Model-Based Temperature Sensor Fault Detection and Fault-Tolerant Control of Urea-Selective Catalyst Reduction Control Systems

Abstract

:1. Introduction

2. Selective Catalyst Reduction Modeling and Control Strategy

2.1. Selective Catalyst Reduction Modeling

Principle of Selective Catalyst Reduction

- (1)

- Urea is injected into the exhaust tailpipe.

- (2)

- What left after completing evaporation of urea solution are solid substances under the corresponding thermal decomposition temperature.

- (3)

- The above solid substances are decomposed into gaseous NH3.

- (4)

- Gaseous NH3 is adsorbed into catalyst along with desorption of NH3.

- (5)

- N2 and H2O are generated based on the reaction between NH3 and NOx.

- (1)

- The components of exhaust gasses are considered as ideal gases, which are homogeneous and incompressible.

- (2)

- Effects of variations in the water and oxygen concentrations of exhaust gases are negligible.

- (3)

- The catalyst convertor may be discretized into several uniform cells along its flow axis.

- (4)

- All variables are homogeneous in the radial direction and only vary along the axis of convertor.

- (5)

- The reaction rate of adsorption/desorption is much slower than that of any other reaction.

- (6)

- Only adsorbed NH3 is involved in NOx reduction processes.

2.2. Control Strategy

- (1)

- In a specific test cycle, maximizing the NOx conversion efficiency and maintaining the ammonia slip within the limits (25 ppm at peak, 10 ppm on average) by regulating the urea dosage.

- (2)

- Calculating the ammonia coverage ratio based on Equations (25) and (26). Meanwhile, calculating the catalyst temperature by Equation (14).

- (3)

- Then the function relationship between ammonia coverage ratio and catalyst temperature can be derived by fitting and interpolation.

- (4)

- To avoid substantial ammonia slip caused by temperature fluctuation, limiting the ammonia coverage ratio at low temperatures.

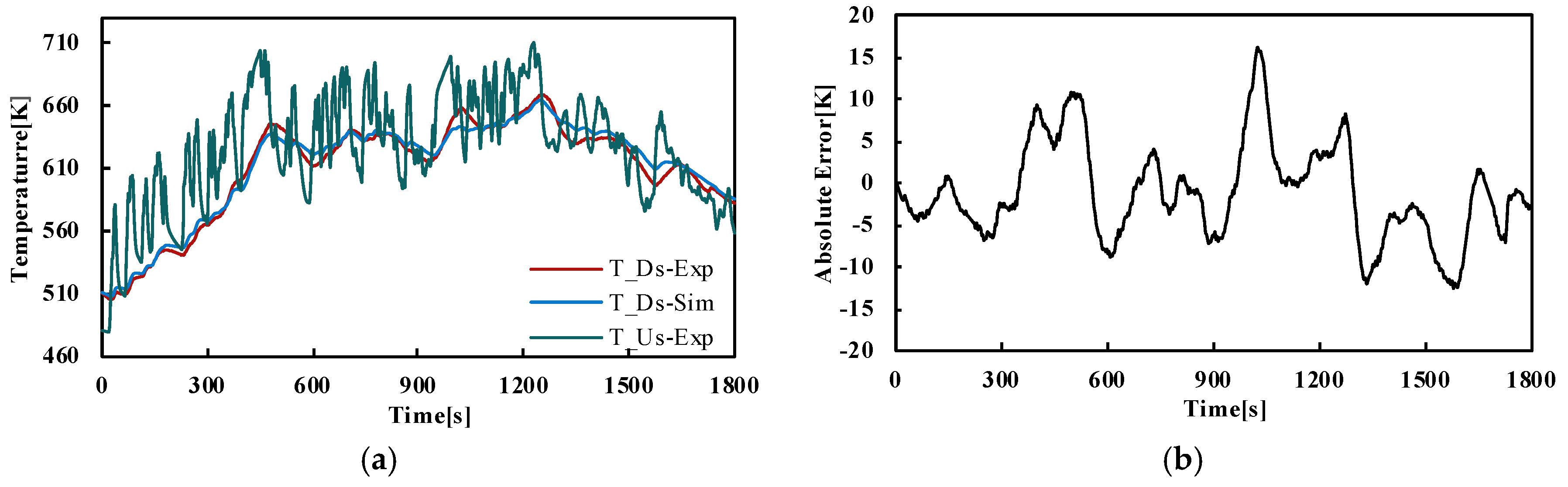

2.3. Parameter Identification and Model Validation

- (1)

- Several assumptions were induced for model simplification.

- (2)

- The operating conditions fluctuate drastically during certain periods of time, which makes it difficult to predict the corresponding NH3 and NOx emissions accurately.

3. Fault Detection and Fault-Tolerant Control

3.1. Description of Faults

3.2. Fault Detection and Fault-Tolerant Control

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tamilselvan, P.; Nallusamy, N.; Rajkumar, S. A comprehensive review on performance, combustion and emission characteristics of biodiesel fuelled diesel engines. Renew. Sustain. Energy Rev. 2017, 79, 1134–1159. [Google Scholar] [CrossRef]

- Liu, J.; Sun, P.; Huang, H.; Meng, J.; Yao, X. Experimental investigation on performance, combustion and emission characteristics of a common-rail diesel engine fueled with polyoxymethylene dimethyl ethers-diesel blends. Appl. Energy 2017, 202, 527–536. [Google Scholar] [CrossRef]

- Yamamoto, K.; Sakai, T. Simulation of continuously regenerating trap with catalyzed DPF. Catal. Today 2015, 242, 357–362. [Google Scholar]

- Ge, J.; Yoon, S.; Choi, N. Using Canola Oil Biodiesel as an Alternative Fuel in Diesel Engines: A Review. Appl. Sci. 2017, 7, 881. [Google Scholar] [CrossRef]

- Di, S.V.; Benedetto, A.D. Modeling and simulation of soot combustion dynamics in a catalytic diesel particulate filter. Chem. Eng. Sci. 2015, 137, 69–78. [Google Scholar]

- Gou, X.; Wu, C.; Zhang, K.; Xu, G.; Si, M.; Wang, Y.; Wang, E.; Liu, L.; Wu, J. Low Temperature Performance of Selective Catalytic Reduction of NO with NH3 under a Concentrated CO2 Atmosphere. Energies 2015, 11, 12331–12341. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Zhang, H.; Wang, J. NOx Sensor Reading Correction in Diesel Engine Selective Catalytic Reduction System Applications. IEEE/ASME Trans. Mech. 2016, 1, 460–471. [Google Scholar] [CrossRef]

- Willems, F.; Cloudt, R.; van den Eijnden, E.; van Genderen, M.; Verbeek, R.; de Jager, B.; Boomsma, W.; van den Heuvel, I. Is Closed-Loop SCR Control Required to Meet Future Emission Targets? SAE Technical Paper 2007-01-1574; SAE: Warrendale, PA, USA, 2007. [Google Scholar]

- Wang, G.; Zhang, J.; Yang, B.; Li, C.; Shuai, S.-H.; Yin, S.; Jian, M. Development of Model Based Closed Loop Control Strategy of SCR System for Heavy-Duty Diesel Engines; SAE Technical Paper 2017-01-2383; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Skaf, Z.; Aliyev, T.; Shead, L.; Steffen, T. The State of the Art in Selective Catalytic Reduction Control; SAE Technical Paper 2014-01-1533; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Willems, F.; Cloudt, R. Experimental Demonstration of a New Model-Based SCR Control Strategy for Cleaner Heavy-Duty Diesel Engines. IEEE Trans. Control Syst. Technol. 2011, 5, 1305–1313. [Google Scholar] [CrossRef]

- Shost, M.; Noetzel, J.; Wu, Mi.; Sugiarto, T.; Bordewyk, T.; Fulks, G.; Fisher, G.B. Monitoring, Feedback and Control of Urea SCR Dosing Systems for NOx Reduction: Utilizing an Embedded Model and Ammonia Sensing; SAE-2008-01-1325; SAE: Warrendale, PA, USA, 2008. [Google Scholar]

- Devarakonda, M.; Parker, G.; Johnson, J.; Strots, V. Model-based control system design in a urea-SCR after treatment system based on NH3 sensor feedback. Int. J. Automot. Technol. 2009, 10, 653–662. [Google Scholar] [CrossRef]

- Hsieh, M.F.; Wang, J. Nonlinear observer designs for diesel engine selective catalytic reduction (SCR) ammonia coverage ratio estimation. In Proceedings of the 48h IEEE Conference on Decision and Control (CDC) Held Jointly with 2009 28th Chinese Control Conference, Shanghai, China, 15–18 December 2009; pp. 6596–6601. [Google Scholar]

- Ming, F.H.; Wang, J. An extended Kalman filter for NOx, sensor ammonia cross-sensitivity elimination in selective catalytic reduction applications. In Proceedings of the 2010 American Control Conference, Baltimore, MD, USA, 30 June–2 July 2010; pp. 3033–3038. [Google Scholar]

- Ming, F.H.; Wang, J. An extended Kalman filter for ammonia coverage ratio and capacity estimations in the application of Diesel engine SCR control and onboard diagnosis. In Proceedings of the 2010 American Control Conference, Baltimore, MD, USA, 30 June–2 July 2010; pp. 5874–5879. [Google Scholar]

- Li, W.; Yan, F.; Hu, J.; Xi, G.; Liu, B.; Zeng, J. NOx conversion efficiency optimization based on NSGA-II and state-feedback nonlinear model predictive control of selective catalytic reduction system in diesel engine. Appl. Energy 2017, 206, 959–971. [Google Scholar]

- Chen, R.; Wang, X. Model-Based Fault Diagnosis of Selective Catalytic Reduction Systems for Diesel Engines. SAE Int. J. Passeng. Cars Electron. Electr. Syst. 2014, 7, 449–453. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Sun, Y.; Chang, C.-F.; Hu, Y. Model-Based Fault Detection and Fault-Tolerant Control of SCR Urea Injection Systems. IEEE Trans. Veh. Technol. 2016, 6, 4645–4654. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Chang, C.; Levijoki, S. Detection of Urea Injection System Faults for SCR Systems; SAE Technical Paper 2012-01-0431; SAE: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Matsumoto, A.; Furui, K.; Ogiso, M.; Kidokoro, T. Model-Based OBD Logic Utilizing Adsorption and Desorption Model of NH3 in SCR Catalyst; SAE Technical Paper 2016-01-0960; SAE: Warrendale, PA, USA, 2016. [Google Scholar] [CrossRef]

- Pezzini, A. A Methodology for Fault Diagnosis of Diesel NOx Aftertreatment Systems. IFAC Proc. Vol. 2009, 8, 911–916. [Google Scholar] [CrossRef]

- Wang, Y.Y.; He, Y. On-Board Diagnostics of Temperature Sensors for Selective Catalyst Reduction System. U.S. Patent 8,515,710, 16 March 2013. [Google Scholar]

- Zhang, H.; Wang, J. Ammonia coverage ratio and input simultaneous estimation in ground vehicle selective catalytic reduction (SCR) systems. J. Frankl. Inst. 2015, 352, 708–723. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J. Removal of NOx sensor ammonia cross sensitivity from contaminated measurements in diesel-engine selective catalytic reduction systems. Fuel 2015, 150, 448–456. [Google Scholar] [CrossRef]

- Devarakonda, M.; Parker, G.; Johnson, J.H.; Strots, V.; Santhanam, S. Adequacy of Reduced Order Models for Model-Based Control in a Urea-SCR Aftertreatment System; SAE Paper 2008-01-0617; SAE: Warrendale, PA, USA, 2008. [Google Scholar]

- Schär, C.M.; Onder, C.H.; Geering, H.P. Control of an SCR catalytic converter system for a mobile heavy-duty application. IEEE Trans. Contr. Syst. Trans. 2006, 14, 641–653. [Google Scholar] [CrossRef]

- Stadlbauer, S.; Waschl, H.; Re, L.D. Adaptive SCR Model for MPC Control Including Aging Effects; SAE Paper 2015-01-1045; SAE: Warrendale, PA, USA, 2015. [Google Scholar]

- Herman, A.; Wu, M.-C.; Cabush, D.; Shost, M. Model Based Control of SCR Dosing and OBD Strategies with Feedback from NH3 Sensors. SAE Int. J. Fuels Lubr. 2009, 1, 375–385. [Google Scholar] [CrossRef]

- Nova, I.; Tronconi, E. Urea-SCR Technology for deNOx After Treatment of Diesel Exhausts; Springer: New York, NY, USA, 2014. [Google Scholar]

- Bonfils, A.; Creff, Y.; Lepreux, O.; Petit, N. Closed-loop control of a SCR system using a NOx, sensor cross-sensitive to NH3. J. Process Control 2014, 2, 368–378. [Google Scholar] [CrossRef]

- Dunia, R.; Qin, S.J.; Edgar, T.F.; Mcavoy, T.J. Identification of faulty sensors using principal component analysis. Process Syst. Eng. 1996, 42, 2797–2812. [Google Scholar] [CrossRef]

- Kullaa, J. Detection, identification, and quantification of sensor fault in a sensor network. Mech. Syst. Signal Process. 2013, 40, 208–221. [Google Scholar] [CrossRef]

- Yu, Y.; Li, W.; Sheng, D.; Chen, J. A novel sensor fault diagnosis method based on modified ensemble empirical mode decomposition and probabilistic neural network. Measurement 2015, 68, 328–336. [Google Scholar] [CrossRef]

- Jan, S.U.; Lee, Y.; Shin, J.; Koo, I. Sensor Fault Classification Based on Support Vector Machine and Statistical Time-Domain Features. IEEE Access 2017, 5, 8682–8690. [Google Scholar] [CrossRef]

- Yuan, X.; Liu, H.; Gao, Y. Diesel Engine SCR Control: Current Development and Future Challenges. Emiss. Control Sci. Technol. 2015, 2, 121–133. [Google Scholar] [CrossRef]

| Parameters | Identified Value | Unit |

|---|---|---|

| Sc | 13,300 | m2/mol |

| αprob | 1.11 × 10−3 | 1 |

| Cs | 4.5 | mol/m3 |

| kdes | 0.514 | 1/s |

| Edes | 15.2 | J/mol |

| kscr | 10 | m2/s |

| Escr | 28,471 | J/mol |

| kox | 3.34 × 106 | 1/s |

| Eox | 1.16 × 105 | J/mol |

| Features | Parameters |

|---|---|

| Engine model | Inline 6-cylinder, YC6J-42 |

| Displacement | 6.6 L |

| Rated power | 132 kW |

| Maximum torque | 660 N·m (1200–1700 r/min) |

| Idle speed | 650 ± 50 r/min |

| Equipment | Application | |

|---|---|---|

| AVL PUMA OPEN test bench | AC electrical dynamometer | Measuring engine speed and torque |

| Dynamometer control system | Controlling speed or torque of dynamometer to change the engine load | |

| Throttle actuator | Regulating the operating condition of engine | |

| Thermal measurement system | Monitoring thermodynamic parameters such as cooling water temperature, intake and exhaust pressure | |

| SEMTECH-EFM2 | Measuring exhaust flow rate | |

| AVL DiGas 4000 light (Port 1) | Measuring NOx concentration at upstream pipe | |

| AVL DiGas 4000 light (Port 2) | Measuring NOx concentration at downstream pipe | |

| NOx sensor | Measuring NOx concentration at downstream pipe | |

| LDS6 | Measuring NH3 slip | |

| Temperature sensor | Measuring upstream and downstream temperature | |

| Fault Type | NOx Emission (g/kWh) | Mean NOx Conversion Efficiency | Mean NH3 Slip (ppm) | Mean Urea Dosage (g/h) |

|---|---|---|---|---|

| No fault | 1.92 | 77.20% | 2.32 | 671.26 |

| Stuck fault | 0.53 | 93.62% | 13.02 | 944.95 |

| Gain fault | 3.02 | 62.57% | 1.74 | 548.66 |

| Drift fault | 4.60 | 44.30% | 1.07 | 337.86 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Wang, J.; Zeng, J.; Zhong, X. Model-Based Temperature Sensor Fault Detection and Fault-Tolerant Control of Urea-Selective Catalyst Reduction Control Systems. Energies 2018, 11, 1800. https://doi.org/10.3390/en11071800

Hu J, Wang J, Zeng J, Zhong X. Model-Based Temperature Sensor Fault Detection and Fault-Tolerant Control of Urea-Selective Catalyst Reduction Control Systems. Energies. 2018; 11(7):1800. https://doi.org/10.3390/en11071800

Chicago/Turabian StyleHu, Jie, Junliang Wang, Jiawei Zeng, and Xianglin Zhong. 2018. "Model-Based Temperature Sensor Fault Detection and Fault-Tolerant Control of Urea-Selective Catalyst Reduction Control Systems" Energies 11, no. 7: 1800. https://doi.org/10.3390/en11071800

APA StyleHu, J., Wang, J., Zeng, J., & Zhong, X. (2018). Model-Based Temperature Sensor Fault Detection and Fault-Tolerant Control of Urea-Selective Catalyst Reduction Control Systems. Energies, 11(7), 1800. https://doi.org/10.3390/en11071800