A Study on the Fuel Economy Potential of Parallel and Power Split Type Hybrid Electric Vehicles

Abstract

1. Introduction

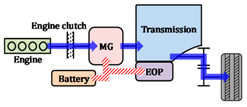

2. Dynamic Programming to Evaluate the Fuel Economy Potential Considering Powertrain Characteristics and Drivetrain Components Losses of Parallel HEV

2.1. Transmission

2.2. Engine

2.3. Motor-Generator

2.4. Battery

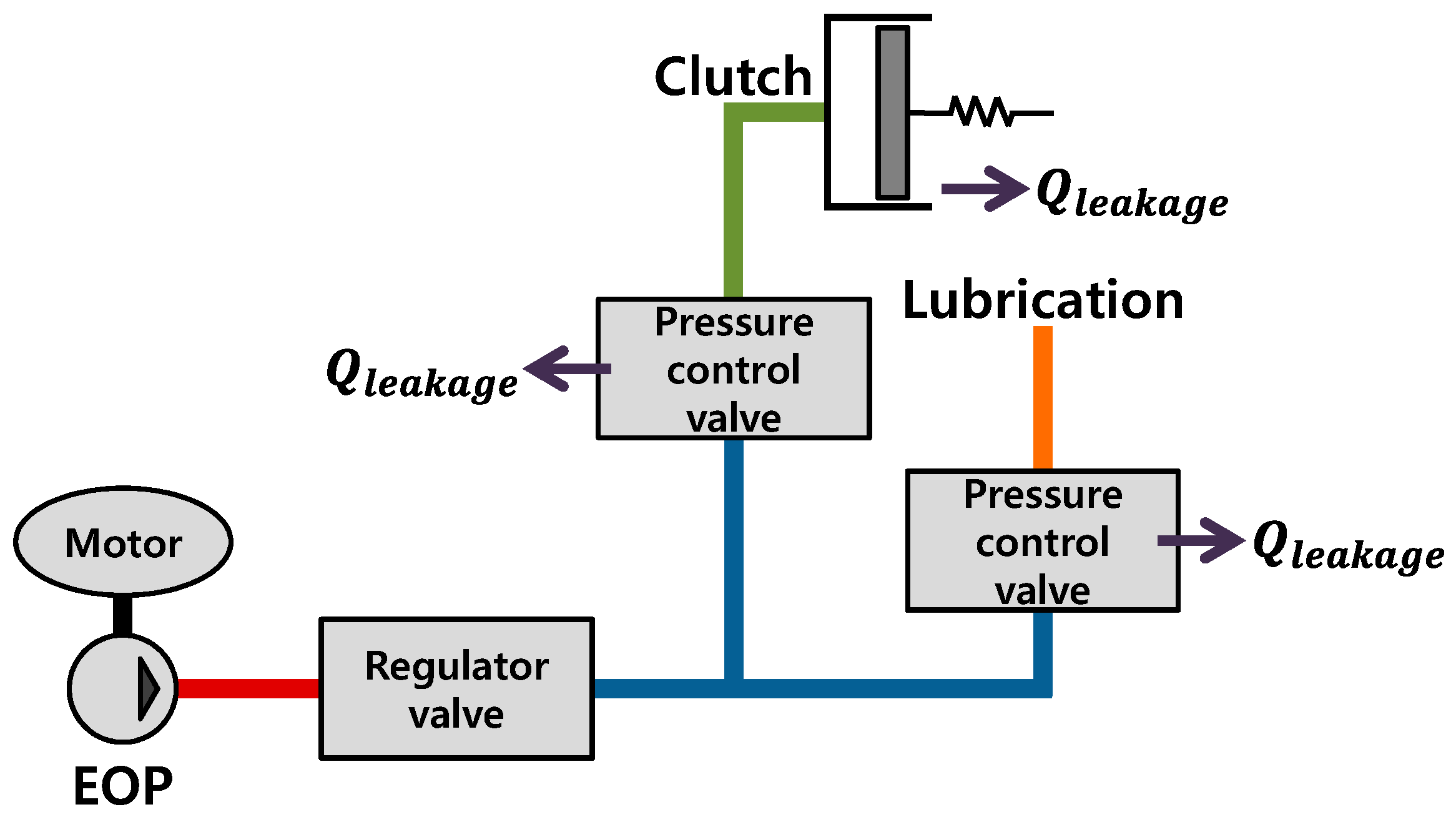

2.5. Electric Oil Pump

2.6. Dynamic Programming for the Fuel Economy Potential of the Parallel HEV

3. Comparative Analysis of the Maximum Fuel Economy Potential of Parallel HEVs for the Number of Gear Steps

- When transmission efficiency and EOP loss are not considered

- When transmission efficiency and EOP loss are considered

3.1. Comparison without Considering Transmission Efficiency and EOP Loss

3.2. Comparison Considering Transmission Efficiency and EOP Loss

4. Comparison of Fuel Economy Potential for Parallel HEV and Power Split Type HEV

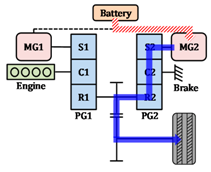

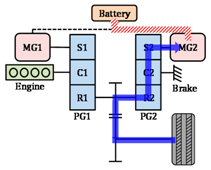

4.1. Target Power Split Type HEV

0–100 kph Acceleration Performance: Within 9.4 s

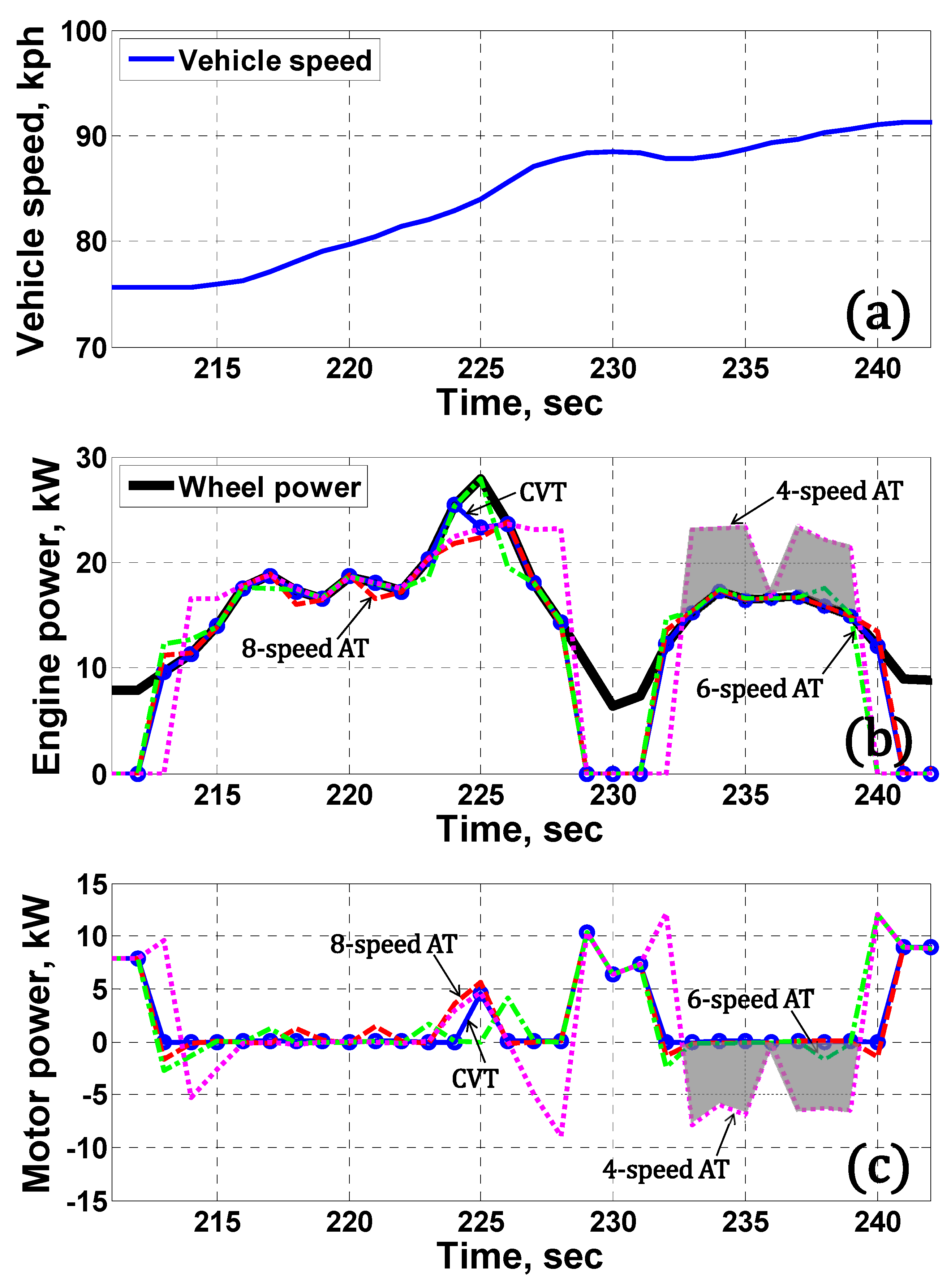

4.2. Comparative Analysis of Power Split Type HEV and Parallel HEV

- Parallel HEV

- Positive factors can be obtained from the small power electronics system loss and relatively low cost using one small capacity MG

- Negative factors are the large drivetrain component loss including the EOP loss inherent from the relatively complicated architecture

- Power split type HEV

- Positive factors come from the improved engine efficiency by the e-CVT function using two mgs and small drivetrain loss from a relatively simple architecture

- Negative factors relate to the large power electronics system loss due to the two large capacity MGs.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| C | battery capacity |

| N | transmission gear ratio |

| P | power |

| Q | flow rate |

| T | torque |

| V | voltage |

| i | current |

| p | pressure |

| efficiency | |

| speed | |

| Subscript | |

| batt | battery |

| pri | primary |

| sec | secondary |

References

- An, F.; Earley, R.; Green-Weiskel, L. Global Overview on Fuel Efficiency and Motor Vehicle Emission Standards: Policy Options and Perspectives for International Cooperation; United Nations Background Paper No. 3; United Nations Department of Economic and Social Affairs: New York, NY, USA, 2011. [Google Scholar]

- Chambliss, S.; Miller, J.; Façanha, C.; Minjares, R.; Blumberg, K. The Impact of Stringent Fuel and Vehicle Standards on Premature Mortality and Emissions. International Council on Clean Transportation, 2013. Available online: https://www.theicct.org/sites/default/files/publications/ICCT_HealthClimateRoadmap_2013_revised.pdf (accessed on 11 August 2018).

- Toyota. Toyota Aims for Sales of More Than 5.5 Million Electrified Vehicles Including 1 Million Zero-Emission Vehicles per Year by 2030. Available online: https://newsroom.toyota.co.jp/en/corporate/20353243.html (accessed on 22 April 2018).

- Krishna, S. Mercedes-Benz Plans Electric Versions of All Its Models by 2022. Available online: https://www.engadget.com/2017/09/11/mercedes-benz-electric-versions-2022/ (accessed on 22 April 2018).

- International Energy Agency (IEA). World Energy Outlook. 2009. Available online: http://www.worldenergyoutlook.org/media/weowebsite/2009/WEO2009.pdf (accessed on 22 April 2018).

- Goppelt, G. The DHT Redefining Hybrid Transmissions. MTZ Worldw. 2016, 77, 8–15. [Google Scholar] [CrossRef]

- Moawad, A.; Rousseau, A. Effect of Transmission Technologies on Fuel Efficiency—Final Report; Argonne National Laboratory: Lemont, IL, USA, 2012; pp. 28–31.

- Moskalik, A.; Hula, A.; Barba, D.; Kargul, J. Investigating the Effect of Advanced Automatic Transmissions on Fuel Consumption Using Vehicle Testing and Modeling. SAE Int. J. Engines 2016, 9, 1916–1928. [Google Scholar] [CrossRef][Green Version]

- Kim, H.; Wi, J.; Yoo, J.; Son, H.; Park, C.; Kim, H. Influence of number of gear step on engine and motor operation characteristics for parallel HEV. In Proceedings of the 2018 Thirteenth International Conference on Ecological Vehicles and Renewable Energies (EVER2018), Monte Carlo, Monaco, 10–12 April 2018. [Google Scholar]

- Kim, N.; Kwon, J.; Rousseau, A. Trade-off between multi-mode powertrain complexity and fuel consumption. In Proceedings of the 25th World Battery, Hybrid and Fuel Cell Electric Vehicle Symposium & Exhibition, Shenzhen, China, 5–8 November 2010. [Google Scholar]

- Kim, J.; Kim, N.; Hwang, S.; Hori, Y.; Kim, H. Motor control of input-split hybrid electric vehicles. Int. J. Automot. Technol. 2009, 10, 733. [Google Scholar] [CrossRef]

- Kim, H.; Kum, D. Comprehensive design methodology of input-and output-split hybrid electric vehicles: In search of optimal configuration. IEEE/ASME Trans. Mechatron. 2016, 21, 2912–2923. [Google Scholar] [CrossRef]

- Son, H.; Park, K.; Hwang, S.; Kim, H. Design methodology of a power split type plug-in hybrid electric vehicle considering drivetrain losses. Energies 2017, 10, 437. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.-T.; Kum, D.; Peng, H. Prius+ and Volt-: Configuration Analysis of Power-Split Hybrid Vehicles With a Single Planetary Gear. IEEE Trans. Veh. Technol. 2012, 61, 3544–3552. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, X.; Pei, H.; Peng, Z. Comparison of power-split and parallel hybrid powertrain architectures with a single electric machine: Dynamic programming approach. Appl. Energy 2016, 168, 683–690. [Google Scholar] [CrossRef]

- Wang, R.; Lukic, S.M. Dynamic programming technique in hybrid electric vehicle optimization. In Proceedings of the 2012 IEEE International Electric Vehicle Conference (IEVC), Greenville, SC, USA, 4–8 March 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1–8. [Google Scholar]

- Wang, X.; He, H.; Sun, F.; Zhang, J. Application study on the dynamic programming algorithm for energy management of plug-in hybrid electric vehicles. Energies 2015, 8, 3225–3244. [Google Scholar] [CrossRef]

- Vroemen, B.G. Component Control for the Zero Inertia Powertrain; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 2001. [Google Scholar]

- Pang, S.; Farrell, J.; Du, J.; Barth, M. Battery state-of-charge estimation. In Proceedings of the American Control Conference, Arlington, VA, USA, 25–27 June 2001; IEEE: Piscataway, NJ, USA, 2001; pp. 1644–1649. [Google Scholar]

- Kim, Y.; Lee, J.; Jo, C.; Kim, Y.; Song, M.; Kim, J.; Kim, H. Development and control of an electric oil pump for automatic transmission-based hybrid electric vehicle. IEEE Trans. Veh. Technol. 2011, 60, 1981–1990. [Google Scholar] [CrossRef]

- Song, M.; Oh, J.; Choi, S.; Kim, Y.; Kim, H. Optimal line pressure control for an automatic transmission-based parallel hybrid electric vehicle considering mode change and gear shift. Adv. Mech. Eng. 2014, 6, 216098. [Google Scholar] [CrossRef]

- Son, H.; Kim, H. Development of near optimal rule-based control for plug-in hybrid electric vehicles taking into account drivetrain component losses. Energies 2016, 9, 420. [Google Scholar] [CrossRef]

- Onori, S.; Serrao, L.; Rizzoni, G. Hybrid Electric Vehicles: Energy Management Strategies; Springer: Berlin, Germany, 2016. [Google Scholar]

- Kirk, D.E. Optimal Control Theory: An Introduction; Courier Corporation: Mineola, NY, USA, 2012. [Google Scholar]

- Kim, N. Energy Management Strategy for Hybrid Electric Vehicles Based on Pontryagin’s Minimum Principle; Seoul National University: Seoul, Korea, 2009. [Google Scholar]

- Department of Energy. Electric and Hybrid Vehicle Research, Development, and Demonstration Program; Petroleum-Equivalent Fuel Economy Calculation. Federal Register; 2000. Available online: https://www.federalregister.gov/documents/2000/06/12/00-14446/electric-and-hybrid-vehicle-research-development-and-demonstration-program-petroleum-equivalent-fuel (accessed on 22 April 2018).

- Wi, J.; Kim, H.; Yoo, J.; Son, H.; Kim, B.; Kim, H. Energy consumption of parallel type hybrid electric vehicle with continuously variable transmission using electric oil pump. In Proceedings of the 2018 Thirteenth International Conference on Ecological Vehicles and Renewable Energies (EVER2018), Monte Carlo, Monaco, 10–12 April 2018. [Google Scholar]

- Negoro, A.B.; Purwadi, A. Performance Analysis on Power Train Drive System of the 2012 Toyota Camry Hybrid. Procedia Technol. 2013, 11, 1054–1064. [Google Scholar] [CrossRef]

- Kim, N.; Rousseau, A.; Rask, E. Autonomie Model Validation with Test Data for 2010 Toyota Prius; SAE Technical Paper 0148-7191; SAE: Warrendale, PA, USA, 2012. [Google Scholar]

- Ma, C.; Kang, J.; Choi, W.; Song, M.; Ji, J.; Kim, H. A comparative study on the power characteristics and control strategies for plug-in hybrid electric vehicles. Int. J. Automot. Technol. 2012, 13, 505–516. [Google Scholar] [CrossRef]

- Autonomie, A. What Can Autonomie Do for You. Available online: https://www.autonomie.net/docs/5%20-%20Presentations/Software/what_can_autonomie.pdf (accessed on 22 April 2018).

- Haka, R.J. Determination of Efficiency (Torque Related Losses) in Planetary Gearsets: Generalized Theory for Simple and Compound Gearsets. In Proceedings of the ASME 2003 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Chicago, IL, USA, 2–6 September 2003; American Society of Mechanical Engineers: New York, NY, USA, 2003; pp. 1085–1097. [Google Scholar]

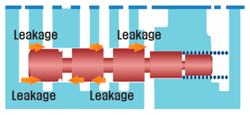

| Location | Leakage Feature | Equations |

|---|---|---|

| Valve spool |  | |

| Seal |  |

| Component | Specification | |

|---|---|---|

| Engine | Max power | 114 kW |

| Max torque | 185 Nm | |

| Max speed | 6000 rpm | |

| Motor-Generator | Max power | 38 kW |

| Max torque | 205 Nm | |

| Max speed | 6000 rpm | |

| Battery | Capacity | 1.6 kWh |

| Nominal voltage | 270 V | |

| Vehicle | Weight | 1800 kg |

| Transmission | AT | 4-speed |

| 6-speed | ||

| 8-speed | ||

| CVT | Metal belt type | |

| Driving Mode | Power Flow | Equations |

|---|---|---|

| EV mode |  | |

| HEV mode |  | |

| Regenerative braking mode |  |

| 4-Speed AT | 6-Speed AT | 8-Speed AT | CVT | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Driving | Braking | Driving | Braking | Driving | Braking | Driving | Braking | ||

| Engine energy (kJ) | 4200 | - | 4148 | - | 4137 | - | 4122 | - | |

| Consumed fuel energy (kJ) | 11,090 | - | 10,939 | - | 10,894 | - | 10,814 | - | |

| Engine efficiency (%) | 37.87 | - | 37.92 | - | 37.97 | - | 38.12 | - | |

| Improvement rate (%) | base | - | 0.13 | - | 0.26 | - | 0.66 | - | |

| Battery energy (kJ) | Discharge (+) | 2522 | 0 | 2417 | 0 | 2389 | 0 | 2333 | 0 |

| Charge (−) | 201 | 2258 | 84 | 2272 | 54 | 2275 | 3 | 2278 | |

| Power electronics system loss (kJ) | Battery + MG | 327 | 249 | 287 | 234 | 277 | 231 | 259 | 228 |

| Total | 576 | 521 | 508 | 487 | |||||

| MG efficiency (%) | 91.05 (EV mode) | 92.87 | 91.72 (EV mode) | 93.46 | 91.78 (EV mode) | 93.56 | 91.94 (EV mode) | 93.71 | |

| Fuel economy (km/L) | 33.84 | 34.31 | 34.45 | 34.70 | |||||

| Improvement rate (%) |  |  |  | ||||||

| 4-Speed AT | 6-Speed AT | 8-Speed AT | CVT | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mode Gear Step | EV | HEV | Regen | EV | HEV | Regen | EV | HEV | Regen | EV | HEV | Regen |

| 1st | 140 | 32 | 217 | 74 | 17 | 159 | 75 | 13 | 149 | 43 | 1 | 113 |

| 2nd | 240 | 76 | 64 | 157 | 41 | 91 | 143 | 34 | 86 | 14 | 2 | 27 |

| 3rd | 100 | 108 | 29 | 169 | 58 | 39 | 167 | 49 | 47 | 7 | 4 | 9 |

| 4th | 13 | 86 | 6 | 68 | 78 | 19 | 52 | 37 | 19 | 17 | 6 | 36 |

| 5th | - | - | - | 15 | 65 | 5 | 35 | 38 | 10 | 18 | 11 | 9 |

| 6th | - | - | - | 6 | 47 | 3 | 6 | 56 | 2 | 52 | 15 | 22 |

| 7th | - | - | - | - | - | - | 8 | 42 | 2 | 44 | 15 | 20 |

| 8th | - | - | - | - | - | - | 2 | 38 | 1 | 68 | 18 | 17 |

| 9th | - | - | - | - | - | - | - | - | - | 90 | 32 | 21 |

| 10th | - | - | - | - | - | - | - | - | - | 67 | 48 | 18 |

| 11th | - | - | - | - | - | - | - | - | - | 46 | 69 | 15 |

| 12th | - | - | - | - | - | - | - | - | - | 16 | 91 | 9 |

| Total | 493 | 302 | 316 | 489 | 306 | 316 | 488 | 307 | 316 | 482 | 312 | 316 |

| Gear Step | 4-Speed AT | 6-Speed AT | 8-Speed AT | CVT |

|---|---|---|---|---|

| 1st | 11.41 | 14.21 | 15.10 | 13.46–14.51 |

| 2nd | 6.33 | 8.57 | 9.30 | 12.42–13.46 |

| 3rd | 4.07 | 6.70 | 5.97 | 11.37–12.42 |

| 4th | 2.76 | 4.25 | 4.68 | 10.32–11.37 |

| 5th | - | 3.06 | 4.07 | 9.27–10.32 |

| 6th | - | 2.37 | 3.38 | 8.22–9.27 |

| 7th | - | - | 2.69 | 7.18–8.22 |

| 8th | - | - | 2.14 | 6.13–7.18 |

| 9th | - | - | - | 5.08–6.13 |

| 10th | - | - | - | 4.03–5.08 |

| 11th | - | - | - | 2.98–4.03 |

| 12th | - | - | - | 1.94–2.98 |

| 4-Speed AT | 6-Speed AT | 8-Speed AT | CVT | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Driving | Braking | Driving | Braking | Driving | Braking | Driving | Braking | ||

| Engine energy (kJ) | 5064 | - | 5003 | - | 4987 | - | 5108 | - | |

| Consumed fuel energy (kJ) | 13,359 | - | 13,187 | - | 13,125 | - | 13,443 | - | |

| Engine efficiency (%) | 37.91 | - | 37.94 | - | 37.99 | - | 38.00 | - | |

| Improvement rate (%) | base | - | 0.08 | - | 0.21 | - | 0.24 | - | |

| Battery energy (kJ) | Discharge (+) | 2411 | 4 | 2255 | 5 | 2223 | 5 | 2105 | 12 |

| Charge (−) | 321 | 2022 | 162 | 2028 | 126 | 2029 | 17 | 2032 | |

| Power electronics system loss (kJ) | Battery + MG | 335 | 242 | 292 | 223 | 278 | 223 | 238 | 224 |

| Total | 577 | 515 | 501 | 462 | |||||

| Transmission | Efficiency (%) | 92.22 | 92.32 | 92.42 | 93.40 | ||||

| EOP loss (kJ) | 220 | 226 | 237 | 490 | |||||

| MG efficiency (%) | 90.35 (EV mode) | 92.25 | 90.72 (EV mode) | 93.05 | 90.95 (EV mode) | 93.06 | 90.36 (EV mode) | 93.21 | |

| Fuel economy (km/L) | 28.09 | 28.46 | 28.59 | 27.92 | |||||

| Improvement rate (%) |  |  |  | ||||||

| Driving Mode | Power Flow | Equations |

|---|---|---|

| EV mode |  | |

| HEV mode |  | |

| Regenerative braking mode |  |

| Drivetrain Components | Loss |

|---|---|

| Reduction gear [22] | |

| Planetary gear set [22,32] (PG1, PG2) | |

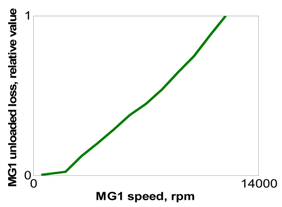

| MG1 unloaded loss [22] |  |

| Power Split Type HEV | Parallel HEV | ||||

|---|---|---|---|---|---|

| Driving | Braking | Driving | Braking | ||

| Engine energy (kJ) | 4998 | - | 4987 | - | |

| Consumed fuel energy (kJ) | 13,094 | - | 13,125 | - | |

| Engine efficiency (%) | 38.17 | - | 37.99 | - | |

| Battery energy (kJ) | Discharge (+) | 3272 | 2 | 2223 | 5 |

| Charge (−) | 1068 | 2123 | 126 | 2029 | |

| Power electronics system loss (kJ) | Battery + MG | 717 | 157 | 278 | 223 |

| Total | 874 | 501 | |||

| Transmission (kJ) | Drivetrain loss | 343 | 635 | ||

| EOP loss | 57 | 237 | |||

| Fuel economy (km/L) | 28.66 | 28.59 | |||

| Improvement rate (%) | 0.24 | base | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Wi, J.; Yoo, J.; Son, H.; Park, C.; Kim, H. A Study on the Fuel Economy Potential of Parallel and Power Split Type Hybrid Electric Vehicles. Energies 2018, 11, 2103. https://doi.org/10.3390/en11082103

Kim H, Wi J, Yoo J, Son H, Park C, Kim H. A Study on the Fuel Economy Potential of Parallel and Power Split Type Hybrid Electric Vehicles. Energies. 2018; 11(8):2103. https://doi.org/10.3390/en11082103

Chicago/Turabian StyleKim, Hyunhwa, Junbeom Wi, Jiho Yoo, Hanho Son, Chiman Park, and Hyunsoo Kim. 2018. "A Study on the Fuel Economy Potential of Parallel and Power Split Type Hybrid Electric Vehicles" Energies 11, no. 8: 2103. https://doi.org/10.3390/en11082103

APA StyleKim, H., Wi, J., Yoo, J., Son, H., Park, C., & Kim, H. (2018). A Study on the Fuel Economy Potential of Parallel and Power Split Type Hybrid Electric Vehicles. Energies, 11(8), 2103. https://doi.org/10.3390/en11082103