The Influence of an Additional Sensor on the Microprocessor Temperature

Abstract

:1. Introduction

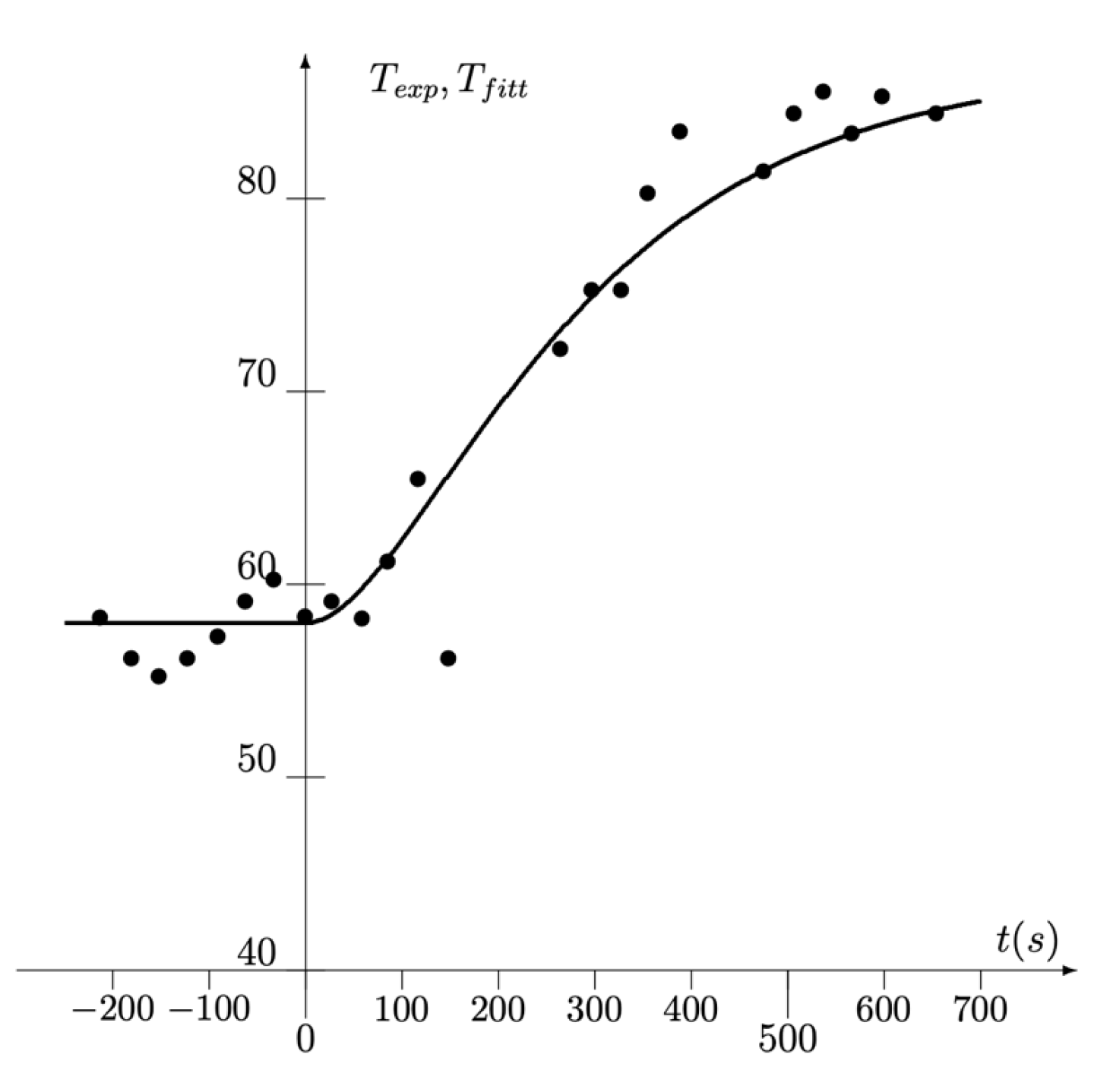

2. Experimental Measurements

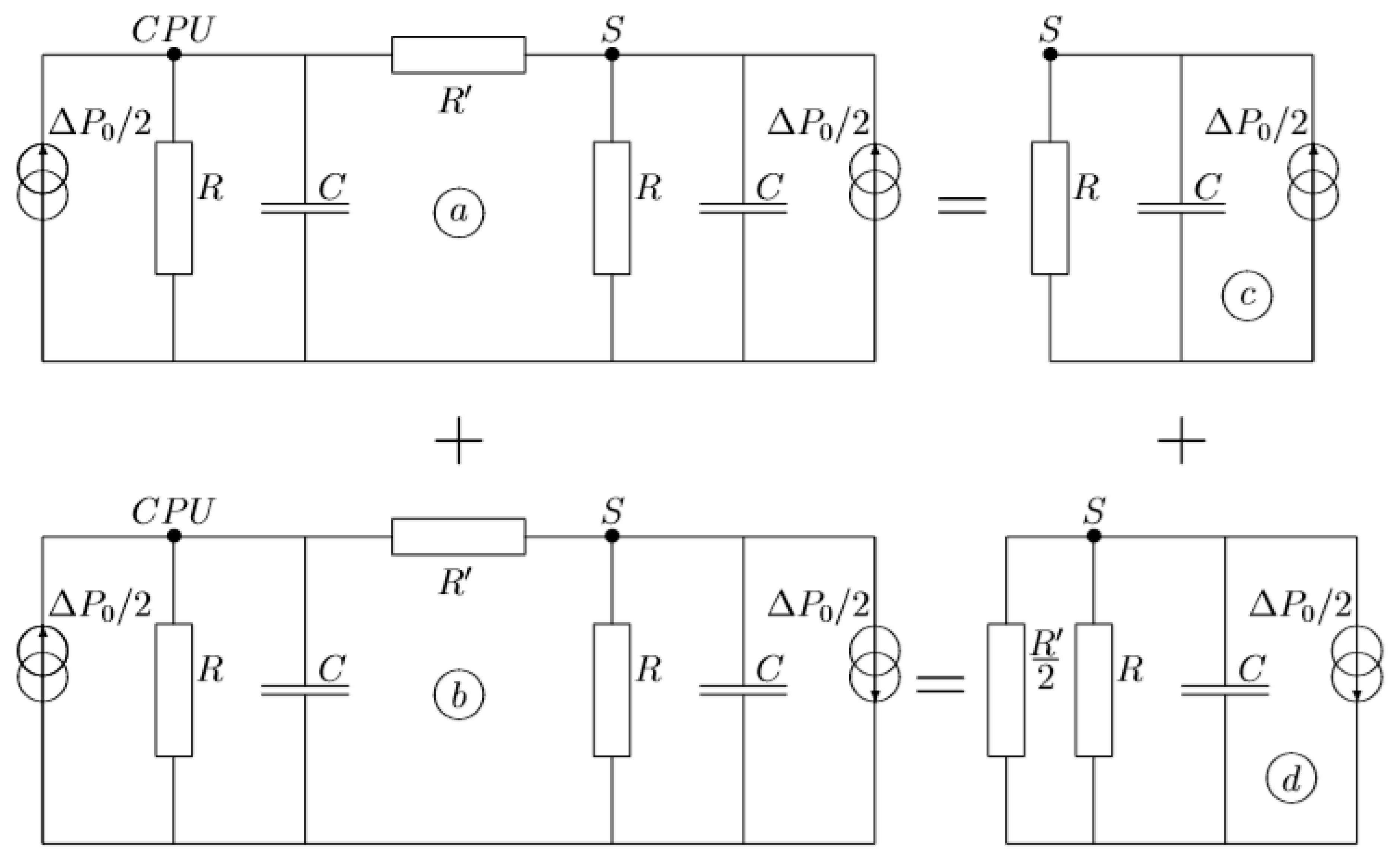

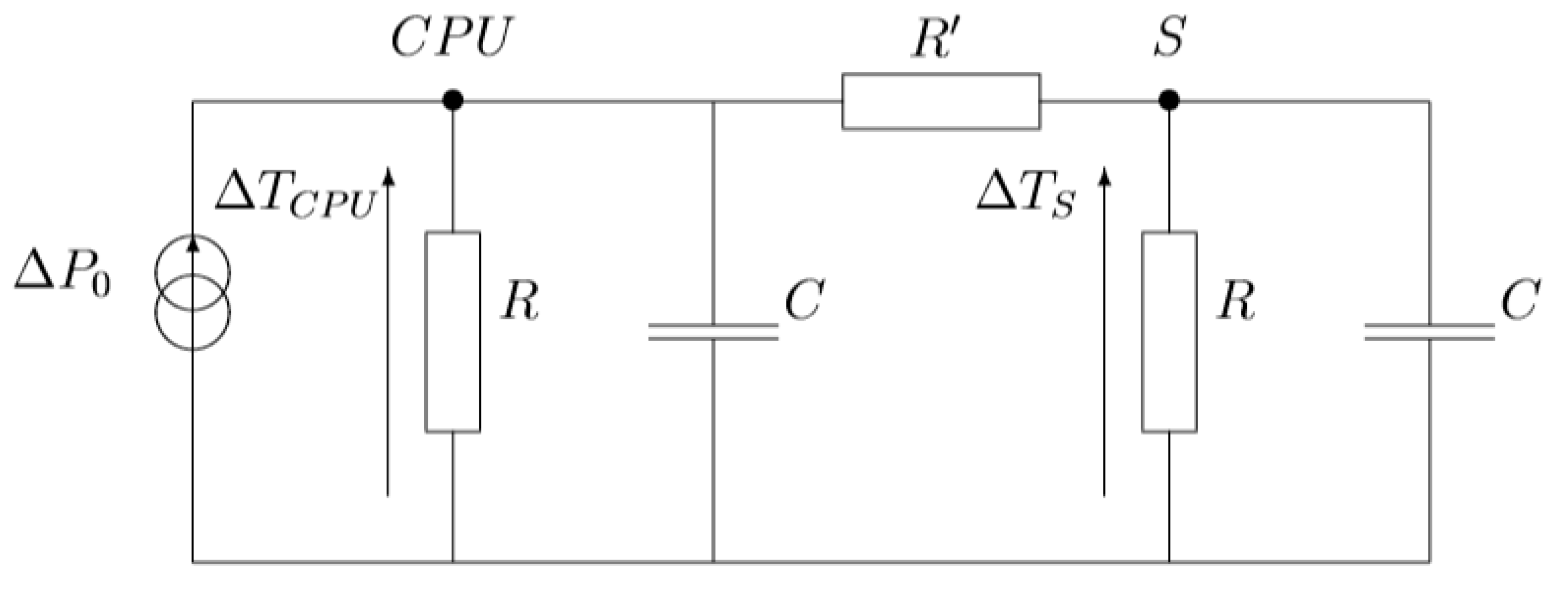

3. Network Model

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Long, J.; Ogrenci-Memik, S.; Memik, G.; Mukherjee, R. Thermal monitoring mechanisms for chip multiprocessors. ACM Trans. Arch. Code Optim. 2008, 5, 1–33. [Google Scholar] [CrossRef] [Green Version]

- Memik, S.O.; Mukherjee, R.; Ni, M.; Long, J. Optimizing Thermal Sensor Allocation for Microprocessors. IEEE Trans. Comput. Des. Integr. Circuits Syst. 2008, 27, 516–527. [Google Scholar] [CrossRef]

- Huang, W.; Stan, M.R.; Skadron, K.; Sankaranarayanan, K.; Ghosh, S.; Velusam, S. Compact thermal modeling for temperature-Aware design. In Proceedings of the the 41st annual Design Automation Conference, San Diego, CA, USA, 19–23 July 2004; pp. 878–883. [Google Scholar]

- Samake, A.; Kocanda, P.; Kos, A. Effective approach of microprocessor throughput enhancement. Microelectron. Int. 2019, 36, 14–21. [Google Scholar] [CrossRef]

- Samake, A.; Kocanda, P.; Kos, A. Improvement of microsystem throughput using new cooling system. Sci. Lett. Rzeszow Univ. Technol. Electrotech. 2016, XXIV, 5–15. [Google Scholar] [CrossRef] [Green Version]

- Poppe, A.; Szekely, V. Dynamic temperature measurements: Tools providing a look into package and mount structures. Electron. Cool. 2002, 8, 10–18. [Google Scholar]

- Székely, V.; Van Bien, T. Fine structure of heat flow path in semiconductor devices: A measurement and identification method. Solid-State Electron. 1988, 31, 1363–1368. [Google Scholar] [CrossRef]

- Szekely, V. On Representation of infinite-Length distributed RC one-Ports. IEEE Trans. Circuits Syst. 1991, 38, 711–719. [Google Scholar] [CrossRef]

- Simon, D.; Boianceanu, C.; De Mey, G.; Topa, V. Experimental Reliability Improvement of Power Devices Operated under Fast Thermal Cycling. IEEE Electron Device Lett. 2015, 36. [Google Scholar] [CrossRef] [Green Version]

- Simon, D.; Boianceanu, C.; De Mey, G.; Topa, V.; Spitzer, A. Reliability Analysis for Power Devices Which Undergo Fast Thermal Cycling. IEEE Trans. Device Mater. Reliab. 2016, 16, 336–344. [Google Scholar] [CrossRef]

- Janicki, M.; de Mey, G.; Napieralski, A. Transient thermal analysis of multilayered structures using Green’s functions. Microelectron. Reliab. 2002, 42, 1064–1069. [Google Scholar] [CrossRef]

- Janicki, M.; De Mey, G.; Napieralski, A. Application of Green’s functions for analysis of transient thermal states in electronic circuits. Microelectron. J. 2002, 33, 733–738. [Google Scholar] [CrossRef]

- Janicki, M.; Banaszczyk, J.; De Mey, G.; Kamiński, M.; Vermeersch, B.; Napieralski, A. Dynamic thermal modelling of a power integrated circuit with the application of structure functions. Microelectron. J. 2009, 40, 1135–1140. [Google Scholar] [CrossRef]

- Janicki, M.; Banaszczyk, J.; Vermeersch, B.; De Mey, G.; Napieralski, A. Generation of reduced dynamic thermal models of electronic systems from time constant spectra of transient temperature responses. Microelectron. Reliab. 2011, 51, 1351–1355. [Google Scholar] [CrossRef]

- Kawka, P.; de Mey, G.; Vermeersch, B. Thermal characterisation of electronics packages using the Nyquist plot of the thermal impedance. IEEE Trans. Compon. Packag. Technol. 2007, 30, 660–665. [Google Scholar] [CrossRef]

- De Mey, G.; Pilarski, J.; Wojcik, M.; Lasota, M.; Banaszczyk, J.; Vermeersch, B.; Napieralski, A. Influence of interface materials on the thermal impedance of electronic packages. Int. Commun. Heat Mass Transf. 2009, 36, 210–212. [Google Scholar] [CrossRef]

- Vermeersch, B.; De Mey, G. Thermal impedance plots of micro-scaled devices. Microelectron. Reliab. 2006, 46, 174–177. [Google Scholar] [CrossRef] [Green Version]

- Vermeersch, B.; De Mey, G. Influence of substrate thickness on thermal impedance of microelectronic structures. Microelectron. Reliab. 2007, 47, 437–443. [Google Scholar] [CrossRef] [Green Version]

- De Mey, G.; Vermeersch, B.; Banaszczyk, J.; Swiatczak, T.; Wiecek, B.; Janicki, M.; Napieralski, A. Thermal impedances of thin plates. Int. J. Heat Mass Transf. 2007, 50, 4457–4460. [Google Scholar] [CrossRef]

- Vermeersch, B.; De Mey, G. A Fixed-Angle Dynamic Heat Spreading Model for (An)Isotropic Rear-Cooled Substrates. J. Heat Transf. 2008, 130, 121301. [Google Scholar] [CrossRef]

- Chatziathanasiou, V.; Chatzipanagiotou, P.; Papagiannopoulos, I.; de Mey, G.; Wiecek, B. Dynamic thermal analysis of underground medium power cables using thermal impedance, time constant distribution and structure function. Appl. Therm. Eng. 2013, 60, 256–260. [Google Scholar] [CrossRef]

- Więcek, B.; De Mey, G.; Chatziathanasiou, V.; Papagiannakis, A.; Theodosoglou, I. Harmonic analysis of dynamic thermal problems in high voltage overhead transmission lines and buried cables. Int. J. Electr. Power Energy Syst. 2014, 58, 199–205. [Google Scholar] [CrossRef]

- Chatzipanagiotou, P.; Chatziathanasiou, V.; De Mey, G.; Więcek, B. Influence of soil humidity on the thermal impedance, time constant and structure function of underground cables: A laboratory experiment. Appl. Therm. Eng. 2017, 113, 1444–1451. [Google Scholar] [CrossRef]

- Papagiannopoulos, I.; Chatziathanasiou, V.; Exizidis, L.; Andreou, G.; de Mey, G.; Wiecek, B. Behaviour of the thermal impedance of buried power cables. Int. J. Electr. Power Energy Syst. 2013, 44, 383–387. [Google Scholar] [CrossRef]

- Kałuża, M.; Więcek, B.; De Mey, G.; Hatzopoulos, A.; Chatziathanasiou, V. Thermal impedance measurement of integrated inductors on bulk silicon substrate. Microelectron. Reliab. 2017, 73, 54–59. [Google Scholar] [CrossRef]

- Legierski, J.; Więcek, B.; De Mey, G. Measurements and simulations of transient characteristics of heat pipes. Microelectron. Reliab. 2006, 46, 109–115. [Google Scholar] [CrossRef]

- De Mey, G.; Wyrzutowicz, J.; De Vos, A.; Marańda, W.; Napieralski, A. Influence of lateral heat diffusion on the thermal impedance measurement of photovoltaic panels. Sol. Energy Mater. Sol. Cells 2013, 112, 1–5. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Mey, G.; Kos, A. The Influence of an Additional Sensor on the Microprocessor Temperature. Energies 2020, 13, 3156. https://doi.org/10.3390/en13123156

De Mey G, Kos A. The Influence of an Additional Sensor on the Microprocessor Temperature. Energies. 2020; 13(12):3156. https://doi.org/10.3390/en13123156

Chicago/Turabian StyleDe Mey, Gilbert, and Andrzej Kos. 2020. "The Influence of an Additional Sensor on the Microprocessor Temperature" Energies 13, no. 12: 3156. https://doi.org/10.3390/en13123156