Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

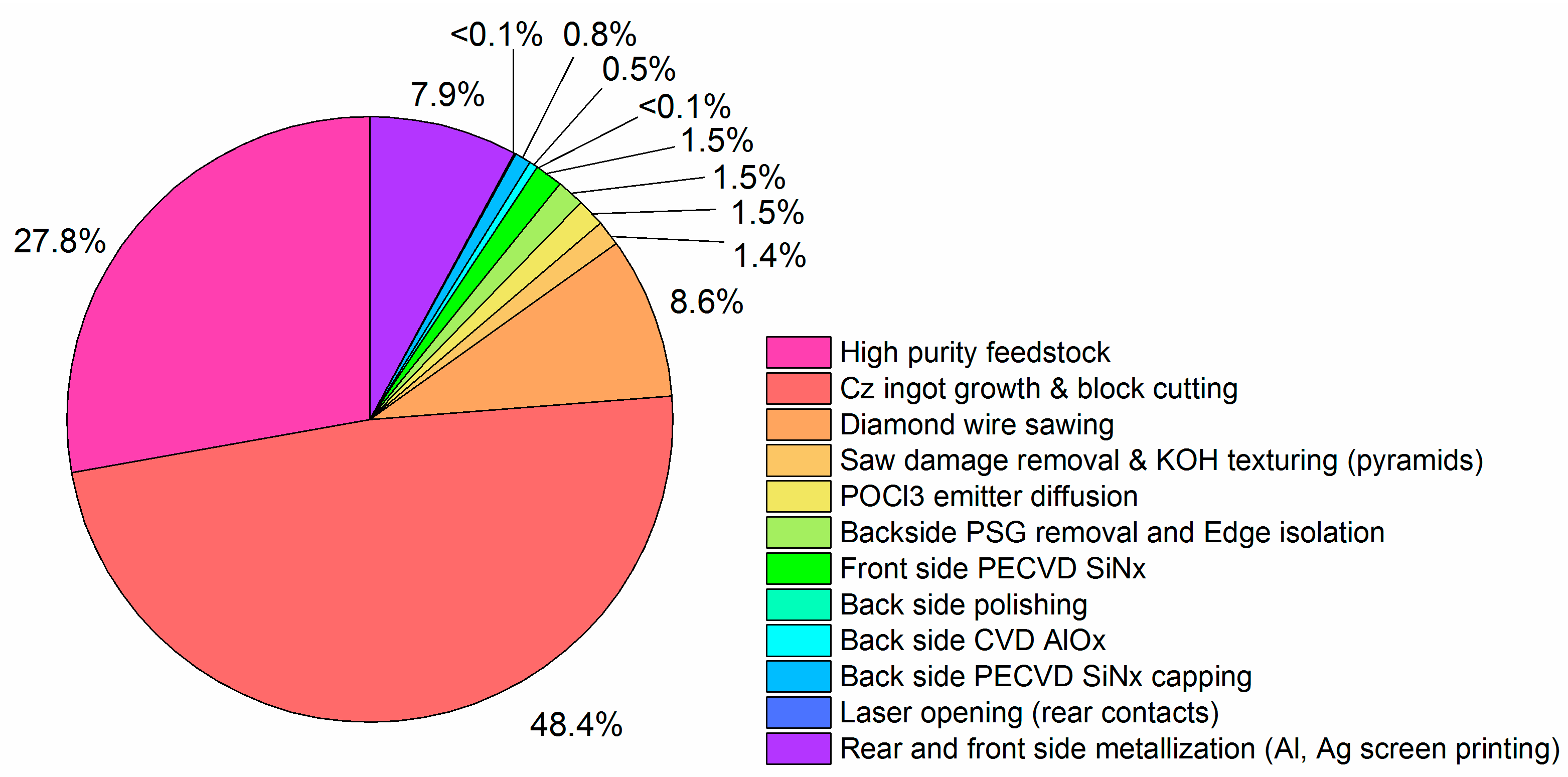

2.1. PERC Production Process

2.2. Costs and Sensitivity Calculations

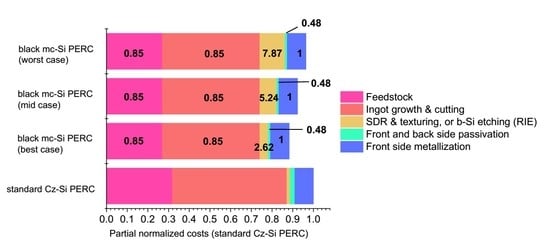

3. Results

4. Discussion

4.1. Black Silicon

4.2. Policies to Accelerate b-Si Deployment in the PV Industry

4.2.1. Policies for Research Support

4.2.2. Policies for Commercialization Support

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ADE | Atmospheric dry etching |

| Ag | Silver |

| Al | Aluminum |

| ALD | Atomic layer deposition |

| AlOx | Aluminum oxide |

| b-Si | Black silicon |

| CVD | Chemical vapor deposition |

| Cz | Czochralski |

| DRIE | Deep reactive ion etching |

| KOH | Potassium hydroxide |

| LID | Light induced degradation |

| MACE | Metal-assisted chemical etching |

| mc-Si | Multicrystalline silicon |

| PECVD | Plasma enhanced chemical vapor deposition |

| PERC | Passivated emitter rear cell |

| POCl3 | Phosphoryl chloride |

| PSG | Phosphosilicate glass |

| PV | Photovoltaic |

| RIE | Reactive ion etching |

| R&D | Research and development |

| ROI | Return on investment |

| SDR | Saw damage removal |

| SiNx | Silicon nitride |

| SME | Small and medium sized enterprises |

| TCO | Transparent conductive oxide |

Appendix A. Costs of All the Production Steps for Both the Standard (Texturized) Cz PERC and the Black Multicrystalline PERC.

| Process Step | Step Costs (US$/Wp) Standard (Texturized) Cz PERC | Source | Step Costs (US$/Wp) Black mc-Si PERC | Source |

|---|---|---|---|---|

| 1 * | 0.0925 | [68] | 0.0786 | [68] |

| 2 * | 0.1610 | [68] | 0.1369 | [68] |

| 3 * | 0.0287 | [68] | 0.0287 | [68] |

| 4+5 | 0.0045 | § | 0.0118 (best case) | § |

| 0.0236 (mid case) | ||||

| 0.0354 (worst case) | ||||

| 6 | 0.0050 | § | 0.0050 | § |

| 7 | 0.0049 | § | 0.0049 | § |

| 8 | 0.0049 | § | 0.0031 | § |

| 9 | 0.0000 | § | ||

| 10 | 0.0016 | § | ||

| 11 | 0.0028 | § | 0.0011 | § |

| 12 | 0.0003 | § | 0.0003 | § |

| 13+14 | 0.0263 | § | 0.0263 | § |

Appendix B

| Source | PERC Cell Architecture | Assumptions | ||

|---|---|---|---|---|

| Cell Size * | Cell Efficiency | Cell Output | ||

| [68] | Both | cm2 | % | Wp/cell |

| 237 | 22 | 5.204 | ||

| § | Standard (texturized) Cz PERC | 244 | 22 | 5.375 |

| Black mc-Si PERC | 246 | 22 | 5.405 | |

| § | Black mc-Si PERC | 243 | 22 | 5.204 |

| § | Black mc-Si PERC | 243 | 22 | 5.204 |

References

- Albrecht, J. The future role of photovoltaics: A learning curve versus portfolio perspective. Energy Policy 2007, 35, 2296–2304. [Google Scholar] [CrossRef]

- Yu, C.F.; van Sark, W.G.J.H.M.; Alsema, E.A. Unraveling the photovoltaic technology learning curve by incorporation of input price changes and scale effects. Renew. Sustain. Energy Rev. 2011, 15, 324–337. [Google Scholar] [CrossRef]

- Hong, S.; Chung, Y.; Woo, C. Scenario analysis for estimating the learning rate of photovoltaic power generation based on learning curve theory in South Korea. Energy 2015, 79, 80–89. [Google Scholar] [CrossRef]

- Trappey, A.J.C.; Trappey, C.V.; Tan, H.; Liu, P.H.Y.; Li, S.-J.; Lin, L.-C. The determinants of photovoltaic system costs: an evaluation using a hierarchical learning curve model. J. Clean. Prod. 2016, 112, 1709–1716. [Google Scholar] [CrossRef]

- Mauleón, I. Photovoltaic learning rate estimation: Issues and implications. Renew. Sustain. Energy Rev. 2016, 65, 507–524. [Google Scholar] [CrossRef]

- Feldman, D.; Barbose, G.; Margolis, R.; Wiser, R.; Darghout, N.; Goodrich, A. Photovoltaic (PV) Pricing Trends: Historical, Recent, and Near-term Projections; Technical Report; Lawrence Berkeley National Lab.: Berkeley, CA, USA, 2012. [Google Scholar]

- Barbose, G.L.; Darghouth, N.R.; Millstein, D.; LaCommare, K.; DiSanti, N.; Widiss, R. Tracking the Sun 10: The Installed Price of Residential and Non-Residential Photovoltaic Systems in the United States. Available online: https://emp.lbl.gov/publications/tracking-sun-10-installed-price (accessed on 25 July 2018).

- PVinsights. Available online: http://pvinsights.com/ (accessed on 25 July 2018).

- Reuters. Solar Costs to Fall Further, Powering Global Demand-Irena. Available online: https://www.reuters.com/article/singapore-energy-solar/solar-costs-to-fall-further-powering-global-demand-irena-idUSL4N1MY2F8 (accessed on 5 March 2018).

- Branker, K.; Pathak, M.J.M.; Pearce, J.M. A review of solar photovoltaic levelized cost of electricity. Renew. Sustain. Energy Rev. 2011, 15, 4470–4482. [Google Scholar] [CrossRef]

- Safi, M. Indian Solar Power Prices Hit Record Low, Undercutting Fossil Fuels. Available online: http://www.theguardian.com/environment/2017/may/10/indian-solar-power-prices-hit-record-low-undercutting-fossil-fuels (accessed on 5 March 2018).

- Drury, E.; Miller, M.; Macal, C.M.; Graziano, D.J.; Heimiller, D.; Ozik, J.; Perry, T.D., IV. The transformation of southern California’s residential photovoltaics market through third-party ownership. Energy Policy 2012, 42, 681–690. [Google Scholar] [CrossRef]

- Branker, K.; Shackles, E.; Pearce, J.M. Peer-to-peer financing mechanisms to accelerate renewable energy deployment. J. Sustain. Financ. Invest. 2011, 1, 138–155. [Google Scholar] [CrossRef]

- Alafita, T.; Pearce, J.M. Securitization of residential solar photovoltaic assets: Costs, risks and uncertainty. Energy Policy 2014, 67, 488–498. [Google Scholar] [CrossRef]

- Hede, S.; Nunes, M.J.L.; Ferreira, P. Credits trading mechanism for corporate social responsibility: An empirically grounded framework. Int. J. Technol. Learn. Innov. Dev. 2014, 7, 49–92. [Google Scholar] [CrossRef]

- Overholm, H. Spreading the rooftop revolution: What policies enable solar-as-a-service? Energy Policy 2015, 84, 69–79. [Google Scholar] [CrossRef]

- Ameli, N.; Kammen, D.M. Innovations in financing that drive cost parity for long-term electricity sustainability: An assessment of Italy, Europe’s fastest growing solar photovoltaic market. Energy Sustain. Dev. 2014, 19, 130–137. [Google Scholar] [CrossRef]

- Coughlin, J.; Cory, K.S. Solar Photovoltaic Financing: Residential Sector Deployment; Technical Report; National Renewable Energy Laboratory: Golden, CO, USA, 2009. [Google Scholar]

- International Energy Agency. Renewables 2017. Available online: https://www.iea.org/publications/renewables2017/ (accessed on 5 March 2018).

- Polman, A.; Knight, M.; Garnett, E.C.; Ehrler, B.; Sinke, W.C. Photovoltaic materials: Present efficiencies and future challenges. Science 2016, 352, aad4424. [Google Scholar] [CrossRef] [PubMed]

- Projected Market Share of Solar Photovoltaic Panels Worldwide in 2030, by Technology. Available online: https://www.statista.com/statistics/492755/solar-pv-panels-market-share-projection-by-cell-technology-globally/ (accessed on 5 March 2018).

- Powell, D.M.; Fu, R.; Horowitz, K.; Basore, P.A.; Woodhouse, M.; Buonassisi, T. The capital intensity of photovoltaics manufacturing: Barrier to scale and opportunity for innovation. Energy Environ. Sci. 2015, 8, 3395–3408. [Google Scholar] [CrossRef]

- Dullweber, T.; Schmidt, J. Industrial silicon solar cells applying the passivated emitter and rear cell (PERC) concept—A review. IEEE J. Photovolt. 2016, 6, 1366–1381. [Google Scholar] [CrossRef]

- Green, M.A. The Passivated Emitter and Rear Cell (PERC): From conception to mass production. Sol. Energy Mater. Sol. Cells 2015, 143, 190–197. [Google Scholar] [CrossRef]

- International Technology Roadmap for Photovoltaic Results 2016 incl. Maturity Report. Available online: http://www.itrpv.net/Reports/Downloads/ (accessed on 16 May 2018).

- Liu, X.; Coxon, P.R.; Peters, M.; Hoex, B.; Cole, J.M.; Fray, D.J. Black silicon: Fabrication methods, properties and solar energy applications. Energy Environ. Sci. 2014, 7, 3223–3263. [Google Scholar] [CrossRef]

- Pasanen, T.P.; Laine, H.S.; Vähänissi, V.; Schön, J.; Savin, H. Black silicon significantly enhances phosphorus diffusion gettering. Sci. Rep. 2018, 8, 1991. [Google Scholar] [CrossRef] [PubMed]

- Pasanen, T.P.; Modanese, C.; Vähänissi, V.; Laine, H.S.; Heikkinen, I.T.S.; Wolny, F.; Oehlke, A.; Kusterer, K.; Wagner, Mt.; Savin, H. Black-silicon eliminates light- and elevated-temperature induced degradation in industrial passivated emitter and rear cells. Prog. Photovolt. 2018. under review. [Google Scholar]

- Davidsen, R.S.; Ormstrup, J.; Ommen, M.L.; Larsen, P.E.; Schmidt, M.S.; Boisen, A.; Nordseth, Ø.; Hansen, O. Angle resolved characterization of nanostructured and conventionally textured silicon solar cells. Sol. Energy Mater. Sol. Cells 2015, 140, 134–140. [Google Scholar] [CrossRef] [Green Version]

- Koynov, S.; Brandt, M.S.; Stutzmann, M. Black nonreflecting silicon surfaces for solar cells. Appl. Phys. Lett. 2006, 88. [Google Scholar] [CrossRef]

- Jura, M.P.; Miller, J.B.; Yim, J.W.L.; Forziati, J.; Murphy, B.; Chleboski, R.; Cooper, I.B.; Rohatgi, A.; Black, M.R. Conventionally-processed silicon nanowire solar cells demonstrating efficiency improvement over standard cells. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 598–600. [Google Scholar]

- Toor, F.; Miller, J.B.; Davidson, L.M.; Nichols, L.; Duan, W.; Jura, M.P.; Yim, J.; Forziati, J.; Black, M.R. Nanostructured silicon via metal assisted catalyzed etch (MACE): chemistry fundamentals and pattern engineering. Nanotechnology 2016, 27, 412003. [Google Scholar] [CrossRef] [PubMed]

- Toor, F.; Miller, J.B.; Davidson, L.M.; Duan, W.; Jura, M.P.; Yim, J.; Forziati, J.; Black, M.R. Metal assisted catalyzed etched (MACE) black Si: optics and device physics. Nanoscale 2016, 8, 15448–15466. [Google Scholar] [CrossRef] [PubMed]

- Beetz, B. Suntech’s Black Silicon Solar Cells Enter Mass Production. Available online: https://www.pv-magazine.com/2018/01/04/suntechs-black-silicon-solar-cells-enter-mass-production/ (accessed on 8 March 2018).

- Hutchins, M. Black is the New Black. Available online: https://www.pv-magazine.com/magazine-archive/black-is-the-new-black/ (accessed on 5 March 2018).

- Savin, H.; Repo, P.; Gastrow, G.V.; Ortega, P.; Calle, E.; Garín, M.; Alcubilla, R. Black silicon solar cells with interdigitated back-contacts achieve 22.1% efficiency. Nat. Nanotechnol. 2015, 10, 624–628. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Davidsen, R.S.; Li, H.; To, A.; Wang, X.; Han, A.; An, J.; Colwell, J.; Chan, C.; Wenham, A.; Schmidt, M.; et al. Black silicon laser-doped selective emitter solar cell with 18.1% efficiency. Sol. Energy Mater. Sol. Cells 2016, 144, 740–747. [Google Scholar] [CrossRef] [Green Version]

- Werner, S.; Lohmüller, E.; Saint-Cast, P.; Greulich, J.M.; Weber, J.; Schmidt, S.; Moldovan, A.; Brand, A.A.; Dannenber, T.; Mack, S.; et al. Key aspects for fabrication of p-type Cz-Si PERC solar cells exceeding 22% conversion efficiency. In Proceedings of the the 33rd European PV Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017. [Google Scholar]

- NREL. Solar Spectra. Air Mass 1.5: ASTM G-173-03. Available online: http://rredc.nrel.gov/solar/spectra/am1.5/ (accessed on 5 March 2018).

- Energy Trend PV. Available online: https://pv.energytrend.com/ (accessed on 2 June 2018).

- Priolo, F.; Gregorkiewicz, T.; Galli, M.; Krauss, T.F. Silicon nanostructures for photonics and photovoltaics. Nat. Nanotechnol. 2014, 9, 19–32. [Google Scholar] [CrossRef] [PubMed]

- Venkatesan, R.; Arivalagan, M.K.; Venkatachalapathy, V.; Pearce, J.M.; Mayandi, J. Effects of silver catalyst concentration in metal assisted chemical etching of silicon. Mater. Lett. 2018, 221, 206–210. [Google Scholar] [CrossRef]

- Saint-Cast, P.; Kafle, B.; Pandey, R.; Ridoy, A.I.; Hofmann, M.; Clochard, L.; Schwarze, T.; Pittroff, M.; Rentsch, J.; Preu, R. Rear passivated mc-Si solar cells textured by atmospheric pressure dry etching. Energy Procedia 2017, 124, 260–266. [Google Scholar] [CrossRef]

- Repo, P.; Haarahiltunen, A.; Sainiemi, L.; Yli-Koski, M.; Talvitie, H.; Schubert, M.C.; Savin, H. Effective Passivation of Black Silicon Surfaces by Atomic Layer Deposition. IEEE J. Photovolt. 2013, 3, 90–94. [Google Scholar] [CrossRef] [Green Version]

- Pasanen, T.P.; Vähänissi, V.; Wolny, F.; Oehlke, A.; Wagner, M.; Juntunen, M.A.; Heikkinen, I.T.S.; Salmi, E.; Sneck, S.; Vahlman, H.; et al. Industrial applicability of AR-coating-free black silicon. In Proceedings of the 35th European PV Solar Energy Conference and Exhibition (EU PVSEC), Brussels, Belgium, 24–28 September 2018. [Google Scholar]

- Heikkinen, I.T.S.; Repo, P.; Vähänissi, V.; Pasanen, T.; Malinen, V.; Savin, H. Efficient surface passivation of black silicon using spatial atomic layer deposition. Energy Procedia 2017, 124, 282–287. [Google Scholar] [CrossRef]

- Dingemans, G.; Terlinden, N.M.; Verheijen, M.A.; van de Sanden, M.C.M.; Kessels, W.M.M. Controlling the fixed charge and passivation properties of Si(100)/Al2O3 interfaces using ultrathin SiO2 interlayers synthesized by atomic layer deposition. J. Appl. Phys. 2011, 110, 093715. [Google Scholar] [CrossRef]

- Terlinden, N.M.; Dingemans, G.; Vandalon, V.; Bosch, R.H.E.C.; Kessels, W.M.M. Influence of the SiO2 interlayer thickness on the density and polarity of charges in Si/SiO2/Al2O3 stacks as studied by optical second-harmonic generation. J. Appl. Phys. 2014, 115, 033708. [Google Scholar] [CrossRef]

- Pasanen, T.P.; Vähänissi, V.; Theut, N.; Savin, H. Surface passivation of black silicon phosphorus emitters with atomic layer deposited SiO2/Al2O3 Stacks. Energy Procedia 2017, 124, 307–312. [Google Scholar] [CrossRef]

- Loo, B.H.W.V.D.; Knoops, H.C.M.; Dingemans, G.J.M.; Lamers, M.W.P.E.; Romijn, I.G.; Weeber, A.W.; Kessels, W.M.M. ”Zero-charge” SiO2/Al2O3 stacks for the simultaneous passivation of n+ and p+ doped silicon surfaces by atomic layer deposition. Sol. Energy Mater. Sol. Cells 2015, 143, 450–456. [Google Scholar]

- Cui, J.; Wan, Y.; Chen, Y.; Verlinden, P.; Cuevas, A. Highly effective electronic passivation of silicon surfaces by atomic layer deposited hafnium oxide. Appl. Phys. Lett. 2017, 110, 021602. [Google Scholar] [CrossRef]

- Ingenito, A.; Isabella, O.; Zeman, M. Nano-cones on micro-pyramids: modulated surface textures for maximal spectral response and high efficiency solar cells. Prog. Photovolt. Res. Appl. 2015, 23, 1649–1659. [Google Scholar] [CrossRef]

- Gastrow, G.V.; Alcubilla, R.; Ortega, P.; Yli-Koski, M.; Conesa-Boj, S.; Fontcuberta I Morral, A.; Savin, H. Analysis of the atomic layer deposited Al2O3 field-effect passivation in black silicon. Sol. Energy Mater. Sol. Cells 2015, 142, 29–33. [Google Scholar] [CrossRef] [Green Version]

- To, A.; Li, W.M.; Li, X.; Hoex, B. The effects of bifacial deposition of ALD AlOx on the contact properties of screen-printed contacts for p-type PERC solar cells. Energy Procedia 2017, 124, 914–921. [Google Scholar] [CrossRef]

- Müller, M.; Fischer, G.; Bitnar, B.; Steckemetz, S.; Schiepe, R.; Mühlbauer, M.; Köhler, R.; Richter, P.; Kusterer, C.; Oehlke, A.; et al. Loss analysis of 22% efficient industrial PERC solar cells. Energy Procedia 2017, 124, 131–137. [Google Scholar] [CrossRef]

- Wang, W.; Donw, J.; Ye, Q.; Yang, Y.; Cai, W.; Sheng, J.; Yang, J.; Zhang, C.; Zhou, X.; Dong, S. Industrially feasible PERC cells on diamond wire sawing multi-crystalline silicon wafers textured by RIE towards 20.78% efficiency. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017; pp. 290–294. [Google Scholar]

- Repo, P.; Benick, J.; Gastrow, G.V.; Vähänissi, V.; Heinz, F.D.; Schön, J.; Schubert, M.C.; Savin, H. Passivation of black silicon boron emitters with atomic layer deposited aluminum oxide. Phys. Status Solidi RRL 2013, 7, 950–954. [Google Scholar] [CrossRef] [Green Version]

- Otto, M.; Kroll, M.; Käsebier, T.; Salzer, R.; Tünnermann, A.; Wehrspohn, R.B. Extremely low surface recombination velocities in black silicon passivated by atomic layer deposition. Appl. Phys. Lett. 2012, 100, 191603. [Google Scholar] [CrossRef]

- Pvbuzz Media. Get Read-The Price for Solar Power Will Drop Even Further. Available online: https://www.pvbuzz.com/price-for-solar-power-drop/ (accessed on 25 February 2018).

- Strupeit, L.; Neij, L. Cost dynamics in the deployment of photovoltaics: Insights from the German market for building-sited systems. Renew. Sustain. Energy Rev. 2017, 69, 948–960. [Google Scholar] [CrossRef]

- Nemet, G.F. Beyond the learning curve: factors influencing cost reductions in photovoltaics. Energy Policy 2006, 34, 3218–3232. [Google Scholar] [CrossRef]

- Parente, V.; Goldemberg, J.; Zilles, R. Comments on experience curves for PV modules. Prog. Photovolt. Res. Appl. 2002, 10, 571–574. [Google Scholar] [CrossRef]

- Candelise, C.; Winskel, M.; Gross, R.J.K. The dynamics of solar PV costs and prices as a challenge for technology forecasting. Renew. Sustain. Energy Rev. 2013, 26, 96–107. [Google Scholar] [CrossRef] [Green Version]

- Breyer, C.; Birkner, C.; Kersten, F.; Gerlach, A.; Goldschmidt, J.C.; Stryi-Hipp, G.; Fraile Montoro, D.; Riede, M. Research and Development Investments in PV–A Limiting Factor for a Fast PV Diffusion? In Proceedings of the 25th European Photovoltaic Solar Energy Conference and Exhibition, Valencia, Spain, 6–10 September 2010. [Google Scholar]

- Tour, A.D.L.; Glachant, M.; Ménière, Y. Predicting the costs of photovoltaic solar modules in 2020 using experience curve models. Energy 2013, 62, 341–348. [Google Scholar] [CrossRef]

- Swanson, R.M. A vision for crystalline silicon photovoltaics. Prog. Photovolt. Res. Appl. 2006, 14, 443–453. [Google Scholar] [CrossRef] [Green Version]

- Ferioli, F.; van der Zwaan, B.C.C. Learning in Times of Change: A Dynamic Explanation for Technological Progress. Environ. Sci. Technol. 2009, 43, 4002–4008. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goodrich, A.; Hacke, P.; Wang, Q.; Sopori, B.; Margolis, R.; James, T.L.; Woodhouse, M. A wafer-based monocrystalline silicon photovoltaics road map: Utilizing known technology improvement opportunities for further reductions in manufacturing costs. Sol. Energy Mate. Sol. Cells 2013, 114, 110–135. [Google Scholar] [CrossRef]

- Hill, J.S. Global Solar Market Demand Expected to Reach 100 Gigawatts in 2017, Says Solar Power Europe. Available online: https://cleantechnica.com/2017/10/27/global-solar-market-demand-expected-reach-100-gw-2017-solarpower-europe/ (accessed on 23 May 2018).

- Tamboli, A.C.; Bobela, D.C.; Kanevce, A.; Remo, T.; Alberi, K.; Woodhouse, M. Low-Cost CdTe/Silicon Tandem Solar Cells. IEEE J. Photovolt. 2017, 7, 1767–1772. [Google Scholar] [CrossRef]

- Liu, J.; Liu, B.; Shen, Z.; Liu, J.; Zhong, S.; Liu, S.; Li, C.; Xia, Y. Characterization of PIII textured industrial multicrystalline silicon solar cells. Sol. Energy 2012, 86, 3004–3008. [Google Scholar] [CrossRef]

- Yoo, J.; Yu, G.; Yi, J. Large-area multicrystalline silicon solar cell fabrication using reactive ion etching (RIE). Sol. Energy Mater. Sol. Cells 2011, 95, 2–6. [Google Scholar] [CrossRef]

- Juntunen, M.; Heinonen, J.; Vähänissi, V.; Repo, P.; Valluru, D.; Savin, H. Near-unity quantum efficiency of broadband black silicon photodiodes with an induced junction. Nat. Photonics 2016, 10, 777–781. [Google Scholar] [CrossRef]

- Huang, Z.; Carev, J.E.; Liu, M.; Mazur, E.; Campbell, J.C. Microstructured silicon photodetector. Appl. Phys. Lett. 2006, 89, 033506. [Google Scholar] [CrossRef]

- Boer, M.J.; Gardeniers, J.G.E.; Jansen, H.V.; Gilde, M.J.; Roelofs, G.; Sasserath, J.N.; Elwenspoek, M.C. Guidelines for etching silicon MEMS structures using fluorine high-density plasmas at cryogenic temperatures. J. Microelectromech. Syst. 2002, 11, 385–401. [Google Scholar] [CrossRef] [Green Version]

- Gesemann, B.; Wehrspohn, R.; Hackner, A.; Müller, G. Large-Scale Fabrication of Ordered Silicon Nanotip Arrays Used for Gas Ionization in Ion Mobility Spectrometers. IEEE Trans. Nanotechnol. 2011, 10, 50–52. [Google Scholar] [CrossRef]

- Joshi, M.; Verma, R. Black Silicon Photovoltaics: Fabrication methods and properties. Int. J. Res. Eng. Sci. 2017, 5, 62–72. [Google Scholar]

- Lv, J.; Zhang, T.; Zhang, P.; Zhao, Y.; Li, S. Review application of nanostructured black silicon. Nanoscale Res. Lett. 2018, 13, 110. [Google Scholar] [CrossRef] [PubMed]

- Kafle, B.; Schön, J.; Fleischmann, C.; Werner, S.; Wolf, A.; Clochard, L.; Duffy, E.; Hofmann, M.; Rentsch, J. On the emitter formation in nanotextured silicon solar cells to achieve improved electrical performances. Sol. Energy Mater. Sol. Cells 2016, 152, 94–102. [Google Scholar] [CrossRef]

- Repo, P.; Benick, J.; Vähänissi, V.; Schön, J.; von Gastrow, G.; Steinhauser, B.; Schubert, M.C.; Hermle, M.; Savin, H. N-type Black Silicon Solar Cells. Energy Procedia 2013, 38, 866–871. [Google Scholar] [CrossRef]

- Peyronnet, R.; Fischer, G.; Blevin, T.; Johnson, E.V.; Drahi, E.; Lemiti, M. Texturing optimization for bifacial n-PERT: Are pyramids and/or black silicon the way to go for thinner devices? Energy Procedia 2017, 124, 250–259. [Google Scholar] [CrossRef]

- What is Horizon 2020? Available online: https://ec.europa.eu/programmes/horizon2020/en/what-horizon-2020 (accessed on 25 April 2018).

- Griliches, Z. Research Costs and Social Returns: Hybrid Corn and Related Innovations. J. Political Econ. 1958, 66, 419–431. [Google Scholar] [CrossRef]

- Griliches, Z. The Search for R&D Spillovers. Available online: http://www.nber.org/papers/w3768 (accessed on 25 July 2018).

- Lenoir, T. Revolution from above: The role of the state in creating the german research system, 1810–1910. Am. Econ. Rev. 1998, 88, 22–27. [Google Scholar]

- Jones, C.I.; Williams, J.C. Measuring the Social Return to R&D. Q. J. Econ. 1998, 113, 1119–1135. [Google Scholar] [CrossRef] [Green Version]

- Hall, B.H. The Financing of Research and Development. Oxf. Rev. Econ. Policy 2002, 18, 35–51. [Google Scholar] [CrossRef] [Green Version]

- Hall, B.H.; Lerner, J. Chapter 14-The Financing of R&D and Innovation. Handb. Econ. Innov. 2010, 1, 609–639. [Google Scholar]

- Levin, R.C.; Klevorick, A.K.; Nelson, R.R.; Winter, S.G.; Gilbert, R.; Griliches, Z. Appropriating the Returns from Industrial Research and Development. Brook. Pap. Econ. Act. 1987, 3, 783–831. [Google Scholar] [CrossRef]

- Mamuneas, T.P.; Ishaq Nadiri, M. Public R&D policies and cost behavior of the US manufacturing industries. J. Public Econ. 1996, 63, 57–81. [Google Scholar] [CrossRef]

- Becker, B. Public R&D Policies and Private R&d Investment: A Survey of the Empirical Evidence. J. Econ. Surv. 2015, 29, 917–942. [Google Scholar] [CrossRef]

- SENTECH: Home of Thin Film Measurement. Available online: https://www.sentech.com/en/site__2235/ (accessed on 29 May 2018).

- InPassion ALD. Available online: http://www.solaytec.com/products/inpassion-ald (accessed on 29 May 2018).

- Lotus Applied Technology. Applications. Available online: http://lotusat.com/roll-to-roll-ald/applications/ (accessed on 29 May 2018).

- Tseng, M.-H.; Yu, H.-H.; Chou, K.-Y.; Jou, J.-H.; Lin, K.-L.; Wang, C.-C.; Tsai, F.-Y. Low-temperature gas-barrier films by atomic layer deposition for encapsulating organic light-emitting diodes. Nanotechnology 2016, 27, 295706. [Google Scholar] [CrossRef] [PubMed]

- Maydannik, P.S.; Kääriäinen, T.O.; Lahtinen, K.; Cameron, D.C.; Söderlund, M.; Soininen, P.; Johansson, P.; Kuusipalo, J.; Moro, L.; Zeng, X. Roll-to-roll atomic layer deposition process for flexible electronics encapsulation applications. J. Vac. Sci. Technol. A 2014, 32, 051603. [Google Scholar] [CrossRef]

- Yersak, A.S.; Sharma, K.; Wallas, J.M.; Dameron, A.A.; Li, X.; Yang, Y.; Hurst, K.E.; Ban, C.; Tenent, R.C.; George, S.M. TEMAZ/O3 atomic layer deposition process with doubled growth rate and optimized interface properties in metal–insulator–metal capacitors. J. Vac. Sci. Technol. A 2018, 36, 01A123. [Google Scholar] [CrossRef]

- Tassey, G. Competing in Advanced Manufacturing: The Need for Improved Growth Models and Policies. J. Econ. Perspect. 2014, 28, 27–48. [Google Scholar] [CrossRef]

- Bloom, N.; Griffith, R.; Van Reenen, J. Do R&D tax credits work? Evidence from a panel of countries 1979–1997. J. Public Econ. 2002, 85, 1–31. [Google Scholar] [CrossRef]

- Rao, N. Do tax credits stimulate R&D spending? The effect of the R&D tax credit in its first decade. J. Public Econ. 2016, 140, 1–12. [Google Scholar] [CrossRef]

- Czarnitzki, D.; Hanel, P.; Rosa, J.M. Evaluating the impact of R&D tax credits on innovation: A microeconometric study on Canadian firms. Res. Policy 2011, 40, 217–229. [Google Scholar] [CrossRef] [Green Version]

- Ali-Yrkkö, J. Impact of Public R&D Financing on Private R&D: Does Financial Constraint Matter? 2004. The Research Institute of the Finnish Economy (ETLA). Available online: https://www.etla.fi/wp-content/uploads/2012/09/dp943.pdf (accessed on 25 July 2018).

- Wilcox, J.A. Do Government Loan Guarantees Lower, Or Raise, Banks’ Non-Guaranteed Lending? Available online: http://siteresources.worldbank.org/INTFR/Resources/WilcoxYasuda_PCG%26JapaneseBanks_FINAL.pdf (accessed on 25 July 2018).

- Zhang, H.; Li, L.; Zhou, D.; Zhou, P. Political connections, government subsidies and firm financial performance: Evidence from renewable energy manufacturing in China. Renew. Energy 2014, 63, 330–336. [Google Scholar] [CrossRef]

- Branker, K.; Pearce, J.M. Financial return for government support of large-scale thin-film solar photovoltaic manufacturing in Canada. Energy Policy 2010, 38, 4291–4303. [Google Scholar] [CrossRef]

- Bartik, T.J. Who Benefits from State and Local Economic Development Policies? Upjohn Press: Kalamazoo, MI, USA, 1991. [Google Scholar] [CrossRef]

- Goodrich, A.C.; Powell, D.M.; James, T.L.; Woodhouse, M.; Buonassisi, T. Assessing the drivers of regional trends in solar photovoltaic manufacturing. Energy Environ. Sci. 2013, 6, 2811–2821. [Google Scholar] [CrossRef]

- Fialka, J. Why China Is Dominating the Solar Industry. Available online: https://www.scientificamerican.com/article/why-china-is-dominating-the-solar-industry/ (accessed on 2 May 2018).

- Zhang, F.; Gallagher, K.S. Innovation and technology transfer through global value chains: Evidence from China’s PV industry. Energy Policy 2016, 94, 191–203. [Google Scholar] [CrossRef]

- Jäger-Waldau, A. PV Status Report. 2017. Available online: http://publications.jrc.ec.europa.eu/repository/bitstream/JRC108105/kjna28817enn.pdf (accessed on 25 July 2018).

- Baily, M.; Lawrence, R. Tax Incentives for R&D: What do the Data Tell Us? Council on Research and Technology: Washington, DC, USA, 1992. [Google Scholar]

- Hall, B.H. R&D Tax Policy during the 1980s: Success or Failure? Tax Policy Econ. 1993, 7, 1–35. [Google Scholar] [CrossRef] [Green Version]

- Hines, J.R. No Place like Home: Tax Incentives and the Location of R&D by American Multinationals. Tax Policy Econ. 1994, 8, 65–104. [Google Scholar] [CrossRef] [Green Version]

- Harju, J.; Kari, S.; Koivisto, A.; Kuusi, T.; Matikka, T.; Määttänen, N.; Pajarinen, M.; Ropponen, O.; Rouvinen, P.; Valkonen, T. Yritysverotus, Investoinnit Ja Tuottavuus. Available online: http://julkaisut.valtioneuvosto.fi/bitstream/handle/10024/160322/Yritysverotus%20investoinnit%20ja%20tuottavuus.pdf (accessed on 25 July 2018).

- Kuusi, T.; Pajarinen, M.; Rouvinen, P.; Valkonen, T. Tutkimuksen Ja Tuotekehityksen Verotuet. Available online: http://pub.etla.fi/ETLA-Muistio-Brief-31.pdf (accessed on 25 July 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Modanese, C.; Laine, H.S.; Pasanen, T.P.; Savin, H.; Pearce, J.M. Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing. Energies 2018, 11, 2337. https://doi.org/10.3390/en11092337

Modanese C, Laine HS, Pasanen TP, Savin H, Pearce JM. Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing. Energies. 2018; 11(9):2337. https://doi.org/10.3390/en11092337

Chicago/Turabian StyleModanese, Chiara, Hannu S. Laine, Toni P. Pasanen, Hele Savin, and Joshua M. Pearce. 2018. "Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing" Energies 11, no. 9: 2337. https://doi.org/10.3390/en11092337

APA StyleModanese, C., Laine, H. S., Pasanen, T. P., Savin, H., & Pearce, J. M. (2018). Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing. Energies, 11(9), 2337. https://doi.org/10.3390/en11092337