Circuit Topology Analysis for LED Lighting and its Formulation Development

Abstract

:1. Introduction

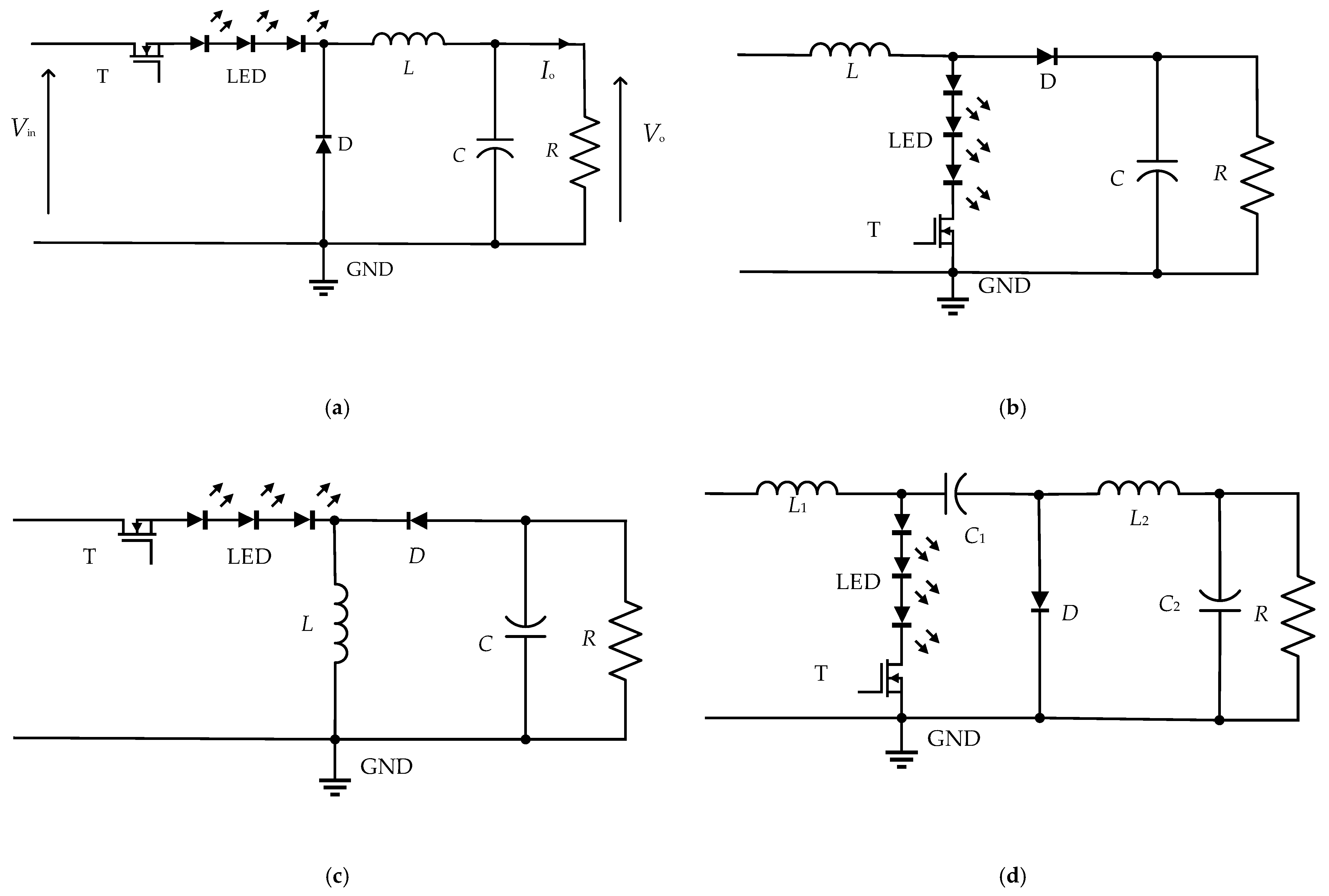

2. LED Driving Circuit Topologies

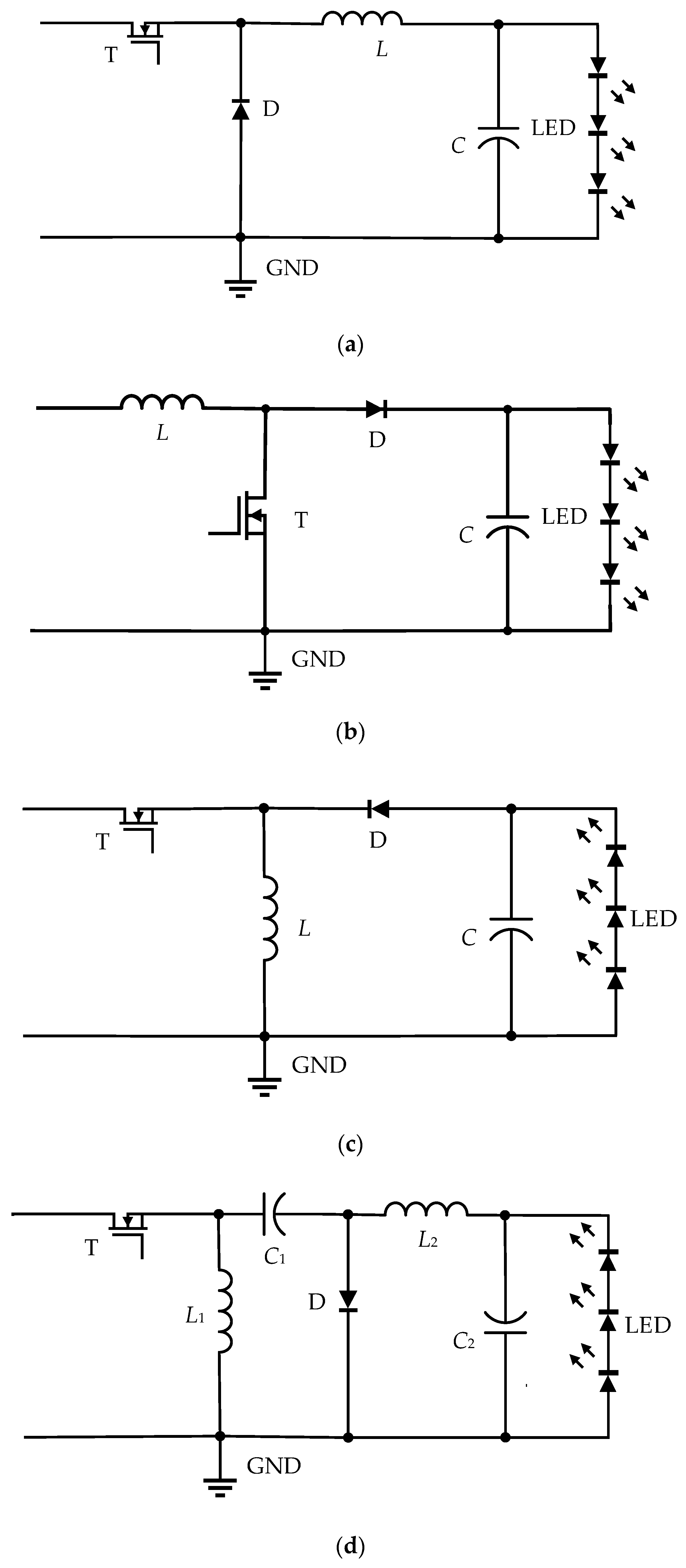

2.1. Basic Topology

2.2. LEDs in Diode Path

2.2.1. LED Buck Converter

2.2.2. LED Boost Converter

2.2.3. LED Buck–Boost Converter

2.2.4. LED Ćuk Converter

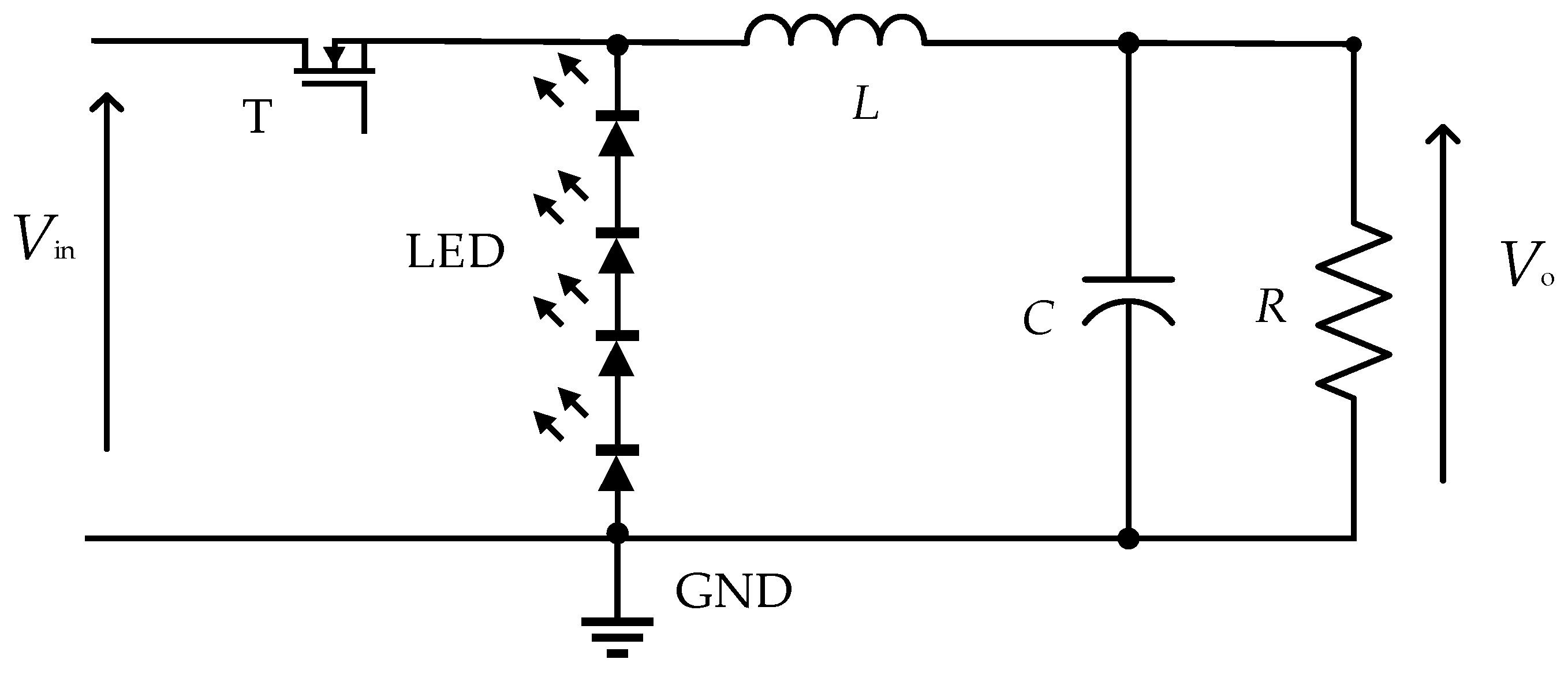

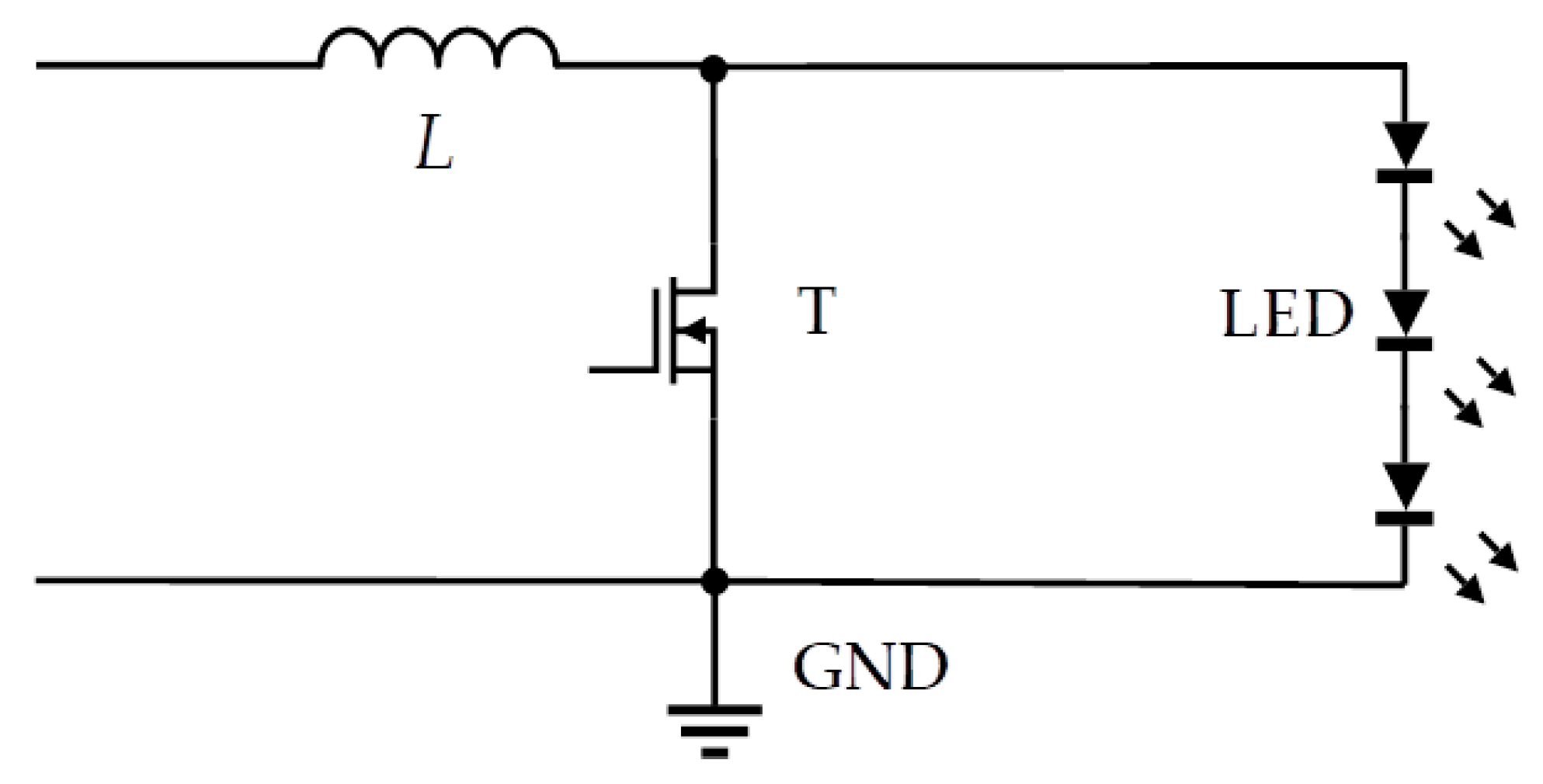

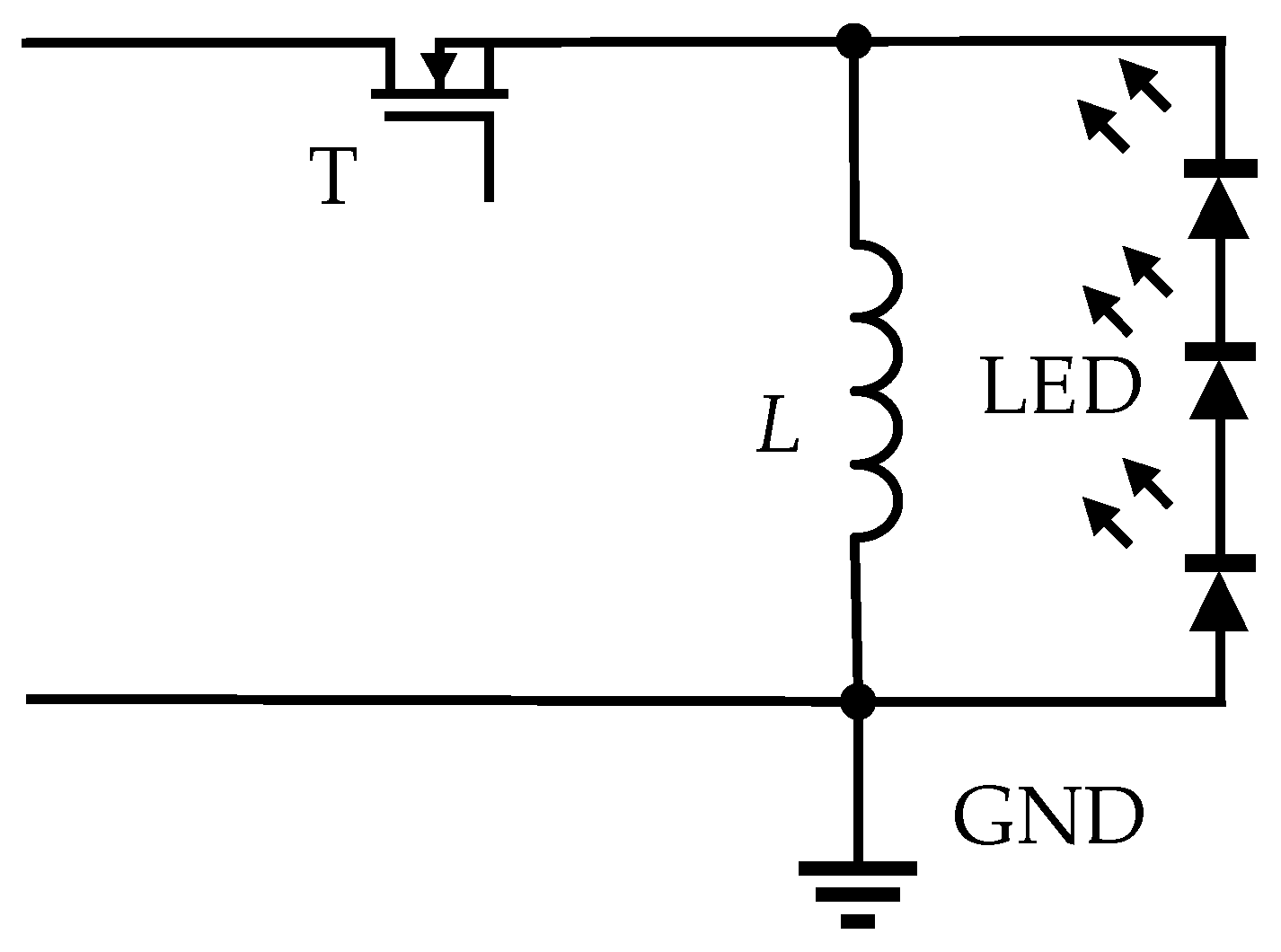

2.3. LEDs in Transistor Path

2.3.1. LED Buck Converter

2.3.2. LED Boost Converter

2.3.3. LED Buck–Boost Converter

2.3.4. LED Ćuk Converter

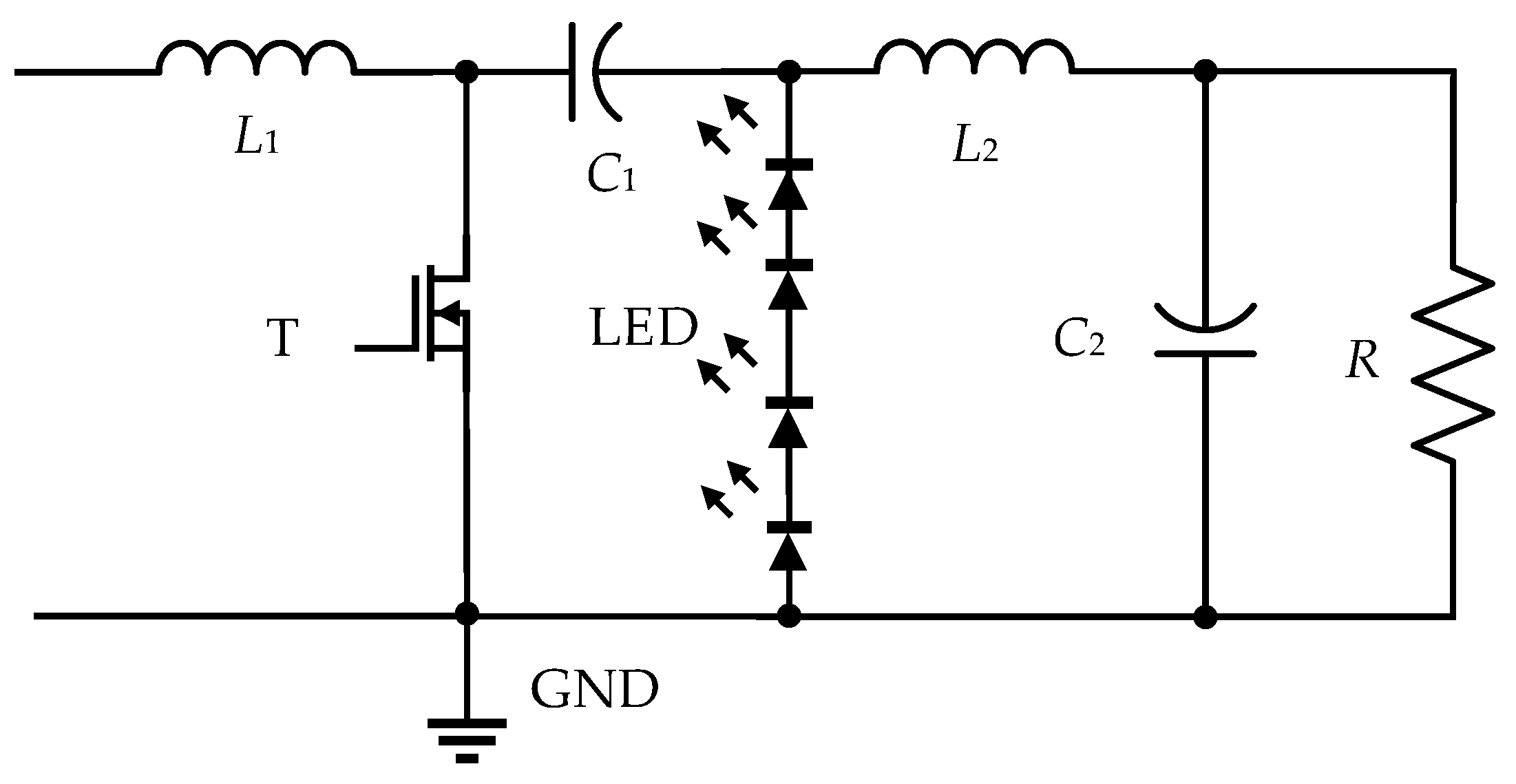

2.4. LEDs in Inductor Path

2.4.1. Buck Converter

2.4.2. Boost Converter

2.4.3. Buck–Boost Converter

2.4.4. Ćuk Converter

2.5. LED Path in General

2.5.1. Buck Converter

2.5.2. Boost Converter

2.5.3. Buck–Boost Converter

2.5.4. Ćuk Converter

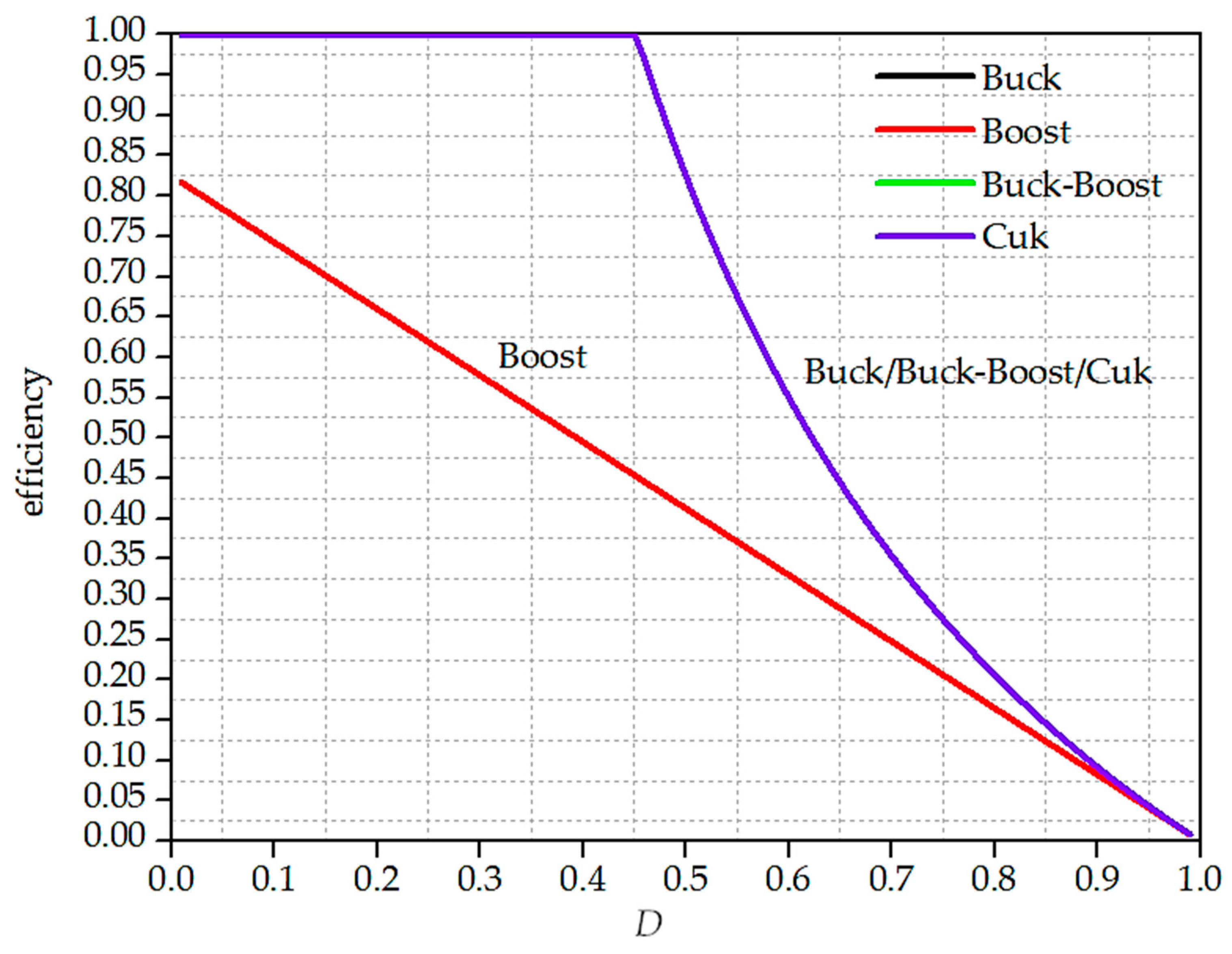

3. Comparison of Circuit Topology

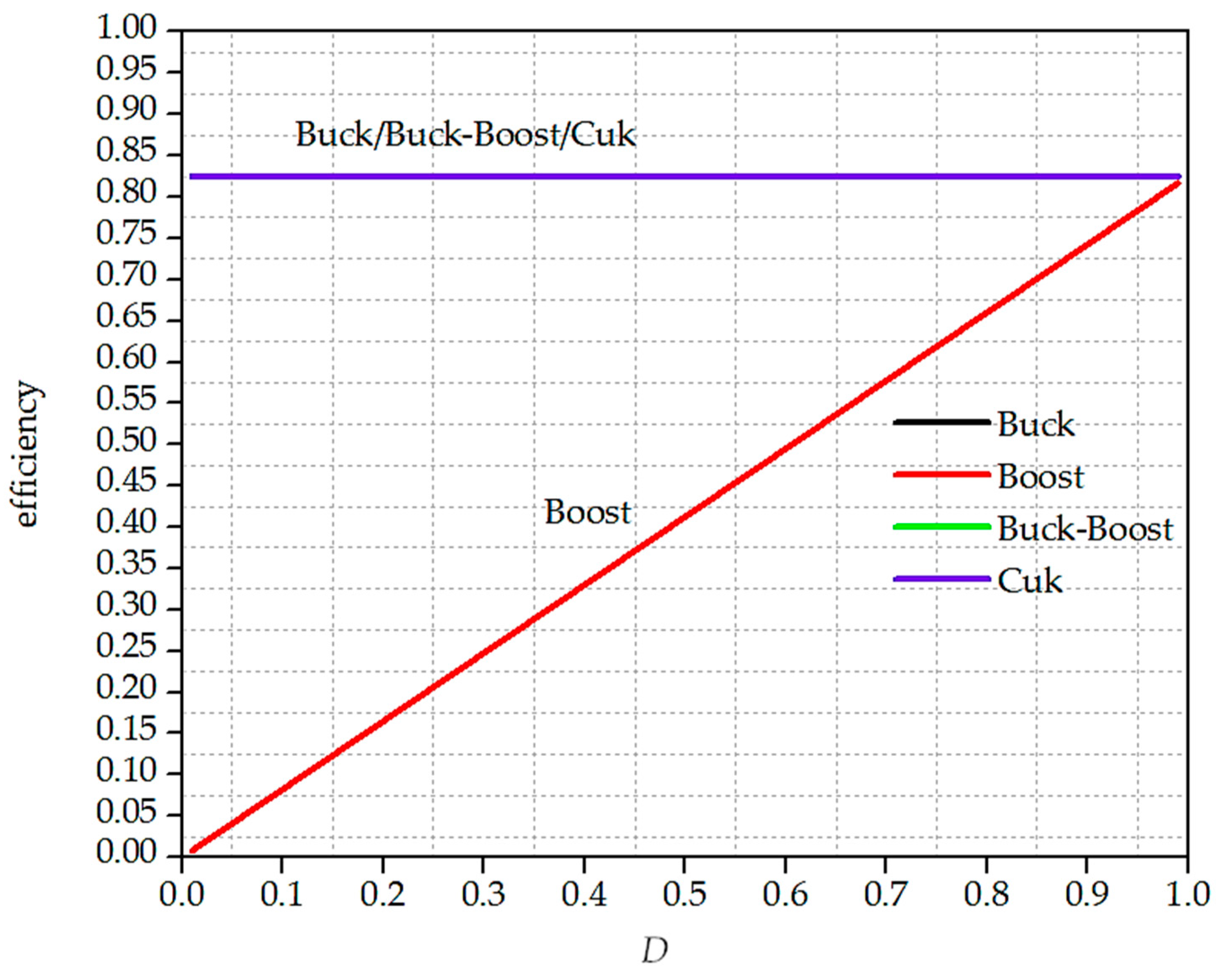

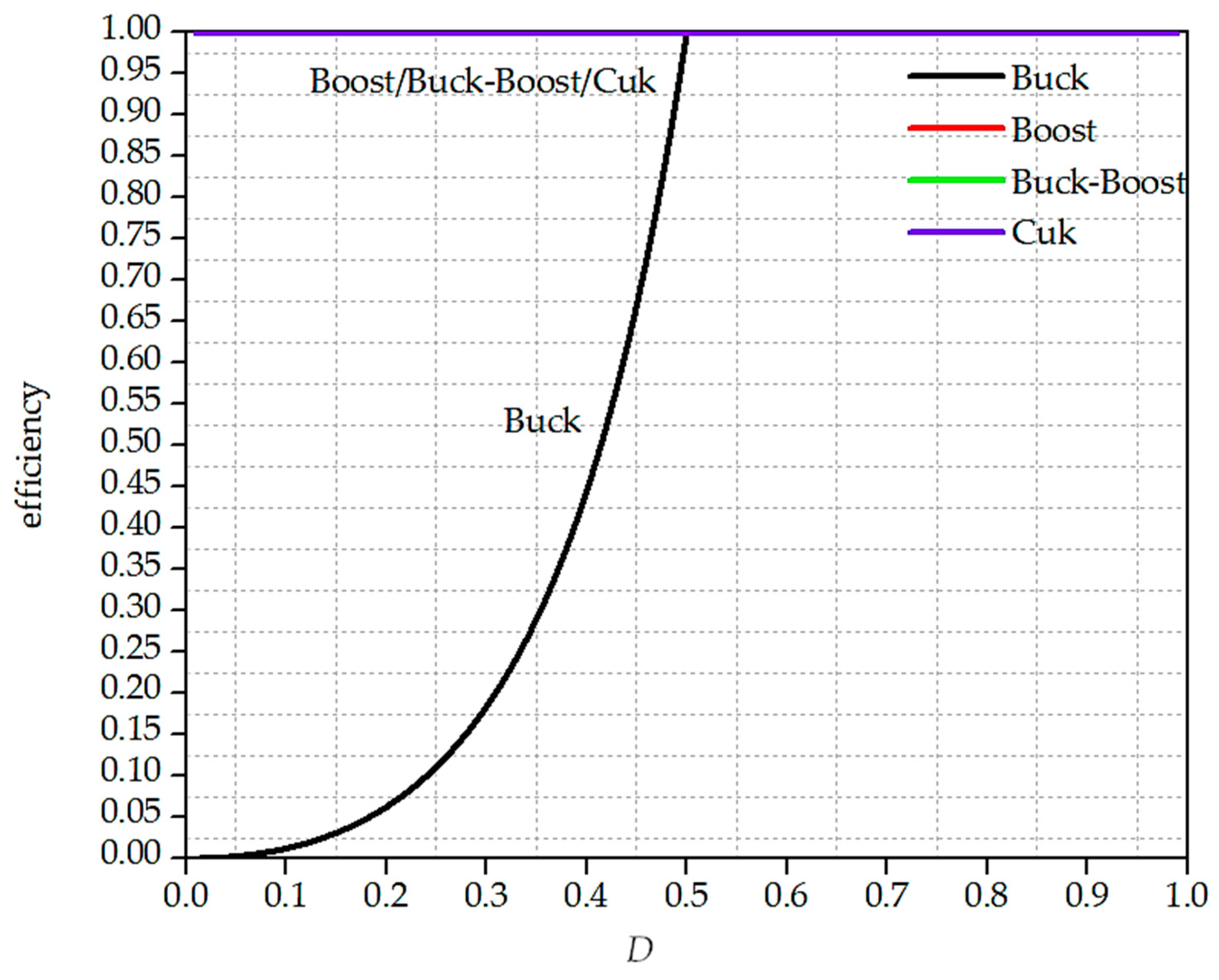

3.1. Efficiency Analysis

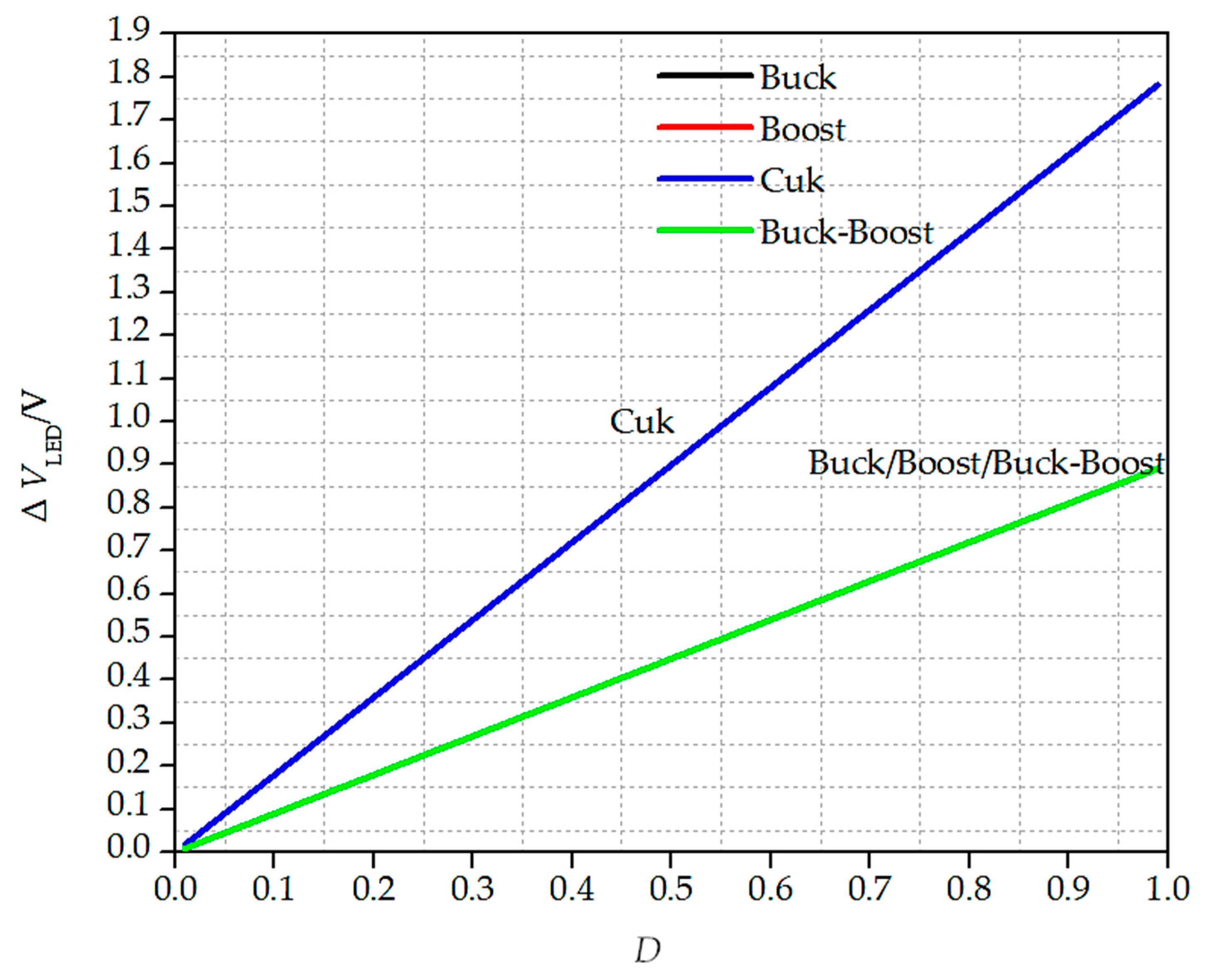

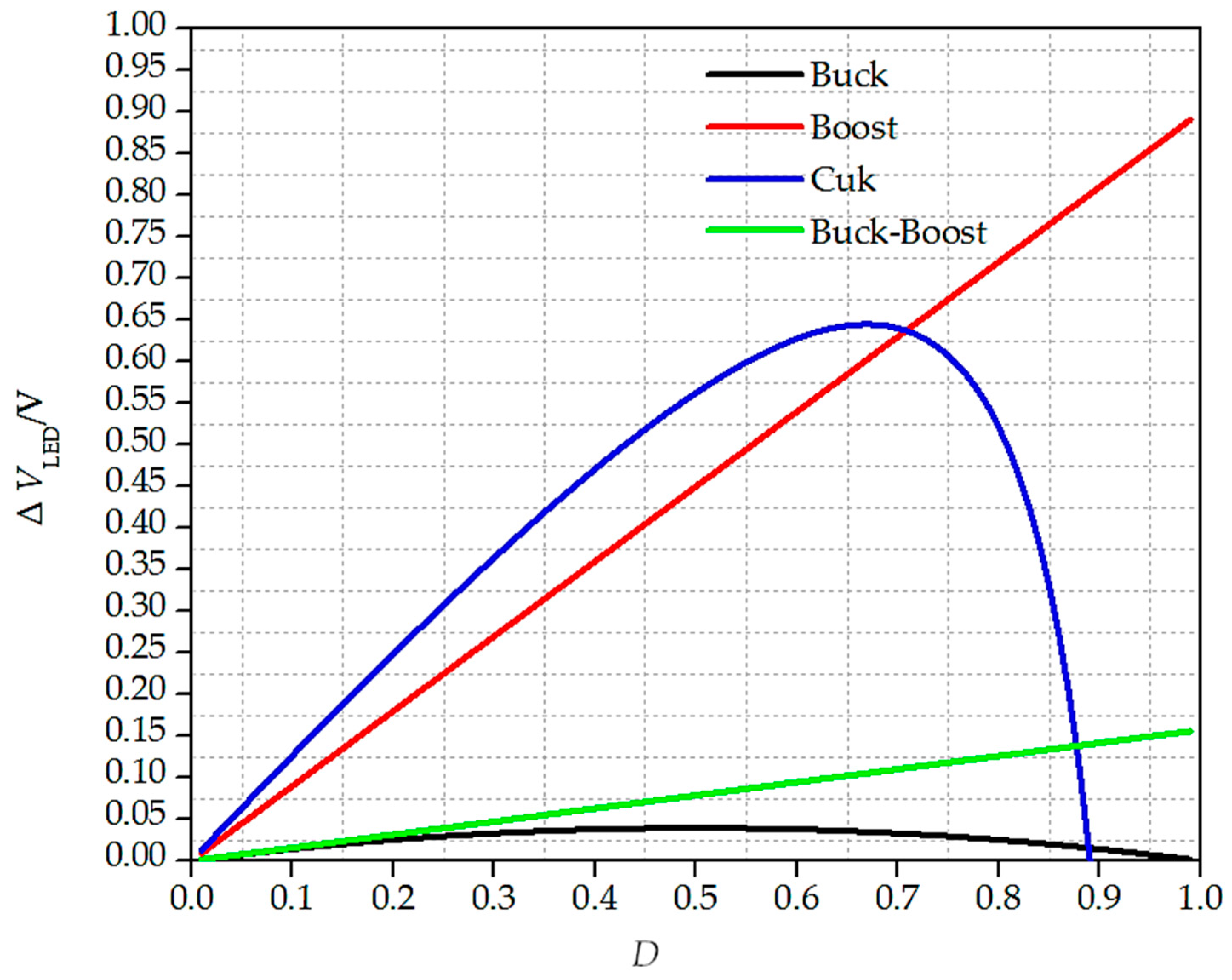

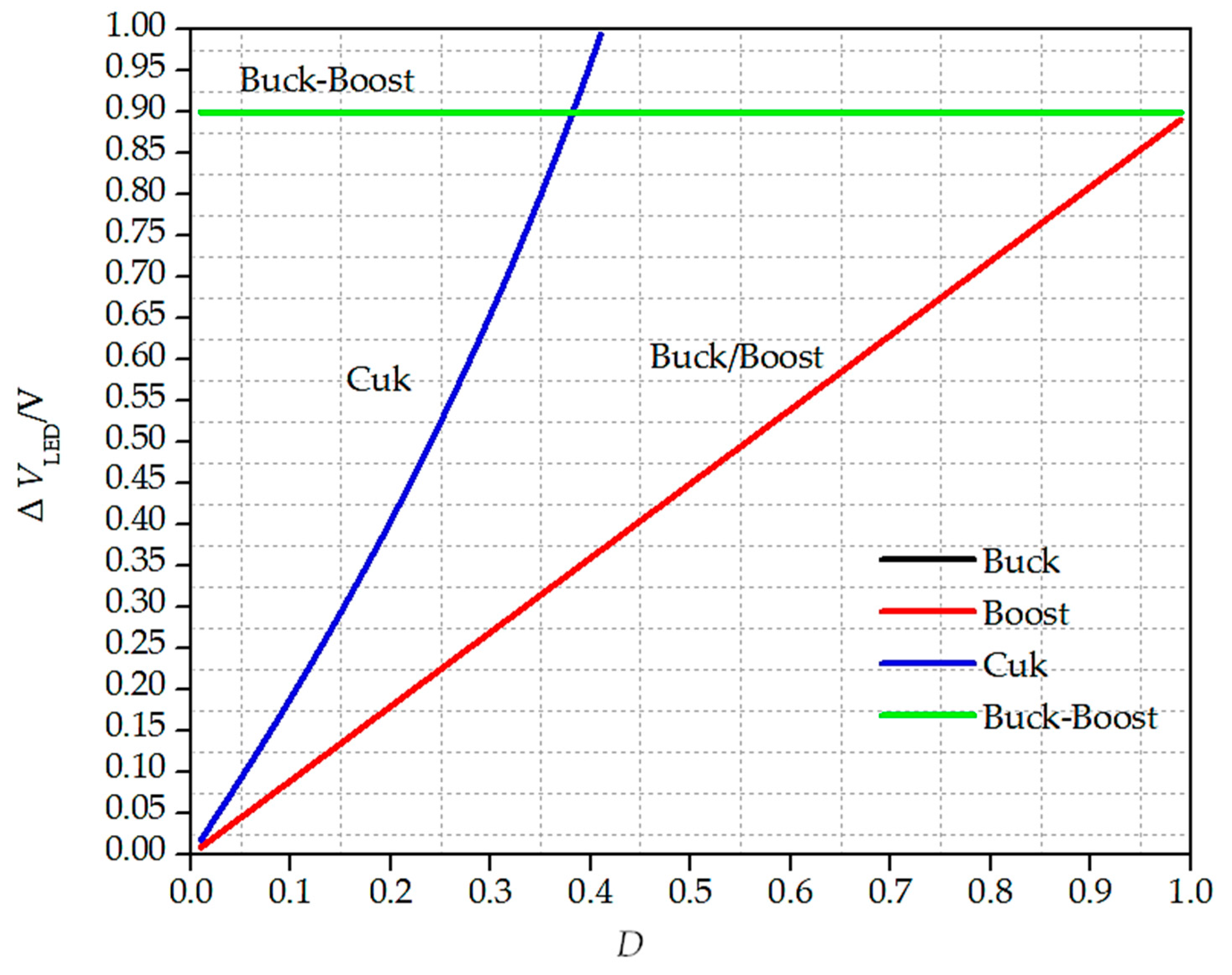

3.2. The Output Ripple Amplitude

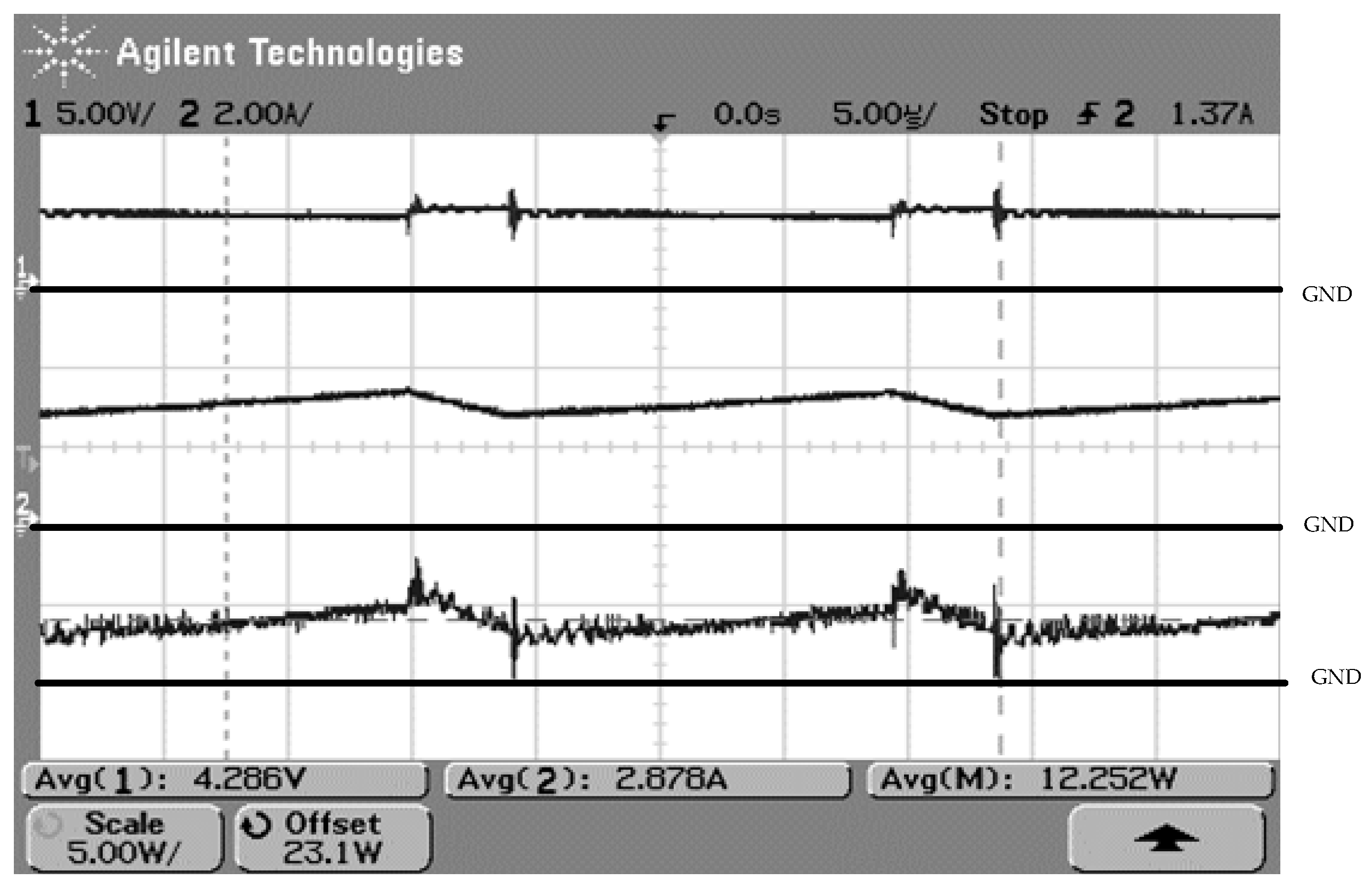

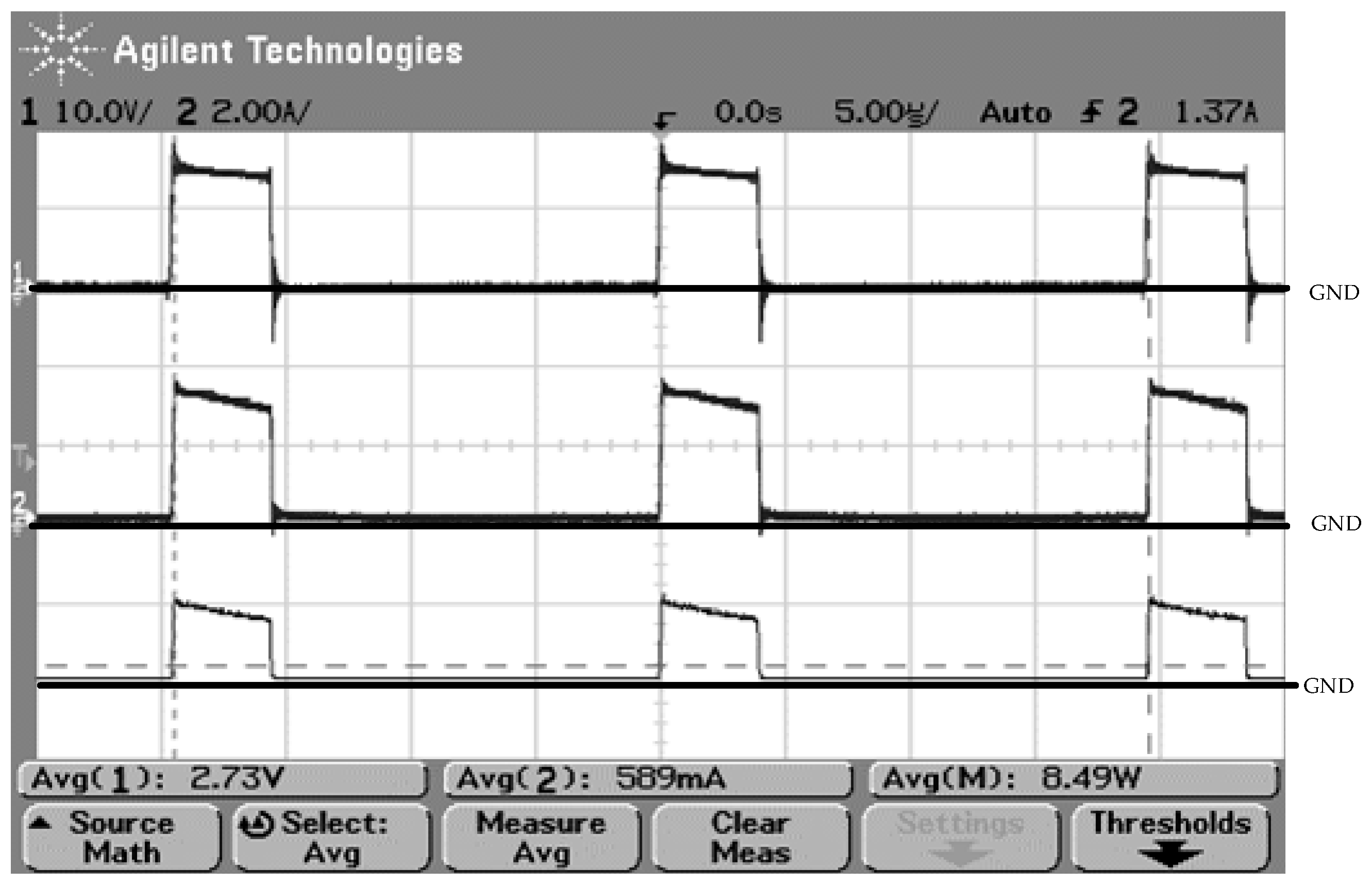

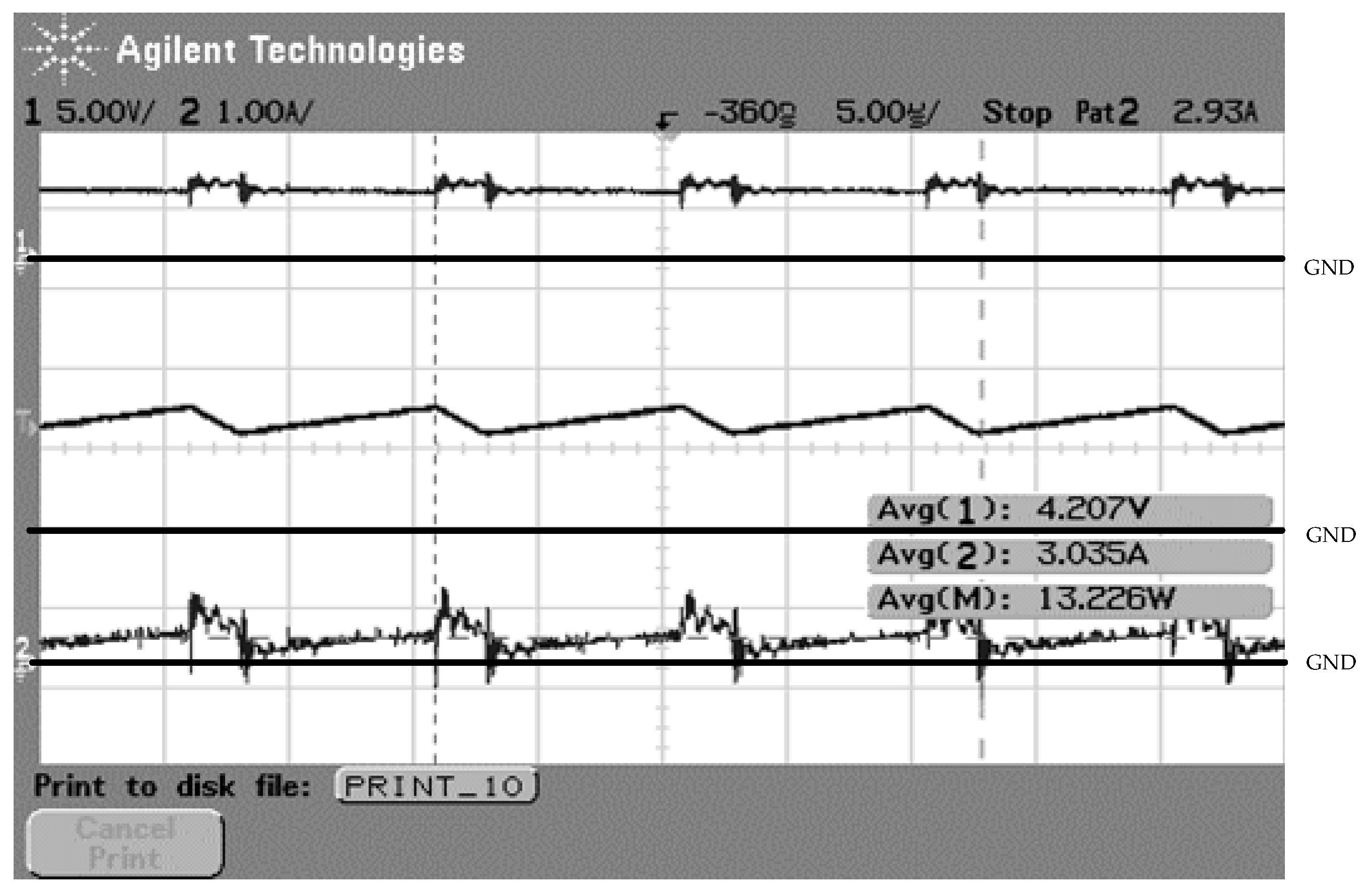

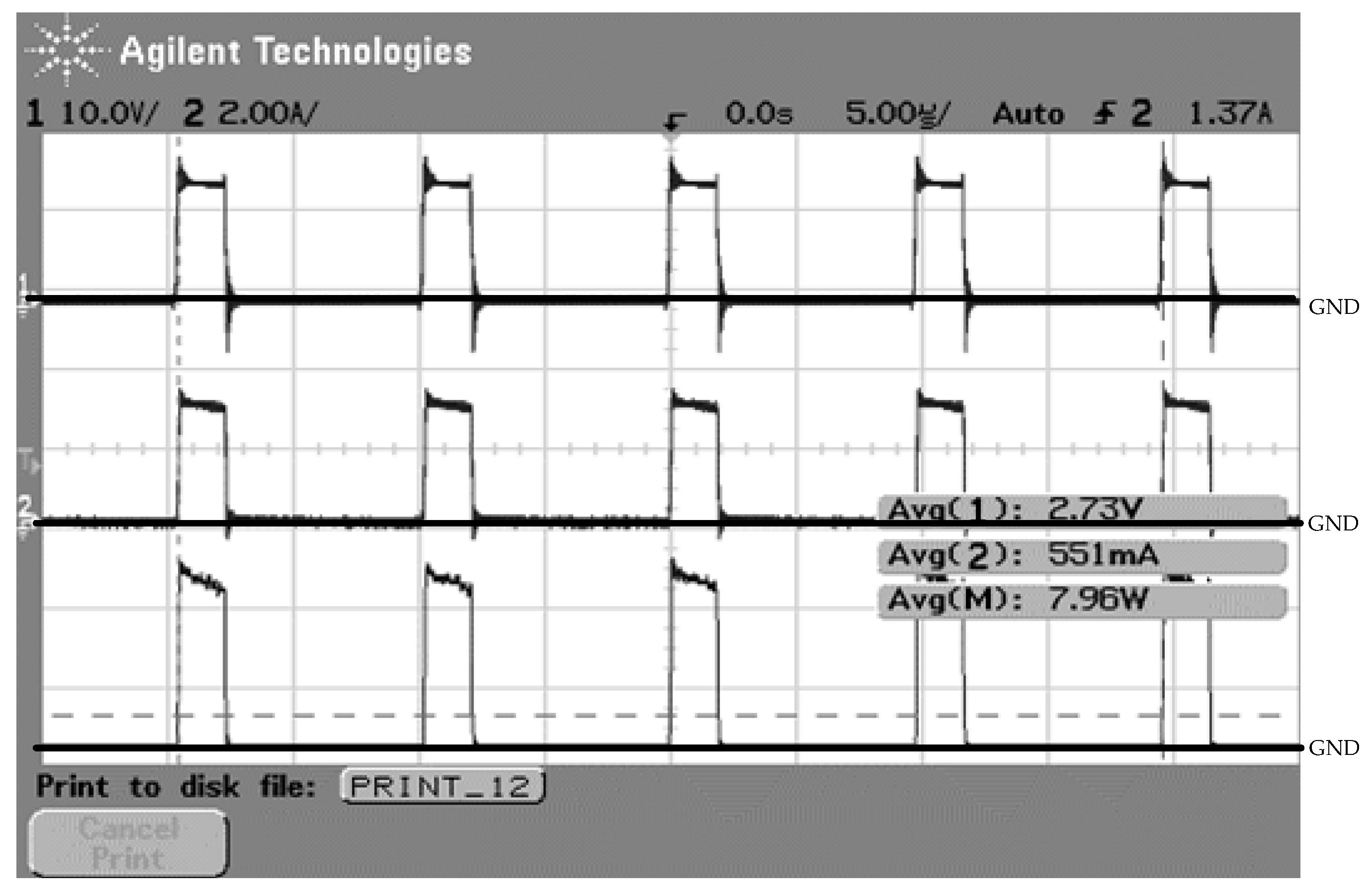

4. Experimental Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Li, S.; Tan, S.; Lee, C.K.; Waffenschmidt, E.; Hui, S.Y.; Tse, C.K. A survey, classification, and critical review of light-emitting diode drivers. IEEE Trans. Power Electron. 2016, 31, 1503–1516. [Google Scholar] [CrossRef]

- Lin, H.; Hu, J.; Zhou, X.; Lu, Z.; Wang, L. New DC Grid Power Line Communication Technology Used in Networked LED Driver. Energies 2018, 11, 3531. [Google Scholar] [CrossRef]

- Arias, M.; Lamar, D.G.; Sebastian, J.; Balocco, D.; Diallo, A.A. High-Efficiency LED Driver Without Electrolytic Capacitor for Street Lighting. IEEE Trans. Ind. Electron. 2013, 49, 127–137. [Google Scholar] [CrossRef]

- Liu, Y.-C.; Chen, C.; Chen, K.-D.; Syu, Y.-L.; Tsai, M.-C. High-Frequency LLC Resonant Converter with GaN Devices and Integrated Magnetics. Energies 2019, 12, 1781. [Google Scholar] [CrossRef]

- Cheng, K.W.E.; Wang, H.; Cheng, D.K.W. Derivation of an Electronic Ballast with a Secondary DC Output. Int. J. Circ. Theor. Appl. 2007, 14, 466. [Google Scholar]

- Yan, W.; Hui, S.Y. An analysis into the dimming control and characteristic of discharge lamps. IEEE Trans. Power Electron. 2005, 20, 1432–1440. [Google Scholar] [CrossRef]

- Dong, P.; Cheng, K.W.E.; Wang, D.H.; Divakar, B.P. Investigation on the Modeling and Ageing Characteristics of the HID Car Headlight Automotive System. J. Key Eng. Mater 2008, 364, 1280–1284. [Google Scholar]

- European Commission. Low Voltage Directive 2006/95/EC; The European Parliament and of The Council, Official Journal of the European Union: Brussels, Belgium, 2006. [Google Scholar]

- Choi, W.Y.; Kwon, J.M.; Kwon, B.H. Efficient LED back-light power supply for liquid-crystal-display. IET Electr. Power Appl. 2007, 1, 133–142. [Google Scholar] [CrossRef]

- Lo, Y.; Wu, K.; Pai, K.; Chiu, H. Design and Implementation of RGB LED Drivers for LCD Backlight Modules. IEEE Trans. Ind. Electron. 2009, 56, 4862–4871. [Google Scholar]

- Cheng, K.W.E. Classical Switched Mode and Resonant Power Converter; The Hong Kong Polytechnic University: Hong Kong, China, 2002; Chapter 2; pp. 15–64. ISBN 962-367-364-7. [Google Scholar]

- Hui, S.Y.; Li, S.N.; Tao, X.H.; Chen, W.; Ng, W.M. A Novel Passive Offline LED Driver with Long Lifetime. IEEE Trans. Power Electron. 2010, 25, 2665–2672. [Google Scholar] [CrossRef]

- Baek, J.; Chae, S. Single-Stage Buck-Derived LED Driver with Improved Efficiency and Power Factor Using Current Path Control Switches. IEEE Trans. Ind. Electron. 2017, 64, 7852–7861. [Google Scholar] [CrossRef]

- Lu, Y.; Czarkowski, D.; Bury, W.E. High efficiency adaptive boost converter for LED drivers. In Proceedings of the 2011 7th International Conference-Workshop Compatibility and Power Electronics (CPE), Tallinn, Estonia, 1–3 June 2011; pp. 315–318. [Google Scholar]

- Mannam, R.; Vangala, N. Soft switching boost converter for DC input LED drivers. In Proceedings of the 2016 7th India International Conference on Power Electronics (IICPE), Patiala, India, 17–19 November 2016; pp. 1–5. [Google Scholar]

- Lin, R.; Chang, Y.; Lee, C. Optimal Design of LED Array for Single-Loop CCM Buck–Boost LED Driver. IEEE Trans. Ind. Electron. 2013, 49, 761–768. [Google Scholar] [CrossRef]

- Mohamed, L.; Hamid, N.F.A.; Isa, Z.M.; Saudin, N.; Ramly, N.H.; Ahamad, N.B. Cuk converter as a LED lamp driver. In Proceedings of the 2012 IEEE International Conference on Power and Energy (PECon), Kota Kinabalu, Malaysia, 2–5 December 2012; pp. 262–267. [Google Scholar]

- Lin, W.; Yuzhen, X.; Zheng, Q.L. A high efficiency integrated step-down Cuk and flyback converter for LED power driver. In Proceedings of the 2015 9th International Conference on Power Electronics and ECCE Asia (ICPE-ECCE Asia), Seoul, Korea, 1–5 June 2015; pp. 60–64. [Google Scholar]

- Chan, H.L.; Cheng, K.W.E.; Sutanto, D. Phase-shift controlled DC-DC converter with bi-directional power flow. IEE Proc.-Electr. Power Appl. 2001, 148, 193–201. [Google Scholar] [CrossRef]

- Lun, W.; Loo, K.H.; Tan, S.; Lai, Y.M.; Tse, C.K. Bilevel Current Driving Technique for LEDs. IEEE Trans. Power Electron 2009, 24, 2920–2932. [Google Scholar]

- Chen, H.; Tan, S.; Hui, S.Y. Color Variation Reduction of GaN-Based White Light-Emitting Diodes Via Peak-Wavelength Stabilization. IEEE Trans. Power Electron. 2014, 29, 3709–3719. [Google Scholar] [CrossRef]

- Cheng, K.W.E. Storage energy for classical switched mode power converters. IEE Proc.-Electr. Power Appl. 2003, 150, 439–446. [Google Scholar] [CrossRef]

- Jang, Y.; Jovanović, M.M. Bridgeless high-power-factor buck converter. IEEE Trans. Power Electron. 2011, 26, 602–611. [Google Scholar] [CrossRef]

- Cheng, H.; Lin, C. Design and Implementation of a High-Power-Factor LED Driver with Zero-Voltage Switching-On Characteristics. IEEE Trans. Power Electron. 2014, 29, 4949–4958. [Google Scholar] [CrossRef]

- Wu, X.; Xie, X.; Chen, Z.; Qian, Z.; Zhao, R. Low voltage and current stress ZVZCS full bridge DC–DC converter using center tapped rectifier reset. IEEE Trans. Ind. Electron. 2008, 55, 1470–1477. [Google Scholar] [CrossRef]

- Hsieh, H.I.; Li, J.S.; Chen, D. Effects of X capacitors on EMI filter effectiveness. IEEE Trans. Ind. Electron. 2008, 55, 949–955. [Google Scholar] [CrossRef]

- Narendran, N.; Gu, Y. Life of LED-based white light sources. IEEE Disp. Technol. 2005, 1, 167. [Google Scholar] [CrossRef]

- Hsieh, Y.Y.; Juang, Y.Z. Analysis and suppression of overcurrent in boost LED drivers. IEEE Disp. Technol. 2013, 9, 388–395. [Google Scholar] [CrossRef]

- Dong, Z.; Tse, C.K.; Hui, S.Y.R. Circuit Theoretic Considerations of LED Driving: Voltage-Source Versus Current-Source Driving. IEEE Trans. Power Electron. 2019, 34, 4689–4702. [Google Scholar] [CrossRef]

- Saini, D.K.; Ayachit, A.; Salvatierra, T.; Kazimierczuk, M.K. Design of zero-voltage-ripple buck dc-dc converter. In Proceedings of the 2017 IEEE 60th International Midwest Symposium on Circuits and Systems (MWSCAS), Boston, MA, USA, 6–9 August 2017; pp. 456–459. [Google Scholar]

- Reddy, U.R.; Narasimharaju, B.L. Single-stage electrolytic capacitor less non-inverting buck-boost PFC based AC–DC ripple free LED driver. IET Power Electron. 2017, 10, 38–46. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, F.; Ni, J. Capacitor clamped current sharing circuit for multistring LEDs. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012; pp. 3568–3574. [Google Scholar]

- Hwu, K.; Jiang, W. Input-Current-Ripple-Free Two-Channel LED Driver. IEEE Trans. Ind. Electron. 2017, 64, 5865–5874. [Google Scholar] [CrossRef]

- Wu, X.K.; Zhang, J.M.; Zhao, M.Q. A simple two-channel LED driver with automatic precise current sharing. IEEE Trans. Ind. Electron. 2011, 58, 4783–4788. [Google Scholar] [CrossRef]

- Zhao, C.; Xie, X.; Liu, S. Multioutput LED drivers with precise passive current balancing. IEEE Trans. Power Electron. 2013, 28, 1438–1448. [Google Scholar] [CrossRef]

- Lee, E.S.; Choi, B.H.; Nguyen, D.T.; Choi, B.G.; Rim, C.T. Static regulated multistage semiactive LED drivers for high-efficiency applications. IEEE Trans. Power Electron. 2015, 31, 6543–6552. [Google Scholar] [CrossRef]

- Maniktala, S. Switching Power Supplies A–Z; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

| Topology | LED in the Diode Path | LED in the Transistor Path | LED in the Inductor Path |

|---|---|---|---|

| Buck | |||

| Boost | close to 1 | ||

| Buck–Boost | close to 1 | ||

| Ćuk | close to 1 |

| Topology | LED in the Diode Path | LED in the Transistor Path | LED In The Inductor Path |

|---|---|---|---|

| Buck | |||

| Boost | |||

| Buck–Boost | |||

| Ćuk |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Cheng, K.W.E.; Shao, J. Circuit Topology Analysis for LED Lighting and its Formulation Development. Energies 2019, 12, 4203. https://doi.org/10.3390/en12214203

Chen W, Cheng KWE, Shao J. Circuit Topology Analysis for LED Lighting and its Formulation Development. Energies. 2019; 12(21):4203. https://doi.org/10.3390/en12214203

Chicago/Turabian StyleChen, William, Ka Wai Eric Cheng, and Jianwei Shao. 2019. "Circuit Topology Analysis for LED Lighting and its Formulation Development" Energies 12, no. 21: 4203. https://doi.org/10.3390/en12214203