rosen, M.A. Review of solar water heaters with integrated collector-storage units. Int. J. Energy Environ. Econ. 2013, 21, 343–382. [Google Scholar]

- Raisul Islam, M.; Sumathy, K.; Ullah Khan, S. Solar water heating systems and their market trends. Renew. Sustain. Energy Rev. 2013, 17, 1–25. [Google Scholar] [CrossRef]

- Shukla, R.; Sumathy, K.; Erickson, P.; Gong, J. Recent advances in the solar water heating systems: A review. Renew. Sustain. Energy Rev. 2013, 19, 173–190. [Google Scholar] [CrossRef]

- Tian, Y.; Zhao, C.Y. A review of solar collectors and thermal energy storage in solar thermal applications. Appl. Energy 2013, 104, 538–553. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, O.; Fardoun, F.; Younes, R.; Louahlia-Gualous, H. Review of water-heating systems: General selection approach based on energy and environmental aspects. Build. Environ. 2014, 72, 259–286. [Google Scholar] [CrossRef]

- Buker, M.S.; Riffat, S.B. Building integrated solar thermal collectors—A review. Renew. Sustain. Energy Rev. 2015, 51, 327–346. [Google Scholar] [CrossRef]

- Souliotis, M.; Singh, R.; Papaefthimiou, S.; Lazarus, I.J.; Andriosopoulos, K. Integrated collector storage solar water heaters: Survey and recent developments. Energy Syst. 2015, 7, 49–72. [Google Scholar] [CrossRef]

- Suman, S.; Khan, M.K.; Pathak, M. Performance enhancement of solar collectors—A review. Renew. Sustain. Energy Rev. 2015, 49, 192–210. [Google Scholar] [CrossRef]

- Colangelo, G.; Favale, E.; Miglietta, P.; De Risi, A. Innovation in flat solar thermal collectors: A review of the last ten years experimental results. Renew. Sustain. Energy Rev. 2016, 57, 1141–1159. [Google Scholar] [CrossRef]

- Jamar, A.; Majid, Z.A.A.; Azmi, W.H.; Norhafana, M.; Razak, A.A. A review of water heating system for solar energy applications. Int. Commun. Heat Mass Transf. 2016, 76, 178–187. [Google Scholar] [CrossRef]

- Singh, R.; Lazarus, I.J.; Souliotis, M. Recent developments in integrated collector storage (ICS) solar water heaters: A review. Renew. Sustain. Energy Rev. 2016, 54, 270–298. [Google Scholar] [CrossRef]

- Grassie, T.; Junaidi, H.; Muneer, T.; Currie, J.; Henderson, D. Study of the Modified Built-in Storage (Integrated Collector Storage) Solar Water Heater for Scottish Weather Conditions. In EuroSun 2006; Groenhout: Antwerp, Belgium, 2006. [Google Scholar]

- Muneer, T.; Maubleu, S.; Asif, M. Prospects of solar water heating for textile industry in Pakistan. Renew. Sustain. Energy Rev. 2006, 10, 1–23. [Google Scholar] [CrossRef]

- McCracken, H. How to Build a Passive Solar Water Heater; Carlos: Alturas, CA, USA, 1978. [Google Scholar]

- Kaushika, N.D.; Sumathy, K. Solar transparent insulation materials: A review. Renew. Sustain. Energy Rev. 2003, 7, 317–351. [Google Scholar] [CrossRef]

- Schmidt, C.; Goetzberger, A. Single-tube integrated collector storage systems with transparent insulation and involute reflector. Sol. Energy 1990, 45, 93–100. [Google Scholar] [CrossRef]

- Chaurasia, P.B.L.; Twidell, J. Collector cum storage solar water heaters with and without transparent insulation material. Sol. Energy 2001, 70, 403–416. [Google Scholar] [CrossRef]

- Reddy, K.S.; Kaushika, N.D. Comparative study of transparent insulation materials cover systems for integrated-collector-storage solar water heaters. Sol. Energy Mater. Sol. Cells 1999, 58, 431–446. [Google Scholar] [CrossRef]

- Kaushika, N.D.; Reddy, K.S. Thermal design and field experiment of transparent honeycomb insulated integrated-collector-storage solar water heater. Appl. Therm. Eng. 1999, 19, 145–161. [Google Scholar] [CrossRef]

- Ghoneim, A.A. Performance optimization of solar collector equipped with different arrangements of square-celled honeycomb. Int. J. Therm. Sci. 2005, 44, 95–105. [Google Scholar] [CrossRef]

- Tripanagnostopoulos, Y.; Souliotis, M.; Nousia, T. Solar ICS systems with two cylindrical storage tanks. Renew. Energy 1999, 16, 665–668. [Google Scholar] [CrossRef]

- Smyth, M.; Eames, P.C.; Norton, B. Heat retaining integrated collector/storage solar water heaters. Sol. Energy 2003, 75, 27–34. [Google Scholar] [CrossRef]

- Chaabane, M.; Mhiri, H.; Bournot, P. Effect of the storage tank thermal insulation on the thermal performance of an integrated collector storage solar water heater (ICSSWH). Heat Mass Transf. 2014, 50, 1335–1341. [Google Scholar] [CrossRef]

- Souza, J.V.D.; Fraisse, G.; Pailha, M.; Xin, S. Experimental study of a partially heated cavity of an integrated collector storage solar water heater (ICSSWH). Sol. Energy 2014, 101, 53–62. [Google Scholar] [CrossRef]

- Swiatek, M.; Fraisse, G.; Pailha, M. Stratification enhancement for an integrated collector storage solar water heater (ICSSWH). Energy Build. 2015, 106, 35–43. [Google Scholar] [CrossRef]

- Kumar, R.; Rosen, M.A. Comparative performance investigation of integrated collector-storage solar water heaters with various heat loss reduction strategies. Int. J. Energy Res. 2011, 35, 1179–1187. [Google Scholar] [CrossRef]

- Garnier, C. Performance Measurement and Mathematical Modelling of Integrated Solar Water Heaters. Ph.D. Thesis, Edinburgh Napier University, Scotland, UK, 2009. [Google Scholar]

- Sarbu, I.; Sebarchievici, C. Chapter 5—Solar Water and Space-Heating Systems, 1st ed.; Academic Press: Cambridge, MA, USA, 2017; ISBN 9780128116623. [Google Scholar]

- Drück, H.; Hahne, E. Test and Comparison of Hot Water Stores for Solar Combisystems. In Proceedings of the EuroSun98-The second ISES-Europe Solar Congress, Portoroz, Slovenia, 14–17 September 1998. [Google Scholar]

- Kablan, M.M. Techno-economic analysis of the Jordanian solar water heating system. Energy 2004, 29, 1069–1079. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Legionella and the Prevention of Legionellosis; Bartam, J., Pond, K., Eds.; WHO: Geneva, Switzerland, 2007; ISBN 9241562978. [Google Scholar]

- Kaushik, S.C.; Kumar, R.; Garg, H.P. Effect of baffle plate on the performance of a triangular built-in-storage solar water heater. Energy Convers. Manag. 1995, 36, 337–342. [Google Scholar] [CrossRef]

- Mohamad, A.A. Integrated Solar Collector—Storage Tank System with Thermal Diode. Sol. Energy 1997, 61, 211–218. [Google Scholar] [CrossRef]

- Faiman, D.; Hazan, H.; Laufer, I. Reducing the heat loss at night from solar water heaters of the integrated collector-storage variety. Sol. Energy 2001, 71, 87–93. [Google Scholar] [CrossRef]

- Ziapour, B.M.; Aghamiri, A. Simulation of an enhanced integrated collector-storage solar water heater. Energy Convers. Manag. 2014, 78, 193–203. [Google Scholar] [CrossRef]

- Smyth, M.; Eames, P.C.; Norton, B. A comparative performance rating for an integrated solar collector/storage vessel with inner sleeves to increase heat retention. Sol. Energy 1999, 66, 291–303. [Google Scholar] [CrossRef]

- Smyth, M.; Eames, P.C.; Norton, B. Annual performance of heat retaining integrated collector/storage solar water heaters in a northern maritime climate. Sol. Energy 2001, 70, 391–401. [Google Scholar] [CrossRef]

- Sokolov, M.; Vaxman, M. Analysis of an integral compact solar water heater. Sol. Energy 1983, 30, 237–246. [Google Scholar] [CrossRef]

- Vaxman, M.; Sokolov, M. Experiments with an integral compact solar water heater. Sol. Energy 1985, 34, 447–454. [Google Scholar] [CrossRef]

- El-Sebaii, A.A. Thermal performance of a shallow solar-pond integrated with a baffle plate. Appl. Energy 2005, 81, 33–53. [Google Scholar] [CrossRef]

- Haskell, C.L. Solar Heater. U.S. Patents 842658A, 29 January 1907. [Google Scholar]

- Youcef-Ali, S. Study and optimization of the thermal performances of the offset rectangular plate fin absorber plates, with various glazing. Renew. Energy 2005, 30, 271–280. [Google Scholar] [CrossRef]

- Gertzos, K.P.; Caouris, Y.G. Optimal arrangement of structural and functional parts in a flat plate integrated collector storage solar water heater (ICSSWH). Exp. Therm. Fluid Sci. 2008, 32, 1105–1117. [Google Scholar] [CrossRef]

- Li, Z.; Wu, Z.G. Analysis of HTFs, PCMs and fins effects on the thermal performance of shell-tube thermal energy storage units. Sol. Energy 2015, 122, 382–395. [Google Scholar] [CrossRef]

- Junaidi, H.A. Optimized Solar Water Heater for Scottish Weather Conditions. Ph.D. Thesis, Edinburgh Napier University, Edinburgh, UK, 2007. [Google Scholar]

- Garnier, C.; Currie, J.I.; Muneer, T.; Girard, A. Computational study of an integrated collector storage solar water heater. In Proceedings of the Eurosun 2008, Lisbon, Portugal, 7–10 October 2008; pp. 1–8. [Google Scholar]

- Mohsen, M.S.; Akash, B.A. On integrated solar water heating system. Int. Commun. Heat Mass Transf. 2002, 29, 135–140. [Google Scholar] [CrossRef]

- Chaabane, M.; Mhiri, H.; Bournot, P. Thermal performance of an integrated collector storage solar water heater (ICSSWH) with a storage tank equipped with radial fins of rectangular profile. Heat Mass Transf. Stoffuebertragung 2013, 49, 107–115. [Google Scholar] [CrossRef]

- Chaouachi, B.; Gabsi, S. Experimental study of integrated collector storage solar water heater under real conditions. Renew Energy Rev. 2006, 9, 75–82. [Google Scholar]

- Duffie, J.; Beckman, W. Solar Engineering of Thermal Processes, 3rd ed.; Wiley: Hoboken, NJ, USA, 2006; Volume 116, ISBN 1118418123. [Google Scholar]

- Norton, B.; Lo, S. Anatomy of a solar collector. Refocus 2006, 7, 32–35. [Google Scholar] [CrossRef]

- Cuce, E.; Riffat, S.B. A state-of-the-art review on innovative glazing technologies. Renew. Sustain. Energy Rev. 2015, 41, 695–714. [Google Scholar] [CrossRef]

- Bishop, R.C. Superinsulated batch heaters for freezing climates. In Proceedings of the Eighth National Passive Solar Conference, Santa Fe, NM, USA, 7–9 September 1983; pp. 807–810. [Google Scholar]

- AL-Khaliffajy, M.; Mossad, R. Optimization of the Air Gap Spacing in a Solar Water Heater with Double Glass. In Proceedings of the 9th Australasian Heat and Mass Transfer Conference, Melbourne, Australia, 2–4 November 2011. [Google Scholar]

- NSG Group Nippon Sheet Glass Spacia—The Principle. Available online: http://www.nsg-spacia.co.jp/tech/index.html (accessed on 24 January 2018).

- Han, Z.M.; Bao, Y.W.; Wu, W.D.; Liu, Z.; Liu, X.G.; Tian, Y. Evaluation of thermal performance for vacuum glazing by using three-dimensional finite element model. Key Eng. Mater. 2012, 492, 328–332. [Google Scholar] [CrossRef]

- Jelle, B.P.; Hynd, A.; Gustavsen, A.; Arasteh, D.; Goudey, H.; Hart, R. Fenestration of today and tomorrow: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 96, 1–28. [Google Scholar] [CrossRef] [Green Version]

- Cuce, E.; Riffat, S.B. Aerogel-Assisted Support Pillars for Thermal Performance Enhancement of Vacuum Glazing: A CFD Research for a Commercial Product. Arab. J. Sci. Eng. 2015, 40, 2233–2238. [Google Scholar] [CrossRef]

- Fang, Y.; Hyde, T.J.; Hewitt, N. Predicted thermal performance of triple vacuum glazing. Sol. Energy 2010, 84, 2132–2139. [Google Scholar] [CrossRef]

- Ahmadzadeh, J.; Gascoigne, M. Efficiency of solar collectors. Energy Convers. Manag. 1976, 16, 13–17. [Google Scholar] [CrossRef]

- Wozniak, S.J. Solar Heating Systems for the UK: Design, Installation and Economic Aspects; Building Research Establishment: Watford, UK, 1979. [Google Scholar]

- Lefkow, A.R.; Lee, J.C. Selective IR reflective coatings. In Proceedings of the Annual DOE Active Solar Heating and Cooling Contractors Review Meeting, Incline Village, NV, USA, 26–28 March 1980. [Google Scholar]

- Bainbridge, D.A. Integral passive solar water heater performance. In Proceedings of the Sixth National Passive Solar Conference, Portland, OR, USA, 8–12 September 1981; pp. 163–167. [Google Scholar]

- Teixeira, V.; Sousa, E.; Costa, M.F.; Nunes, C.; Rosa, L.; Carvalho, M.J.; Collares-Pereira, M.; Roman, E.; Gago, J. Spectrally selective composite coatings of Cr-Cr2O3 and Mo-Al2O3 for solar energy applications. Thin Solid Films 2001, 392, 320–326. [Google Scholar] [CrossRef]

- Muneer, T.; Adodahab, N.; Weir, G.; Kubie, J. Windows in Buildings; Architectural Press: New York, NY, USA, 2000. [Google Scholar]

- Frid, S.E.; Arsatov, A.V.; Oshchepkov, M.Y. Engineering solutions for polymer composites solar water heaters production. Therm. Eng. 2016, 63, 399–403. [Google Scholar] [CrossRef]

- Lavan, Z.; Thompson, J. Experimental study of thermally stratified hot water storage tanks. Sol. Energy 1977, 19, 519–524. [Google Scholar] [CrossRef]

- Zurigat, Y.H.; Ghajar, A.J.; Moretti, P.M. Stratified thermal storage tank inlet mixing characterization. Appl. Energy 1988, 30, 99–111. [Google Scholar] [CrossRef]

- Carlsson, P.F. Heat storage for large low flow solar heating systems. In Proceedings of the ISES Solar World Conference; Hungarian Energy Society: Budapest, Hungary, 1993; pp. 441–445. [Google Scholar]

- Hegazy, A.A.; Diab, M.R. Performance of an improved design for storage-type domestic electrical water-heaters. Appl. Energy 2002, 71, 287–306. [Google Scholar] [CrossRef]

- Hegazy, A.A. Effect of inlet design on the performance of storage-type domestic electrical water heaters. Appl. Energy 2007, 84, 1338–1355. [Google Scholar] [CrossRef]

- Chung, J.D.; Cho, S.H.; Tae, C.S.; Yoo, H. The effect of diffuser configuration on thermal stratification in a rectangular storage tank. Renew. Energy 2008, 33, 2236–2245. [Google Scholar] [CrossRef]

- Dragsted, J.; Furbo, S.; Dannemand, M.; Bava, F. Thermal stratification built up in hot water tank with different inlet stratifiers. Sol. Energy 2017, 147, 414–425. [Google Scholar] [CrossRef]

- Prabhu, P.A.; Shinde, N.N.; Patil, P. Review of Phase Change Materials for Thermal Energy Storage Applications. Int. J. Eng. Res. Appl. 2012, 2, 871–875. [Google Scholar]

- Pereira da Cunha, J.; Eames, P. Thermal energy storage for low and medium temperature applications using phase change materials—A review. Appl. Energy 2016, 177, 227–238. [Google Scholar] [CrossRef] [Green Version]

- Pandey, A.K.; Hossain, M.S.; Tyagi, V.V.; Abd Rahim, N.; Selvaraj, J.A.L.; Sari, A. Novel approaches and recent developments on potential applications of phase change materials in solar energy. Renew. Sustain. Energy Rev. 2018, 82, 281–323. [Google Scholar] [CrossRef]

- Hamed, M.; Fallah, A.; Ben Brahim, A. Numerical analysis of charging and discharging performance of an integrated collector storage solar water heater. Int. J. Hydrogen Energy 2017, 42, 8777–8789. [Google Scholar] [CrossRef]

- Haillot, D.; Nepveu, F.; Goetz, V.; Py, X.; Benabdelkarim, M. High performance storage composite for the enhancement of solar domestic hot water systems. Part 2: Numerical system analysis. Sol. Energy 2012, 86, 64–77. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Lin, S.C. Performance evaluation of a solar water heater integrated with a PCM nanocomposite TES at various inclinations. Sol. Energy 2014, 109, 82–92. [Google Scholar] [CrossRef]

- Chaabane, M.; Mhiri, H.; Bournot, P. Thermal performance of an integrated collector storage solar water heater (ICSSWH) with phase change materials (PCM). Energy Convers. Manag. 2014, 78, 897–903. [Google Scholar] [CrossRef]

- Tarhan, S.; Sari, A.; Yardim, M.H. Temperature distributions in trapezoidal built in storage solar water heaters with/without phase change materials. Energy Convers. Manag. 2006, 47, 2143–2154. [Google Scholar] [CrossRef]

- Devanarayanan, K.; Kalidasa Murugavel, K. Integrated collector storage solar water heater with compound parabolic concentrator—Development and progress. Renew. Sustain. Energy Rev. 2014, 39, 51–64. [Google Scholar] [CrossRef]

- Souliotis, M.; Quinlan, P.; Smyth, M.; Tripanagnostopoulos, Y.; Zacharopoulos, A.; Ramirez, M.; Yianoulis, P. Heat retaining integrated collector storage solar water heater with asymmetric CPC reflector. Sol. Energy 2011, 85, 2474–2487. [Google Scholar] [CrossRef]

- Souliotis, M.; Chemisana, D.; Caouris, Y.G.; Tripanagnostopoulos, Y. Experimental study of integrated collector storage solar water heaters. Renew. Energy 2013, 50, 1083–1094. [Google Scholar] [CrossRef]

- Varghese, J.; Samsher, M.K. A parametric study of a concentrating integral storage solar water heater for domestic uses. Appl. Therm. Eng. 2017, 111, 734–744. [Google Scholar] [CrossRef]

- Ziapour, B.M.; Palideh, V.; Mokhtari, F. Performance improvement of the finned passive PVT system using reflectors like removable insulation covers. Appl. Therm. Eng. 2016, 94, 341–349. [Google Scholar] [CrossRef]

- Incropera, F.P.; DeWitt, D.P.; Bergmann, T.L.; Lavine, A.S. Principles of Heat and Mass Transfer, 7th ed.; Wiley & Sons: New York, NY, USA, 2013. [Google Scholar]

- Stickney, B.L.; Nagy, C. Performance comparisons of several passive solar water heaters. In Proceedings of the Fifth National Passive Solar Conference, Amherst, MA, USA, 19–26 October 1980; pp. 1071–1075. [Google Scholar]

- Burton, J.W.; Zweig, P. Side by side comparison of integral passive solar water heaters. In Proceedings of the Sixth National Passive Solar Conference, Portland, OR, USA, 8 September 1981; pp. 136–140. [Google Scholar]

- Tiller, J.S.; Wochatz, V. Performance of integrated passive solar water heaters (Breadbox-type) under varying design conditions in the South-eastern US. In Proceedings of the Seventh National Passive Solar Conference, Knoxville, TN, USA, 30 August–1 September 1982; pp. 975–980. [Google Scholar]

- Cummings, J.; Clark, G. Performance of integrated passive solar water heaters in US climates. In Proceedings of the Eighth National Passive Solar Conference, Santa Fe, NM, USA, 7–9 September 1983; pp. 791–796. [Google Scholar]

- Fasulo, A.; Odicino, L.; Perello, D. Development of CPC with low thermal losses. Sol. Wind Technol. 1987, 4, 157–162. [Google Scholar] [CrossRef]

- Tripanagnostopoulos, Y.; Yianoulis, P. Integrated collector-storage systems with suppressed thermal losses. Sol. Energy 1992, 48, 31–43. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B. Interior colour rendering of daylight transmitted through a suspended particle device switchable glazing. Sol. Energy Mater. Sol. Cells 2017, 163, 218–223. [Google Scholar] [CrossRef]

- Kumar, R.; Rosen, M.A. Thermal performance of integrated collector storage solar water heater with corrugated absorber surface. Appl. Therm. Eng. 2010, 30, 1764–1768. [Google Scholar] [CrossRef]

- Gardner, L. The use of stainless steel in structures. Prog. Struct. Eng. Mater. 2005, 7, 45–55. [Google Scholar] [CrossRef] [Green Version]

- Ziapour, B.M.; Palideh, V.; Baygan, M. Performance comparison of four passive types of photovoltaic-thermal systems. Energy Convers. Manag. 2014, 88, 732–738. [Google Scholar] [CrossRef]

- Popel’O, S.; Frid, S.E.; Mordynskii, A.V.; Suleimanov, M.Z.; Arsatov, A.V.; Oschepkov, M.Y. Results of the development of a solar accumulation-type water heater made of polymer and composite materials. Therm. Eng. 2013, 60, 267–269. [Google Scholar] [CrossRef]

- Oshchepkov, M.Y.; Frid, S.E. Modeling of the Warm Water Displacement from Stratified Tanks of Integrated Collector Storage Solar Water Heaters. Appl. Sol. Energy 2016, 52, 173–177. [Google Scholar] [CrossRef]

- Sopian, K.; Syahri, M.; Abdullah, S.; Othman, M.Y.; Yatim, B. Performance of a non-metallic unglazed solar water heater with integrated storage system. Renew. Energy 2004, 29, 1421–1430. [Google Scholar] [CrossRef]

- Souliotis, M.; Papaefthimiou, S.; Caouris, Y.G.; Zacharopoulos, A.; Quinlan, P.; Smyth, M. Integrated collector storage solar water heater under partial vacuum. Energy 2017, 139, 991–1002. [Google Scholar] [CrossRef]

- Smyth, M.; Quinlan, P.; Mondol, J.D.; Zacharopoulos, A.; McLarnon, D.; Pugsley, A. The evolutionary thermal performance and development of a novel thermal diode pre-heat solar water heater under simulated heat flux conditions. Renew. Energy 2017, 113, 1160–1167. [Google Scholar] [CrossRef]

| Reference | Year | Title | System(s) Reviewed | Design Aspects Reviewed |

|---|---|---|---|---|

| [6] | 2006 | Integrated collector storage solar water heaters | ICSSWH | Additional insulation; Baffles; Cavity evacuation; Collector material; Glazing; phase change material (PCM); Reflectors; Selective absorber surfaces |

| [4] | 2011 | A comprehensive review on solar water heaters | Thermo-syphon | Additional insulation; Collector material; Glazing; Selective absorber surfaces |

| [10] | 2013 | Review of solar water heaters with integrated collector-storage units | ICSSWH | Additional insulation; Baffle Plates; Glazing; Inlet valve configuration; PCM; Reflectors; Selective absorber surfaces |

| [11] | 2013 | Solar water heating systems and their market trends | ICSSWH; Thermo-syphon; Direct/indirect circulation; Air | Additional insulation; Baffle plates; PCM; Reflectors |

| [12] | 2013 | Recent advances in the solar water heating systems: A review | Flat-plate; Evacuated tube; compound parabolic concentrator (CPC) | Additional insulation; Baffle plates; Collector material; Glazing; Reflectors; Selective absorber surfaces |

| [13] | 2013 | A review of solar collectors and thermal energy storage in solar thermal applications | Non-concentrating (inc. flat-plate); concentrating collectors | General overview of current technologies; Fins; PCM |

| [14] | 2014 | Review of water-heating systems: General selection approach based on energy and environmental aspects | ICSSWH; Thermo-syphon; Active; PV/T; PCM | Fins; PCM; Reflectors; Selective absorber surfaces |

| [15] | 2015 | Building integrated solar thermal collectors—A review | PV/T & solar thermal | General overview of current technologies |

| [16] | 2015 | Integrated collector storage solar water heaters: Survey and recent developments | ICSSWH | Additional insulation; Baffle plate/inner sleeve; PCM; Thermal diodes |

| [17] | 2015 | Performance enhancement of solar collectors–A review | Flat-plate; PV/T; Evacuated tube; Compound parabolic | Nanofluids; Selective absorber surfaces |

| [18] | 2016 | Innovation in flat solar thermal collectors: A review of the last ten years experimental results | Flat-plate; ICSSWH; PV/T | Additional insulation; Collector material; Fins; Nanofluids; Selective absorber surfaces |

| [19] | 2016 | A review of water heating system for solar energy applications | Flat-plate; Evacuated tube; Concentrating; ICSSWH | Auxiliary immersion heating; Nanofluids |

| [20] | 2016 | Recent developments in integrated collector storage (ICS) solar water heaters: A review | ICSSWH | Additional insulation; Baffle plate/inner sleeve; Thermal diodes |

| TIM Thickness (m) | Efficiency (%) | |||

|---|---|---|---|---|

| Single Glazing | Double Glazing | MMA Slab | Honeycomb | |

| 0.025 | 0.106 | 0.32 | 0.299 | 0.328 |

| 0.05 | 0.11 | 0.329 | 0.374 | 0.41 |

| 0.075 | 0.119 | 0.346 | 0.396 | 0.439 |

| 0.1 | 0.128 | 0.357 | 0.404 | 0.45 |

| Heat Gain/Retention Strategy | Heat Loss Mechanism Impacted |

|---|---|

| Additional insulation | Reduces convective, conductive, and radiative heat losses |

| Auxiliary heating | Provides additional heat to meet demand/combat bacteria and freezing |

| Baffle plate/inner sleeve | Reduces convective heat losses and promotes thermal stratification |

| Fins | Promotes heat transfer to the bulk water body through conduction |

| Glazing | Impacts on radiative heat losses and transmissivity, creates an air cavity which supresses internal convection |

| Inlet pipe configuration | Impacts on thermal stratification and therefore heat gain |

| Phase change materials | Can impact on conductive, convective and radiative heat losses depending on their use. Provides stored heat during non-collection periods |

| Reflectors | Impacts on the level of incident radiation, can reflect radiative heat losses |

| Selective absorber surfaces | Enhances the absorption and reduces the emission of solar radiation |

| Storage tank/collector material | Impacts on conductive heat losses |

| Thermal diodes | Reduces convective heat losses |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saint, R.M.; Garnier, C.; Pomponi, F.; Currie, J. Thermal Performance through Heat Retention in Integrated Collector-Storage Solar Water Heaters: A Review. Energies 2018, 11, 1615. https://doi.org/10.3390/en11061615

Saint RM, Garnier C, Pomponi F, Currie J. Thermal Performance through Heat Retention in Integrated Collector-Storage Solar Water Heaters: A Review. Energies. 2018; 11(6):1615. https://doi.org/10.3390/en11061615

Chicago/Turabian StyleSaint, Ruth M., Céline Garnier, Francesco Pomponi, and John Currie. 2018. "Thermal Performance through Heat Retention in Integrated Collector-Storage Solar Water Heaters: A Review" Energies 11, no. 6: 1615. https://doi.org/10.3390/en11061615