Life-Cycle Assessment of the Use of Peach Pruning Residues for Electricity Generation

Abstract

:1. Introduction

2. Materials and Methods

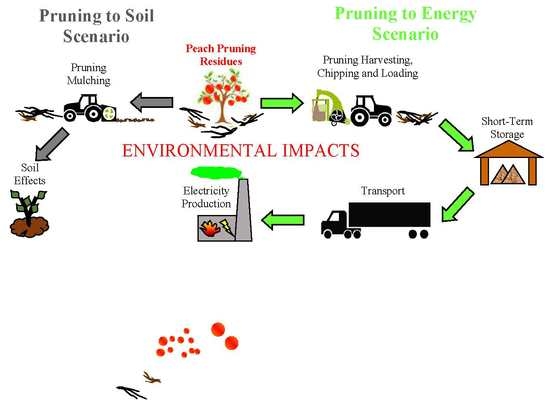

2.1. Goal and Scope

2.2. Life-Cycle Inventory: Description of Biomass Sources

2.3. Life-Cycle Inventory: Description of Materials and Energy Flows

3. Results: Life-Cycle Impact Assessment (LCIA)

3.1. Climate Change Potential

3.2. Other Environmental Impacts

4. Discussion: Life-Cycle Interpretation

4.1. General

4.2. Sensitivity Analysis—Change in Substituted Energy Source for Power Generation

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| BAP | biomass action plan |

| DM | dry mass |

| FM | fresh mass |

| GHG | greenhouse gas |

| GWP | Global Warming Potential |

| IE | inhabitant equivalent |

| ILCD | international life cycle data |

| IPCC | intergovernmental panel on climate change |

| ISO | The International Organization for Standardization |

| LCA | life cycle assessment |

| LHV | lower heating value |

| ORC | Organic Rankine Cycle |

| PPR | peach pruning residues |

| PtE | pruning to energy |

| PtS | pruning to soil |

| SBR | Styrene–Butadiene Rubber |

References

- European Commission (EC). Biomass Action Plan; COM (2005)628 Final; European Commission: Brussels, Belgium, 2005. [Google Scholar]

- European Commission (EC). Going Climate Neutral by 2050. A Strategic Long Term Vision for a Prosperous, Modern, Competitive and Climate Neutral EU Economy; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- European Commission (EC). Sustainable and Optimal Use of Biomass for Energy in the EU Beyond 2020; Final Report; European Commission: Brussels, Belgium, 2017; Available online: https://ec.europa.eu/energy/studies/sustainable-and-optimal-use-biomass-energy-eu-beyond-2020_en?redir=1 (accessed on 8 April 2020).

- Gavrilescu, M. Biomass power for energy and sustainable development. Environ. Eng. Manag. 2008, 7, 617–640. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Monforti-Ferrario, F.; Nita, V. The role of biomass and bioenergy in a future bioeconomy: Policies and facts. Environ. Dev. 2015, 15, 3–34. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Causer, T.P.; Ciolkosz, D. Biomass for energy: A review on supply chain management models. Renew. Sustain. Energy Rev. 2020, 120, 109658. [Google Scholar] [CrossRef]

- Carvalho, M.; Rommel, Y.; Araújo, V.; de Góis, L.M.; Coelho Junior, L.M. Urban Pruning Waste: Carbon Footprint Associated with Energy Generation and Prospects for Clean Development Mechanisms. Rev. Árvore 2019, 43. [Google Scholar] [CrossRef]

- Beuchelt, T.D.; Nassl, M. Applying a sustainable development lens to global biomass potentials. Sustainability 2019, 11, 5078. [Google Scholar] [CrossRef] [Green Version]

- Sagani, A.; Hagidimitriou, M.; Dedoussis, V. A Study of Burning Olive Tree Pruning Biomass for Electricity Generation. In Proceedings of the World Bioenergy Conference, Jönköping, Sweden, 3–5 June 2014; The Swedish Bioenergy Association, Ed.; The Swedish Bioenergy Association: Stockholm, Sweden, 2014; pp. 66–70. [Google Scholar]

- Hamelin, L.; Borzęcka, M.; Kozak, M.; Pudełko, R. A spatial approach to bioeconomy: Quantifying the residual biomass potential in the EU-27. Renew. Sustain. Energy Rev. 2019, 100, 127–142. [Google Scholar] [CrossRef]

- Dyjakon, A. Harvesting and baling of pruned biomass in apple orchards for energy production. Energies 2018, 11, 1680. [Google Scholar] [CrossRef] [Green Version]

- EuroPruning. Best Practice Brochure for a Sustainable and Sound Utilization of Wood Prunings as Biomass Feedstock. Deliverable report D8.4. 2016. Available online: www.europruning.eu (accessed on 14 February 2020).

- García-Galindo, D.; Gómez-Palmero, M.; Pueyo, E.; Germer, S.; Pari, L.; Afano, V.; Dyjakon, A.; Sagarna, J.; Rivera, S.; Poutrin, C. Agricultural Pruning as Biomass Resource: Generation, Potentials and Current Fates. An Approach to its State in Europe. In Proceedings of the 24th European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016; pp. 1579–1595. [Google Scholar] [CrossRef]

- Dyjakon, A.; García-Galindo, D. Implementing agricultural pruning to energy in Europe: Technical, economic and implementation potentials. Energies 2019, 12, 1513. [Google Scholar] [CrossRef] [Green Version]

- FAOSTAT. 2018. Available online: http://www.fao.org/faostat/en/#data/QC/ (accessed on 24 March 2020).

- Cavalaglio, G.; Cotana, S. Recovery of vineyards pruning residues in an agro-energetic chain. In Proceedings of the 15th European Biomass Conference and Exhibition, Berlin, Germany, 7–11 May 2007. [Google Scholar]

- Bilandzija, N.; Voca, N.; Kricka, T.; Matin, A.; Jurisic, V. Energy potential of fruit tree pruned biomass in Croatia. Span. J. Agric. Res. 2012, 10, 292–298. [Google Scholar] [CrossRef] [Green Version]

- Pruning Biomass Potential for Energy in Europe. Available online: http://www.gruppo-panacea.it/home/en/residual-biomass2/125-pruning-biomass-potential-for-energy-in-europe/173-pruning-biomass-potential-for-energy-in-europe (accessed on 24 March 2020).

- Pari, L.; Alfano, V.; Garcia-Galindo, D.; Suardi, A.; Santangelo, E. Pruning biomass potential in Italy related to crop characteristics, agricultural practices and agro-climatic conditions. Energies 2018, 11, 1365. [Google Scholar] [CrossRef] [Green Version]

- Bosona, T.; Gebresenbet, G.; Dyjakon, A. Implementing life cycle cost analysis methodology for evaluating agricultural pruning-to-energy initiatives. Bioresour. Technol. Rep. 2019, 6, 54–62. [Google Scholar] [CrossRef]

- Dyjakon, A.; Den Boer, J.; Gebresenbet, G.; Bosona, T.; Adamczyk, F. Economic analysis of the collection and transportation of pruned branches from orchards for energy production. Wood 2020, 205. [Google Scholar] [CrossRef]

- Intini, F.; Kühtz, S.; Rospi, G. Life Cycle Assessment (LCA) of an energy recovery plant in the olive oil industries. Int. J. Energy Environ. 2012, 3, 541–552. [Google Scholar]

- Gaspar, J.P.; Gaspar, P.D.; Dinho da Silva, P.; Simões, M.P.; Espírito Santo, C. Energy life-cycle assessment of fruit products—Case study of Beira Interior’s Peach (Portugal). Sustainability 2018, 10, 3530. [Google Scholar] [CrossRef] [Green Version]

- Kowalczyk, Z.; Kwaśniewski, D. Life cycle assessment (LCA) in energy willow cultivation on plantations with varied surface area. Agric. Eng. 2019, 23, 11–19. [Google Scholar] [CrossRef]

- Recchia, L.; Boncinelli, P.; Cini, E.; Vieri, M.; Garbati Pegna, F.; Sarri, D. Multicriteria Analysis and LCA Techniques: With Applications to Agro-Engineering Problems; Springer: London, UK, 2011. [Google Scholar]

- Caldeira-Pires, A.; Benoist, A.; da Luz, S.M.; Silverio, C.S.; Silveira, C.M.; Machado, F.S. Implications of removing straw from soil for bioenergy: An LCA of ethanol production using total sugarcane biomass. J. Clean. Prod. 2018, 181, 249–259. [Google Scholar] [CrossRef]

- Christoforou, E.A.; Fokaides, P.A. Life Cycle Assessment (LCA) of Olive Husk Torrefaction. Renew. Energy 2016, 90, 257–266. [Google Scholar] [CrossRef]

- Chary, K.; Aubin, J.; Guindéa, L.; Sierra, J.; Blazy, J.-M. Cultivating biomass locally or importing it? LCA of biomass provision scenarios for cleaner electricity production in a small tropical island. Biomass Bioenergy 2018, 110, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Perilhona, C.; Alkadeea, D.; Descombes, G.; Lacour, S. Life cycle assessment applied to electricity generation from renewable biomass. Energy Procedia 2012, 18, 165–176. [Google Scholar] [CrossRef]

- Beagle, E.; Belmont, E. Comparative life cycle assessment of biomass utilization for electricity generation in the European Union and the United States. Energy Policy 2019, 128, 267–275. [Google Scholar] [CrossRef]

- EuroPruning. Report with Recommendation for Wood Prunings Utilisation for Sustainable Soil Management; Project Report D7.3; Project (FP7–312078); EuroPruning: Fraga, Spain, 2016. [Google Scholar]

- ISO. 14040:2006—Environmental Management—Life Cycle Assessment—Principles and Framework; International Organisation for Standardisation (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- EC—JRC. Recommendations Based on Existing Environmental Impact Assessment Models and Factors for Life Cycle Assessment in European Context; EC—JRC: Brussels, Belgium, 2011; ISBN 978-92-79-17451-3. [Google Scholar]

- EuroPruning. Report on Environmental Evaluation of the Supply Chain; Project Report D8.1; Project (FP7–312078); EuroPruning: Fraga, Spain, 2016. [Google Scholar]

- Benini, L.; Mancini, L.; Sala, S.; Manfredi, S.; Schau, E.M.; Pant, R. Normalisation Method and Data for Environmental Footprints; European Commission, JRC, Publications Office of the EU: Luxembourg, 2014; ISBN 978-92-79-40847-2. [Google Scholar]

- Thinkstep. ES: Electricity Grid Mix ts. GaBi Process, 2020 Database. Available online: http://www.w3.org/1999/xlink" xlink:href="http://www.gabi-software.com/international/databases/gabi-data-search/?id=8323&no_cache=1&tx_fufgabilcidocumentation_pi1%5BAdvancedSearch%5D=0&tx_fufgabilcidocumentation_pi1%5Bsuchbegriff%5D=ES%3A+Electricity+grid+mix+ts.+GaBi+process%2C+2020+database&search=Search&tx_fufgabilcidocumentation_pi1%5Bmatch%5D=2&tx_fufgabilcidocumentation_pi1%5BCountry%5D=&tx_fufgabilcidocumentation_pi1%5BProcessTypeName%5D=&tx_fufgabilcidocumentation_pi1%5BDatabaseName%5D=&tx_fufgabilcidocumentation_pi1%5BProcessDataSource%5D=" ext-link-type="uri (accessed on 14 February 2020).

- Suardi, A.; Council for Agricultural Research and Economics, Rome, Latium, Italy. Personal Communication, 2016.

- Eggleston, S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Hayama, Japan, 2006; Volume 5. [Google Scholar]

- Faist, M.; Reinhard, J.; Zah, R. RBS GHG Calculation Methodology; Version 2.1; EPFL: Lausanne, Switzerland, 2011. [Google Scholar]

- Den Boer, J.; Gomez-Palmero, M.; Sebastian, F.; García-Galindo, D.; Dyjakon, A.; Bukowski, P.; Den Boer, E.; Germer, S.; Bischoff, W.-A. Pruning residues: Energy production or mulching? Environmental impacts of almond pruning residues use. In Proceedings of the 24th European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016; pp. 1485–1489. [Google Scholar] [CrossRef]

- Den Boer, E.; Den Boer, J. Environmental effects of the management of municipal waste, including the impact of organic recycling. In Microbiological Environmental Hygiene; Hakalehto, E.E., Ed.; Nova Science Publishers: New York, NY, USA, 2018; pp. 293–315. [Google Scholar]

- Morlat, R.; Chaussod, R. Long-term additions of organic amendments in a Loire Valley Vineyard. I Effects on properties of a calcareous sandy soil. Am. J. Enol. Vitic. 2008, 59, 353–363. [Google Scholar]

- EuroPruning. Summary of Organic Matter and Nutrient Balances in Permanent Crop Agro-Systems; Project report D7.2; Project (FP7–312078); EuroPruning: Fraga, Spain, 2016. [Google Scholar]

- Dyjakon, A.; Den Boer, J.; Szumny, A.; Den Boer, E. Local energy use of biomass from apple orchards-An LCA study. Sustainability 2019, 11, 1604. [Google Scholar] [CrossRef] [Green Version]

- Nieto, O.; Castro, J.; Fernandez, E. Long-term effects of residue management on soil fertility in Mediterranean olive grove: Simulating carbon sequestration with RothC model. In Principles, Application and Assessment in Soil Science; Burcu, E., Ozkaraova, G., Eds.; IntechOpen: London, UK, 2011; ISBN 978-953-307-740-6. [Google Scholar]

- Nieto, O.; Castro, J.; Fernandez, E.; Smith, P. Simulation of soil organic carbon stocks in a Mediterranean olive grove under different soil-management systems using the RothC model. Soil Use Manag. 2010, 26, 118–125. [Google Scholar] [CrossRef]

- Ruiz, D.; San Miguel, G.; Corona, B.; Lopez, F.R. LCA of a multifunctional bioenergy chain based on pellet production. Fuel 2018, 215, 601–611. [Google Scholar] [CrossRef]

- Boschiero, M.; Cherubini, F.; Carla, N.; Zerbe, S. Life cycle assessment of bioenergy production from orchards woody residues in Northern Italy. J. Clean. Prod. 2016, 112, 2569–2580. [Google Scholar] [CrossRef]

- Cowie, A.L.; Smith, P.; Johnson, D. Does soil carbon loss in biomass production systems negate the greenhouse benefits of bioenergy? Mitig. Adapt. Strat. Glob. Chang. 2006, 11, 979–1002. [Google Scholar] [CrossRef]

| Energy Source | Share in the Electricity Mix |

|---|---|

| Nuclear | 21.35% |

| Lignite | 0.67% |

| Hard coal | 12.59% |

| Coal gases | 0.37% |

| Natural gas | 19.23% |

| Heavy fuel oil | 6.16% |

| Biomass | 1.47% |

| Biogas | 0.33% |

| Waste | 0.54% |

| Hydro | 14.51% |

| Wind | 17.81% |

| Photovoltaic | 2.94% |

| Thermal solar | 2.03% |

| Parameter | Unit | Value | Parameter | Unit | Value |

|---|---|---|---|---|---|

| Theoretical pruning potential | tFM·ha−1 | 3.15 | Moisture content (storage end) | % | 16.1 |

| Pruning biomass yield | tFM·ha−1 | 2.59 | Lower heating value | MJ·kgDM−1 | 18.0 |

| Harvesting losses | tFM·ha−1 | 0.34 | Ash content (DM) | % | 3.79 |

| Moisture content (storage begin) | % | 20.6 | Bulk density (storage end) | kgFM∙m−3 | 166 |

| Bulk density (storage begin) | kgFM∙m−3 | 175 | Pruning capacity | tFM·h−1 | 1.13 |

| Mass of pruning after 6 months of storage | tDM·ha−1 | 1.38 | Carbon | kg·tDM−1 | 501 |

| Chlorine | mg·kgDM−1 | 110 | Mercury | mg·kgDM−1 | 0.005 |

| Major elements in ash | Minor elements in ash | ||||

| Al | g·kg−1 | 4.09 | As | mg·kg−1 | 3.50 |

| Si | g·kg−1 | 112 | Cd | mg·kg−1 | 0.775 |

| K | g·kg−1 | 51.4 | Cr | mg·kg−1 | 25.2 |

| Na | g·kg−1 | 2.10 | Cu | mg·kg−1 | 727 |

| Ca | g·kg−1 | 334 | Mn | mg·kg−1 | 162 |

| Mg | g·kg−1 | 13.2 | Ni | mg·kg−1 | 25.8 |

| Fe | g·kg−1 | 2.65 | Pb | mg·kg−1 | 4.05 |

| P | g·kg−1 | 15.4 | V | mg·kg−1 | 5.79 |

| Ti | g·kg−1 | 0.117 | Zn | mg·kg−1 | 583 |

| Parameter | Unit | Value | Standard Process |

|---|---|---|---|

| Stainless steel | kg | 5 | Stainless steel white-hot rolled coil (304) (eurofer, GaBi) |

| Steel | kg | 4050 | Steel plate (World Steel, GaBi) |

| Aluminum | kg | 80 | Aluminum extrusion profile (GaBi) |

| Copper | kg | 1 | Copper Wire Mix (DKI/ECI) |

| Plastics | kg | 10.0 | Polyvinylchloride pipe (PVC) (PlasticsEurope, GaBi) |

| Rubber | kg | 30.0 | SBR Mix + Natural rubber tapped latex (not conserved, 36%) (GaBi) |

| Tires | kg | 45 | SBR Mix + Natural rubber tapped latex (not conserved, 36%) (GaBi) |

| Rubber pipes | kg | 40 | SBR Mix + Natural rubber tapped latex (not conserved, 36%) (GaBi) |

| Hydraulic oil | kg | 105 | Lubricants at the refinery (GaBi) |

| Paint | kg·kg−1 | 0.007 | Alkyd paint, 60% insolvent, at the plant (GaBi) |

| Electricity | MJ·kg−1 | 7.02 | Electricity, low voltage, at the grid, country-specific (Ecoinvent) |

| Heat from coal | MJ·kg−1 | 0.7 | Hard coal, burned in industrial furnace 1–10 MW (Ecoinvent) |

| Heat from gas | MJ·kg−1 | 4.1 | Natural gas, burned in industrial furnace >100 kW (Ecoinvent) |

| Heat from oil | MJ·kg−1 | 7.9 | Light fuel oil, burned in boiler 100 kW, non-modulating (Ecoinvent) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Den Boer, J.; Dyjakon, A.; Den Boer, E.; García-Galindo, D.; Bosona, T.; Gebresenbet, G. Life-Cycle Assessment of the Use of Peach Pruning Residues for Electricity Generation. Energies 2020, 13, 2734. https://doi.org/10.3390/en13112734

Den Boer J, Dyjakon A, Den Boer E, García-Galindo D, Bosona T, Gebresenbet G. Life-Cycle Assessment of the Use of Peach Pruning Residues for Electricity Generation. Energies. 2020; 13(11):2734. https://doi.org/10.3390/en13112734

Chicago/Turabian StyleDen Boer, Jan, Arkadiusz Dyjakon, Emilia Den Boer, Daniel García-Galindo, Techane Bosona, and Girma Gebresenbet. 2020. "Life-Cycle Assessment of the Use of Peach Pruning Residues for Electricity Generation" Energies 13, no. 11: 2734. https://doi.org/10.3390/en13112734