The Impact of Selected Biofuels on the Skoda Roomster 1.4TDI Engine’s Operational Parameters

Abstract

:1. Introduction

2. Materials and Methods

- Density at 15 °C by EN ISO 3675

- Kinematic viscosity at 40 °C by EN ISO 3104

- CFPP—Cold filter plugging point by EN 116

- Cetane number by EN ISO 5165

- Cetane index by EN ISO 4264

- Flash point by EN 22719

3. Results

3.1. Results of Chemical Properties

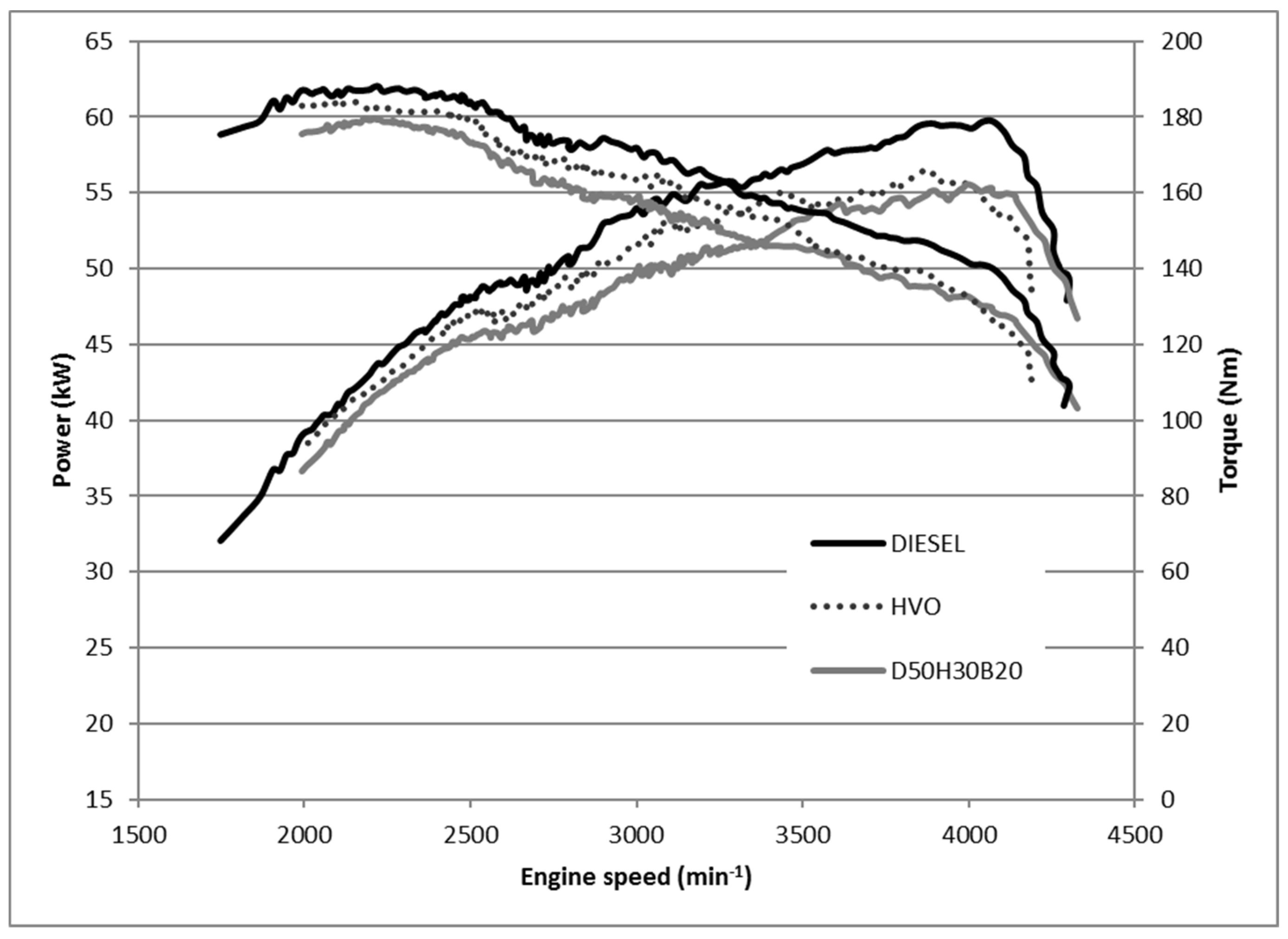

3.2. Results of Performance Parameters

3.3. Results of Emission Parameters

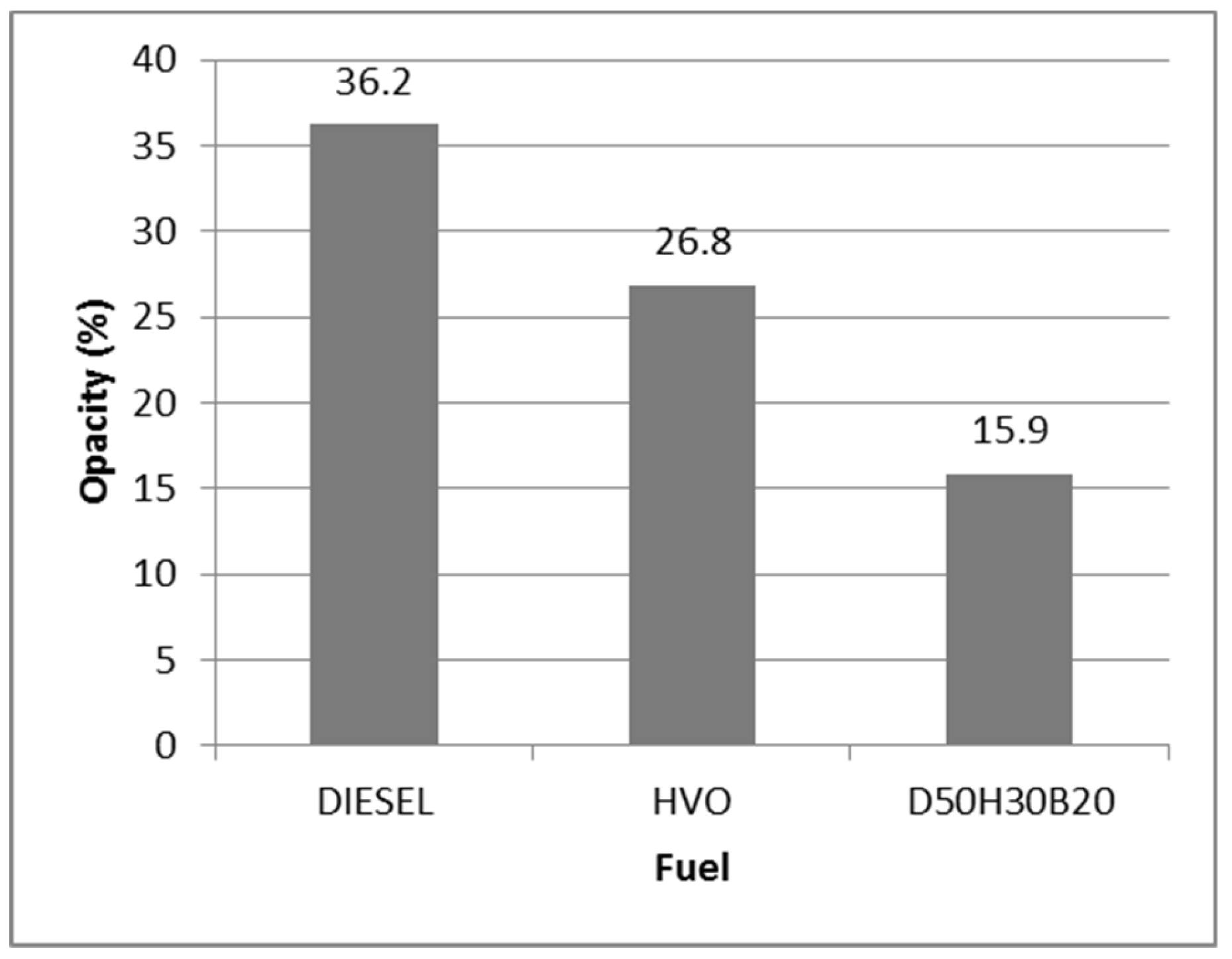

3.4. Results of Opacity

3.5. Results of Fuel Consumption

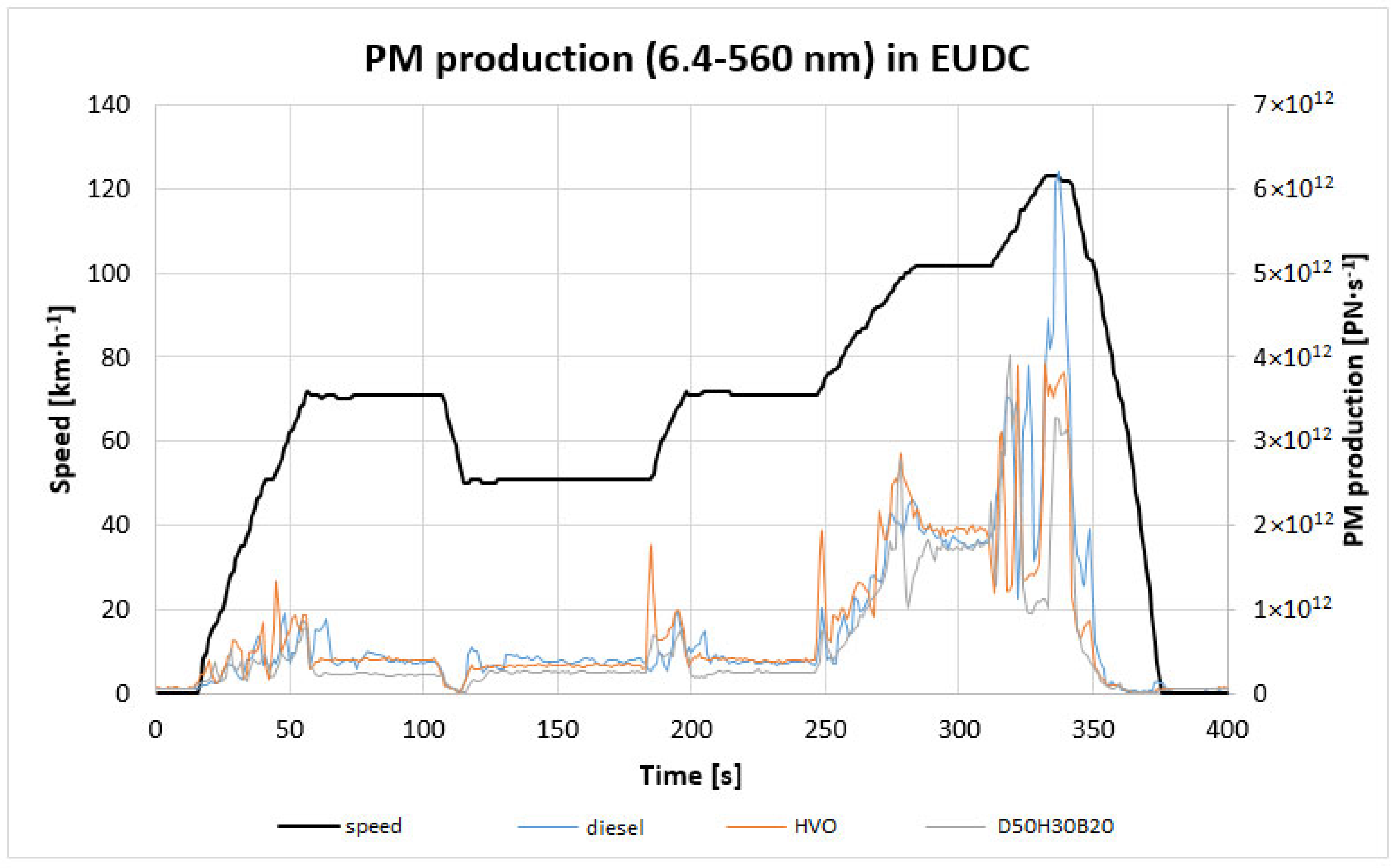

3.6. Results of PM Production

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- European Automobile Manufacturers Association. Share of Diesel in New Passenger Cars. ACEA. 2015. Available online: http://www.acea.be/statistics/tag/category/share-of-diesel-in-new-passenger-cars (accessed on 1 March 2019).

- Dockery, D.W.; Schwartz, J.; Spengler, J.D. Air pollution and daily mortality: Associations with particulates and acid aerosols. Environ. Res. 1992, 59, 362–370. [Google Scholar] [CrossRef]

- Pourazar, J.; Frew, A.J.; Blomberg, A.; Helleday, R.; Kelly, F.J.; Wilson, S. Diesel exhaust exposure enhances the expression of IL-13 in the bronchial epithelium of healthy subjects. Respir. Med. 2004, 98, 821–825. [Google Scholar] [CrossRef]

- Goyal, P.; Jaiswal, N.; Kumar, A.; Dadoo, J.K.; Dwarakanath, M. Air quality impact assessment of NOx and PM due to diesel vehicles in Delhi. Transp. Res. Part D Trans. Environ. 2010, 15, 298–303. [Google Scholar] [CrossRef]

- Jacobson, M.Z. Global direct radioactive forcing due to multicomponent anthropogenic and naturals aerosols. J. Geophys. Res. 2001, 106, 1551–1568. [Google Scholar] [CrossRef]

- Koch, D. Transport and direct radiative forcing of carbonaceous and sulphate aerosols in the GSISS GCM. J. Geophys. Res. 2011, 106, 11–32. [Google Scholar]

- European Union. Directive 28/2009/CE of the European Parliament and of the Council; European Union: Brussels, Belgium, 2009. [Google Scholar]

- Yilmaz, N.; Morton, B. Effects of preheating vegetable oils on performance and emission characteristics of two diesel engines. Biomass Bioenergy 2011, 35, 2028–2033. [Google Scholar] [CrossRef]

- Masjuki, H.H.; Kalam, M.A.; Maleque, M.A.; Kubo, A.; Nonaka, T. Performance, emissions and wear characteristics of an indirect injection diesel engine using coconut oil blended fuel. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2001, 215, 393–404. [Google Scholar] [CrossRef]

- Pexa, M.; Mařík, J. The Impact of biofuels and technical condition to its smoke–Zetor 8641 Forterra. Agron. Res. 2014, 12, 367–372. [Google Scholar]

- Hönig, V.; Hromádko, J. Possibilities of using vegetable oil to power diesel engines as well as their impact on engine oil. Agron. Res. 2014, 12, 323–332. [Google Scholar]

- Stumborg, M.; Wong, A.; Hogan, E. Hydroprocessed vegetable oils for diesel fuel improvement. Bioresour. Technol. 1996, 56, 13–18. [Google Scholar] [CrossRef]

- Kuronen, M.; Mikkonen, S.; Aakko, P.; Murtonen, T. Hydrotreated Vegetable Oil as Fuel for Heavy Duty Diesel Engines; SAE Technical Paper 2007-01-4031; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Huber, G.W.; O’Connor, P.; Corma, A. Processing biomass in conventional oilrefineries: Production of high quality diesel by hydrotreating vegetable oils in heavy vacuum oil mixtures. Appl. Catal. A 2007, 329, 120–129. [Google Scholar] [CrossRef]

- Da Rocha Filho, D.N.; Brodzki, D.; Djéga-Mariadassou, G. Formation of alkanes, alkylcykloalkanes and alkylbenzenes during the catalytic hydrocracking of vegetable oils. Fuel 1993, 72, 543–549. [Google Scholar] [CrossRef]

- Aatola, H.; Larmi, M.; Sarjovaara, T.; Mikkonen, S. Hydrotreated Vegetable Oil (HVO) as a Renewable Diesel Fuel: Trade Off between NOx, Particular Emission, and Fuel Consumption of a Heavy Duty Engine; SAE Technical Paper 2008-01-2500; SAE International: Warrendale, PA, USA, 2008. [Google Scholar]

- Lapuerta, M.; Armas, O.; Hernandez, J.J.; Tsolakis, A. Potential for reducing emissions in a diesel engine by fuelling with conventional biodiesel and Fisher-Tropsch diesel. Fuel 2010, 89, 3106–3113. [Google Scholar] [CrossRef]

- Duckhan, K.; Seonghwan, K.; Sehun, O.; No, S.-Y. Engine performance and emission characteristics of hydrotreated vegetable oil in light duty diesel engines. Fuel 2014, 125, 36–43. [Google Scholar] [CrossRef]

- Birzietis, G.; Pirs, V.; Dukulis, I.; Gailis, M. Effect of commercial diesel fuel and hydrotreated vegetable oil blend on automobile performance. Agron. Res. 2017, 15, 964–970. [Google Scholar]

- Lapuerta, M.; Villajos, M.; Agudelo, J.R.; Boehman, A.L. Key properties and blending strategies of hydrotreated vegetable oil as biofuel for diesel engines. Fuel Process Technol. 2011, 92, 2406–2411. [Google Scholar] [CrossRef]

- Yehliu, K.; Boehman, A.L. Effect of alternative fuels on exhaust emissions during diesel engine operation with matched combustion phasing. Fuel 2012, 89, 438–456. [Google Scholar] [CrossRef]

- Armas, O.; García-Contreras, R.; Ramos, A. Impact of alternative fuels on performance and pollutant emissions of light duty engine tested under the new European driving cycle. Appl. Energy 2013, 107, 183–190. [Google Scholar] [CrossRef]

- Li, X.; Huang, Z.; Wang, J.; Zhang, W. Diesel particle size distribution estimation from digital image analysis. Aerosol Sci. Technol. 2007, 37, 369–381. [Google Scholar] [CrossRef]

- Chuepeng, S.; Xu, H.; Tsolakis, A.; Wyszynski, M.; Price, P. Particulate Matter size distribution in the exhaust gas of a modern diesel Engine fuelled with biodiesel blend. Biomass Bioenergy 2011, 35, 4280–4289. [Google Scholar] [CrossRef]

- Pexa, M.; Čedík, J.; Pražan, R. Smoke and NOx emission of combustion engine using biofuels. Agron. Res. 2016, 14, 547–555. [Google Scholar]

- Millo, F.; Debnath, B.K.; Vlachos, T.; Ciaravino, C.; Postrioti, L.; Buitoni, G. Effects of different biofuels blends on performance and emissions of an automotive diesel engine. Fuel 2015, 159, 614–627. [Google Scholar] [CrossRef]

- Ricardo, S.-B.; Kousoulidou, M.; Clairotte, M.; Giechaskiel, B.; Nuottimäki, J.; Sarjovaara, T.; Lonza, L. Impact of HVO blends on modern diesel passenger cars emissions during real world operation. Fuel 2019, 235, 1427–1435. [Google Scholar]

- Sarvi, A.; Lyyranen, J.; Jokiniemi, J.; Zevenhoven, R. Particulate emissions from large-scale medium-speed diesel engines: 1. Particle size distribution. Fuel Process. Technol. 2011, 92, 1855–1861. [Google Scholar] [CrossRef]

- Vojtisek-Lom, M.; Beránek, V.; Mikuška, P.; Křůmal, K.; Coufalík, P.; Sikorová, J.; Topinka, J. Blends of butanol and hydrotreated vegetable oil as drop-in replacement for diesel engines: Effects on combustion and emissions. Fuel 2017, 197, 407–421. [Google Scholar] [CrossRef]

- Hönig, V.; Hromádko, J.; Orsák, M. Využití biobutanolu ve vznětových motorech a jeho vliv na parametry motorové nafty (In Czech). Chemické Listy 2015, 109, 722–725. [Google Scholar]

| Combustion Engine | |

|---|---|

| Design | compression ignition, turbo charged |

| Fuel System | unit injector system |

| Number of Cylinders and Valves | 3 in row, 6 valves |

| Fuel | diesel |

| Volume of Cylinders | 1422 ccm |

| Power | 59 Kw at 4000 rpm |

| Torque | 195 Nm at 2200 rpm |

| EU Limit | EU4 |

| Manufacture Year | 2006 |

| Mileage | 102,000 km |

| Car Body | |

| Service Weight | 1240 kg |

| Total Weight | 1755 kg |

| Drive Performance | |

| Max. Speed | 165 km·h−1 |

| Acceleration 0–100 km·h−1 | 14.7 s |

| Declared Fuel Consumption (Urban/Extra-Urban/Combination) | 5.1/3.76/4.26 (liter·100 km−1) |

| Measured Quantity | Range | Resolution | Accuracy |

|---|---|---|---|

| Absorption coefficient (k) | 0–16 m−1 | 0.01 m−1 | ± 0.15 m−1*); ± 0.30 m−1**) |

| Opacity (N) | 0–100% | 0.1% | ± 2% absolute |

| Temperature | 0–150 °C | 1 °C | ± 2 °C |

| RPM | 400–2000 min−1 | 10 min−1 | ± 20 min−1 |

| 2001–9999 min−1 | ± 2% RV | ||

| Acceleration time | 0–99.99 s | 0.1 s | ± 0.2 s |

| Particle Size Range | 5.6–560 nm |

| Particle Size Resolution | 16 channels per decade (32 total) |

| Electrometer Channels | 20 |

| Time Resolution | 10 size distribution per second |

| Sample Flow | 10 L·min−1 |

| Dilution Accessories | Rotation disk thermodilution |

| Measured Values | Measurement Range | Resolution | Accuracy |

|---|---|---|---|

| CO | 0 … 10 % Vol. | 0.001 % Vol. | 0 … 0.67%: 0.02% absolute, 0.67% … 10%: 3% of measured value |

| CO2 | 0 … 16 % Vol. | 0.01 % Vol. | 0 … 10%: 0.3% absolute, 10 … 16%: 3% m.v. |

| HC | 0 … 20, 000 ppm | 1 ppm | 10 ppm or 5% m.v. |

| NOX | 0 … 5 000 ppm | 1 ppm | 0 … 1000 ppm: 25 ppm, 1000 … 4000 ppm: 4% m.v. |

| O2 | 0 … 22 % Vol. | 0.1 % Vol. | 0 … 3%: 0,1% 3 … 21%: 3% |

| Maximum Capacity | 6200 g |

| Unit(d)/Accuracy | 0.01 g |

| Verifiable Unit | 0.1 g |

| A Class of Accuracy | I |

| Acceptable Measurement Temperature | 0–35 °C |

| Standard Communication Interface | RS 232 |

| Measured Parameter | Units | Diesel | D50H30B20 | HVO |

|---|---|---|---|---|

| Density at 15 °C | kg∙m−3 | 839 | 810 | 780 |

| Kinematic viscosity at 40 °C | mm2∙s−1 | 2.64 | 2.35 | 2.82 |

| Flash point | °C | 68 | 35 | 97 |

| Cloud point | °C | −5 | −18 | −28 |

| Cold filter plugging point | °C | −17 | −30 | −30 |

| Cetane number | - | 51.8 | 54.1 | >70.0 |

| Cetane index | - | 50.9 | 53.2 | 75.2 |

| Fuel | Max. Power (kW) | Max. Torque (Nm) |

|---|---|---|

| Diesel | 60 | 188 |

| HVO | 57 | 184 |

| D50H30B20 | 56 | 180 |

| Fuel | CO (g∙km−1) | CO2 (g∙km−1) | NOx (g∙km−1) | HC (g∙km−1) |

|---|---|---|---|---|

| DIESEL | 0.173 | 122 | 0.151 | 0.031 |

| HVO | 0.050 | 147 | 0.251 | 0.033 |

| D50H30B20 | 0.234 | 155 | 0.301 | 0.046 |

| EU 4 limit | 1 | 127 | 0.08 | 0.1 |

| Fuel | Consumption per NEDC (g) | Distance (m) | Consumption (L·100·km−1) |

|---|---|---|---|

| Diesel | 459 | 11074 | 4.94 |

| HVO | 489 | 11117 | 5.64 |

| D50H30B20 | 494 | 11140 | 5.47 |

| Fuel | PN (6.4–560 nm) per NEDC (PN∙NEDC−1) | PN per 1 km (PN∙km−1) | Procentual Difference (%) |

|---|---|---|---|

| Diesel (6.4–560 nm) | 4.86 × 1014 | 4.39 × 1014 | 100.00 |

| Diesel (23–560 nm) | 4.16 × 1014 | 3.76 × 1014 | 100.00 |

| HVO (6.4–560 nm) | 4.39 × 1014 | 3.95 × 1014 | 90.42 |

| HVO (23–560 nm) | 3.76 × 1014 | 3.38 × 1014 | 90.32 |

| D50H30B20 (6.4–560 nm) | 2.28 × 1014 | 2.04 × 1014 | 46.89 |

| D50H30B20 (23–560 nm) | 1.98 × 1014 | 1.78 × 1014 | 47.69 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kotek, M.; Mařík, J.; Zeman, P.; Hartová, V.; Hart, J.; Hönig, V. The Impact of Selected Biofuels on the Skoda Roomster 1.4TDI Engine’s Operational Parameters. Energies 2019, 12, 1388. https://doi.org/10.3390/en12071388

Kotek M, Mařík J, Zeman P, Hartová V, Hart J, Hönig V. The Impact of Selected Biofuels on the Skoda Roomster 1.4TDI Engine’s Operational Parameters. Energies. 2019; 12(7):1388. https://doi.org/10.3390/en12071388

Chicago/Turabian StyleKotek, Martin, Jakub Mařík, Petr Zeman, Veronika Hartová, Jan Hart, and Vladimir Hönig. 2019. "The Impact of Selected Biofuels on the Skoda Roomster 1.4TDI Engine’s Operational Parameters" Energies 12, no. 7: 1388. https://doi.org/10.3390/en12071388