Energy Pile Field Simulation in Large Buildings: Validation of Surface Boundary Assumptions

Abstract

1. Introduction

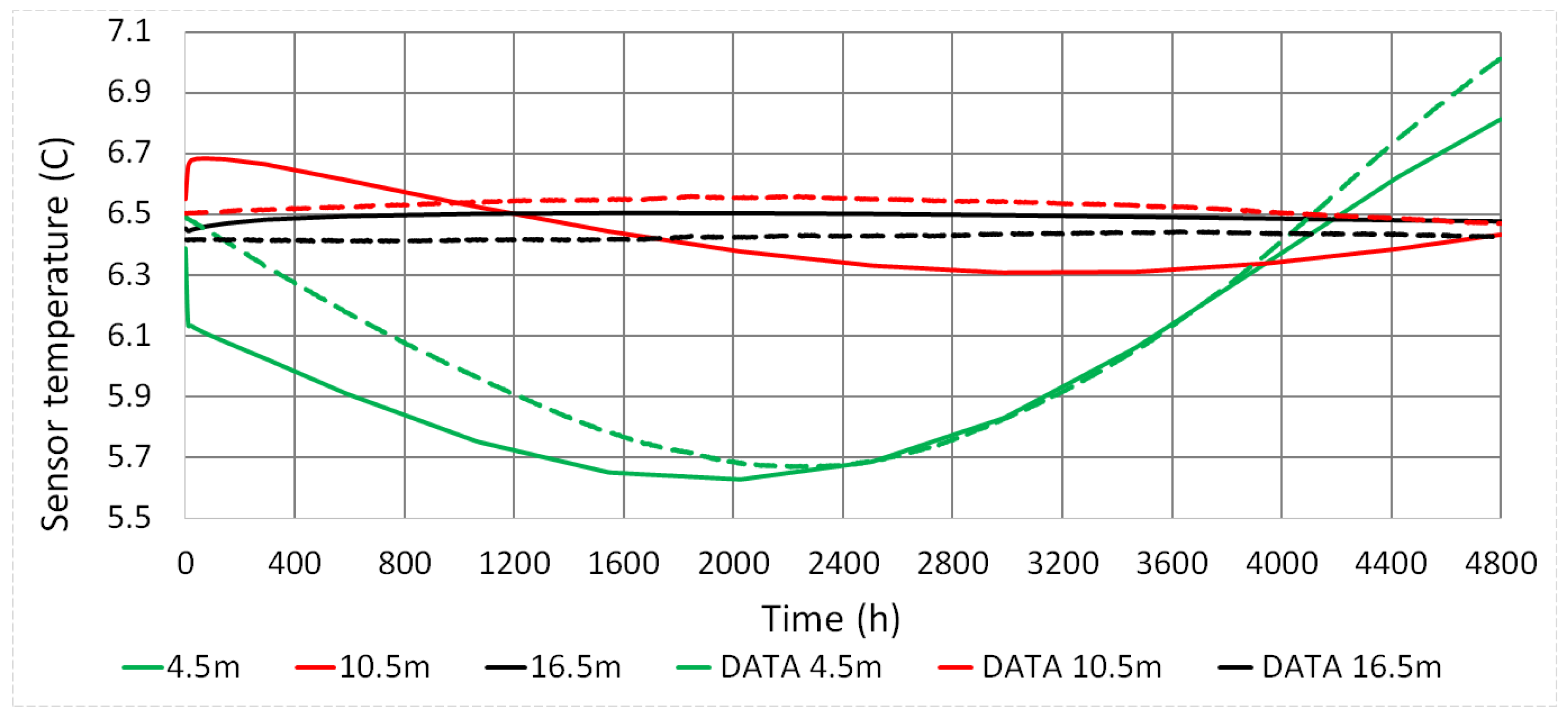

2. Validation of a COMSOL Model for a Single Pile against Measured Data

2.1. Method

2.2. Results

3. Ground Surface Boundary Analysis in COMSOL

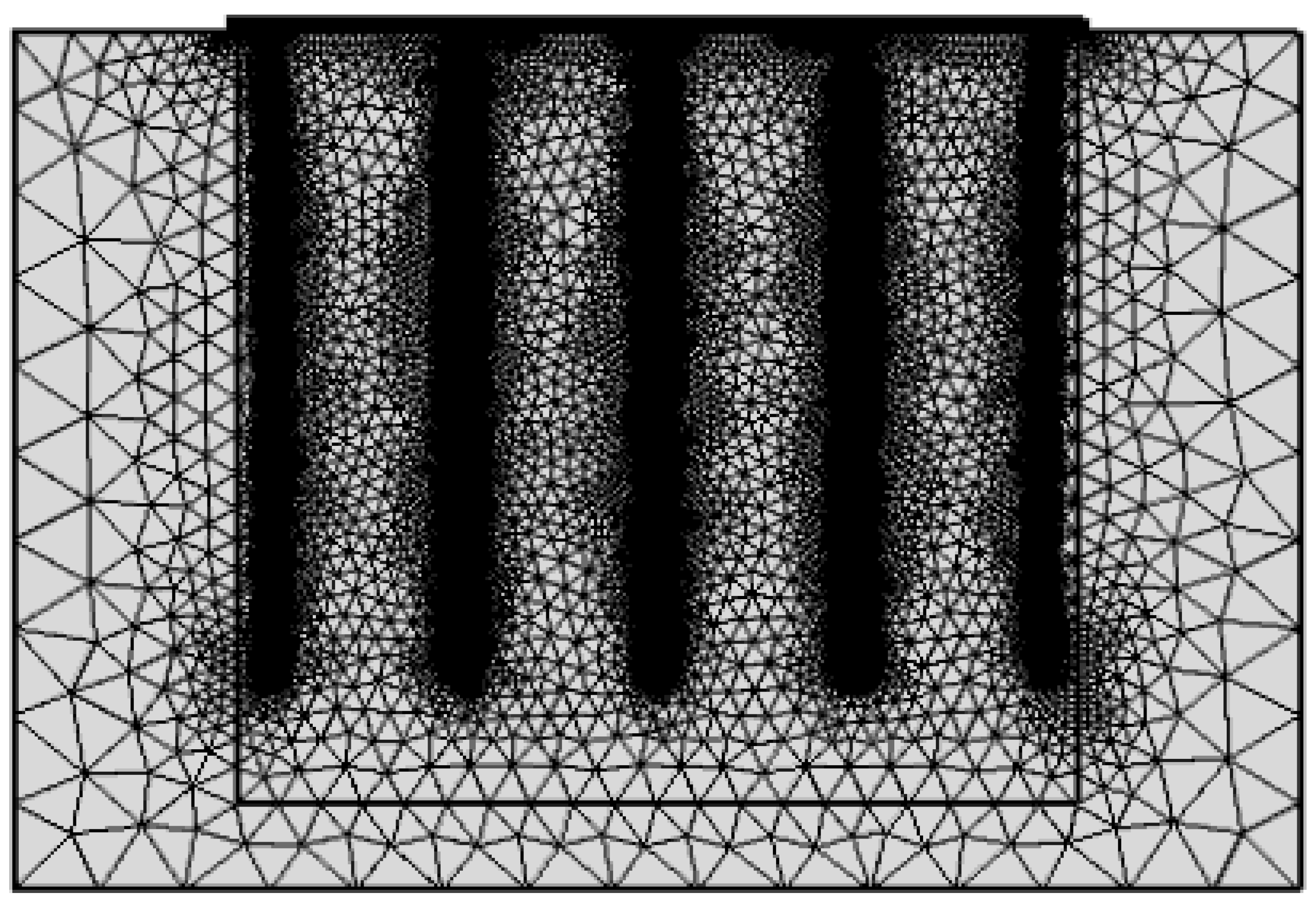

3.1. Method

Brine Flow Modelling

3.2. Results

4. IDA-ICE Borehole Model Validation against COMSOL

4.1. Method

4.2. Results

5. Impact of Boundary Conditions on Energy Efficiency Calculations

5.1. Method

5.2. Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| GHE | Ground Heat Exchangers |

| FEM | Finite Element Method |

| FDM | Finite Difference Method |

| b.c. | Boundary Conditions |

| Nomenclature | |

| Density [kg/m] | |

| Specific heat at constant pressure [kJ/(kgK)] | |

| T | Temperature [°C] |

| Thermal conductivity [W/(mK)] | |

| Time step [h] | |

References

- European Parliament. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the energy performance of buildings. Off. J. Eur. Union 2010, 53, 13–35. [Google Scholar]

- Lund, J.W.; Boyd, T.L. Direct utilization of geothermal energy 2015 worldwide review. Geothermics 2016, 60, 66–93. [Google Scholar] [CrossRef]

- Agemar, T.; Weber, J.; Moeck, I.S. Assessment and Public Reporting of Geothermal Resources in Germany: Review and Outlook. Energies 2018, 11, 332. [Google Scholar] [CrossRef]

- Park, K.S.; Kim, S. Utilising Unused Energy Resources for Sustainable Heating and Cooling System in Buildings: A Case Study of Geothermal Energy and Water Sources in a University. Energies 2018, 11, 1836. [Google Scholar] [CrossRef]

- Aydin, M.; Sisman, A. Experimental and computational investigation of multi U-tube boreholes. Appl. Energy 2015, 145, 163–171. [Google Scholar] [CrossRef]

- Bose, J.E.; Smith, M.; Spitler, J. Advances in ground source heat pump systems-an international overview. In Proceedings of the 7th IEA Heat Pump Conference, Beijing, China, 19–22 May 2002; Volume 324, pp. 313–324. [Google Scholar]

- Spitler, J. Editorial: Ground-Source Heat Pump System Research—Past, Present, and Future. HVAC R Res. 2005, 11, 165–167. [Google Scholar] [CrossRef]

- Brandl, H. Energy foundations and other thermo-active ground structures. Geotechnique 2006, 56, 81–122. [Google Scholar] [CrossRef]

- Lautkankare, R.; Sarola, V.; Kanerva-Lehto, H. Energy piles in underpinning projects—Through holes in load transfer structures. DFI J. J. Deep Found. Inst. 2014, 8, 3–14. [Google Scholar] [CrossRef]

- Faizal, M.; Bouazza, A.; Singh, R.M. Heat transfer enhancement of geothermal energy piles. Renew. Sustain. Energy Rev. 2016, 57, 16–33. [Google Scholar] [CrossRef]

- Bourne-Webb, P.; Burlon, S.; Javed, S.; Kuerten, S.; Loveridge, F. Analysis and design methods for energy geostructures. Renew. Sustain. Energy Rev. 2016, 65, 402–419. [Google Scholar] [CrossRef]

- Li, M.; Lai, A.C. Review of analytical models for heat transfer by vertical ground heat exchangers (GHEs): A perspective of time and space scales. Appl. Energy 2015, 151, 178–191. [Google Scholar] [CrossRef]

- Fadejev, J.; Simson, R.; Kurnitski, J.; Haghighat, F. A review on energy piles design, sizing and modelling. Energy 2017, 122, 390–407. [Google Scholar] [CrossRef]

- Ingersoll, L.R.; Zobel, O.J.; Ingersoll, A.C. Heat conduction with engineering, geological and other applications. Q. J. R. Meteorol. Soc. 1955, 81, 647–648. [Google Scholar] [CrossRef]

- Goldenberg, H. A problem in radial heat flow. Br. J. Appl. Phys. 1951, 2, 233. [Google Scholar] [CrossRef]

- Hu, P.; Zha, J.; Lei, F.; Zhu, N.; Wu, T. A composite cylindrical model and its application in analysis of thermal response and performance for energy pile. Energy Build. 2014, 84, 324–332. [Google Scholar] [CrossRef]

- Abdelaziz, S.L.; Ozudogru, T.Y. Selection of the design temperature change for energy piles. Appl. Therm. Eng. 2016, 107, 1036–1045. [Google Scholar] [CrossRef]

- Hellström, G. Ground Heat Storage: Thermal Analyses of Duct Storage Systems. Ph.D. Thesis, School of Mathematical Physics, Lund University, Lund, Sweden, 1991. [Google Scholar]

- Claesson, J.; Hellström, G. Analytical studies of the influence of regional groundwater flow on the performance of borehole heat exchangers. In Proceedings of the 8th International Conference on Thermal Energy Storage, Terrastock 2000, Stuttgart, Germany, 28 August–1 September 2000; pp. 195–200. [Google Scholar]

- Bozis, D.; Papakostas, K.; Kyriakis, N. On the evaluation of design parameters effects on the heat transfer efficiency of energy piles. Energy Build. 2011, 43, 1020–1029. [Google Scholar] [CrossRef]

- Rosa, M.D.; Ruiz-Calvo, F.; Corberán, J.M.; Montagud, C.; Tagliafico, L.A. Borehole modelling: A comparison between a steady-state model and a novel dynamic model in a real ON/OFF GSHP operation. J. Phys. Conf. Ser. 2014, 547, 012008. [Google Scholar] [CrossRef]

- Kwong Lee, C.; Nam Lam, H. Thermal Response Test Analysis for an Energy Pile in Ground-Source Heat Pump Systems. In Progress in Sustainable Energy Technologies: Generating Renewable Energy; Dincer, I., Midilli, A., Kucuk, H., Eds.; Springer: Cham, Switzerland, 2014; pp. 605–615. [Google Scholar]

- Li, Z.; Zheng, M. Development of a numerical model for the simulation of vertical U-tube ground heat exchangers. Appl. Therm. Eng. 2009, 29, 920–924. [Google Scholar] [CrossRef]

- Nam, Y.; Ooka, R.; Hwang, S. Development of a numerical model to predict heat exchange rates for a ground-source heat pump system. Energy Build. 2008, 40, 2133–2140. [Google Scholar] [CrossRef]

- Lazzari, S.; Priarone, A.; Zanchini, E. Long-term performance of BHE (borehole heat exchanger) fields with negligible groundwater movement. Energy 2010, 35, 4966–4974. [Google Scholar] [CrossRef]

- Diersch, H.J.; Bauer, D.; Heidemann, W.; Rühaak, W.; Schätzl, P. Finite element modeling of borehole heat exchanger systems: Part 2. Numerical simulation. Comput. Geosci. 2011, 37, 1136–1147. [Google Scholar] [CrossRef]

- Salvalai, G. Implementation and validation of simplified heat pump model in IDA-ICE energy simulation environment. Energy Build. 2012, 49, 132–141. [Google Scholar] [CrossRef]

- Fadejev, J.; Kurnitski, J. Geothermal energy piles and boreholes design with heat pump in a whole building simulation software. Energy Build. 2015, 106, 23–34. [Google Scholar] [CrossRef]

- Østergaard, D.; Svendsen, S. Space heating with ultra-low-temperature district heating—A case study of four single-family houses from the 1980s. Energy Procedia 2017, 116, 226–235. [Google Scholar] [CrossRef]

- Schweiger, G.; Heimrath, R.; Falay, B.; O’Donovan, K.; Nageler, P.; Pertschy, R.; Engel, G.; Streicher, W.; Leusbrock, I. District energy systems: Modelling paradigms and general-purpose tools. Energy 2018, 164, 1326–1340. [Google Scholar] [CrossRef]

- Lee, C.; Lam, H. A simplified model of energy pile for ground-source heat pump systems. Energy 2013, 55, 838–845. [Google Scholar] [CrossRef]

- Mehrizi, A.A.; Porkhial, S.; Bezyan, B.; Lotfizadeh, H. Energy pile foundation simulation for different configurations of ground source heat exchanger. Int. Commun. Heat Mass Transf. 2016, 70, 105–114. [Google Scholar] [CrossRef]

- Xiao, J.; Luo, Z.; Martin, J.R.; Gong, W.; Wang, L. Probabilistic geotechnical analysis of energy piles in granular soils. Eng. Geol. 2016, 209, 119–127. [Google Scholar] [CrossRef]

- Pryor, R.W. Multiphysics Modeling Using COMSOL: A First Principles Approach, 1st ed.; Jones and Bartlett Publishers, Inc.: Burlington, MA, USA, 2009. [Google Scholar]

- Dupray, F.; Laloui, L.; Kazangba, A. Numerical analysis of seasonal heat storage in an energy pile foundation. Comput. Geotech. 2014, 55, 67–77. [Google Scholar] [CrossRef]

- Diersch, H.J.; Bauer, D.; Heidemann, W.; Rühaak, W.; Schätzl, P. Finite element modeling of borehole heat exchanger systems: Part 1. Fundamentals. Comput. Geosci. 2011, 37, 1122–1135. [Google Scholar] [CrossRef]

- Park, H.; Lee, S.R.; Yoon, S.; Choi, J.C. Evaluation of thermal response and performance of PHC energy pile: Field experiments and numerical simulation. Appl. Energy 2013, 103, 12–24. [Google Scholar] [CrossRef]

- Cecinato, F.; Loveridge, F.A. Influences on the thermal efficiency of energy piles. Energy 2015, 82, 1021–1033. [Google Scholar] [CrossRef]

- Ng, C.; Ma, Q.; Gunawan, A. Horizontal stress change of energy piles subjected to thermal cycles in sand. Comput. Geotech. 2016, 78, 54–61. [Google Scholar] [CrossRef]

- Go, G.H.; Lee, S.R.; Yoon, S.; byul Kang, H. Design of spiral coil PHC energy pile considering effective borehole thermal resistance and groundwater advection effects. Appl. Energy 2014, 125, 165–178. [Google Scholar] [CrossRef]

- Loveridge, F.; Powrie, W. 2D thermal resistance of pile heat exchangers. Geothermics 2014, 50, 122–135. [Google Scholar] [CrossRef]

- Alberdi-Pagola, M.; Poulsen, S.E.; Jensen, R.L.; Madsen, S. Thermal design method for multiple precast energy piles. Geothermics 2019, 78, 201–210. [Google Scholar] [CrossRef]

- Batini, N.; Loria, A.F.R.; Conti, P.; Testi, D.; Grassi, W.; Laloui, L. Energy and geotechnical behaviour of energy piles for different design solutions. Appl. Therm. Eng. 2015, 86, 199–213. [Google Scholar] [CrossRef]

- Caulk, R.; Ghazanfari, E.; McCartney, J.S. Parameterization of a calibrated geothermal energy pile model. Geomech. Energy Environ. 2016, 5, 1–15. [Google Scholar] [CrossRef]

- Loria, A.F.R.; Vadrot, A.; Laloui, L. Analysis of the vertical displacement of energy pile groups. Geomech. Energy Environ. 2018, 16, 1–14. [Google Scholar] [CrossRef]

- Li, M.; Lai, A.C. Heat-source solutions to heat conduction in anisotropic media with application to pile and borehole ground heat exchangers. Appl. Energy 2012, 96, 451–458. [Google Scholar] [CrossRef]

- Park, S.; Lee, D.; Lee, S.; Chauchois, A.; Choi, H. Experimental and numerical analysis on thermal performance of large-diameter cast-in-place energy pile constructed in soft ground. Energy 2017, 118, 297–311. [Google Scholar] [CrossRef]

- McCartney, J.S.; Murphy, K.D. Investigation of potential dragdown/uplift effects on energy piles. Geomech. Energy Environ. 2017, 10, 21–28. [Google Scholar] [CrossRef]

- Sung, C.; Park, S.; Lee, S.; Oh, K.; Choi, H. Thermo-mechanical behavior of cast-in-place energy piles. Energy 2018, 161, 920–938. [Google Scholar] [CrossRef]

- Singh, R.; Bouazza, A.; Wang, B. Near-field ground thermal response to heating of a geothermal energy pile: Observations from a field test. Soils Found. 2015, 55, 1412–1426. [Google Scholar] [CrossRef]

- Suryatriyastuti, M.; Mroueh, H.; Burlon, S. Understanding the temperature-induced mechanical behaviour of energy pile foundations. Renew. Sustain. Energy Rev. 2012, 16, 3344–3354. [Google Scholar] [CrossRef]

- Eguaras-Martínez, M.; Vidaurre-Arbizu, M.; Martín-Gómez, C. Simulation and evaluation of Building Information Modeling in a real pilot site. Appl. Energy 2014, 114, 475–484. [Google Scholar] [CrossRef]

- Uotinen, V.M.; Repo, T.; Vesamäki, H. Energy piles—Ground energy system integrated to the steel foundation piles. In Proceedings of the 16th Nordic Geotechnical Meeting (NGM 2012), Copenhagen, Denmark, 9–12 May 2012; pp. 837–844. [Google Scholar]

- Jõeleht, A.; Kukkonen, I.T. Physical properties of Vendian to Devonian sedimentary rocks in Estonia. GFF 2002, 124, 65–72. [Google Scholar] [CrossRef]

- Kukkonen, I.; Lindberg, A. Thermal Properties of Rocks at the Investigation Sites: Measured and Calculated Thermal Conductivity, Specific Heat Capacity and Thermal Diffusivity; Working Report; Ilmo Kukkonen Antero Lindberg: Helsinki, Finland, 1998. [Google Scholar]

- Bauer, D.; Heidemann, W.; Diersch, H.J. Transient 3D analysis of borehole heat exchanger modeling. Geothermics 2011, 40, 250–260. [Google Scholar] [CrossRef]

- Al-Khoury, R.; Kölbel, T.; Schramedei, R. Efficient numerical modeling of borehole heat exchangers. Comput. Geosci. 2010, 36, 1301–1315. [Google Scholar] [CrossRef]

| Temperature Sensor | Depth, m |

|---|---|

| Ground surface | 0 |

| Pile top | −0.5 |

| T28 | −0.5 |

| T29 | −2.5 |

| T30 | −4.5 |

| T31 | −6.5 |

| T32 | −8.5 |

| T33 | −10.5 |

| T34 | −12.5 |

| T35 | −14.5 |

| T36 | −16.5 |

| Layer nr | Depth, m | , t/m | , kJ/kgK | , W/mK |

|---|---|---|---|---|

| 1 | 3.73 | 1.4 | 1.8 | 0.87 |

| 2 | 5.67 | 1.72 | 1.82 | 1.24 |

| 3 | 5.84 | 1.66 | 1.78 | 1.08 |

| 4 | 6.5 | 1.80 | 1.71 | 1.25 |

| 5 | 6.67 | 1.83 | 1.72 | 1.39 |

| 6 | 6.84 | 1.91 | 1.57 | 1.42 |

| 7 | 12.9 | 2.03 | 1.40 | 1.89 |

| 8 | 12.91 | 2.01 | 1.39 | 1.81 |

| 9 | 15.90 | 2.06 | 2.32 | 1.92 |

| 10 | 15.91 | 2.05 | 2.33 | 1.91 |

| 11 | 19 | 1.99 | 2.39 | 1.53 |

| 12 | 19.01 | 1.95 | 2.41 | 1.5 |

| 13 | 23.3 | 2.28 | 2.10 | 2.52 |

| 14 | 26.7 | 2.21 | 2.16 | 2.44 |

| 17 | 18 | 19 | 20 |

| 13 | 14 | 15 | 16 |

| 9 | 10 | 11 | 12 |

| 5 | 6 | 7 | 8 |

| 1 | 2 | 3 | 4 |

| Case | Floor Slab Heat Flux, kWh/a | Heating Need, kWh/a | Heat Flux, % Difference | Heating Need, % Difference |

|---|---|---|---|---|

| COMSOL | 24066 | 142900 | - | - |

| IDA-ICE slab | 24073 | 142580 | 0.03% | 0.2% |

| IDA-ICE outlet | 37127 | 150196 | 54% | 5% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrantelli, A.; Fadejev, J.; Kurnitski, J. Energy Pile Field Simulation in Large Buildings: Validation of Surface Boundary Assumptions. Energies 2019, 12, 770. https://doi.org/10.3390/en12050770

Ferrantelli A, Fadejev J, Kurnitski J. Energy Pile Field Simulation in Large Buildings: Validation of Surface Boundary Assumptions. Energies. 2019; 12(5):770. https://doi.org/10.3390/en12050770

Chicago/Turabian StyleFerrantelli, Andrea, Jevgeni Fadejev, and Jarek Kurnitski. 2019. "Energy Pile Field Simulation in Large Buildings: Validation of Surface Boundary Assumptions" Energies 12, no. 5: 770. https://doi.org/10.3390/en12050770

APA StyleFerrantelli, A., Fadejev, J., & Kurnitski, J. (2019). Energy Pile Field Simulation in Large Buildings: Validation of Surface Boundary Assumptions. Energies, 12(5), 770. https://doi.org/10.3390/en12050770