Desiccant-Based Air Handling Unit Alternatively Equipped with Three Hygroscopic Materials and Driven by Solar Energy

Abstract

:1. Introduction

- -

- different solar thermal field configurations, three collecting surfaces (about 20, 27 and 34 m2) and different tilt angles (20–55°);

- -

- three desiccant rotor materials, that is the one which is actually installed in an available test plant (silica-gel), a composite material denominated MIL101@GO-6 (MILGO), made of graphite oxide dispersed in the MIL101 metal organic framework structure, and a naturally occurring zeolite-rich tuff, denominated Campanian Ignimbrite, which is rich in phillipsite and chabazite and is widespread in many areas of Campania region, in southern Italy.

2. Hygroscopic Materials: Modeling and Characterization

3. Methodology: Simulation Models, Plant Configuration and Analyses

- numerical simulations, carried out to dynamically assess the energy flows in the considered plants;

- energy and environmental analyses based on seasonal and annual aggregated results.

3.1. Plants Simulation Model Characteristics and Operation

3.2. Energy and Environmental Indexes

- -

- the solar fraction (SF), that is the share of thermal enegy from the solar subsystem on the total thermal energy required by the AHU in the IS;

- -

- the solar energy factor (SEF), that represents the ratio between the solar energy used in the AHU and that totally available.

- -

- the ratio between the solar energy used to regenerate the desiccnt wheel () and the total regeneration energy ():

- -

- the ratio between the solar energy used to regenerate the desiccant rotor and the total termal energy available from SC in summer (),

- -

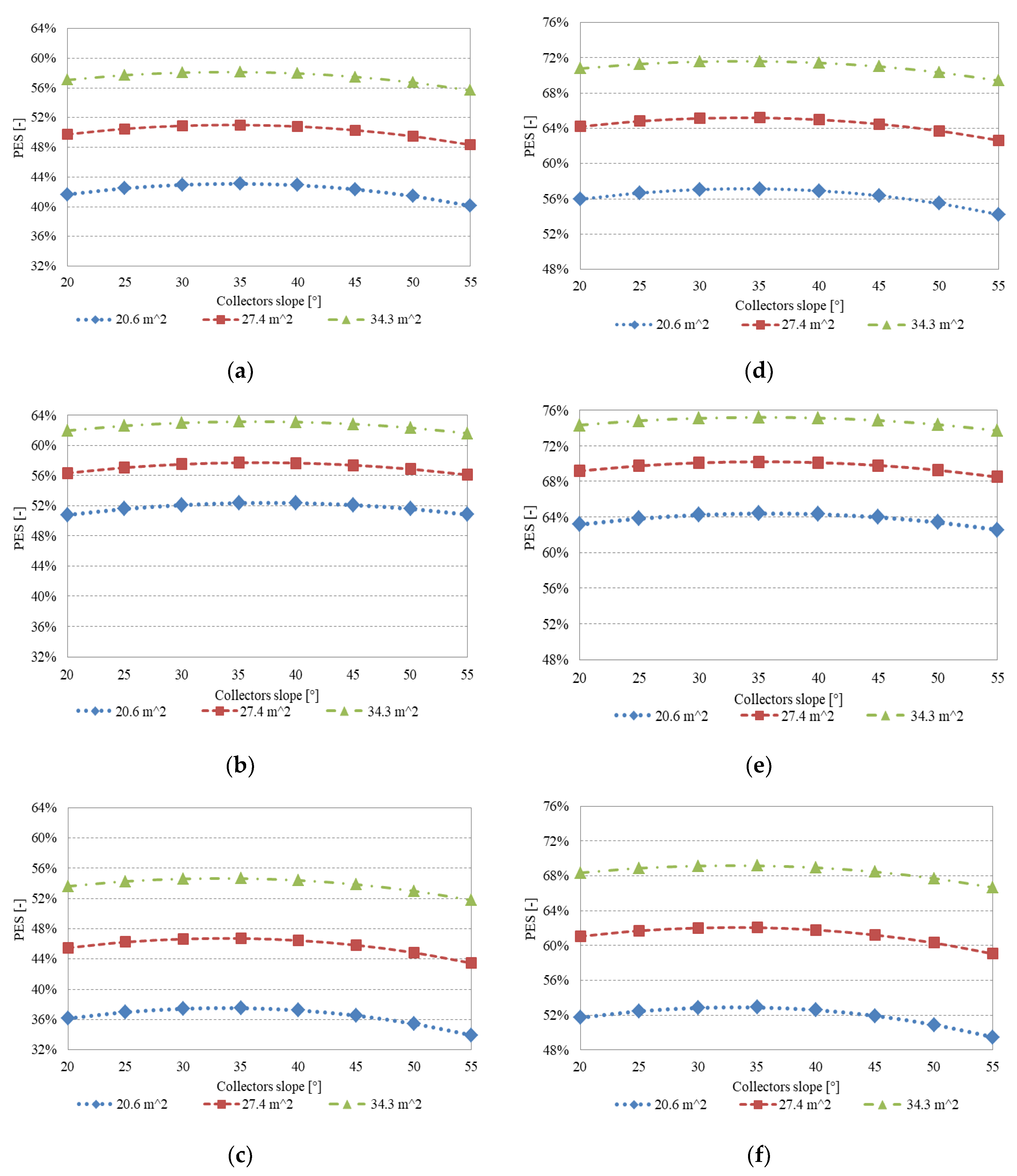

- the primary energy saving (PES) achieved by IS with respect to CS;

- -

- the equivalent CO2 emissions avoided by IS with respect to CS.

4. Results

4.1. Energy Analysis

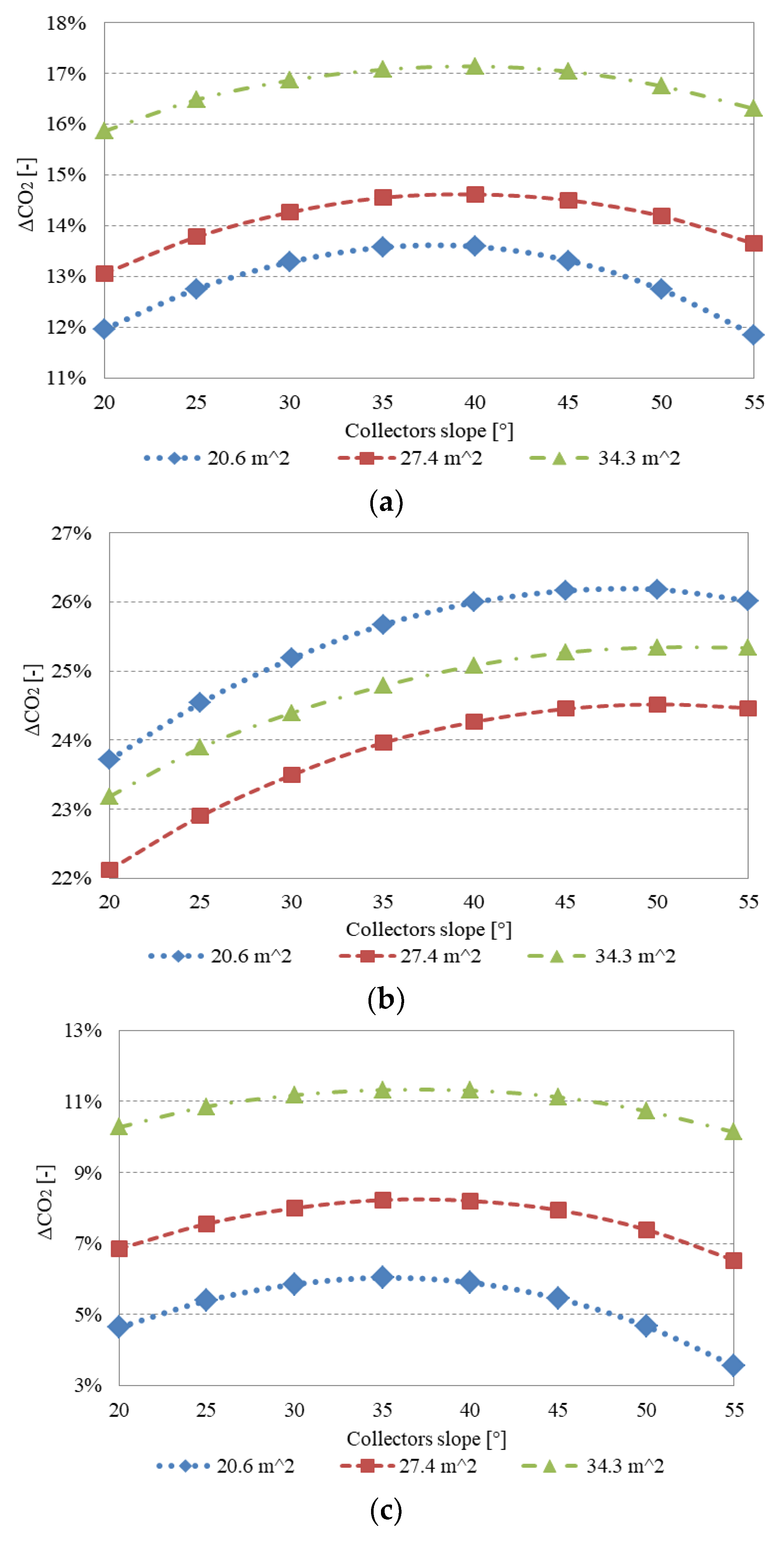

4.2. Environmental Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| CO2 | Equivalent CO2 emission (kg/year) |

| cp | Specific heat (J/kgK) |

| Ds | Surface diffusion coefficient (m2/s) |

| E | Energy (MWh/y) |

| F1, F2 | Isopotential lines |

| K | Effective mass transfer coefficient (1/s) |

| k | Thermal conductivity (W/mK) |

| M | Moisture content of adsorbent material (kgwater/kgadsorbent) |

| Mw | Molecular weight of water (kg/mol) |

| PES | Primary Energy Saving (%) |

| qs | isosteric heat of adsorption (J/mol) |

| SEF | Solar Energy Factor (-) |

| SF | Solar Fraction (-) |

| T, t | Temperature (K), (°C) |

| V | air superficial velocity (m/s) |

| z | Axial coordinate (m) |

| Greek symbols | |

| α | Specific emission factor of electricity drawn from the grid (kg CO2/kW hel) |

| β | Specific emission factor of primary energy related to natural gas combustion (kg CO2/kW hEp) |

| ΔCO2 | Equivalent CO2 avoided emission (%) |

| ε | Void fraction (-) |

| η | Efficiency (-) |

| θ | Time (s) |

| ρ | Density (kg/m3) |

| ω | Air absolute humidity (kgwater/kgdry air) or (gwater/kgdry air) |

| Superscripts | |

| CS | Conventional System |

| DC | Dry cooler |

| DWreg | Desiccant Wheel regeneration |

| IS | Innovative System |

| postheat | Post-heating phase |

| preheat | Pre-heating phase |

| TS | Thermal Storage |

| US | User |

| Subscripts | |

| amb | Ambient |

| aux | Auxiliaries |

| B | Boiler |

| CH | Chiller |

| Co | Cooling |

| Cooling | Cooling mode |

| d | Adsorbent materia |

| e | At equilibrium condition |

| EG | Electric Grid |

| el | Electric |

| F1, F2 | Isopotential lines |

| Heating | Heating mode |

| in | Initial |

| m | moist air |

| non-HVAC | not related to HVAC |

| p | Primary |

| PP | Power Plant |

| proc | Process |

| reg | Regeneration |

| SC | Solar thermal Collector |

| th | Thermal |

| tot, Total | Total |

| Acronyms | |

| AHU | Air Handling Unit |

| B | Boiler |

| CC | Cooling Coil |

| CF | Cross-Flow heat exchanger |

| CH | Chiller |

| COP | Coefficient Of Performance |

| CS | Conventional System |

| DW | Desiccant Wheel |

| EC | Evaporative Cooler |

| HC, HC2 | Heating Coils |

| HVAC | Heating, Ventilation and Air-Conditioning |

| HW-HX | Hot Water Heat exchanger |

| IS | Innovative System |

| MILGO Hygroscopic material, consisting graphite oxide dispersed in the MIL101 metal organic framework network structure | |

| SC | Solar thermal Collector |

| SEF | Solar Energy Factor |

| SF | Solar Fraction |

| TS | Thermal Storage |

References

- Zheng, X.; Ge, T.S.; Wang, R.Z. Recent progress on desiccant materials for solid desiccant cooling systems. Energy 2014, 74, 280–294. [Google Scholar] [CrossRef]

- Asim, N.; Emdadi, Z.; Mohammad, M.; Yarmo, M.A.; Sopian, K. Agricultural solid wastes for green desiccant applications: An overview of research achievements, opportunities and perspectives. J. Clean. Prod. 2015, 91, 26–35. [Google Scholar] [CrossRef]

- Jani, D.B.; Mishra, M.; Sahoo, P.K. Performance analysis of a solid desiccant assisted hybrid space cooling system using TRNSYS. J. Build. Eng. 2018, 19, 26–35. [Google Scholar] [CrossRef]

- Al-Alili, A.; Hwang, Y.; Radermacher, R. Performance of a desiccant wheel cycle utilizing new zeolite material: Experimental investigation. Energy 2015, 81, 137–145. [Google Scholar] [CrossRef]

- Kanoğlu, M.; Çarpınlıoğlu, M.Ö.; Yıldırım, M. Energy and exergy analyses of an experimental open-cycle desiccant cooling system. Appl. Therm. Eng. 2004, 24, 919–932. [Google Scholar] [CrossRef]

- Subramanyam, N.; Maiya, M.P.; Srinivasa Murthy, S. Application of desiccant wheel to control humidity in air-conditioning systems. Appl. Therm. Eng. 2004, 24, 2777–2788. [Google Scholar] [CrossRef]

- Jia, C.X.; Dai, Y.J.; Wu, J.Y.; Wang, R.Z. Experimental comparison of two honeycombed desiccant wheels fabricated with silica gel and composite desiccant material. Energy Convers. Manag. 2006, 47, 2523–2534. [Google Scholar] [CrossRef]

- White, S.D.; Goldsworthy, M.; Reece, R.; Spillmann, T.; Gorur, A.; Lee, D.Y. Characterization of desiccant wheels with alternative materials at low regeneration temperatures. Int. J. Refrig. 2011, 34, 1786–1791. [Google Scholar] [CrossRef]

- Eicker, U.; Schürger, U.; Köhler, M.; Ge, T.; Dai, Y.; Li, H.; Wang, R. Experimental investigations on desiccant wheels. Appl. Therm. Eng. 2012, 42, 71–80. [Google Scholar] [CrossRef]

- Jia, C.X.; Dai, Y.J.; Wu, J.Y.; Wang, R.Z. Analysis on a hybrid desiccant air-conditioning system. Appl. Therm. Eng. 2006, 26, 2393–2400. [Google Scholar] [CrossRef]

- Fong, K.F.; Lee, C.K. Impact of adsorbent characteristics on performance of solid desiccant wheel. Energy 2018, 144, 1003–1012. [Google Scholar] [CrossRef]

- Intini, M.; Goldsworthy, M.; White, S.; Joppolo, C.M. Experimental analysis and numerical modelling of an AQSOA zeolite desiccant wheel. Appl. Therm. Eng. 2015, 80, 20–30. [Google Scholar] [CrossRef]

- Goldsworthy, M.J. Measurements of water vapour sorption isotherms for RD silica gel, AQSOA-Z01, AQSOA-Z02, AQSOA-Z05 and CECA zeolite 3A. Microporous Mesoporous Mater. 2014, 196, 59–67. [Google Scholar] [CrossRef]

- Enteria, N.; Yoshino, H.; Mochida, A.; Satake, A.; Yoshie, R.; Takaki, R.; Yonekura, H.; Mitamura, T.; Tanaka, Y. Performance of solar-desiccant cooling system with silica–gel (SiO2) and titanium dioxide (TiO2) desiccant wheel applied in East Asian climates. Sol. Energy 2012, 86, 1261–1279. [Google Scholar] [CrossRef]

- Rajamani, M.; Maliyekkal, S.M. Chitosan reinforced boehmite nanocomposite desiccant: A promising alternative to silica gel. Carbohydr. Polym. 2018, 194, 245–251. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Yu, Y.; Ma, C.; Xiao, J.; Xia, Q.; Li, Y. Adsorption isotherms and kinetics of water vapor on novel adsorbents MIL-101(Cr)@GO with super-high capacity. Appl. Therm. Eng. 2015, 84, 118–125. [Google Scholar] [CrossRef]

- Caputo, D.; Iucolano, F.; Pepe, F.; Colella, C. Modeling of water and ethanol adsorption data on a commercial zeolite-rich tuff and prediction of the relevant binary isotherms. Microporous Mesoporous Mater. 2007, 105, 260–267. [Google Scholar] [CrossRef]

- Bareschino, P.; Diglio, G.; Pepe, F.; Angrisani, G.; Roselli, C.; Sasso, M. Numerical study of a MIL101 metal organic framework based desiccant cooling system for air conditioning application. Appl. Therm. Eng. 2017, 124, 641–651. [Google Scholar] [CrossRef]

- Bareschino, P.; Diglio, G.; Pepe, F. Modelling of a Zeolite-Rich Tuff Desiccant Wheel. Adv. Sci. Lett. 2017, 23, 6002–6006. [Google Scholar] [CrossRef]

- Maclaine-Cross, I.L.; Banks, P.J. Coupled heat and mass transfer in regenerators– predictions using an analogy with heat transfer. Int. J. Heat Mass Transf. 1972, 15, 1225–1242. [Google Scholar] [CrossRef]

- Howe, R.R. Model and Performance Characteristics of a Conditioning System Which Utilizes a Rotary Desiccant Dehumidifier. Master’s Thesis, University of Wisconsin, Madison, WI, USA, 1983. [Google Scholar]

- Jurinak, J.J. Open Cycle Solid Desiccant Cooling: Component Models and System Simulations. Ph.D. Thesis, University of Wisconsin, Madison, WI, USA, 1982. [Google Scholar]

- Banks, P.J. Prediction of Heat and Mass Regenerator performance using nonlinear analogy method: Part 1—basis. ASME J. Heat Transf. 1985, 107, 222–229. [Google Scholar] [CrossRef]

- Angrisani, G.; Roselli, C.; Sasso, M. Experimental validation of constant efficiency models for the subsystems of an unconventional desiccant-based Air Handling Unit and investigation of its performance. Appl. Therm. Energy 2012, 33–34, 100–108. [Google Scholar] [CrossRef]

- Solar Energy Laboratory. TRNSYS 17, a TRaNsient System Simulation Program; University of Wisconsin: Madison, WI, USA, 2010. [Google Scholar]

- Thermal Energy System Specialists Components Library v. 17.01; Thermal Energy System Specialists: Madison, WI, USA, 2004.

- Angrisani, G.; Roselli, C.; Sasso, M.; Tariello, F.; Vanoli, G.P. Performance Assessment of a Solar-Assisted Desiccant-Based Air Handling Unit Considering Different Scenarios. Energies 2016, 9, 724. [Google Scholar] [CrossRef]

- Angrisani, G.; Roselli, C.; Sasso, M.; Tariello, F. Dynamic performance assessment of a micro-trigeneration system with a desiccant-based air handling unit in Southern Italy climatic conditions. Energy Convers. Manag. 2014, 80, 188–201. [Google Scholar] [CrossRef]

- Angrisani, G.; Canelli, M.; Roselli, C.; Sasso, M. Calibration and validation of a thermal energy storage model: Influence on simulation results. Appl. Therm. Eng. 2014, 67, 190–200. [Google Scholar] [CrossRef]

- Angrisani, G.; Roselli, C.; Sasso, M.; Tariello, F. Dynamic performance assessment of a solar-assisted desiccant-based air handling unit in two Italian cities. Energy Convers. Manag. 2016, 113, 331–345. [Google Scholar] [CrossRef]

| Parameter | Opaque Components | Transparent Components | |||||

|---|---|---|---|---|---|---|---|

| Roof | External Walls (N/S) | External Walls (E/W) | On the Ground Floor | North | South | East/West | |

| U (W/m2 K) | 2.30 | 1.11 | 1.11 | 0.297 | 2.83 | 2.83 | 2.83 |

| Area (m2) | 63.5 | 36 | 15.87 | 63.5 | 8.53 | 9.40 | 0.976 |

| g (-) | - | - | - | - | 0.755 | 0.755 | 0.755 |

| Component (Reference) | Type | Library | Main Parameters | Value | Units |

|---|---|---|---|---|---|

| Cross flow heat exchanger [24] | 91 | Standard | Effectiveness | 0.446 | - |

| Humidifier [24] | 506 c | TESS | Saturation efficiency | 0.551 | - |

| Natural gas boiler [24] | 6 | Standard | Nominal thermal power | 24.1 | kW |

| Efficiency | 0.902 | - | |||

| Air-cooled chiller [24] | 655 | TESS | Rated capacity | 8.50 | kW |

| Rated COP | 2.98 | - | |||

| Heating coil [24] | 670 | TESS | Liquid specific heat | 4.190 | kJ/(kg·K) |

| Effectiveness | 0.864 | - | |||

| Cooling coil [24] | 508 | TESS | Liquid specific heat | 4.190 | kJ/(kg·K) |

| Bypass fraction | 0.177 | - | |||

| Storage tank [29] | 60 f | Standard | Volume | 971 | L |

| Height | 2.04 | m | |||

| Tank loss coefficient | 1.37 | W/(m2·K) | |||

| Liquid specific heat | 4.190 | kJ/(kg·K) | |||

| Evacuated solar collectors | 71 | Standard | Tested flow rate | 8.43 × 10−3 | kg/(s·m2) |

| Intercept efficiency | 0.676 | - | |||

| Efficiency slope | 1.15 | W/(m2·K) | |||

| Efficiency curvature | 0.004 | W/(m2·K2) | |||

| Fluid specific heat | 3.85 | kJ/(kg·K) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bareschino, P.; Pepe, F.; Roselli, C.; Sasso, M.; Tariello, F. Desiccant-Based Air Handling Unit Alternatively Equipped with Three Hygroscopic Materials and Driven by Solar Energy. Energies 2019, 12, 1543. https://doi.org/10.3390/en12081543

Bareschino P, Pepe F, Roselli C, Sasso M, Tariello F. Desiccant-Based Air Handling Unit Alternatively Equipped with Three Hygroscopic Materials and Driven by Solar Energy. Energies. 2019; 12(8):1543. https://doi.org/10.3390/en12081543

Chicago/Turabian StyleBareschino, Piero, Francesco Pepe, Carlo Roselli, Maurizio Sasso, and Francesco Tariello. 2019. "Desiccant-Based Air Handling Unit Alternatively Equipped with Three Hygroscopic Materials and Driven by Solar Energy" Energies 12, no. 8: 1543. https://doi.org/10.3390/en12081543