Electrically Driven Supersonic Combustion

Abstract

:1. Introduction

2. Plasma-Assisted Ignition and Flameholding in Supersonic Airflow

2.1. Early Efforts

2.2. Non-Equilibrium Ignition in Supersonic Airflow

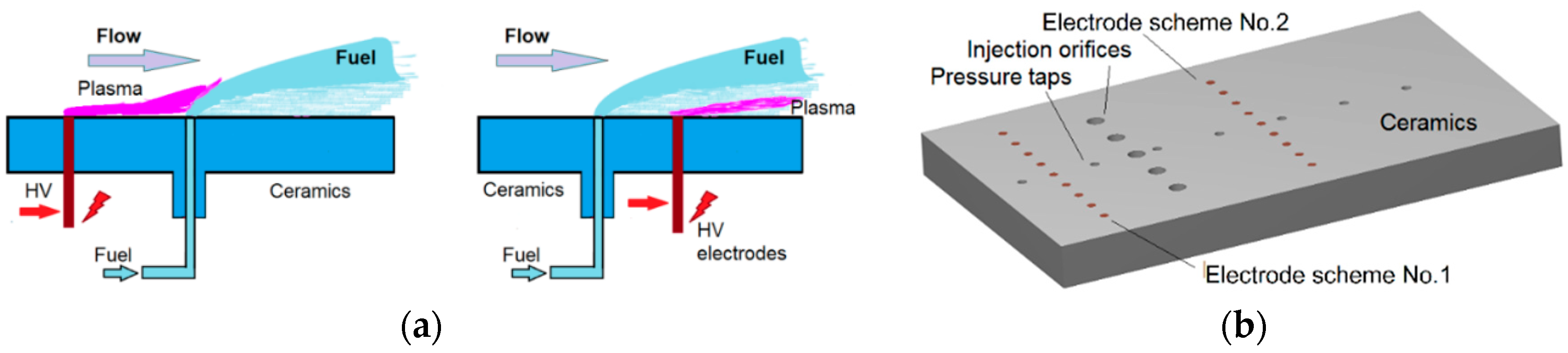

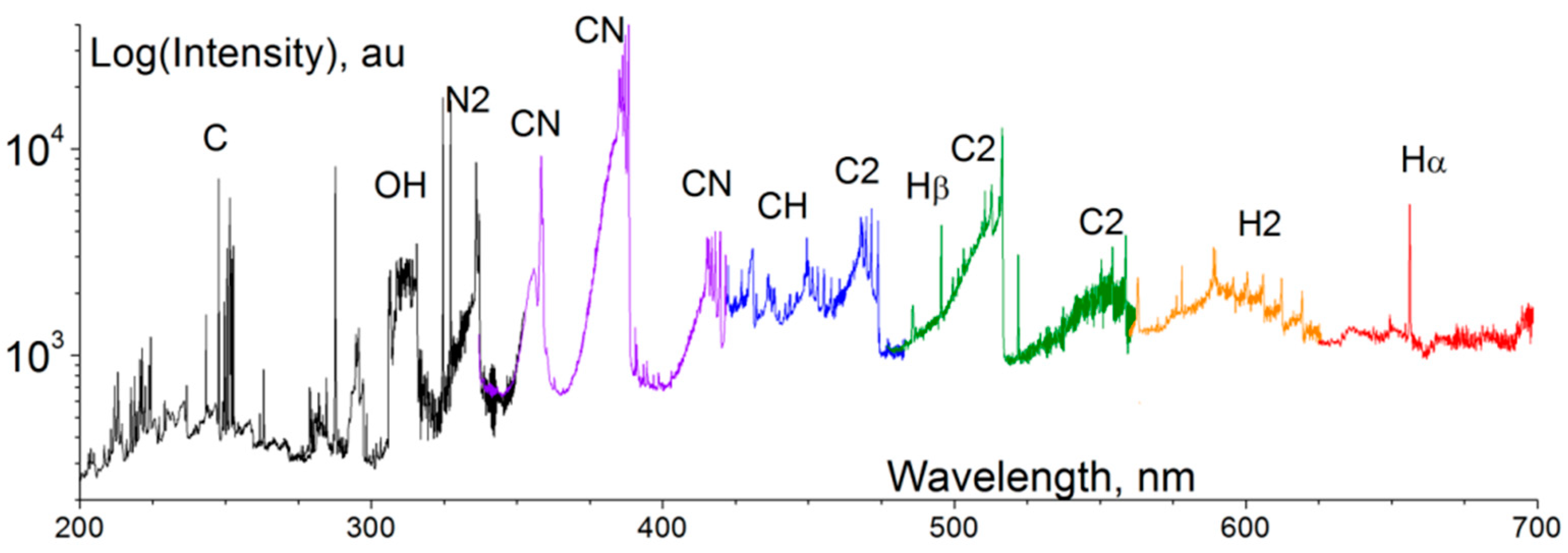

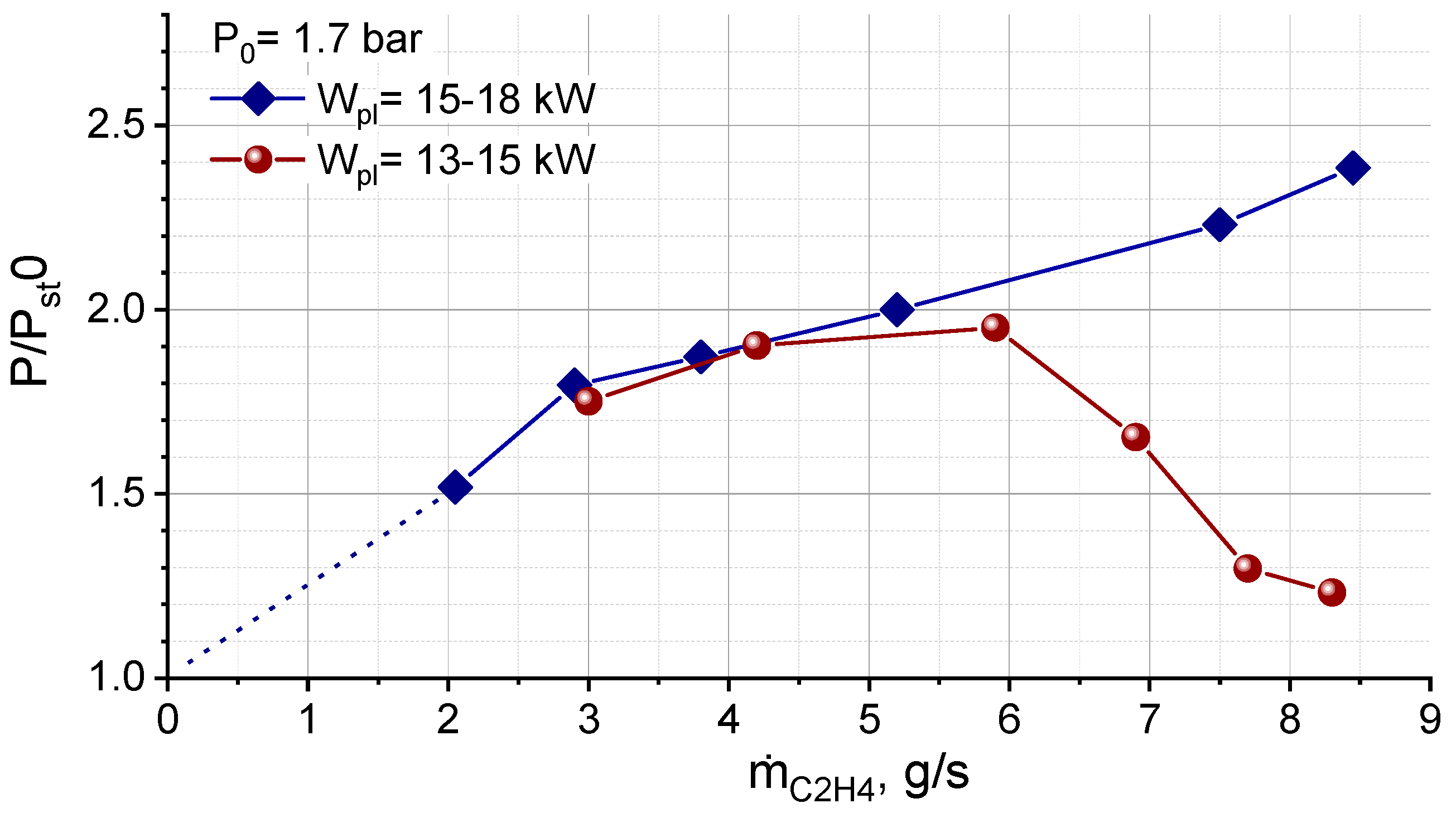

2.3. Supersonic Combustion Control with Quasi-DC Discharge

3. Mixing Enhancement by Electric Discharges

3.1. Plasma-Based Mixing Mechanisms

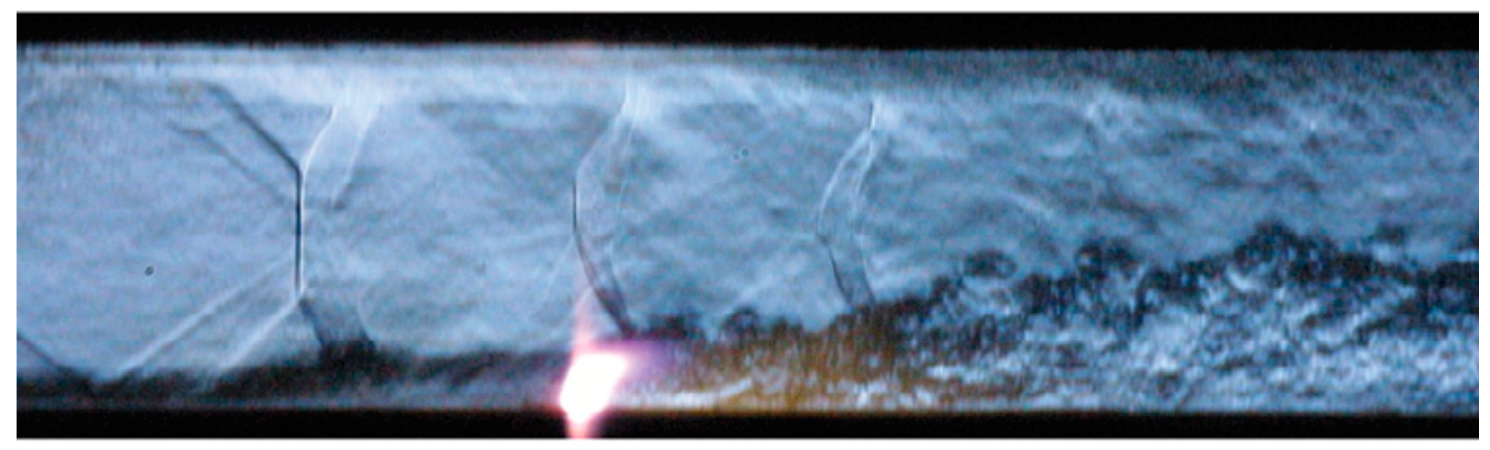

3.2. Turbulent Decay of Pulsed Discharge Channel

4. Transitional Phenomena and Instabilities

4.1. Ignition Time and Flame Extinction Time

4.2. Instability of Plasma-Flow Interaction

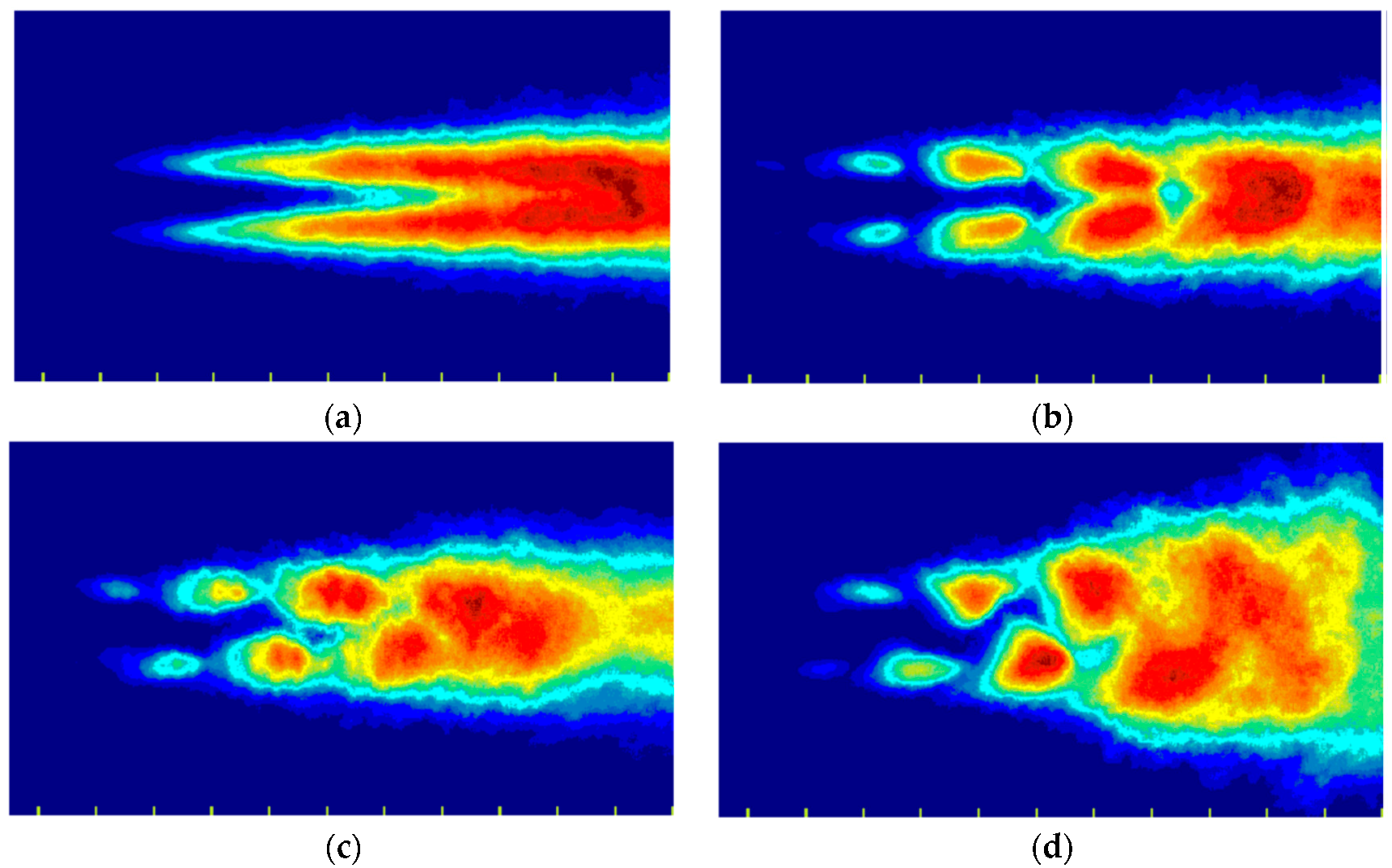

4.3. Rapid Combustion Instability

5. Discussion and Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Jacobsen, L.; Carter, C.; Baurle, R.A.; Jackson, T.A.; Williams, S.; Bivolaru, D.; Kuo, S.; Barnett, J.; Tam, C.-J. Plasma-assisted ignition in scramjets. J. Propuls. Power 2008, 24, 641–654. [Google Scholar] [CrossRef]

- Leonov, S.; Yarantsev, D.; Sabelnikov, V. Electrically driven combustion near the plane wall in a supersonic duct. In Progress in Propulsion Physic; EUCASS Book Series; EDP Sciences: Les Ulis, France, 2011; Volume 2, pp. 519–530. [Google Scholar] [CrossRef]

- Starikovskiy, A.; Aleksandrov, N. Plasma-assisted ignition and combustion. Prog. Energy Combust. Sci. 2013, 39, 61–110. [Google Scholar] [CrossRef] [Green Version]

- Starikovskaya, S.M. Plasma assisted ignition and combustion. J. Phys. D Appl. Phys. 2006, 39, 61–110. [Google Scholar] [CrossRef]

- Ju, Y.; Sun, W. Plasma assisted combustion: Dynamics and chemistry. Prog. Energy Combust. Sci. 2015, 48, 21–83. [Google Scholar] [CrossRef]

- Samukawa, S.; Hori, M.; Rauf, S.; Tachibana, K.; Bruggeman, P.; Kroesen, G.; Whitehead, J.C.; Murphy, A.B.; Gutsol, A.F.; Starikovskaia, S.; et al. The 2012 Plasma Roadmap. J. Phys. D Appl. Phys. 2012, 45, 253001. [Google Scholar] [CrossRef]

- Starikovskii, Y. Plasma supported combustion. Proc. Combust. Inst. 2005, 30, 2405–2417. [Google Scholar] [CrossRef]

- Singleton, D.; Pendleton, S.; Gundersen, M. The role of non-thermal transient plasma for enhanced flame ignition in C2H4–air. J. Phys. D Appl. Phys. 2011, 44, 022001. [Google Scholar] [CrossRef]

- Sun, W.; Uddi, M.; Wona, S.H.; Ombrello, T.; Carter, C.; Ju, Y. Kinetic effects of non-equilibrium plasma-assisted methane oxidation on diffusion flame extinction limits. Combust. Flame 2012, 159, 221–229. [Google Scholar] [CrossRef]

- Adamovich, V.; Choi, I.; Jiang, N.; Kim, J.-H.; Keshav, S.; Lempert, W.; Mintusov, E.; Nishihara, M.; Samimy, M.; Uddi, M. Plasma Assisted Ignition and High-Speed Flow Control: Non-Thermal and Thermal Effects. Plasma Sources Sci. Technol. 2009, 18, 034018. [Google Scholar] [CrossRef]

- Tsolas, N.; Lee, J.G.; Yetter, R.A. Flow reactor studies of non-equilibrium plasma-assisted oxidation of n-alkanes. Philos. Trans. A Math. Phys. Eng. Sci. 2015, 373. [Google Scholar] [CrossRef] [PubMed]

- Pilla, G.; Galley, D.; Lacoste, D.; Lacas, F.; Veynante, D.; Laux, C. Stabilization of a turbulent premixed flame using a nanosecond repetitively pulsed plasma. IEEE Trans. Plasma Sci. 2006, 34, 2471–2477. [Google Scholar] [CrossRef]

- Kim, W.; Mungal, M.G.; Cappelli, M.A. Formation and role of cool flames in plasma-assisted premixed combustion. Appl. Phys. Lett. 2008, 92. [Google Scholar] [CrossRef]

- Aleksandrov, N.; Anikin, N.; Bazelyan, E.; Zatsepin, D.; Starikovskaia, S.; Starikovskii, A. Chemical Reactions and Ignition Initiation in Hydrocarbon-Air Mixtures by High-Voltage Nanosecond Gas Discharge; AIAA Paper 2001-2949; AIAA: Reston, VA, USA, 2011. [Google Scholar]

- Deminsky, M.A.; Kochetov, I.V.; Napartovich, A.P.; Leonov, S.B. Modeling of Plasma Assisted Combustion in Premixed Supersonic Gas Flow. Int. J. Hyperson. 2010, 1, 5–15. [Google Scholar] [CrossRef]

- Leonov, S.; Carter, C.; Yarantsev, D. Experiments on Electrically Controlled Flameholding on a Plane Wall in Supersonic Airflow. J. Propuls. Power 2009, 25, 289–298. [Google Scholar] [CrossRef]

- Lee, D.H.; Kim, K.-T.; Kang, H.S.; Song, Y.-H.; Park, J.E. Plasma-Assisted Combustion Technology for NOx Reduction in Industrial Burners. Environ. Sci. Technol. 2013, 47, 10964–10970. [Google Scholar] [CrossRef] [PubMed]

- Wolk, B.; DeFilippo, A.; Chen, J.-Y.; Dibble, R.; Nishiyama, A.; Ikeda, Y. Enhancement of flame development by microwave-assisted spark ignition in constant volume combustion chamber. Combust. Flame 2013, 160, 1225–1234. [Google Scholar] [CrossRef]

- Pancheshnyi, S.; Lacoste, D.; Bourdon, A.; Laux, C. Ignition of Propane-Air Mixtures by a Repetitively Pulsed Nanosecond Discharge. IEEE Trans. Plasma Sci. 2006, 34, 2478–2487. [Google Scholar] [CrossRef]

- Karpenko, E.; Messerle, V.; Ustimenko, A. Plasma-aided solid fuel combustion. Proc. Combust. Inst. 2007, 31, 3353–3360. [Google Scholar] [CrossRef]

- Billingsley, M.; O’Brien, W.; Schetz, J. Plasma Torch Atomizer-Igniter for Supersonic Combustion of Liquid Hydrocarbon Fuel; AIAA Paper 2006-7970; AIAA: Reston, VA, USA, 2006. [Google Scholar]

- Takita, A.; Shishido, K.; Kurumada, K. Ignition in a supersonic flow by a plasma jet of mixed feedstock including CH4. Proc. Combust. Inst. 2011, 33, 2383–2389. [Google Scholar] [CrossRef]

- Li, F.; Yua, X.-L.; Tong, Y.-G.; Shen, Y.; Chen, J.; Chen, L.-H.; Chang, X.-Y. Plasma-assisted ignition for a kerosene fueled scramjet at Mach 1.8. Aerosp. Sci. Technol. 2013, 28, 72–78. [Google Scholar] [CrossRef] [Green Version]

- Firsov, A.; Savelkin, K.; Yarantsev, D.; Leonov, S. Plasma-enhanced mixing and flameholding in supersonic flow. Philos. Trans. A 2015, 373. [Google Scholar] [CrossRef] [PubMed]

- Ma, A.; Lei, Q.; Wu, Y.; Xu, W.; Ombrello, T.M.; Carter, C.D. From ignition to stable combustion in a cavity flameholder studied via 3D tomographic chemiluminescence at 20 kHz. Combust. Flame 2016, 165, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Vincent-Randonnier, A.; Packan, D.; Sabelnikov, V.; LeJouan, F.; Rouxel, B.; Roux, P.; Leonov, S. First Experiments on Plasma Assisted Supersonic Combustion at LAERTE Facility; AIAA Paper 2017-1975; AIAA: Reston, VA, USA, 2017. [Google Scholar]

- Leonov, S.B.; Kochetov, I.V.; Napartovich, A.P.; Sabel’nikov, V.A.; Yarantsev, D.A. Plasma-Induced Ethylene Ignition and Flameholding in Confined Supersonic Air Flow at Low Temperatures. IEEE Trans. Plasma Sci. 2011, 39, 781–787. [Google Scholar] [CrossRef]

- Savelkin, V.; Yarantsev, D.A.; Adamovich, I.V.; Leonov, S.B. Ignition and flameholding in a supersonic combustor by an electrical discharge combined with a fuel injector. Combust. Flame 2015, 162, 825–835. [Google Scholar] [CrossRef]

- Gruber, R.; Donbar, J.M.; Carter, C.D.; Hsu, K.-Y. Mixing and Combustion Studies Using Cavity-Based Flameholders in a Supersonic Flow. J. Propuls. Power 2004, 20, 769–778. [Google Scholar] [CrossRef]

- Leonov, S.B.; Firsov, A.A.; Isaenkov, Y.I.; Shurupov, M.A.; Yarantsev, D.A. Plasma-Based Fast Mixing and Ignition in Supersonic Flow; AIAA Paper 2011-2327; AIAA: Reston, VA, USA, 2011. [Google Scholar]

- Houpt, A.; Hedlund, B.; Ombrello, T.; Carter, C.; Leonov, S. Quasi-DC Electrical Discharge Characterization in a Supersonic Flow. Exp. Fluids 2017, 58, 25. [Google Scholar] [CrossRef]

- Houpt, A.; Hedlund, B.; Leonov, S.; Ombrello, T.; Carter, C. Dynamic Response of an Oblique Shock Wave Generated by a Q-DC Discharge in Pulse-Repetitive Mode; AIAA Paper 2017-3476; AIAA: Reston, VA, USA, 2017. [Google Scholar]

- Falempin, F.; Firsov, A.; Yarantsev, D.; Goldfeld, M.; Timofeev, K.; Leonov, S. Plasma control of shock wave configuration in off-design mode of M = 2 inlet. Exp. Fluids 2015, 56. [Google Scholar] [CrossRef]

- Leonov, S.; Adamovich, I.; Soloviev, V. Dynamics of near-surface electric discharges and mechanisms of their interaction with the airflow, Topical Review. Plasma Sources Sci. Technol. 2016, 25. [Google Scholar] [CrossRef]

- Houpt, A.W.; Hedlund, B.E.; Leonov, S.B.; Ombrello, T.; Carter, C.D.; Leiweke, R. Cavity-Based Flow Control in A Supersonic Duct Utilizing a Q-DC Plasma Shock Wave Generator; AIAA Paper 2018-1140; AIAA: Reston, VA, USA, 2018. [Google Scholar]

- Kimura, A.; Aoki, H.; Kato, M. The use of a plasma jet for flame stabilization and promotion of combustion in supersonic air flows. Combust. Flame 1981, 42, 297–305. [Google Scholar] [CrossRef]

- Masuya, G.; Kudou, K.; Komuro, T.; Tani, K.; Kanda, T.; Wakamatsu, Y.; Chinzei, N.; Sayama, M.; Ohwaki, K.; Kimura, I. Some Governing Parameters of Plasma Torch Igniter/Flameholder in a Scramjet Combustor. J. Propuls. Power 1993, 9, 176–181. [Google Scholar] [CrossRef]

- Sato, Y.; Sayama, M.; Ohwaki, K.; Masuya, G.; Komuro, T.; Kudou, K.; Murakami, A.; Tani, K.; Wakamatsu, Y.; Kanda, T. Effectiveness of plasma torches for ignition and flameholding in scramjet. J. Propuls. Power 1992, 8, 883–889. [Google Scholar] [CrossRef]

- Wagner, T.C.; O’brien, W.F.; Northam, G.B.; Eggers, J.M. Plasma torch igniter for scramjets. J. Propuls. Power 1989, 5, 548–554. [Google Scholar] [CrossRef]

- Cross, A.; Sanders, D.; O’Brien, W.F.; Schetz, J.A. Operation of Plasma-Torch for Supersonic Combustion Applications with Simulated Cracked JP-7 Feedstock; AIAA Paper 2003-6935; AIAA: Reston, VA, USA, 2003. [Google Scholar]

- Billingsley, M.; Sanders, D.; O’Brien, W.; Schetz, J. Improved Plasma Torches for Application in Supersonic Combustion; AIAA Paper 2005-3423; AIAA: Reston, VA, USA, 2005. [Google Scholar]

- Bonanos, A.M.; Schetz, J.A.; O’Brien, W.F.; Goyne, C.P. Dual-Mode Combustion Experiments with an Integrated Aeroramp-Injector/Plasma-Torch Igniter. J. Propuls. Power 2008, 24, 267–273. [Google Scholar] [CrossRef]

- Northam, G.B.; McClinton, C.R.; Wagner, T.C.; O’Brien, W. Development and Evaluation of a Plasma Jet Flameholder for Scramjets; AIAA Paper 84-1408; AIAA: Reston, VA, USA, 1984. [Google Scholar]

- Takita, A.; Uemoto, T.; Sato, T.; Ju, Y.; Masuya, G.; Ohwaki, K. Ignition Characteristics of Plasma Torch for Hydrogen Jet in an Airstream. J. Propuls. Power 2000, 16, 227–233. [Google Scholar] [CrossRef]

- Takita, A. Ignition and Flame-Holding by Oxygen, Nitrogen and Argon Plasma Torches in Supersonic Airflow. Combust. Flame 2002, 128, 301–313. [Google Scholar] [CrossRef]

- Watanabe, J.; Abe, N.; Takita, K. Effect of a Rearward-Facing Step on Plasma Ignition in Supersonic Flow. J. Spacecr. Rockets 2009, 46, 561–567. [Google Scholar] [CrossRef]

- Kitagawa, T.; Moriwaki, A.; Murakami, K.; Takita, K.; Masuya, G. Ignition Characteristics of Methane and Hydrogen Using a Plasma Torch in Supersonic Flow. J. Propuls. Power 2003, 19, 853–858. [Google Scholar] [CrossRef]

- Kobayashi, A.; Tomioka, S.; Mitani, T. Supersonic Flow Ignition by Plasma Torch and H2/O2 Torch. J. Propuls. Power 2004, 20, 294–301. [Google Scholar] [CrossRef]

- Jacobsen, S.; Carter, C.D.; Jackson, T.A.; Schetz, J.A.; O’Brien, W.F.; Boguzko, G.S.; Elliott, M.; Crafton, J.W. Experimental Investigation of a DC Plasma-Torch Igniter; AIAA Paper 2002-5228; AIAA: Reston, VA, USA, 2002. [Google Scholar]

- Jacobsen, L.; Carter, C.; Baurie, R.; Jackson, T. Plasma-Assisted Ignition in Scramjet; AIAA Paper 2003-0871; AIAA: Reston, VA, USA, 2003. [Google Scholar]

- Kuo, S.P.; Koretzky, E.; Orlick, L. Design and Electrical Characteristics of a Modular Plasma Torch. IEEE Trans. Plasma Sci. 1999, 27, 752–758. [Google Scholar] [CrossRef]

- Klimov, A.; Bityurin, V.; Brovkin, V.; Leonov, S. Plasma Generators for Combustion. In Proceedings of the Workshop on Thermo-chemical Processes in Plasma Aerodynamics, Saint Petersburg, Russia, 30 May–3 June 2000; p. 74. [Google Scholar]

- Klimov, A.; Byturin, V.; Brovkin, V.; Vinogradov, V.; Wie, D.V. Plasma Assisted Combustion; AIAA Paper 2001-491; AIAA: Reston, VA, USA, 2001. [Google Scholar]

- Chintala, A.; Bao, A.; Lou, G.; Adamovich, I. Measurements of Combustion Efficiency in Nonequilibrium RF Plasma Ignited Flows. Combust. Flame 2006, 144, 744–756. [Google Scholar] [CrossRef]

- Chintala, A.; Meyer, R.; Hicks, A.; Bao, A.; Rich, J.; Lempert, W.; Adamovich, I. Non-Thermal Ignition of Premixed Hydrocarbon-Air Flows by Nonequilibrium RF Plasma. J. Propuls. Power 2005, 21, 583–590. [Google Scholar] [CrossRef]

- Esakov, I.; Grachev, L.P.; Khodataev, K.V.; Vinogradov, V.A.; Wie, D.M.V. Propane–Air Mixture Combustion Assisted by MW Discharge in a Speedy Airflow. IEEE Trans. Plasma Sci. 2006, 34, 2497–2506. [Google Scholar] [CrossRef]

- Grachev, L.; Khodataev, K.; Wie, D.V.; Esakov, I. Investigation of the Undercritical Microwave Streamer gas Discharge for Jet Engine Fuel Ignition; AIAA Paper 2001-2939; AIAA: Reston, VA, USA, 2001. [Google Scholar]

- Kopyl, V.; Surkont, O.S.; Shibkov, V.M.; Shibkova, L.V. Stabilization of liquid hydrocarbon fuel combustion by using a programmable microwave discharge in a subsonic airflow. Plasma Phys. Rep. 2012, 38, 503–512. [Google Scholar] [CrossRef]

- Ivanov, V.V.; Skvortsov, V.V.; Efimov, B.G.; Pyndyk, A.M.; Kireev, A.Y.; Krasheninnikov, V.N.; Shilenkov, S.V. Spectroscopic Investigations of Longitudinal Discharge in Supersonic Flow of Air with Injection of Propane into the Discharge Zone. High Temp. 2008, 46, 3–10. [Google Scholar] [CrossRef]

- Chernikov, V.; Ershov, A.; Shibkov, V.; Timofeev, B.; Timofeev, I.; Vinogradov, V.; Wie, D.V. Gas Discharges in Supersonic Flows of Air-Propane Mixture; AIAA Paper 2001-2948; AIAA: Reston, VA, USA, 2001. [Google Scholar]

- Adamovich, A.; Lempert, W.; Nishihara, M.; Rich, J.; Utkin, Y. Repetitively Pulsed Nonequilibrium Plasmas for Magnetohydrodynamic Flow Control and Plasma-Assisted Combustion. J. Propuls. Power 2008, 24, 1198–1215. [Google Scholar] [CrossRef] [Green Version]

- Galley, D.; Pilla, G.; Lacoste, D.; Ducruix, S.; Lacas, F.; Veynante, D.; Laux, C. Plasma-Enhanced Combustion of a Lean Premixed Air-Propane Turbulent Flame using a Repetitively Pulsed Nanosecond Discharge; AIAA Paper 2005-1193; AIAA: Reston, VA, USA, 2005. [Google Scholar]

- Buriko, Y.; Vinogradov, V.; Goltsev, V.; Waltrup, P. Influence of Active Radical Concentration on Self-Ignition Delay of Hydrocarbon Fuel/Air Mixture. J. Propuls. Power 2002, 18, 1049–1058. [Google Scholar] [CrossRef]

- Liu, A.; Wang, F.; Li, G.; Kuthi, A.; Gutmark, E.; Ronney, P.; Gundersen, M. Transient plasma ignition. IEEE Trans. Plasma Sci. 2005, 33, 326–327. [Google Scholar]

- Matveev, A.; Matveeva, S.; Gutsol, A. Non-Equilibrium Plasma Igniters and Pilots for Aerospace Application; AIAA Paper 2005-1191; AIAA: Reston, VA, USA, 2005. [Google Scholar]

- Grytsinin, S.I.; Kossyi, I.A.; Misakyan, M.A.; Silakov, V.P.; Tarasova, N.M.; Temchin, S.M. Features of Gaseous Mixtures Combustion Initiated by High-Current Slipping Surface Discharge. J. Thermophys. Heat Transf. 2002, 16, 450–454. [Google Scholar] [CrossRef]

- Leonov, S.B.; Yarantsev, D.A.; Napartovich, A.P.; Kochetov, I.V. Plasma-Assisted Ignition and Flameholding in High-Speed Flow; AIAA Paper 2006-563; AIAA: Reston, VA, USA, 2006. [Google Scholar]

- Lacoste, D.; Moeck, J.; Durox, D.; Laux, C.; Schuller, T. Effect of Nanosecond Repetitively Pulsed Discharges on the Dynamics of a Swirl-Stabilized Lean Premixed Flame. J. Eng. Gas Turbines Power 2013, 135. [Google Scholar] [CrossRef]

- Leonov, S.B.; Yarantsev, D.A. Near Surface Electrical Discharge in Supersonic Airflow: Properties and Flow Control. J. Propuls. Power 2008, 24, 1168–1181. [Google Scholar] [CrossRef]

- Su, C.; Li, Y.; Cheng, B.; Wang, J.; Cao, J.; Li, Y. MHD Flow Control of Oblique Shock Waves around Ramps in Low-temperature Supersonic Flows. Chin. J. Aeronaut. 2010, 23, 22–32. [Google Scholar]

- Sun, A.; Li, Y.; Cheng, B.; Cui, W.; Liu, W.; Xiao, Q. The characteristics of surface arc plasma and its control effect on supersonic flow. Phys. Lett. A 2014, 378, 2672–2682. [Google Scholar] [CrossRef]

- Korolev, Y.D.; Frants, O.B.; Landl, N.V.; Geyman, V.G.; Matveev, I.B. Glow-to-Spark Transitions in a Plasma System for Ignition and Combustion Control. IEEE Trans. Plasma Sci. 2007, 35, 1651–1657. [Google Scholar] [CrossRef]

- Kimmel, L.; Hayes, J.R.; Crafton, J.W.; Fonov, S.D.; Menart, J.; Shang, J. Surface Discharge for High-Speed Boundary Layer Control; AIAA Paper 2006-710; AIAA: Reston, VA, USA, 2006. [Google Scholar]

- Vincent-Randonnier, A.; Larigaldie, S.; Magre, P.; Sabel’nikov, V. Plasma assisted combustion: effect of a coaxial DBD on a methane diffusion flame. Plasma Sources Sci. Technol. 2007, 16, 149. [Google Scholar] [CrossRef]

- Kosarev, A.; Khorunzhenko, V.I.; Mintoussov, E.I.; Sagulenko, P.N.; Popov, N.A.; Starikovskaia, S.M. A nanosecond surface dielectric barrier discharge at elevated pressures: Time-resolved electric field and efficiency of initiation of combustion. Plasma Sources Sci. Technol. 2012, 21, 045012. [Google Scholar] [CrossRef]

- Kim, W.; Mungal, M.; Cappelli, M. The role of in situ reforming in plasma enhanced Ultra Lean premixed methane/air flames. Combust. Flame 2010, 157, 374–383. [Google Scholar] [CrossRef]

- Leonov, S.; Isaenkov, Y.; Yarantsev, D.; Kochetov, I.; Napartovich, A.; Shneider, M. Unstable Pulse Discharge in Mixing Layer of Gaseous Reactants; AIAA Paper 2009-0820; AIAA: Reston, VA, USA, 2009. [Google Scholar]

- Leonov, B.; Yarantsev, D.A. Instability in Post-Discharge Thermal Cavity. IEEE Trans. Plasma Sci. 2008, 36, 978–979. [Google Scholar] [CrossRef]

- Brieschenk, S.; O’Byrne, S.; Kleine, H. Laser-induced plasma ignition studies in a model scramjet engine. Combust. Flame 2013, 160, 145–148. [Google Scholar] [CrossRef]

- O’Briant, S.A.; Gupta, S.B.; Vasu, S.S. Review: Laser ignition for aerospace propulsion. Propuls. Power Res. 2016, 5, 1–21. [Google Scholar] [CrossRef]

- An, A.; Wang, Z.; Yang, L.; Li, X.; Zhu, J. Experimental investigation on the impacts of ignition energy and position on ignition processes in supersonic flows by laser induced plasma. Acta Astronaut. 2017, 137, 444–449. [Google Scholar] [CrossRef]

- Dumitrache, A.; Baumgardner, M.; Boissiere, A.; Maria, A.; Roucis, J.; Marchese, A.J.; Yalin, A. A study of laser induced ignition of methane–air mixtures inside a Rapid Compression Machine. Proc. Combust. Inst. 2017, 36, 3431–3439. [Google Scholar] [CrossRef]

- Esakov, I.; Grachev, L.P.; Khodataev, K.V. Efficiency of Microwave Discharges for Propane Ignition in Cold High-Speed Airflows; AIAA Paper 2005-989; AIAA: Reston, VA, USA, 2005. [Google Scholar]

- Popov, A. Fast gas heating in a nitrogen-oxygen discharge plasma: I. Kinetic mechanism. J. Phys. D Appl. Phys. 2011, 44. [Google Scholar] [CrossRef]

- Fridman, A.; Gutsol, A.; Gangoli, S.; Ju, Y.; Ombrello, T. Characteristics of Gliding Arc and Its Application in Combustion Enhancement. J. Propul. Power 2008, 24, 1216–1228. [Google Scholar] [CrossRef]

- Macheret, S.O.; Shneider, M.N.; Miles, R.B. Energy Efficiency of Plasma-Assisted Combustion in Ram/Scramjet Engines; AIAA Paper 2005-5371; AIAA: Reston, VA, USA, 2005. [Google Scholar]

- Do, H.; Mungal, M.G.; Cappelli, M.A. Jet Flame Ignition in a Supersonic Crossflow Using a Pulsed Nonequilibrium Plasma Discharge. IEEE Trans. Plasma Sci. 2008, 36, 2918–2923. [Google Scholar] [CrossRef]

- Do, H.; Cappelli, M.A.; Mungal, M.G. Plasma assisted cavity flame ignition in supersonic flows. Combust. Flame 2010, 157, 1783–1794. [Google Scholar] [CrossRef]

- Do, H.; Im, S.-K.; Cappelli, M.A.; Mungal, M.G. Plasma assisted flame ignition of supersonic flows over a flat wall. Combust. Flame 2010, 157, 2298–2305. [Google Scholar] [CrossRef]

- Leonov, S.; Sabelnikov, V. Electrically driven supersonic combustor. In Proceedings of the 6th European Symposium on Aerodynamics for Space Vehicles, Versailles, France, 27 November 2008. [Google Scholar]

- Leonov, S.B.; Savelkin, C.V.; Yarantsev, D.A.; Carter, C.; Sermanov, V.N.; Starodubtsev, M.A. Experiments on Plasma-Assisted Combustion in M = 2 Hot Test-Bed PWT-50H; AIAA Paper 2008-1359; AIAA: Reston, VA, USA, 2008. [Google Scholar]

- Golovnov, A.; Pozdnyakov, G. The Observation of the Combustion Initiated by a Free Electrons Cloud; AIAA Paper 2005-3426; AIAA: Reston, VA, USA, 2005. [Google Scholar]

- Bychkov, A.; Bychkov, D.; Denisiuk, S.; Gudovich, V.; Kochetov, I.; Ardelyan, N. Electron-Beams for Plasma Impact on Gas Flammable Mixtures; AIAA Paper 2009-693; AIAA: Reston, VA, USA, 2009. [Google Scholar]

- Adamovich, A.; Rich, J.; Palm, P.; Plonjes, E.; Buoni, M.; Subramaniam, V. Electron-Beam Generated High Pressure Air Plasmas Enhanced by Optical Pumping; AIAA Paper 2001-346; AIAA: Reston, VA, USA, 2001. [Google Scholar]

- Goldfeld, M.A.; Pozdnyakov, G.A. Ignition of Hydrocarbon-Air Supersonic Flow by Volumetric Ionization. J. Therm. Sci. 2015, 24, 583–590. [Google Scholar] [CrossRef]

- Leonov, S.; Bityurin, V.; Yarantsev, D. The Effect of Plasma-Induced Separation; AIAA-2003-3853; AIAA: Reston, VA, USA, 2003. [Google Scholar]

- Zhou, S.; Nie, W.; Che, X. Numerical Investigation of Influence of Quasi-DC Discharge Plasma on Fuel Jet in Scramjet Combustor. IEEE Trans. Plasma Sci. 2015, 43, 896–905. [Google Scholar] [CrossRef]

- Wang, A.; Li, Y.; Cheng, B.; Su, C.; Song, H.; Wu, Y. The mechanism investigation on shock wave controlled by plasma aerodynamic actuation. Acta Phys. Sin. 2009, 58, 5513–5519. [Google Scholar]

- Zhou, S.; Nie, W.; Feng, W.; Cheng, Y. Effect of the arc plasma at upstream of the jet on scramjet combustor’s performance. Missiles Space Veh. 2013, 54, 52–55. [Google Scholar]

- Yan, H.; Liu, F.; Xu, J. Oblique Shock Control by Surface Arc Discharge Plasma; AIAA Paper 2016-3776; AIAA: Reston, VA, USA, 2016. [Google Scholar]

- Leonov, S.; Firsov, A.; Yarantsev, D.; Bolshov, M.; Kuritsyn, Y.; Liger, V.; Mironeko, V. Temperature Measurement in Plasma-Assisted Combustor by TDLAS; AIAA Paper 2012-3181; AIAA: Reston, VA, USA, 2012. [Google Scholar]

- Bolshov, M.; Kuritsyn, Y.; Liger, V.; Mironenko, V.; Yarantsev, D.; Leonov, S. Measurements of the temperature and water vapor concentration in a hot zone by tunable diode laser absorption spectrometry. Appl. Phys. B 2010, 100, 397–407. [Google Scholar] [CrossRef]

- Yarantsev, A.; Leonov, S.; Biturin, V.; Savelkin, K. Spectroscopic Diagnostics of Plasma-Assisted Combustion in High-Speed Flow; AIAA Paper 2005-3396; AIAA: Reston, VA, USA, 2005. [Google Scholar]

- Laux, O.; Spence, T.G.; Kruger, C.H.; Zare, R.N. Optical diagnostics of atmospheric pressure air plasmas. Plasma Sources Sci. Technol. 2003, 12, 125–138. [Google Scholar] [CrossRef]

- Raizer, Y.P. Gas Discharge Physics; Springer: Berlin, Germany, 1991. [Google Scholar]

- Leonov, S.B.; Yarantsev, D.A. Control of separation phenomena in high-speed flow by means of the surface electric discharge. Fluid Dyn. 2008, 43, 945–953. [Google Scholar] [CrossRef]

- Kalra, A.; Zaidi, S.; Miles, R.; Macheret, S. Shockwave–turbulent boundary layer interaction control using magnetically driven surface discharges. Exp. Fluids 2011, 50, 547–559. [Google Scholar] [CrossRef]

- Leonov, S.B.; Houpt, A.; Hedlund, B. Experimental Demonstration of Plasma-Based Flameholder in a Model Scramjet; AIAA Paper 2017-2249; AIAA: Reston, VA, USA, 2017. [Google Scholar]

- Leonov, S.; Houpt, A.; Elliott, S.; Hedlund, B. Ethylene Ignition and Flameholding by Electrical Discharge in Supersonic Combustor. J. Propuls. Power 2018, 34, 499–509. [Google Scholar] [CrossRef]

- Leonov, B.; Hedlund, B.E.; Houpt, A.W. Morphology of a Q-DC Discharge within a Fuel Injection Jet in a Supersonic Cross-Flow; AIAA Paper 2018-1060; AIAA: Reston, VA, USA, 2018. [Google Scholar]

- Mungal, M.G.; Dimotakis, P.E. Mixing and Combustion with Low Heat Release in a Turbulent Shear Layer. J. Fluid Mech. 1984, 148, 349–382. [Google Scholar] [CrossRef]

- Kuznetsov, R.; Sabelnikov, V.A. Turbulence and Combustion; Hemisphere Publishing Corporation: Philadelphia, PA, USA, 1990. [Google Scholar]

- Ottino, M. The Kinematics of Mixing: Stretching, Chaos, and Transport; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Broadwell, E.; Breidenthal, R.E. A simple model of mixing and chemical reactions in a turbulent shear layer. J. Fluid Mech. 1982, 125, 397–410. [Google Scholar] [CrossRef]

- Cremer, A.; McMurtry, P.A.; Kerstein, A.R. Effects of turbulent and scalar length scale distributions on turbulent mixing processes. Phys. Fluids A 1994, 6, 2143–2153. [Google Scholar] [CrossRef]

- Seiner, M.; Dash, S.M.; Kenzakowski, D.C. Historical Survey on Enhanced Mixing in Scramjet Engines. J. Propuls. Power 2001, 17, 1273–1286. [Google Scholar] [CrossRef]

- Hiejima, T. Effects of streamwise vortex breakdown on supersonic combustion. Phys. Rev. E 2016, 93. [Google Scholar] [CrossRef] [PubMed]

- Ogawa, H.; Kodera, M. Physical Insight into Fuel/Air Mixing with Hypermixer Injectors for Scramjet Engines. J. Propuls. Power 2015, 31, 1423–1435. [Google Scholar] [CrossRef]

- Barnes, F.W.; Segal, C. Cavity-based flameholding for chemically-reacting supersonic flows. Prog. Aerosp. Sci. 2015, 76, 24–41. [Google Scholar] [CrossRef]

- Urzay, J. Supersonic Combustion in Air-Breathing Propulsion Systems for Hypersonic Flight. Annu. Rev. Fluid Mech. 2018, 50, 593–627. [Google Scholar] [CrossRef]

- Leonov, S.B.; Carter, C.D.; Hedlund, B.E.; Houpt, A.W.; Ombrello, T.; Firsov, A.A. Control of Amplitude and Position of Reflected Shock Wave by Stripwise Plasma; AIAA Paper 2018-0683; AIAA: Reston, VA, USA, 2018. [Google Scholar]

- Bocharov, A.; Bityurin, V.; Klement’eva, I.; Leonov, S. Study of Plasma and MHD Assisted Mixing and Combustion; AIAA Paper 2002-5878; AIAA: Reston, VA, USA, 2002. [Google Scholar]

- Bocharov, A.; Bityurin, V.; Leonov, S.; Baranov, D. Numerical Simulation and Experimental Study of MHD-Driven Mixing and Combustion; AIAA Paper 2002-492; AIAA: Reston, VA, USA, 2002. [Google Scholar]

- Zheltovodov, A.A.; Pimonov, E.A. Intensification of Mixing of Parallel Compressible Flows Using a Localized Pulse-Periodic Energy Supply. Tech. Phys. Lett. 2013, 39, 1016–1018. [Google Scholar] [CrossRef]

- Liu, A.; Yan, H.; Zheltovodov, A. Effect of Pulsed Periodic Energy Deposition on Mixing of Supersonic Flow Interaction with Oblique Shock; AIAA Paper 2018-1531; AIAA: Reston, VA, USA, 2018. [Google Scholar]

- Samimy, A.; Adamovich, I.; Webb, B.; Kastner, J.; Hileman, J.; Palm, P. Development and Characterization of Plasma Actuators for High Speed Jet Control. Exp. Fluids 2004, 37, 577–588. [Google Scholar] [CrossRef]

- Samimy, A.; Kearney-Fischer, M.; Kim, J.-H. High-speed and high-Reynolds-number jet control using localized arc filament plasma actuators. J. Propuls. Power 2012, 28, 269–280. [Google Scholar] [CrossRef]

- Samimy, A.; Webb, N.; Crawley, M. Excitation of Free Shear-Layer Instabilities for High-Speed Flow Control. AIAA J. 2018, 56, 1770–1891. [Google Scholar] [CrossRef]

- Samimy, A.; Kim, J.-H.; Kastner, J.; Adamovich, I.; Utkin, Y. Active Control of High-speed and High Reynolds Number Jets Using Plasma Actuators. J. Fluid Mech. 2007, 578, 305–330. [Google Scholar] [CrossRef]

- Kim, J.-H.; Nishihara, M.; Adamovich, I.; Samimy, M.; Gorbatov, S.; Pliavaka, F. Development of Localized Arc Filament RF Plasma Actuators for High-Speed and High Reynolds Number Flow Control. Exp. Fluids 2010, 49, 497–511. [Google Scholar] [CrossRef]

- Hahn, A.; Kearney-Fischer, M.; Samimy, M. On factors influencing arc filament plasma actuator performance in control of high speed jets. Exp. Fluids 2011, 51, 591–603. [Google Scholar] [CrossRef]

- Utkin, Y.G.; Keshav, J.; Kim, J.-H.; Kastner, J.; Adamovich, I.V.; Samimy, M. Development and Use of Localized Arc Filament Plasma Actuators for High-speed Flow Control. J. Phys. D Appl. Phys. 2007, 40, 685–694. [Google Scholar] [CrossRef]

- Kearney-Fischer, A.; Kim, J.-H.; Samimy, M. A Study of Mach Wave Radiation Using Active Control. J. Fluid Mech. 2011, 681, 261–292. [Google Scholar] [CrossRef]

- Kopiev, F.; Akishev, Y.S.; Belyaev, I.V.; Berezhetskaya, N.K.; Bityurin, V.A.; Faranosov, F.A.; Grushin, M.E.; Klimov, A.I.; Kopiev, V.A.; Kossyi, I.A.; et al. Instability wave control in turbulent jet by plasma actuarors. J. Phys. D Appl. Phys. 2014, 47, 505201. [Google Scholar] [CrossRef]

- Klement’eva, A.; Bityurin, V.; Bocharov, A. Electrical Discharge Influence on Gas Flow Structure and Mixing; AIAA Paper 2009-1045; AIAA: Reston, VA, USA, 2009. [Google Scholar]

- Klementyeva, B.; Biturin, V.A.; Tolkunov, B.N.; Moralev, I.A. Experimental Study of Electrical Discharges in Gas Flows under External Magnetic Field. High Temp. 2011, 49, 788–796. [Google Scholar] [CrossRef]

- Greig, P.; Pechacek, R.E.; Raleigh, M. Channel cooling by turbulent convective mixing. Phys. Fluids 1985, 28, 2357–2364. [Google Scholar] [CrossRef]

- Shneider, M.N. Turbulent decay of after-spark channels. Phys. Plasmas 2006, 13. [Google Scholar] [CrossRef]

- Shurupov, M.A.; Leonov, S.B.; Firsov, A.A.; Yarantsev, D.A.; Isaenkov, Y.I. Gasdynamic Instabilities during Decay of the Submicrosecond Spark Discharge Channel. High Temp. 2014, 52, 169–179. [Google Scholar] [CrossRef]

- Leonov, S.; Isaenkov, Y.; Scheider, M.; Firsov, A.; Yarantsev, D. High-Power Filamentary Pulse Discharge in Supersonic Flow; AIAA Paper 2010-259; AIAA: Reston, VA, USA, 2010. [Google Scholar]

- Leonov, S.B.; Firsov, A.A.; Shurupov, M.; Michael, J.B.; Shneider, M.; Miles, R.B.; Popov, N.A. Femtosecond laser guiding of a high-voltage discharge and the restoration of dielectric strength in air and nitrogen. Phys. Plasmas 2012, 19. [Google Scholar] [CrossRef]

- Firsov, A.; Shurupov, M.A.; Yarantsev, D.; Leonov, S.B. Mixing Measurements by Probe Breakdown Fluorescence; AIAA Paper 2013-2765; AIAA: Reston, VA, USA, 2013. [Google Scholar]

- Leonov, S.B.; Isaenkov, Y.I.; Firsov, A.A.; Nothnagel, S.L.; Gimelshein, S.F.; Shneider, M.N. Jet Regime of the Afterspark Channel Decay. Phys. Plasmas 2010, 17, 053505. [Google Scholar] [CrossRef]

- Kochetov, V.; Napartovich, A.P.; Leonov, S.B. The Discharge Development along the Border of the Gases Jets. In Proceedings of the 11th International Workshop on Magneto-Plasma Aerodynamics, Moscow, Russia, 10–12 April 2012. [Google Scholar]

- Dahm, J.A.; Dimotakis, P.E. Measurements of entrainment and mixing in turbulent jets. AIAA J. 1987, 25, 1216–1223. [Google Scholar] [CrossRef] [Green Version]

- Ehn, A.; Zhu, J.; Li, X.; Kiefer, J. Advanced Laser-Based Techniques for Gas-Phase Diagnostics in Combustion and Aerospace Engineering. Appl. Spectrosc. 2017, 7, 341–366. [Google Scholar] [CrossRef] [PubMed]

- Estruch, D.; Lawson, N.; Garry, K. Application of Optical Measurement Techniques to Supersonic and Hypersonic Aerospace Flows. J. Aerosp. Eng. 2009, 22, 383–395. [Google Scholar] [CrossRef]

- Aldén, M.; Bood, J.; Li, Z.; Richter, M. Visualization and Understanding of Combustion Processes Using Spatially and Temporally Resolved Laser Diagnostic Techniques. Proc. Combust. Inst. 2011, 33, 69–97. [Google Scholar] [CrossRef]

- Schulz, A.; Sick, V. Tracer-LIF diagnostics: Quantitative measurement of fuel concentration, temperature and fuel/air ratio in practical combustion systems. Prog. Energy Combust. Sci. 2005, 31, 75–121. [Google Scholar] [CrossRef]

- Gamba, M.; Miller, V.; Mungal, M.; Hanson, R. Temperature and Number Density Measurement in Non-uniform Supersonic Flowfields Undergoing Mixing using Toluene PLIF Thermometry. Appl. Phys. B Lasers Opt. 2015, 120, 285–304. [Google Scholar] [CrossRef]

- Tuttle, S.G.; Carter, C.D.; Hsu, K.-Y. Particle Image Velocimetry in a Nonreacting and Reacting High-Speed Cavity. J. Propuls. Power 2014, 30, 576–591. [Google Scholar] [CrossRef]

- Do, H.; Carter, C.D.; Liu, Q.; Ombrello, T.M.; Hammack, S.; Lee, T.; Hsu, K.-Y. Simultaneous gas density and fuel concentration measurements in a supersonic combustor using laser induced breakdown. Proc. Combust. Insit. 2015, 35, 2155–2162. [Google Scholar] [CrossRef] [Green Version]

- McGann, A.; Carter, C.D.; Ombrello, T.M.; Hammack, S.; Lee, T.; Do, H. Gas property measurements in a supersonic combustor using nanosecond gated laser-induced breakdown spectroscopy with direct spectrum matching. Proc. Combust. Inst. 2017, 36, 2857–2864. [Google Scholar] [CrossRef]

- Zimmer, A.; Tachibana, S. Laser induced plasma spectroscopy for local equivalence ratio measurements in an oscillating combustion environment. Proc. Combust. Inst. 2007, 31, 737–745. [Google Scholar] [CrossRef]

- Leonov, S.; Houpt, A.; Elliott, S. Instabilities in Plasma-Assisted Supersonic Combustor. AIAA Energy Forum 2018, in press. [Google Scholar]

- Yang, V.; Li, J.; Choi, J.Y.; Lin, K.-C. Ignition Transient in an Ethylene Fueled Scramjet Engine with Air Throttling; AIAA Papers 2010-409 and 2010-410; AIAA: Reston, VA, USA, 2010. [Google Scholar]

| Discharge Type | Typ. Power | Benefits | Disadvantages | Refs. |

|---|---|---|---|---|

| Longitudinal surface arc, DC | 1–10 kW | High temperature | Location in boundary layer, electrodes erosion, low efficiency | [69,70,71] |

| Transverse Near-Surface Quasi-DC | 1–30 kW | Mixing, long time of interaction, high temperature | Electrodes erosion, low volume of treatment | [31,69] |

| Glow discharge | 0.1–1 kW, continuous | Large volume, effective in radicals generation | Operation at low density | [72,73] |

| Volumetric arc | 1–10 kW | High temperature, long time of interaction | High level of required power | [59,60] |

| Plasma torch | 1–30 kW | High temperature, fuel through plasma | Plasma inside the torch device, low efficiency | [1,40,41,45,47,51] |

| RF filamentary | 0.1–1 kW | High speed of penetration, mixing, single-electrode | Low power deposition, unpredictable position | [52,53,54,55] |

| Microwave | 1–10 kW 0.1–10 J/pulse | Initiator or electrodeless, high efficiency in radicals generation | Complex equipment, large breakdown threshold at high pressure, sensitive to flow | [18,52,56,58] |

| DBD/Corona | 1 W/cm2 | Effective in radicals generation | Location in near-surface layer, low density of energy deposition | [34,74,75] |

| Nanosecond pulse discharge | 0.01–1 J/pulse | Effective in radicals generation, high-speed of penetration | Low-pressure application for homogeneous appearance | [12,14,68,76] |

| Short-pulse long spark | 1–100 J/pulse | High density of energy deposition, effective mixing | Short time of interaction, high-voltage | [77,78] |

| Laser spark | Wide range | High density of energy deposition. | Small volume of interaction, low energetic efficiency of lasers | [79,80,81,82] |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leonov, S.B. Electrically Driven Supersonic Combustion. Energies 2018, 11, 1733. https://doi.org/10.3390/en11071733

Leonov SB. Electrically Driven Supersonic Combustion. Energies. 2018; 11(7):1733. https://doi.org/10.3390/en11071733

Chicago/Turabian StyleLeonov, Sergey B. 2018. "Electrically Driven Supersonic Combustion" Energies 11, no. 7: 1733. https://doi.org/10.3390/en11071733