Effect of Polycyclic Compounds Fillers on Electrical Treeing Characteristics in XLPE with DC-Impulse Voltage

Abstract

:1. Introduction

2. Experiment

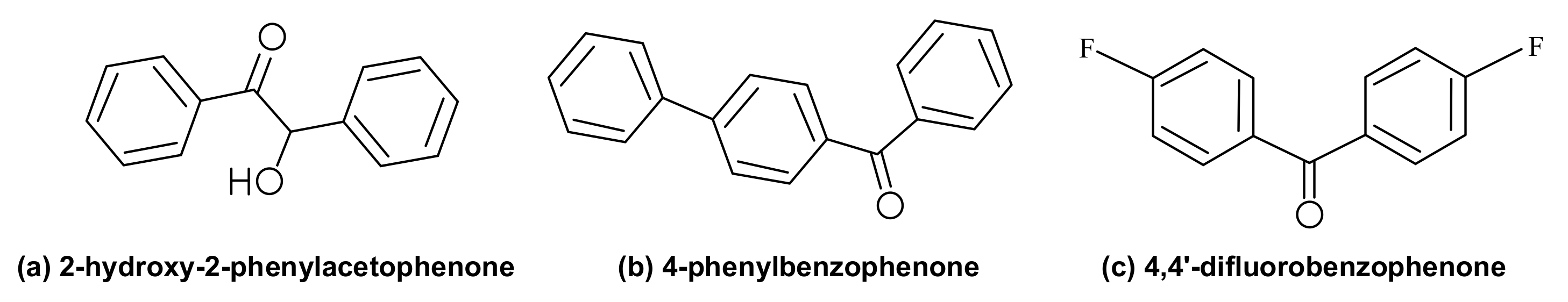

2.1. Test Samples and Electrode Arrangement

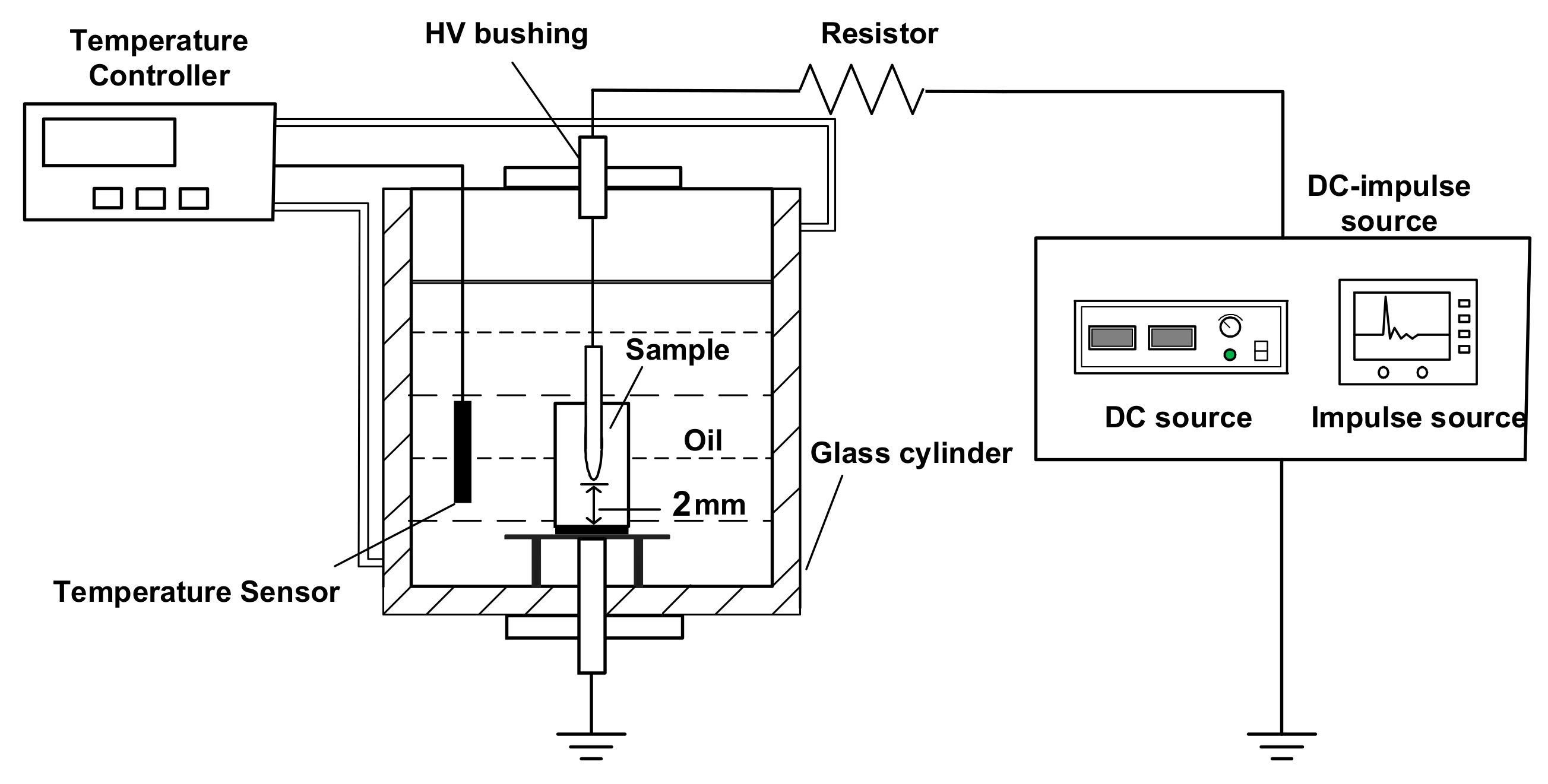

2.2. Experimental Apparatus and Procedure

3. Results

3.1. Electrical Tree Degradation

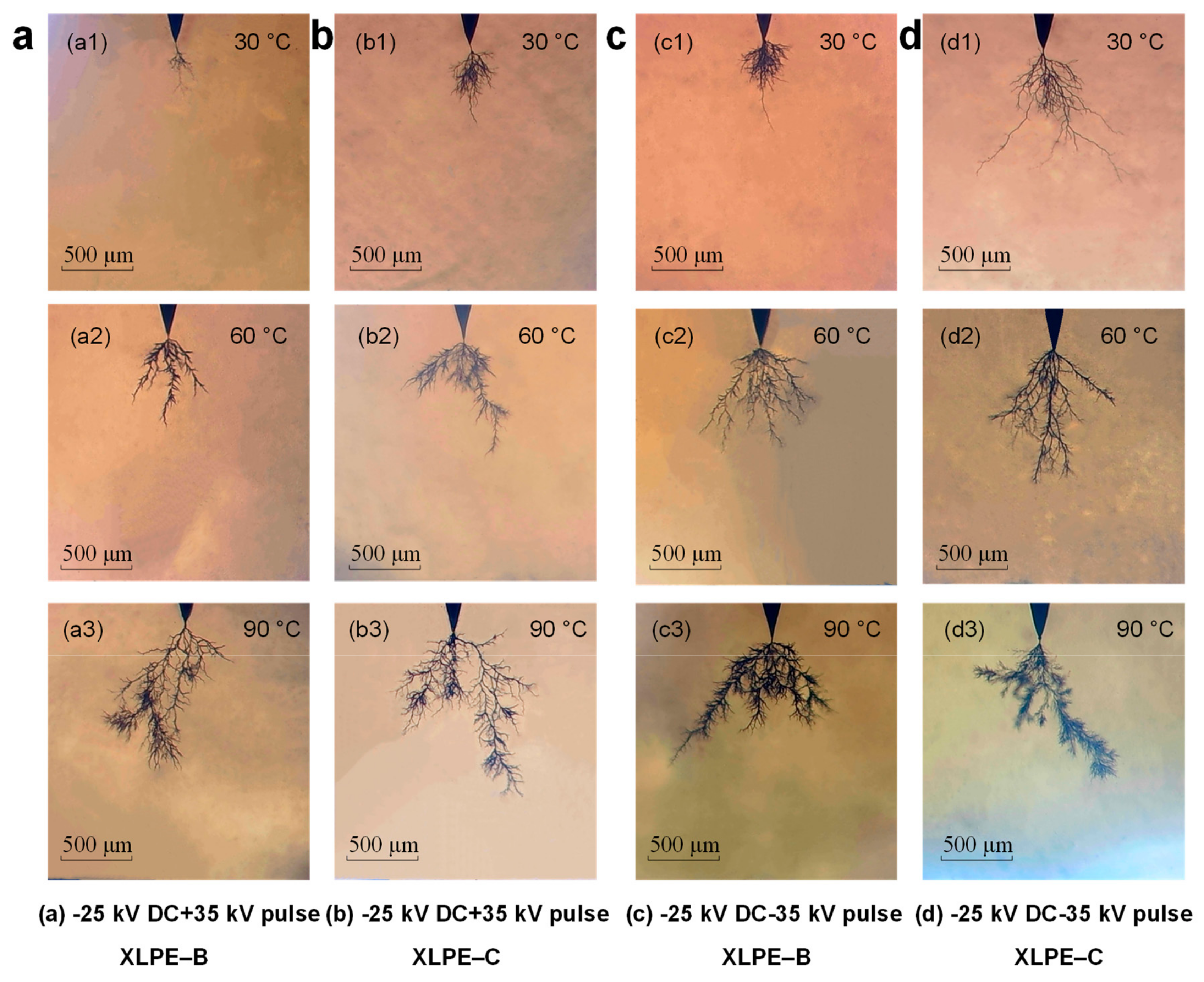

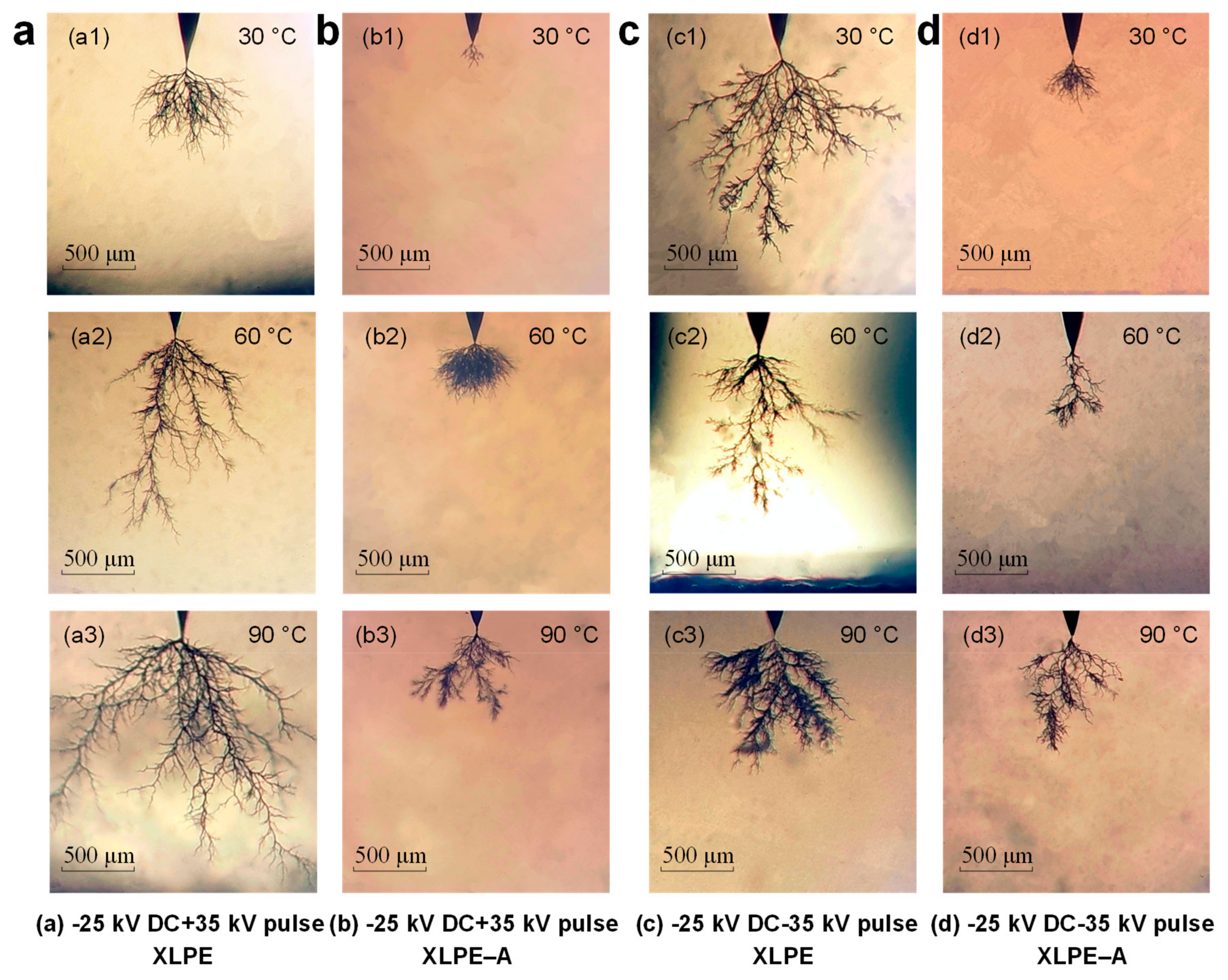

3.1.1. Tree Structure

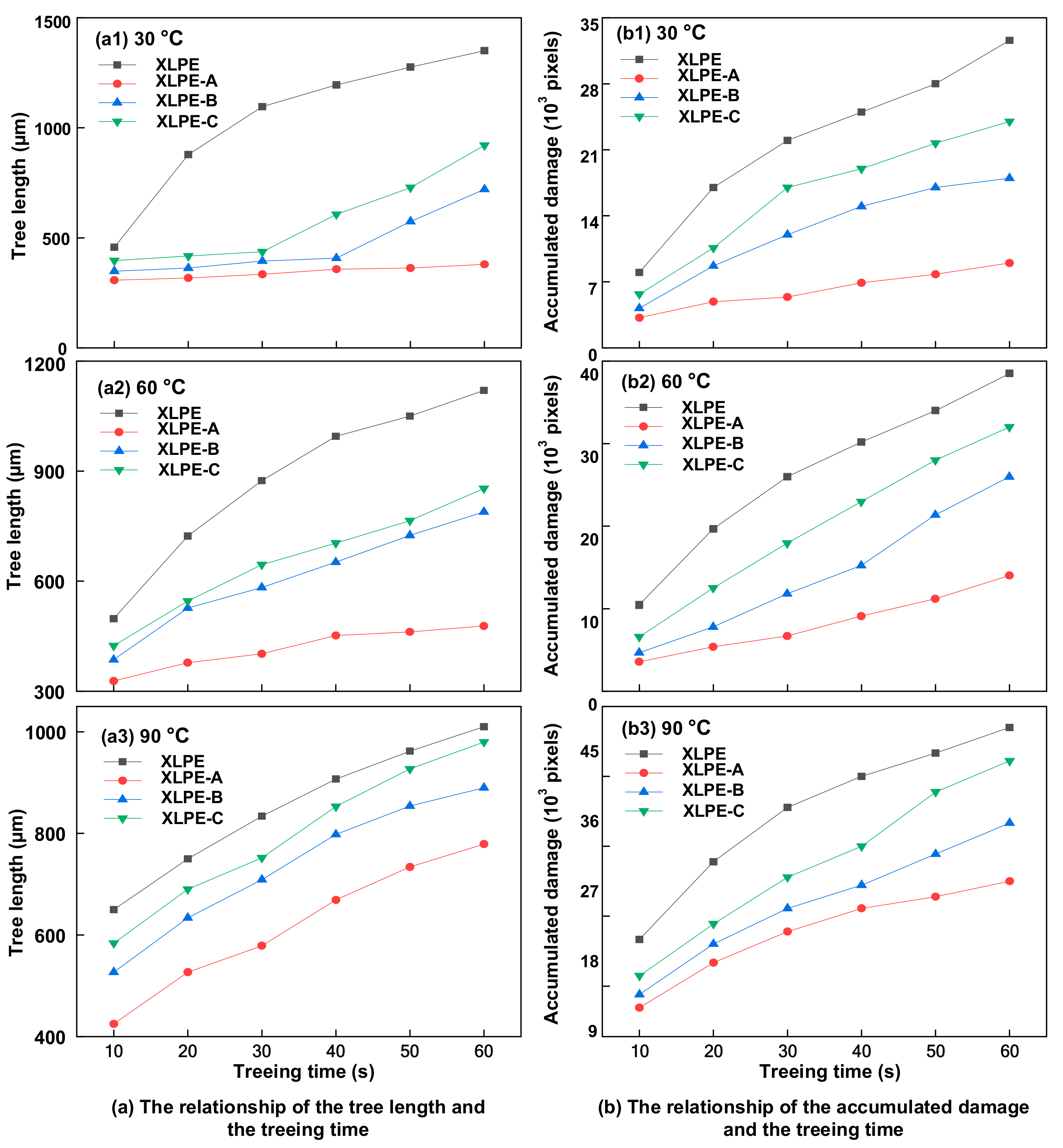

3.1.2. Electrical Treeing Characteristics with Opposite Polarity DC-Impulse Voltage

3.1.3. Electrical Treeing Characteristics with the Same Polarity DC-Impulse Voltage

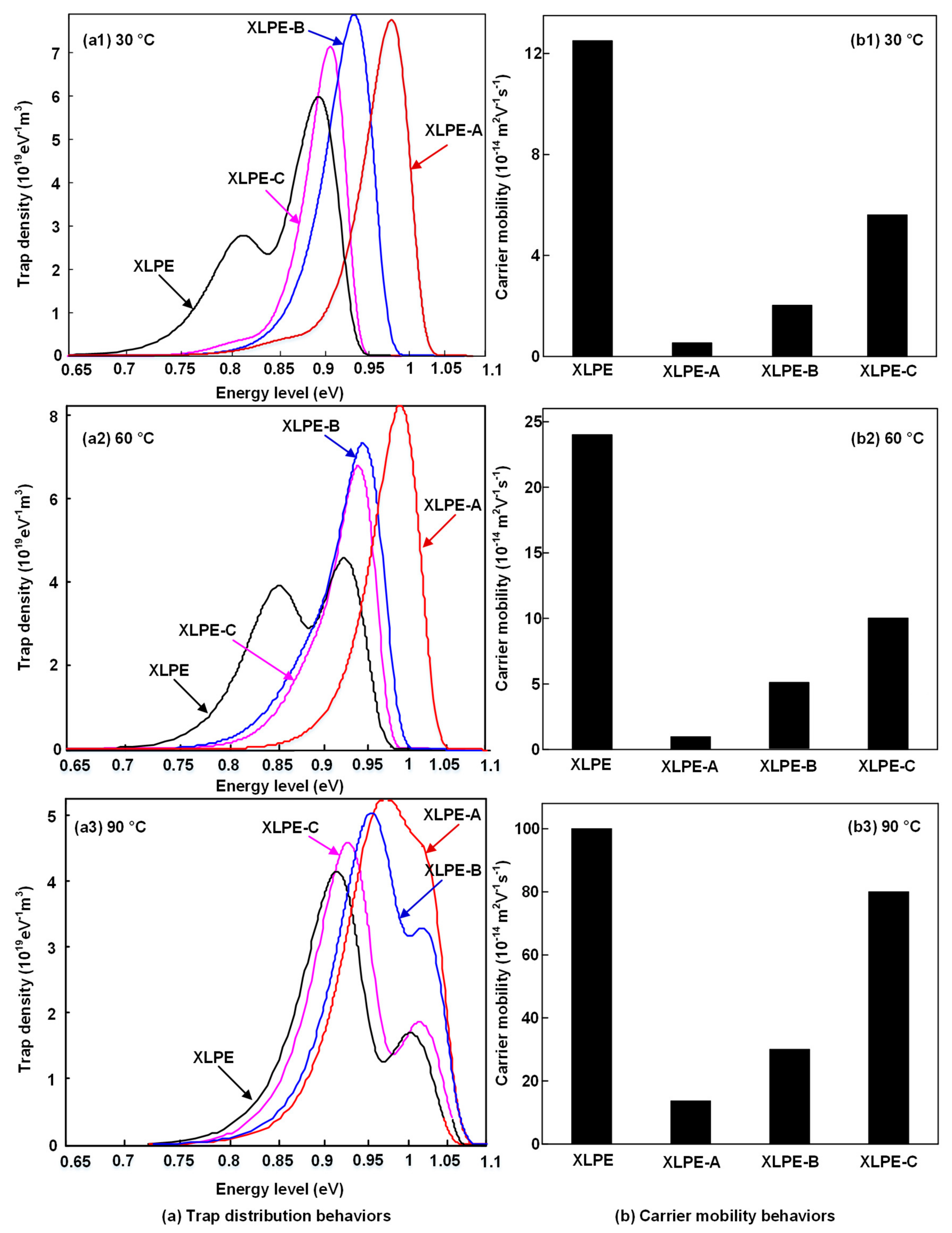

3.2. Trap Distribution and Carrier Mobility Behaviors

4. Discussion

4.1. Mechanism of Polycyclic Compounds Fillers Inhibiting Electrical Treeing Growth

4.2. Electrical Tree Dependence on Polycyclic Compounds with DC-Impulse Voltage

4.3. Electrical Tree Dependence on Polycyclic Compounds at Different Temperatures

5. Conclusions

- (1)

- The addition of the polycyclic compound changes the electrical tree structure, which is related to the type of the polycyclic compound, the temperature and the relative polarity of DC and impulse voltage.

- (2)

- The electrical treeing characteristics are related to the type of polycyclic compounds. The three type of polycyclic compounds all inhibit the length and accumulated damage of the electrical tree with DC-impulse voltages at 30, 60, and 90 °C. The energy level and trap density are the largest in XLPE-A composite, decreasing the charge transport, and leading to the suppression of the electrical treeing growth, improving the lifetime of XLPE. The polycyclic compound A has great application prospects in HVDC cables.

- (3)

- The effect of the polycyclic compound is related to the relative polarity of the applied DC-impulse voltage. Although three types of polycyclic compounds can suppress the electrical tree propagation at different DC-impulse voltages, the suppression effect with the same polarity is worse than with the opposite polarity, which is related to the difference in the mechanism of electrical tree growth with different impulse polarities.

- (4)

- The effect of the polycyclic compound is related to the temperature. With the temperature increasing, the suppression effect to electrical treeing growth of polycyclic compounds decreases. However, the three types of polycyclic compounds can still suppress the electrical treeing growth at 30, 60, and 90 °C, which can improve the lifetime of XLPE cables.

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A

References

- Danikas, M.G.; Tanaka, T. Nanocomposites-a review of electrical treeing and breakdown. IEEE Trans. Dielectr. Electr. Insul. 2009, 25, 19–24. [Google Scholar] [CrossRef]

- Saito, Y.; Fukuzawa, M.; Nakamura, H. On the mechanism of tree initiation. IEEE Trans. Electr. Insul. 1977, 1, 31–34. [Google Scholar] [CrossRef]

- Han, T.; Du, B.X.; Ma, T.T.; Wang, F.Y.; Gao, Y.; Lei, Z.P.; Li, C.Y. Electrical tree in HTV silicone rubber with temperature gradient under repetitive pulse voltage. IEEE Access 2019, 7, 41250–41260. [Google Scholar] [CrossRef]

- Jiang, C.; Hou, Y.X.; Yu, J.Z.; Wei, Z.J.; Chen, X.R.; Zhou, H. Electrical treeing of polyethylene blends with/without voltage stabilizer. In Proceedings of the IEEE 2018 12th International Conference on the Properties and Applications of Dielectric Materials, Xi’an, China, 20–24 May 2018; pp. 266–269. [Google Scholar]

- Kisin, S.; Doelder, J.D.; Eaton, R.F. Quantum mechanical criteria for choosing appropriate voltage stabilization additives for polyethylene. Polym. Degrad. Stab. 2009, 94, 171–175. [Google Scholar] [CrossRef]

- Han, T.; Du, B.X.; Su, J.G.; Gao, Y.; Xing, Y.Q.; Fang, S.C.; Li, C.Y.; Lei, Z.P. Inhibition effect of graphene nanoplatelets on electrical degradation in silicone rubber. Polymers 2019, 11, 968. [Google Scholar] [CrossRef] [PubMed]

- Yamano, Y. Roles of polycyclic compounds in increasing breakdown strength of LDPE film. IEEE Trans. Electr. Insul. 2006, 13, 773–781. [Google Scholar] [CrossRef]

- Jarvid, M.; Johansson, A.; Kroon, R.; Bjuggren, J.M.; Wutzel, H.; Englund, V.; Gubanski, S.; Andersson, M.R.; Muller, C. A new application area for fullerenes: Voltage stabilizers for power cable insulation. Adv. Mater. 2015, 27, 897–902. [Google Scholar] [CrossRef]

- Vincent, G.A. Anti-Treeing Additives. U.S. Patent 4,840,983, 20 June 1989. [Google Scholar]

- Jarvid, M.; Johansson, A.; Bjuggren, J.M.; Wutzel, H.; Englund, V.; Gubanski, S.; Muller, C.; Andersson, M.R. Tailored side-chain architecture of benzil voltage stabilizers for enhanced dielectric strength of cross-linked polyethylene. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 1047–1054. [Google Scholar] [CrossRef]

- Opydo, W.; Dobrzycki, A. Detection of electric tree of solid dielectrics with the method of acoustic emission. Electr. Eng. 2012, 94, 37–48. [Google Scholar] [CrossRef]

- Dobrzycki, A.; Mikulski, S.; Opydo, W. Using ANN and SVM for the detection of acoustic emission signals accompanying epoxy resin electrical treeing. Appl. Sci. 2019, 9, 1523. [Google Scholar] [CrossRef]

- Schurch, R.; Rowland, S.M.; Bradley, R.S.; Withers, P.J. Imaging and analysis techniques for electrical trees using X-ray computed tomography. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 53–63. [Google Scholar] [CrossRef]

- Li, S.T.; Min, D.M.; Wang, W.W.; Chen, G. Linking traps to dielectric breakdown through charge dynamics for polymer nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2777–2785. [Google Scholar] [CrossRef]

- Tanaka, Y.; Ohnuma, N.; Katsunami, K. Effects of crystallinity and electron mean-free-path on dielectric strength of low-density polyethylene. IEEE Trans. Dielectr. Electr. Insul. 1991, 26, 258–265. [Google Scholar] [CrossRef]

- Shimizu, N.; Laurent, C. Electrical tree initiation. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 651–659. [Google Scholar] [CrossRef]

- Kao, K.C. New theory of electrical discharge and breakdown in low-mobility condensed insulators. J. Appl. Phys. 1984, 55, 752–755. [Google Scholar] [CrossRef]

- Wang, W.W.; Min, D.M.; Li, S.T. Understanding the conduction and breakdown properties of polyethylene nanodielectrics: Effect of deep traps. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 564–572. [Google Scholar] [CrossRef]

- Hingorani, N.G. Transient overvoltage on a bipolar HVDC overhead line caused by DC line faults. IEEE Trans. Power Appar. Syst. 1970, PAS-89, 592–610. [Google Scholar] [CrossRef]

- Lu, W.X.; Ooi, B.T. DC overvoltage control during loss of converter in multiterminal voltage-source converter-based HVDC (M-VSC-HVDC). IEEE Trans. Power Deliv. 2003, 18, 915–920. [Google Scholar]

- Zhou, C.H.; Wang, P. A study of temporary overvoltage at HVDC rectifier stations. In Proceedings of the 2011 IEEE Electrical Power and Energy Conference, Winnipeg, MB, Canada, 3–5 October 2011; pp. 211–215. [Google Scholar]

- Hagiwara, M.; Akagi, H. Control and experiment of pulsewidth-modulated modular multilevel converters. IEEE Trans. Power Electron. 2009, 24, 1737–1746. [Google Scholar] [CrossRef]

- Murata, Y.; Katakai, S.; Kanaoka, M. Impulse breakdown superposed on ac voltage in XLPE cable insulation. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 361–365. [Google Scholar] [CrossRef]

- Du, B.X.; Su, J.G.; Xue, J.S. Tree growth characteristics of epoxy resin in LN2 under DC superimposed pulse voltage. IEEE Trans. Appl. Superconduct. 2018, 28, 1–5. [Google Scholar] [CrossRef]

- Zhu, L.W.; Du, B.X.; Su, J.G.; Han, T.; Danikas, M.G. Electrical treeing initiation and breakdown phenomenon in polypropylene under DC and pulse combined voltages. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 202–210. [Google Scholar] [CrossRef]

- Bozzo, R.; Gemme, C.; Guastavino, F. The effects of temperature on the tree growth phenomena and relevant PD. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Virginia Beach, VA, USA, 22–25 October 1995; pp. 69–72. [Google Scholar]

- Shimizu, N.; Shibata, Y.; Ito, K.; Imai, K.; Nawata, M. Electrical tree at high temperature in xlpe and effect of oxygen. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Victoria, BC, Canada, 15–18 October 2000; pp. 329–332. [Google Scholar]

- Wang, Y.; Li, G.; Wu, J. Effect of temperature on space charge detrapping and periodic grounded DC tree in cross-linked polyethylene. IEEE Trans. Dielectr. Electr. Insul. 2017, 23, 3704–3711. [Google Scholar] [CrossRef]

- Du, B.X.; Zhu, L.W.; Han, T. Effect of ambient temperature on electrical treeing and breakdown phenomenon of polypropylene with repetitive pulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2216–2224. [Google Scholar] [CrossRef]

- Du, B.X.; Zhu, L.W.; Han, T. Effect of low temperature on electrical treeing of polypropylene with repetitive pulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1915–1923. [Google Scholar] [CrossRef]

- Han, T.; Du, B.X.; Su, J.G. Electrical tree initiation and growth in silicone rubber under combined dc-pulse voltage. Energies 2018, 11, 764. [Google Scholar] [CrossRef]

- Chen, G.; Tham, C. Electrical treeing characteristics in XLPE power cable insulation in frequency range between 20 and 500 Hz. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 179–188. [Google Scholar] [CrossRef] [Green Version]

- Zhou, F.S.; Li, J.Y.; Liu, M.X.; Min, D.M.; Li, S.T.; Xia, R. Characterizing traps distribution in LDPE and HDPE through isothermal surface potential decay method. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1174–1182. [Google Scholar] [CrossRef]

- Li, J.Y.; Zhou, F.S.; Min, D.M.; Li, S.T.; Xia, R. The energy distribution of trapped charges in polymers based on isothermal surface potential decay model. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1723–1732. [Google Scholar] [CrossRef]

- Zhou, F.S.; Li, J.Y.; Yan, Z.M.; Zhang, X.; Yang, Y.Q.; Liu, M.X.; Min, D.M.; Li, S.T. Investigation of charge trapping and detrapping dynamics in LDPE, HDPE and XLPE. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3742–3751. [Google Scholar] [CrossRef]

- Chen, X.R.; Hu, L.B.; Xu, Y.; Cao, X.L.; Gubanski, S.M. Investigation of temperature effect on electrical trees in XLPE cable insulation. In Proceedings of the Electrical Insulation and Dielectric Phenomena, Montreal, QC, Canada, 14–17 October 2012; pp. 612–615. [Google Scholar]

- Liu, Y.; Cao, X.L. Electrical tree initiation in XLPE cable insulation by application of DC and impulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1691–1698. [Google Scholar]

- Ashcraft, A.C.; Eichhorn, R.M.; Shaw, R.G. Laboratory studies of treeing in solid dielectrics and voltage stabilization of polyethylene. In Proceedings of the IEEE International Conference on Electrical Insulation, Montreal, QC, Canada, 14–16 June 2016; pp. 213–218. [Google Scholar]

- Du, B.X.; Han, C.L.; Li, J. Effect of voltage stabilizers on the space charge behavior of XLPE for HVDC cable application. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 34–42. [Google Scholar] [CrossRef]

- Serra, S.; Tosatti, E.; Iarlori, S.; Scandolo, S.; Santoro, G. Interchain electron states in polyethylene. Phys. Rev. B 2000, 62, 4389–4393. [Google Scholar] [CrossRef]

- Du, B.X.; Su, J.G.; Tian, M.; Han, T.; Li, J. Understanding trap effects on electrical treeing phenomena in EPDM/POSS composites. Sci. Rep. 2018, 8, 8481–8495. [Google Scholar] [CrossRef]

- Zheng, X.Q.; Chen, G. Propagation Mechanism of Electrical Tree in XLPE Cable Insulation by Investigating a Double Electrical Tree Structure. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 800–807. [Google Scholar] [CrossRef]

- Bamji, S.S.; Bulinski, A.T.; Densley, R.J. Degradation mechanism at XLPE/semicon interface subjected to high electrical stress. IEEE Trans. Dielectr. Electr. Insul. 1991, 26, 278–284. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, H.; Liu, P.; Peng, Z.R. Space charge characteristics of epoxy-based nanocomposites filled with graphene oxide. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Toronto, ON, Canada, 16–19 October 2016; pp. 691–694. [Google Scholar]

- Zhao, L.; Su, J.C.; Pan, Y.F.; Li, R.; Zheng, L.; Zhang, Y.; Wu, X.L.; Zhao, P.C. Calculation on heating effect due to void discharge in polymers in cumulative breakdown process. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3113–3121. [Google Scholar] [CrossRef]

| DC (kV) | Pulse (kV) | Temperature (°C) | XLPE | XLPE-A | XLPE-B | XLPE-C |

|---|---|---|---|---|---|---|

| −25 | +35 | 30 | Branch | Bush | Bush-branch | Bush-branch |

| 60 | Branch | Bush | Branch | Branch | ||

| 90 | Branch | Bush-branch | Branch | Branch | ||

| −35 | 30 | Branch | Bush | Bush-branch | Bush-branch | |

| 60 | Branch | Branch | Branch | Branch | ||

| 90 | Branch | Branch | Branch | Branch |

| Type | Temperature (°C) | Shallow Trap Depth / (eV) | Deep Trap Depth / (eV) |

|---|---|---|---|

| XLPE | 30 | 0.81 | 0.88 |

| 60 | 0.85 | 0.91 | |

| 90 | 0.91 | 1 | |

| XLPE-A | 30 | / | 0.98 |

| 60 | / | 0.97 | |

| 90 | 0.98 | 1.02 | |

| XLPE-B | 30 | / | 0.93 |

| 60 | / | 0.94 | |

| 90 | 0.95 | 1.02 | |

| XLPE-C | 30 | / | 0.9 |

| 60 | / | 0.93 | |

| 90 | 0.92 | 1.01 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, L.; Du, B.; Li, H.; Hou, K. Effect of Polycyclic Compounds Fillers on Electrical Treeing Characteristics in XLPE with DC-Impulse Voltage. Energies 2019, 12, 2767. https://doi.org/10.3390/en12142767

Zhu L, Du B, Li H, Hou K. Effect of Polycyclic Compounds Fillers on Electrical Treeing Characteristics in XLPE with DC-Impulse Voltage. Energies. 2019; 12(14):2767. https://doi.org/10.3390/en12142767

Chicago/Turabian StyleZhu, Lewei, Boxue Du, Hongna Li, and Kai Hou. 2019. "Effect of Polycyclic Compounds Fillers on Electrical Treeing Characteristics in XLPE with DC-Impulse Voltage" Energies 12, no. 14: 2767. https://doi.org/10.3390/en12142767