A Numerical Study of Small-Scale Longitudinal Heat Conduction in Plate Heat Exchangers

Abstract

:1. Introduction

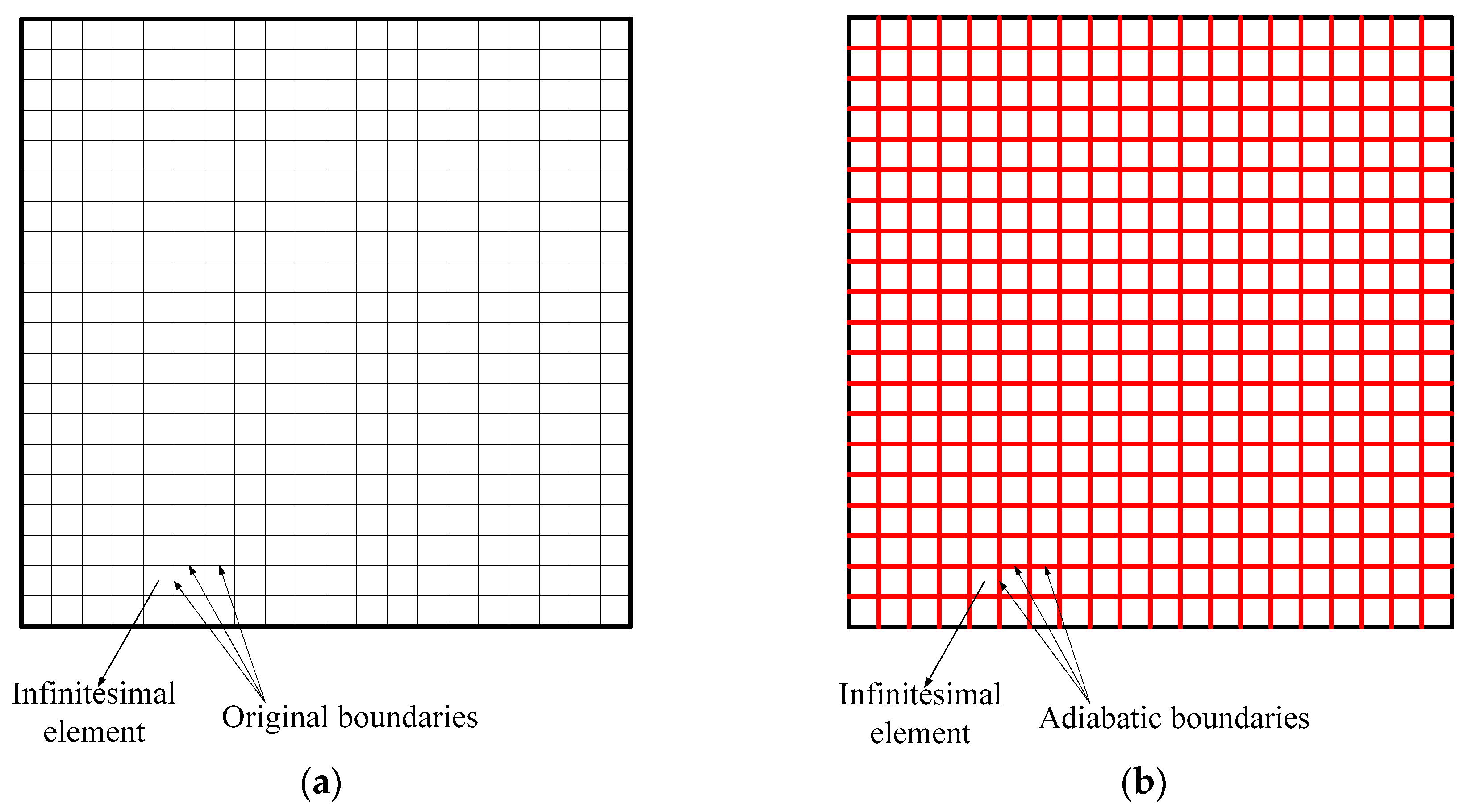

2. Physical and Numerical Model

3. Heat Transfer Models with and without Longitudinal Heat Conduction

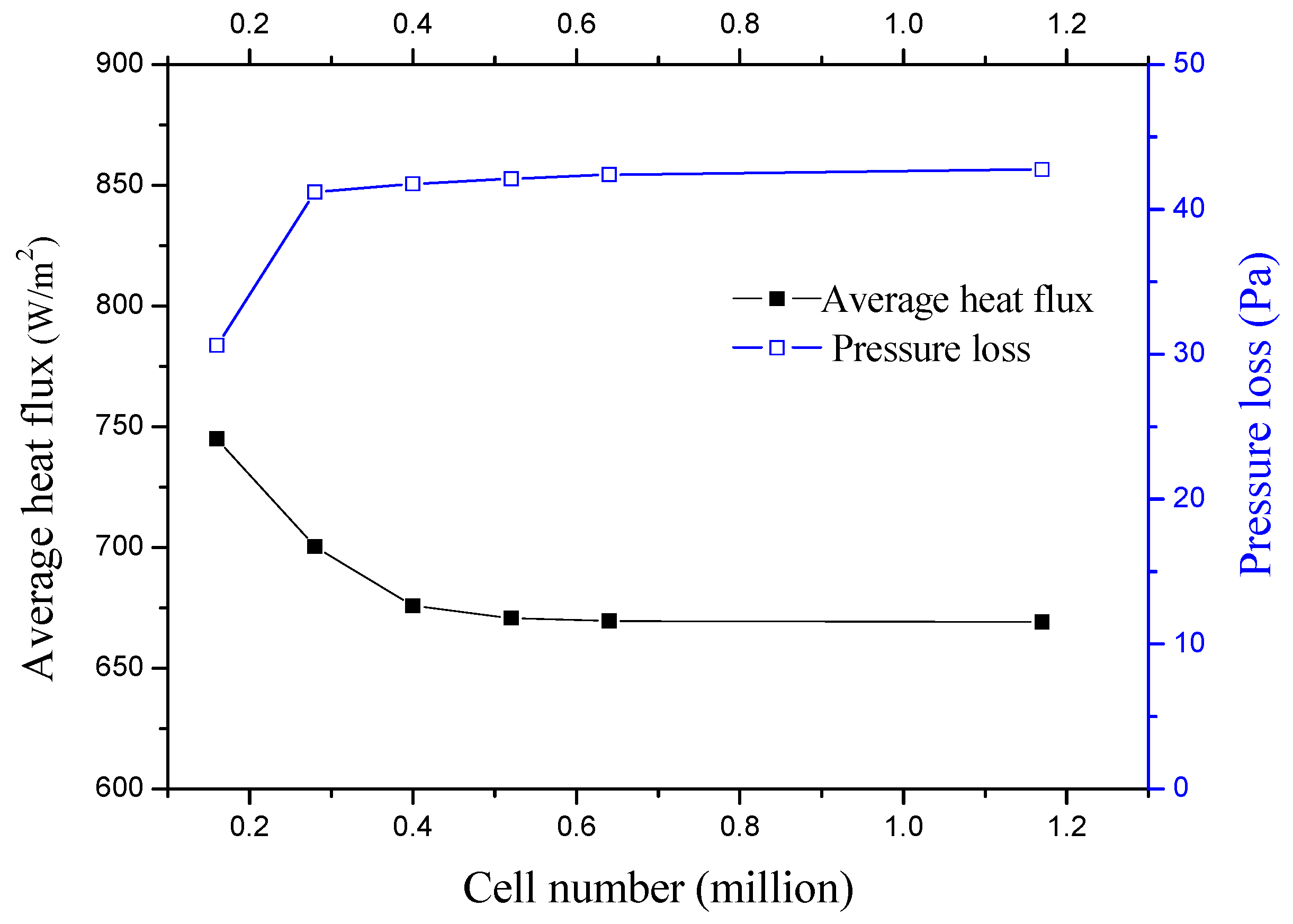

4. Grid Independence and Code Validation

5. Results and Discussion

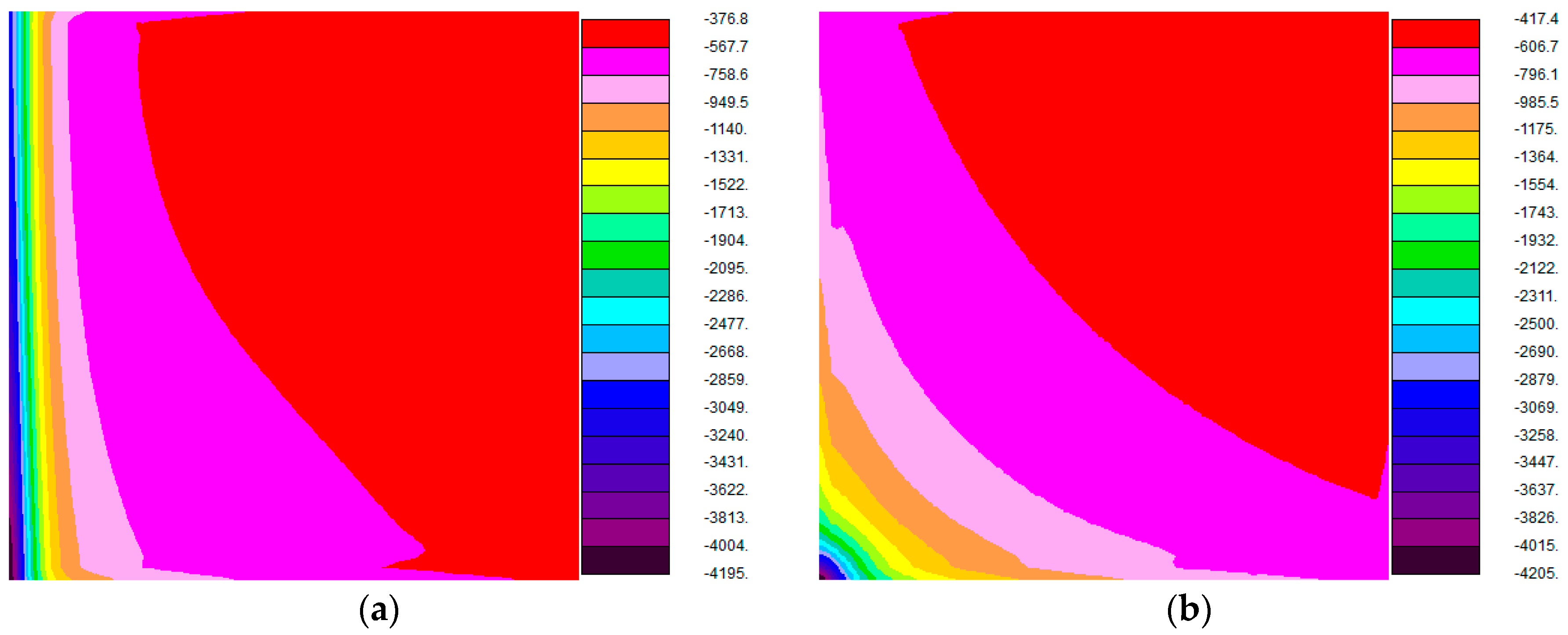

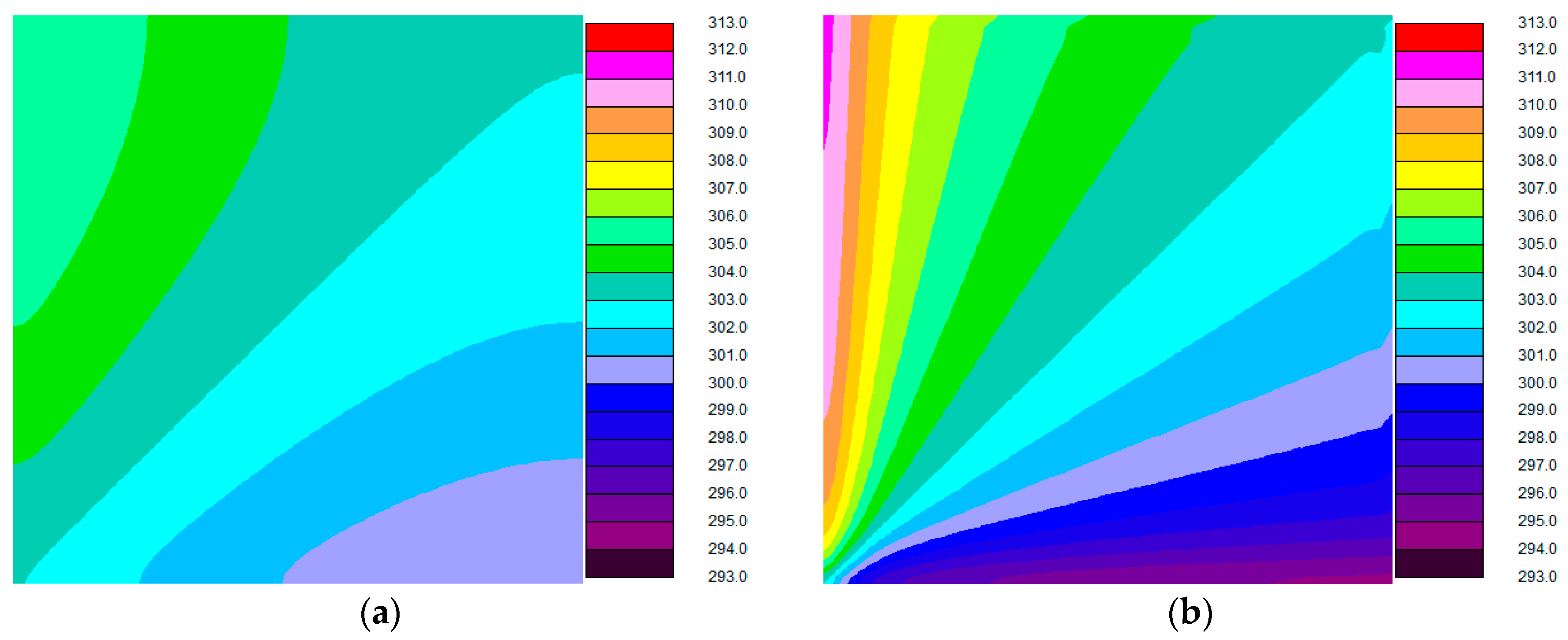

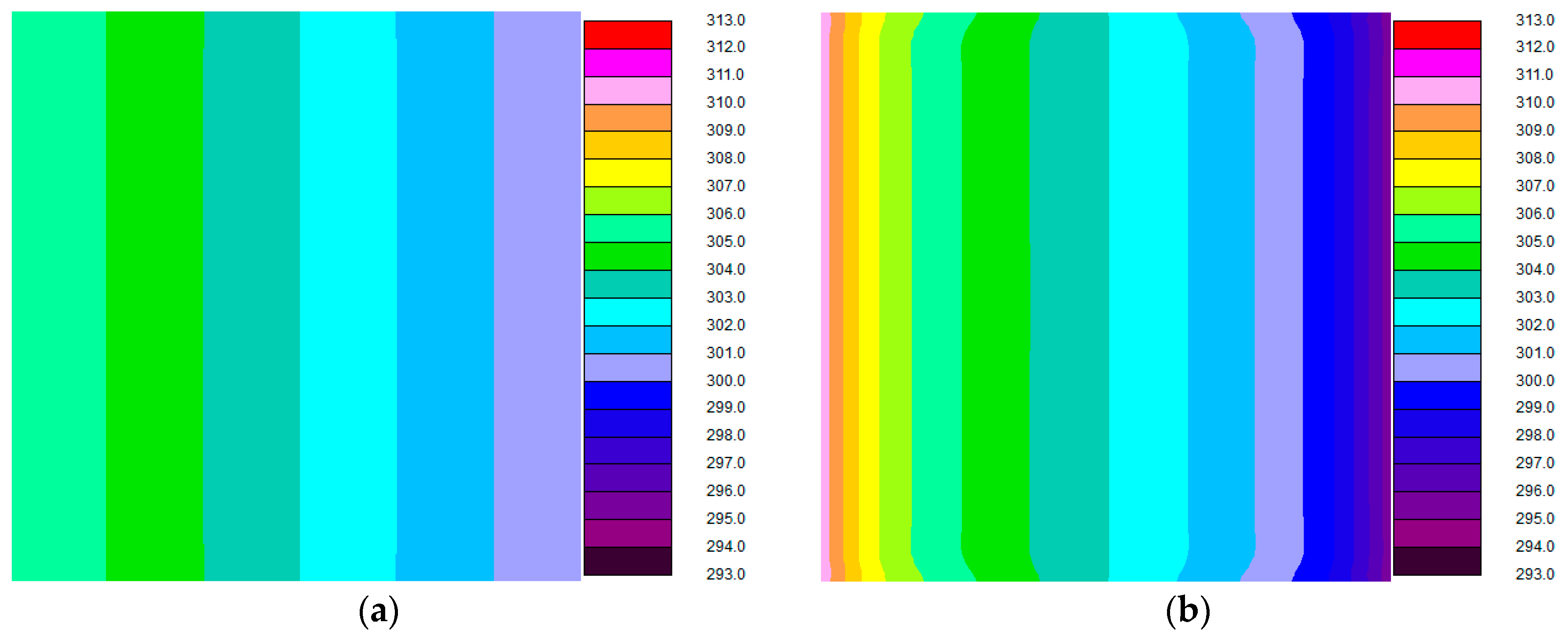

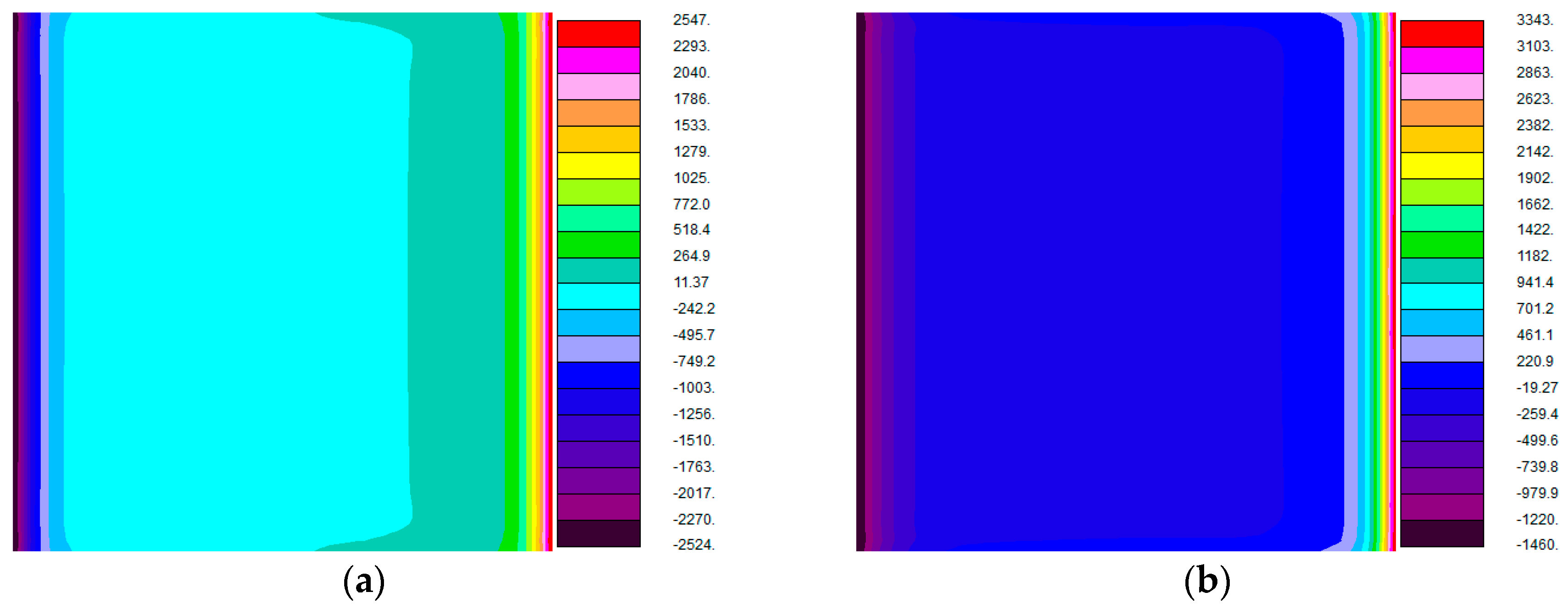

5.1. Effect of Small-Scale Longitudinal Heat Conduction on Balanced Flow

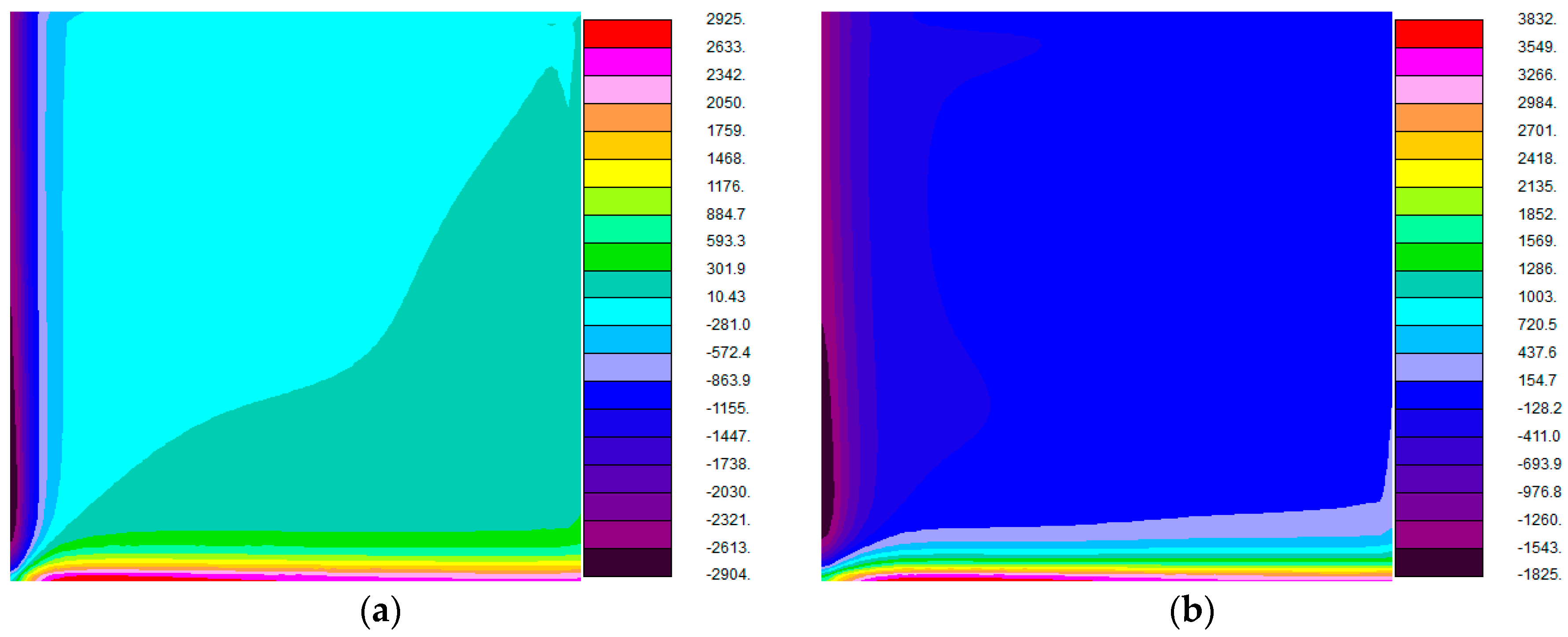

5.2. Effect of Small-Scale Longitudinal Heat Conduction on Unbalanced Flow

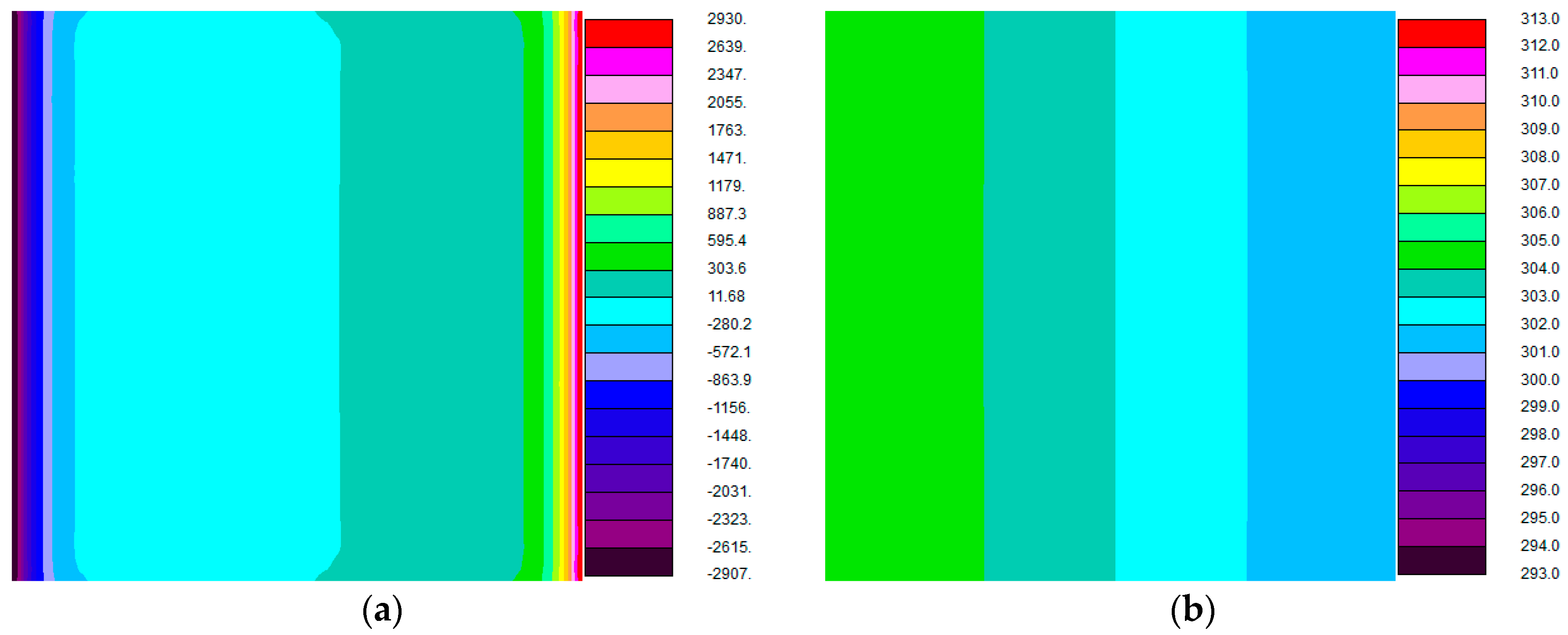

5.3. Effect of Plate Thermal Conductivity on Small-Scale Longitudinal Heat Conduction

6. Conclusions

- (1)

- Small-scale longitudinal heat conduction occurs in the plate and a more uniform temperature profile of the plate can be obtained due to small scale longitudinal heat conduction. In balanced flow, the contributions of longitudinal heat conduction of counter-flow and cross-flow plate heat exchangers are −3.15% and −0.09%, respectively. The effect of small-scale longitudinal heat conduction reduces the heat transfer performance significantly for counter-flow plate heat exchanger, whereas for cross-flow plate heat exchanger the heat transfer performance is reduced slightly. For the parallel-flow plate heat exchanger small-scale longitudinal heat conduction is very weak and the contribution of longitudinal heat conduction is zero. The small-scale longitudinal heat conduction has no effect on parallel-flow plate heat exchanger in balanced flow.

- (2)

- In unbalanced flow, the small-scale longitudinal heat conduction is weakened for both counter-flow and cross-flow plate heat exchangers. The contributions of longitudinal heat conduction of these two heat exchangers are −1.73% and 0.53%, respectively. For counter-flow plate heat exchanger, the effect of small-scale longitudinal heat conduction reduces the heat transfer performance lesser than that in balanced flow, whereas the effect of small-scale longitudinal heat conduction enhance the heat transfer performance of cross-flow plate heat exchangers. For parallel-flow plate heat exchanger, the small-scale longitudinal heat conduction is strengthened significantly in unbalanced flow. However, the contribution of longitudinal heat conduction is only 0.05%.

- (3)

- The small-scale longitudinal heat conduction is influenced by thermal conductivity of the plate. The contributions of longitudinal heat conduction for counter-flow stainless-steel, brass and silver plate heat exchangers in balanced flow are −0.54%, −2.07% and −4.01%, respectively. The higher the thermal conductivity of the plate, the stronger the small-scale longitudinal heat conduction and the larger the thermal performance reduction.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| C | heat capacity rate, W/K |

| cp | specific heat, J/(kg·K) |

| f | Fanning friction factor |

| f0 | baseline Fanning friction factor |

| H | channel height |

| k | turbulence kinetic energy |

| L | plate length, m2/s2 |

| Nu | Nusselt number |

| Nu0 | baseline Nusselt number |

| p | static pressure |

| Pr | Prandtl number |

| Prt | turbulent Prandtl number |

| heat flux, W/m2 | |

| longitudinal heat conduction heat flux, W/m2 | |

| average heat flux, W/m2 | |

| ReH | Reynolds number based on channel height |

| T | temperature, K |

| U | area-averaged velocity in inlet section, m/s |

| u | velocity, m/s |

| Greek | |

| η | contribution of longitudinal heat conduction, % |

| λ | fluid thermal conductivity, W/(m·K) |

| λm | solid thermal conductivity, W/(m·K) |

| dynamic viscosity, Pa·s | |

| turbulent viscosity | |

| ρ | density, kg/m3 |

| Subscripts | |

| i, j | 1, 2, 3 |

| c | cold side |

| h | hot side |

| f | flow |

| w | solid wall |

| in | inlet |

| out | outlet |

| wi | heat transfer model with longitudinal heat conduction |

| wo | heat transfer model without longitudinal heat conduction |

References

- Wang, Q.W.; Zeng, M.; Ma, T.; Du, X.P.; Yang, J.F. Recent development and application of several high-efficiency surface heat exchangers for energy conversion and utilization. Appl. Energy 2014, 135, 748–777. [Google Scholar] [CrossRef]

- Bhutta, M.M.A.; Hayat, N.; Bashir, M.H.; Khan, A.R.; Ahmad, K.N.; Khan, S. CFD applications in various heat exchangers design: A review. Appl. Therm. Eng. 2012, 32, 1–12. [Google Scholar] [CrossRef]

- Ranganayakulu, C.; Luo, X.; Kabelac, S. The single-blow transient testing technique for offset and wavy fins of compact plate-fin heat exchangers. Appl. Therm. Eng. 2017, 111, 1588–1595. [Google Scholar] [CrossRef]

- Ranganayakulu, C.; Pallavi, P. Development of heat transfer coefficient and friction factor correlations for offset fins using CFD. Int. J. Numer. Methods Heat Fluid Flow 2011, 21, 935–951. [Google Scholar]

- Ranganayakulu, C.; Seetharamu, K.N.; Sreevatsan, K.V. The effects of longitudinal heat conduction in compact plate-fin and tube-fin heat exchangers using a finite element model. Int. J. Heat Mass Transf. 1997, 40, 1261–1277. [Google Scholar] [CrossRef]

- Ranganayakulu, C.; Seetharamu, K.N. The combined effects of longitudinal heat conduction, flow nonuniformity and temperature nonuniformity in crossflow plate-fin heat exchangers. Int. Commun. Heat Mass Transf. 1999, 26, 669–678. [Google Scholar] [CrossRef]

- Ranganayakulu, C.; Seetharamu, K.N. The combined effects of wall longitudinal heat conduction and inlet fluid flow maldistribution in crossflow plate-fin heat exchangers. Heat Mass Transf. 2000, 36, 247–256. [Google Scholar] [CrossRef]

- Venkatarathnam, G.; Narayanan, S.P. Performance of a counter flow heat exchanger with longitudinal heat conduction through the wall separating the fluid streams from the environment. Cryogenics 1999, 39, 811–819. [Google Scholar] [CrossRef]

- Narayanan, S.P.; Venkatarathnam, G. Performance degradation due to longitudinal heat conduction in very high NTU counterflow heat exchangers. Cryogenics 1998, 38, 927–930. [Google Scholar] [CrossRef]

- Kumar, S.S.; Raju, L.R.; Nandi, T.K. Thermal performance of perforated plate matrix heat exchangers with effects from outer wall and flow channel geometry. Cryogenics 2015, 72, 153–160. [Google Scholar] [CrossRef]

- Raju, L.R.; Nandi, T.K. Effective NTU of a counterflow heat exchanger with unbalanced flow and longitudinal heat conduction through fluid separating and outer walls. Appl. Therm. Eng. 2017, 112, 1172–1177. [Google Scholar] [CrossRef]

- Arici, M.E. Heat transfer analysis for a concentric tube heat exchanger including the wall axial conduction. Heat Transf. Eng. 2010, 31, 1034–1041. [Google Scholar] [CrossRef]

- Heidarinejad, G.; Moshari, S. Novel modeling of an indirect evaporative cooling system with cross-flow configuration. Energy Build. 2015, 92, 351–362. [Google Scholar] [CrossRef]

- Hettiarachchi, H.D.M.; Golubovic, M.; Worek, W.M. The effect of longitudinal heat conduction in cross flow indirect evaporative air coolers. Appl. Therm. Eng. 2007, 27, 1841–1848. [Google Scholar] [CrossRef]

- Lin, T.Y.; Kandlikar, S.G. A theoretical model for axial heat conduction effects during single-phase flow in microchannels. J. Heat Transf. 2012, 134, 020902. [Google Scholar] [CrossRef]

- Rahimi, M.; Mehryar, R. Numerical study of axial heat conduction effects on the local Nusselt number at the entrance and ending regions of a circular microchannel. Int. J. Therm. Sci. 2012, 59, 87–94. [Google Scholar] [CrossRef]

- Maranzana, G.; Perry, I.; Maillet, D. Mini- and micro-channels: Influence of axial conduction in the walls. Int. J. Heat Mass Transf. 2004, 47, 3993–4004. [Google Scholar] [CrossRef]

- Lin, M.; Wang, Q.W.; Guo, Z.X. Investigation on evaluation criteria of axial wall heat conduction under two classical thermal boundary conditions. Appl. Energy 2016, 162, 1662–1669. [Google Scholar] [CrossRef]

- Abu-Khader, M.M. Plate heat exchangers: Recent advances. Renew. Sustain. Energy Rev. 2012, 16, 1883–1891. [Google Scholar] [CrossRef]

- Miao, Q.W.; You, S.J.; Zheng, W.D.; Zheng, X.J.; Zhang, H.; Wang, Y.R. A grey-box dynamic model of plate heat exchangers used in an urban heating system. Energies 2017, 10, 1398. [Google Scholar] [CrossRef]

- Ciofalo, M.; Stasiek, J.; Collins, M.W. Investigation of flow and heat transfer in corrugated passages—II. Numerical simulations. Int. J. Heat Mass Transf. 1996, 39, 165–192. [Google Scholar] [CrossRef]

- Rogiers, F.; Baelmans, M. Towards maximal heat transfer rate densities for small-scale high effectiveness parallel-plate heat exchangers. Int. J. Heat Mass Transf. 2010, 53, 605–614. [Google Scholar] [CrossRef]

- Buckinx, G.; Rogiers, F.; Baelmans, M. Thermal design and optimization of small-scale high effectiveness cross-flow heat exchangers. Int. J. Heat Mass Transf. 2013, 60, 210–220. [Google Scholar] [CrossRef]

- Ciofalo, M. Local effects of longitudinal heat conduction in plate heat exchangers. Int. J. Heat Mass Transf. 2007, 50, 3019–3025. [Google Scholar] [CrossRef]

- Doo, J.H.; Ha, M.Y.; Min, J.K.; Stieger, R.; Rolt, A.; Son, C. Theoretical prediction of longitudinal heat conduction effect in cross-corrugated heat exchanger. Int. J. Heat Mass Transf. 2012, 55, 4129–4138. [Google Scholar] [CrossRef]

- Ma, T.; Zhang, J.; Borjigin, S.; Chen, Y.T.; Wang, Q.W.; Zeng, M. Numerical study on small-scale longitudinal heat conduction in cross-wavy primary surface heat exchanger. Appl. Therm. Eng. 2015, 76, 272–282. [Google Scholar] [CrossRef]

- Borjigin, S.; Peng, Y.Y.; Ma, T.; Chen, Y.T.; Zeng, M.; Wang, Q.W. Parameter study on longitudinal heat conduction in a cross-wavy primary surface heat exchanger. In Proceedings of the 1st Thermal and Fluid Engineering Summer Conference, New York, NY, USA, 9–12 August 2015. [Google Scholar]

- CD-adapco; Methodology, STAR-CD. Version 4.16 CD-adapco; CD-adapco: Melville, NY, USA, 2011. [Google Scholar]

- Zhang, L.; Che, D.F. Turbulence models for fluid flow and heat transfer between cross-corrugated plates. Numer. Heat Transf. A 2011, 60, 410–440. [Google Scholar] [CrossRef]

- Elyyan, M.A.; Rozati, A.; Tafti, D.K. Investigation of dimpled fins for heat transfer enhancement in compact heat exchangers. Int. J. Heat Mass Transf. 2008, 51, 2950–2966. [Google Scholar] [CrossRef]

- Won, S.Y.; Ligrani, P.M. Numerical predictions of flow structure and local Nusselt number ratios along and above dimpled surfaces with different dimple depths in a channel. Numer. Heat Transf. A 2004, 46, 549–570. [Google Scholar] [CrossRef]

- Ligrani, P.M.; Burgess, N.K.; Won, S.Y. Nusselt numbers and flow structure on and above a shallow dimpled surface within a channel including effects of inlet turbulence intensity level. J. Turbomach. 2005, 127, 321–330. [Google Scholar] [CrossRef]

- Zhang, L.; Che, D.F. Influence of corrugation profile on the thermalhydraulic performance of cross-corrugated plates. Numer. Heat Transf. A 2011, 59, 267–296. [Google Scholar] [CrossRef]

| Type of Heat Exchanger | , W/m2 | η, % | Plate Temperature Difference, K | ||

|---|---|---|---|---|---|

| wi | wo | wi | wo | ||

| Counter-flow | 680.67 | 702.13 | −3.15 | 5.37 | 14.95 |

| Cross-flow | 667.96 | 668.57 | −0.09 | 5.84 | 16.44 |

| Parallel-flow | 660.52 | 660.52 | 0 | 0.01 | 0.04 |

| Type of Heat Exchanger | , W/m2 | η, % | Plate Temperature Difference, K | ||

|---|---|---|---|---|---|

| wi | wo | wi | wo | ||

| Counter-flow | 869.495 | 884.515 | −1.73 | 5.53 | 13.85 |

| Cross-flow | 858.225 | 853.685 | 0.53 | 6 | 15.52 |

| Parallel-flow | 853.53 | 853.085 | 0.05 | 0.64 | 2.99 |

| Plate Material/Thermal Conductivity, W/(m·K) | , W/m2 | η, % | Plate Temperature Difference, K | ||

|---|---|---|---|---|---|

| wi | wo | wi | wo | ||

| Stainless-steel/15.1 | 698.04 | 701.81 | −0.54 | 11.55 | 14.94 |

| Brass/109 | 687.84 | 702.11 | −2.07 | 7.46 | 14.95 |

| Silver/427 | 675.05 | 702.145 | −4.01 | 3.82 | 14.95 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borjigin, S.; Ma, T.; Zeng, M.; Wang, Q. A Numerical Study of Small-Scale Longitudinal Heat Conduction in Plate Heat Exchangers. Energies 2018, 11, 1727. https://doi.org/10.3390/en11071727

Borjigin S, Ma T, Zeng M, Wang Q. A Numerical Study of Small-Scale Longitudinal Heat Conduction in Plate Heat Exchangers. Energies. 2018; 11(7):1727. https://doi.org/10.3390/en11071727

Chicago/Turabian StyleBorjigin, Saranmanduh, Ting Ma, Min Zeng, and Qiuwang Wang. 2018. "A Numerical Study of Small-Scale Longitudinal Heat Conduction in Plate Heat Exchangers" Energies 11, no. 7: 1727. https://doi.org/10.3390/en11071727

APA StyleBorjigin, S., Ma, T., Zeng, M., & Wang, Q. (2018). A Numerical Study of Small-Scale Longitudinal Heat Conduction in Plate Heat Exchangers. Energies, 11(7), 1727. https://doi.org/10.3390/en11071727