Potential Effects of Vacuum Insulating Glazing Application for Reducing Greenhouse Gas Emission (GHGE) from Apartment Buildings in the Korean Capital Region

Abstract

:1. Introduction

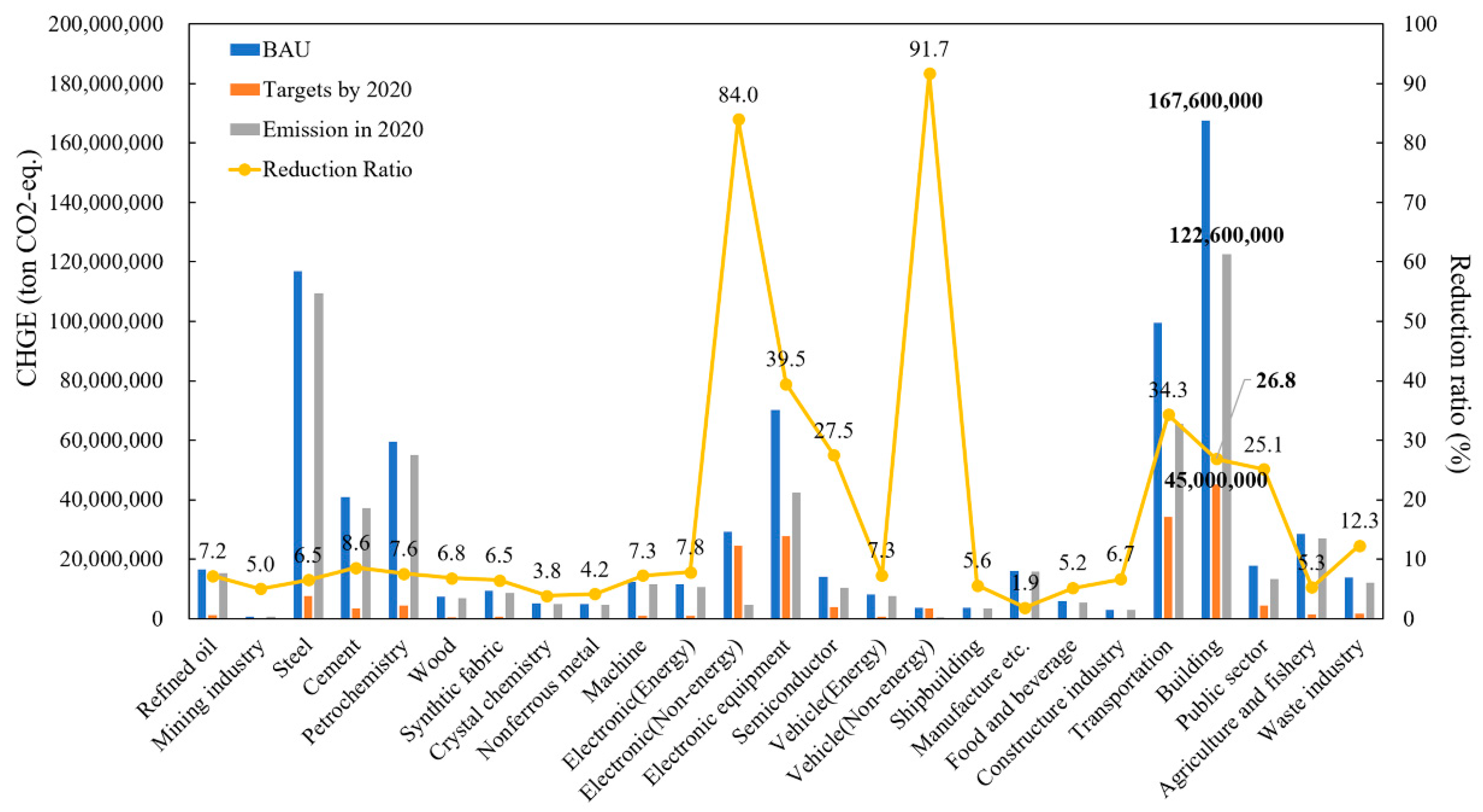

2. The Korean GHGE Reduction Goal

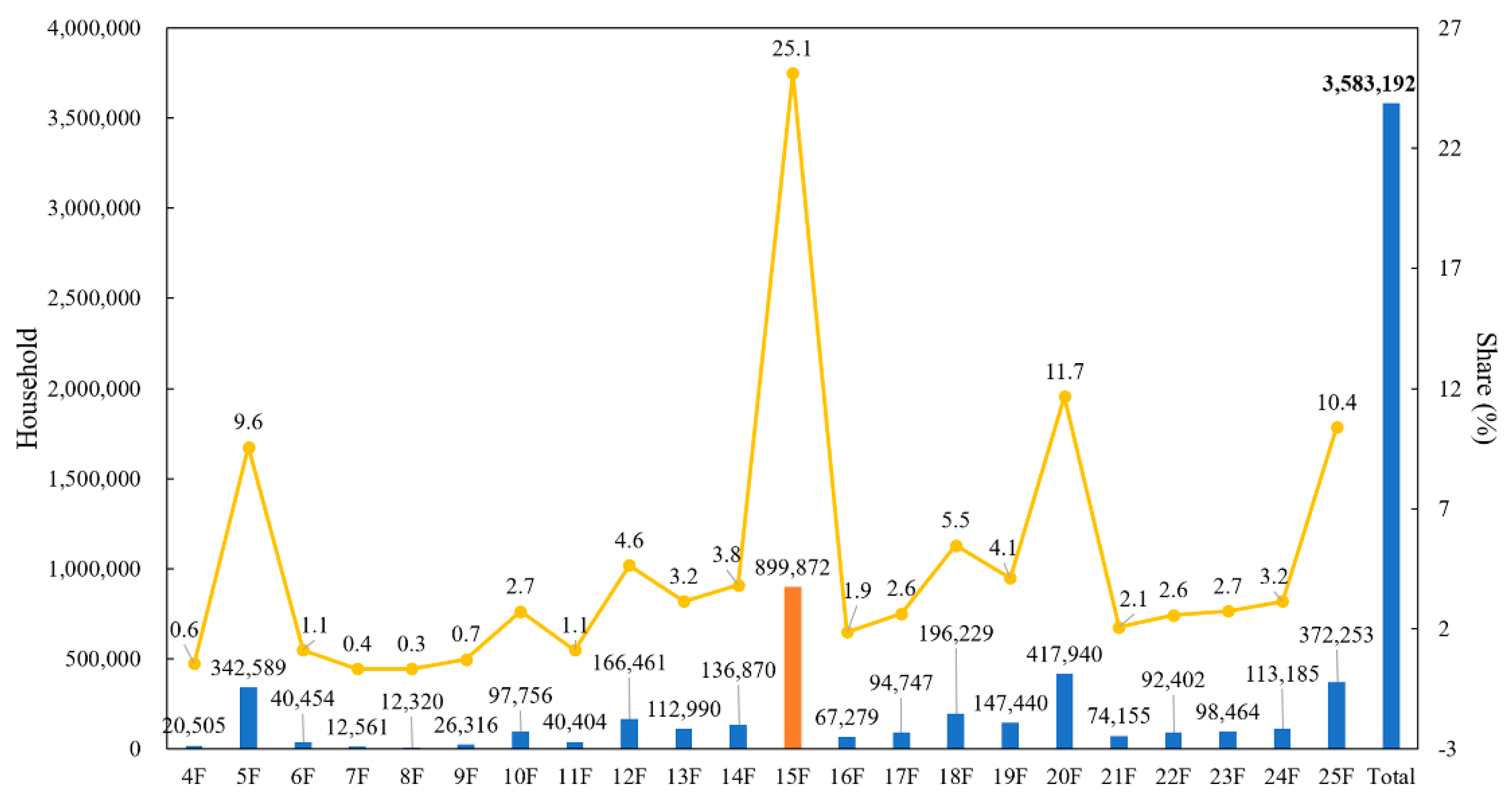

3. Building Status in the Capital Region

4. Analysis Method of GHGE

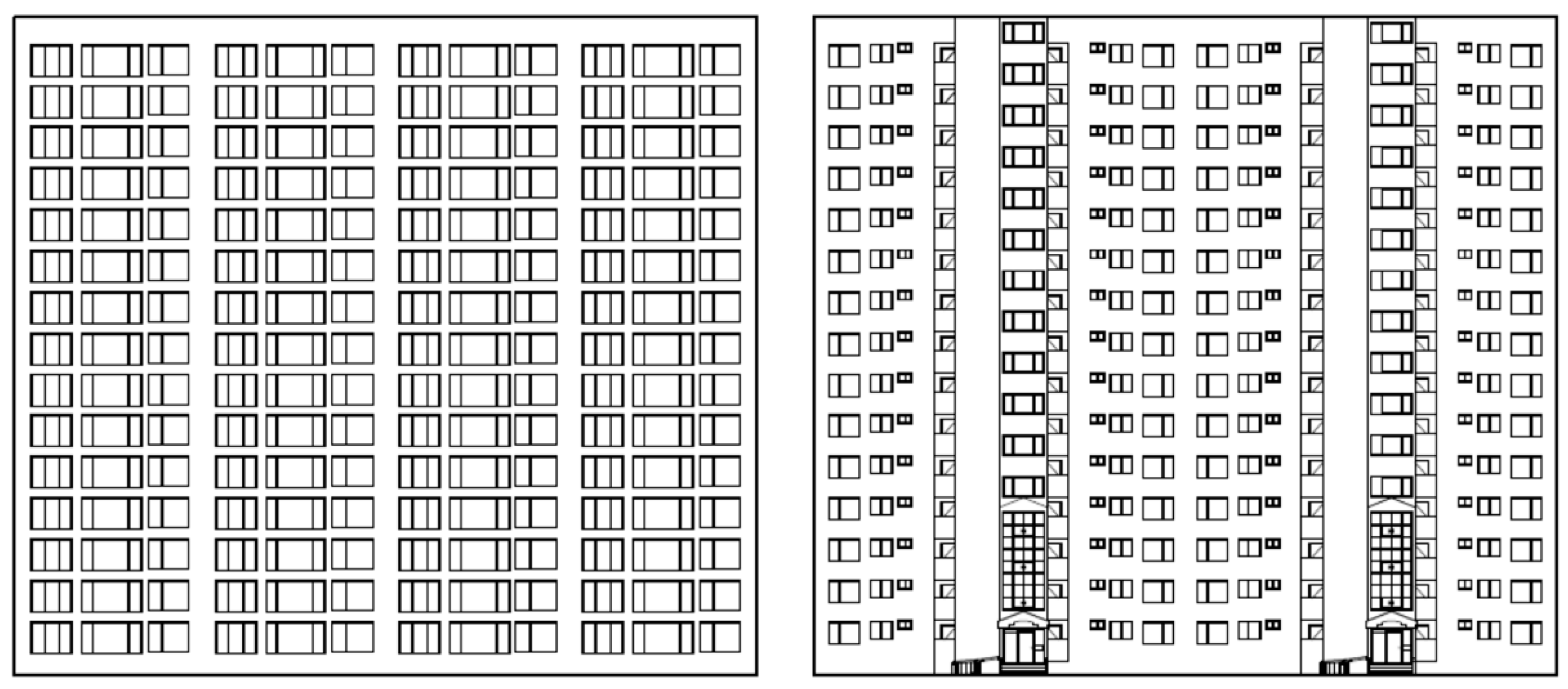

4.1. The Standard Apartment Building

4.2. Design of the Conventional IG and VIG

4.3. Internal and External Conditions

4.4. Cooling and Heating Periods

4.5. Conditions for the Calculation of Energy Demand and GHGEs

5. Results and Discussion

5.1. Energy Demand

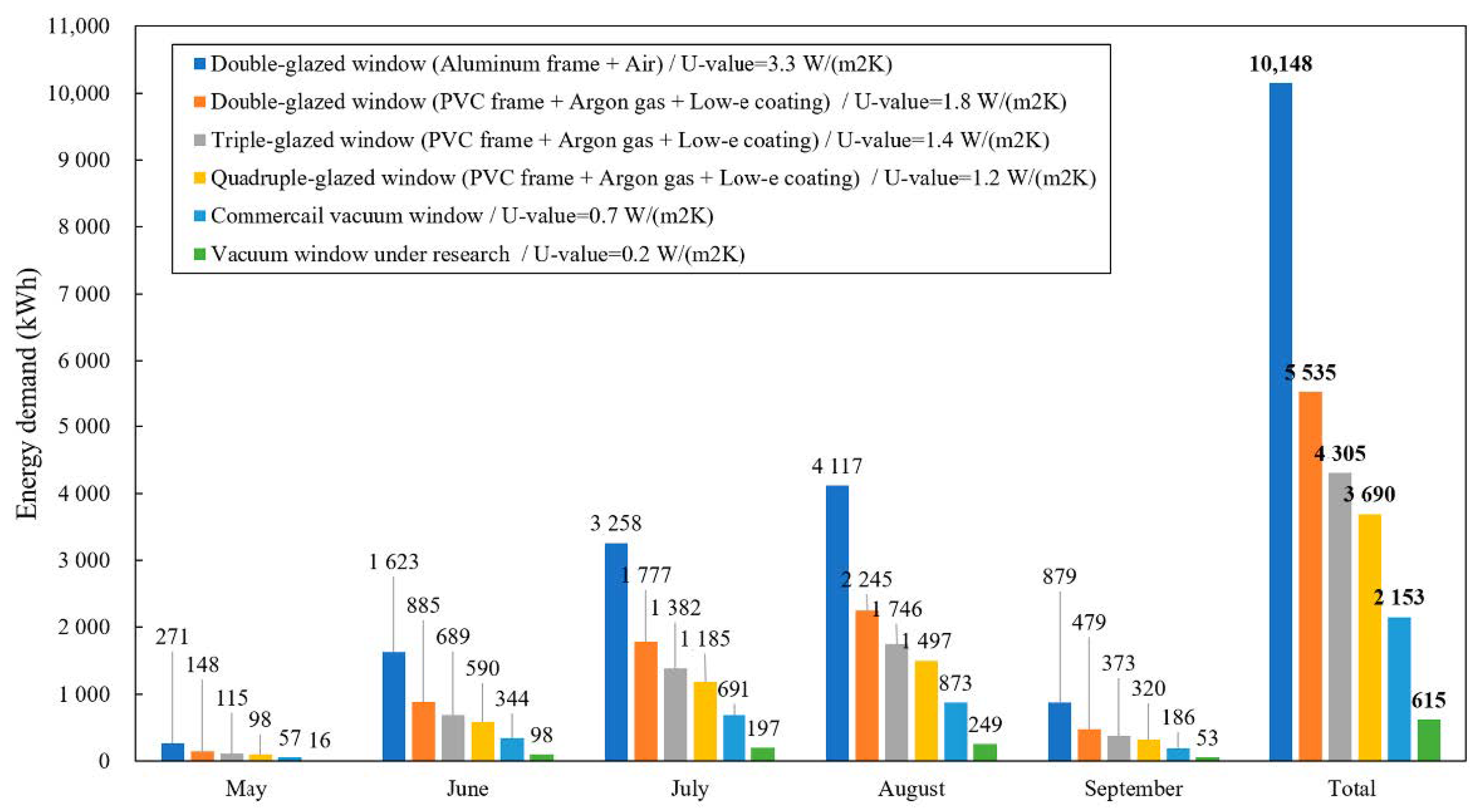

5.1.1. Cooling Energy Demand

5.1.2. Heating Energy Demand

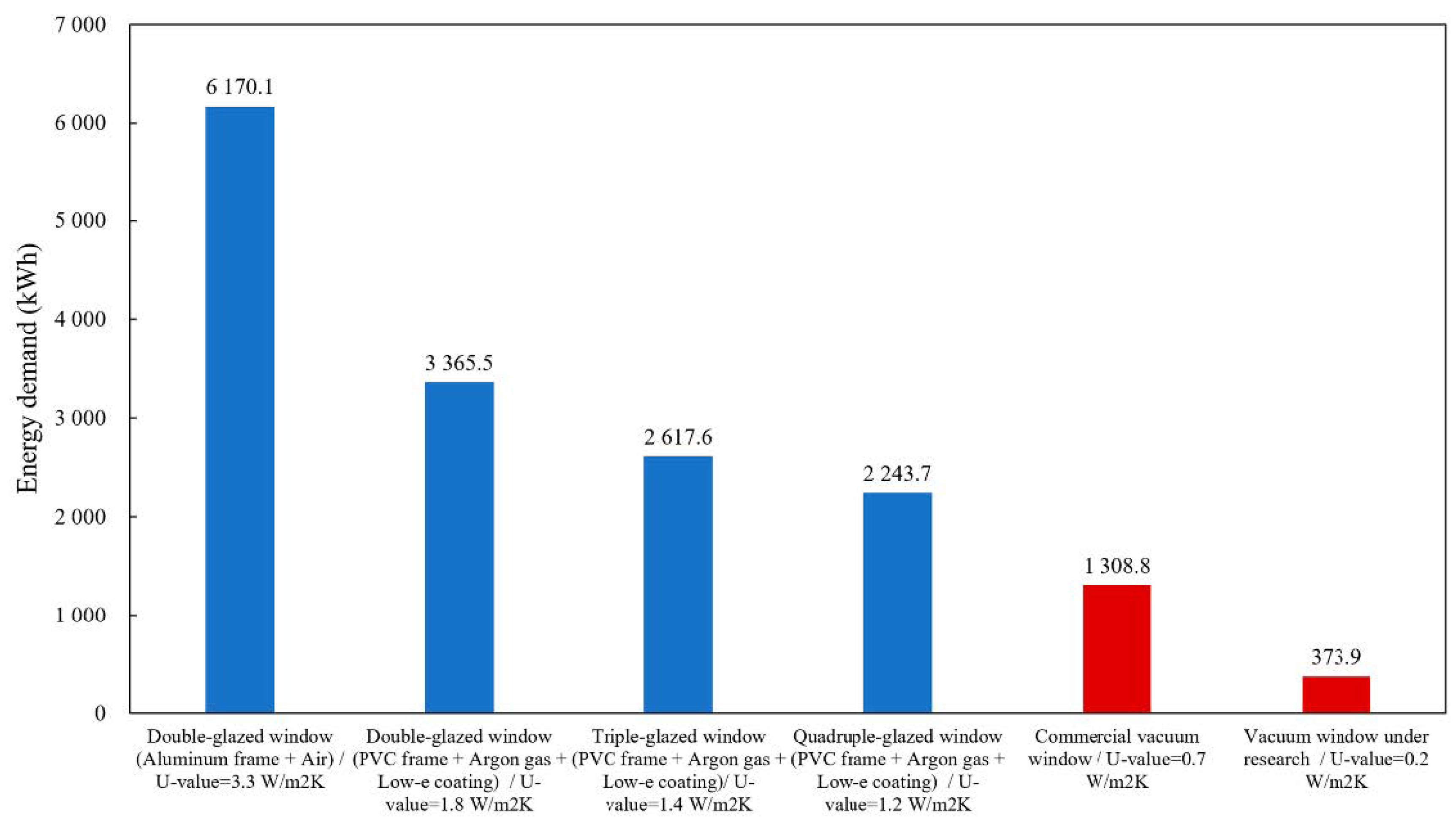

5.1.3. Annual Energy Demand for a Household

5.2. GHGE

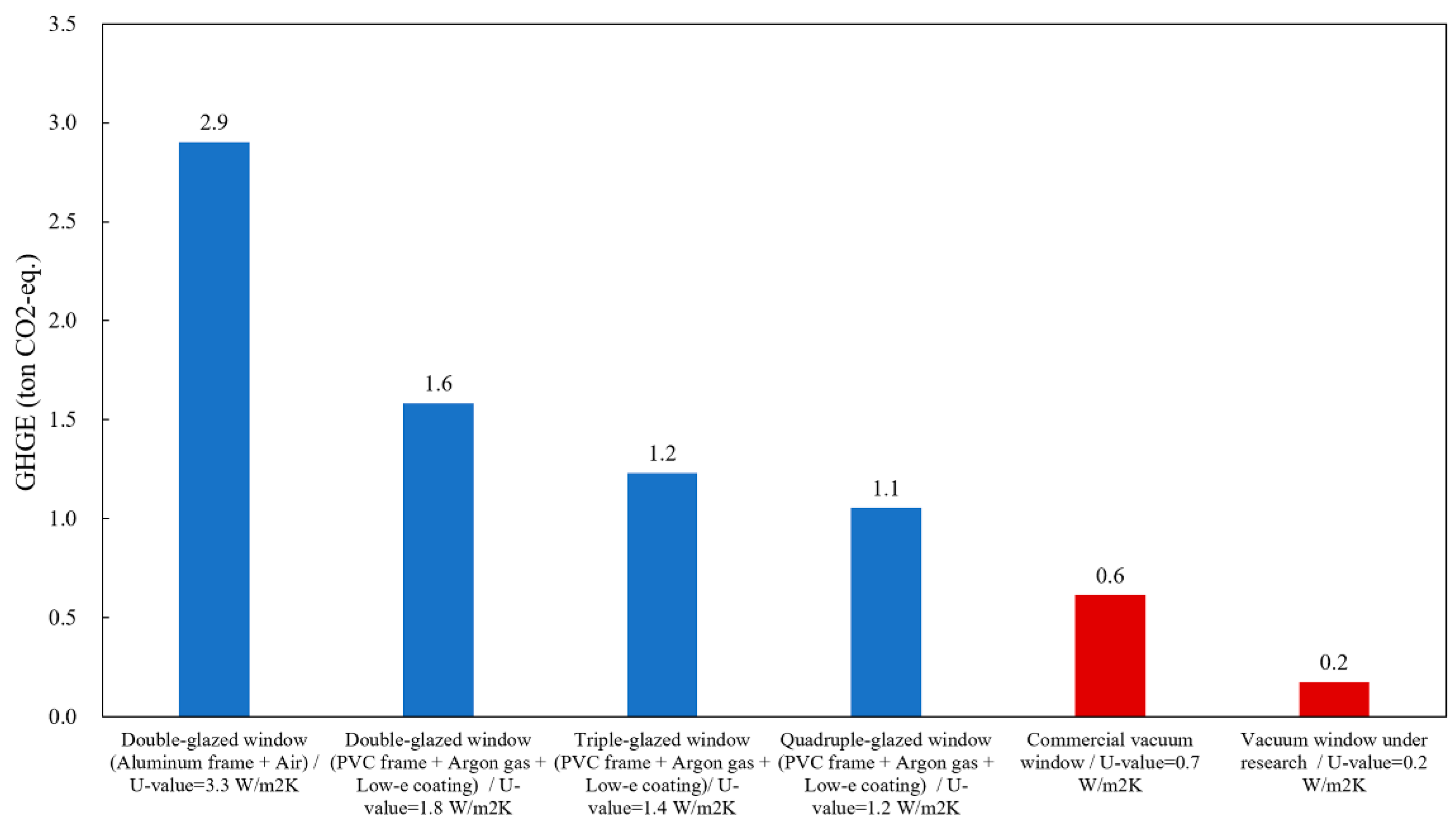

5.2.1. Annual GHGEs for a Household

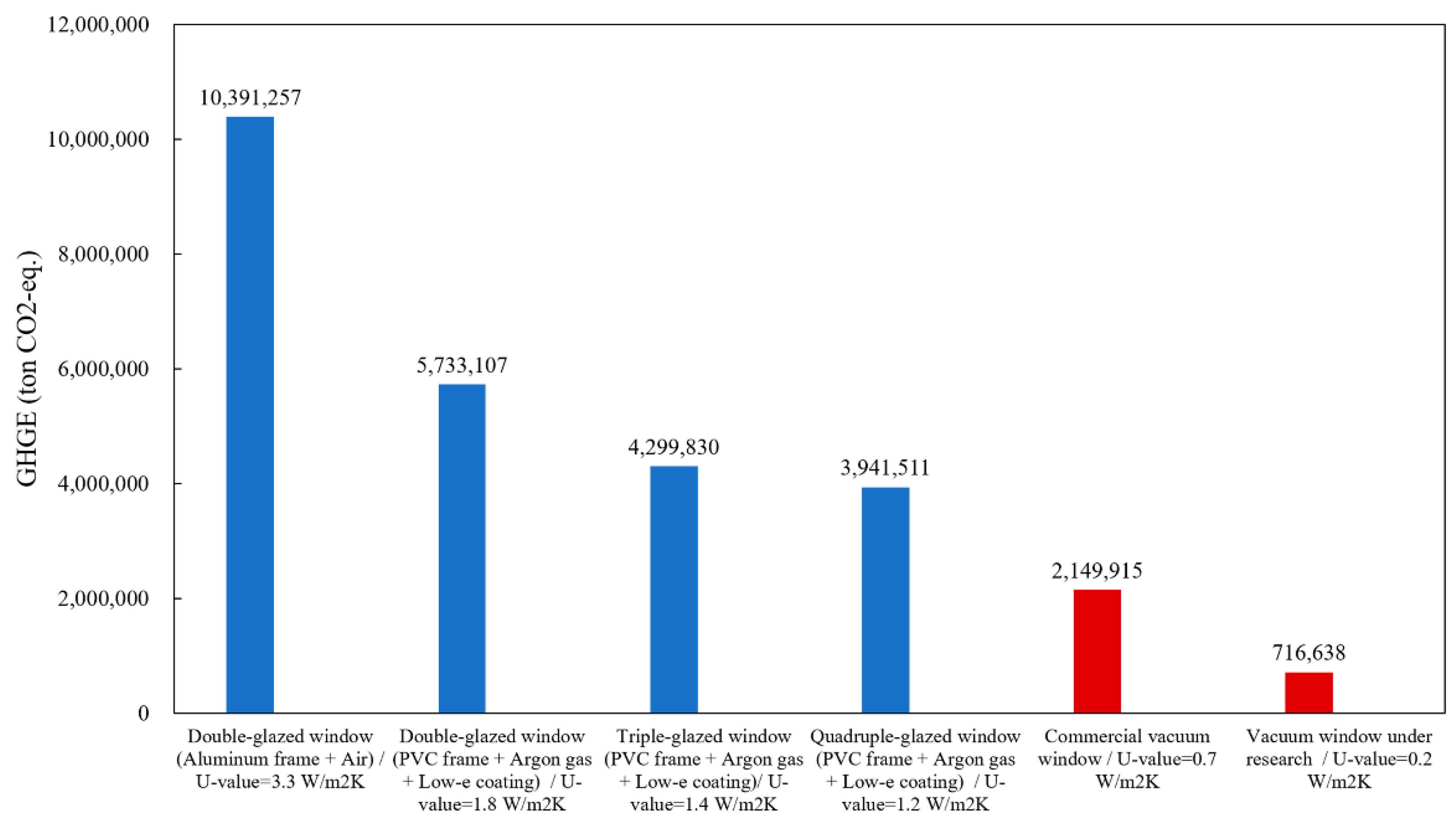

5.2.2. Annual GHGEs of Apartment Buildings in the Capital Region

5.3. VIG Supply Strategy for a Reduction in GHGE

6. Conclusions

- Korea aims to reduce GHGEs to 37% below BAU by 2030. The building sector accounts for ~27% of the total reduction goal, which is the highest amount in the domestic industrial sectors. Thus, building sector GHGE reduction is necessary to reach the national GHGE reduction goal.

- About 25% of all buildings in the country is located in the capital region. Since residential apartment buildings account for approximately 64% of the buildings in the capital, it is important to reduce their energy consumption to meet the GHGE reduction goals. Moreover, apartment buildings have high window-to-wall area ratios and mainly utilize IG with low energy performance. The usage of such windows increases energy consumption and GHGEs for cooling and heating periods. Hence, it is necessary to introduce an advanced window system with superior energy performance to replace the existing windows.

- Recently, a VIG has been developed as an advanced window system. So far, the commercial VIG that have been completed have U-values of 0.7 W/m2·K, but research to develop a with a U-value of 0.2 W/m2·K is actively occurring. If these VIGs are applied to the apartment buildings located in the capital region, GHGEs from energy consumption during cooling and heating periods will be significantly reduced.

- In order to confirm the effects of the VIG, we applied them to all apartment buildings in the capital region and analyzed the amounts of GHGE reduction. When a commercial VIG with a U-value of 0.7 W/m2·K was applied, GHGEs were reduced from 45% to 79% compared to the existing IG with U-values ranging from 1.2 to 3.3 W/m2·K. In addition, when the under-development VIG with a U-value of 0.2 W/m2·K replaced the existing windows, GHGEs decreased by between 82% and 93%.

- The study results suggest that these VIG can significantly reduce GHGEs by improving the energy performance of apartment building envelopes due to their low U-values. If this study were to be expanded to all building sectors, including residential and nonresidential buildings, the VIG GHGE reduction would be even greater.

Author Contributions

Funding

Conflicts of Interest

References

- United Nations Framework Convention on Climate Change. Adoption of the Paris Agreement 2015. Available online: https://unfccc.int/resource/docs/2015/cop21/eng/l09r01.pdf (accessed on 25 May 2020).

- United Nations Framework Convention on Climate Change. Nationally Determined Contributions (NDCs). Available online: https://unfccc.int/nationally-determined-contributions-ndcs (accessed on 25 May 2020).

- UNFCCC. Submission by the Republic of Korea: Intended Nationally Determined Contribution. 2015. Available online: https://www4.unfccc.int/sites/ndcstaging/PublishedDocuments/Republic%20of%20Korea%20First/INDC%20Submission%20by%20the%20Republic%20of%20Korea%20on%20June%2030.pdf (accessed on 25 May 2020).

- Australian Sustainable Built Environmental Council. Defining Zero Emission Buildings Review and Recommendations: Final Report. 2011. Available online: https://www.asbec.asn.au/files/ASBEC_Zero_Carbon_Definitions_Final_Report_Release_Version_15112011_0.pdf (accessed on 25 May 2020).

- International Energy Agency. Technology Roadmap: Energy Efficient Building Envelopes. 2013. Available online: https://www.iea.org/reports/technology-roadmap-energy-efficient-building-envelopes (accessed on 25 May 2020).

- Cuce, E. Development of Innovative Window and Fabric Technologies for Low-Carbon Building. Ph.D. Dissertation, The University of Nottingham, Nottingham, UK, 2014. Available online: https://www.researchgate.net/publication/303443747_Development_of_innovative_window_and_fabric_technologies_for_low-carbon_buildings (accessed on 25 May 2020).

- Yoo, S.; Jeong, H.; Ahn, B.; Han, H.; Seo, D.; Lee, J.; Jang, C. Thermal transmittance of window systems and effects on building heating energy use and energy efficiency rating in South Korea. Energy Build. 2013, 67, 224–236. [Google Scholar] [CrossRef] [Green Version]

- Danny Harvey, L.D. Reducing energy use in the buildings sector: Measures, costs, and examples. Energy Eff. 2009, 2, 139–163. [Google Scholar] [CrossRef]

- Jelle, B.P.; Hynd, A.; Gustavsen, A.; Arasteh, D.; Goudey, H.; Hart, R. Fenestration of today and tomorrow: A state-of-the-art review and future research opportunities. Solar Energy Mater. Solar Cells 2012, 96, 1–28. [Google Scholar] [CrossRef] [Green Version]

- Kamalisarvestani, M.; Saidur, R.; Mekhilef, S.; Javadi, F.S. Performance, materials and coating technologies of thermochromic thin films on smart windows. Renew. Sustain. Energy Rev. 2013, 26, 353–364. [Google Scholar] [CrossRef]

- Van Den Bergh, S.; Hart, R.; Jelle, B.P.; Gustavsen, A. Window spacers and edge seals in insulating glass units: A state-of-the-art review and future perspectives. Solar Energy 2013, 58, 263–280. [Google Scholar] [CrossRef]

- Cuce, E.; Riffat, S.B. A state-of-the-art review on innovative glazing technologies. Renew. Sustain. Energy Rev. 2015, 41, 695–714. [Google Scholar] [CrossRef]

- Malvoni, M.; Baglivo, C.; Congedo, P.M.; Laforgia, D. CFD modeling to evaluate the thermal performances of window frames in accordance with the ISO 10077. Energy 2016, 111, 430–443. [Google Scholar] [CrossRef]

- Murakami, S.; Levine, M.D.; Yoshino, H.; Inoue, T.; Ikaga, T.; Shimoda, Y.; Miura, S.; Sera, T.; Nishio, M.; Sakamoto, Y.; et al. Overview of energy consumption and GHG mitigation technologies in the building sector of Japan. Energy Eff. 2009, 2, 179–194. [Google Scholar] [CrossRef]

- Fang, Y.; Hyde, T.J.; Arya, F.; Hewitt, N.; Eames, P.C.; Norton, B.; Miller, S. Indium alloy-sealed vacuum glazing development and context. Renew. Sustain. Energy Rev. 2014, 37, 480–501. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M. Vacuum glazing for highly insulating window: Recent developments and future prospects. Renew. Sustain. Energy Rev. 2016, 54, 1345–1357. [Google Scholar] [CrossRef]

- Benson, D.K.; Tracy, C.E. Laser Sealed Vacuum Insulation Window. U.S. Patent 4683154, 19 August 1987. [Google Scholar]

- Collins, R.E.; Robinson, S.J. Evacuated glazing. Solar Energy 1991, 47, 27–38. [Google Scholar] [CrossRef]

- Garrison, J.D.; Collins, R.E. Manufacture and cost of vacuum glazing. Solar Energy 1995, 55, 151–161. [Google Scholar] [CrossRef]

- Collins, R.E.; Simko, T.M. Current status of the science and technology of vacuum glazing. Solar Energy 1998, 62, 189–213. [Google Scholar] [CrossRef]

- Griffiths, P.W.; Di Leo, M.; Cartwright, P.; Eames, P.C.; Yianoulis, P.; Leftheriotis, G.; Norton, B. Fabrication of evacuated glazing at low temperature. Solar Energy 1998, 63, 243–249. [Google Scholar] [CrossRef]

- Ng, N.; Collins, R.E.; So, L. Photodesorption of gases in vacuum glazing. J. Vac. Sci. Technol. A Vac. Surf. Films 2003, 21, 1776–1783. [Google Scholar] [CrossRef]

- Ng, N.; Collins, R.E.; So, L. Thermal and optical evolution of gas in vacuum glazing. Mater. Sci. Eng. B 2005, 119, 258–264. [Google Scholar] [CrossRef]

- Fang, Y.; Eames, P.C.; Hyde, T.J.; Norton, B. Complex multimaterial insulating frames for windows with evacuated glazing. Solar Energy 2005, 79, 245–261. [Google Scholar] [CrossRef]

- Fang, Y.; Eames, P.C.; Norton, B.; Hyde, T.J. Experimental validation of a numerical model for heat transfer in vacuum glazing. Solar Energy 2006, 80, 564–577. [Google Scholar] [CrossRef]

- Fang, Y.; Eames, P.C.; Norton, B. Effect of glass thickness on the thermal performance of evacuated glazing. Solar Energy 2007, 81, 395–404. [Google Scholar] [CrossRef]

- Fang, Y.; Eames, P.C.; Norton, B.; Hyde, T.J.; Zhao, J.; Wang, J.; Huang, Y. Low emittance coatings and the thermal performance of vacuum glazing. Solar Energy 2007, 81, 8–12. [Google Scholar] [CrossRef]

- Fang, Y.; Hyde, T.; Eames, P.C.; Hewitt, N. Theoretical and experimental analysis of the vacuum pressure in a vacuum glazing after extreme thermal cycling. Solar Energy 2009, 83, 1723–1730. [Google Scholar] [CrossRef]

- Fang, Y.; Hyde, T.; Hewitt, N.; Eames, P.C.; Norton, B. Comparison of vacuum glazing thermal performance predicted using two- and three-dimensional models and their experimental validation. Solar Energy Mater. Solar Cells 2009, 93, 1492–1498. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.; Eames, P.C.; Norton, B.; Hyde, T.; Huang, Y.; Hewitt, N. The thermal performance of an electrochromic vacuum glazing with selected low-emittance coatings. Solar Energy 2010, 84, 516–525. [Google Scholar] [CrossRef]

- Fang, Y.; Hyde, T.J.; Hewitt, N. Predicted thermal performance of triple vacuum glazing. Solar Energy 2010, 84, 2132–2139. [Google Scholar] [CrossRef]

- Minaai, T.; Kumagai, M.; Nara, A.; Tanemura, S. Study of the outgassing behavior of SnO2: F films on glass in vacuum under external energy excitation. Mater. Sci. Eng. B 2005, 119, 252–257. [Google Scholar] [CrossRef]

- Fang, Y.; Eames, P.C. Thermal performance of an electrochromic vacuum glazing. Energy Convers. Manag. 2006, 47, 3602–3610. [Google Scholar] [CrossRef]

- Fang, Y.; Eames, P.C. The effect of glass coating emittance and frame rebate on heat transfer through vacuum and electrochromic vacuum glazed windows. Solar Energy Mater. Solar Cells 2006, 90, 2683–2695. [Google Scholar] [CrossRef]

- Manz, H.; Brunner, S.; Wullschleger, L. Triple vacuum glazing: Heat transfer and basic mechanical design constraints. Solar Energy 2006, 80, 1632–1642. [Google Scholar] [CrossRef]

- Wang, J.; Eames, P.C.; Zhao, J.F.; Hyde, T.; Fang, Y. Stresses in vacuum glazing fabricated at low temperature. Solar Energy Mater. Solar Cells 2007, 91, 290–303. [Google Scholar] [CrossRef]

- Zhao, J.F.; Eames, P.C.; Hyde, T.J.; Fang, Y.; Wang, J. A modified pump-out technique used for fabrication of low temperature metal sealed vacuum glazing. Solar Energy 2007, 81, 1072–1077. [Google Scholar] [CrossRef]

- Wullschleger, L.; Manz, H.; Ghazi Wakili, K. Finite element analysis of temperature-induced deflection of vacuum glazing. Constr. Build. Mater. 2009, 23, 1378–1388. [Google Scholar] [CrossRef]

- Guardian Glass Website. Available online: http://www.guardianglass.com (accessed on 25 May 2020).

- Pilkington Spacia UK. Pilkington Spacia Ultra-Thin Energy-Efficient Vacuum Glazing. 2016. Available online: https://www.pilkington.com/en-gb/uk/products/product-categories/thermal-insulation/pilkington-spacia/ (accessed on 25 May 2020).

- Specia Vacuum Glass Japan. Vacuum Window Spacia. 2016. Available online: https://shinku-glass.jp/product/st/ (accessed on 25 May 2020).

- Jeong, S.Y.; Baek, N.C.; Yoon, J.H.; Shin, U.; Kim, Y.K.; Kang, S.H. The study on energy performance measurement and energy self-sufficiency analysis of KIER zero energy solar house II. J. Arch. Inst. Korea 2011, 27, 307–314. [Google Scholar]

- Korea Land & Housing Corporation. Green Remodeling Project. 2016. Available online: http://www.lh.or.kr/contents/cont.do?sCode=user&mId=196&mPid=193 (accessed on 25 May 2020).

- Ministry of Science, ICT and Future Planning Korea. Selection Result for New Industry and Creating Project Assignment. 2016. Available online: http://www.korea.kr/news/pressReleaseView.do;JSESSIONID_KOREA=m7fWkDYBttMQj4B1wzvCpG8JyscuJJhi_4RxKoDQaBlq7bBWQKkF!468719327!643091080?newsId=156062188&pageIndex=4414&repCodeType=&repCode=&startDate=2008-02-29&endDate=2019-08-28&srchWord= (accessed on 25 May 2020).

- Ministry of Environment. Roadmap for Reaching National Greenhouse Reduction Goals. 2014. Available online: http://www.me.go.kr/home/web/board/read.do?pagerOffset=30&maxPageItems=10&maxIndexPages=10&searchKey=&searchValue=&menuId=286&orgCd=&boardId=339265&boardMasterId=1&boardCategoryId=&decorator (accessed on 25 May 2020).

- Korea Statistical Information Service. Total Population and Household Investigation. 2015. Available online: http://kosis.kr/statisticsList/statisticsListIndex.do?menuId=M_01_01&vwcd=MT_ZTITLE&parmTabId=M_01_01 (accessed on 25 May 2020).

- Choi, I.J.; Park, I.S. A study on the changes in the compositions of unit plan of apartments: Based on each actual area ratio of the apartment plans constructed in Busan area between 1970–2000s. J. Arch. Inst. Korea 2008, 10, 53–62. [Google Scholar]

- The National Law Information Center. Design Standard for Energy Saving in Buildings. 2016. Available online: http://www.law.go.kr/LSW/main.html (accessed on 25 May 2020).

- Suh, S.J. Building Equipment; Iljinsa Publishing Company: Seoul, Korea, 2003. [Google Scholar]

- Yu, A.; Shinsuke, K.; Satoru, K.; Harunori, Y.; Yasuhiko, M.; Tadahiko, I. Environmental engineering. In Architectural Environment Engineering; Lee, J., Keum, J., Do, G., Kim, S., Kim, J., Kim, H., Lee, S., Park, H., Kim, J.D., Kim, Y., Eds.; Sigmapress Publishing Company: Seoul, Korea, 2003; pp. 144–150. [Google Scholar]

- Lee, K.; Baek, H.J.; Cho, C.H. Future projection of changes in cooling and heating degree days in Korea. J. Clim. Res. 2014, 9, 1–13. [Google Scholar] [CrossRef]

- Pusat, S.; Ekmekci, I. A study on degree-day regions of Turkey. Energy Eff. 2016, 9, 232–525. [Google Scholar] [CrossRef]

- Friess, W.A.; Rakhshan, K.; Davis, M.P. A global survey of adverse energetic effects of increased wall insulation in office buildings: Degree day and climate zone indicators. Energy Eff. 2017, 10, 97–116. [Google Scholar] [CrossRef]

- Climate and Average Weather in South Korea. Weather & Climate. Available online: https://weather-and-climate.com/average-monthly-Rainfall-Temperature-Sunshine-in-South-Korea (accessed on 25 May 2020).

- Kim, D.; Lee, B. The development of the calibration method of building energy consumption by HDDm and CDDm. J. Korean Sol. Energy Soc. 2018, 38, 15–26. [Google Scholar]

- Sohn, C.W.; Yang, Y.S. Effect of types cooling system on electrical energy requirement in Korea. Soc. Air-Condit. Refrig. Eng. Korea 1995, 1995, 477–483. [Google Scholar]

- Lee, K.S.; Park, S.K.; Oh, S.K. Thermal comfort analysis on discharge system of a standing type air-conditioner in living room of an apartment. Soc. Air-Condit. Refrig. Eng. Korea 2002, 2002, 31–36. [Google Scholar]

- Koo, J.O. Thermal characteristics of the floor heating system (Ondol) with light weight concrete base. J. Adv. Miner. Aggreg. Compos. 2003, 8, 161–170. [Google Scholar]

- Yang, K.W.; Rhee, K.N.; Ryu, S.R.; Yeo, M.S.; Kim, K.W. A study on the thermal performance simulation considering hydronic analysis for radiant floor heating system. J. Arch. Inst. Korea 2008, 24, 321–328. [Google Scholar]

- Lim, S.Y.; Kim, H.J.; Yoo, S.H. The demand function for residential heat through district heating system and its consumption benefits in Korea. Energy Policy 2016, 97, 155–160. [Google Scholar] [CrossRef]

- Korea Energy Agency. Oil Conversion Tons Calculated. 2010. Available online: http://co2.kemco.or.kr/toe/toe.aspx (accessed on 25 May 2020).

- Korea Environment Corporation. National Greenhouse Gas Inventory Report Korea. 2015. Available online: https://www.keco.or.kr/kr/business/climate/communityid/187/view.do?idx=16284 (accessed on 25 May 2020).

- Korea Energy Economics Institute. A Study on Energy Consumption and Retrospective Estimation by Types in a Residential Sector. 2010. Available online: http://www.keei.re.kr/main.nsf/index.html?open&p=%2Fweb_keei%2Fd_results.nsf%2Fmain_all%2F0B6BF220B0D8EBF4492579C30039A7C8&s=%3FOpenDocument%26menucode%3DS0%26category%3D%25EA%25B8%25B0%25EB%25B3%25B8%25EC%2597%25B0%25EA%25B5%25AC (accessed on 25 May 2020).

- Korea Environmental Industry and Technology Institute. Explanation book on Green Standard for Energy and Environmental Design (G-SEED). 2016. Available online: https://www.gbc.re.kr/app/data/regulation/list.do (accessed on 25 May 2020).

- Korea Institute of Registered Architecture. Guideline for Building Energy Efficiency Rating. 2013. Available online: http://www.kira.or.kr/jsp/main/02/01.jsp?page=97&ba_bbsId=BBS_00_LAW_INFO&%3Bmode=read&ba_id=115554&bbsLocale=&sc_keyword=&sc_ba_authorNameL=&sc_ba_bbsId=BBS_00_LAW_INFO&mode=read&sc_ba_cateId=&sc_scType=1&sc_ba_titleL= (accessed on 25 May 2020).

| Structure | Number of Households | Number of Floors | Width (m) | Height (m) | Envelope Area (m2) | Window Area (m2) | Window Ratio (%) |

|---|---|---|---|---|---|---|---|

| Reinforced concrete | 60 | 15 | 41.5 | 46.8 | 3290 | 1316 | 40 |

| No. | Window Type | Window Structure | U-Value (W/m2·K) |

|---|---|---|---|

| 1 | Double-glazed window (standard) | Aluminum frame + air | 3.3 |

| 2 | Double-glazed window | PVC frame + argon gas + low-e coating | 1.8 |

| 3 | Triple-glazed window | PVC frame + argon gas + low-e coating | 1.4 |

| 4 | Quadruple-glazed window | PVC frame + argon gas + low-e coating | 1.2 |

| 5 | VIG I | Commercial VIG | 0.7 |

| 6 | VIG II | VIG under research | 0.2 |

| Month | Total Days (Days) | Cooling Period (Days) | Non-Cooling and Heating Period (Days) | Heating Period (Days) |

|---|---|---|---|---|

| 1 | 31 | 0 | 0 | 31 |

| 2 | 28 | 0 | 0 | 28 |

| 3 | 31 | 0 | 0 | 31 |

| 4 | 30 | 0 | 3 | 27 |

| 5 | 31 | 6 | 15 | 10 |

| 6 | 30 | 23 | 7 | 0 |

| 7 | 31 | 30 | 1 | 0 |

| 8 | 31 | 31 | 0 | 0 |

| 9 | 30 | 14 | 16 | 0 |

| 10 | 31 | 0 | 6 | 25 |

| 11 | 30 | 0 | 0 | 30 |

| 12 | 31 | 0 | 0 | 31 |

| Total | 365 | 104 | 48 | 213 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, S.; Kim, S. Potential Effects of Vacuum Insulating Glazing Application for Reducing Greenhouse Gas Emission (GHGE) from Apartment Buildings in the Korean Capital Region. Energies 2020, 13, 2828. https://doi.org/10.3390/en13112828

Baek S, Kim S. Potential Effects of Vacuum Insulating Glazing Application for Reducing Greenhouse Gas Emission (GHGE) from Apartment Buildings in the Korean Capital Region. Energies. 2020; 13(11):2828. https://doi.org/10.3390/en13112828

Chicago/Turabian StyleBaek, Sanghoon, and Sangchul Kim. 2020. "Potential Effects of Vacuum Insulating Glazing Application for Reducing Greenhouse Gas Emission (GHGE) from Apartment Buildings in the Korean Capital Region" Energies 13, no. 11: 2828. https://doi.org/10.3390/en13112828