A New Wind Power Accommodation Strategy for Combined Heat and Power System Based on Bi-Directional Conversion

Abstract

:1. Introduction

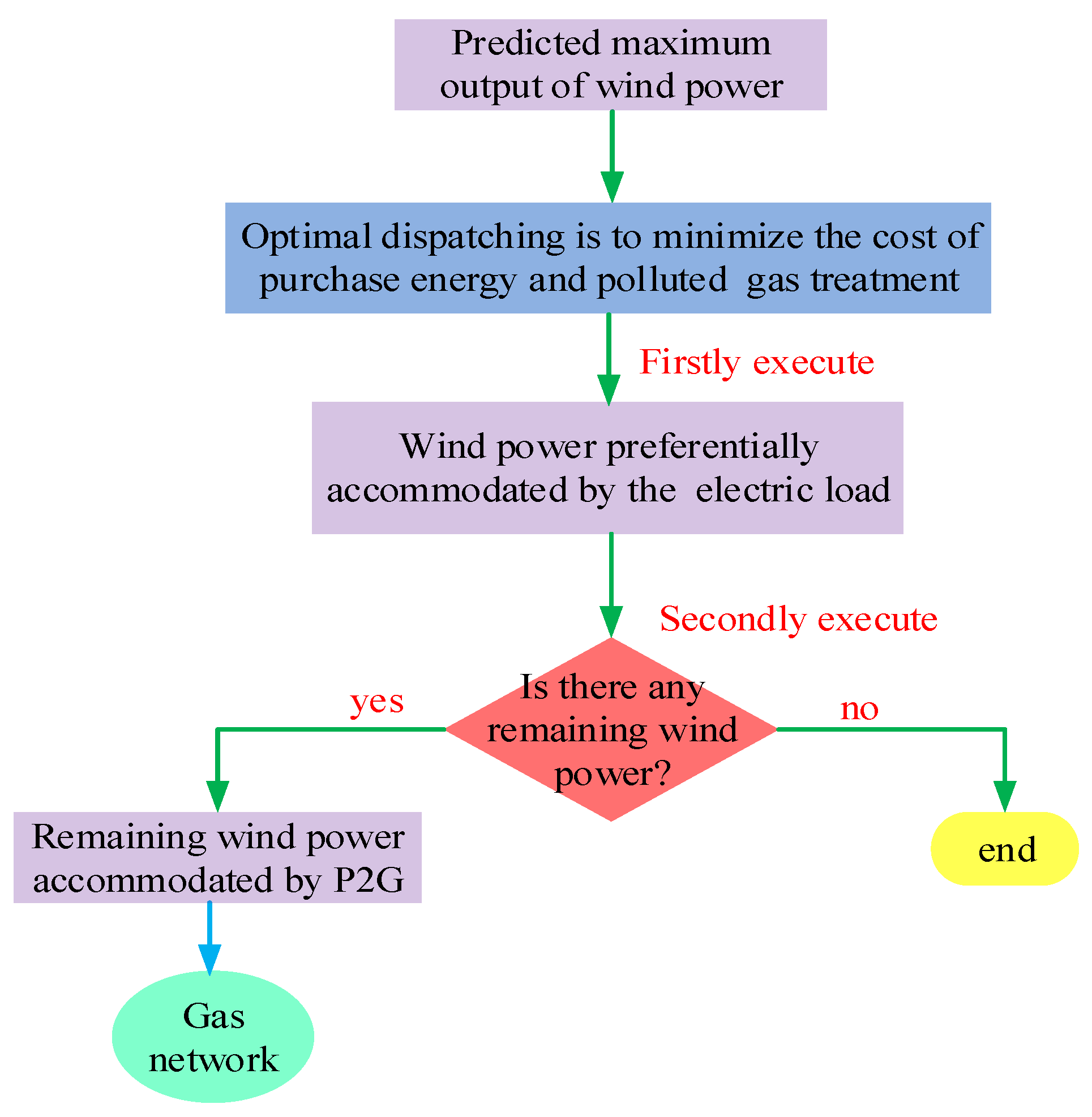

- Decouple two operating modes of CHP units simultaneously, i.e., “Following the Electric Load” and “Following the Thermal Load”, which further improve the ability to accommodate wind power.

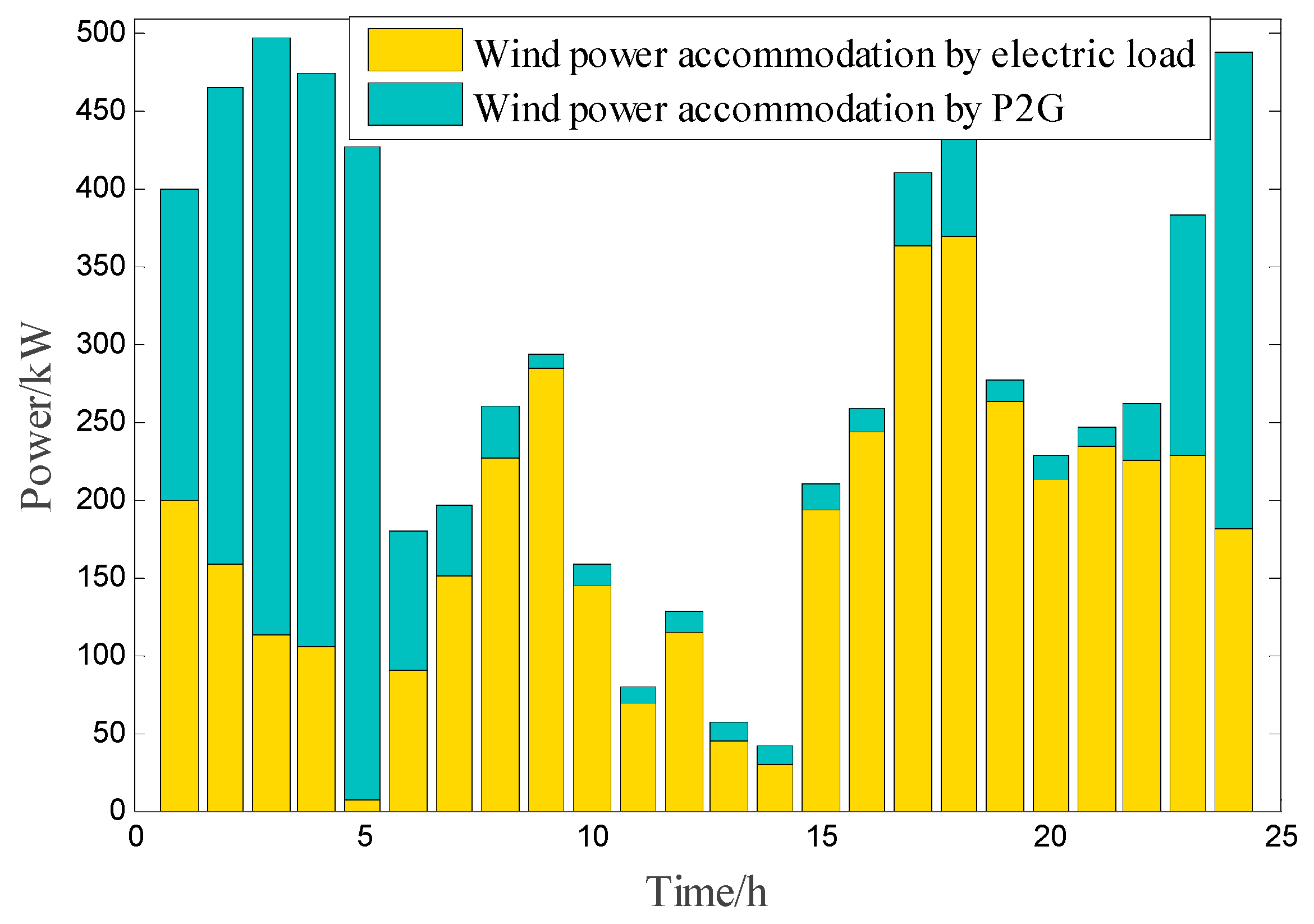

- Realize electro-gas bidirectional conversion (wind power to gas to electricity) by P2G and fuel cell, which can realize indirect power supply of wind power across time scales.

- Store the large-scale excess wind power, i.e., the wind power which cannot be used by electric load, in the form of gas by using P2G technology. When the user needs electrical energy or thermal energy, the gas produced by P2G is used to generate power.

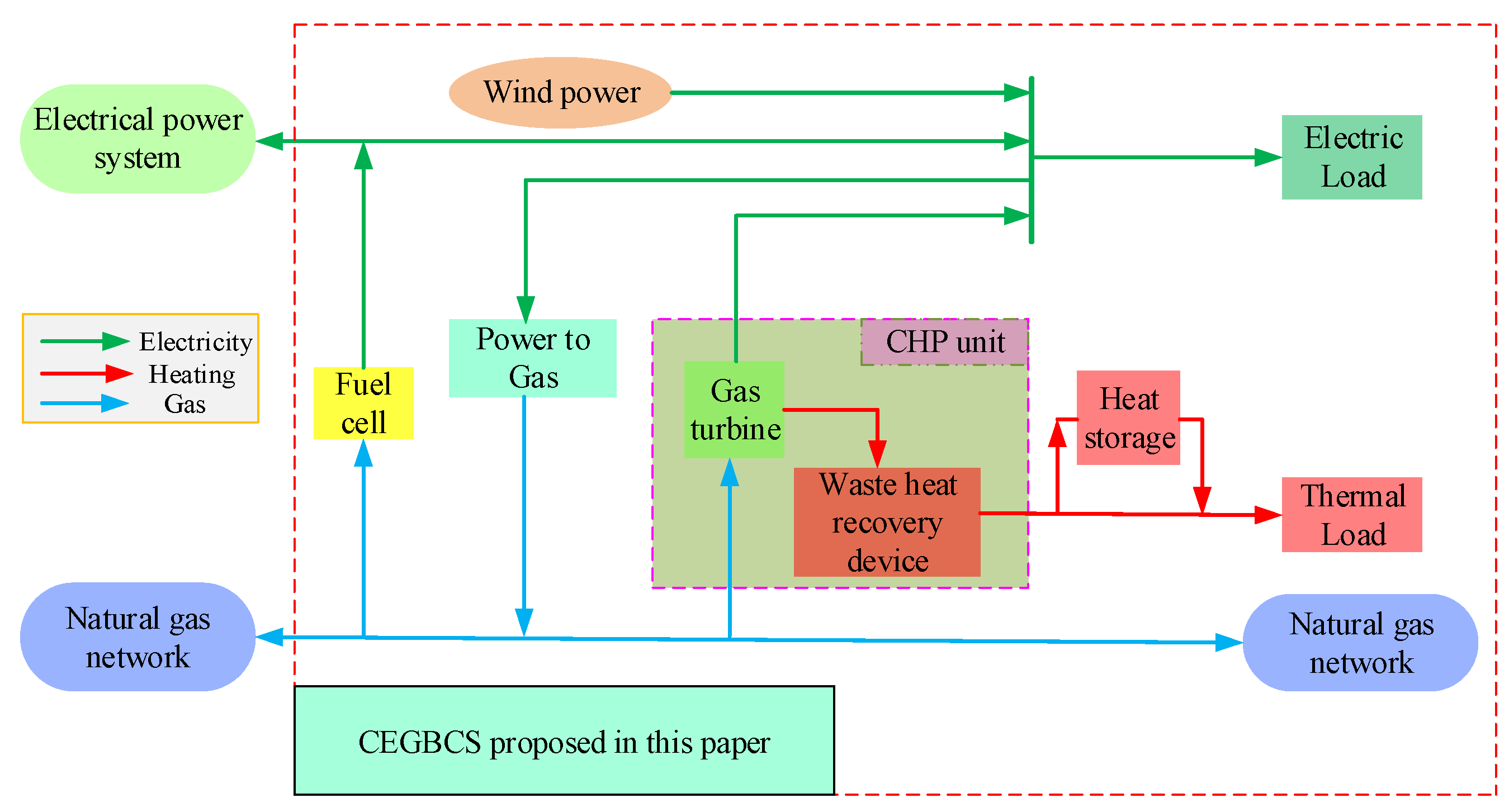

2. Operation Characteristics of Internal Devices in Combined Electro-Gas Bi-Directional Conversion System (CEGBCS)

2.1. Operating Characteristics of Power to Gas

2.2. Operating Characteristics of Proton Exchange Membrane Fuel Cells

3. Dual-Mode Decoupling of Combined Electro-Gas Bi-Directional Conversion System (CEGBCS) and Wind Power Accommodation Strategy

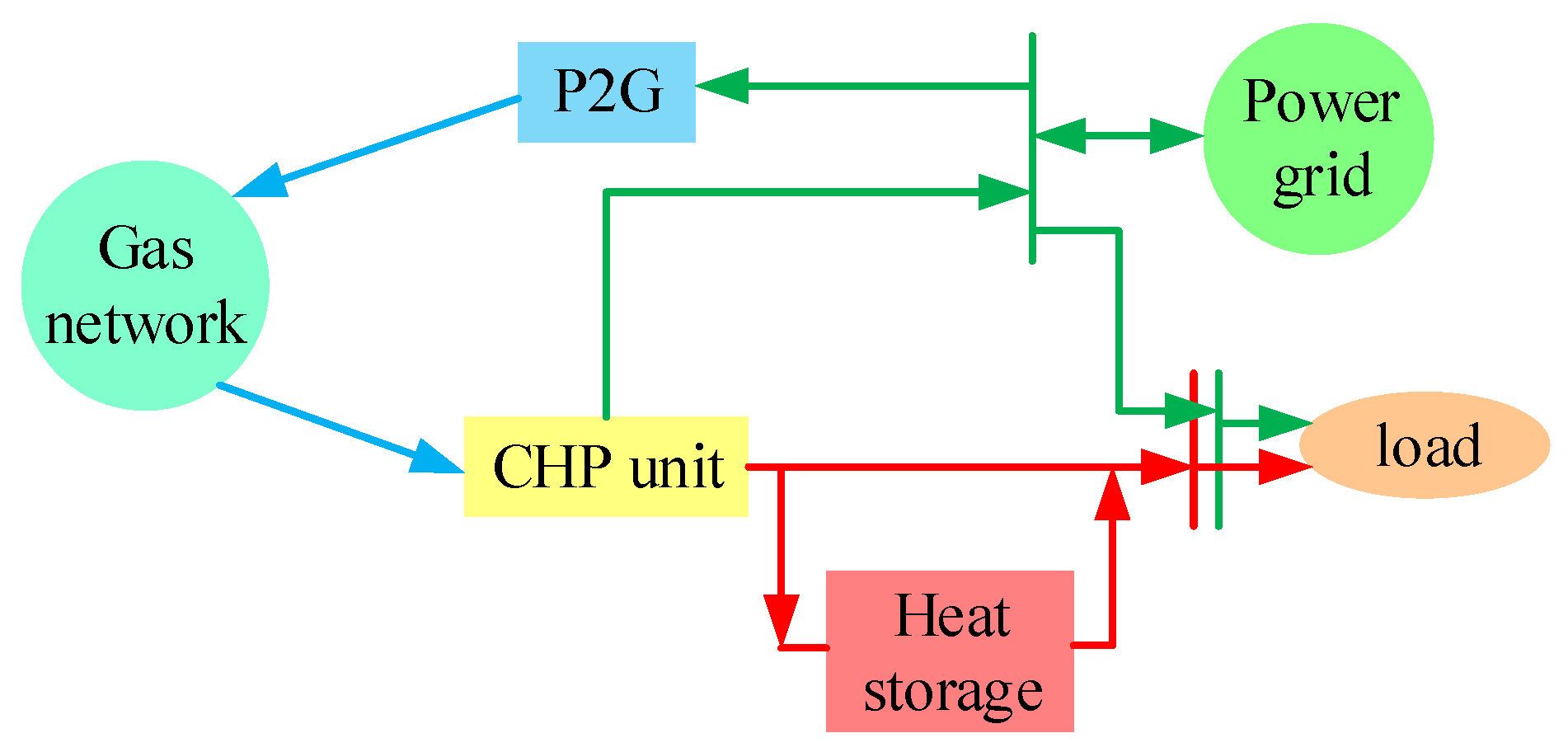

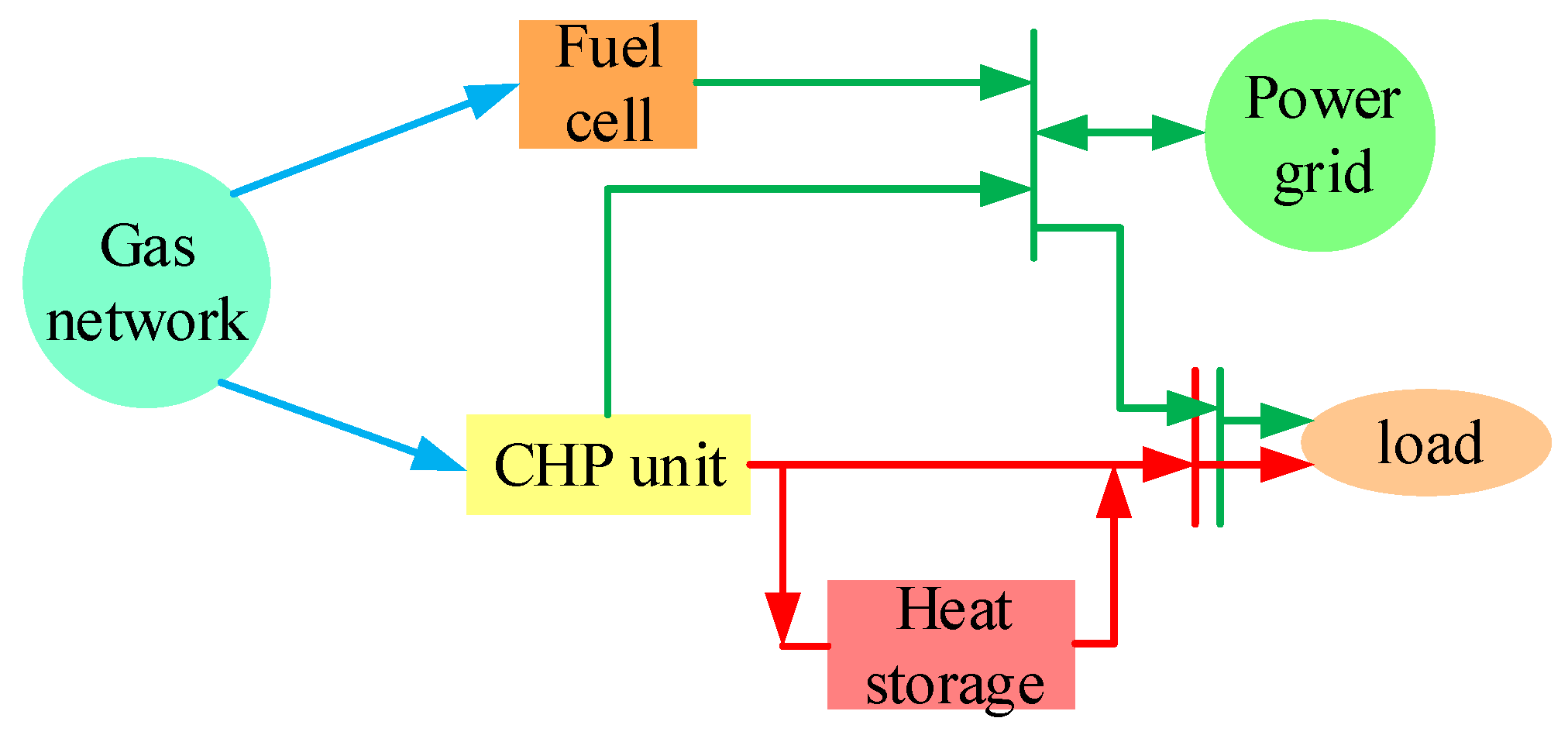

3.1. Decoupling Principle of Combined Heat and Power (CHP) for the Mode of “Following the Thermal Load”

3.2. Decoupling Principle of Combined Heat and Power (CHP) for the Mode of “Following the Electric Load”

3.3. Wind Power Accommodation Strategy

4. Coordinated Optimal Scheduling of Combined Electro-Gas Bi-Directional Conversion System (CEGBS)

4.1. Mathematical Modeling of Combined Electro-Gas Bi-Directional Conversion System (CEGBS) Internal Devices

4.1.1. Combined Heat and Power (CHP) Unit Model

4.1.2. Power to Gas (P2G)

4.1.3. Fuel Cell Model

4.1.4. Heat Storage Model

4.2. Coordinated Optimization Modeling of Combined Electro-Gas Bi-Directional Conversion System (CEGBS)

4.2.1. Objective Function of Optimal Scheduling

4.2.2. Operational Constraints

4.2.3. Solution Method

5. Simulation Study

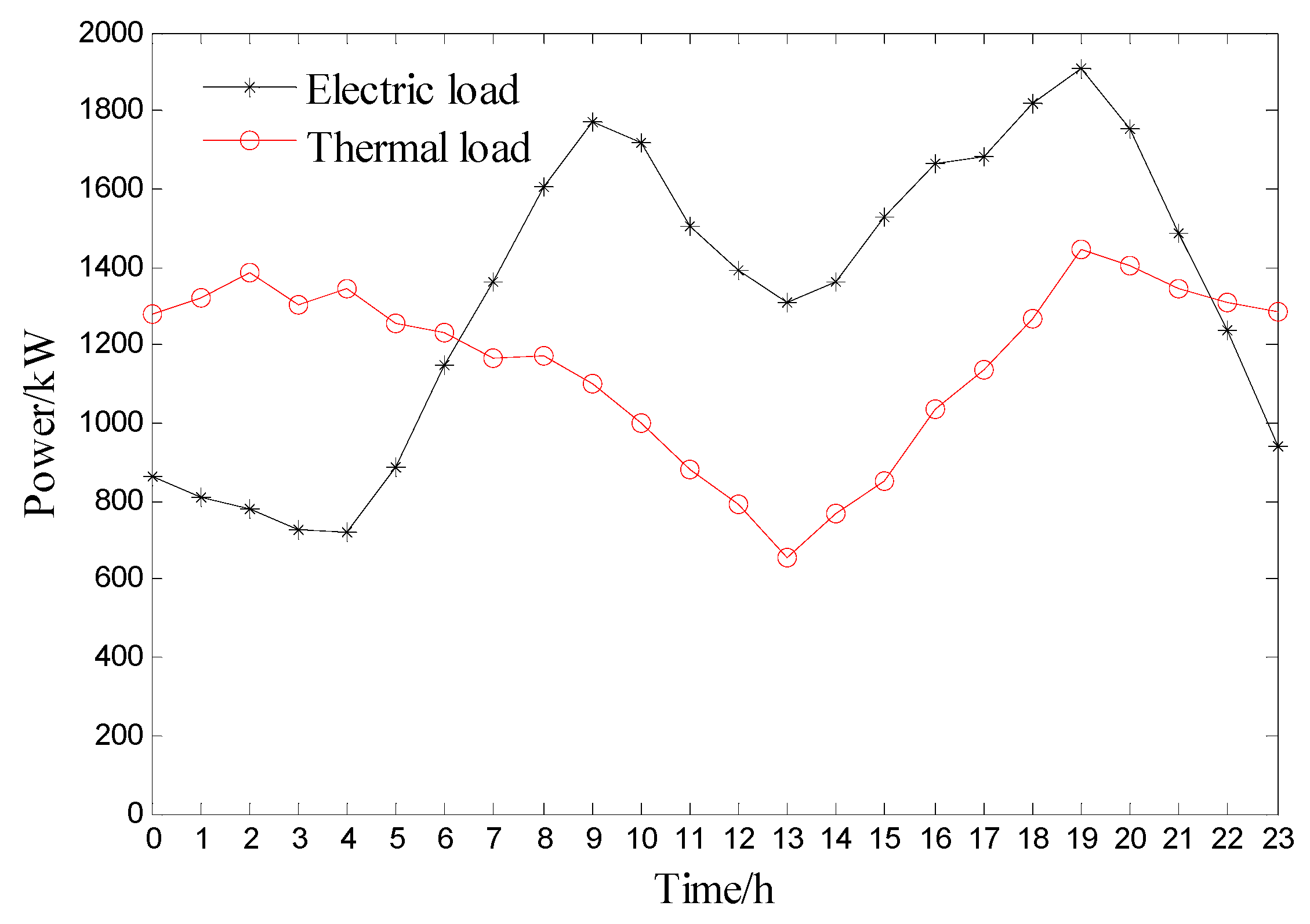

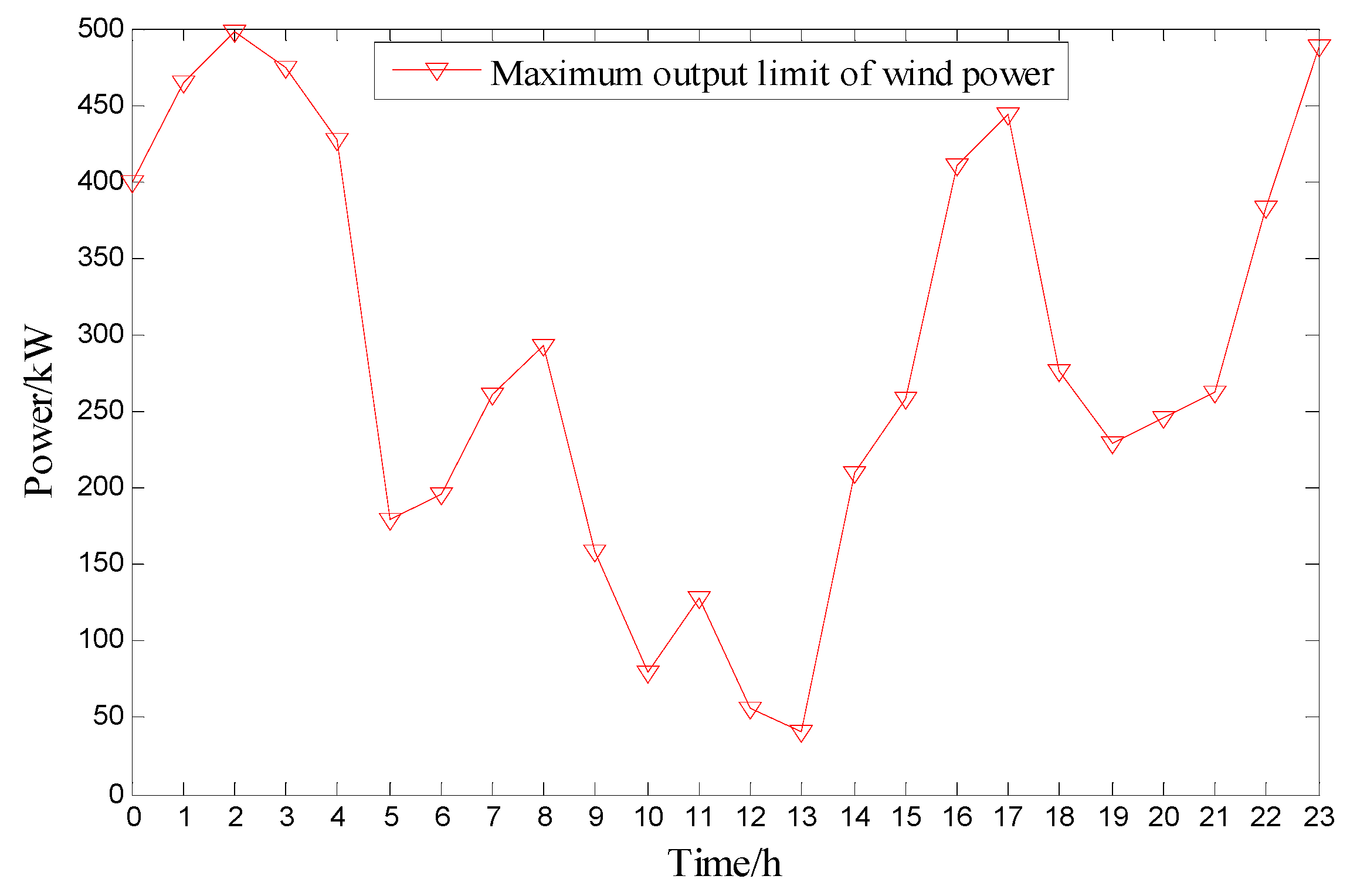

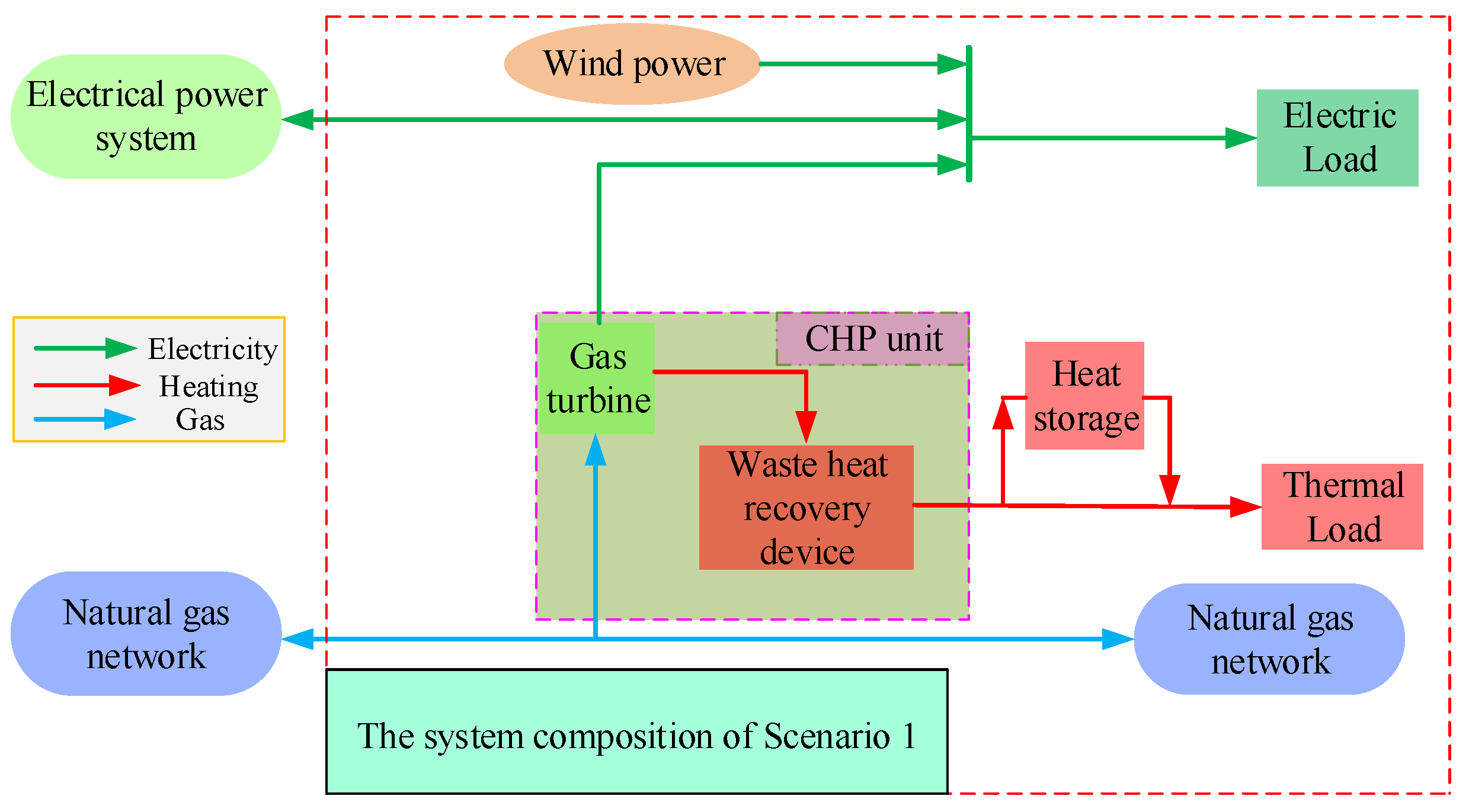

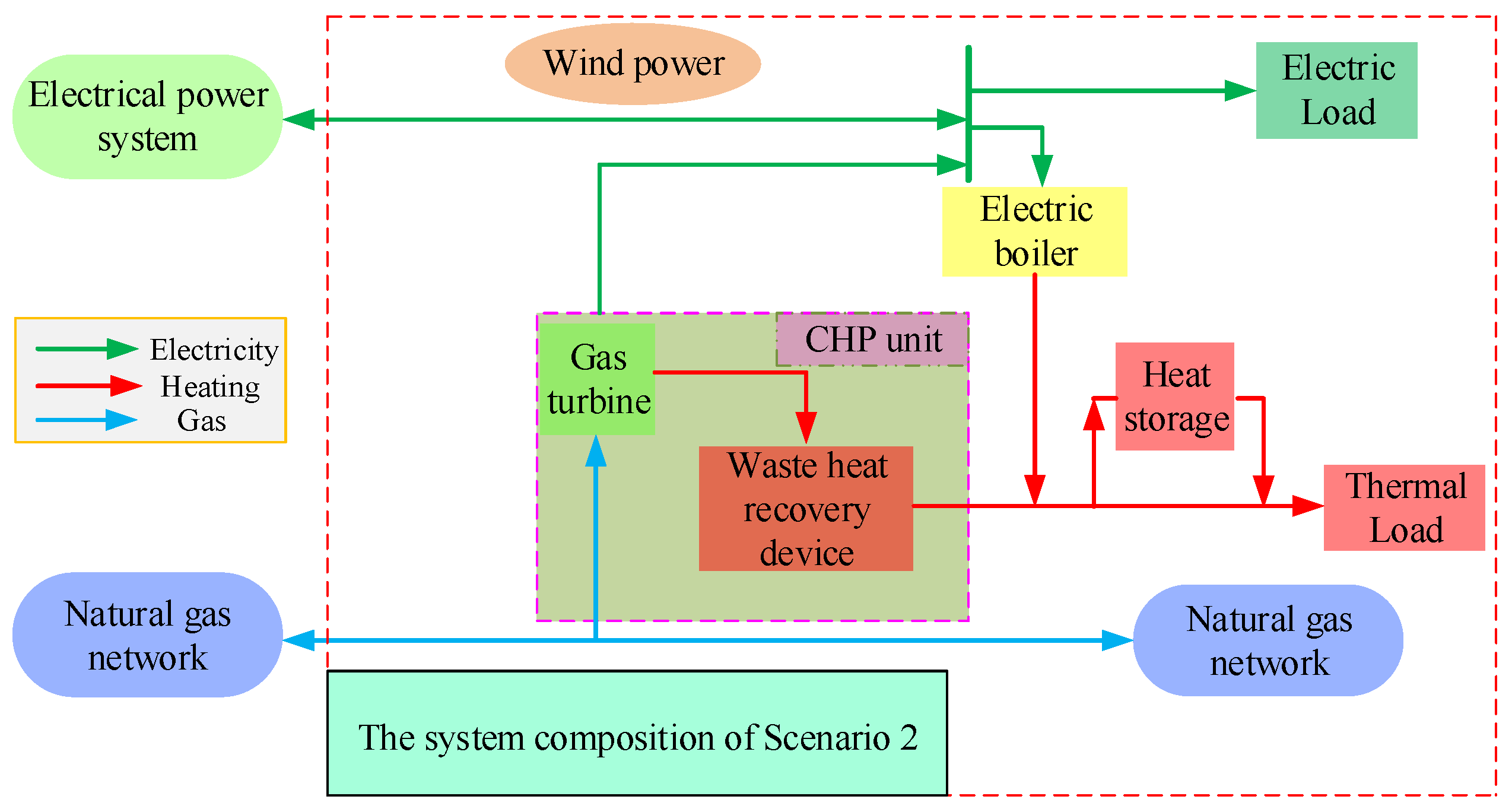

5.1. Scenario Description

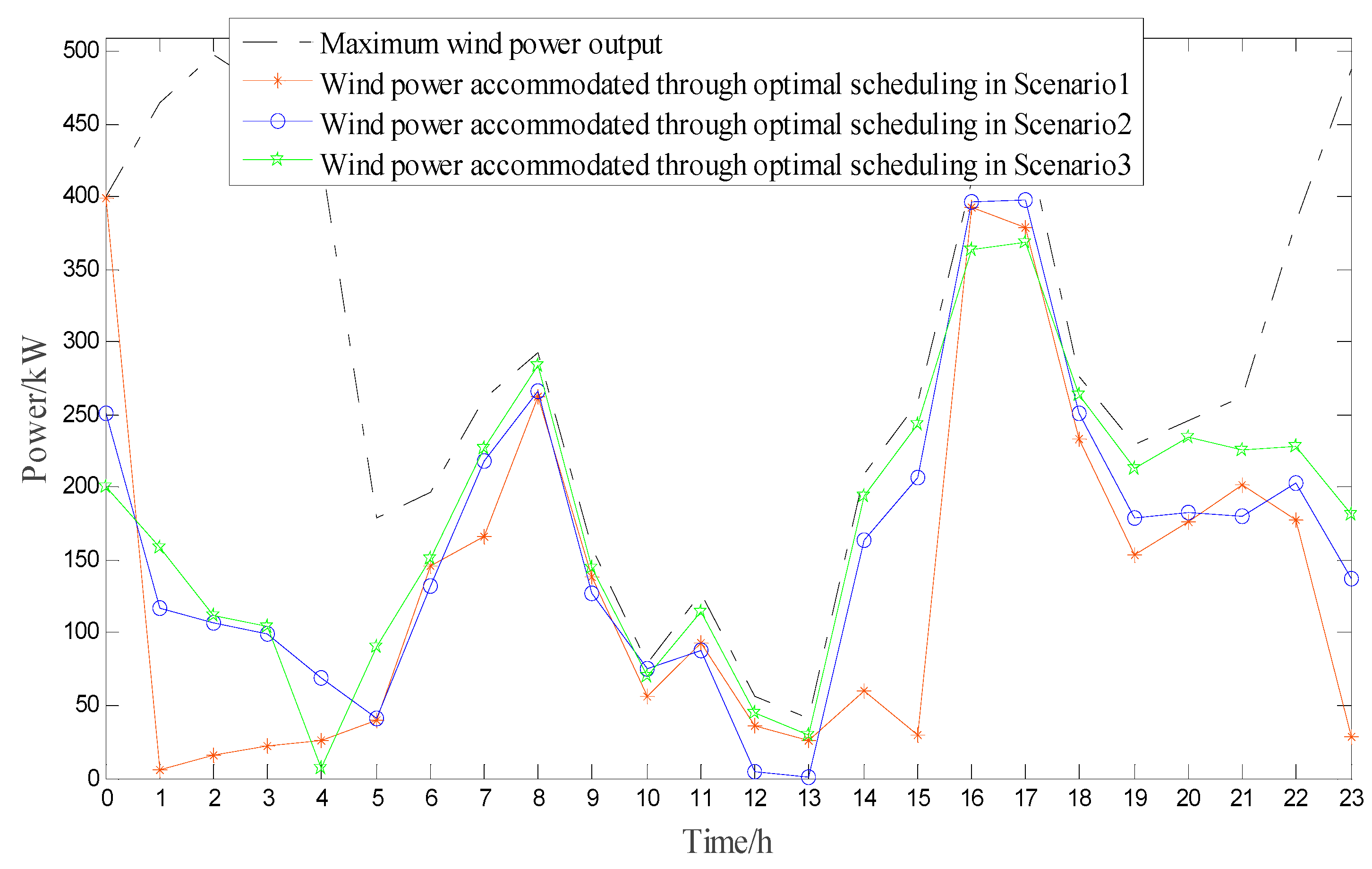

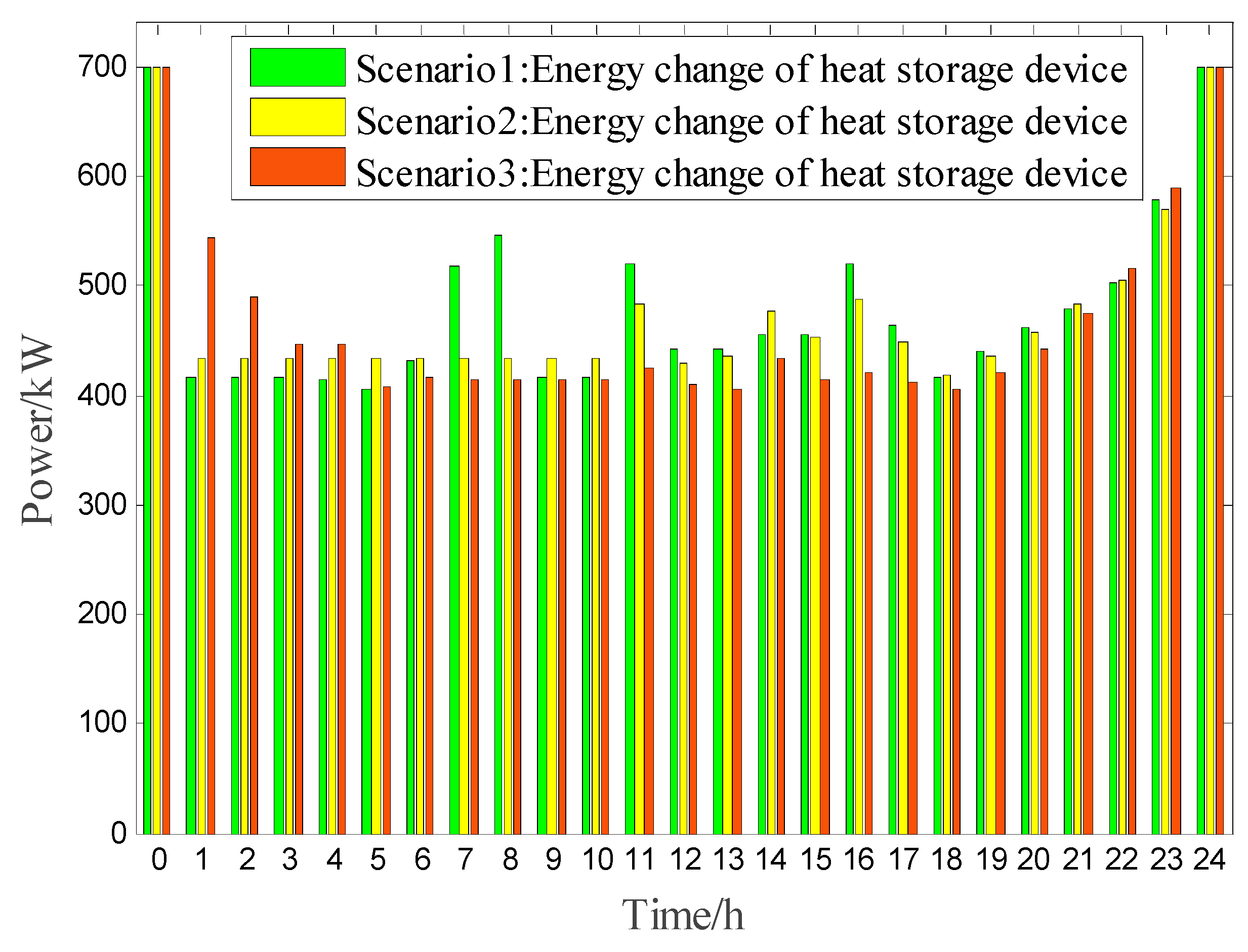

5.2. Simulation Result Analysis

6. Conclusions

- This system can simultaneously decouple two operating modes (“Following the Electric load” and Following the Heat load) of CHP unit.

- The CEGBS system can also realize large-scale local accommodation of wind power and long-term, low-cost indirect storage of remaining wind power.

- The CEGBCS can realize bidirectional conversion between the electro-gas or electro-thermal energy.

- The simulation results show that the CEGBCS proposed in this paper is not only superior to the existing methods, but also has the lowest operating cost and the best environmental benefit.

Author Contributions

Funding

Conflicts of Interest

References

- Xue, Y.; Lei, X.; Xue, F.; Yu, C.; Dong, Z.; Wen, F.; Ju, P. A review on impacts of wind power uncertainties on power systems. Proc. CSEE 2014, 34, 5029–5040. [Google Scholar]

- Holttinen, H.; Meibom, P.; Orths, A.; Lange, B.; O’Malley, M.; Tande, J.O.; Estanqueiro, A.; Gomez, E.; Söder, L.; Strbac, G. Impact of large amounts of wind power on design and operation of power systems, results of IEA collaboration. Wind Energy 2011, 14, 179–192. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, G.; Huang, B.; Liu, W. Optimum electric boiler capacity configuration in a regional power grid for a wind power accommodation scenario. Energies 2016, 9, 144. [Google Scholar] [CrossRef]

- State Energy Administration Wind Power Grid Operation in the First Half of 2017. Available online: http://www.nea.gov.cn/2017-07/24/c_136468307.htm (accessed on 24 July 2017).

- Zhang, L.; Ye, T.; Xin, Y.; Han, F.; Fan, G. Problems and measures of power grid accommodating large scale wind power. Proc. CSEE 2010, 30, 1–9. [Google Scholar]

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Appl. Energy 2015, 137, 511–536. [Google Scholar] [CrossRef] [Green Version]

- Brekken, T.; Yokochi, A.; von Jouanne, A.; Yen, Z.Z.; Hapke, H.M.; Halamay, D.A. Optimal energy storage sizing and control for wind power applications. IEEE Trans. Sustain. Energy 2011, 2, 69–77. [Google Scholar] [CrossRef]

- Atwa, Y.; El-Saadany, E.F. Optimal allocation of ESS in distribution systems with a high penetration of wind energy. IEEE Trans. Power Syst. 2010, 25, 1815–1822. [Google Scholar] [CrossRef]

- Zhen, L.; Hu, W.; Lu, Q.Y.; Min, Y.; Yuan, F.; Gao, Z. Research on planning and operation model for energy storage system to optimize wind power integration. Proc. CSEE 2014, 34, 2533–2543. [Google Scholar]

- Zheng, Y.; Dong, Z.; Luo, F.; Meng, K.; Qiu, J.; Wong, K.P. Optimal allocation of energy storage system for risk mitigation of DISCOs with high renewable penetrations. IEEE Trans. Power Syst. 2014, 29, 212–220. [Google Scholar] [CrossRef]

- Hu, Z.; Ding, H.; Kong, T. A joint daily operational optimization model for wind power and pumped-storage plant. Autom. Electr. Power Syst. 2012, 36, 36–41. [Google Scholar]

- Zhang, N.; Kang, C.; Kirschen, D.S.; Xia, Q.; Xi, W.; Huang, J.; Zhang, Q. Planning pumped storage capacity for wind power integration. IEEE Trans. Sustain. Energy 2013, 4, 393–401. [Google Scholar] [CrossRef]

- Lyu, Q.; Jiang, H.; Chen, T.; Wang, H.; Lyu, Y.; Li, W. Wind power accommodation by combined heat and power plant with electric boiler and its national economic evaluation. Autom. Electr. Power Syst. 2014, 38, 6–12. [Google Scholar]

- Li, W.; Li, T.; Wang, H.; Dong, J.; Li, Y.; Cui, D.; Ge, W.; Yang, J.; Okoye, M.O. Optimal dispatch model considering environmental cost based on combined heat and power with heat energy storage and demand response. Energies 2019, 12, 817. [Google Scholar] [CrossRef]

- Chen, L.; Xu, F.; Wang, X.; Min, Y.; Ding, M.; Huang, P. Implementation and effect of heat storage in improving wind power accommodation. Proc. CSEE 2015, 35, 4283–4290. [Google Scholar]

- Zhang, N.; Lu, X.; McElroy, M.; Nielsen, C.P.; Chen, X.; Deng, Y.; Kang, C. Reducing curtailment of wind electricity in China by employing electric boilers for heat and pumped hydro for energy storage. Appl. Energy 2016, 184, 987–994. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Kang, C.; O’Malley, M.; Xia, Q.; Bai, J.; Chun, L.; Sun, R.; Wang, W.; Li, H. Increasing the flexibility of combined heat and power for wind power integration in China: Modeling and implications. IEEE Trans. Power Syst. 2015, 30, 1848–1857. [Google Scholar] [CrossRef]

- Meibom, P.; Kiviluoma, J.; Barth, R.; Brand, H.; Weber, C.; Larsen, H.V. Value of electric heat boilers and heat pumps for wind power integration. Wind Energy 2010, 10, 321–337. [Google Scholar] [CrossRef]

- Qadrdan, M.; Abeysekera, M.; Chaudry, M.; Wu, J.; Jenkins, N. Role of power-to-gas in an integrated gas and electricity system in Great Britain. Int. J. Hydrog. Energy 2015, 40, 5763–5775. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, D.; Jia, H.; Wang, W.; Guo, B.; Qu, B.; Fan, M. Research on optimal day-ahead economic dispatching strategy for microgrid considering P2G and multi-source energy storage system. Proc. CSEE 2017, 37, 3067–3077. [Google Scholar]

- Yan, X.; Zhang, X.; Gu, C.; Li, F. Power to gas: Addressing renewable curtailment by converting to hydrogen. Front. Energy 2018, 12, 1–9. [Google Scholar] [CrossRef]

- Tsupari, E.; Janne, K.; Vakkilainen, E. Economic feasibility of power-to-gas integrated with biomass fired CHP plant. J. Energy Storage 2016, 5, 62–69. [Google Scholar] [CrossRef]

- Ursua, A.; Gandia, L.; Sanchis, P. Hydrogen production from water electrolysis: Current status and future trends. Proc. IEEE 2012, 100, 410–426. [Google Scholar] [CrossRef]

- Belderbos, A.; Delarue, E.; D’Haeseleer, W. Possible role of power-to-gas in future energy systems. In Proceedings of the 12th International Conference on the European Energy Market (EEM), Lisbon, Portugal, 19–22 May 2015. [Google Scholar]

- Li, Y.; Liu, W.; Zhao, J. Optimal dispatch of combined electricity-gas-heat energy systems with power-to-gas devices and benefit analysis of wind power accommodation. Power Syst. Technol. 2016, 40, 3680–3689. [Google Scholar]

- Wu, G. Current challenge and perspective of PGM-free cathode catalysts for PEM fuel cells. Front. Energy 2017, 11, 286–298. [Google Scholar] [CrossRef]

- Pandian, M. Efficiency and economics analysis of proton exchange membrane fuel cell. In Proceedings of the 2010 Conference Proceedings IPEC, Singapore, 27–29 October 2011. [Google Scholar]

- Zhang, J.; Cao, P.; Xu, L.; Wang, Y. Modeling nanostructured catalyst layer in PEMFC and catalyst utilization. Front. Chem. Sci. Eng. 2011, 5, 297–302. [Google Scholar] [CrossRef]

- Morteza, N.; Saeed, A. Optimal economic dispatch of FC-CHP based heat and power micro-grids. Appl. Eng. 2017, 114, 756–769. [Google Scholar]

- Pijarski, P.; Wvdra, M.; Kacejko, P. Optimal control of wind power generation. Adv. Sci. Technol. 2018, 12, 9–18. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, N.; You, S. The Dual Control with Consideration of Security Operation and Economic Efficiency for Energy Hub. IEEE Trans. Smart Grid 2019, 14, 1–12. [Google Scholar] [CrossRef]

- Shahbaz, H.; Mohammed, A.; Salman, K.; Hussain, A.; Saqib, M.A. Implementation and comparison of particle swarm optimization and genetic algorithm techniques in combined economic emission dispatch of an independent power Plant. Energies 2019, 12, 2037. [Google Scholar]

- Yazdani, A.; Jayabarathi, T.; Ramesh, V.; Raghunathan, T. Combined heat and power economic dispatch problem using firefly algorithm. Front. Energy 2013, 7, 133–139. [Google Scholar] [CrossRef]

- Wu, X.; Wang, X.; Wang, J.; Bie, Z. Economic generation scheduling of a microgrid using mixed integer programming. Proc. CSEE 2013, 33, 1–9. [Google Scholar]

| Parameter | Value | Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|---|---|

| (kW) | 600 | (kW) | 800 | (kW·h) | 400 | (kW·h) | 1000 |

| 0.98 | 0.98 | 0.002 | (kW) | 1000 | |||

| 0.3 | 1.8 | 0.001 | (kW) | 1500 | |||

| 0.89 | 0.7 | 0.65 | (kW) | 600 | |||

| (kW) | 700 | (yuan/kg) | 0.031 | (kg/(kW·h)) | 0.23 | (kg/(kW·h)) | 0.972 |

| (kW) | 1000 | (kW) | −200 | (kWh/m3) | 9.89 | - | - |

| Scene | GT | HB | FC | P2G | EB | WT | HS |

|---|---|---|---|---|---|---|---|

| Scenario 1 | √ | √ | × | × | × | √ | √ |

| Scenario 2 | √ | √ | × | × | √ | √ | √ |

| Scenario 3 | √ | √ | √ | √ | × | √ | √ |

| Time/h | Scenario 1 | Scenario 2 | Scenario 3 | Time/h | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|---|---|---|---|

| 0 | 399.82 | 251.60 | 200.30 | 12 | 92.59 | 87.65 | 114.96 |

| 1 | 5.74 | 117.25 | 159.35 | 13 | 36.65 | 4.21 | 44.90 |

| 2 | 15.23 | 107.12 | 112.35 | 14 | 25.34 | 0.22 | 29.95 |

| 3 | 22.15 | 98.87 | 104.91 | 15 | 60.33 | 163.52 | 193.86 |

| 4 | 26.56 | 69.32 | 6.38 | 16 | 29.59 | 207.46 | 243.55 |

| 5 | 40.06 | 41.59 | 90.17 | 17 | 392.54 | 396.82 | 364.17 |

| 6 | 146.36 | 132.04 | 151.77 | 18 | 379.32 | 398.13 | 369.49 |

| 7 | 166.59 | 217.71 | 226.85 | 19 | 233.49 | 251.02 | 263.82 |

| 8 | 263.22 | 266.75 | 284.13 | 20 | 154.25 | 179.45 | 213.81 |

| 9 | 138.20 | 127.54 | 144.81 | 21 | 176.77 | 182.79 | 235.13 |

| 10 | 56.23 | 75.37 | 69.72 | 22 | 201.69 | 180.43 | 225.79 |

| 11 | 399.82 | 251.60 | 200.30 | 23 | 178.31 | 203.51 | 228.11 |

| Scene | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|

| Cost of electricity purchase/yuan | 10,900 | 11,518 | 4988.4 |

| Cost of gas purchase/yuan | 15,100 | 13,518 | 16,776 |

| Environmental costs/yuan | 739.8541 | 733.8270 | 594.9098 |

| Total cost/yuan | 26,740.8541 | 25,769.827 | 22,359.3098 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Yin, Z.; Yang, D.; Zhou, B. A New Wind Power Accommodation Strategy for Combined Heat and Power System Based on Bi-Directional Conversion. Energies 2019, 12, 2458. https://doi.org/10.3390/en12132458

Luo Y, Yin Z, Yang D, Zhou B. A New Wind Power Accommodation Strategy for Combined Heat and Power System Based on Bi-Directional Conversion. Energies. 2019; 12(13):2458. https://doi.org/10.3390/en12132458

Chicago/Turabian StyleLuo, Yanhong, Zhenxing Yin, Dongsheng Yang, and Bowen Zhou. 2019. "A New Wind Power Accommodation Strategy for Combined Heat and Power System Based on Bi-Directional Conversion" Energies 12, no. 13: 2458. https://doi.org/10.3390/en12132458