1. Introduction

Railway transportation is an essential means of transportation; it cannot be replaced by others owing to its own superiorities such as safety, energy efficiency, comfortable nature, punctuality, large volume of transport, convenient, accurate parking, etc. [

1]. Automatic train operation (ATO) target velocity trajectory optimization is a practical multiple optimization problem for railway transportation, the multiple performance indicators such as energy consumption, parking punctuality, comfort, accurate parking, and so on. Of particular note is the increasing energy demand, thus energy-saving is becoming a research hot spot in automatic train operation [

2]. Many researchers’ studies about energy efficiency or energy-saving have been proposed in recent literatures [

3,

4,

5,

6]. The function of automatic train operation (ATO) target velocity trajectory optimization is crucial, it could make the train in the real-time optimal state as much as possible with multi-objective comprehensive performance index satisfied, so as to reduce energy consumption in automatic train operation. Therefore, improving the optimization and tracking control effect involves using the corresponding optimization algorithm effectively by incorporating improvement strategies appropriately.

Multi-objective train operation optimization has been a hot issue in the field of railway research in recent years. To obtain more satisfactory optimization results, a multi-objective optimization model of the speed trajectory for the high-speed train is established and an improved algorithm based on differential evolution and simulated annealing algorithms is designed [

7]. A genetic algorithm with the binary encoding method is designed for obtain the high-quality timetables of urban rail transit systems based on two-objective (energy-saving strategies and service quality levels) model formulated [

8]. A method about design speed profiles to be programmed robustly and efficiently is proposed in automatic train operation equipment for one metro line based on the two indicators of the running time and the energy consumption [

9]. The balance between saving energy and running faster has been investigated, and an improved genetic algorithm is used to search the ideal optimal train target trajectories [

10]. A novel multiple optimization model based on switching optimization framework for moving block signal (MBS) system is proposed [

11]. A predictive train rescheduling model incorporating the model predictive control (MPC) mechanism and the non-analytical prediction model are proposed to be taken into consideration synergistic safe and efficient operations in high speed trains [

12]. A microsimulation system about train timetable evaluation from the viewpoint of passengers to simulate both train operation and passengers’ train choice behavior is developed [

13].

Further research is necessary based on some of the above research results, and three crucial factors about multi-objective automatic train operation (ATO) target velocity trajectory optimization should be taken seriously. First, there are many uncertainties and complex relations in actual automatic train operation (ATO), and it is difficult to obtain ideal optimization results only by using traditional optimization algorithm. Many literatures (e.g., [

7,

8,

9,

10], etc.) have studied and improved traditional optimization algorithms about automatic train operation (ATO) optimization, so as to obtain more ideal optimization results. It is easy for traditional optimization algorithms to fall into the local optimum, and there are also problems of blind searching, premature stagnation, and slow convergence, in the end of iteration especially. Compared with improved traditional algorithms, the improved shark smell optimization (SSO) algorithm has more powerful searching capabilities, even in the end of the iteration. To improve the global optimization performance of shark smell optimization (SSO) algorithm, relevant researchers have proposed quite a few improvement strategies and relevant experiments showing that the improved SSO algorithm has more effective performance than other algorithms contrasted. The intrinsic mechanism of SSO algorithm is introduced in detail [

14]. To solve the optimal capacitor placement problem satisfying the operating constraints, a new shark smell optimization (SSO) algorithm is proposed [

15]. A new model for multiyear expansion planning of distribution networks (MEPDN) is proposed, and, to solve the above MEPDN model optimization problem, a new evolutionary algorithm-based solution method called Binary Chaotic Shark Smell Optimization (BCSSO) is presented [

16]. A novel forecasting algorithm based on neural network (NN) and a novel chaotic shark smell optimization (CSSO) algorithm are proposed [

17].

Meanwhile, the driving experience for automatic train operation (ATO) target velocity trajectory optimization should not be ignored. A considerable number of researchers are interested in researching the affect of driving experience for automatic train operation (ATO) optimization, such as in [

3,

4,

9,

10], etc. In addition, a series of manual driving strategies that will minimize energy consumption for high-speed trains have been researched [

18]; an expert system that contains expert rules and a heuristic expert inference method about intelligent train operation optimization for subway has been developed [

19]; an intelligent safe driving method (ISDMs) is proposed to obtain better speed–distance curves [

20]. Note that preference indices of driving experience are applied in automatic train operation algorithm [

21]. Preference information is widely used in multiple decision-making (MPDM) problems such as multi-objective optimization problems, plenty of research findings show that the optimization performance of multi-objective optimization algorithm can be significantly improved using incorporated appropriate preference information. A new method to solve multiple decision-making (MPDM) problems based on the preference information is proposed [

22]. A preference information based on the weighted sum aggregation is proposed to better solve the multi-objective optimization problem, and the numerical experiments show that the method has obvious advantages in both calculation accuracy and computation time [

23]. A multi-criteria selection method that the preference scale changes with the change of multi-criteria decision-making problem is proposed, and Monte Carlo method is used to verify the feasibility of the algorithm [

24].

In fact, during automatic train operation, there are extensive problems need to be considered such as real-time velocity sampled inaccurately, signal delay, and packet loss in transmission and a certain degree of unstable in tracking control system, so a certain proportion of literatures use real vehicle experiments and actual driving data (Ning’xi line, Yizhuang line, Shanghai Railway Transit in China) to verify the effectiveness of the algorithm [

4,

19,

21]. Due to the situation of the actual automatic train operation experiment, it is difficult to implement, and traditional simulation based on pure software environment cannot truly reflect the actual automatic train operation process; hardware-in-the-loop simulation (HILS) is often used in automatic train operation due to its characteristics [

25,

26]. At present, plenty of HILS-related products are researched, developed, and applied in various fields of rail vehicles, traction control system, hybrid electric vehicles, and electric cars, and numerous relative research findings have been achieved [

27,

28,

29,

30].

Based on the above research findings, an effective automatic train operation velocity trajectory optimization algorithm that can give full play to the role of driving preference information is needed, and multi-objective shark smell optimization algorithm with powerful optimization should also be emphasized, so as to achieve more satisfactory optimization results for the automatic train operation (ATO). An improved multi-objective shark smell optimization algorithm using incorporated composite angle cosine for automatic train operation is proposed in this paper on the basis of literatures [

14,

23,

28] and several similar literatures. The following summarizes the main contributions of this paper.

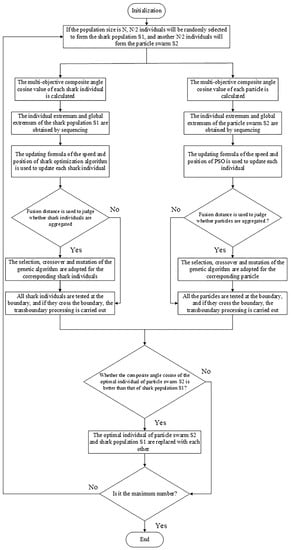

(I) An improved multi-objective shark smell optimization algorithm (ISSO) based on incorporated composite angle cosine, dual-population mechanism and fusion distance measurement index is proposed to solve practical automatic train operation (ATO) target velocity trajectory optimization effectively.

(II) To verify the effectiveness of ISSO, two scenarios about rail transit line No.12 and Jinpu line No.1 in Dalian, China are chosen for simulation test. The results of Matlab/simulation and hardware-in-the-loop simulation (HILS) show that the ISSO proposed in this paper (ISSO) (I) has good performance in optimization precision, (II) has fast optimization speed, and (III) can obtain the smooth target velocity trajectory tracked control by “Controller” easily achievable.

The paper is organized as follows.

Section 2 introduces the optimization model of automatic train operation.

Section 3 illustrates the improved multi-objective shark smell optimization algorithm (ISSO) using incorporated composite angle cosine for automatic train operation proposed in this paper.

Section 4 provides the Matlab/simulation results and hardware-in-the-loop simulation (HILS) results to illustrate the proposed method.

Section 5 concludes this article.

4. Experimental Simulation

4.1. Data and Parameters for Experimental Simulation

In this paper, the scenarios about Jinpu line No.1 and rail transit line No.12 in Dalian, China are selected as the research objects. Jinpu line No.1 is the intercity railway line that is 46.76 km long and has 11 stations in the initial stage, which extend from Jiuli light rail station to the terminal of Zhenxing road in Dalian under construction. Rail transit line No.12 is an urban rail transit line that is 40.38 km long and has 8 stations, which extend from Hekou station to terminal of Lvshun New Port. The simulation running line of scenario about Jinpu line No.1 is from the Jiuli to the 19th bureau, and the interval length between the above two station is 2.74 km. The running simulation line of scenario about rail transit line No.12 is from Lvshun New Port to Tieshan Town, and the interval length between the above two station is 2.94 km, with two long downhill and a long uphill ramps. The main parameters of the above scenarios are shown in

Table 2 and

Table 3, ramp parameters and velocity limit for automatic train operation are shown in

Figure 5.

The calculation formula of traction characteristics is expressed as follows,

where

is the instantaneous traction of vehicles,

is the vehicle’s maximum traction,

is the maximum traction power of the vehicle,

is the switching velocity of the constant power zone and the reduced power zone,

is the switching velocity of the traction starting region and constant torque region, and

is the maximum design speed of the vehicle.

Simulation optimization results must satisfy the following conditions; the train instantaneous speed cannot surpass the speed limit, the train must finish the whole process, and the parking error is less than m. The improved shark smell optimization algorithm parameters are set as follows; the particle swarm size is 40, the weight coefficient is , the acceleration coefficients and are , crossover probability is 0.7, mutation probability is 0.09, selection probability is 0.5, the iteration number is 200, the shark population size is 40, the random number , , , , speed limit factor is 1.3, and the weight coefficient is . Setting parameters for the optimization algorithm is necessary to consider the convergence speed and optimization effect, such as population size and iteration number, with the increase of population size, the global search ability of the optimization algorithm will be enhanced, but the convergence speed will be reduced; similarly, with the increase of the number of iterations, the finding opportunity of optimal solution will be increase, and the more computing time and resource will be expend. The parameters characteristics and multiple experimental simulation results are taken into account for the above parameters setting. The multi-objective optimization parameters of the ATO scenario simulation of Jinpu line No.1 in Dalian are set as follows; the scheduled running time is ; ; ; ; the intrinsic weight factors ; and are, respectively, , , and ; the target demand vector is . The multi-objective optimization parameters of the ATO scenario simulation of rail transit line No.12 in Dalian are set as follows; the scheduled running time is 180 s, , , , the intrinsic weight factors , , and are, respectively, , , and , the target demand vector is .

4.2. Matlab/simulink Simulation Results for Automatic Train Operation Scenarios

According to the automatic train operation scenarios of rail transit line No.12 and Jinpu line No.1 in Dalian, China, the approximate optimal solutions are obtained by using the improved algorithm proposed in this paper, traditional improved shark smell optimization algorithm (chaotic shark smell optimization) [

17] and traditional improved particle swarm optimization (dynamic multiple populations particle swarm optimization algorithm based on decomposition) [

43], the above Matlab/simulink platform is chosen as a simulation platform. The specific configuration of the Matlab/simulink platform used in this paper is described as follow: the Matlab/simulink revision is Matlab GUI 2016b; the major computer configuration is “CPU Core i9-7920X @ 2.9 GHZ” and “Windows 10”. The specific Matlab/simulink optimization simulation results are shown in

Figure 6 and

Figure 7 and

Table 4,

Table 5,

Table 6 and

Table 7, and three different algorithms are recorded as ISSO, CSSO, and dMOPSO.

As can be seen in

Table 4,

Table 5,

Table 6 and

Table 7, the optimization solution obtained by the improved ISSO is superior to that of CSSO and dMOPSO, and three indexes of energy saving, punctuality, and comfort have been improved considerably. The ATO experiment simulation scenario for Jinpu line No.1 from Jiuli to the 19th bureau is a typical slope with ups and downs. It is necessary to keep the train at high speed before driving down the long down ramp. The ATO experiment simulation scenario for rail transit line No.12 from Lvshun New Port to Tieshan Town is in the hilly of Dalian Lvshunkou district, and the hilly region is the typical characteristics of Dalian. When the train is running in such a terrain, the control sequence should be concise. The train speeds up in the long down slope and slows down in the long up slope as much as possible, which can save energy and avoid turbulence. As can be seen from

Figure 6a,b and

Figure 7a,b ( the target velocity trajectory and control sequence ), the improved algorithm ISSO can obtain extremely simple control sequence and make the most of long down and up slopes, so as to obtain the target velocity trajectory as smooth as possible. As can be seen from

Figure 6c,d and

Figure 7c,d (the iterative convergence curves), the convergence rate of ISSO is faster than that of CSSO and dMOPSO. Even in the late iterations, ISSO has a strong ability of global convergence performance.

Compared with other comparison optimization algorithms, ISSO has several obvious advantages in matlab/simulation environment, as there is huge difference between matlab/simulation environment and actual scenario yet, the effectiveness of ISSO is necessary to further test and verify.

4.3. HILS Results for Automatic Train Operation Scenarios

Matlab/Simulink is a simulation technology that is completely separated from the real train operation environment. Therefore, some problems (such as real-time velocity sampled inaccurately, signal delay and packet loss in transmission, a certain degree of unstable in tracking control system, etc.) need to be considered in the actual control process and are cannot be truly reflected. To more effectively test the performance of the optimization algorithm in the actual train operation environment, dSPACE hardware-in-the-loop simulation (HILS) technology is adopted to write the verified optimization algorithm or control algorithm to the chip of the optimizer or controller. Compared to traditional simulation platform based on pure software environment, dSPACE HILS platforms contain the real on-board equipments, which can truly reflect the the real situation for automatic train operation. Due to the restriction of funds and experiment conditions, it is difficult to implement the corresponding actual automatic train operation experiment. Moreover, compared with real actual experiments, dSPACE HILS has the advantages of low experimental cost, implement easily, and high security protection of personal and equipment [

33]. Therefore, HILS is highly valued by researchers and developers, abundant HILS-related products are researched, developed, and applied in various fields and numerous relative research results have been achieved [

44,

45]. The semi-physical simulation equipments in automatic train operation mainly include optimizer, controller, sensors, simulator, conditioning circuit, signal conditioning unit, and connector. The simulation topology diagram of automatic train operation HILS platform, the structure diagram for automatic train operation HILS, and the physical diagram of controller cabinet and simulation cabinet for automatic train operation HILS are shown in

Figure 8 and

Figure 9.

As can be seen from

Figure 8, the Controller/Optimizer and its Service equipment make up the automatic train operation HILS platform, the Monitor serves as the monitoring center for human–computer interaction, and the Alarm set and Circuit breaker are the warning and protection center. Alarm set detects the working status of each HILS device in real-time, and the Circuit breaker is used to protect equipment by breaking when a certain kind of exception is detected. As can be seen from

Figure 9, the automatic train operation HILS platform contains various actual hardware, and simulation hardware for automatic train operation. The “lower-layer control loop” based on controller and “upper-layer optimization loop” based on optimizer of HILS constitute the two independent communication systems, respectively, and there is a certain connection between the two loops. “Controller” is also named as traction control unit (TCU), which could provide control commands for corresponding equipments in real-time using a proper control algorithm in real-time, enable the the urban rail vehicle to track the ideal profile curve; “Optimizer” is also named as main processor unit (MPU), which could provide the velocity ideal trajectory profile (target speed curve of automatic train operation) for “lower-layer control loop” tracking control based on ’dSPACE emulator’. Second, the “dSPACE emulator”, “conditioning circuit”, “signal processing unit”, “sensors”, “connectors”, and so on are service equipments for ATO HILS: “dSPACE emulator” provides some correlative simulation environments for the automatic train operation HILS, the related models included such as accurate braking model, traction transformer model, running line model, velocity fluctuation model, etc.; “conditioning circuit” can regulate electrical waves properly for “Controller” appropriately; “signal processing unit” can regulate net signals properly for “Optimizer” appropriately; and the “sensors” and “connectors” are used to feed electrical waves and net signals back to the “Controller” and “Optimizer” in real-time. Third, the “DC power source”, “Converter system”, “Electric motor”, “Digital rheostat box”, and “Gear box” are simulation electric hardware equipments of in place of the actual: “DC power source” acts as the actual pantograph; “Converter system” transfer the electric energy from “DC power source” to “Electric motor” through a series of current-voltage conversion processes, it includes AC–DC converter, DC–AC converter, low-pass filters, etc.; “Electric motor” acts as the actual urban rail vehicle motors set; the capacity of simulation circuit loop is smaller than actual. In Figure 11, “train controller cabinet” and “train emulator cabinet” are the vital equipments for automatic train operation HILS, except controller and emulator, conditioning circuit, signal processing unit and corresponding switch groups are included.

Obviously, compared with these automatic train operation scenarios based on pure software (such as Matlab/simulink simulation), their identical scenarios based on HILS are closer to actual. Therefore, based on the same scenarios, tracking control algorithm and HILS platform, the comprehensive performance index for automatic train operation obtained by optimization algorithms could reflect the optimization performance of these algorithms effectively. To further verify the effectiveness of the algorithm, according to the automatic train operation scenarios of rail transit line No.12 and Jinpu line No.1 in Dalian, China, the approximate optimal solutions are obtained by using ISSO, CSSO, and dMOPSO, the above ATO HILS platform is chosen as simulation platform. The specific configuration of the ATO HILS platform used in this paper is described as follow: the Matlab/simulink revision is Matlab GUI 2016b; the major computer configuration is “CPU Core i9-7920X @ 2.9 GHZ” and “Windows 10”; the core chip of “Controller” and “Optimizer” is “TMS320F28335”; the simulation software of “dSPACE emulator” is dSPACE software(revision is control desk 6.1); the communication protocol of the ATO HILS is MVB (multifunction vehicle bus); the MPC (model predictive control) algorithm is adopted as tracking control algorithm; the three optimization algorithms (ISSO, CSSO, and dMOPSO) used are written in the kernel chip of “Optimizer” in “upper-layer optimization loop” for contrasting. The specific HILS optimization results obtained by “Optimizer” in “upper-layer optimization loop” are shown in

Figure 10 and

Figure 11 and

Table 8,

Table 9,

Table 10 and

Table 11.

In

Figure 10a,b and

Figure 11a,b (which is related to the optimization effect of automatic train operation process), the power is switched on, the pantograph is raised, the dSPACE simulator is in the working state (the “dSPACE” button is pressed), the human–computer interaction signal is normal (the “Design” button is green), and the circuit breaker is normally closed, which is in a normal optimization simulation state.

According to optimization simulation results of different algorithms in

Table 8,

Table 9,

Table 10 and

Table 11, compared with the traditional improved particle swarm optimization algorithm (dMOPSO) and traditional improved shark smell optimization algorithm (CSSO), the improved algorithm proposed in this paper (ISSO) has the obvious performance improvement effect, the three indexes of energy saving, punctuality and comfort of target velocity trajectory have been improved considerably; meanwhile, and the convergence evolution generations and computation time have been reduced considerably. As can be seen from

Figure 10a,b and

Figure 11a,b, the ideal target velocity trajectory obtained by ISSO was the smoothest, compared with the contrasted algorithms (CSSO and dMOPSO), ISSO obtained extremely simple control sequence and made use of the most of long down and up slopes sufficiently, it enables the train to reduce unnecessary traction and braking status and to make full use of coasting status as much as possible. As can be seen from

Figure 10c,d and

Figure 11c,d, compared with contrasted algorithms (CSSO and dMOPSO), the three optimization objective indexes and two unified goals obtained by ISSO have been improved to a considerable extent not only in the optimization effect but also in the computation efficiency.

Compared with the improving optimization effect of ATO target velocity trajectory optimization, improving the actual tracking control effect is more practical. The optimization effect calculation speed could estimate the performance of the ATO target velocity trajectory optimization algorithms, achievable difficulty for tracking control is also a significant evaluation index. To better verify the effectiveness of the ISSO, the “lower-layer control loop” is used to tracking control according to optimal target velocity trajectory generated by the “upper-layer control loop”. The MPC (model predictive control) algorithm has some its own advantages such as good performance in tracking precision, powerful robustness, fast tracking speed, etc. and widely in ATO traction system, so it is selected as tracking control algorithm in this paper. The specific HILS tracking control results obtained by “Controller” in “lower-layer control loop” are shown in

Figure 12 and

Figure 13 and

Table 12 and

Table 13.

In

Figure 12 and

Figure 13 (which relate to the tracking control effect of automatic train operation process according to optimization result), the power is switched on, the pantograph is raised, the dSPACE simulator is in the simulation state (the “dSPACE” button is pressed), the design parameters cannot be changed (the “Design” button is white), and the circuit breaker is normally closed, which is in a normal tracking control simulation state.

According to optimization simulation results of different algorithms from

Table 12 and

Table 13, compared with the traditional improved particle swarm optimization algorithm (dMOPSO) and traditional improved shark smell optimization algorithm (CSSO), the corresponding tracking control curve tracking the target velocity trajectory, obtained by improved algorithm proposed in this paper (ISSO), has the obvious performance improvement effect, the its three indexes of energy-saving, punctuality, and comfort have been improved considerably. As can be seen from

Figure 12 and

Figure 13, compared with the contrasted algorithms (CSSO and dMOPSO), the corresponding tracking control curve for ISSO has better tracking control effects. As can be seen from the enlarged areas of

Figure 12 and

Figure 13, the velocity fluctuation of the velocity distance trajectory curves corresponding to ISSO is weaker, because the target velocity trajectory obtained by ISSO was more ideal and tracking controlled easily in the automatic train operation simulation scenarios.

To verify that the improved algorithm (ISSO) in this paper has more superiorities, such as optimization effect, calculation speed, easily achievable in tracking control, etc., two scenarios about rail transit line No.12 and Jinpu line No.1 in Dalian, China are chosen as optimized objects for ISSO and some comparison algorithms, the corresponding optimization and tracking control results of matlab/simulation and hardware-in-the-loop simulation (HILS) as shown in

Table 4,

Table 5,

Table 6,

Table 7,

Table 8,

Table 9,

Table 10,

Table 11,

Table 12 and

Table 13 and

Figure 5 and

Figure 6, and

Figure 10,

Figure 11,

Figure 12 and

Figure 13. Obviously, compared with the contrasted algorithms (CSSO and dMOPSO), the corresponding optimization and tracking control results obtained by ISSO are more ideal. It is indicate that ISSO is a appropriate algorithm with powerful optimization capability, so as to solving practical automatic train operation more effectively.

5. Conclusions

Automatic train operation target velocity trajectory optimization is a very complex issue that needs to take into account multiple objectives, and the ideal optimization solution is not easy to be obtained. An improved multi-objective dual-population shark smell optimization algorithm using incorporated composite angle cosine for automatic train operation velocity trajectory optimization is proposed in this paper, and the specific advantages are described as follows.

For the multi-objective optimization problem, the evaluation index of the solution is very important. Nonetheless, the linear weighted target belongs to the common multi-objective unified target, and there is a problem that subjective parameters are selected blindly. In this paper, the multi-objective angle cosine is used as evaluation index, which can effectively avoid the blind selection of subjective parameters. To make the evaluation index more reasonable, on the basis of the preference information, the composite angle cosine which takes into account both the preference difference and the numerical difference is be used as the evaluation index of the solution in this paper.

Because the updating rules of velocities and positions in the SSO and PSO make all individuals close to the extreme individuals, after a long iteration, the extreme individuals will form a certain degree of dominance over the population, which makes it difficult to converge globally. First, the dual-population evolution mechanism is used to jump out of the local optimum. Second, to suppress the local convergence of optimization algorithm, it is necessary to determine accurately whether the individual aggregation occurs in shark population. In this paper, the fusion distance can be used to take into account the relativity and independence of speed and time, which can detect whether there is the phenomenon of individual aggregation preciously, so the local convergence is better suppressed. At the same time, this paper also introduces the dual-population collaborative optimization mechanism of SSO algorithm and particle swarm algorithm to further improve the optimization performance of the algorithm.

According to the the Matlab/simulink results and HILS results about automatic train operation scenarios, compared with the conventional improved shark smell optimization algorithm and the conventional improved particle swarm optimization algorithm, the improved algorithm (ISSO) proposed in this paper improves the calculation accuracy and optimization ability of the optimization algorithm to some extent, so that more ideal target velocity trajectory can be obtained. This clearly shows that ISSO have been improved to a considerable extent for the automatic train operation target velocity trajectory optimization not only in the pure software scenarios but also in the semi-physical scenarios. As the automatic train operation HILS is close to its actual experiment, the problem that the ISSO has worse improvement optimization effect in the actual than anticipatory could be avoid to certain extent.