Partial Discharges in Insulating Systems of Low Voltage Electric Motors Fed by Power Electronics—Twisted-Pair Samples Evaluation

Abstract

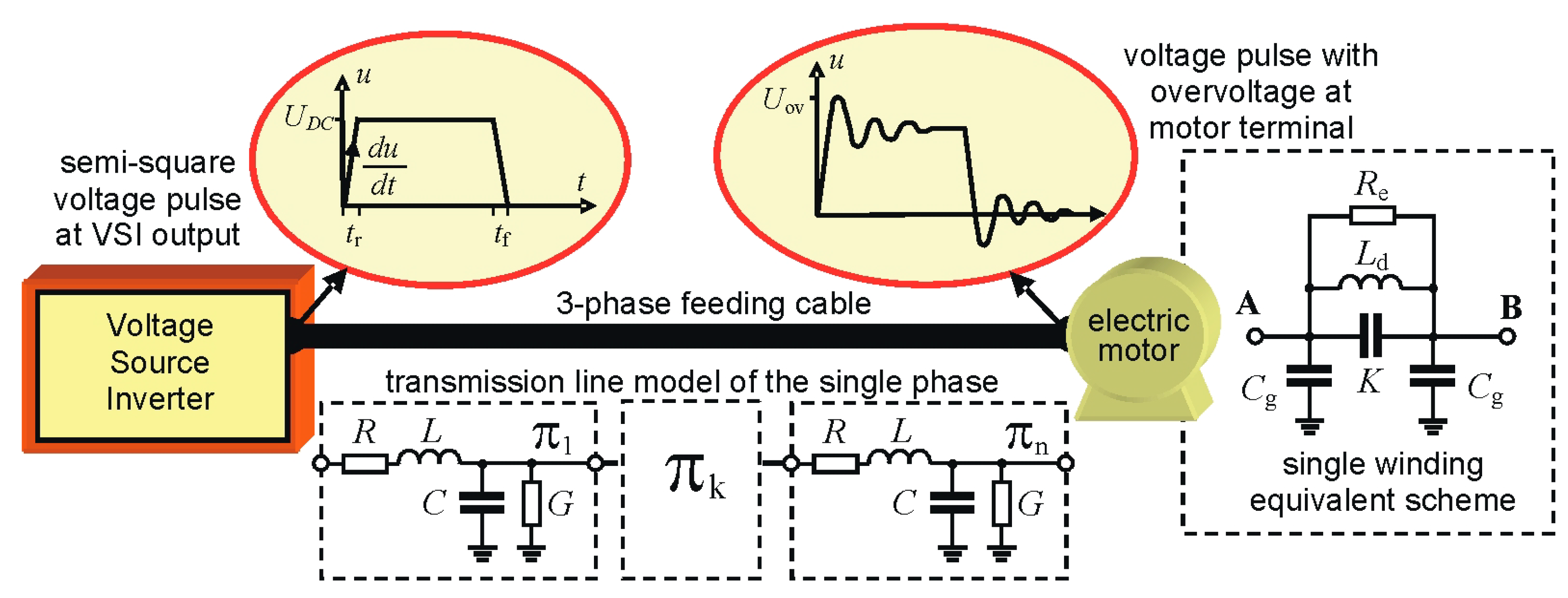

:1. Introduction

- High repetition rate of PWM voltage pulses with associated overvoltages;

- High steepness of voltage rise;

- Electric charge injection and accumulation processes, dependent not only on the properties of dielectric materials, but also on the time-varying motor control sequences.

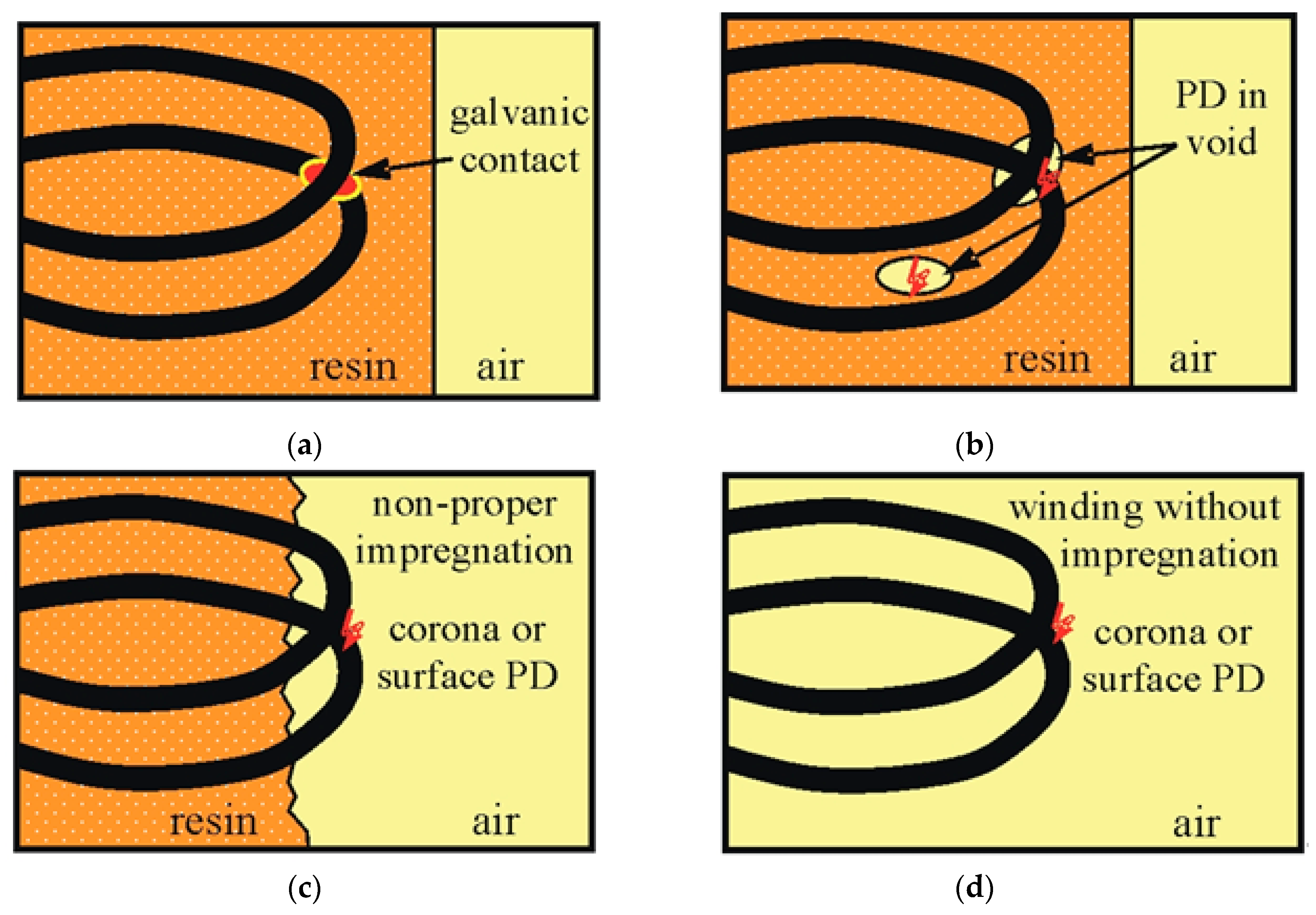

2. Modeling of Turn-to-Turn Insulation of Stator Winding in Laboratory Tests

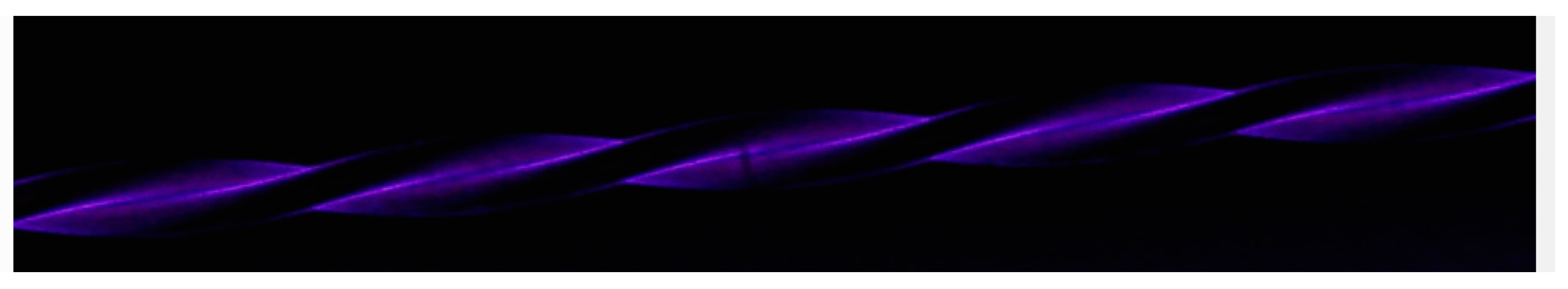

2.1. Twisted-Pair Sample Preparation

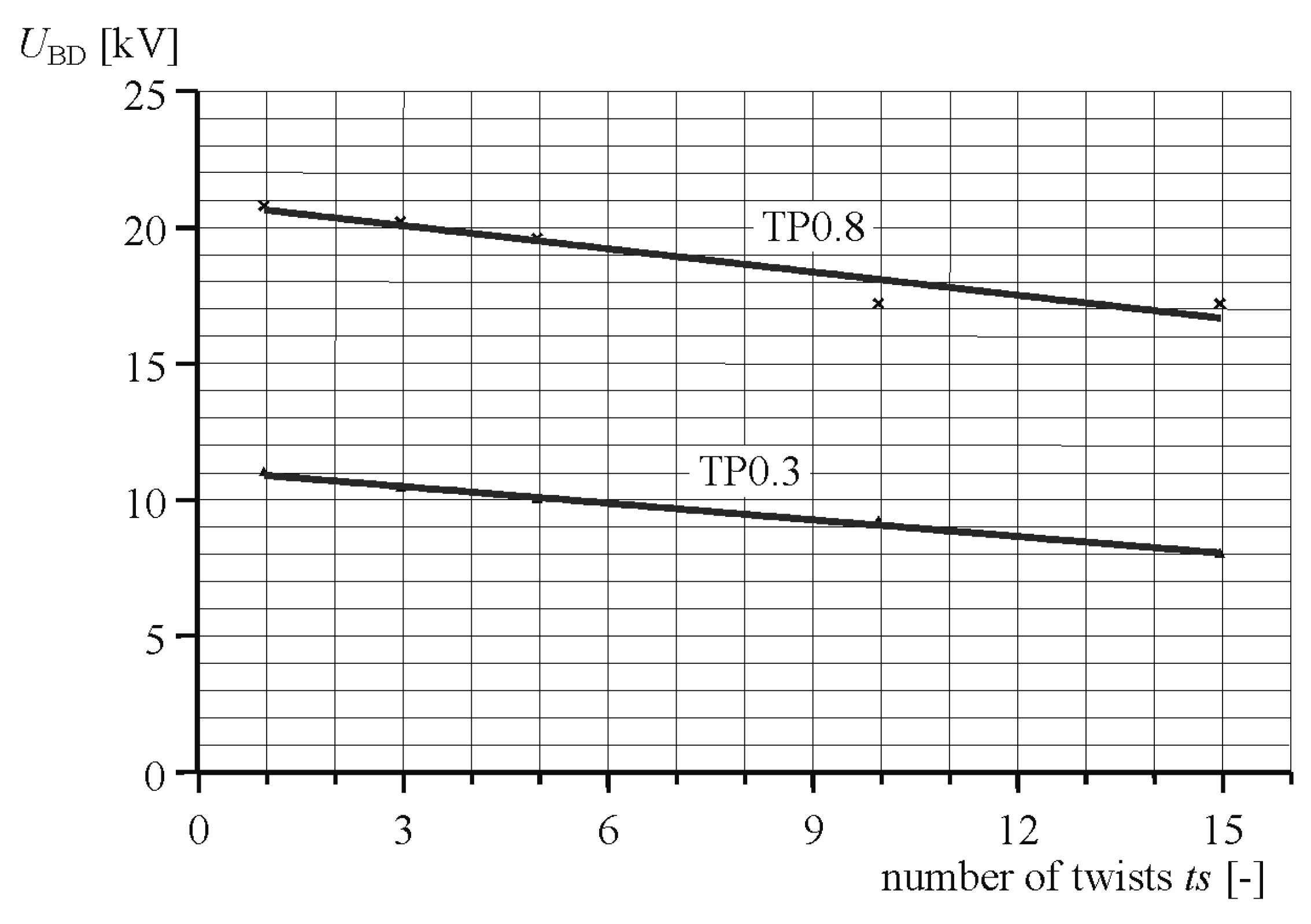

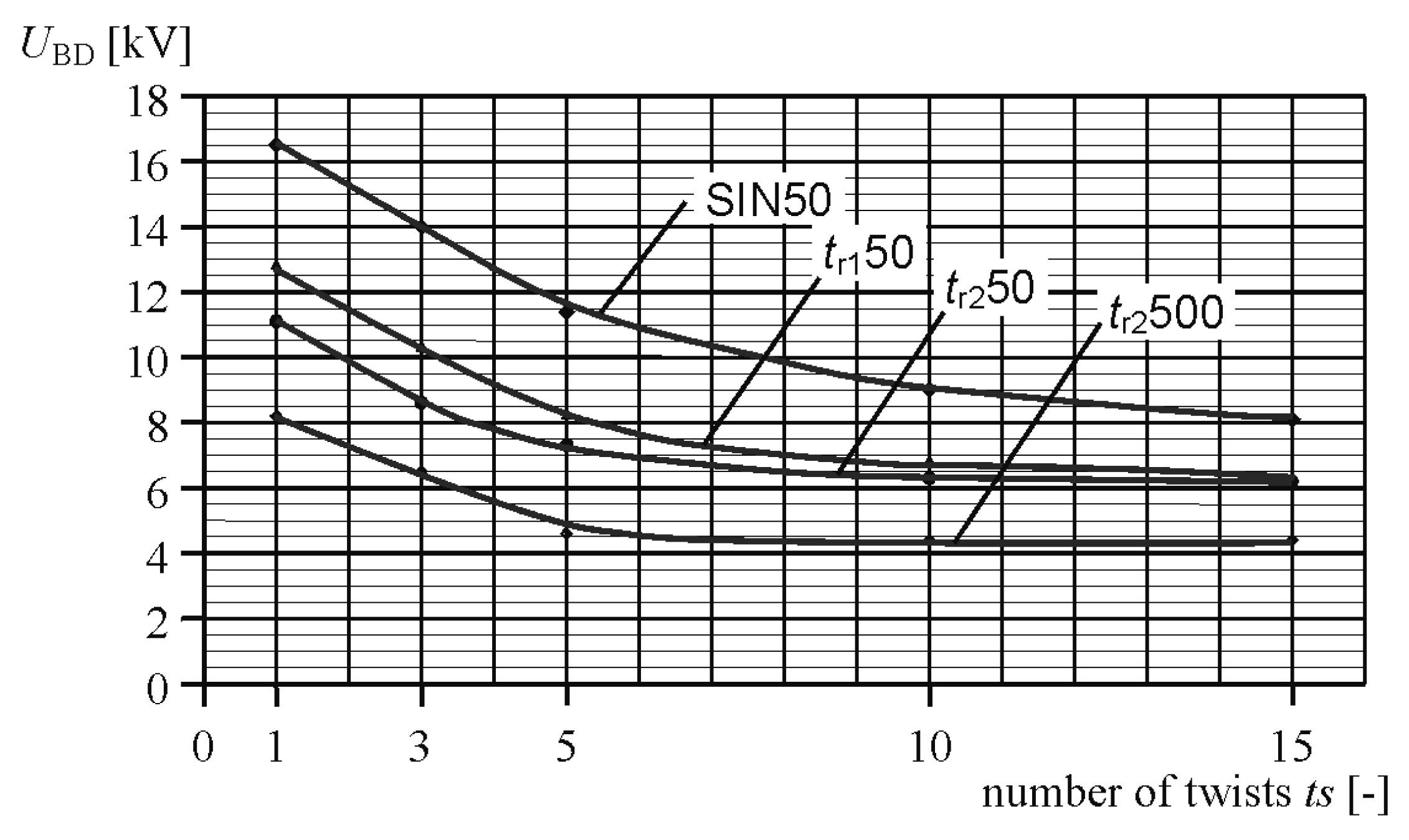

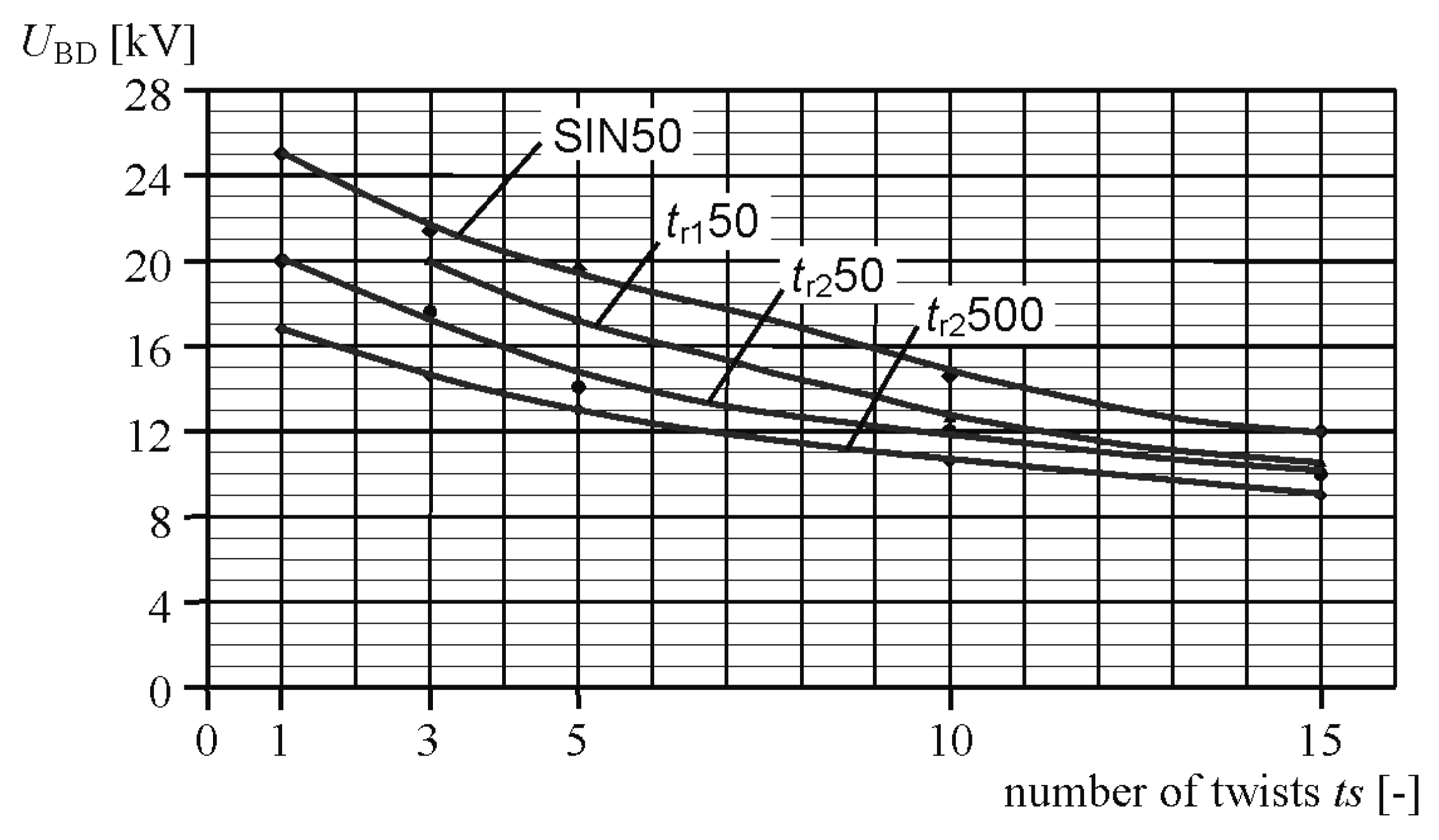

2.2. Breakdown Voltage in Twisted-Pair Samples with Different Number of Twists Time to Breakdown

- Two values of rise time at f = 50Hz: tr1 = 1 kV/160 µs denoted as SSV1, and tr2 = 1 kV/5.8 µs denoted as SSV2;

- Rise time tr2 at frequency f = 500Hz, tr2 = 1 kV/5.8 µs denoted as SSV3.

- When rise-time tr is shorter, the breakdown voltage is smaller, i.e.,: if tr2 < tr1 then UBD SSVtr2 < UBD SSVtr1;

- Further increase of frequency of voltage SSV will lead to the decrease of breakdown voltage UBD UBD SSVtr2(500 Hz) < UBD SSVtr2(50 Hz);

- Breakdown voltage at SSV is smaller than at sinusoidal voltage: UBD SSV < UBD VSIN50;

- There is a distinct impact of the number of twists ts on the breakdown voltage UBD for ts = 1 ÷ 3, but in the range ts = 10 ÷ 15 this influence is practically negligible, breakdown voltage UBD in the case of ts = 1 is much higher than for ts = 15: UBD SSVts=15 < UBD SSVts=1.

2.3. Evaluation of Time to Breakdown

3. Numerical Modelling of Electric Field in Twisted-Pair Sample

3.1. Geometry of Twisted-Pair Insulation System

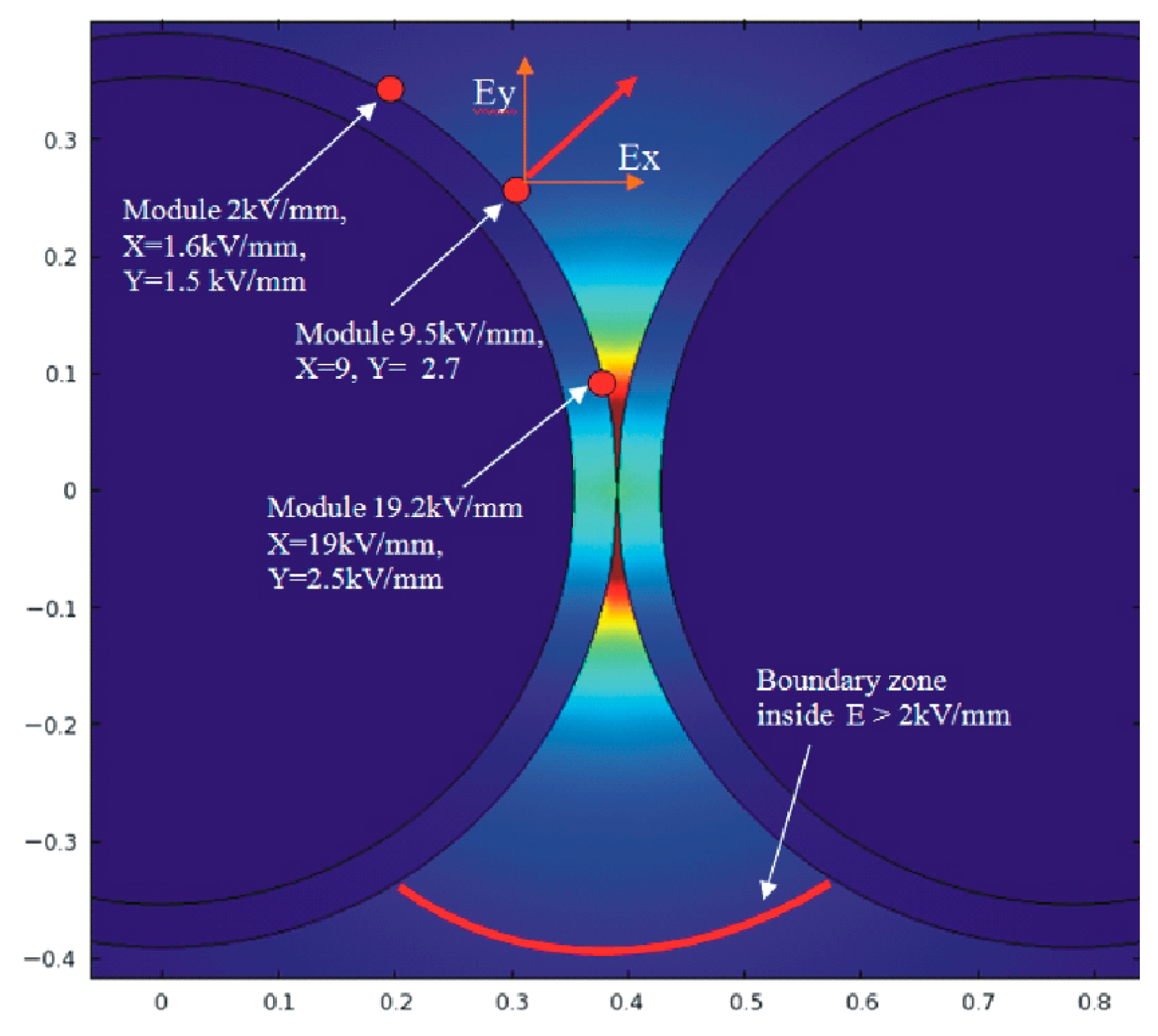

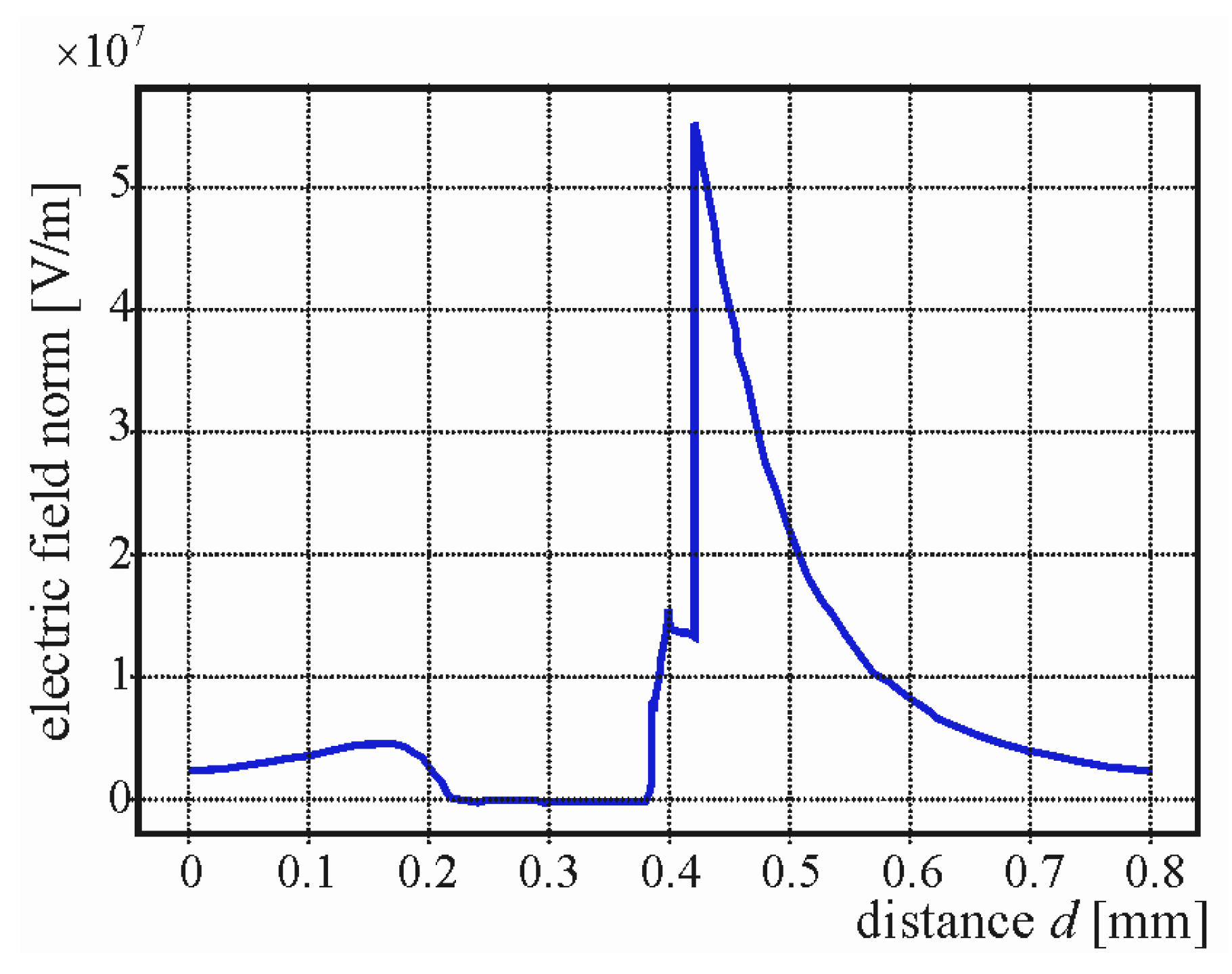

- Zone 1 (Figure 10c) is located in the area of the microgap between adjacent winding wires. This area is characterized by a high intensity of the electric field, with the dominant normal component of the field strength, perpendicular to the surface of the wires’ insulation. The field strength in the insulation is significantly smaller than the field strength in the gap due to the difference in the dielectric relative permittivity (εr about 3.8 to 4.2 for used solid insulation).

- Zone 2 (Figure 10c) covers the area between the curvatures of both wires, with the widening area of the air insulation. Due to the geometry of this part of the insulating system, there is also a tangential component present in addition to the normal component of the field on the surface of the wires insulation.

3.2. Simulations of Electric Field in Parallel Configuration of Wires in Twisted Pair Sample

3.2.1. Case 1: Two Wires with Direct Contact

3.2.2. Case 2: Two Wires with Microgap between Them

3.3. Electric Field Distribution in Twist Configuration of Magnet Wires Samples

3.4. Impact of Wire Insulation Conductivity on Electric Field Distribution in Twisted-Pair Samples

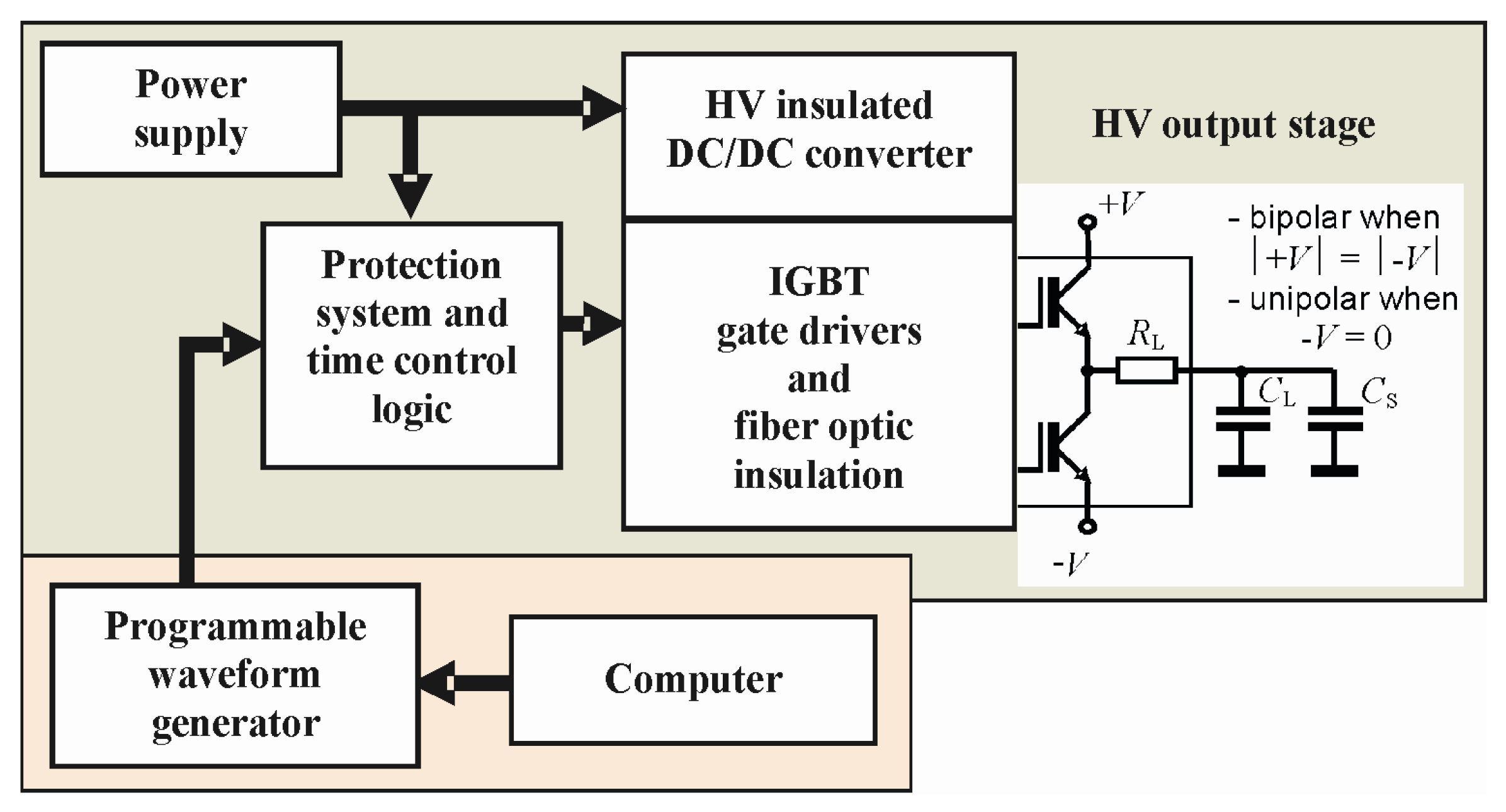

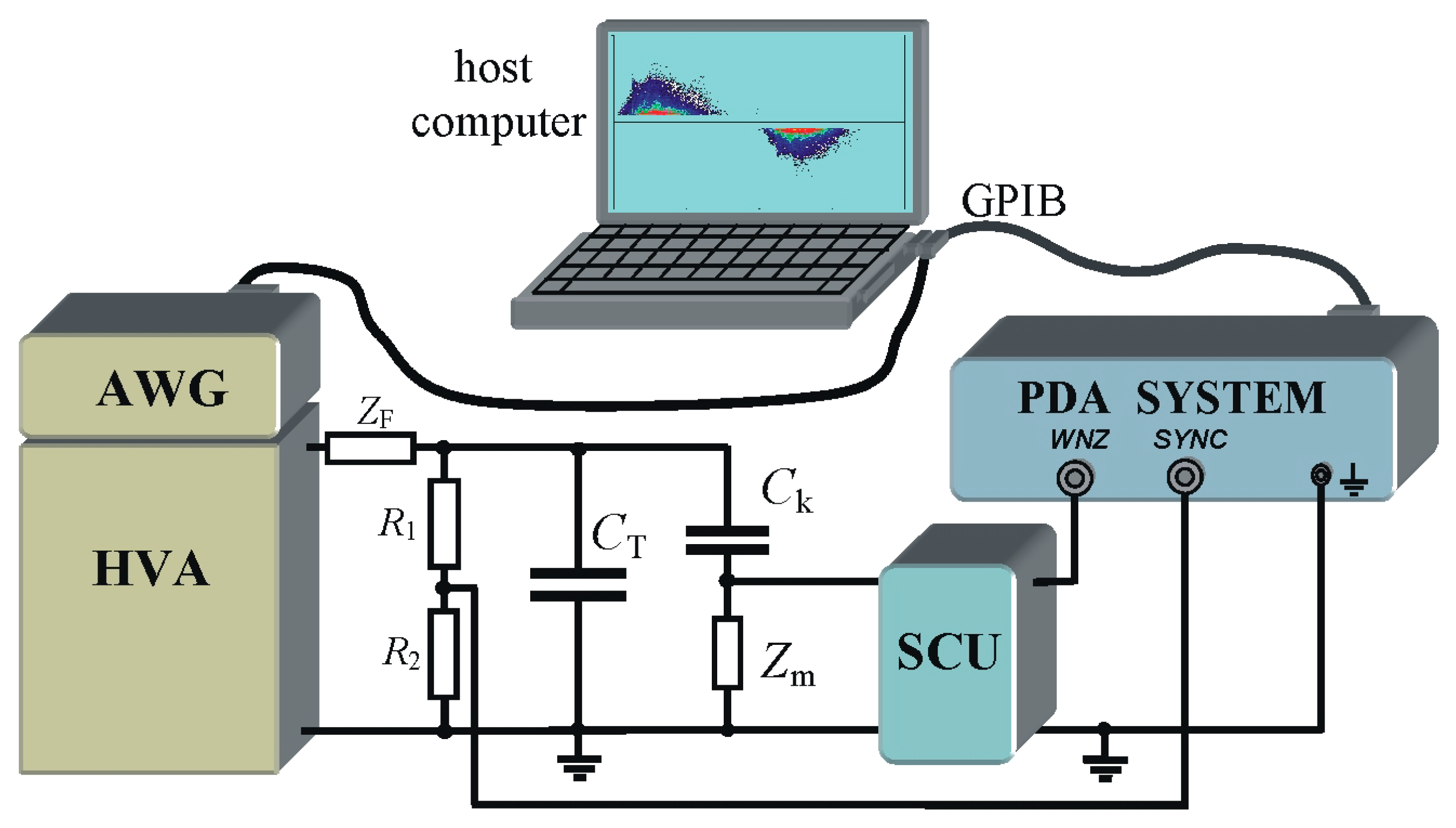

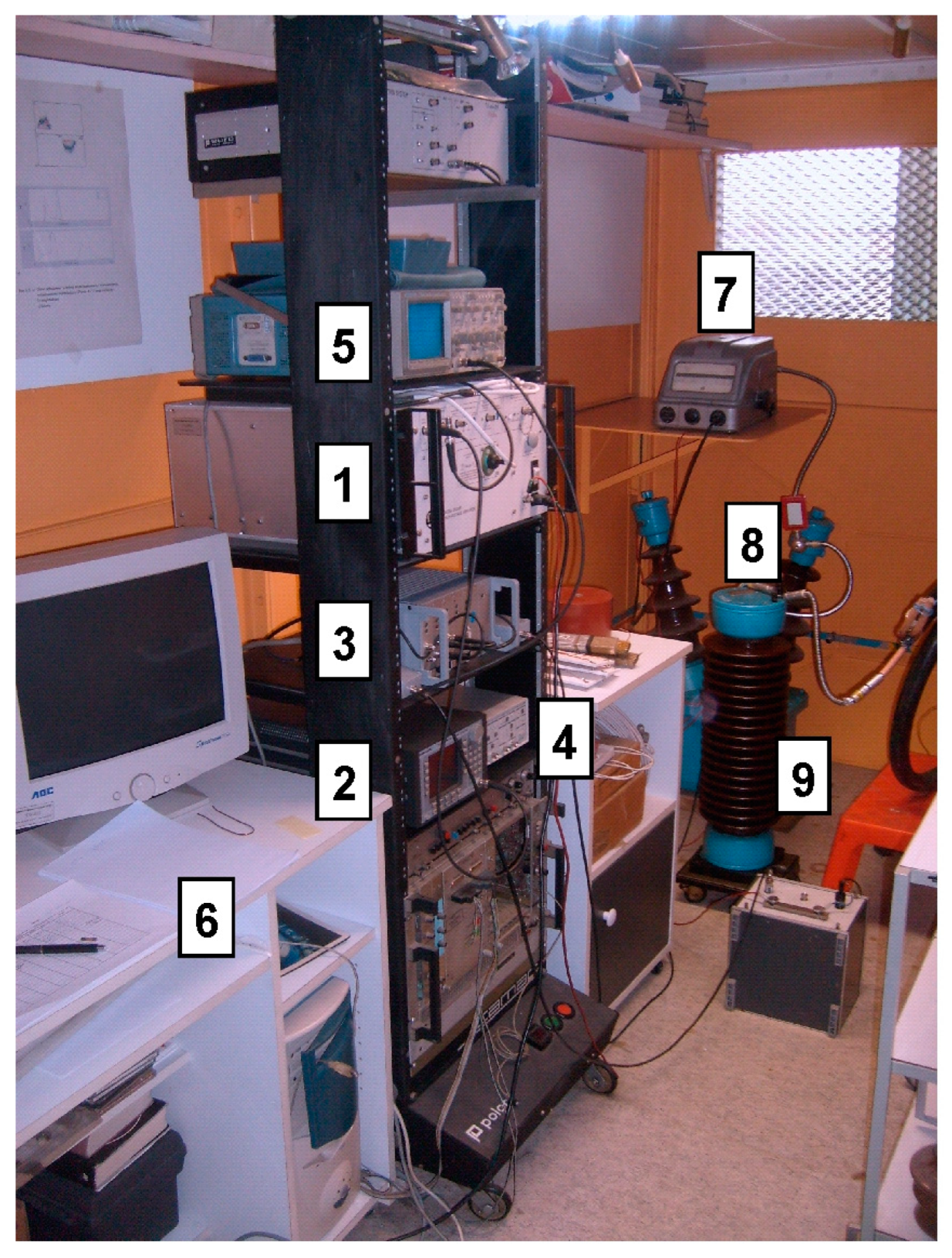

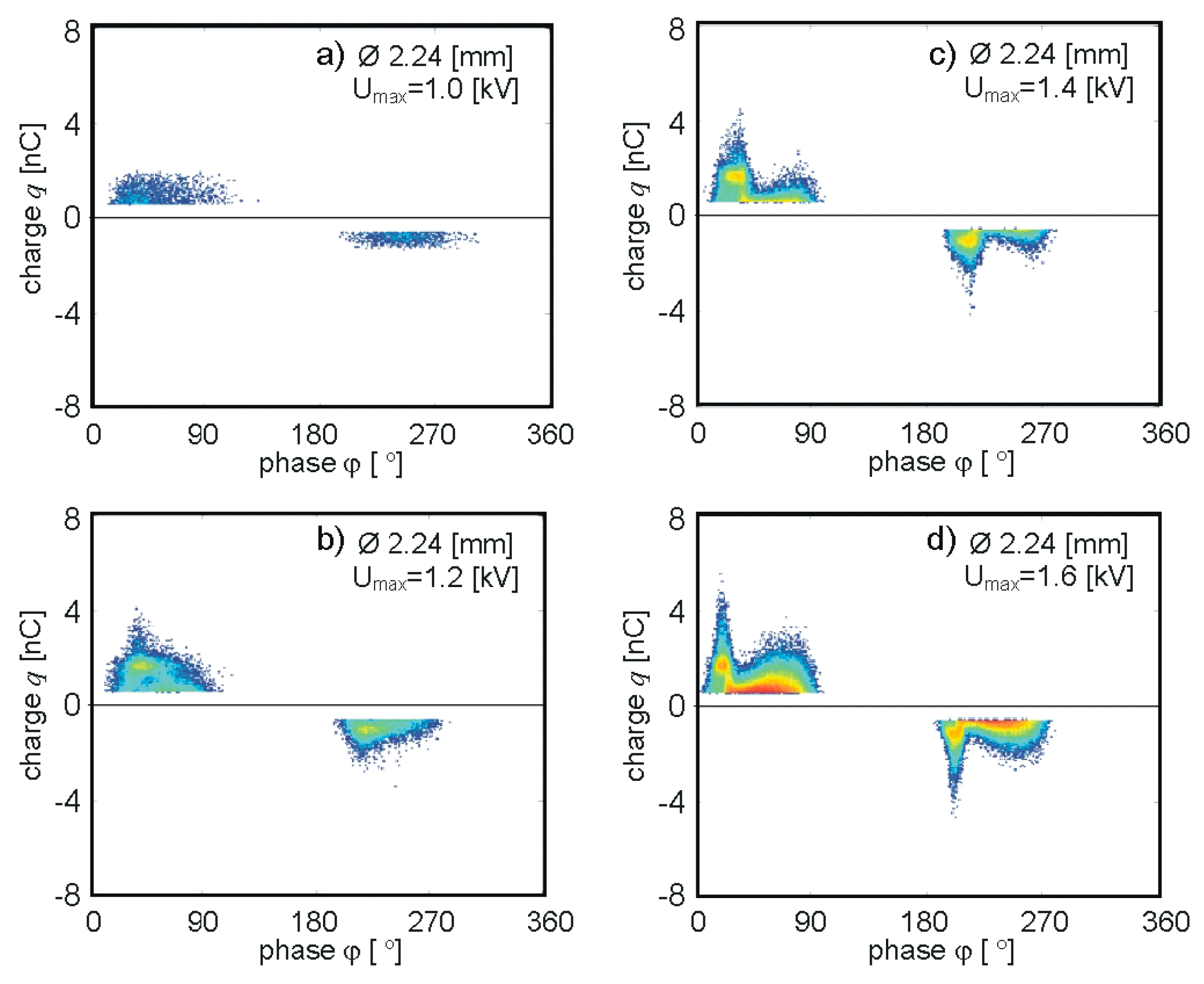

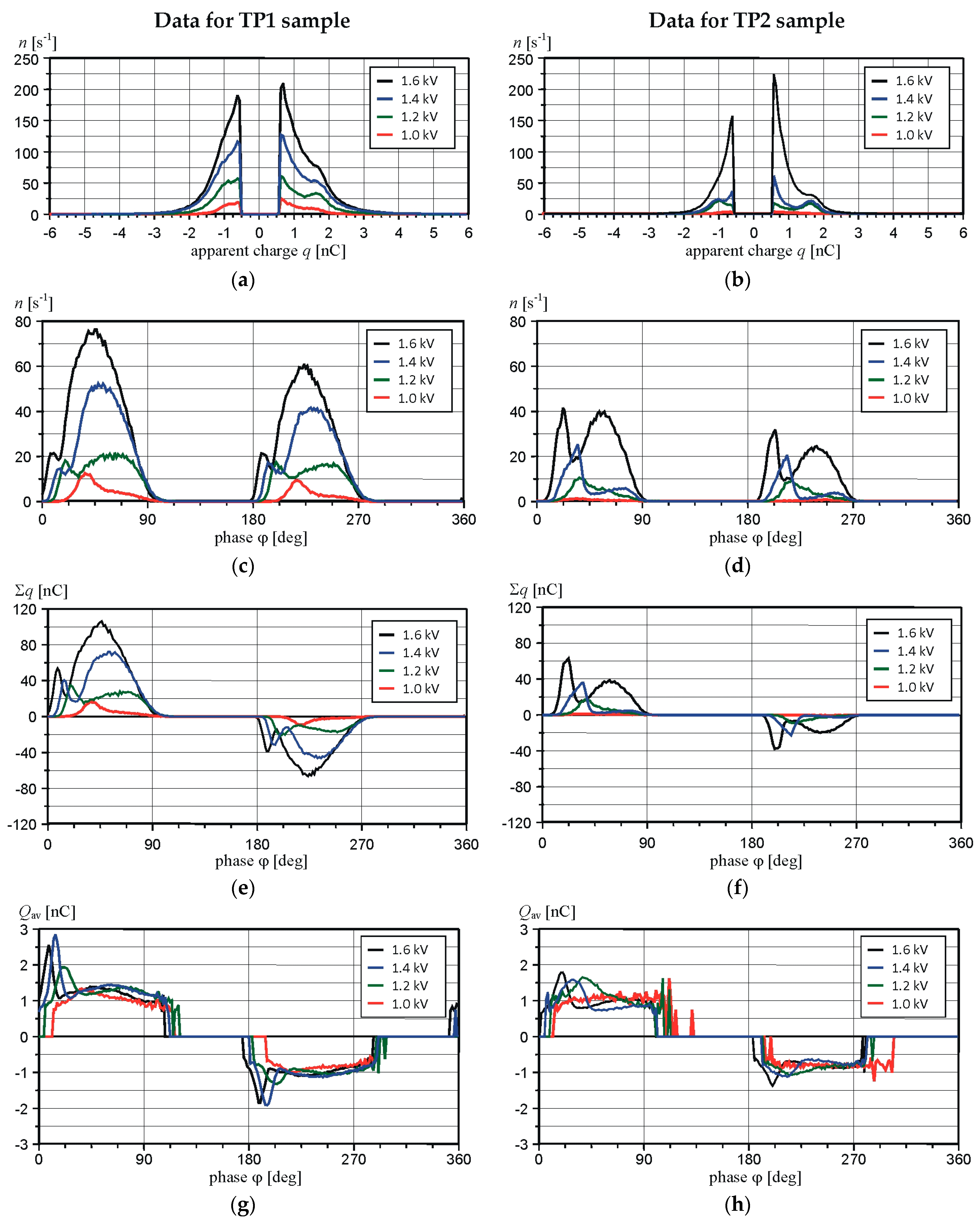

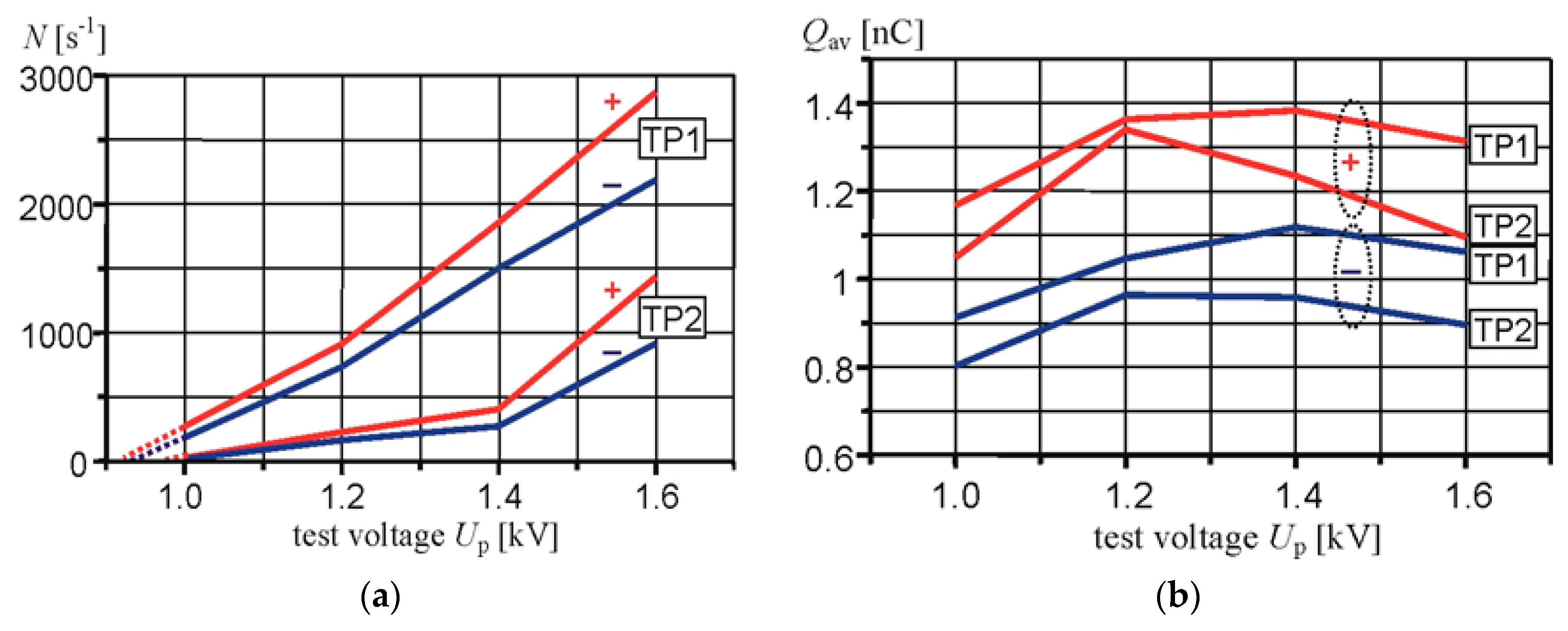

4. PD Measurements in Model TP Samples

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bonnett, A.H. Analysis of the impact of pulse-width modulated inverter voltage waveforms on AC induction motors. IEEE Trans. Ind. Appl. 1996, 32, 386–392. [Google Scholar] [CrossRef]

- Weijun, Y. Failure mechanism of winding insulations in inverter-fed motors. IEEE Electr. Insul. Mag. 1997, 13, 18–23. [Google Scholar] [CrossRef]

- Kerkman, R.J.; Leggate, D.; Skibinski, G. Interaction of drive modulation and cable parameters on AC motor transients. IEEE Trans. Ind. Appl. 1997, 33, 722–731. [Google Scholar] [CrossRef]

- Fabiani, D.; Montanari, G.C.; Cavallini, A.; Mazzanti, G. Relation between space charge accumulation and partial discharge activity in enameled wires under PWM-like voltage waveforms. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 393–405. [Google Scholar] [CrossRef]

- Lebey, T.; Castelan, P.; Montanari, G.C.; Ghinello, I. Influence of PWM-type voltage waveforms on reliability of machine insulation system. In Proceedings of the 8th International Conference on Harmonics and Quality of Power, Athens, Greece, 14–16 October 1998; Volume 2, pp. 994–998. [Google Scholar]

- Grzybowski, S.; Shrestha, P.; Cao, L. Electrical aging phenomena of XLPE and EPR cable insulation energized by switching impulses. In Proceedings of the 2008 International Conference on High Voltage Engineering and Application, Chongqing, China, 9–12 November 2008; pp. 422–425. [Google Scholar] [CrossRef]

- Florkowska, B.; Florkowski, M.; Furgał, J.; Roehrich, J.; Zydron, P. Impact of Fast Transient Phenomena on Electrical Insulation Systems; Publishing House AGH: Kraków, Poland, 2012; ISBN 978-83-7464-480-8. [Google Scholar]

- Wheeler, J.C.G. Effects of converter pulses on the electrical insulation in low and medium voltage motors. IEEE Elect. Insul. Mag. 2005, 21, 22–29. [Google Scholar] [CrossRef]

- Stone, G.C.; Culbert, I.; Boulter, E.A.; Dhirani, H. Electrical Insulation for Rotating Machines: Design, Evaluation, Aging, Testing, and Repair, 2nd ed.; IEEE Press - John Wiley & Sons Inc.: Hoboken, NJ, USA, 2014; ISBN 978-1-118-05706-3. [Google Scholar]

- Hayakawa, N.; Okubo, H. Partial discharge characteristics of inverter-fed motor coil samples under ac and surge voltage conditions. IEEE Electr. Insul. Mag. 2005, 21, 5–10. [Google Scholar] [CrossRef]

- Melfi, M.; Sung, J.; Bell, S.; Skibinski, G. Effect of surge voltage risetime on the insulation of low-voltage machines fed by PWM converters. IEEE Trans. Ind. Appl. 1998, 34, 766–775. [Google Scholar] [CrossRef]

- Florkowski, M.; Furgał, J. High Frequency Methods for Condition Assessment of Transformers and Electrical Machines; Publishing House AGH: Kraków, Poland, 2013; ISBN 978-83-7464-614-7. [Google Scholar]

- Oyegoke, B. Voltage distribution in the stator winding of an induction motor following a voltage surge. Electr. Eng. 2000, 82, 199–205. [Google Scholar] [CrossRef]

- Florkowska, B.; Zydron, P.; Florkowski, M. Effects of inverter pulses on the electrical insulation system of motors. In Proceedings of the 2011 IEEE International Symposium on Industrial Electronics, Gdansk, Poland, 27–30 June 2011; pp. 573–578. [Google Scholar] [CrossRef]

- Lindell, E.; Bengtsson, T.; Blennow, J.; Gubanski, S.M. Influence of rise time on partial discharge extinction voltage at semi-square voltage waveforms. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 141–148. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Murata, T.; Fukumoto, N.; Nagata, M.; Wakimoto, Y.; Yoshimitsu, T. Investigation of partial discharge with twisted enameled wires in atmospheric humid air by optical emission spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 839–845. [Google Scholar] [CrossRef]

- Yanaze, N.; Nakaya, H.; Kozako, M.; Hikita, M.; Tomizawa, K.; Ohya, M. Partial discharge inception voltage measurement and location identification of enamel coating ribbon wire used for low-voltage motors. In Proceedings of the 2014 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Des Moines, IA, USA, 19–22 October 2014; pp. 192–195. [Google Scholar] [CrossRef]

- Guastavino, F.; Ratto, A.; Dardano, A.; Torello, E.; Biondi, G.; Loggi, G.; Ceci, A. Comparison among the PD resistance behavior of different enameled wires when subjected to PWM voltage. In Proceedings of the 2011 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Cancun, Mexico, 16–19 October 2011; pp. 314–317. [Google Scholar] [CrossRef]

- Florkowski, M.; Florkowska, B.; Roehrich, J.; and Zydron, P. Measurement and analysis of surface partial discharges at semi-square voltage waveforms. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 990–996. [Google Scholar] [CrossRef]

- Wang, P.; Xu, H.; Wang, J.; Wang, W.; Cavallini, A. Effect of repetitive impulsive voltage duty cycle on partial discharge features and insulation endurance of enameled wires for inverter-fed low voltage machines. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2123–2131. [Google Scholar] [CrossRef]

- IEC 60851-5:2008+AMD1:2011 CSV, Winding Wires—Test Methods—Part 5: Electrical Properties; IEC: Geneva, Switzerland, 2011.

- IEC 60172, Test Procedure for the Determination of the Temperature Index of Enamelled Winding Wires; IEC: Geneva, Switzerland, 2015.

- Hoang, A.T.; Serdyuk, Y.V.; Gubanski, S.M. Mechanisms of surface potential decay on enamel wire coatings. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3470–3480. [Google Scholar] [CrossRef]

- IEC 60270:2000+AMD1:2015 CSV, High-Voltage Test Techniques—Partial Discharge Measurements; IEC: Geneva, Switzerland, 2015.

- IEC TS 61934, Electrical Insulating Materials and Systems—Electrical Measurement of Partial Discharges (PD) under Short Rise Time and Repetitive Voltage Impulses; IEC: Geneva, Switzerland, 2011.

- Florkowski, M.; Florkowska, B.; Furgał, J.; Zydron, P. Impact of high voltage harmonics on interpretation of partial discharge patterns. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 2009–2016. [Google Scholar] [CrossRef]

- Florkowski, M.; Florkowska, B.; Zydron, P. Chopped Partial Discharge Sequence. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3451–3458. [Google Scholar] [CrossRef]

- Wang, P.; Cavallini, A.; Montanari, G.C.; Wu, G. Effect of rise time on PD pulse features under repetitive square wave voltages. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 245–254. [Google Scholar] [CrossRef]

- Illias, H.; Chen, G.; Lewin, P.L. Partial discharge behavior within a spherical cavity in a solid dielectric material as a function of frequency and amplitude of the applied voltage. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 432–443. [Google Scholar] [CrossRef]

- Kikuchi, H.; Hanawa, H. Inverter surge resistant enameled wire with nanocomposite insulating material. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 99–106. [Google Scholar] [CrossRef]

- Guastavino, F.; Ratto, A.; Torello, E.; Biondi, G. Aging tests on nanostructured enamels for winding wire insulation. IEEE Trans. Ind. Electron. 2014, 61, 5550–5557. [Google Scholar] [CrossRef]

- Yoo, J.; Kim, Y.; Kwon, S.; Lee, J.; Seo, Y.-S. Surge-resistant nanocomposite enameled wire using silica nanoparticles with binary chemical compositions on the surface. J. Nanomater. 2015, 231672. [Google Scholar] [CrossRef]

- Guastavino, F.; Torello, E.; Cordano, D.; Della Giovanna, L. Surface PD evolution of conventional and nanocomposite enamels. In Proceedings of the 2016 IEEE International Conference on Dielectrics (ICD), Montpellier, France, 3–7 July 2016; pp. 760–763. [Google Scholar] [CrossRef]

| Sample Type | Breakdown Voltage UBD [kV] | ||||

|---|---|---|---|---|---|

| ts = 1 | ts = 3 | ts = 5 | ts = 10 | ts = 15 | |

| TP0.3 | 11 | 10.2 | 10.0 | 9 | 8 |

| TP0.8 | 21.0 | 20.0 | 19.6 | 17.5 | 17.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Florkowski, M.; Florkowska, B.; Zydron, P. Partial Discharges in Insulating Systems of Low Voltage Electric Motors Fed by Power Electronics—Twisted-Pair Samples Evaluation. Energies 2019, 12, 768. https://doi.org/10.3390/en12050768

Florkowski M, Florkowska B, Zydron P. Partial Discharges in Insulating Systems of Low Voltage Electric Motors Fed by Power Electronics—Twisted-Pair Samples Evaluation. Energies. 2019; 12(5):768. https://doi.org/10.3390/en12050768

Chicago/Turabian StyleFlorkowski, Marek, Barbara Florkowska, and Pawel Zydron. 2019. "Partial Discharges in Insulating Systems of Low Voltage Electric Motors Fed by Power Electronics—Twisted-Pair Samples Evaluation" Energies 12, no. 5: 768. https://doi.org/10.3390/en12050768