Experimental Investigation of Fracture Propagation Behavior Induced by Hydraulic Fracturing in Anisotropic Shale Cores

Abstract

:1. Introduction

2. Materials and Methods

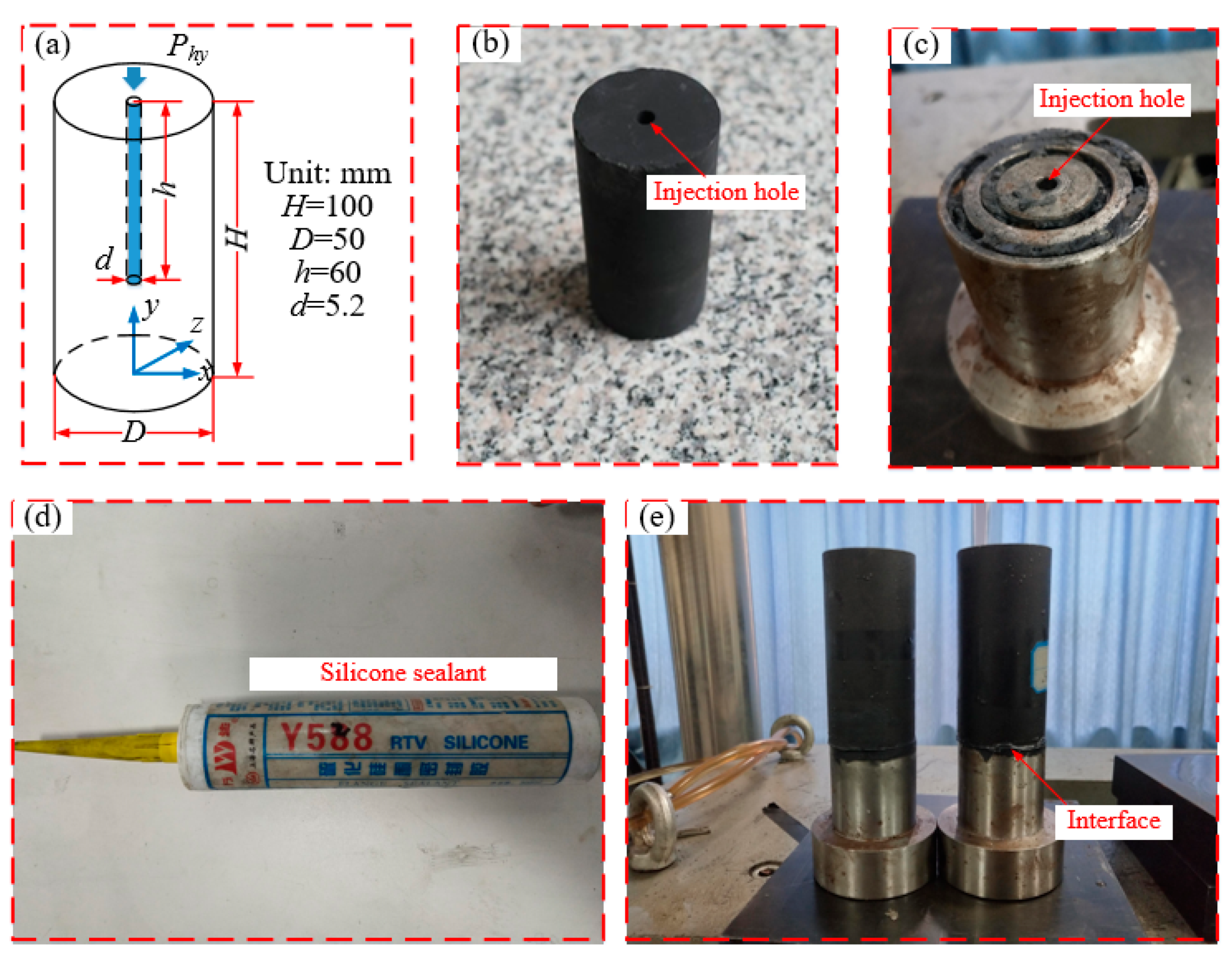

2.1. Specimen Preparations

2.2. Experimental Apparatus

3. Results and Analysis

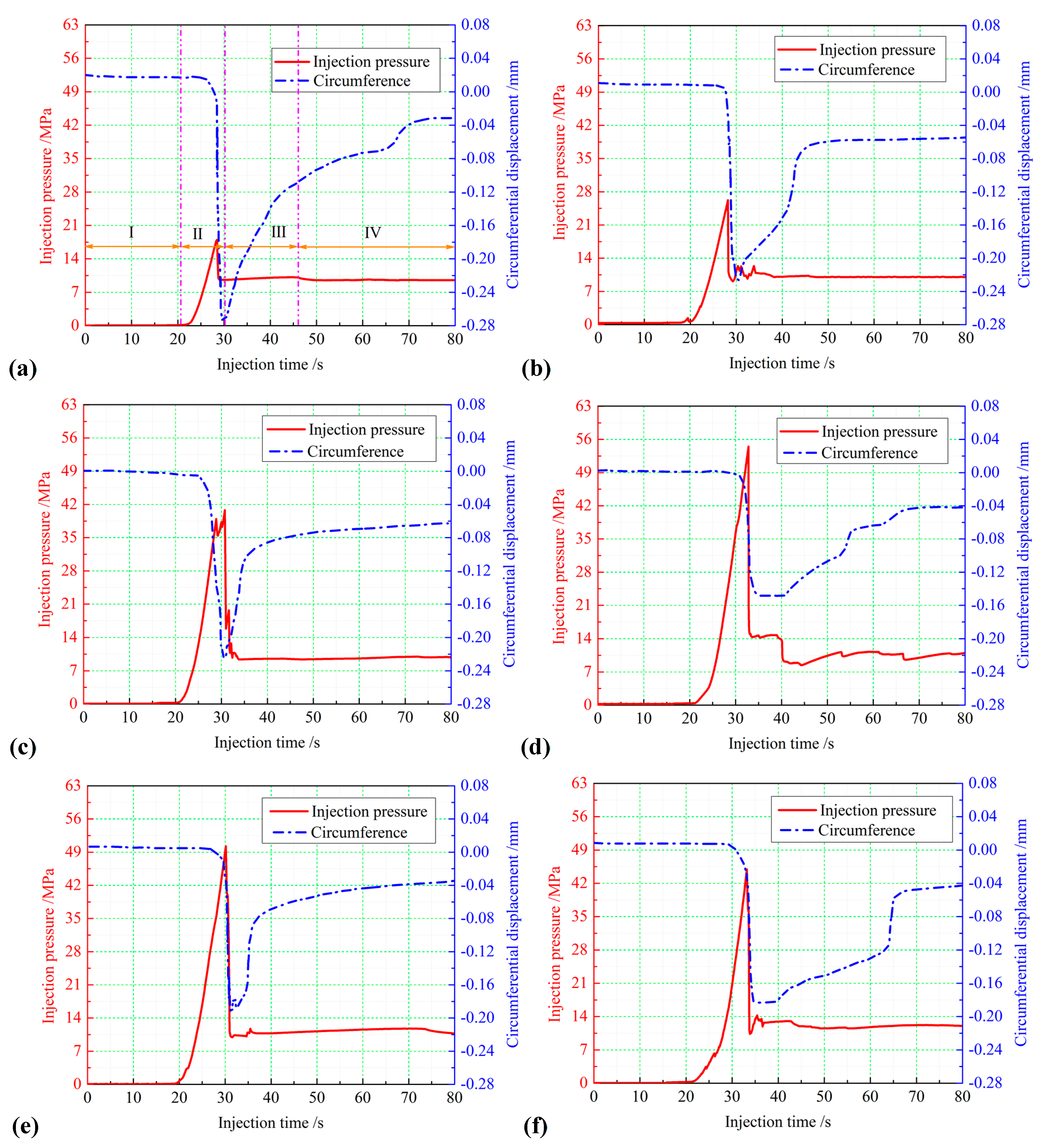

3.1. Breakdown Pressure

3.2. Propagation Modes

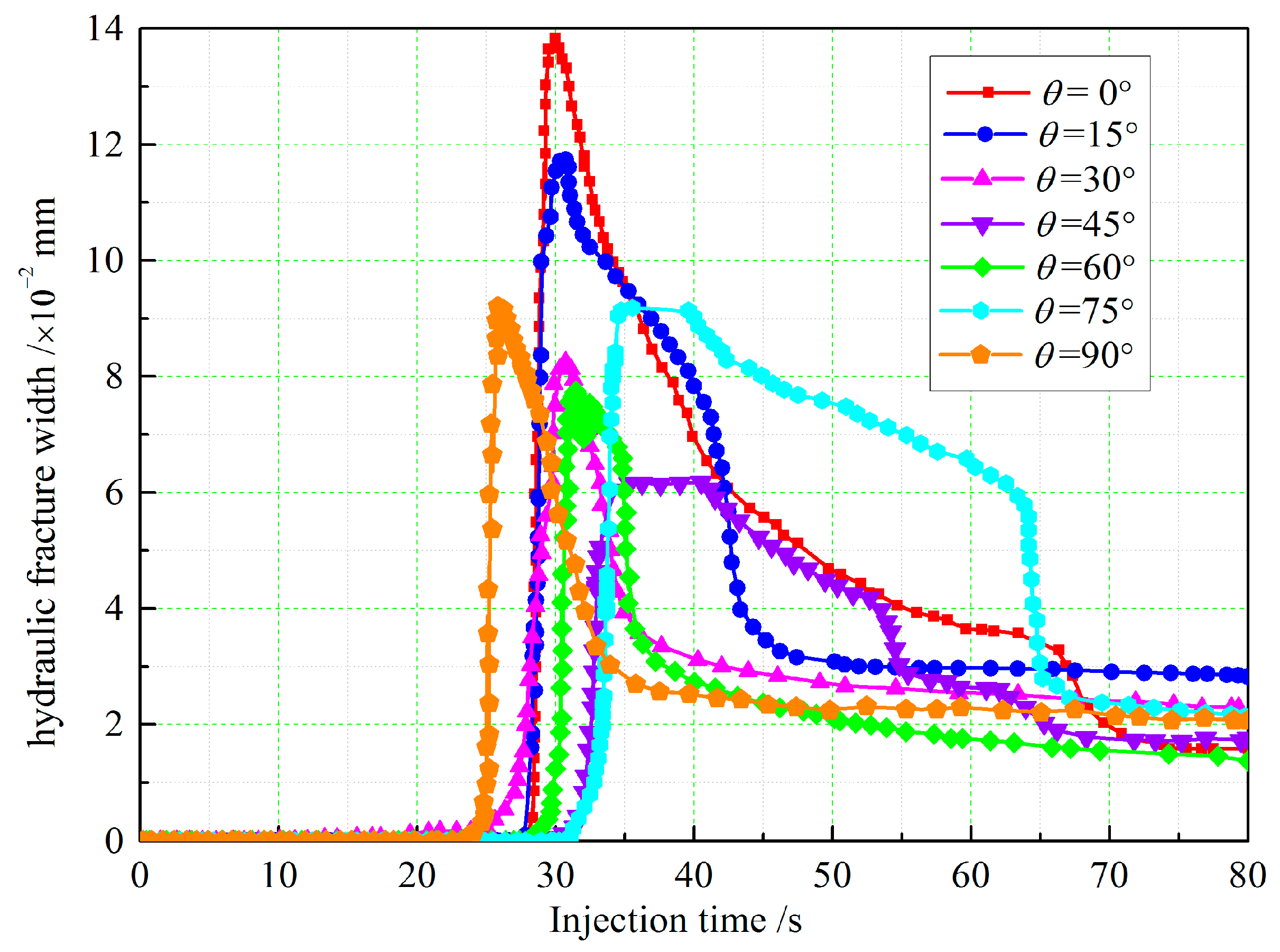

3.3. Fracture with Evolution

4. Discussion

5. Conclusions

- (1)

- Anisotropy has a significant effect on the breakdown pressure, circumferential displacement and fracturing efficiency of shale specimens. When anisotropic angle θ ≤ 15°, since of the small tensile strength of shale specimens, HF can easily initiate and propagate between BP, resulting in a smaller breakdown pressure. Especially for shale specimens at θ = 0°, the fracturing efficiency is much higher than other operating conditions. When θ = 45°, the critical stress intensity factor increases the strength of shale specimen, leading to the rapid increase of breakdown pressure, while the circumferential strain and fracturing efficiency are relatively low. When θ ≥ 60°, the breakdown pressure decreases, but it is still higher than that at smaller θ.

- (2)

- Due to the effect of bedding plane, two symmetrical HF cannot be formed in some shale specimens. When HF and bedding plane (BP) interact, increasing deviator stress and approaching angle help HF cross BP. When θ ≤ 15°, the bedding-plane mode is ubiquitous in all shale reservoirs. While θ ranged from 30°–45°, a comprehensive propagation pattern of bedding-plane and crossing is presented. When θ ≥ 60°, the HFN pattern changes from comprehensive mode to crossing mode. The propagation mode obtained from physical tests and the theoretical analysis are mutually verified.

- (3)

- With the increase of θ, the maximum width of HF decreases first and then increases gradually, but the ultimate width of HF shows an opposite trend. Therefore, the closure proportion is the highest when the propagation pattern is the bedding-plane mode (θ ≤ 15°). The closure proportion of the crossing mode is the second. Only when the bedding-plane and crossing HF occur simultaneously, the closure proportion is the smallest, the fracturing effect is the best with the lowest requirement for the proppant. The results can provide some basic data for the design in hydraulic fracturing of tight oil/gas reservoirs.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, Q.; Lu, H.; Shen, C.; Liu, J.; Peng, P.A.; Hsu, C.S. Impact of Inorganically Bound Sulfur on Late Shale Gas Generation. Energy Fuels 2014, 28, 785–793. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.Y.; Guo, J.C.; Zhao, X.; Lu, Q.; Luo, B.; Feng, Y.C. Hydraulic Fracture Initiation Pressure of Anisotropic Shale Gas Reservoirs. Geomech. Eng. 2014, 7, 403–430. [Google Scholar] [CrossRef]

- Lu, Y.; Ge, Z.; Yang, F.; Xia, B.; Tang, J. Progress on the Hydraulic Measures for Grid Slotting and Fracking to Enhance Coal Seam Permeability. Int. J. Min. Sci. Technol. 2017, 27, 867–871. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, J.; Wu, H. Experimental and Numerical Study on Hydraulic Fracture Propagation in Coalbed Methane Reservoir. J. Nat. Gas Sci. Eng. 2016, 35, 455–467. [Google Scholar] [CrossRef]

- Zhu, S.Y.; Du, Z.M.; Li, C.L.; Salmachi, A.; Peng, X.L.; Wang, C.W.; Yue, P.; Deng, P. A Semi-Analytical Model for Pressure-Dependent Permeability of Tight Sandstone Reservoirs. Transp. Porous Media 2018, 122, 235–252. [Google Scholar] [CrossRef]

- Li, Y.; Yang, S.; Zhao, W.; Li, W.; Zhang, J. Experimental of Hydraulic Fracture Propagation Using Fixed-Point Multistage Fracturing in a Vertical Well in Tight Sandstone Reservoir. J. Pet. Sci. Eng. 2018, 171, 704–713. [Google Scholar] [CrossRef]

- Chen, M.; Sun, Y.; Fu, P.; Carrigan, C.R.; Lu, Z.; Tong, C.H. Surrogate-Based Optimization of Hydraulic Fracturing in Pre-Existing Fracture Networks. Comput. Geosci. 2013, 58, 69–79. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, S.; Ma, X.; Zhou, T.; Zeng, B. Numerical Investigation of Hydraulic Fracture Network Propagation in Naturally Fractured Shale Formations. J. Struct. Geol. 2016, 84, 1–13. [Google Scholar] [CrossRef]

- Ezulike, D.O.; Dehghanpour, H. A Model for Simultaneous Matrix Depletion into Natural and Hydraulic Fracture Networks. J. Nat. Gas Sci. Eng. 2014, 16, 57–69. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, M.; Zhang, G. Analysis of the Influence of a Natural Fracture Network on Hydraulic Fracture Propagation in Carbonate Formations. Rock Mech. Rock Eng. 2014, 47, 575–587. [Google Scholar] [CrossRef]

- Zolfaghari, A.; Dehghanpour, H.; Holyk, J. Water sorption behaviour of gas shales: I. Role of clays. Int. J. Coal Geol. 2017, 179, 130–138. [Google Scholar] [CrossRef]

- Zolfaghari, A.; Dehghanpour, H.; Xu, M. Water sorption behaviour of gas shales: II. Pore size distribution. Int. J. Coal Geol. 2017, 179, 187–195. [Google Scholar] [CrossRef]

- Bohloli, B.; De Pater, C.J. Experimental Study on Hydraulic Fracturing of Soft Rocks: Influence of Fluid Rheology and Confining Stress. J. Pet. Sci. Eng. 2006, 53, 1–12. [Google Scholar] [CrossRef]

- Zhang, D.; Ranjith, P.G.; Perera, M.S.A. The Brittleness Indices Used in Rock Mechanics and their Application in Shale Hydraulic Fracturing: A Review. J. Pet. Sci. Eng. 2016, 143, 158–170. [Google Scholar] [CrossRef]

- Kolykhalov, I.V.; Martynyuk, P.A.; Sher, E.N. Modeling Fracture Growth Under Multiple Hydraulic Fracturing Using Viscous Fluid. J. Min. Sci. 2016, 52, 662–669. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Tang, C.A. Effect of Injection Rate on Hydraulic Fracturing in Naturally Fractured Shale Formations: A Numerical Study. Environ. Earth Sci. 2016, 75, 935. [Google Scholar] [CrossRef]

- Hofmann, H.; Babadagli, T.; Zimmermann, G. Numerical Simulation of Complex Fracture Network Development by Hydraulic Fracturing in Naturally Fractured Ultratight Formations. J. Energy Resour. Technol. 2014, 136, 42905. [Google Scholar] [CrossRef]

- Osiptsov, A.A. Fluid Mechanics of Hydraulic Fracturing: A Review. J. Pet. Sci. Eng. 2017, 156, 513–535. [Google Scholar] [CrossRef]

- Fan, T.G.; Zhang, G.Q. Laboratory Investigation of Hydraulic Fracture Networks in Formations with Continuous Orthogonal Fractures. Energy 2014, 74, 164–173. [Google Scholar] [CrossRef]

- Dehghan, A.N.; Goshtasbi, K.; Ahangari, K.; Jin, Y. Experimental Investigation of Hydraulic Fracture Propagation in Fractured Blocks. Bull. Eng. Geol. Environ. 2015, 74, 887–895. [Google Scholar] [CrossRef]

- Gu, H.; Weng, X.; Lund, J.B.; Mack, M.G.; Ganguly, U.; Suarez-Rivera, R. Hydraulic Fracture Crossing Natural Fracture at Nonorthogonal Angles: A Criterion and its Validation. SPE Prod. Oper. 2012, 27, 20–26. [Google Scholar] [CrossRef]

- Wang, W.; Li, X.; Lin, B.; Zhai, C. Pulsating Hydraulic Fracturing Technology in Low Permeability Coal Seams. Int. J. Min. Sci. Technol. 2015, 25, 681–685. [Google Scholar] [CrossRef]

- Olson, J.E.; Taleghani, A.D. Modeling Simultaneous Growth of Multiple Hydraulic Fractures and their Interaction with Natural Fractures. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 19–21 January 2009; Society of Petroleum Engineers: Richardson, TX, USA, 2009. [Google Scholar]

- Wang, Y.; Li, X.; Zhang, B. Analysis of Fracturing Network Evolution Behaviors in Random Naturally Fractured Rock Blocks. Rock Mech. Rock Eng. 2016, 49, 4339–4347. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, J.; Braun, A.; Han, Z. Sensitivity Analysis on the Interaction Between Hydraulic and Natural Fractures Based on an Explicitly Coupled Hydro-Geomechanical Model in PFC2D. J. Pet. Sci. Eng. 2018, 167, 638–653. [Google Scholar] [CrossRef]

- Wanniarachchi, W.A.M.; Ranjith, P.G.; Perera, M.S.A.; Rathnaweera, T.D.; Zhang, D.C.; Zhang, C. Investigation of effects of fracturing fluid on hydraulic fracturing and fracture permeability of reservoir rocks: An experimental study using water and foam fracturing. Eng. Fract. Mech. 2018, 194, 117–135. [Google Scholar] [CrossRef]

- Mohammadnejad, T.; Andrade, J.E. Numerical modeling of hydraulic fracture propagation, closure and reopening using XFEM with application to in-situ stress estimation. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 2033–2060. [Google Scholar] [CrossRef]

- Chong, Z.; Li, X.; Hou, P.; Chen, X.; Wu, Y. Moment Tensor Analysis of Transversely Isotropic Shale Based on the Discrete Element Method. Int. J. Min. Sci. Technol. 2017, 27, 507–515. [Google Scholar] [CrossRef]

- Dubey, R.K.; Gairola, V.K. Influence of Structural Anisotropy on the Uniaxial Compressive Strength of Pre-Fatigued Rocksalt From Himachal Pradesh, India. Int. J. Rock Mech. Min. Sci. 2000, 6, 993–999. [Google Scholar] [CrossRef]

- Song, H.; Jiang, Y.; Elsworth, D.; Zhao, Y.; Wang, J.; Liu, B. Scale Effects and Strength Anisotropy in Coal. Int. J. Coal Geol. 2018, 195, 37–46. [Google Scholar] [CrossRef]

- Taniguchi, T.; Mitsumata, T.; Sugimoto, M.; Koyama, K. Anisotropy in Elastic Modulus of Hydrogel Containing Magnetic Particles. Phys. A Stat. Mech. Appl. 2006, 370, 240–244. [Google Scholar] [CrossRef]

- Collet, O.; Gurevich, B.; Madadi, M.; Pervukhina, M. Modeling Elastic Anisotropy Resulting from the Application of Triaxial Stress. Geophysics 2014, 79, C135–C145. [Google Scholar] [CrossRef]

- Wang, X.; Shi, F.; Liu, H.; Wu, H. Numerical Simulation of Hydraulic Fracturing in Orthotropic Formation Based on the Extended Finite Element Method. J. Nat. Gas Sci. Eng. 2016, 33, 56–69. [Google Scholar] [CrossRef]

- Asadpoure, A.; Mohammadi, S. Developing New Enrichment Functions for Crack Simulation in Orthotropic Media by the Extended Finite Element Method. Int. J. Numer. Methods Eng. 2007, 69, 2150–2172. [Google Scholar] [CrossRef]

- Pan, R.; Cheng, Y.; Yuan, L.; Yu, M.; Dong, J. Effect of Bedding Structural Diversity of Coal on Permeability Evolution and Gas Disasters Control with Coal Mining. Nat. Hazards 2014, 73, 531–546. [Google Scholar] [CrossRef]

- Warpinski, N.R.; Teufel, L.W. Influence of Geologic Discontinuities on Hydraulic Fracture Propagation. J. Pet. Technol. 1987, 39, 209–220. [Google Scholar] [CrossRef]

- He, J.; Lin, C.; Li, X.; Zhang, Y.; Chen, Y. Initiation, Propagation, Closure and Morphology of Hydraulic Fractures in Sandstone Cores. Fuel 2017, 208, 65–70. [Google Scholar] [CrossRef]

- Zolfaghari, A.; Dehghanpour, H.; Ghanbari, E.; Bearinger, D. Fracture characterization using flowback salt-concentration transient. SPE J. 2016, 21, 233–244. [Google Scholar] [CrossRef]

| Parameters | Axis Parallel to the Layer | Axis Vertical to the Layer | ||||

|---|---|---|---|---|---|---|

| 0°-1 | 0°-2 | Mean | 90°-1 | 90°-2 | Mean | |

| Uniaxial compression strength, UCS/MPa | 102.14 | 110.57 | 106.36 | 148.84 | 152.27 | 150.56 |

| Elastic modulus/GPa | 16.38 | 15.17 | 15.78 | 31.01 | 28.74 | 29.88 |

| Poisson’s ratio | 0.31 | 0.29 | 0.30 | 0.29 | 0.27 | 0.28 |

| Shear modulus/GPa | 6.25 | 5.88 | 6.07 | 12.02 | 11.31 | 11.67 |

| No. | Anisotropic Angle θ/° | σV/MPa | σcon/MPa | ∆σ/MPa | qin/mL·s−1 | σpb/MPa |

|---|---|---|---|---|---|---|

| 1 | 0° | 20 | 10 | 10 | 0.1 | 18.61 |

| 2 | 15° | 20 | 10 | 10 | 0.1 | 26.22 |

| 3 | 30° | 20 | 10 | 10 | 0.1 | 40.78 |

| 4 | 45° | 20 | 10 | 10 | 0.1 | 54.50 |

| 5 | 60° | 20 | 10 | 10 | 0.1 | 50.24 |

| 6 | 75° | 20 | 10 | 10 | 0.1 | 44.91 |

| 7 | 90° | 20 | 10 | 10 | 0.1 | 39.82 |

| 8 | 45° | 15 | 10 | 5 | 0.1 | 59.65 |

| 9 | 45° | 25 | 10 | 15 | 0.1 | 50.36 |

| 10 | 75° | 20 | 10 | 10 | 0.2 | 51.74 |

| 11 | 90° | 20 | 10 | 10 | 0.2 | 47.79 |

| No | θ/° | Failure Mode | Maximum Width/×10−2 mm | Ultimate Width/×10−2 mm | Closure ×10−2 mm | Closure Proportion/% |

|---|---|---|---|---|---|---|

| 1 | 0 | Bedding-plane | 13.82 | 3.16 | 10.66 | 77.13 |

| 2 | 15 | Bedding-plane | 11.74 | 5.46 | 6.28 | 53.49 |

| 3 | 30 | Bedding-plane + Crossing | 8.26 | 6.27 | 1.99 | 24.09 |

| 4 | 45 | Bedding-plane + Crossing | 6.17 | 4.26 | 1.91 | 30.96 |

| 5 | 60 | Crossing | 7.74 | 3.43 | 4.31 | 55.68 |

| 6 | 75 | Crossing | 9.18 | 4.28 | 4.90 | 53.38 |

| 7 | 90 | Crossing | 9.21 | 4.14 | 5.07 | 55.05 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chong, Z.; Yao, Q.; Li, X. Experimental Investigation of Fracture Propagation Behavior Induced by Hydraulic Fracturing in Anisotropic Shale Cores. Energies 2019, 12, 976. https://doi.org/10.3390/en12060976

Chong Z, Yao Q, Li X. Experimental Investigation of Fracture Propagation Behavior Induced by Hydraulic Fracturing in Anisotropic Shale Cores. Energies. 2019; 12(6):976. https://doi.org/10.3390/en12060976

Chicago/Turabian StyleChong, Zhaohui, Qiangling Yao, and Xuehua Li. 2019. "Experimental Investigation of Fracture Propagation Behavior Induced by Hydraulic Fracturing in Anisotropic Shale Cores" Energies 12, no. 6: 976. https://doi.org/10.3390/en12060976